Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

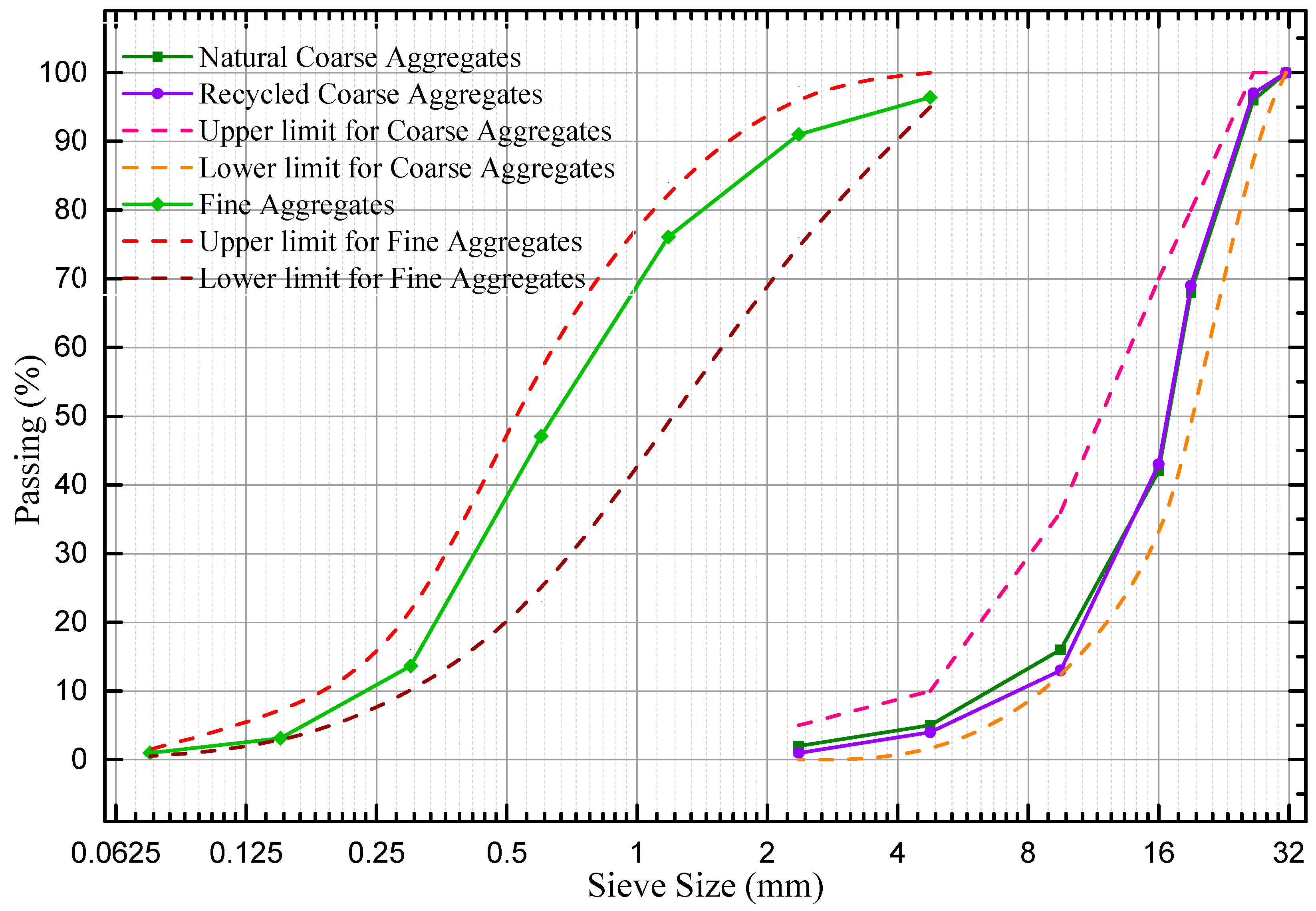

2.1.1. Recycled Coarse Aggregates

2.1.2. Fine Aggregates

2.1.3. Waste Fibers

2.1.4. Cement

2.2. Specimens

2.2.1. Concrete Mixes

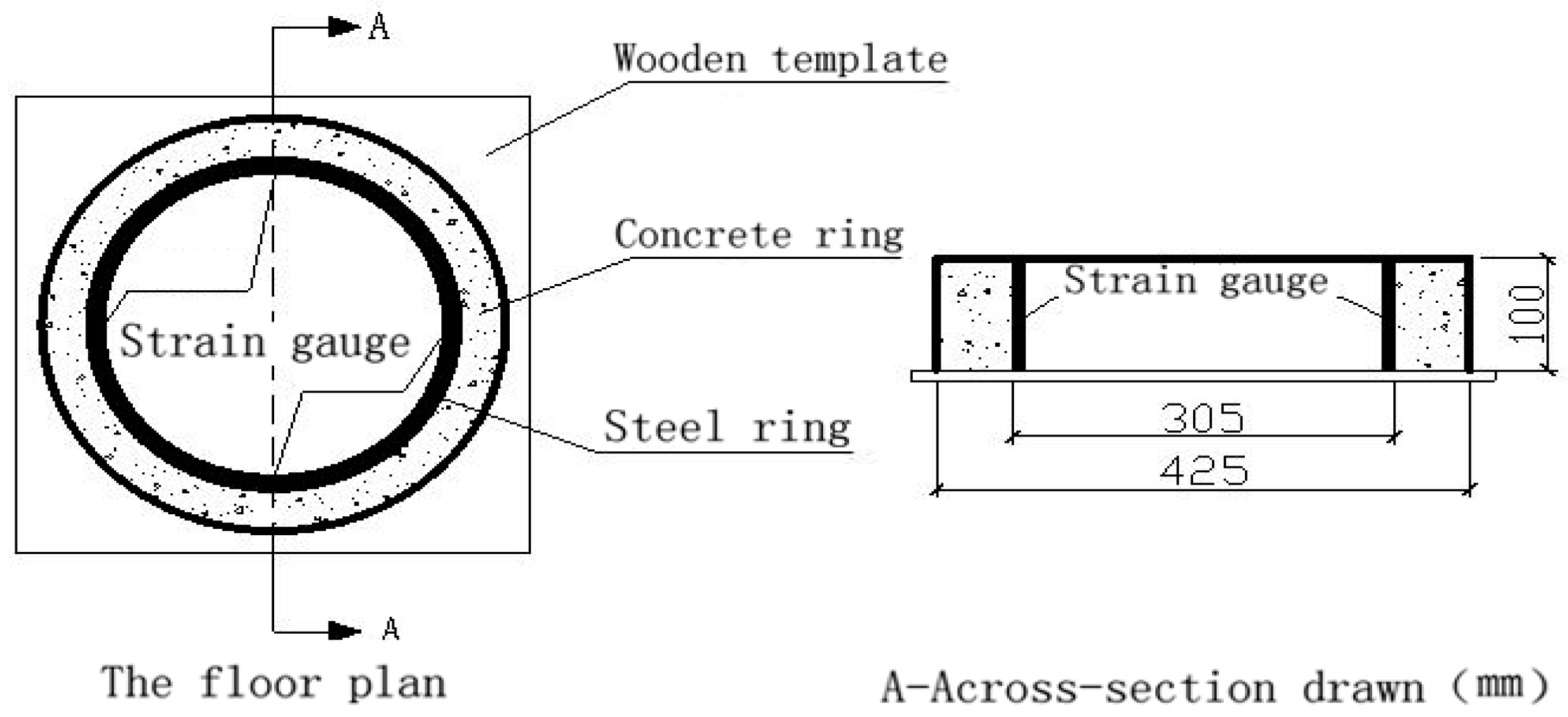

2.2.2. Specimens for Plat-Ring-Type Test

2.2.3. Specimens for Free Shrinkage Test

2.3. Testing Methods

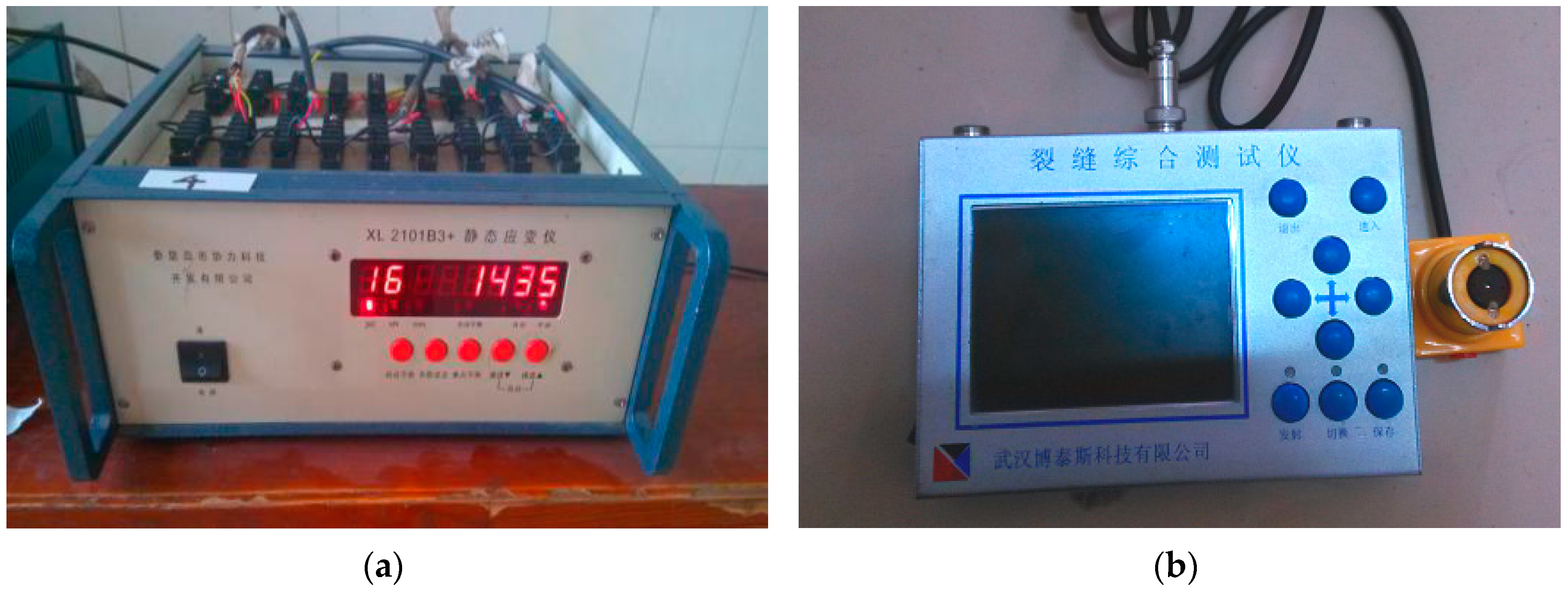

2.3.1. Plat-Ring-Type Test

2.3.2. Free Shrinkage Test

