Microstructural Evolution and Mechanical Properties of an Advanced γ-TiAl Based Alloy Processed by Spark Plasma Sintering

Abstract

1. Introduction

2. Experimental Procedure

3. Results

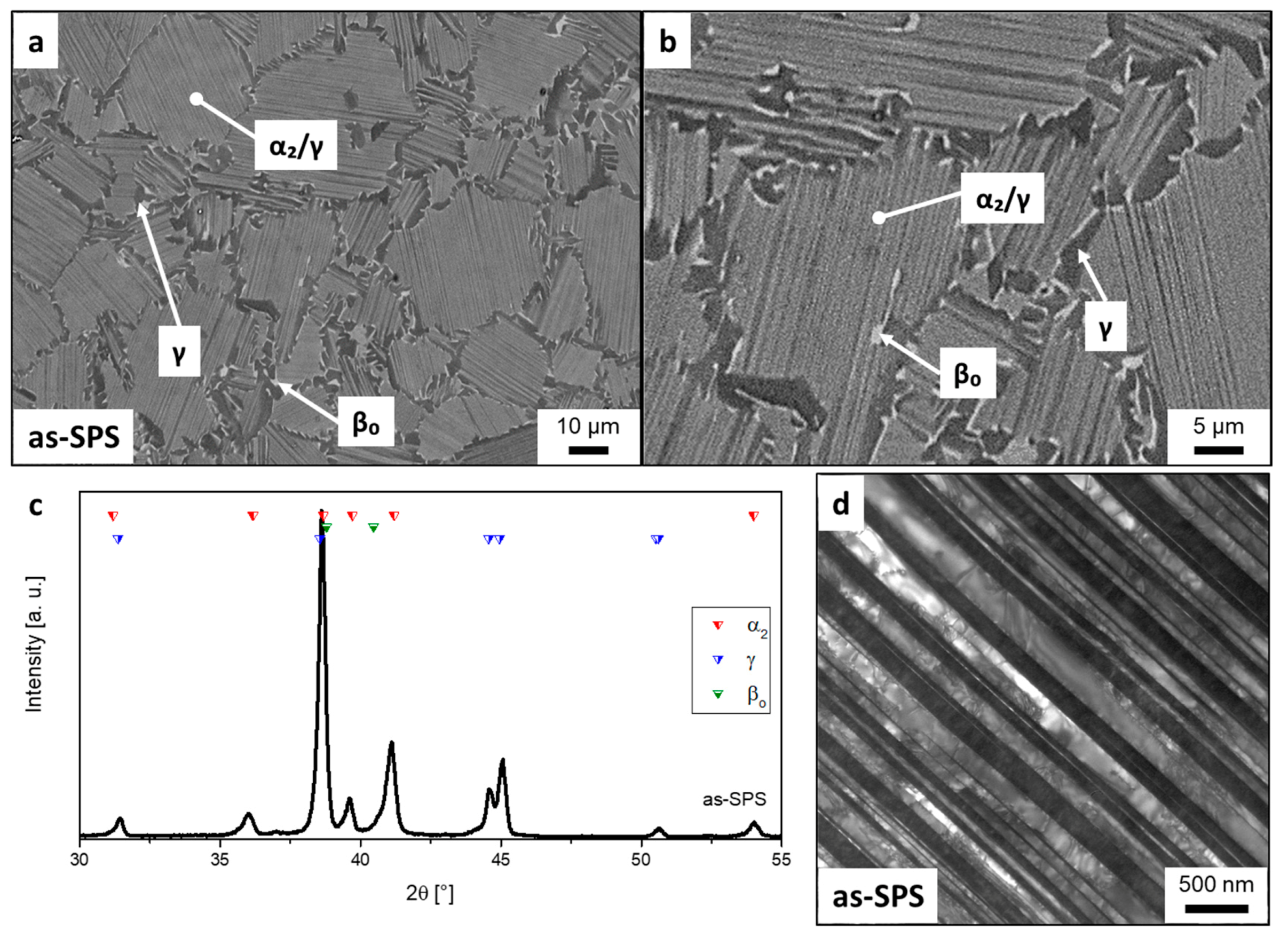

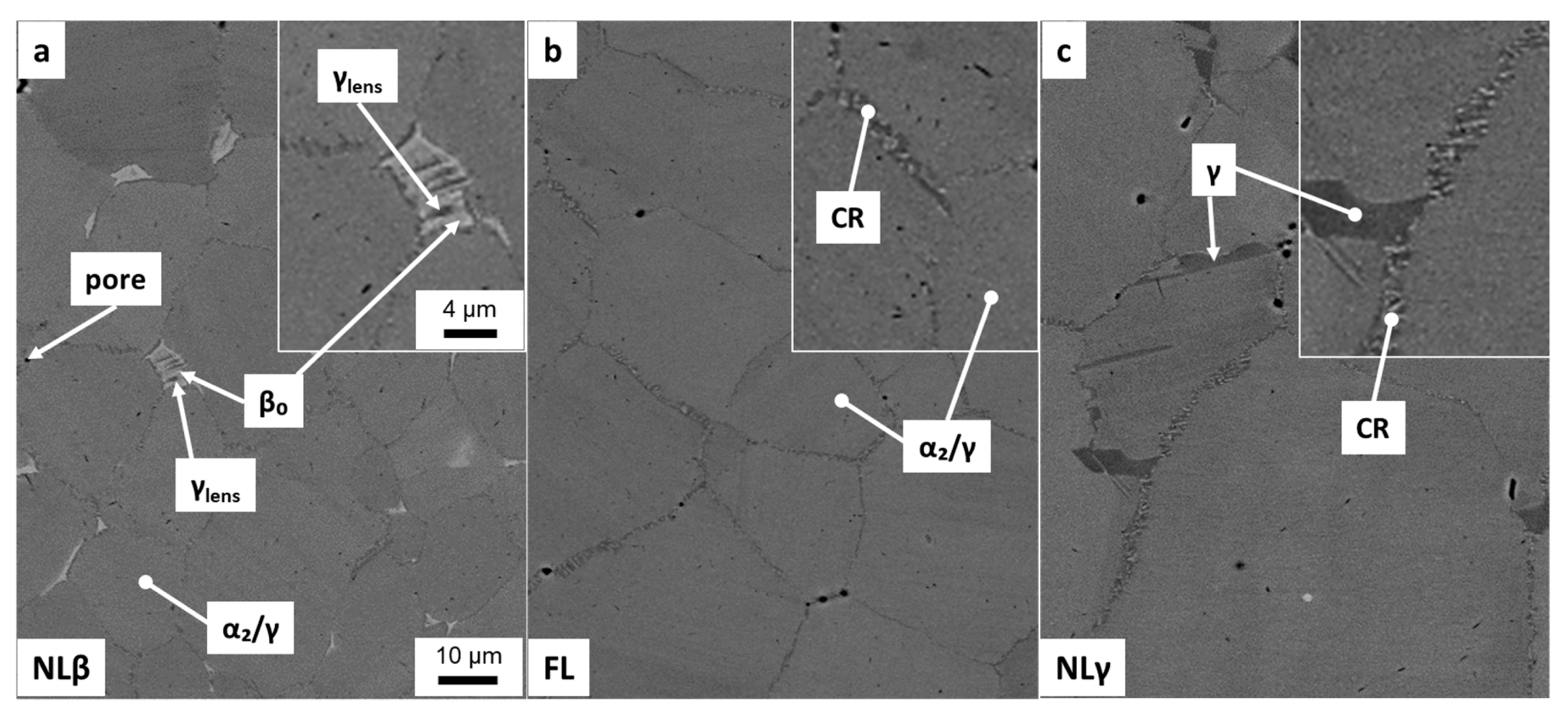

3.1. Microstructure

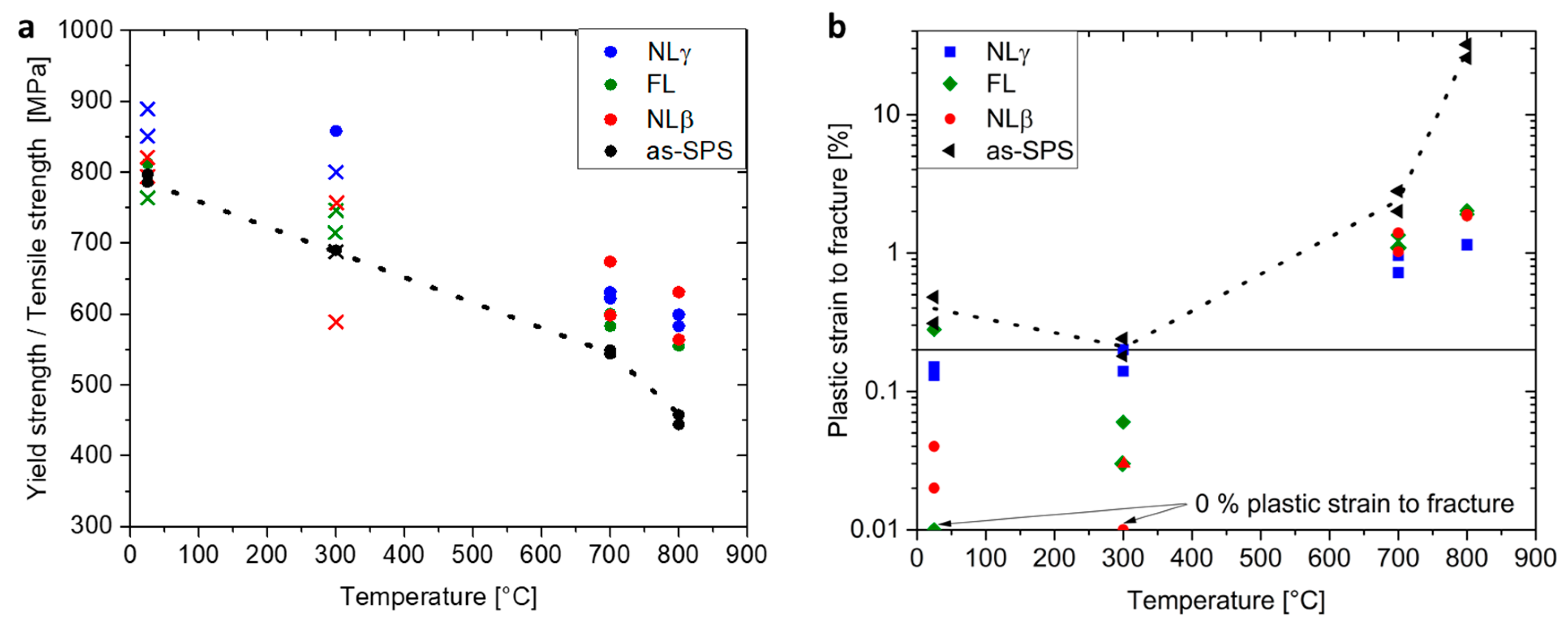

3.2. Mechanical Testing

4. Discussion

5. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mayer, S.; Erdely, P.; Fischer, F.D.; Holec, D.; Kastenhuber, M.; Klein, T.; Clemens, H. Intermetallic β-solidifying γ-TiAl based alloys—From fundamental research to application. Adv. Eng. Mater. 2017, 19, 1600735. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Habel, U.; Heutling, F.; Kunze, C.; Smarsly, W.; Das, C.; Clemens, H. Forged Intermetallic γ-TiAl Based Alloy Low Pressure Turbine Blade in the Geared Turbofan. