Magnetic and Dielectric Properties of Nano- and Micron-BiFeO3/LDPE Composites with Magnetization Treatments

Abstract

:1. Introduction

2. Experiments

2.1. Material Preparation

2.2. Characterization and Test

3. Results and Discussion

3.1. Infrared Spectrum

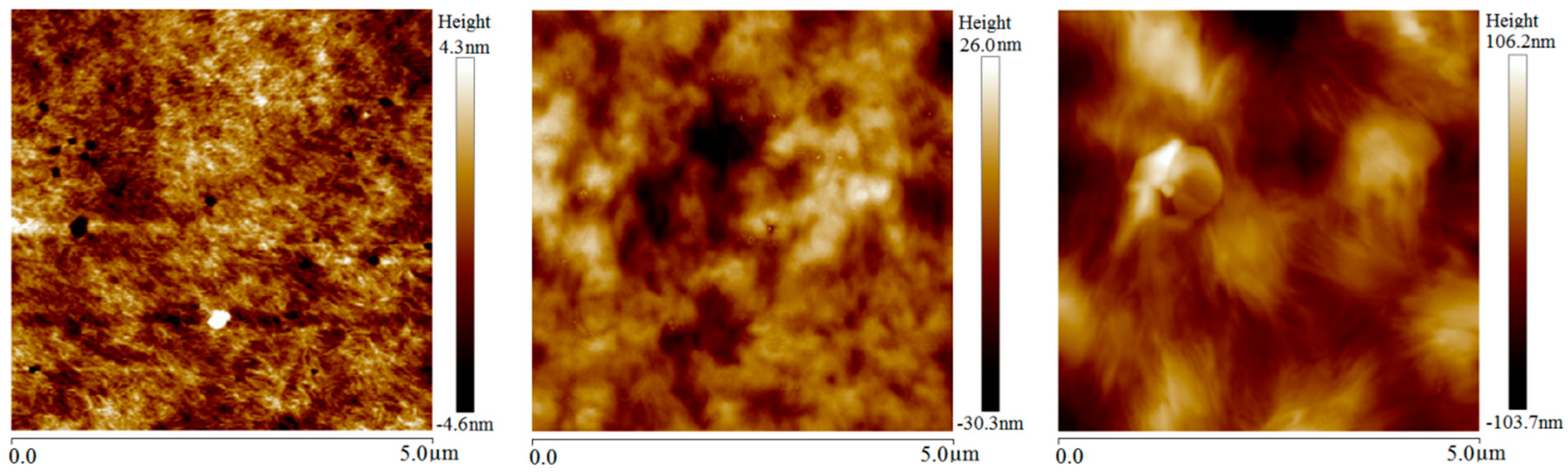

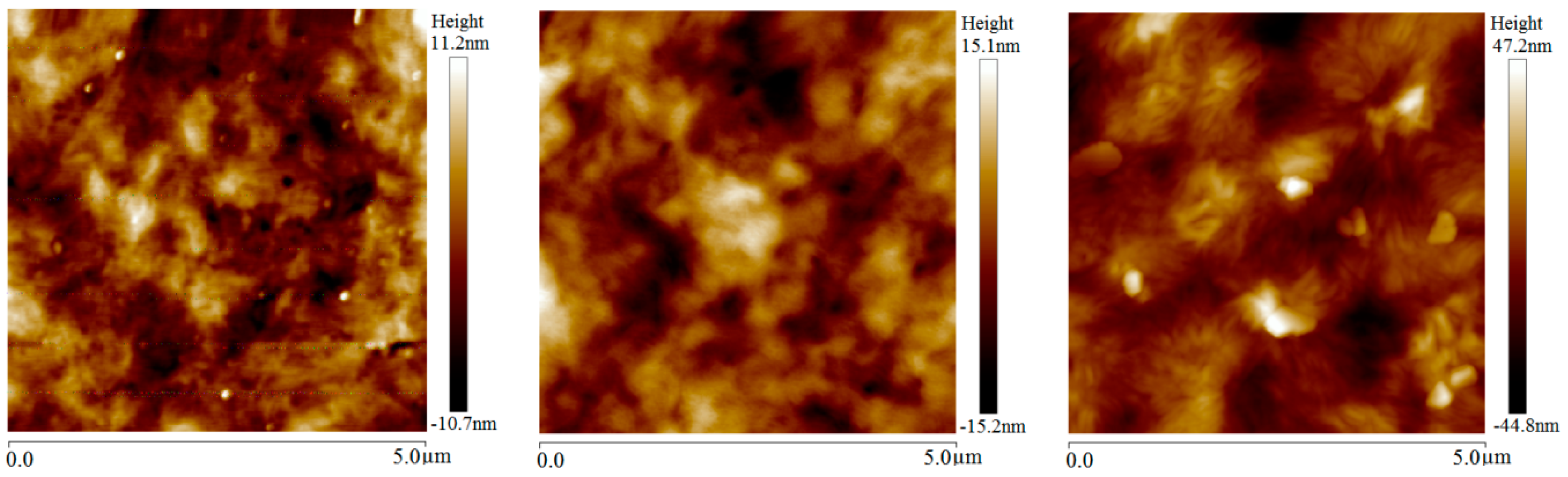

3.2. Crystalline Morphology

