Influence of Adhesive in FSW: Investigation on Fatigue Behavior of Welded, Weld-Bonded, and Adhesive-Bonded Joints in Aluminum AA 6082 T6

Abstract

1. Introduction

2. Materials and Methods

2.1. Adhesive Bonding (AB)

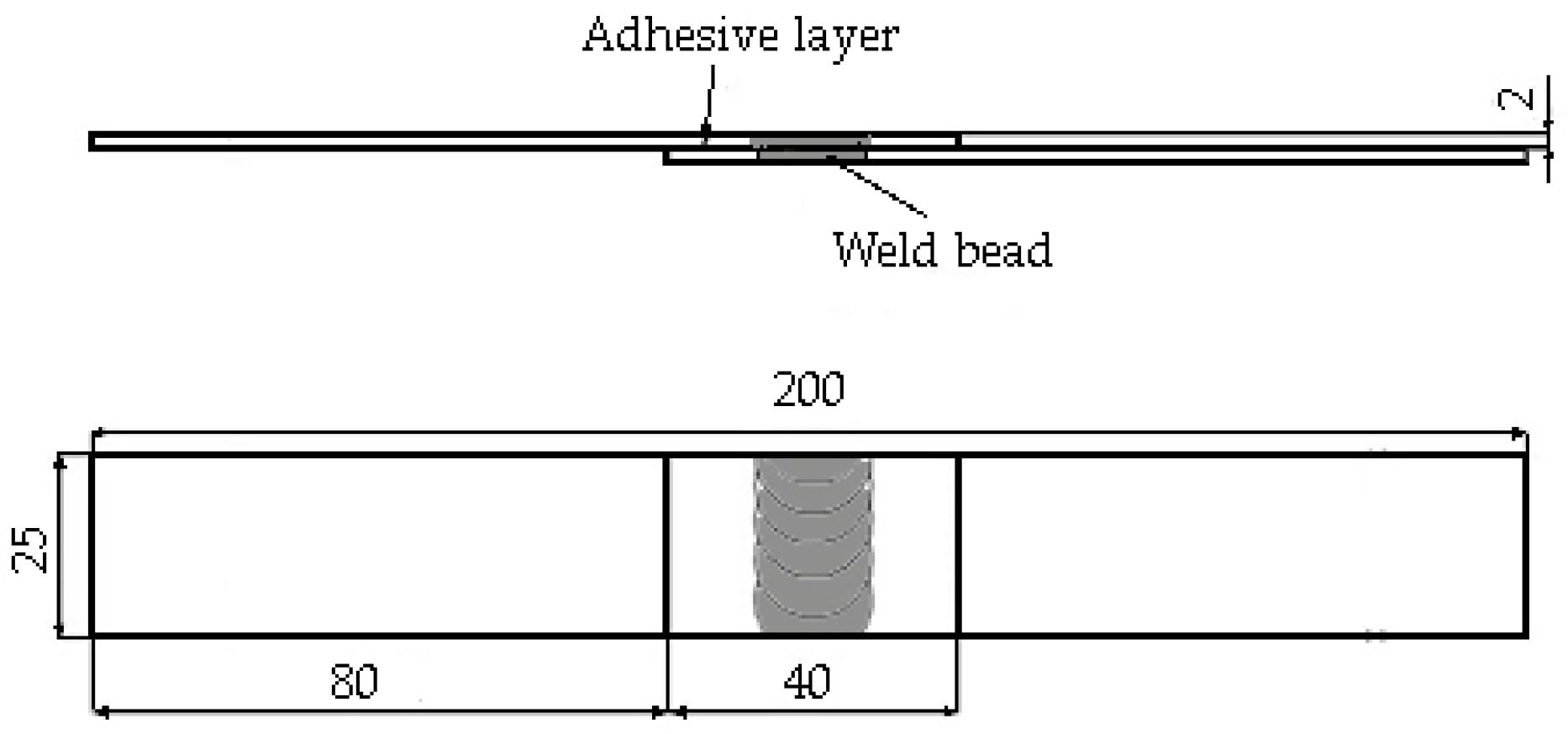

2.2. Friction Stir Welding (FSW)