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; Venkatesh, V., Pilchak, A.L., Allison, J.E., Ankern, S., Boyer, R., Christodoulou, J., Fraser, H.L., Imam, M.A., Kosaka, Y., Rack, H.J., et al., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 1223–1227. [Google Scholar]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot-workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Couret, A.; Voisin, T.; Thomas, M.; Monchoux, J.-P. Development of a TiAl alloy by spark plasma sintering. JOM 2017, 69, 2576–2582. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Durand, L.; Karnatak, N.; Thomas, M.; Couret, A. An innovative way to produce γ-TiAl blades. Adv. Eng. Mater. 2015, 17, 1408–1413. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Hantcherli, M.; Mayer, S.; Clemens, H.; Couret, A. Microstructures and mechanical properties of a multi-phase β-solidifying TiAl alloy densified by spark plasma sintering. Acta Mater. 2014, 73, 107–115. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Kim, Y.-W. Microstructural evolution and mechanical properties of a forged gamma titanium aluminide alloy. Acta Metal. Mater. 1992, 40, 1121–1134. [Google Scholar] [CrossRef]

- Mayer, S.; Kastenhuber, M.; Clemens, H. Advanced titanium aluminides - how to improve the creep resistance via compositional and microstructural optimization. Mater. Sci. Forum 2018, 941, 1484–1489. [Google Scholar] [CrossRef]

- Takeyama, M.; Nakamura, M.; Kumagai, T.; Kikuchi, M. Cooling rate dependence of the α/γ phase transformation in titanium aluminides and its application to alloy development. Struct. Intermet. 1993, 167–176. Available online: https://jglobal.jst.go.jp/en/detail?JGLOBAL_ID=200902116917348286&rel=0 (accessed on 12 April 2019).

