Comparison of Screw-In Forces during Movement of Endodontic Files with Different Geometries, Alloys, and Kinetics

Abstract

1. Introduction

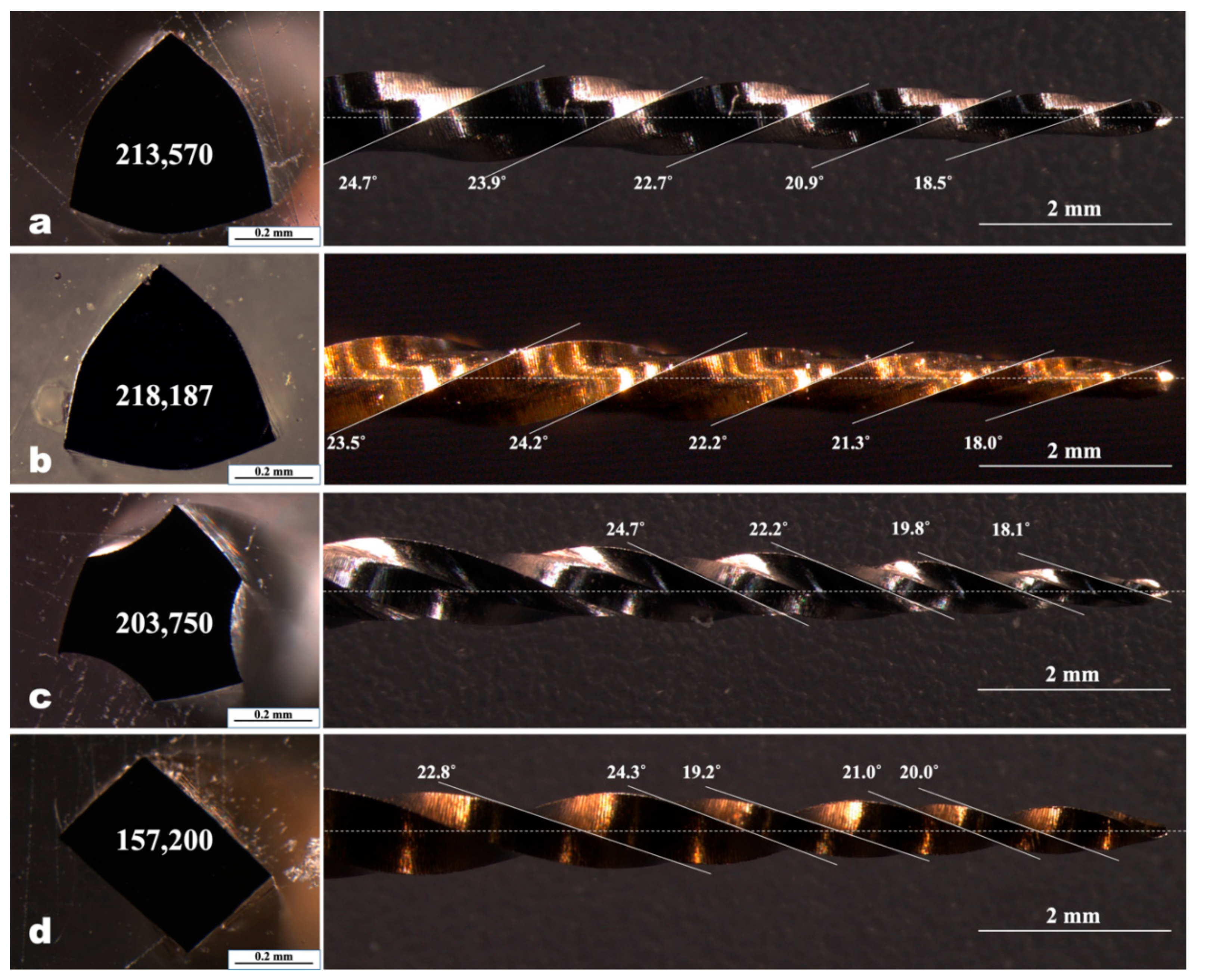

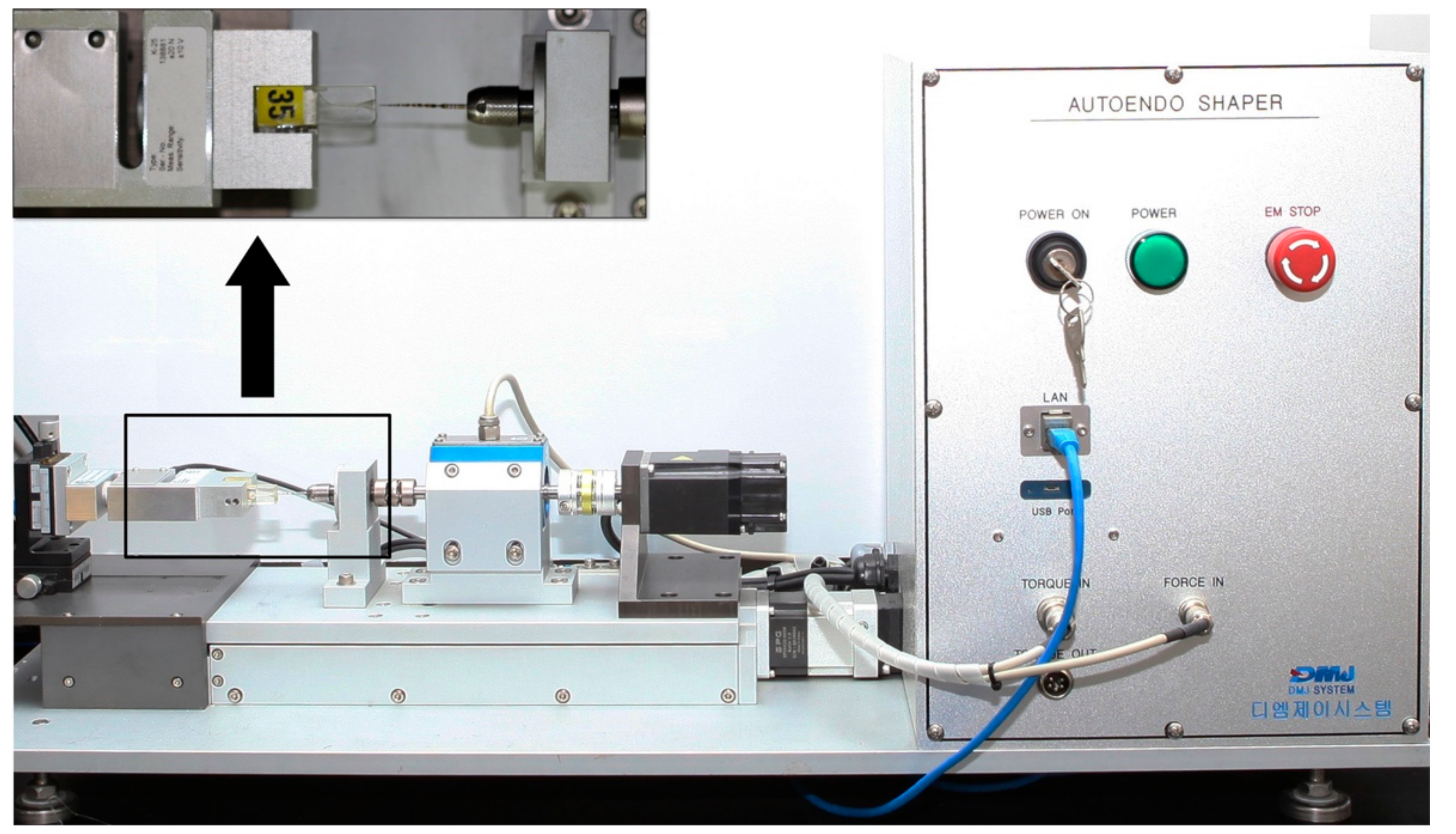

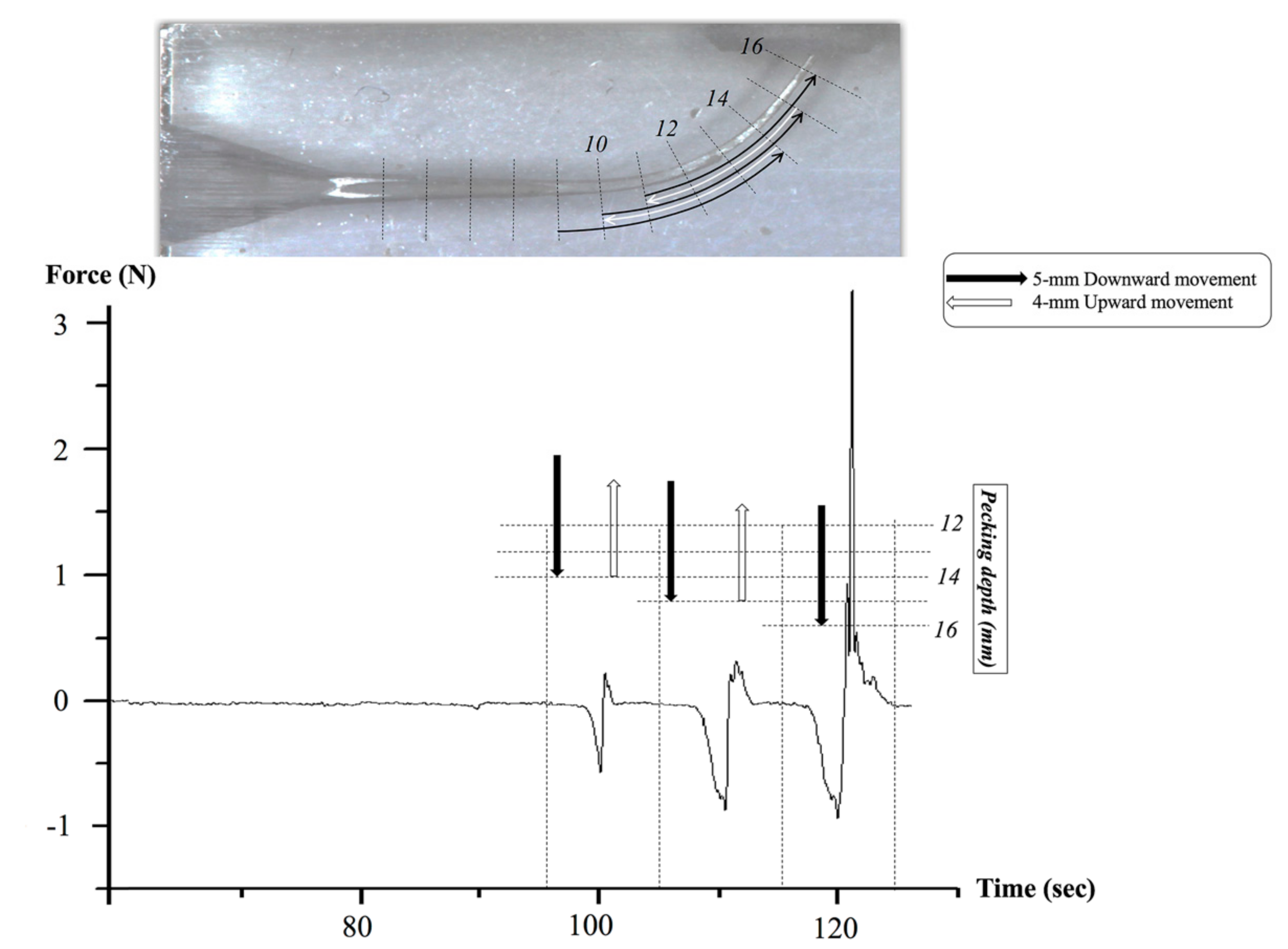

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Walia, H.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef]

- Sonntag, D.; Guntermann, A.; Kim, S.K.; Stachniss, V. Root canal shaping with manual stainless steel files and rotary Ni-Ti files performed by students. Int. Endod. J. 2003, 36, 246–255. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-C.; Cheung, G.S.-P.; Lee, C.-J.; Kim, B.-M.; Park, J.-K.; Kang, S.-I. Comparison of Forces Generated During Root Canal Shaping and Residual Stresses of Three Nickel–Titanium Rotary Files by Using a Three-Dimensional Finite-element Analysis. J. Endod. 2008, 34, 743–747. [Google Scholar] [CrossRef]