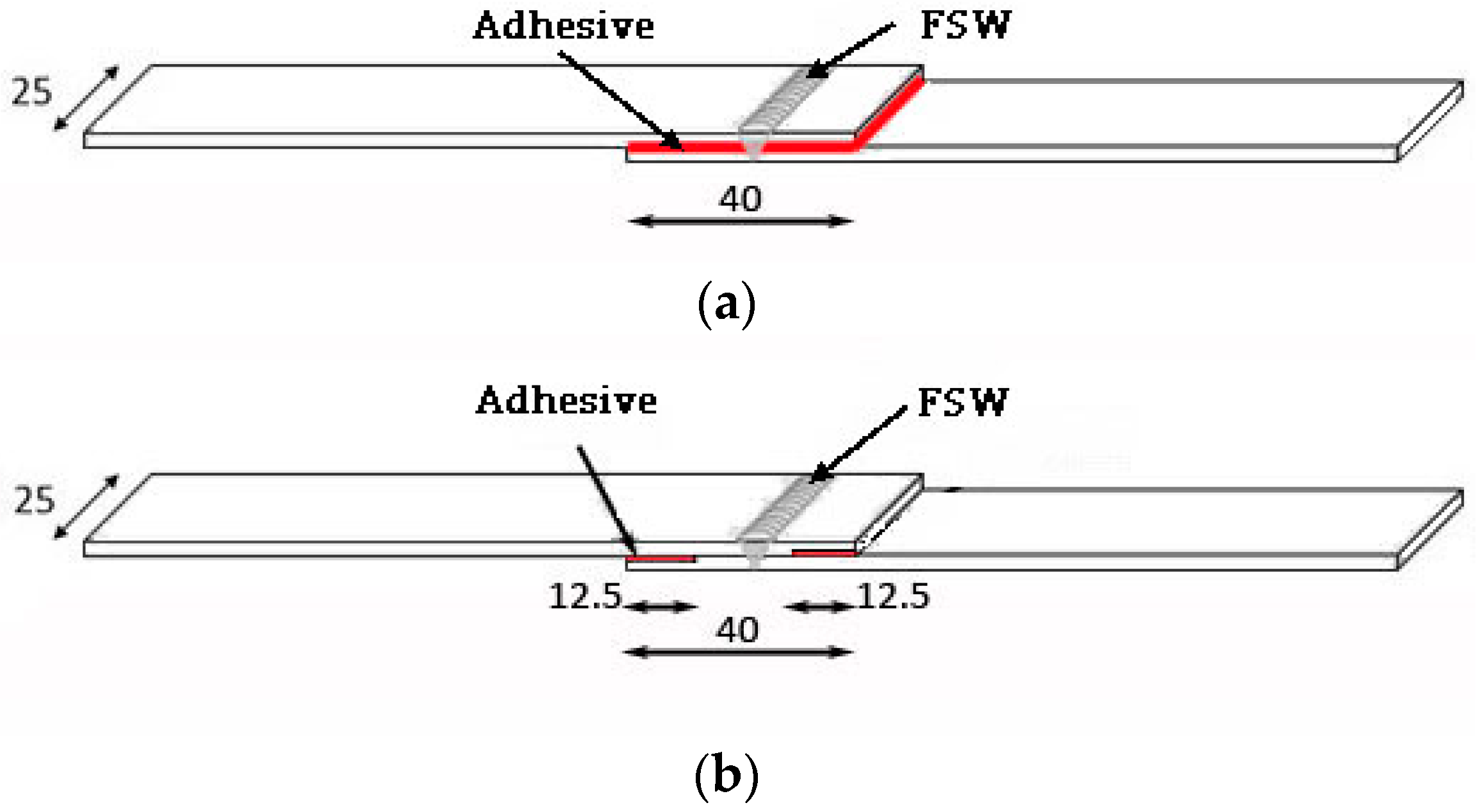

2.3. Friction Stir Weld-Bonding (FSWB)

2.4. Quasi-Static and Dynamic Tests

3. Results and Discussion

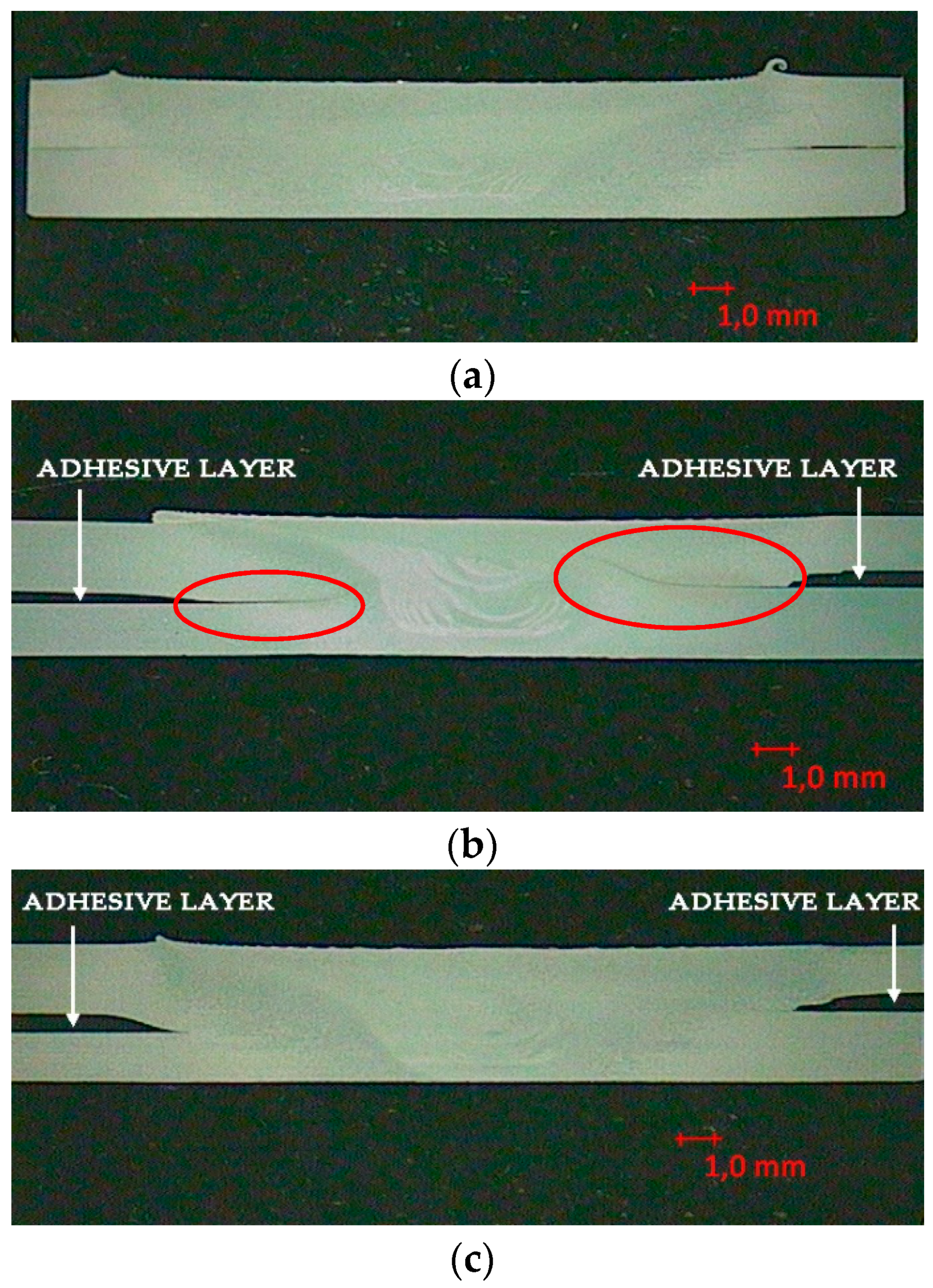

