Effect of Microbiological Growth Components for Bacteria-Based Self-Healing on the Properties of Cement Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mortar Tests

2.1.1. Mix Proportions

2.1.2. Test Methods

- r is the inner radius of the capillary tube;

- σ is the surface tension coefficient of the tested liquid;

- θ is the contact angle;

- ρ is the density of the tested liquid;

- g is the gravitational acceleration;

- h is the height of the liquid column in the capillary tube.

- △Fx is the surface tension of the tested solution;

- ρx is the density of the tested solution;

- ρw is the density of pure water;

- Hx is the height of the tested solution in the capillary tube;

- Hw is the height of pure water in the capillary tube.

- Mo is the mass (g) after curing for another 7 days;

- Mj is the mass (g) after the required absorption time.

2.2. Paste Tests

3. Results and Discussion

3.1. Surface Tension of Saturated Solutions

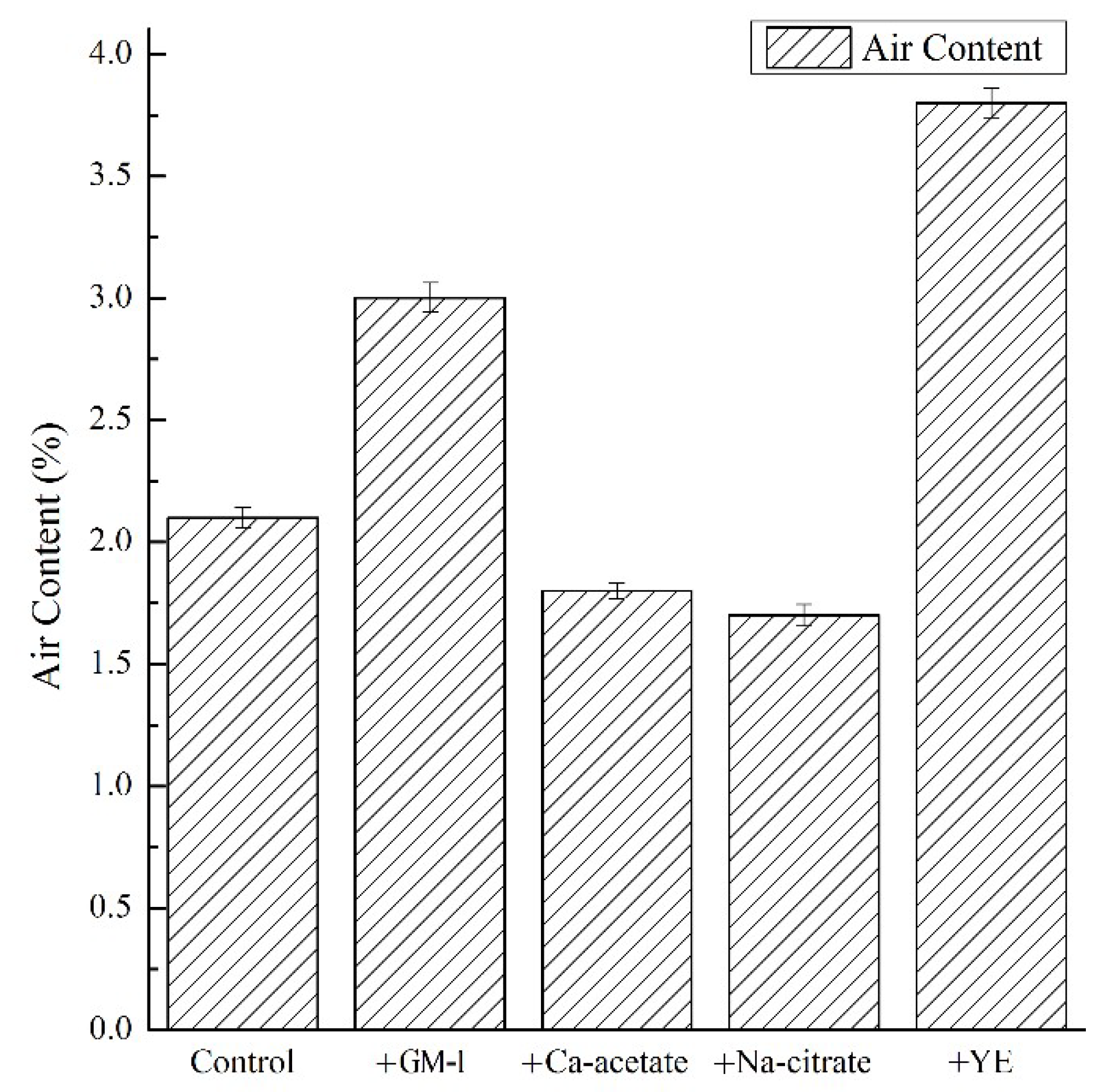

3.2. Air Content of Mortar

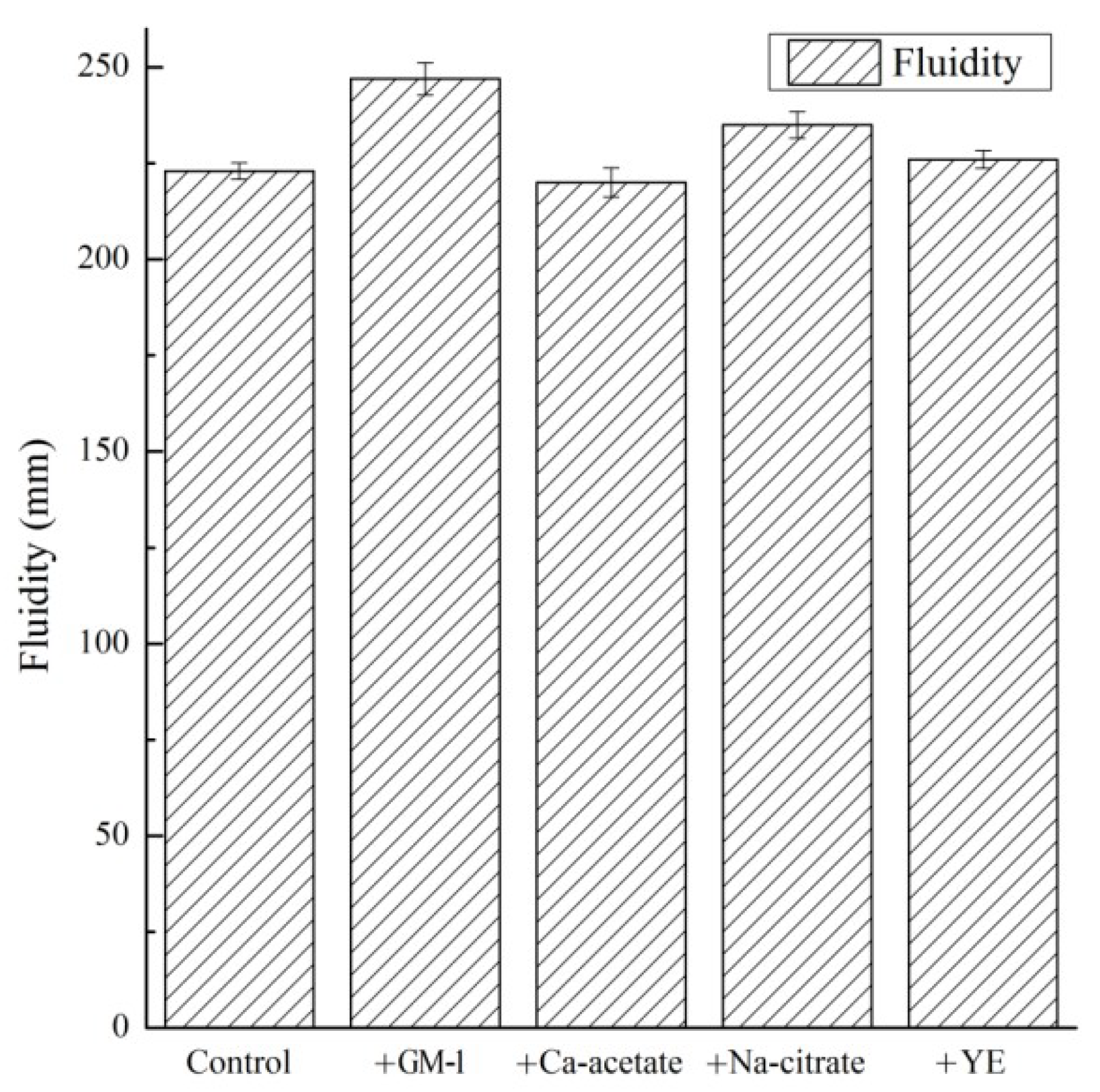

3.3. Fluidity of Mortar

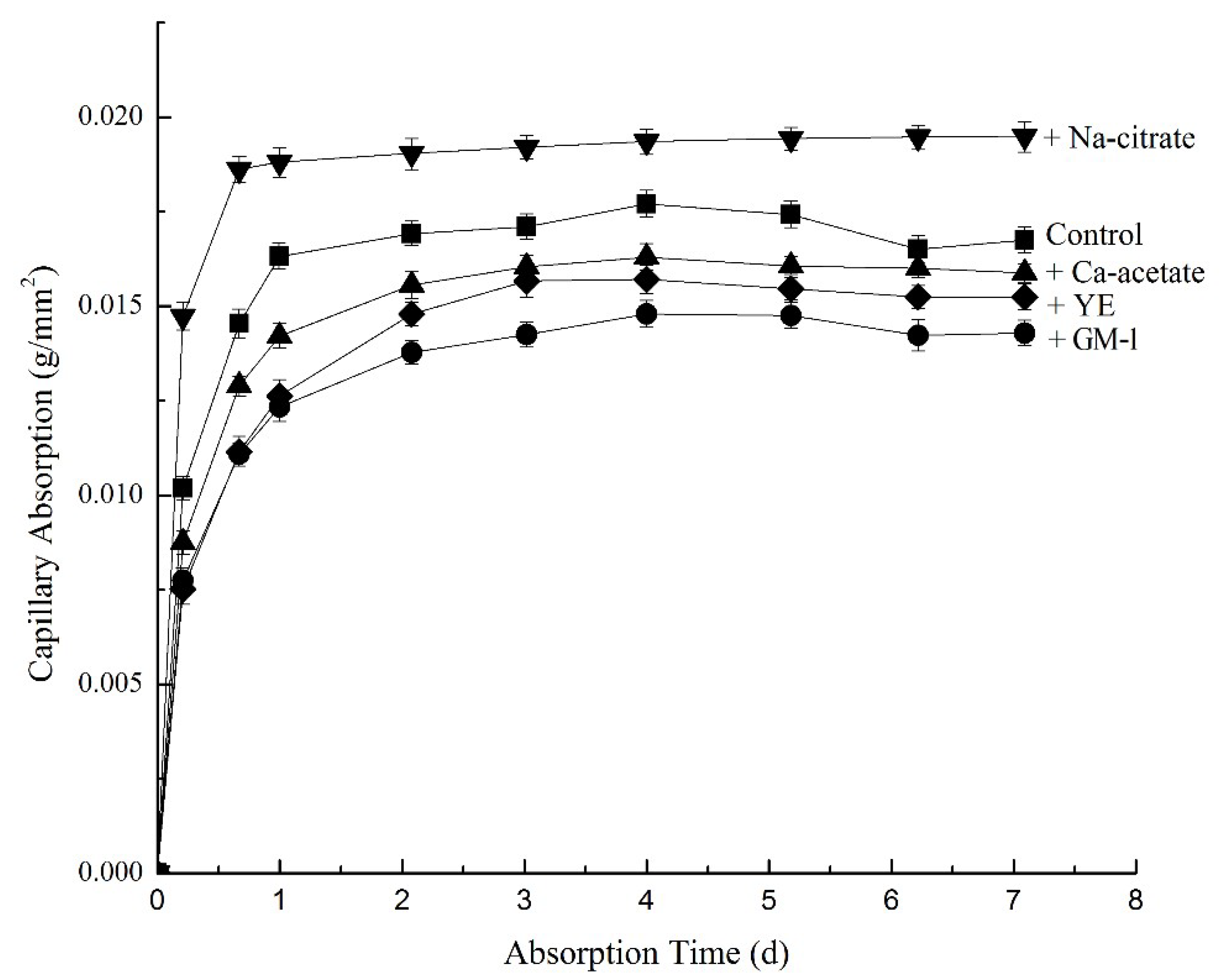

3.4. Capillary Absorption of Mortar