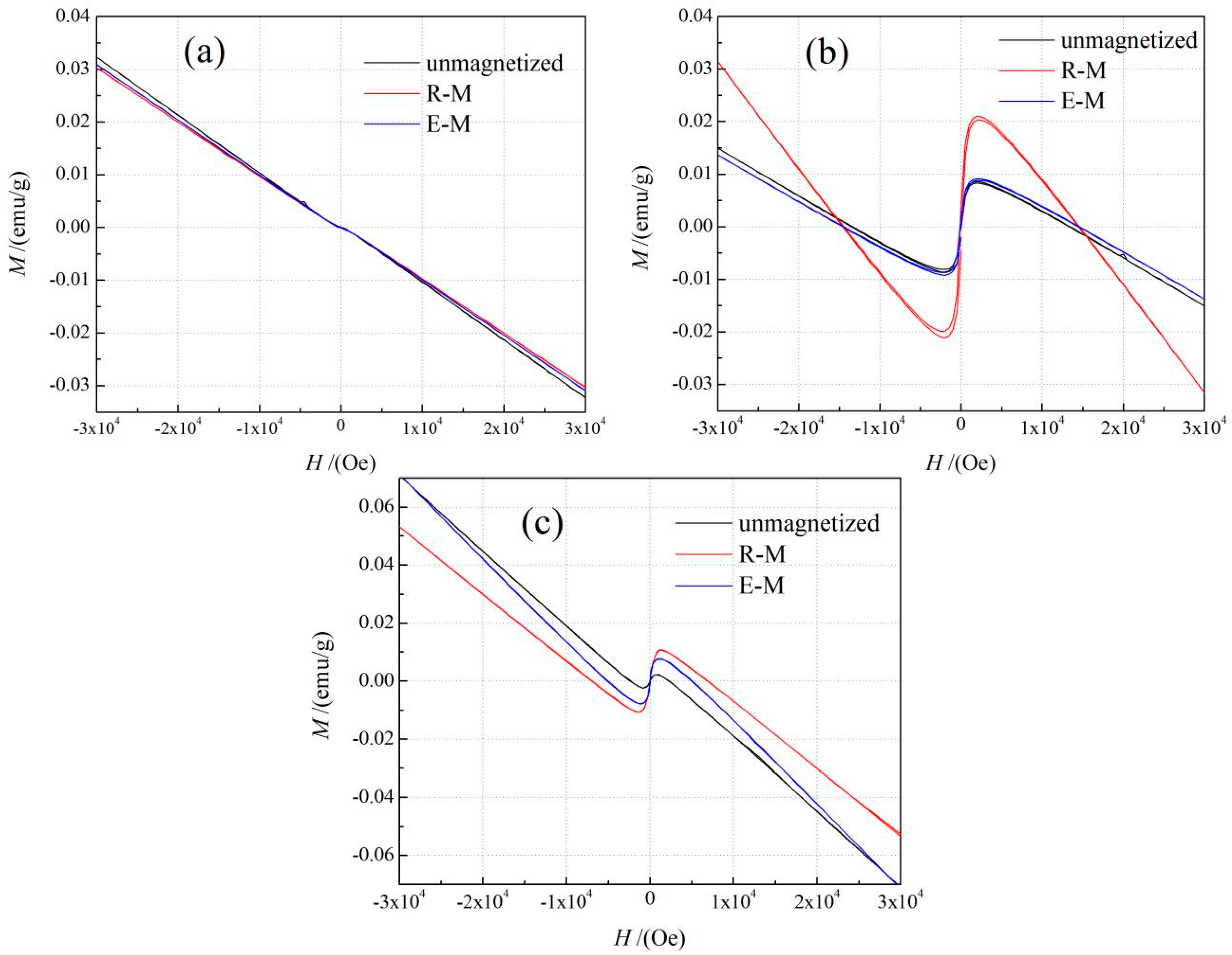

3.3. Magnetic Performance

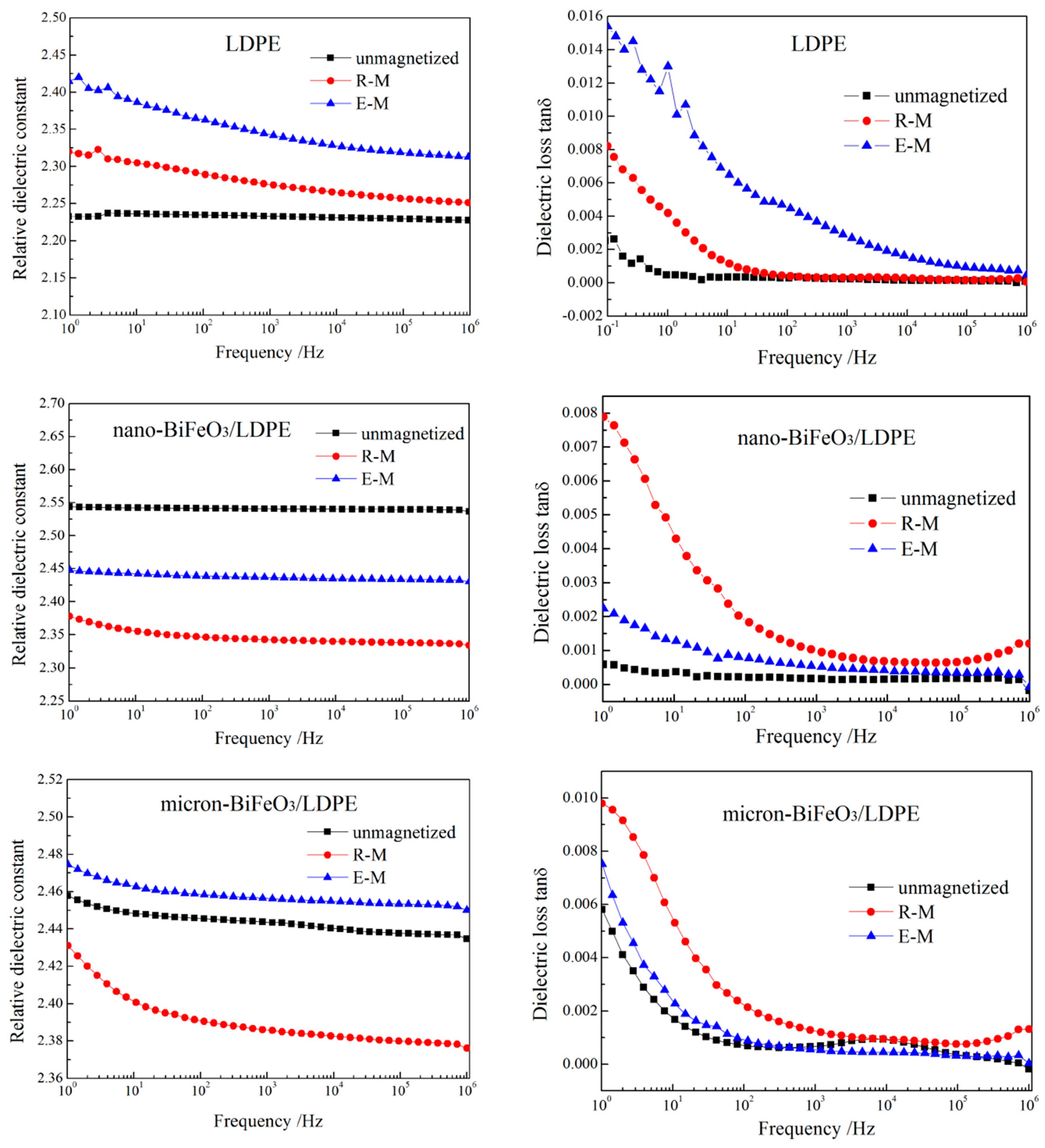

3.4. Dielectric Spectrum

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dang, Z.-M.; Yuan, J.-K.; Zha, J.-W.; Zhou, T.; Li, S.-T.; Hu, G.-H. Fundamentals, processes and applications of high-permittivity polymer–matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Yuan, J.-K.; Yao, S.-H.; Liao, R.-J. Flexible Nanodielectric Materials with High Permittivity for Power Energy Storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Li, N.; Ma, Y.; Du, F.; Li, F.; He, X.; Lin, X.; Gao, H.; Chen, Y. The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 2007, 45, 1614–1621. [Google Scholar] [CrossRef]