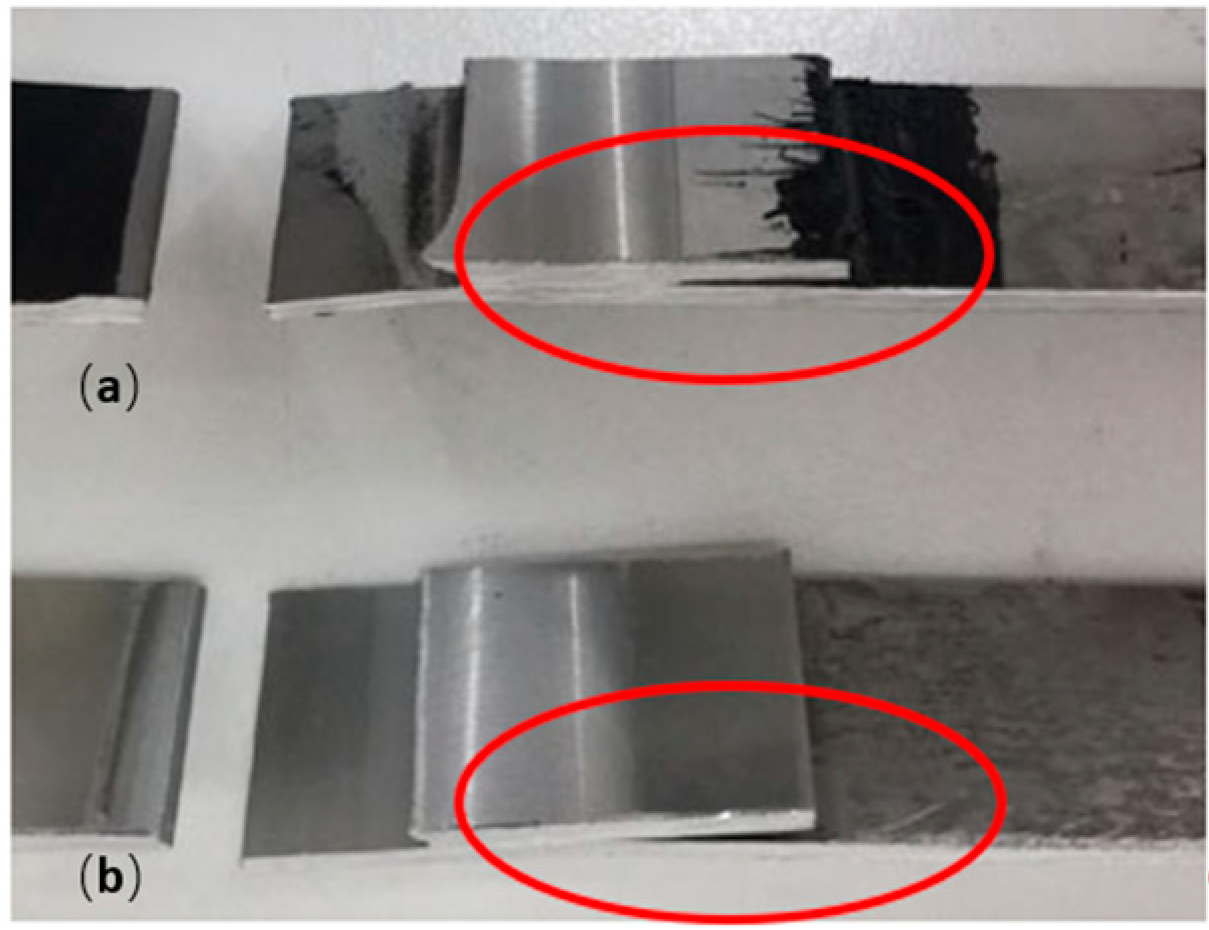

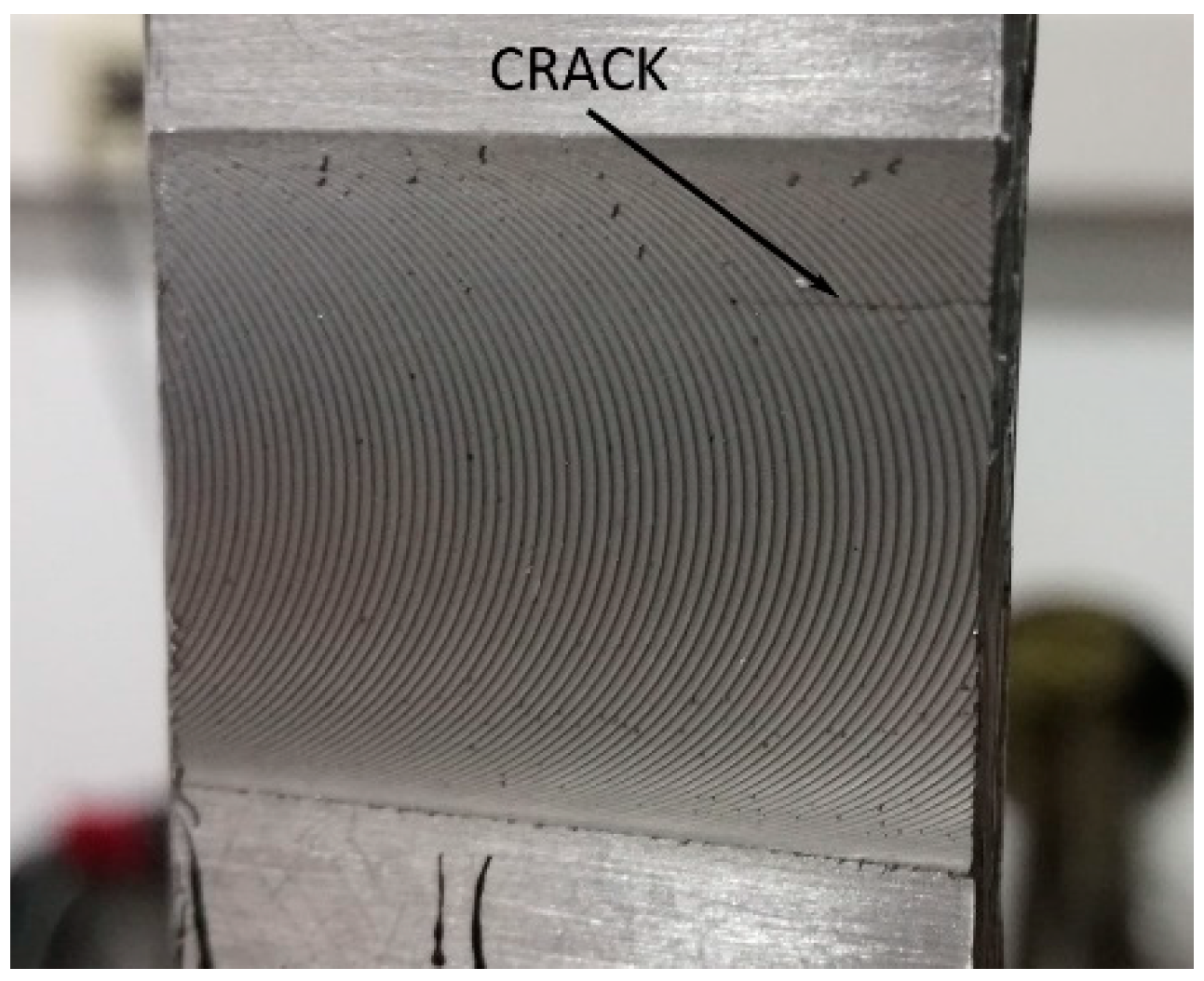

3.1. Macrographic Analysis

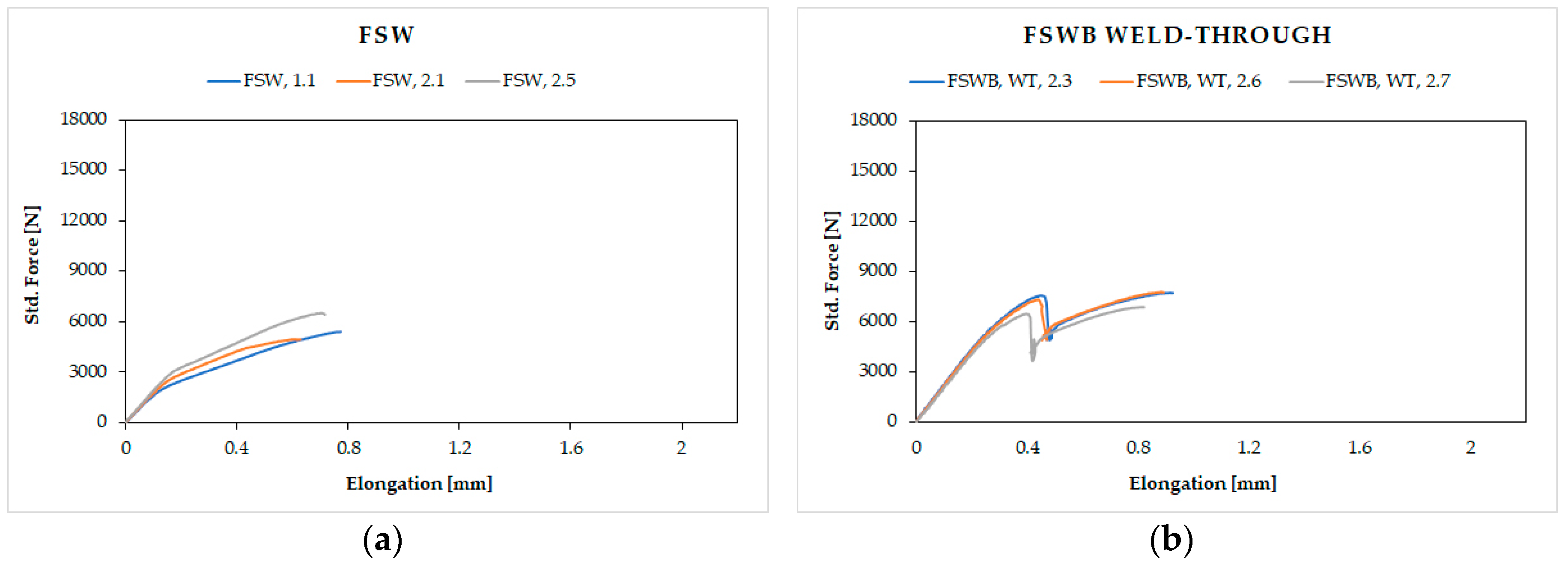