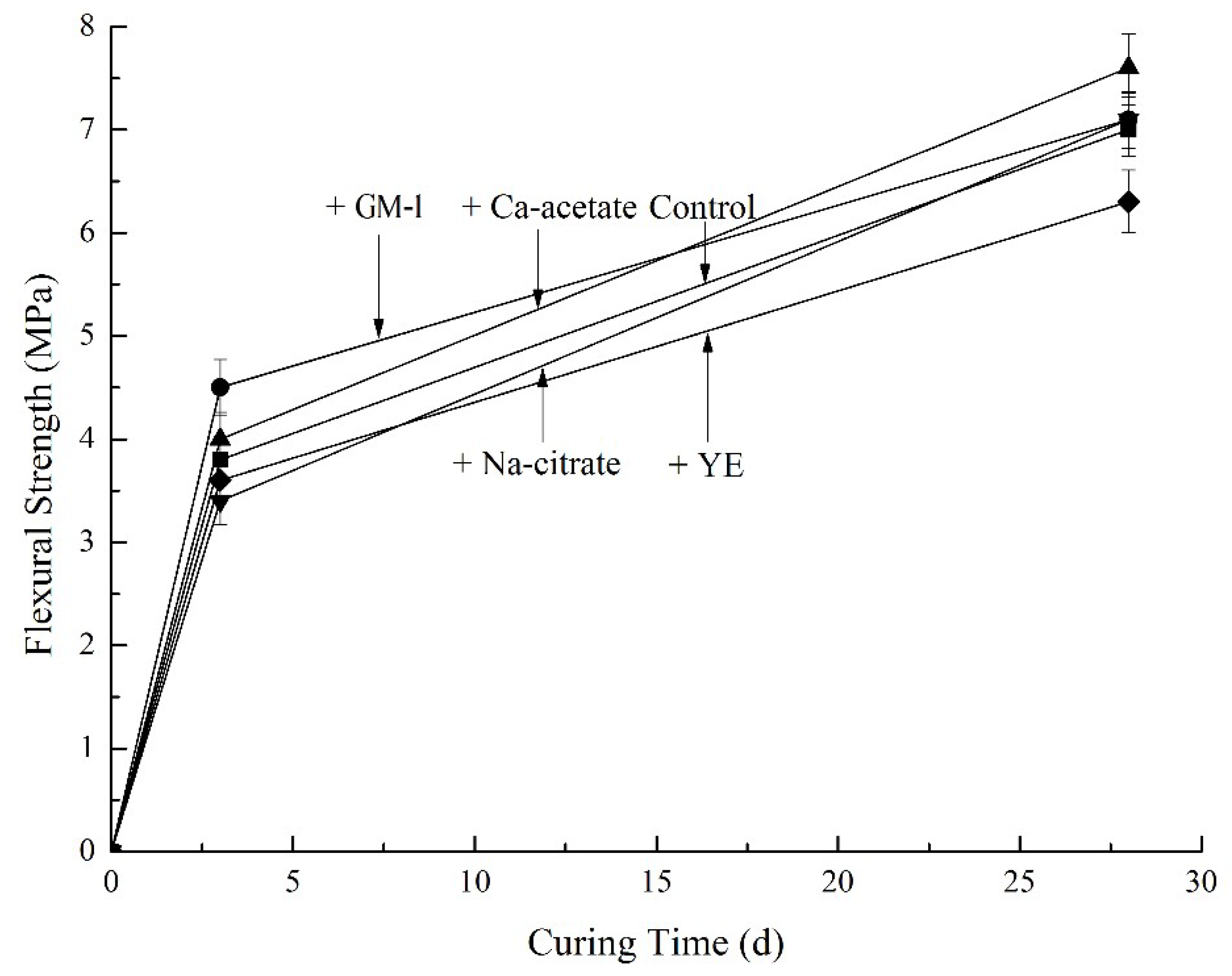

3.5. Strength Development of Mortar

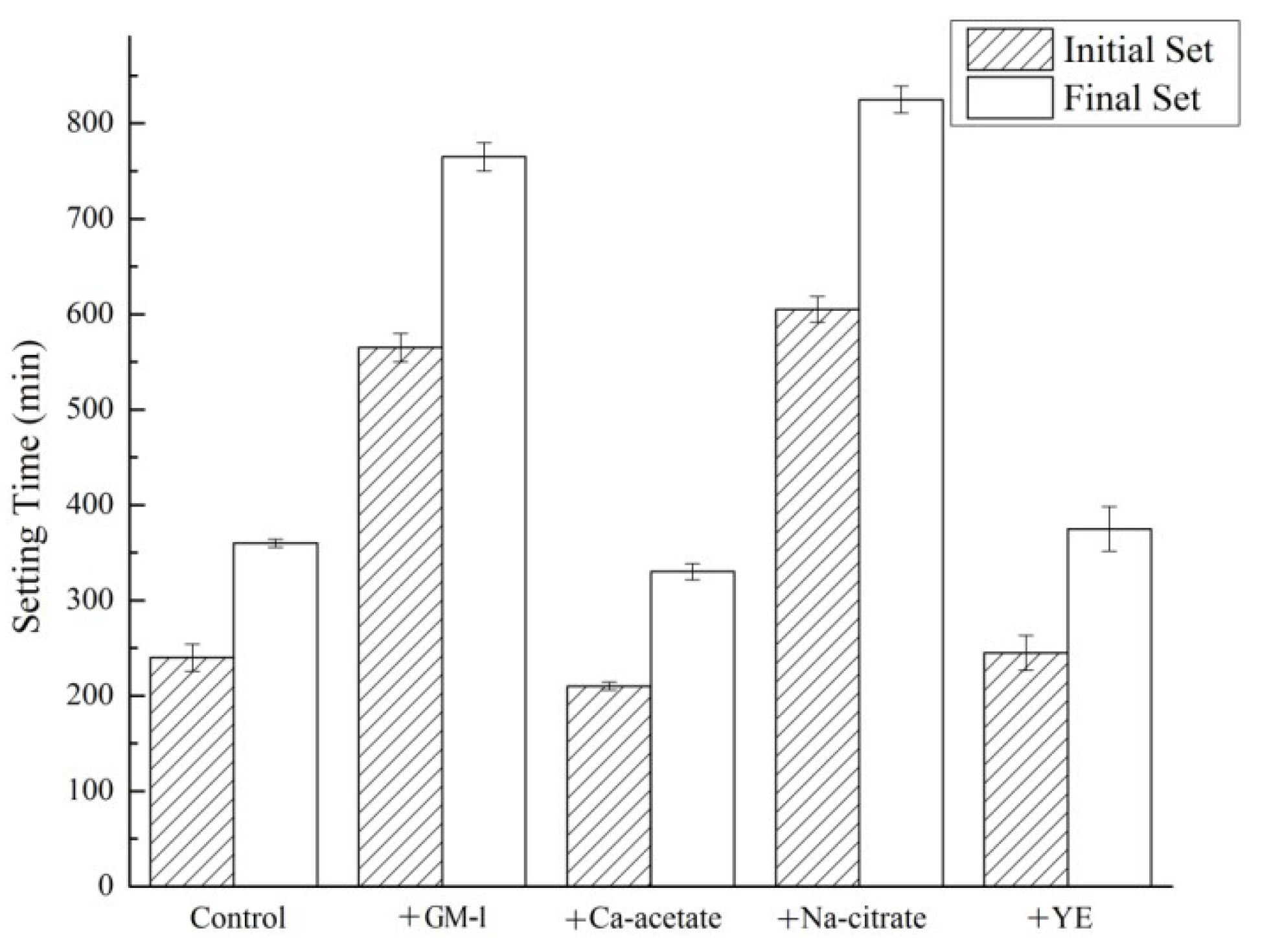

3.6. Setting of Cement Paste

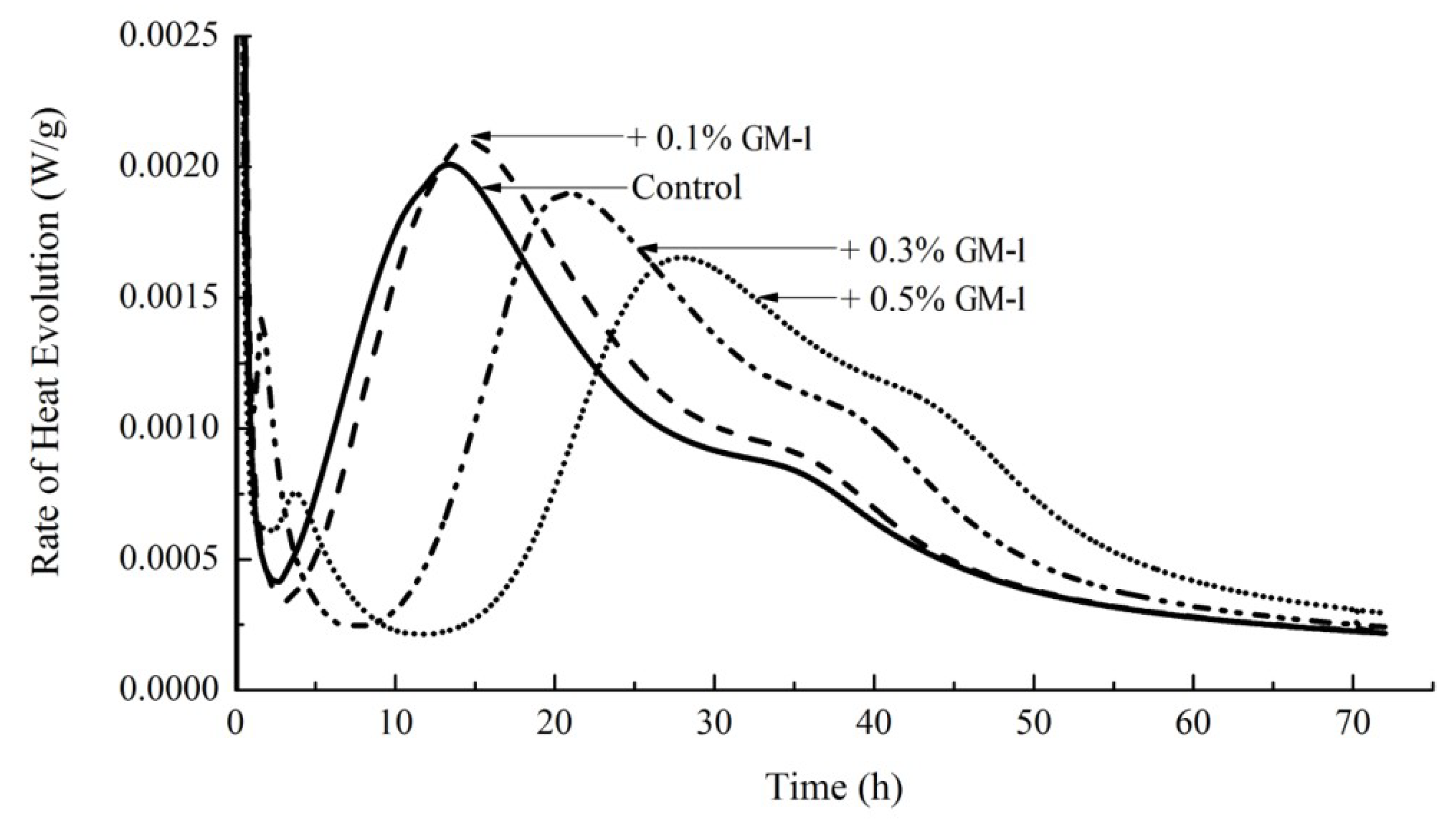

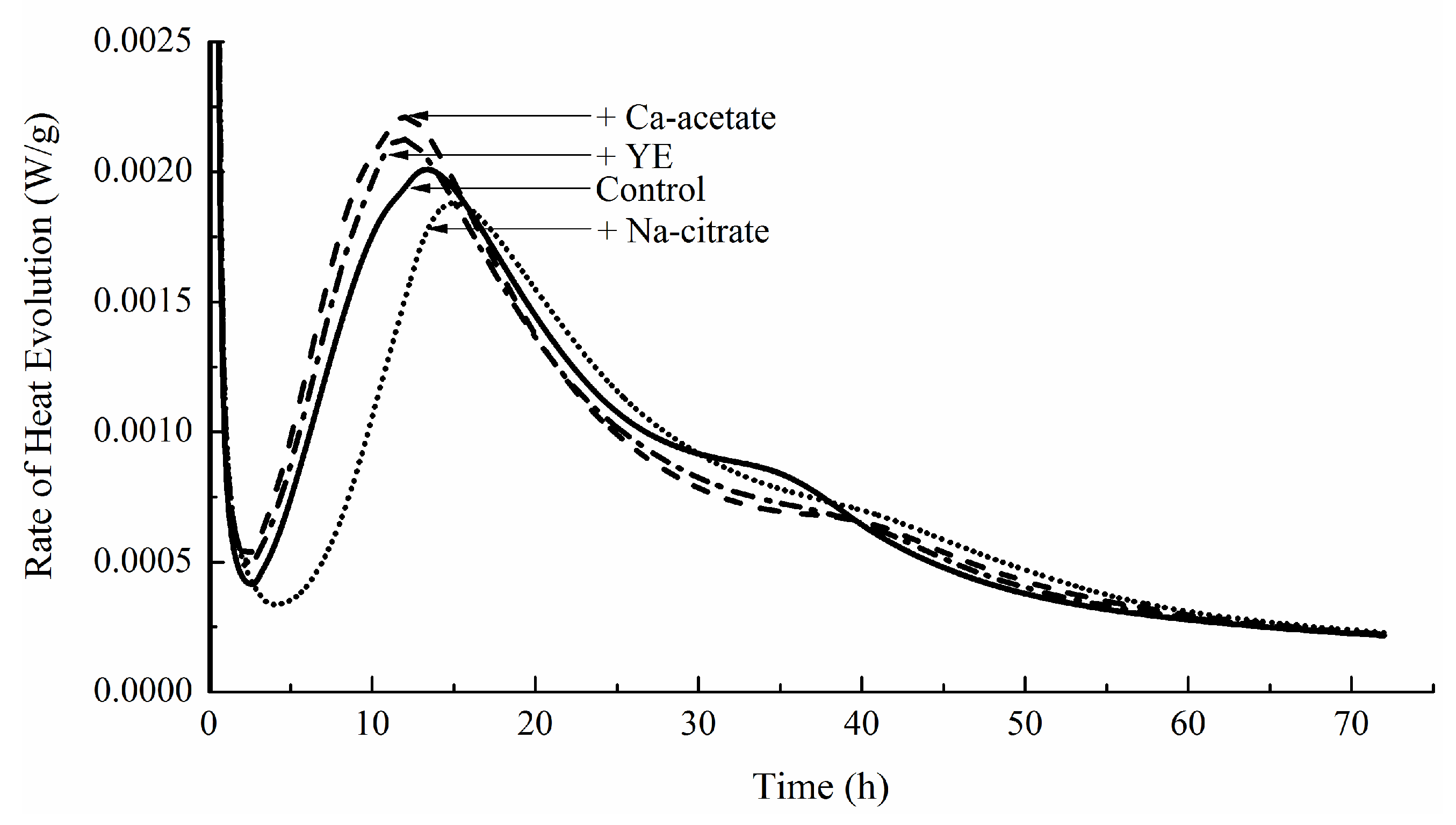

3.7. Hydration Kinetics of Cement Paste