- Beschliesser, M.; Chatterjee, A.; Lorich, A.; Knabl, W.; Kestler, H.; Dehm, G.; Clemens, H. Designed fully lamellar microstructures in a γ-TiAl based alloy: Adjustment and microstructural changes upon long-term isothermal exposure at 700 and 800 °C. Mater. Sci. Eng. A 2002, 329, 124–129. [Google Scholar] [CrossRef]

- Wallgram, W.; Schmölzer, T.; Cha, L.; Das, G.; Güther, V.; Clemens, H. Technology and mechanical properties of advanced γ-TiAl based alloys. Int. J. Mater. Res. 2009, 100, 1021–1030. [Google Scholar] [CrossRef]

- Klein, T.; Clemens, H.; Mayer, S. Advancement of compositional and microstructural design of intermetallic γ-TiAl based alloys determined by atom probe tomography. Materials 2016, 9, 755. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Klein, T.; Clemens, H.; Mayer, S. Tailoring microstructure and chemical composition of advanced γ-TiAl based alloys for improved creep resistance. Intermetallics 2018, 97, 27–33. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.-P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ-TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef]

- Gerling, R.; Clemens, H.; Schimansky, F.P. Powder metallurgical processing of intermetallic gamma titanium aluminides. Adv. Eng. Mater. 2004, 6, 23–38. [Google Scholar] [CrossRef]

- Schatt, W.; Wieters, K.-P.; Kieback, B. Pulvermetallurgie: Technologien und Werkstoffe; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Achtermann, M.; Fürwitt, W.; Güther, V.; Nicolai, H.-P. Method for Producing of γ-TiAl base Alloy. European Patent EP2342365, 13 July 2011. [Google Scholar]

- Güther, V.; Allen, M.; Klose, J.; Clemens, H. Metallurgical processing of titanium aluminides on industrial scale. Intermetallics 2018, 103, 12–22. [Google Scholar] [CrossRef]

- Voisin, T.; Durand, L.; Karnatak, N.; Gallet, S.L.; Thomas, M.; Berre, Y.L.; Castagné, J.-F.; Couret, A. Temperature control during spark plasma sintering and application to up-scaling and complex shaping. J. Mater. Process. Technol. 2013, 213, 269–278. [Google Scholar] [CrossRef]

- Schloffer, M.; Schmoelzer, T.; Mayer, S.; Schwaighofer, E.; Hawranek, G.; Schimansky, F.-P.; Pyczak, F.; Clemens, H. The characterisation of a powder metallurgically manufactured TNM™ titanium aluminide alloy using complimentary quantitative methods. Pract. Metall. 2011, 48, 594–604. [Google Scholar] [CrossRef]

- McCusker, L.B.; Dreele, R.B.V.; Cox, D.E.; Louër, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef]

- Cha, L.; Clemens, H.; Dehm, G. Microstructure evolution and mechanical properties of an intermetallic Ti-43.5Al-4Nb-1Mo-0.1B alloy after ageing below the eutectoid temperature. Int. J. Mater. Res. 2011, 102, 703–708. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Klein, T.; Rashkova, B.; Weißensteiner, I.; Clemens, H.; Mayer, S. Phase transformations in a β-solidifying γ-TiAl based alloy during rapid solidification. Intermetallics 2017, 91, 100–109. [Google Scholar] [CrossRef]

- Lamirand, M.; Bonnentien, J.-L.; Guérin, S.; Ferrière, G.; Chevalier, J.-P. Effects of interstitial oxygen on microstructure and mechanical properties of Ti-48Al-2Cr-2Nb with fully lamellar and duplex microstructures. Metall. Mater. Trans. A 2006, 37, 2369–2378. [Google Scholar] [CrossRef]