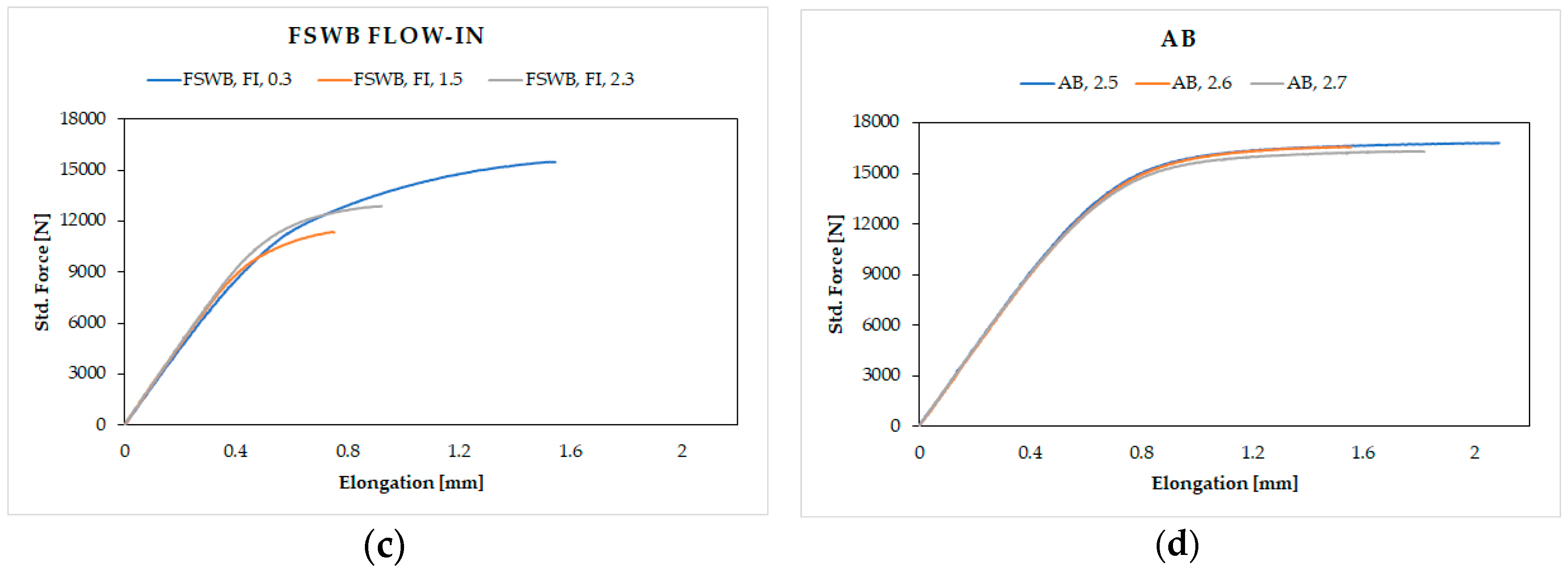

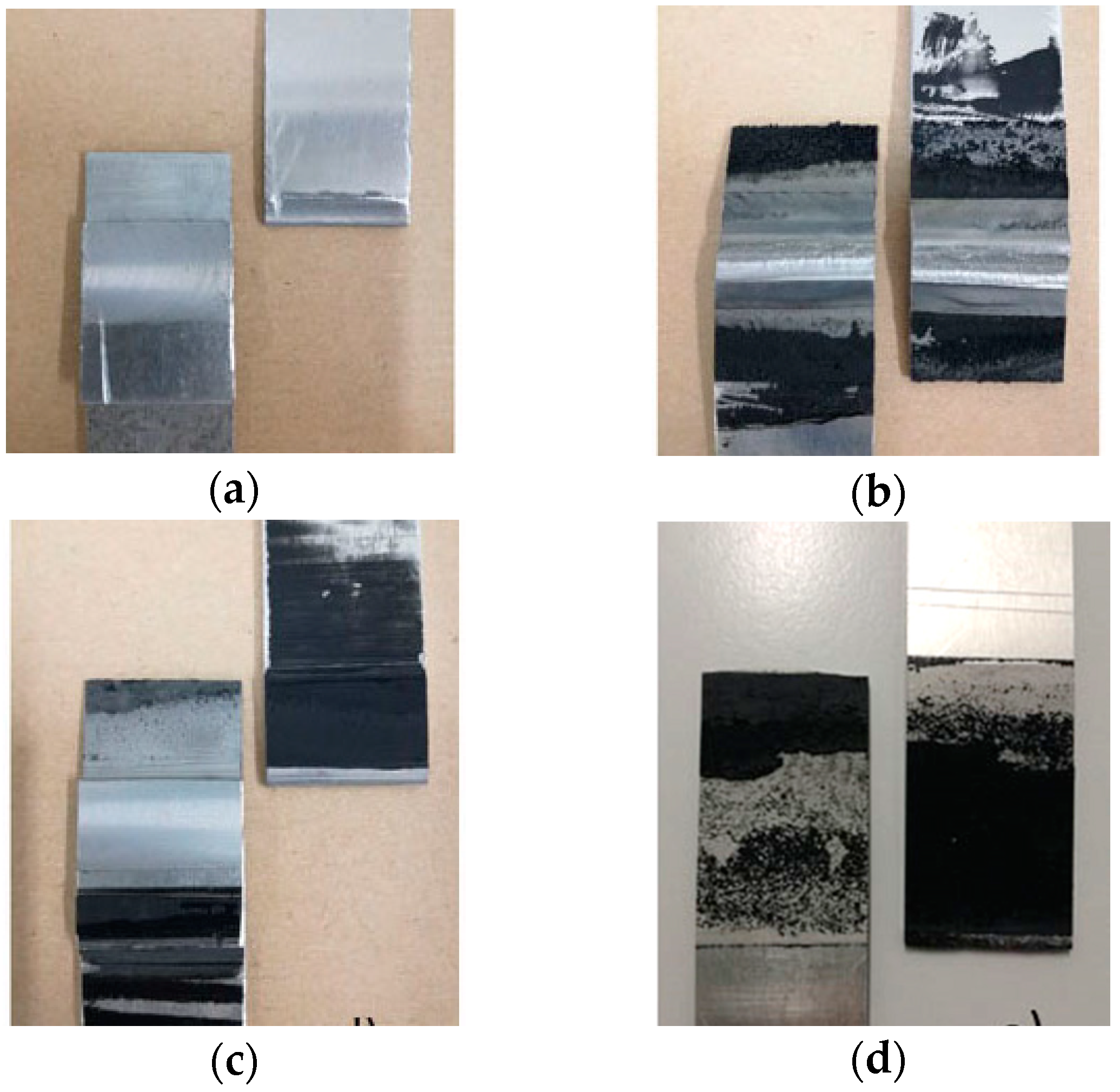

3.2. Single Lap-Shear Tests

3.3. Fatigue Tests

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petrie, E.M. Weldbonding—A Hybrid Method of Assembly. Met. Finish. 2013, 111, 42–44. [Google Scholar] [CrossRef]