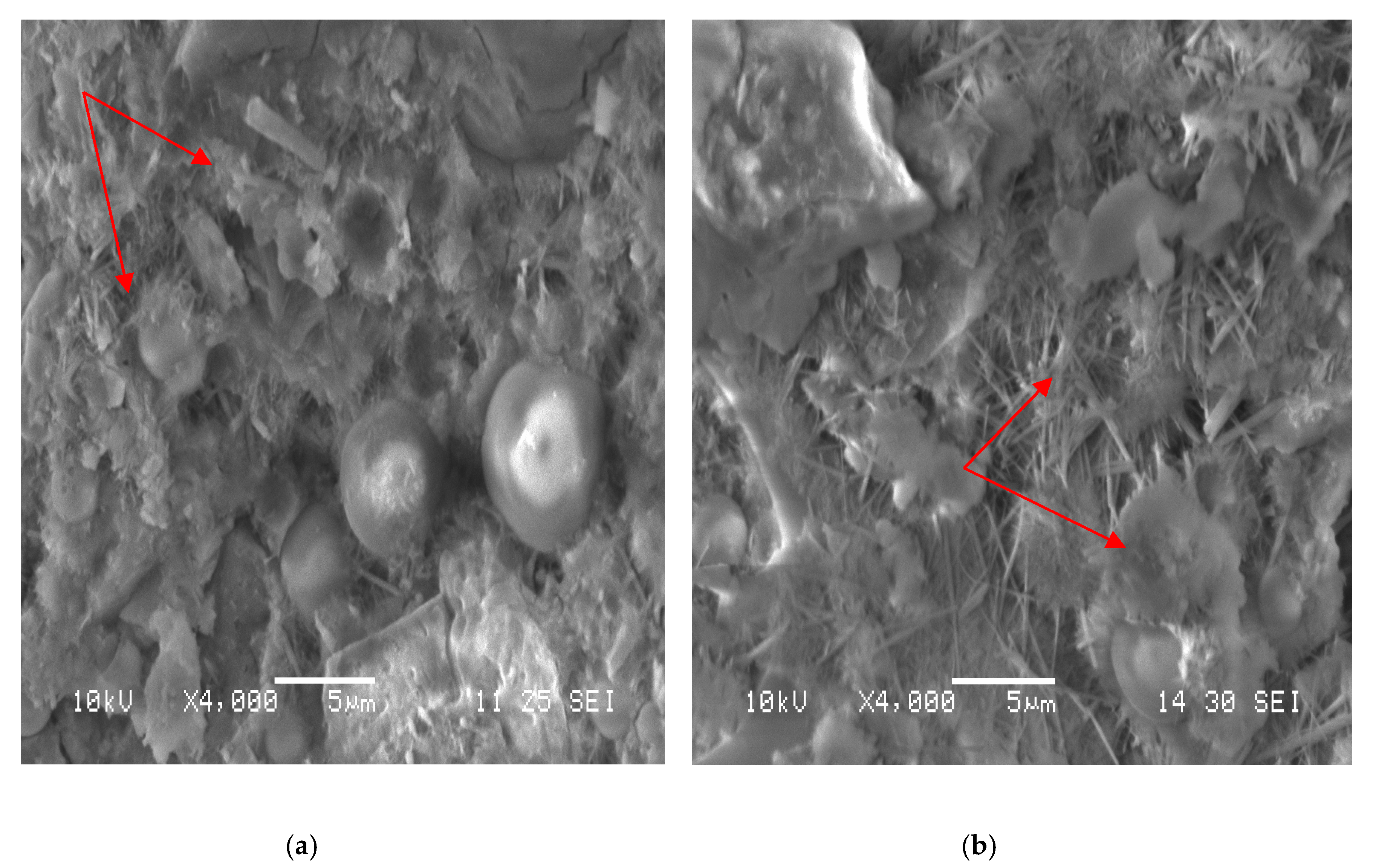

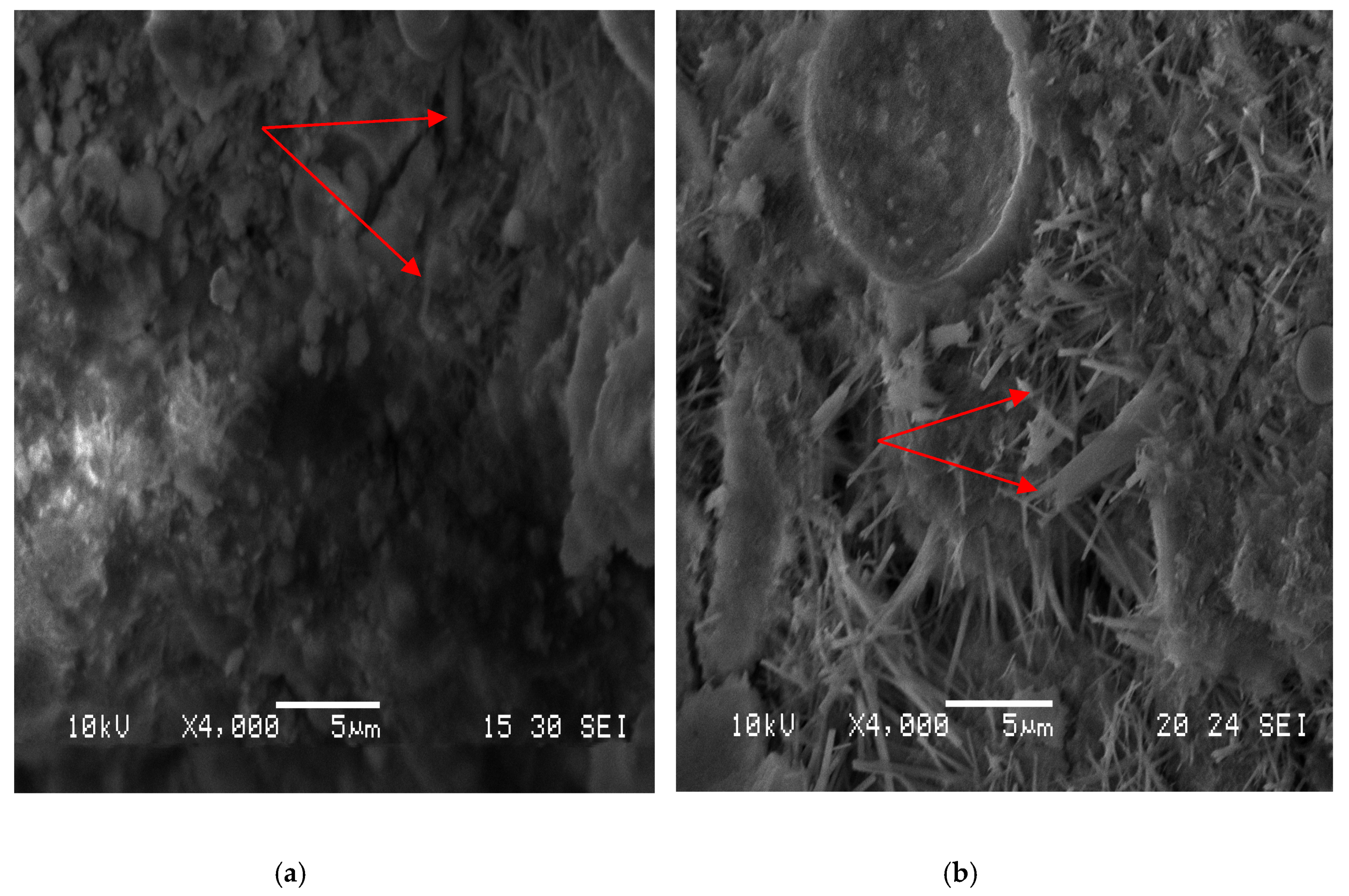

3.8. Microstructure of Cement Paste

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alazhari, M.S.; Al Shebani, M.M. Assessment of concrete quality in Libya. Procedia. Eng. 2013, 54, 117–126. [Google Scholar] [CrossRef]