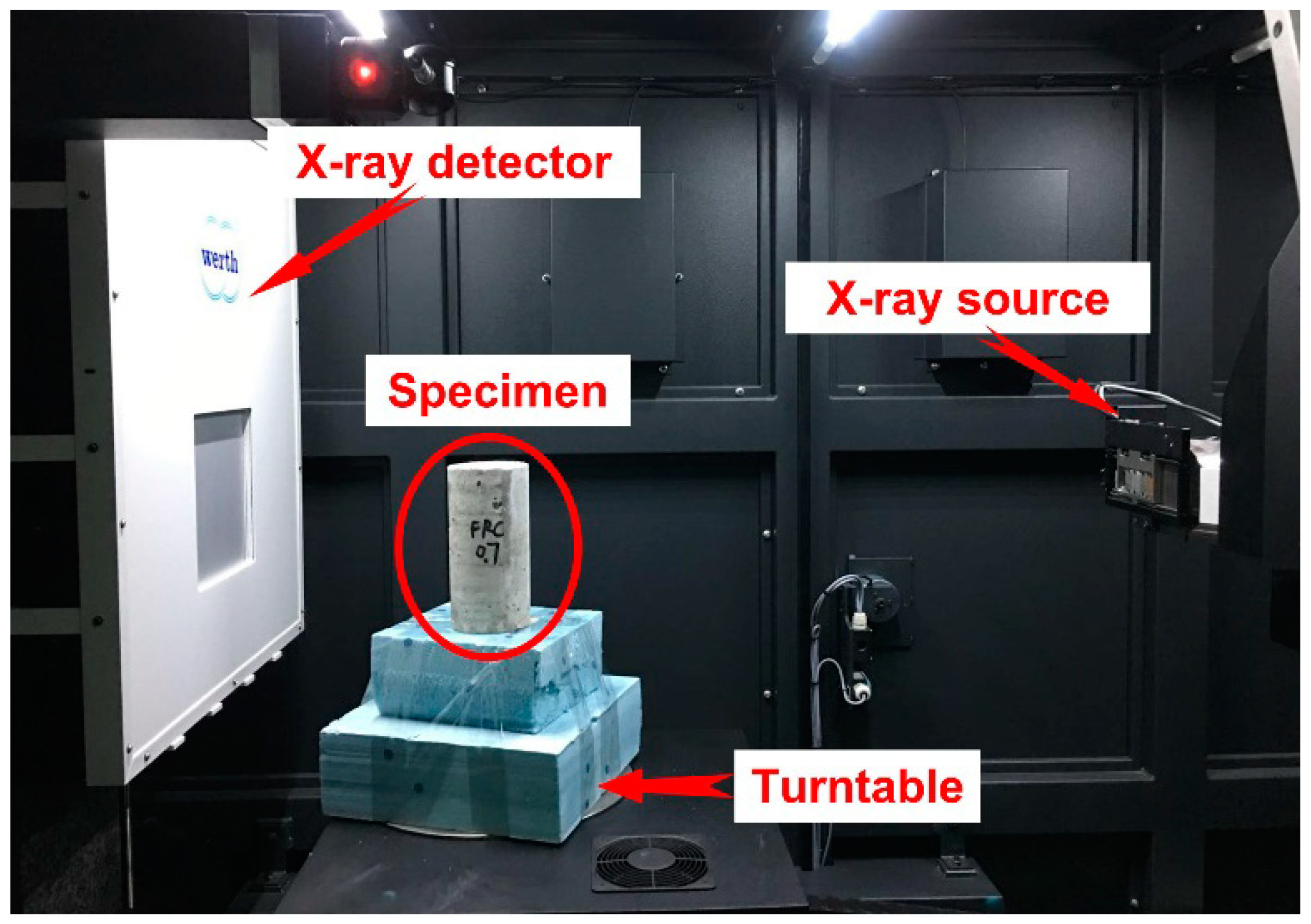

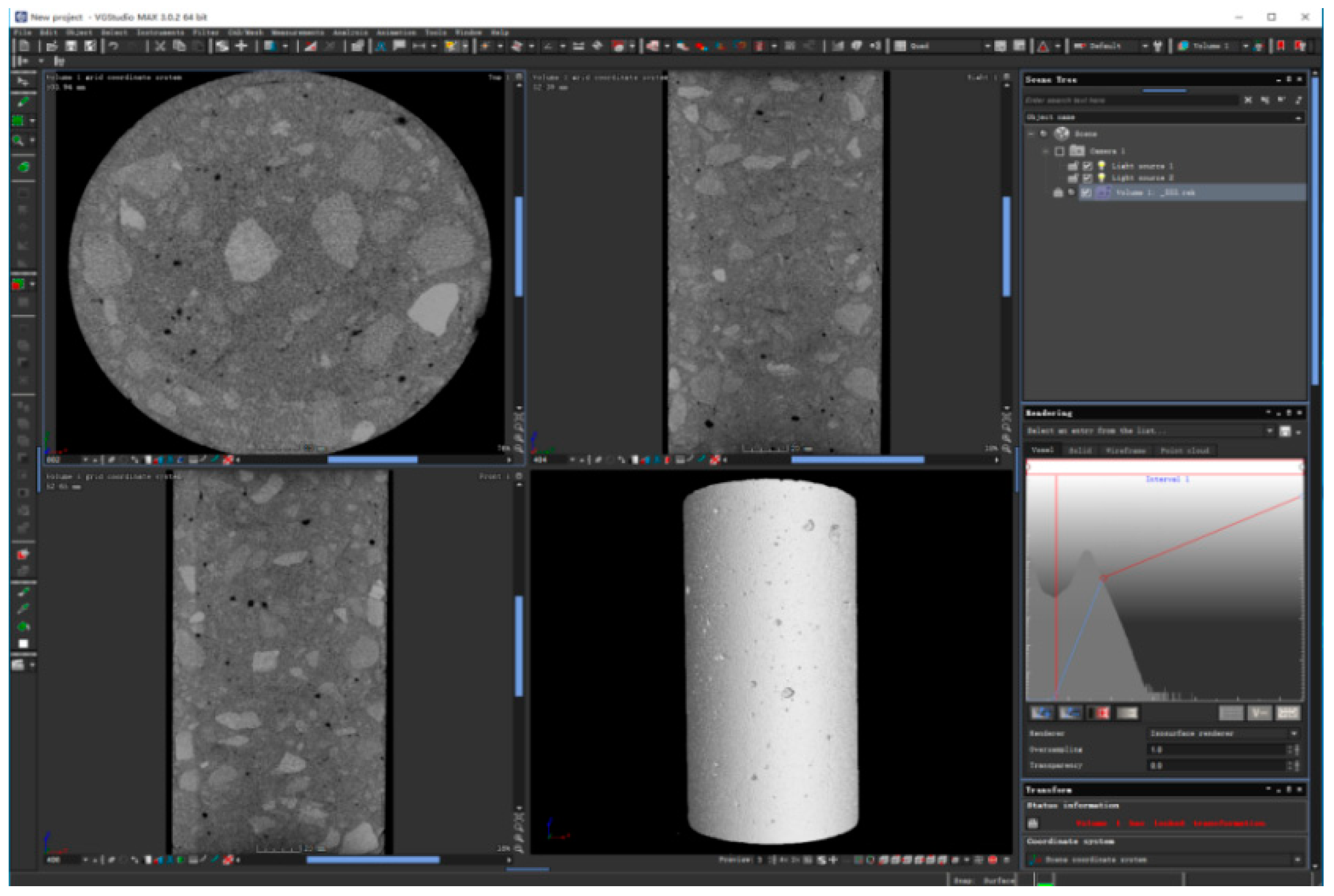

2.3.3. X-Ray Computed Tomography

2.3.4. Compressive Strength and Flexural Strength Tests

3. Results and Discussions

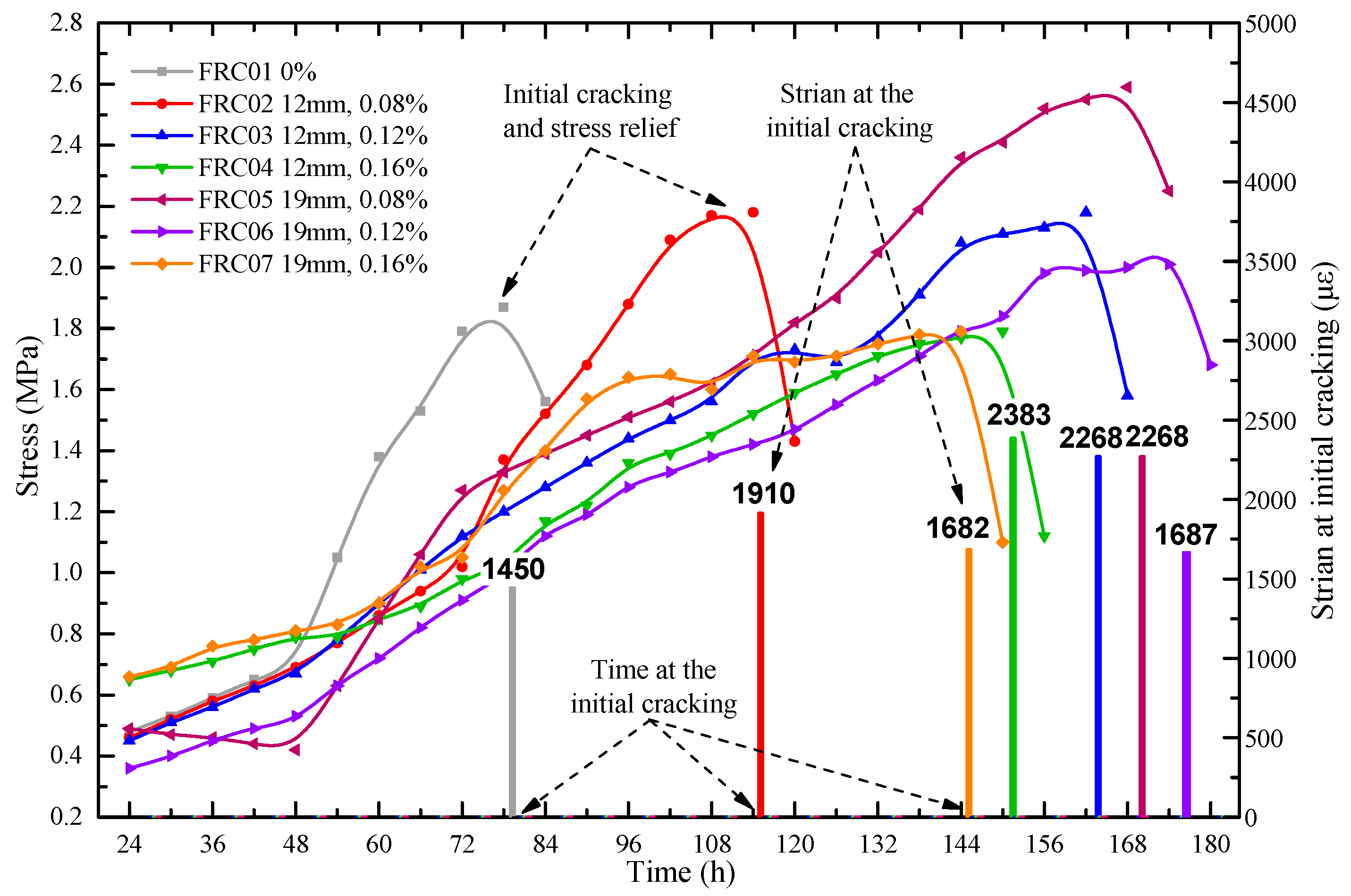

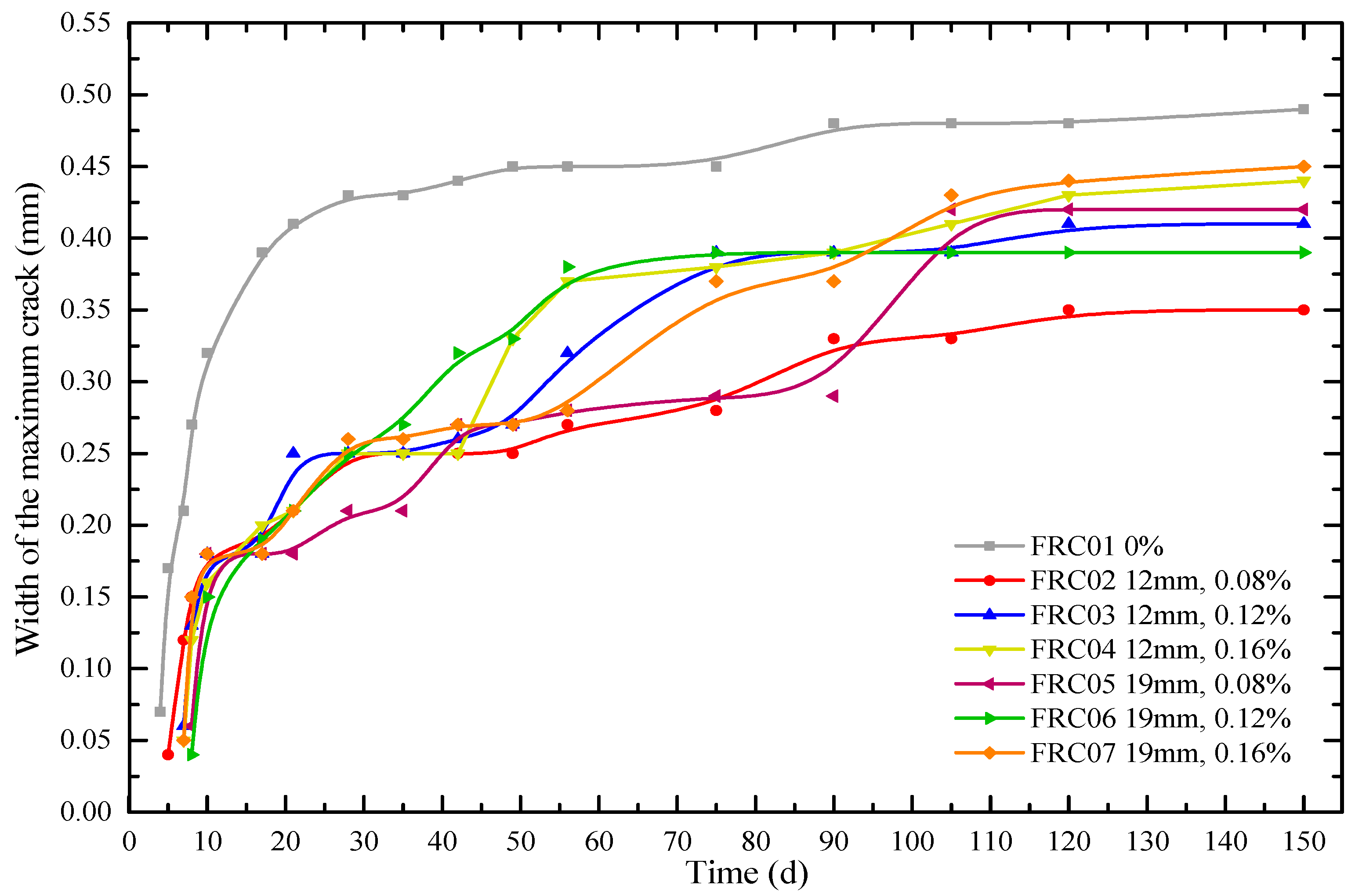

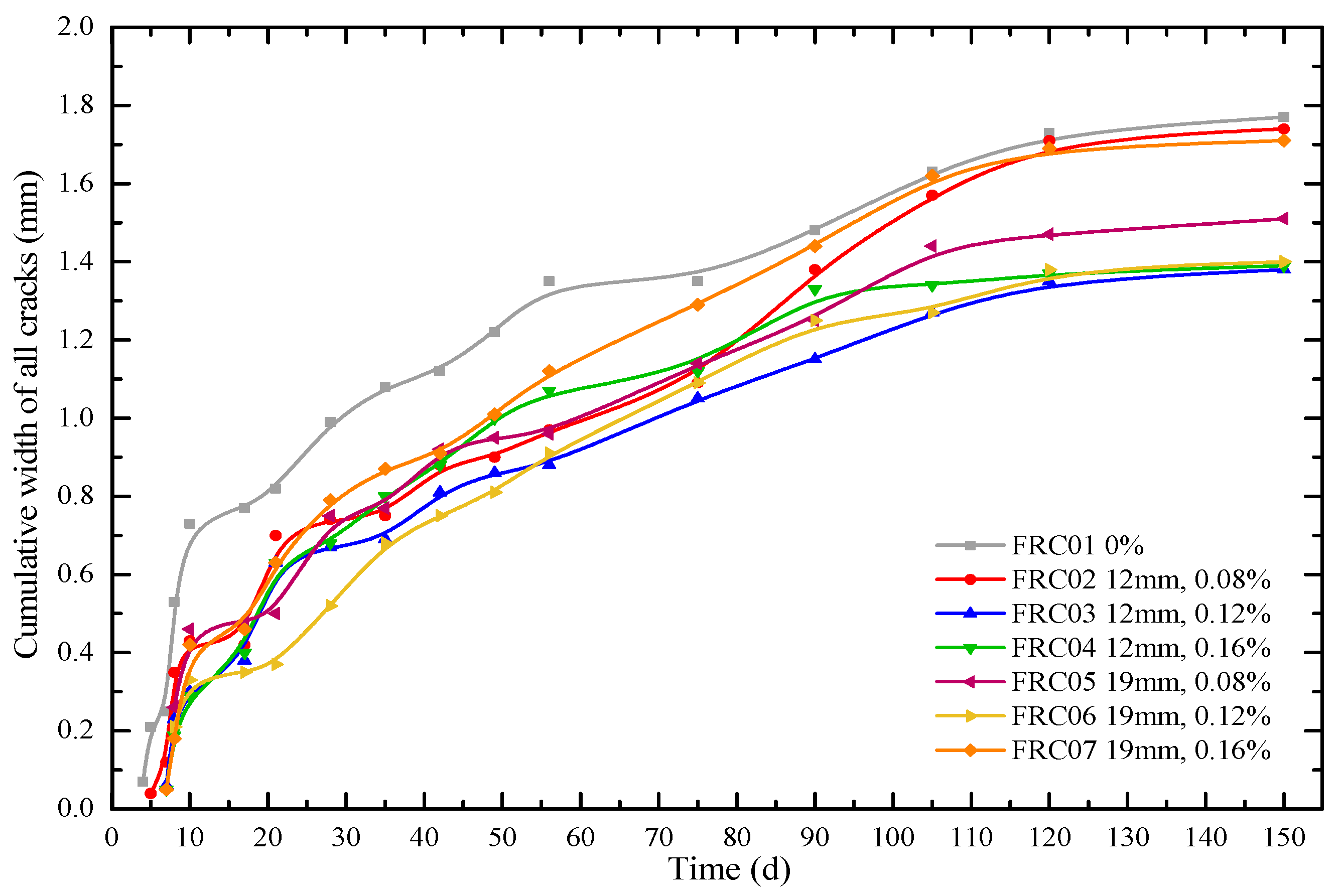

3.1. Shrinkage Cracking Performance

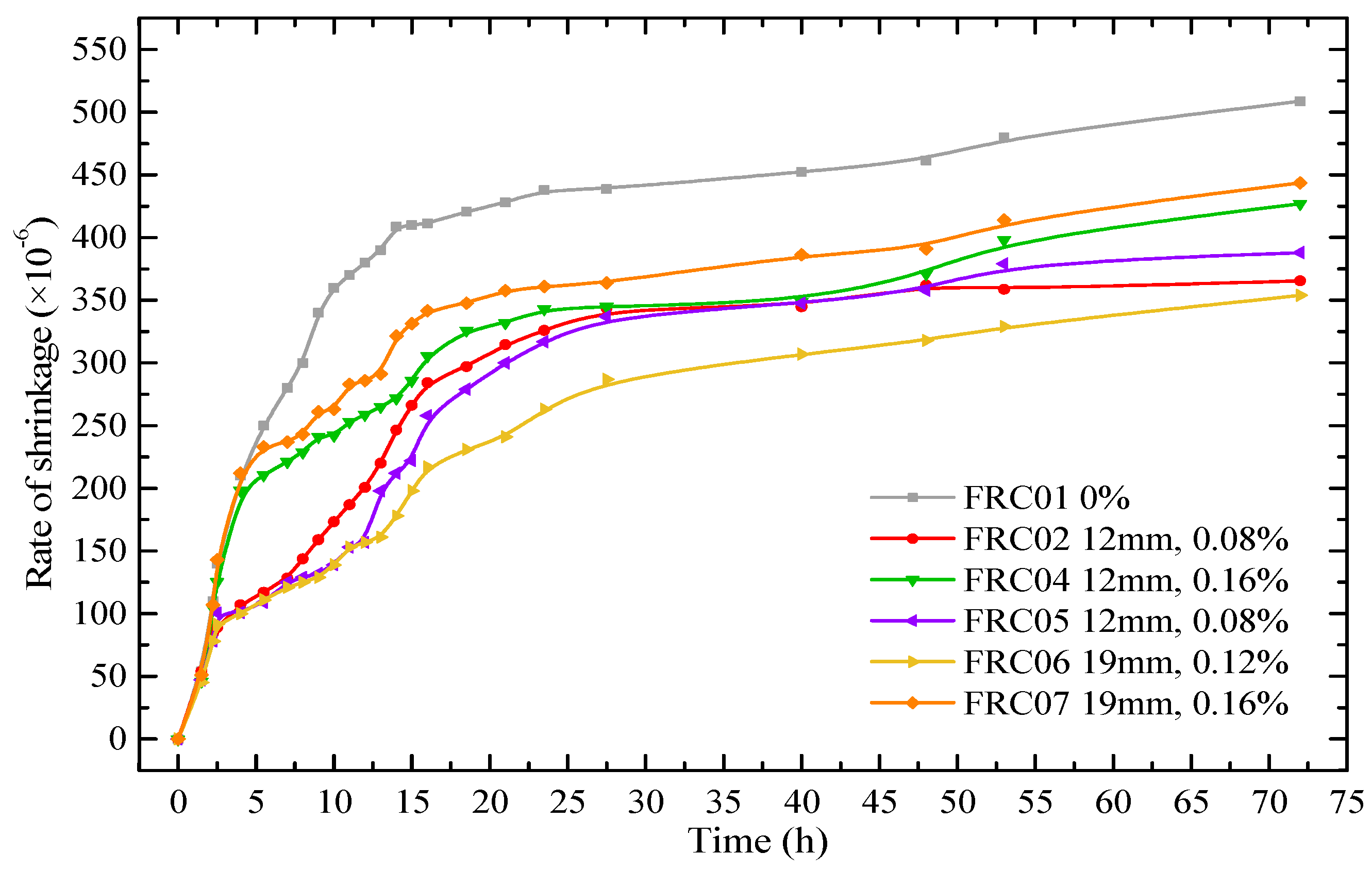

3.2. Free Shrinkage Behavior