- Ding, H.; Nie, G.; Chen, R.; Guo, J.; Fu, H. Influence of oxygen on microstructure and mechanical properties of directionally solidified Ti–47Al–2Cr–2Nb alloy. Mater. Des. 2012, 41, 108–113. [Google Scholar] [CrossRef]

- Lefebvre, W.; Menand, A.; Loiseau, A. Influence of oxygen on phase transformations in a Ti-48 At. pct Al alloy. Metall. Mater. Trans. A 2003, 34, 2067–2075. [Google Scholar] [CrossRef]

- Wegmann, G.; Gerling, R.; Schimansky, F.-P. Temperature induced porosity in hot isostatically pressed gamma titanium aluminide alloy powders. Acta Mater. 2003, 51, 741–752. [Google Scholar] [CrossRef]

- Wimler, D.; Kardos, S.; Lindemann, J.; Clemens, H.; Mayer, S. Aspects of powder characterization for additive manufacturing. Pract. Metallogr. 2018, 55, 620–636. [Google Scholar] [CrossRef]

- Dlouhý, A.; Kuchařová, K. Creep and microstructure of near-gamma TiAl alloys. Intermetallics 2004, 12, 705–711. [Google Scholar] [CrossRef]

- Maruyama, K.; Yamamoto, R.; Nakakuki, H.; Fujitsuna, N. Effects of lamellar spacing, volume fraction and grain size on creep strength of fully lamellar TiAl alloys. Mater. Sci. Eng. A 1997, 239–240, 419–428. [Google Scholar] [CrossRef]

| Ti | Al | Nb | Mo | B | O |

|---|---|---|---|---|---|

| bal. | 43.45 | 4.05 | 1.02 | 0.10 | 1300 |

| Type of Microstructure | Heat Treatment | Phase Fractions Measured via XRD * | Quantitative Morphological Analysis of SEM Micrographs ** | Lamellar Spacing | Hardness | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| α2 | γ | βo | α2/γ-colonies | globular γ | βo+γlens | |||||

| [vol.%] | [vol.%] | [vol.%] | fraction [vol.%] | size [µm] | fraction [vol.%] | fraction [vol.%] | [nm] | [HV10] | ||

| as-SPS | - | 35 | 61 | 4 | 94 | 19 | 5 | <1 | 83 ± 7 | 378 ± 8 |

| NLβ | 1290 °C/30 min/AC + 850 °C/6 h/FC | 27 | 71 | ≤2 | 97 | 20 | <1 | 2 | 8 ± 9 | 466 ± 4 |

| FL | 1265 °C/ 30 min/AC + 850 °C/6 h/FC | 30 | 68 | ≤2 | 98 | 29 | <1 | <1 | 10 ± 6 | 461 ± 7 |

| NLγ | 1290 °C/30 min/FC 1245 °C/30 min/AC + 850 °C/6 h/FC | 30 | 68 | ≤2 | 97 | 45 | 2 | <1 | 9 ± 8 | 445 ± 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wimler, D.; Lindemann, J.; Clemens, H.; Mayer, S. Microstructural Evolution and Mechanical Properties of an Advanced γ-TiAl Based Alloy Processed by Spark Plasma Sintering. Materials 2019, 12, 1523. https://doi.org/10.3390/ma12091523

Wimler D, Lindemann J, Clemens H, Mayer S. Microstructural Evolution and Mechanical Properties of an Advanced γ-TiAl Based Alloy Processed by Spark Plasma Sintering. Materials. 2019; 12(9):1523. https://doi.org/10.3390/ma12091523

Chicago/Turabian StyleWimler, David, Janny Lindemann, Helmut Clemens, and Svea Mayer. 2019. "Microstructural Evolution and Mechanical Properties of an Advanced γ-TiAl Based Alloy Processed by Spark Plasma Sintering" Materials 12, no. 9: 1523. https://doi.org/10.3390/ma12091523

APA StyleWimler, D., Lindemann, J., Clemens, H., & Mayer, S. (2019). Microstructural Evolution and Mechanical Properties of an Advanced γ-TiAl Based Alloy Processed by Spark Plasma Sintering. Materials, 12(9), 1523. https://doi.org/10.3390/ma12091523