- Kim, T.O.; Cheung, G.S.P.; Lee, J.M.; Kim, B.M.; Hur, B.; Kim, H.C. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. Int. Endod. J. 2009, 42, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; Kim, H.J.; Lee, C.J.; Kim, B.M.; Park, J.K.; Versluis, A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int. Endod. J. 2009, 42, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.-W.; Cheung, G.S.; Zheng, Y.-F. Influence of Cross-sectional Design and Dimension on Mechanical Behavior of Nickel-Titanium Instruments under Torsion and Bending: A Numerical Analysis. J. Endod. 2010, 36, 1394–1398. [Google Scholar] [CrossRef]

- Versluis, A.; Kim, H.-C.; Lee, W.; Kim, B.-M.; Lee, C.-J. Flexural Stiffness and Stresses in Nickel-Titanium Rotary Files for Various Pitch and Cross-sectional Geometries. J. Endod. 2012, 38, 1399–1403. [Google Scholar] [CrossRef]

- Ha, J.-H.; Kim, S.K.; Cohenca, N.; Kim, H.-C. Effect of R-phase Heat Treatment on Torsional Resistance and Cyclic Fatigue Fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef]

- Lam, P.; Palamara, J.; Messer, H. Fracture Strength of Tooth Roots following Canal Preparation by Hand and Rotary Instrumentation. J. Endod. 2005, 31, 529–532. [Google Scholar] [CrossRef]

- Kim, H.-C.; Lee, M.-H.; Yum, J.; Versluis, A.; Lee, C.-J.; Kim, B.-M. Potential Relationship between Design of Nickel-Titanium Rotary Instruments and Vertical Root Fracture. J. Endod. 2010, 36, 1195–1199. [Google Scholar] [CrossRef]

- Ha, J.-H.; Park, S.-S. Influence of glide path on the screw-in effect and torque of nickel-titanium rotary files in simulated resin root canals. Restor. Dent. Endod. 2012, 37, 215–219. [Google Scholar] [CrossRef]

- Adorno, C.G.; Yoshioka, T.; Suda, H. Crack Initiation on the Apical Root Surface Caused by Three Different Nickel-Titanium Rotary Files at Different Working Lengths. J. Endod. 2011, 37, 522–525. [Google Scholar] [CrossRef]

- Diemer, F.; Calas, P. Effect of Pitch Length on the Behavior of Rotary Triple Helix Root Canal Instruments. J. Endod. 2004, 30, 716–718. [Google Scholar] [CrossRef]

- Park, H. A comparison of Greater Taper files, ProFiles, and stainless steel files to shape curved root canals. Oral Surgery Oral Med. Oral Pathol. Oral Radiol. Endod. 2001, 91, 715–718. [Google Scholar] [CrossRef]

- Sattapan, B.; Nervo, G.J.; E Palamara, J.; Messer, H.H. Defects in Rotary Nickel-Titanium Files After Clinical Use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef]

- Sjögren, U.; Hägglund, B.; Sundqvist, G.; Wing, K. Factors affecting the long-term results of endodontic treatment. J. Endod. 1990, 16, 498–504. [Google Scholar] [CrossRef]

- Smith, C.S.; Setchell, D.J.; Harty, F.J. Factors influencing the success of conventional root canal therapy—A five-year retrospective study. Int. Endod. J. 1993, 26, 321–333. [Google Scholar] [CrossRef]

- Ha, J.H.; Cheung, G.S.; Versluis, A.; Lee, C.J.; Kwak, S.W.; Kim, H.C. “Screw-in” tendency of rotary nickel-titanium files due to design geometry. Int. Endod. J. 2015, 48, 666–672. [Google Scholar] [CrossRef]

- Ha, J.-H.; Kwak, S.W.; Kim, S.-K.; Kim, H.-C. Screw-in forces during instrumentation by various file systems. Restor. Dent. Endod. 2016, 41, 304–309. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.-M.; Zheng, Y.-F.; Peng, B.; Haapasalo, M. Current Challenges and Concepts of the Thermomechanical Treatment of Nickel-Titanium Instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef]

- Dentsply maillefer. Available online: http://www.dentsplymaillefer.com/product-category/glide-path-shaping/waveone (accessed on 8 August 2018).