- Besharati Givi, M.K.; Asadi, P. General Introduction. In Advances in Friction Stir Welding and Processing; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Akinlabi, E.T.; Akinlabi, S.A. Friction stir welding of dissimilar metals. In Advances in Friction Stir Welding and Processing; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Ponte, M. Theoretical and applicative study of Friction Stir Welding technology on aluminum alloys and metal matrix composite materials. Ph.D. Thesis, University of Genoa, Genoa, Italy, March 2007. [Google Scholar]

- Lertora, E.; Mandolfino, C.; Gambaro, C.; Pizzorni, M. Hybrid FSWeld-bonded joint fatigue behaviour. In Proceedings of the AIP Conference Proceedings, Malang City, Indonesia, 7–8 March 2018; AIP Publishing: Melville, NY, USA, 2018. [Google Scholar]

- Fortunato, J.; Anand, C.; Braga, D.F.O.; Groves, R.M.; Moreira, P.M.G.P.; Infante, V. Friction stir weld-bonding defect inspection using phased array ultrasonic testing. Int. J. Adv. Manuf. Technol. 2017, 93, 3125–3134. [Google Scholar] [CrossRef]

- Reis, L.; Infante, V.; De Freitas, M.; Duarte, F.F.; Moreira, P.M.G.; Castro, P.M.S.T. Fatigue Behaviour of Aluminium Lap Joints Produced by Laser Beam and Friction Stir Welding. Procedia Eng. 2014, 74, 293–296. [Google Scholar] [CrossRef]

- Costa, M.I.; Verdera, D.; Leitão, C.; Rodrigues, D.M. Dissimilar friction stir lap welding of AA 5754-H22 / AA 6082-T6 aluminium alloys: Influence of material properties and tool geometry on weld strength. Mater. Des. 2015, 87, 721–731. [Google Scholar] [CrossRef]

- Cognard, P. Handbook of Adhesives and Sealants, Volume 1—Basic Concepts and High Tech Bonding; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 9, 1–49. [Google Scholar] [CrossRef]

- Beber, V.C.; Schneider, B.; Brede, M. Experimental investigation and numerical prediction of static strength and fracture behaviour of notched epoxy-based structural adhesives. Int. J. Adhes. Adhes. 2019. [Google Scholar] [CrossRef]

- Firmo, J.P.; Roquette, M.G.; Correia, J.R.; Azevedo, A.S. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications. Int. J. Adhes. Adhes. 2019. [Google Scholar] [CrossRef]

- De Zeeuw, C.; De Freitas, S.T.; Zarouchas, D.; Schilling, M.; Fernandes, L.; Portella, P.D. Creep Behaviour of Steel Bonded Joints under Hygrothermal Conditions. Int. J. Adhes. Adhes. 2019. [Google Scholar] [CrossRef]

- Moroni, F.; Pirondi, A.; Kleiner, F. Experimental analysis and comparison of the strength of simple and hybrid structural joints. Int. J. Adhes. Adhes. 2010, 30, 367–379. [Google Scholar] [CrossRef]

- Xu, W.; Chen, D.L.; Liu, L.; Mori, H.; Zhou, Y. Microstructure and mechanical properties of weld-bonded and resistance spot welded magnesium-to-steel dissimilar joints. Mater. Sci. Eng. A 2012, 537, 11–24. [Google Scholar] [CrossRef]

- Marques, G.P.; Campilho, R.D.S.G.; Da Silva, F.J.G.; Moreira, R.D.F. Adhesive selection for hybrid spot-welded/bonded single-lap joints: Experimentation and numerical analysis. Compos. Part B Eng. 2016, 84, 248–257. [Google Scholar] [CrossRef]

- Wang, H.Y.; Liu, L.M. Analysis of the influence of adhesives in laser weld bonded joints. Int. J. Adhes. Adhes. 2014, 52, 77–81. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, G.; Dwivedi, D.K. TIG spot weld bonding of 409 L ferritic stainless steel. Int. J. Adhes. Adhes. 2018, 84, 350–359. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Lai, X. Effect of Epoxy Adhesive on Nugget Formation in Resistance Welding of SAE1004/DP600/DP780 Steel Sheets. Materials 2018, 11, 1828. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.F.; Sharma, G.; Dwivedi, D.K. Weld-bonding of 6061 aluminium alloy. Int. J. Adv. Manuf. Technol. 2015, 78, 863–873. [Google Scholar] [CrossRef]