- De Belie, N.; Wang, J.; Bundur, Z.B.; Paine, K. Bacteria-based concrete. In Eco-efficient Repair and Rehabilitation of Concrete Infrastructures, 1st ed.; Pacheco-Torgal, F., Melchers, R., de Belie, N., Shi, X., Van Tittelboom, K., Saez Perez, A., Eds.; Woodhead Publishing: Duxford, UK, 2017; Volume 2, pp. 531–567. [Google Scholar]

- Wang, J.; Ersan, Y.C.; Boon, N.; De Belie, N. Application of microorganisms in concrete: A promising sustainable strategy to improve concrete durability. Appl. Microbiol. Biotechnol. 2016, 100, 2993–3007. [Google Scholar] [CrossRef] [PubMed]

- Ongley, E.D. Control of Water Pollution from Agriculture, 1st ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 1996; Volume 55, pp. 37–52. [Google Scholar]

- Achal, V.; Mukerjee, A.; Reddy, M.S. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Chen, X.; Han, Y.X.; Zhang, G.R.; Ma, Cong.; Zhu, X.J. Activity investigation of Sporosarcinapasturii as concrete crack healing agent. J. Build. Mater. 2018, 2018. 21, 484–489. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Sharma, T.; Alazhari, M.S.A.; Cooper, R.; Heath, A.; Paine, K. Alkaliphilic Bacillus species show potential application in concrete crack repair by virtue of rapid spore production and germination then extracellular calcite formation. J. Appl. Microbiol. 2017, 122, 1233–1244. [Google Scholar] [CrossRef] [PubMed]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Alazhari, M.; Sharma, T.; Heath, A.; Cooper, R.; Paine, K. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr. Build. Mater. 2018, 160, 610–619. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Field performance of bacteria-based repair system: Pilot study in a parking garage, Case Stud. Constr. Mater. 2015, 2, 11–17. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A review of self-healing concrete for damage management of structures. Adv. Mater. Interf. 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Formia, A.; Antonaci, P.; Pugno, N.M.; Tulliani, J.-M. Setup of extruded cementitious hollow tubes as containing/releasing devices in self-healing systems. Materials 2015, 8, 1897–1923. [Google Scholar] [CrossRef] [PubMed]

- Formia, A.; Ircio, S.; Bertola, F.; Canonico, F.; Antonaci, P.; Pugno, N.M.; Tulliani, J.-M. Experimental analysis of self-healing cement-based materials incorporating extruded cementitious hollow tubes. J. Intell. Mater. Syst. Struct. 2016, 27, 2633–2652. [Google Scholar] [CrossRef]

- Paine, K.; Horne, I.; Tan, L.; Sharma, T.; Heath, A.; Cooper, R.; Virgoe, J.; Palmer, D.; Kerr, A. Microencapsulated spores and growth media for self-healing mortars. In Proceedings of the 6th International Symposium on Life-Cycle Civil Engineering, Ghent, Belgium, 28–31 October 2018; CRC Press: Ghent, Belgium, 2018; pp. 2247–2254. [Google Scholar]

- Wang, J.; Dewanckele, J.; Cnudde, V.; Van Vlierberghe, S.; Verstraete, W.; De Belite, N. X-ray computed tomography proof of bacteria-based self-healing in concrete. Cem. Concr. Compos. 2014, 53, 289–304. [Google Scholar] [CrossRef]

- Sharma, T.; Alazhari, M.S.A.; Cooper, R.; Heath, A.; Paine, K. The requirements for autonomic microbiologically induced calcite precipitation in concrete. In Proceedings of the 5th International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015. [Google Scholar]

- Bundur, Z.B.; Kirisits, M.J.; Ferron, R.D. Biomineralized cement-based materials: Impact of inoculating vegetative bacterial cells on hydration and strength. Cem. Concr. Res. 2015, 67, 237–245. [Google Scholar] [CrossRef]

- Amiri, A.; Bundur, Z.B. Use of corn-steep liquor as an alternative carbon source for biomineralization in cement-based materials and its impact on performance. Constr. Build. Mater. 2018, 165, 655–662. [Google Scholar] [CrossRef]

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: a promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1–14. [Google Scholar] [CrossRef]

- BS EN197-1, 2000. Cement. Composition, Specifications and Conformity Criteria for Common Cements. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030159150 (accessed on 19 April 2019).

- BS EN 196-1, 2005. Methods of Testing Cement. Determination of Strength. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000019983596 (accessed on 19 April 2019).

- Guo, R. Summarization of surface tension measurement. Metrol. & Meas. Tech. 2009, 36, 62–64. [Google Scholar] [CrossRef]

- BS EN 1015-7, 1999. Methods of Test for Mortar for Masonry. Determination of Air Content of Fresh Mortar. Available online: https://bsol.bsigroup.com/Search/Search?searchKey=BS+EN+1015-7 (accessed on 19 April 2019).

- BS EN 1015-3, 1999. Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table). Available online: https://bsol.bsigroup.com/Search/Search?searchKey=BS+EN+1015-3+ (accessed on 19 April 2019).

- BS EN 480-5, 2005. Admixtures for Concrete, Mortar and Grout. Test Methods. Determination of Capillary Absorption. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000030129086 (accessed on 19 April 2019).

- BS EN 196-3, 2005. Methods of Testing Cement. Determination of Setting Times and Soundness. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000030179180 (accessed on 19 April 2019).