- Wu, H.; Zhu, X. Microstructures, magnetic, and dielectric properties of Ba-doped BiFeO3 nanoparticles synthesized via molten salt route. J. Am. Ceram. Soc. 2019, 102, 4698–4709. [Google Scholar] [CrossRef]

- Ni, X.; Zheng, Z.; Hu, X.; Xiao, X. Silica-coated iron nanocubes: Preparation, characterization and application in microwave absorption. J. Colloid Interface Sci. 2010, 341, 18–22. [Google Scholar] [CrossRef]

- Liu, P.-B.; Huang, Y.; Sun, X. Excellent Electromagnetic Absorption Properties of Poly(3,4-ethylenedioxythiophene)-Reduced Graphene Oxide–Co3O4 Composites Prepared by a Hydrothermal Method. ACS Appl. Mater. Interfaces 2013, 5, 12355–12360. [Google Scholar] [CrossRef]

- Ben Ishai, P.; Talary, M.S.; Caduff, A.; Levy, E.; Feldman, Y. Electrode polarization in dielectric measurements: A review. Meas. Sci. Technol. 2013, 24, 102001. [Google Scholar] [CrossRef]

- Bangruwa, J.S.; Kumar, S.; Chauhan, A.; Kumar, P.; Verma, V. Modified Magnetic and Electrical Properties of Perovskite-Spinel Multiferroic Composites. J. Supercond. Nov. Magn. 2019, 32, 2559–2569. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.; Safronov, A.P.; Bhagat, S.M.; Lofland, S.; Beketov, I.V.; Prieto, L.M. Tailoring functional properties of Ni nanoparticles-acrylic copolymer composites with different concentrations of magnetic filler. J. Appl. Phys. 2015, 117, 123917. [Google Scholar] [CrossRef]

- Azizi, S.; David, E.; Frechette, M.; Nguyentri, P.; Ouelletplamondon, C. Electrical and thermal phenomena in low-density polyethylene/carbon black composites near the percolation threshold. J. Appl. Polym. Sci. 2019, 136, 47043. [Google Scholar] [CrossRef]

- Peng, S.; Zeng, Q.; Yang, X.; Hu, J.; Qiu, X.; He, J. Local Dielectric Property Detection of the Interface between Nanoparticle and Polymer in Nanocomposite Dielectrics. Sci. Rep. 2016, 6, 38978. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.C.; Huang, X.R.; Zeng, L.J.; Li, R.F.; Tian, H.F.; Fu, X.W.; Wang, Y.; Zhong, W.H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Wang, Y.S.; Wang, N.H.; Sun, Q.H. Effects of surface topography and morphology on space charge packet in polyethylene. High Volt. Eng. 2009, 35, 108–113. [Google Scholar]

- Wang, J.F.; Zheng, X.Q.; Liu, L.W.; Kong, Z.D.; Huang, J.F.; Yang, P.C. Influence of crystalline morphology on water treeing in LDPE effect of crystal morphology of LDPE on aging characteristics of water tree. High Volt. Eng. 2010, 36, 678–684. [Google Scholar]

- Kouki, N.; Hcini, S.; Aldawas, R.; Boudard, M. Structural, Infrared, Magnetic, and Electrical Properties of Ni0.6Cd0.2Cu0.2Fe2O4 Ferrites Synthesized Using Sol-Gel Method Under Different Sintering Temperatures. J. Supercond. Nov. Magn. 2019, 32, 2209–2218. [Google Scholar] [CrossRef]

- Saci, H.; Bouhelal, S.; Bouzarafa, B.; López, D.; Fernández-García, M. Reversible crosslinked low density polyethylenes: Structure and thermal properties. J. Polym. Res. 2016, 23, 68. [Google Scholar] [CrossRef]

- Pu, H.-T.; Cheng, J.-F. Orientation of LDPE crystals from microscale to nanoscale via microlayer or nanolayer coextrusion. Chin. J. Polym. Sci. 2016, 34, 1411–1422. [Google Scholar]

- Da Silva, D.J.; Wiebeck, H. CARS-PLS regression and ATR-FTIR spectroscopy for eco-friendly and fast composition analyses of LDPE/HDPE blends. J. Polym. Res. 2018, 25, 112. [Google Scholar] [CrossRef]

- Matsuba, G.; Sakamoto, S.; Ogino, Y.; Nishida, K.; Kanaya, T. Crystallization of Polyethylene Blends under Shear Flow. Effects of Crystallization Temperature and Ultrahigh Molecular Weight Component. Macromolecules 2007, 40, 7270–7275. [Google Scholar] [CrossRef]