- Schneider, S.W. A comparison of canal preparations in straight and curved root canals. Oral Surgery Oral Med. Oral Pathol. 1971, 32, 271–275. [Google Scholar] [CrossRef]

- Shen, Y.; Qian, W.; Abtin, H.; Gao, Y.; Haapasalo, M. Effect of Environment on Fatigue Failure of Controlled Memory Wire Nickel-Titanium Rotary Instruments. J. Endod. 2012, 38, 376–380. [Google Scholar] [CrossRef]

- Elanghy, A.M.; Elsaka, S.E. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 2016, 49, 1073–1078. [Google Scholar] [CrossRef]

- Yum, J.; Cheung, G.S.-P.; Park, J.-K.; Hur, B.; Kim, H.-C. Torsional Strength and Toughness of Nickel-Titanium Rotary Files. J. Endod. 2011, 37, 382–386. [Google Scholar] [CrossRef]

- Gambarini, G.; Plotino, G.; Grande, N.M.; Al-Sudani, D.; De Luca, M.; Testarelli, L.; Al-Sudani, D. Mechanical properties of nickel-titanium rotary instruments produced with a new manufacturing technique. Int. Endod. J. 2011, 44, 337–341. [Google Scholar] [CrossRef]

- Kim, H.-C.; Sung, S.Y.; Ha, J.-H.; Solomonov, M.; Lee, J.-M. Stress Generation during Self-Adjusting File Movement: Minimally Invasive Instrumentation. J. Endod. 2013, 39, 1572–1575. [Google Scholar] [CrossRef]

- Baek, S.-H.; Lee, C.-J.; Versluis, A.; Kim, B.-M.; Lee, W.; Kim, H.-C. Comparison of Torsional Stiffness of Nickel-Titanium Rotary Files with Different Geometric Characteristics. J. Endod. 2011, 37, 1283–1286. [Google Scholar] [CrossRef]

- Gao, Y.; Gutmann, J.L.; Wilkinson, K.; Maxwell, R.; Ammon, D. Evaluation of the Impact of Raw Materials on the Fatigue and Mechanical Properties of ProFile Vortex Rotary Instruments. J. Endod. 2012, 38, 398–401. [Google Scholar] [CrossRef]

- Topçuoğlu, H.S.; Düzgün, S.; Aktı, A.; Topçuoğlu, G. Laboratory comparison of cyclic fatigue resistance of WaveOne Gold, Reciproc and WaveOne files in canals with a double curvature. Int. Endod. J. 2017, 50, 713–717. [Google Scholar] [CrossRef]

- Dentsply Sirona. Wave One Gold. Available online: http://www.dentsplymaillefer.com/product-category/glide-path-shaping/waveone-gold (accessed on 12 November 2018).

| Group | Mean ± SD |

|---|---|

| ProTaper Universal, F2 (PTU) | 1.941 ± 0.290 a |

| ProTaper Gold, F2 (PTG) | 1.234 ± 0.246 c |

| WaveOne, Primary (WOP) | 1.622 ± 0.130 b |

| WaveOne Gold, Primary (WOG) | 0.976 ± 0.062 d |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, S.W.; Lee, C.-J.; Kim, S.K.; Kim, H.-C.; Ha, J.-H. Comparison of Screw-In Forces during Movement of Endodontic Files with Different Geometries, Alloys, and Kinetics. Materials 2019, 12, 1506. https://doi.org/10.3390/ma12091506

Kwak SW, Lee C-J, Kim SK, Kim H-C, Ha J-H. Comparison of Screw-In Forces during Movement of Endodontic Files with Different Geometries, Alloys, and Kinetics. Materials. 2019; 12(9):1506. https://doi.org/10.3390/ma12091506

Chicago/Turabian StyleKwak, Sang Won, Chan-Joo Lee, Sung Kyo Kim, Hyeon-Cheol Kim, and Jung-Hong Ha. 2019. "Comparison of Screw-In Forces during Movement of Endodontic Files with Different Geometries, Alloys, and Kinetics" Materials 12, no. 9: 1506. https://doi.org/10.3390/ma12091506

APA StyleKwak, S. W., Lee, C.-J., Kim, S. K., Kim, H.-C., & Ha, J.-H. (2019). Comparison of Screw-In Forces during Movement of Endodontic Files with Different Geometries, Alloys, and Kinetics. Materials, 12(9), 1506. https://doi.org/10.3390/ma12091506