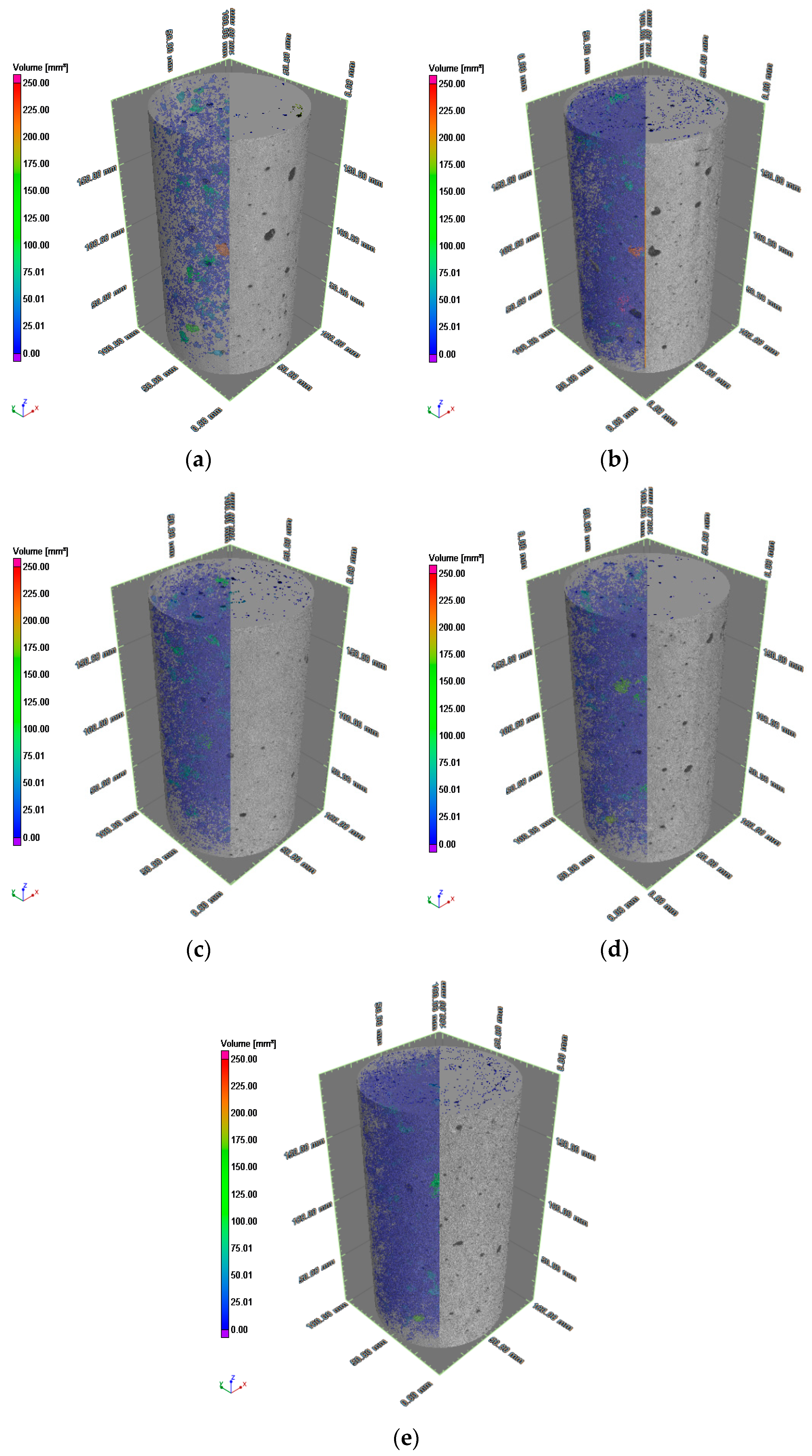

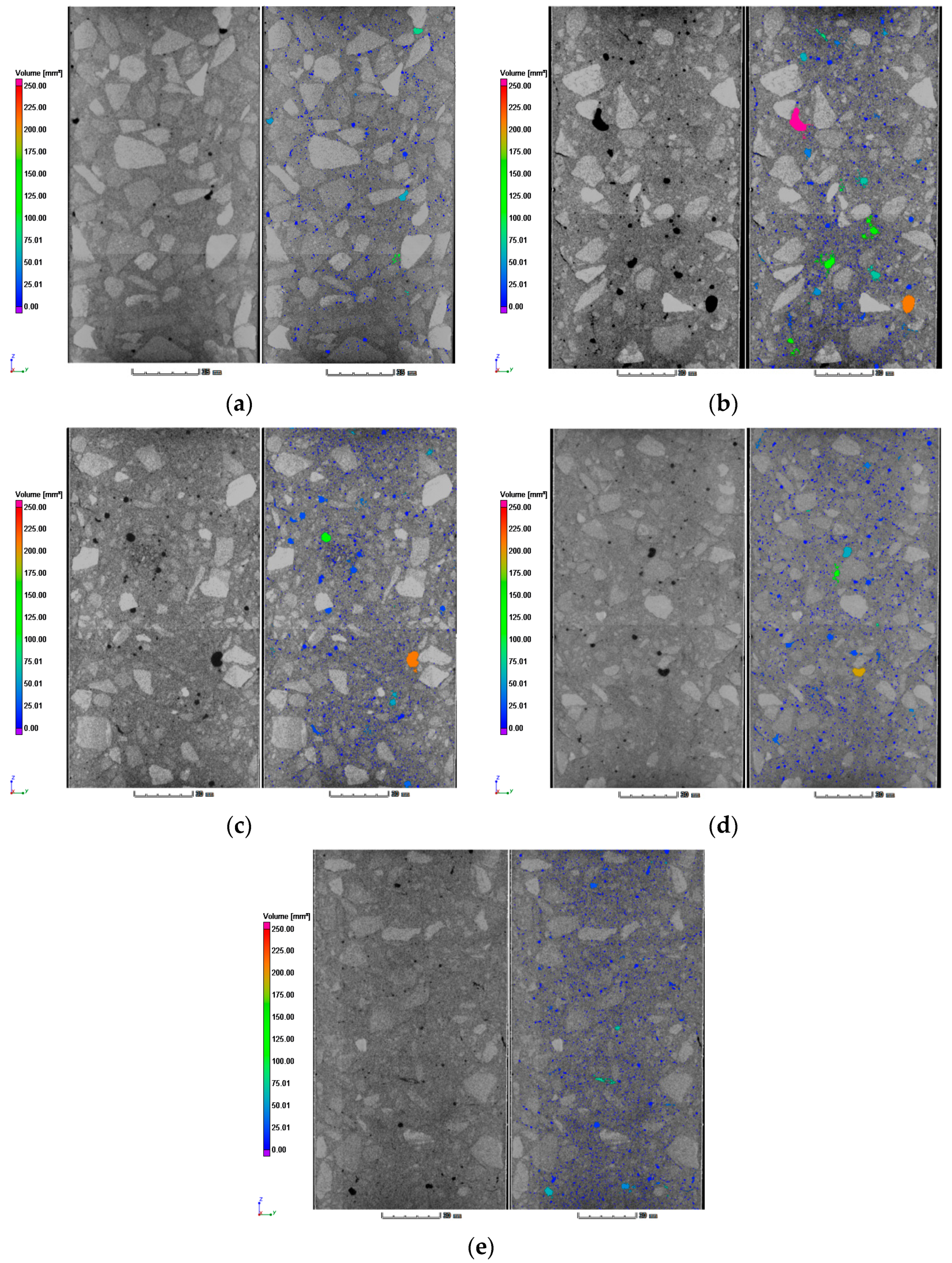

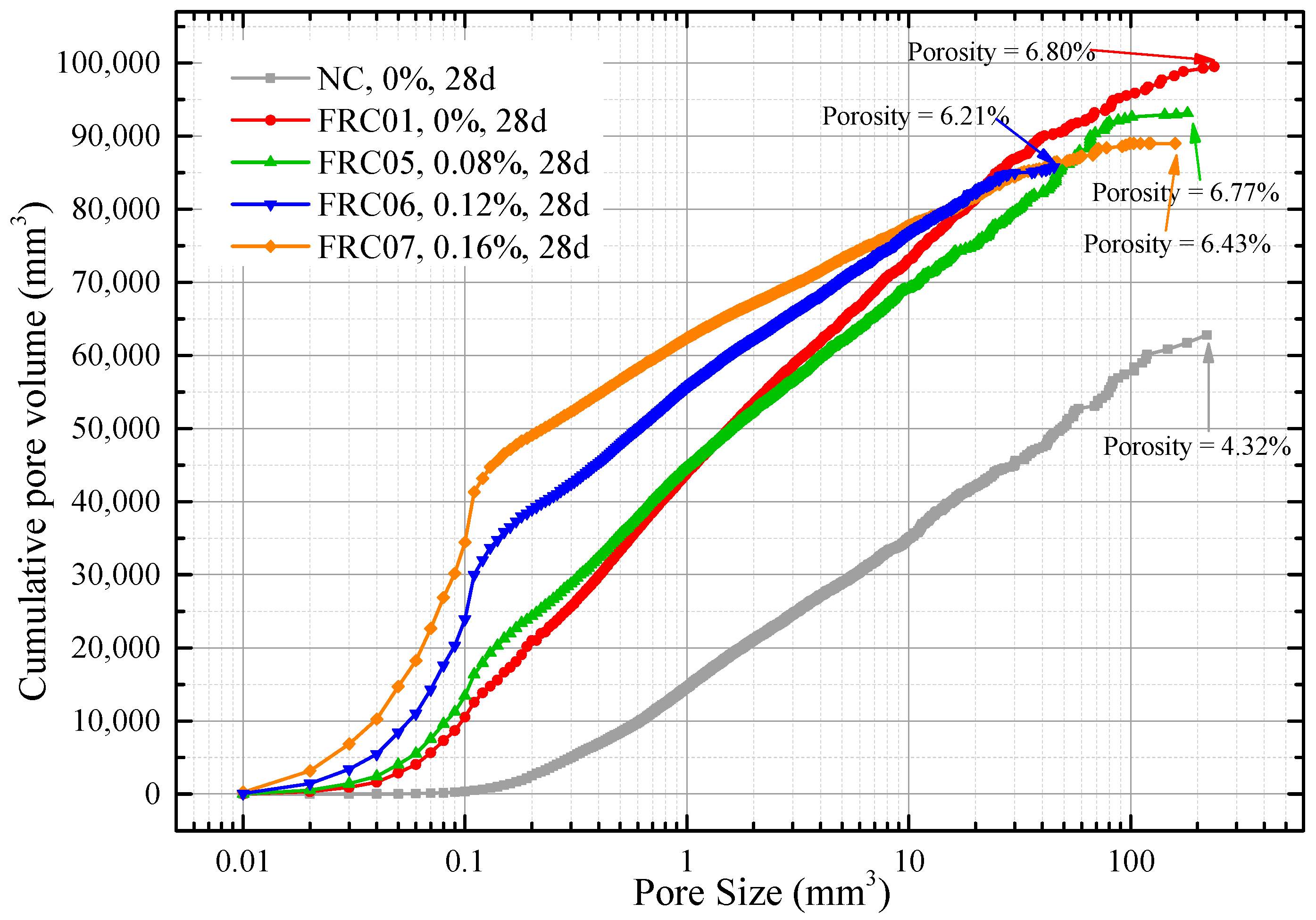

3.3. Characteristics of Pore Structures

3.4. Compressive Strength and Flexural Strength

4. Conclusions

- (1)

- In the early age of RAC, the growth speed of shrinkage and cracking is fast, and the growth speed slows down with the increase of curing time. The number of cracks and shrinkage rate gradually stabilize after 90 days. The early shrinkage of all specimens is consistent with the long-term shrinkage.