- Yamamoto, T. Computer modeling of polymer crystallization–Toward computer-assisted materials’ design. Polymer 2009, 50, 1975–1985. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Li, J.Y.; Ma, Y.X.; Yan, Q.M.; Ouyang, B.H. The role of thermo-oxidative aging at different temperatures on the crystal structure of crosslinked polyethylene. J. Mater. Sci. Mater. Electron. 2018, 29, 3696–3703. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Wang, Y.H.; Qi, J.; Tian, Y.; Zhang, J.K.; Wei, M.B.; Liu, Y.Q.; Yang, J.H. Structural, magnetic and impedance spectroscopy properties of Ho3+ modified BiFeO3 multiferroic thin film. J. Mater. Sci. Mater. Electron. 2019, 30, 2942–2952. [Google Scholar] [CrossRef]

- Verho, T.; Paajanen, A.; Vaari, J.; Laukkanen, A. Crystal Growth in Polyethylene by Molecular Dynamics: The Crystal Edge and Lamellar Thickness. Macromolecules 2018, 51, 4865–4873. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zhong, L.; Zhang, K.; Gao, J.; Xu, M. Temperature Dependence of Mechanical, Electrical Properties and Crystal Structure of Polyethylene Blends for Cable Insulation. Materials 2018, 11, 1922. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castillo, M.E.; Shvartsman, V.; Gobeljic, D.; Gao, Y.; Landers, J.; Wende, H.; Lupascu, D.C. Effect of particle size on ferroelectric and magnetic properties of BiFeO3 nanopowders. Nanotechnology 2013, 24, 355701. [Google Scholar] [CrossRef] [PubMed]

| Samples | A723 (a.u.) | A1459 (a.u.) | α (k) |

|---|---|---|---|

| LDPE | 0.321 | 0.267 | 1.202 |

| LDPE R-M | 0.194 | 0.155 | 1.252 |

| LDPE H-M | 0.419 | 0.310 | 1.352 |

| nano-BiFeO3/LDPE | 0.056 | 0.076 | 0.737 |

| nano-BiFeO3/LDPE R-M | 0.229 | 0.201 | 1.139 |

| nano-BiFeO3/LDPE H-M | 0.276 | 0.215 | 1.284 |

| micro-BiFeO3/LDPE | 0.024 | 0.039 | 0.615 |

| micro-BiFeO3/LDPE R-M | 0.031 | 0.048 | 0.646 |

| micro-BiFeO3/LDPE H-M | 0.181 | 0.228 | 0.794 |

| Samples | Mmax (emu/g) | MR (emu/g) | HC (Oe) |

|---|---|---|---|

| LDPE | 0.032 | 0.081 × 10−3 | 0.442 |

| LDPE R-M | 0.030 | 0.047 × 10−3 | 0.518 |

| LDPE H-M | 0.031 | 0.048 × 10−3 | 0.518 |

| nano-BiFeO3/LDPE | 0.015 | 1.932 × 10−3 | 0.455 |

| nano-BiFeO3/LDPE R-M | 0.031 | 4.415 × 10−3 | 0.341 |

| nano-BiFeO3/LDPE H-M | 0.014 | 1.956 × 10−3 | 0.341 |

| micro-BiFeO3/LDPE | 0.071 | 0.010 × 10−3 | 0.323 |

| micro-BiFeO3/LDPE R-M | 0.053 | 0.690 × 10−3 | 7.039 |

| micro-BiFeO3/LDPE H-M | 0.071 | 0.165 × 10−3 | 9.285 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Fan, Y.-Z.; Hua, Y.; Sun, W.-F. Magnetic and Dielectric Properties of Nano- and Micron-BiFeO3/LDPE Composites with Magnetization Treatments. Materials 2020, 13, 120. https://doi.org/10.3390/ma13010120

Song W, Fan Y-Z, Hua Y, Sun W-F. Magnetic and Dielectric Properties of Nano- and Micron-BiFeO3/LDPE Composites with Magnetization Treatments. Materials. 2020; 13(1):120. https://doi.org/10.3390/ma13010120

Chicago/Turabian StyleSong, Wei, Yu-Zhang Fan, Yu Hua, and Wei-Feng Sun. 2020. "Magnetic and Dielectric Properties of Nano- and Micron-BiFeO3/LDPE Composites with Magnetization Treatments" Materials 13, no. 1: 120. https://doi.org/10.3390/ma13010120

APA StyleSong, W., Fan, Y.-Z., Hua, Y., & Sun, W.-F. (2020). Magnetic and Dielectric Properties of Nano- and Micron-BiFeO3/LDPE Composites with Magnetization Treatments. Materials, 13(1), 120. https://doi.org/10.3390/ma13010120