- Fujii, T.; Tohgo, K.; Suzuki, Y.; Yamamoto, T.; Shimamura, Y.; Ojima, Y. Fatigue properties of spot welded and spot weld-bonded joints of steel sheet. Procedia Eng. 2011, 10, 1075–1080. [Google Scholar] [CrossRef][Green Version]

- Hayat, F. Comparing Properties of Adhesive Bonding, Resistance Spot Welding, and Adhesive Weld Bonding of Coated and Uncoated DP 600 Steel. J. Iron Steel Res. Int. 2011, 18, 70–78. [Google Scholar] [CrossRef]

- Banerjee, P.; Sarkar, R.; Pal, T.K.; Shome, M. Effect of nugget size and notch geometry on the high cycle fatigue performance of resistance spot welded DP590 steel sheets. J. Mater. Process. Technol. 2016, 238, 226–243. [Google Scholar] [CrossRef]

- Melander, A.; Larsson, M.; Stensio, H.; Gustavsson, A.; Linder, J. Fatigue performance of weldbonded high strength sheet steels tested in Arctic, room temperature and tropical environments. Int. J. Adhes. Adhes. 2000, 20, 415–425. [Google Scholar] [CrossRef]

- Braga, D.F.O.; De Sousa, L.M.C.; Infante, V.; Da Silva, L.F.M.; Moreira, P.M.G.P. Aluminum Friction Stir Weldbonding. Procedia Eng. 2015, 114, 223–231. [Google Scholar] [CrossRef][Green Version]

- Braga, D.F.O.; De Sousa, L.M.C.; Infante, V.; Da Silva, L.F.M.; Moreira, P.M.G.P. Aluminium friction-stir weld-bonded joints. J. Adhes. 2016, 92, 665–678. [Google Scholar] [CrossRef]

- Wegman, R.F.; Van Twisk, J. Aluminum and aluminum alloys. In Surface Preparation Techniques for Adhesive Bonding, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Bohler High speed steel Brochure. 2005, pp. 1–16. Available online: https://www.bohler-edelstahl.com/en/high-speed-steel-195.php (accessed on 13 March 2019).

- ASTM International D1002 Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading; ASTM: West Conshohocken, PA, USA, 2010.

- International Organization for Standardization ISO 9664: Adhesives—Test Methods for Fatigue Properties of Structural Adhesives in Tensile Shear; ISO: Geneva, Switzerland, 1993.

| Si | Mg | Mn | Cu | Fe | Cr | Zn | Ti | Other | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.7–1.3 | 0.6–1.2 | 0.4–1.0 | 0.1 | 0.5 | 0.25 | 0.2 | 0.1 | 0.15 | Bal. |

| Tensile Ultimate Strength [MPa] | Tensile Yield Strength [MPa] | Elongation at Break [%] | Young’s Modulus [GPa] |

|---|---|---|---|

| 290–310 | 250–260 | 10 | 70 |

| Property | Component | |

|---|---|---|

| Chemical | Base | Epoxy resin |

| Accelerator | Amine modified | |

| Color | Base | Black |

| Accelerator | White | |

| Consistency | Base | No sag paste |

| Accelerator | No sag paste | |

| Mix ratio | 2 part Base: 1 part Accelerator | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lertora, E.; Mandolfino, C.; Pizzorni, M.; Gambaro, C. Influence of Adhesive in FSW: Investigation on Fatigue Behavior of Welded, Weld-Bonded, and Adhesive-Bonded Joints in Aluminum AA 6082 T6. Materials 2019, 12, 1242. https://doi.org/10.3390/ma12081242

Lertora E, Mandolfino C, Pizzorni M, Gambaro C. Influence of Adhesive in FSW: Investigation on Fatigue Behavior of Welded, Weld-Bonded, and Adhesive-Bonded Joints in Aluminum AA 6082 T6. Materials. 2019; 12(8):1242. https://doi.org/10.3390/ma12081242

Chicago/Turabian StyleLertora, Enrico, Chiara Mandolfino, Marco Pizzorni, and Carla Gambaro. 2019. "Influence of Adhesive in FSW: Investigation on Fatigue Behavior of Welded, Weld-Bonded, and Adhesive-Bonded Joints in Aluminum AA 6082 T6" Materials 12, no. 8: 1242. https://doi.org/10.3390/ma12081242

APA StyleLertora, E., Mandolfino, C., Pizzorni, M., & Gambaro, C. (2019). Influence of Adhesive in FSW: Investigation on Fatigue Behavior of Welded, Weld-Bonded, and Adhesive-Bonded Joints in Aluminum AA 6082 T6. Materials, 12(8), 1242. https://doi.org/10.3390/ma12081242