- Şahin, Y.; AKkaya, Y.; Boylu, F.; Taşdemir, M.A.Y. Characterization of air entraining admixtures in concrete using surface tension measurements. Cem. Concr. Compos. 2017, 82, 95–104. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zong, L. Evaluation of Relationship between Water Absorption and Durability of Concrete Materials. Adv. Mater. Sci. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Collepardi, M.; Massidda, L. Hydration of tricalcium silicate. J. Am. Ceram. Soc. 1971, 54, 419–422. [Google Scholar] [CrossRef]

- Ramachandran, V.S. Concrete Admixtures Handbook, 2nd ed.; William Andrew: New York, NY, USA, 1996; pp. 185–285. [Google Scholar] [CrossRef]

- Möschner, G.; Lothenbach, B.; Figi, R.; Kretzschmar, R. Influence of citric acid on the hydration of Portland cement. Cem. Concr. Res. 2009, 39, 275–282. [Google Scholar] [CrossRef]

- Ramachandran, M.S.; Lowery, M.S. Conduction calorimetric investigation of the effect of retarders on the hydration of Portland cement. Thermochim. Acta 1992, 195, 373–387. [Google Scholar] [CrossRef]

- Yu, S.Q.; Li, X.G.; Tan, H.B.; He, C. Adsorption behavior and retarding mechanism of sodium citrate on cement hydration process. Concrete 2013, 45, 72–75. [Google Scholar] [CrossRef]

- Quraish, M.A.; Nayak, D.K.; Singh, B.N.; Kumar, V.; Pandey, K.K. Experimental Studies on Effects of Sodium Citrate, Calcium Nitrite and Hexamine as Corrosion Inhibitor in Concrete. J. Steel. Struct. Constr. 2017, 2, 1000117. [Google Scholar] [CrossRef]

| Component | Function |

|---|---|

| Major Components | |

| Calcium acetate | Soluble calcium salt providingCa2+ for CaCO3 precipitation. |

| Sodium citrate | A source of carbon and energy. |

| Yeast extract | A complex source of nitrogen, vitamins, amino acids, and carbon (trace) for bacteria to grow. |

| Minor Components | |

| Sodium glutamate | An amino acid involved in protein synthesis and other fundamental processes such as glycolysis, gluconeogenesis, and the citric acid cycle. It is also a key metabolite linking nitrogen and carbon metabolism. |

| Alanine | Germination triggers, specific to Bacillus, which aid the formation of vegetative cells from spores. |

| Inosine | |

| Magnesium chloride | Used to activate enzymes and aids metabolism of carbohydrates, fats, and amino acids. |

| Sodium chloride | Controls the water activity that is required for the growth of vegetative cells and endospores. |

| Manganese sulphate | Mn is a key component required for sporulation (for repetitive self-healing). |

| Monopotassium phosphate | pH buffering agent. |

| Self-Healing Component | GM-1 | Ca-Acetate | Na-Citrate | YE |

|---|---|---|---|---|

| Calcium acetate (Ca-acetate) | 55.9 | 100.0 | – | – |

| Sodium citrate (Na-citrate) | 18.7 | – | 100.0 | – |

| Yeast extract (YE) | 12.1 | – | – | 100.0 |

| Sodium glutamate | 3.7 | – | – | – |

| Alanine | 1.9 | – | – | – |

| Inosine | 1.9 | – | – | – |

| Magnesium chloride | 1.9 | – | – | – |

| Sodium chloride | 1.9 | – | – | – |

| Manganese sulfate monohydrate | 1.2 | – | – | – |

| Potassium hypophosphite | 0.9 | – | – | – |

| Total | 100.0 | 100.0 | 100.0 | 100.0 |

| Group | Component/Cement Mass Ratio | Growth Media, g | Cement, g | Water, g | Standard Sand, g |

|---|---|---|---|---|---|

| Control | 0% | 0 | 450 | 225 | 1350 |

| GM-1 | 0.50% | 2.25 | 450 | 225 | 1350 |

| Ca-acetate | 0.28% | 1.30 | 450 | 225 | 1350 |

| Na-citrate | 0.09% | 0.43 | 450 | 225 | 1350 |

| YE | 0.06% | 0.28 | 450 | 225 | 1350 |

| Group | Control | GM-1 | Ca-Acetate | Na-Citrate | YE |

|---|---|---|---|---|---|

| Solute/Solvent 1 | 0/100 | 16.5/100 | 35/100 | 10/100 | 2/100 |

| Density (g/cm3) | 1.000 | 1.165 | 1.350 | 1.100 | 1.020 |

| Height 2(mm) | 145 | 102 | 118 | 140 | 120 |

| Surface Tension (mN/m) | 72.8 | 59.6 | 79.9 | 77.2 | 61.4 |

| Self-Healing Component | GM-2 |

|---|---|

| Calcium acetate (Ca-acetate) | 66.2 |

| Sodium citrate (Na-citrate) | – |

| Yeast extract (YE) | 20.5 |

| Sodium glutamate | 3.7 |

| Alanine | 1.9 |

| Inosine | 1.9 |

| Magnesium chloride | 1.9 |

| Sodium chloride | 1.9 |

| Manganese sulfate monohydrate | 1.2 |

| Potassium hypophosphite | 0.9 |

| Total | 100.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Yuan, J.; Alazhari, M. Effect of Microbiological Growth Components for Bacteria-Based Self-Healing on the Properties of Cement Mortar. Materials 2019, 12, 1303. https://doi.org/10.3390/ma12081303

Chen X, Yuan J, Alazhari M. Effect of Microbiological Growth Components for Bacteria-Based Self-Healing on the Properties of Cement Mortar. Materials. 2019; 12(8):1303. https://doi.org/10.3390/ma12081303

Chicago/Turabian StyleChen, Xin, Jie Yuan, and Mohamed Alazhari. 2019. "Effect of Microbiological Growth Components for Bacteria-Based Self-Healing on the Properties of Cement Mortar" Materials 12, no. 8: 1303. https://doi.org/10.3390/ma12081303

APA StyleChen, X., Yuan, J., & Alazhari, M. (2019). Effect of Microbiological Growth Components for Bacteria-Based Self-Healing on the Properties of Cement Mortar. Materials, 12(8), 1303. https://doi.org/10.3390/ma12081303