- (2)

- The results of the plat-ring-type test indicate that the addition of the waste fibers cannot only delay the initial cracking time of the recycled concrete but also reduce the number of cracks in recycled concrete ring specimens and the width of cracks. As to the results of the free shrinkage test, the addition of the waste fibers can decrease the early and long-term shrinkage rate of the recycled concrete effectively.

- (3)

- The results of both the plat-ring-type shrinkage test and free shrinkage test show that the cracking resistance performance of specimens reinforced by 19-mm fibers is better than that of 12 mm. The RAC reinforced by 19 mm and 0.12% (volume fraction) waste fibers has the optimal performance of cracking resistance, especially.

- (4)

- The addition of a small volume of waste fibers will not change the porosity of recycled concrete, significantly, but it can change the law of pore size distribution. Still, the addition of fibers can make the pore size of recycled concrete more uniform.

- (5)

- This paper mainly focuses on the reinforcement of RAC by adding waste fibers. Although there is slightly higher variability in mechanical properties of fibers, the addition of waste fibers has a certain effectiveness on improving the performance of concrete. After adding the waste fibers, the flexural strength of RAC was improved. When the addition of the volume fraction of the 19-mm fiber was 0.12%, the flexural strength of recycled concrete was 43% higher than that of recycled concrete without fiber. The compressive strength of the concrete whose recycled fine aggregate replacement ratio was 100% was lower than that of NAC, and the addition of fiber has no significant effect on the compressive strength of recycled concrete specimens. The air void in concrete has a negative effect on compressive strength.

- (6)

- In this paper, only one concrete mix design is considered. More mix designs can be considered in further studies.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gonzàlez Corominas, A.; Etxeberria Larrañaga, M.; Poon, C.S. Influence of steam curing on the pore structures and mechanical properties of fly-ash high performance concrete prepared with recycled aggregates. Cem. Concr. Compos. 2016, 71, 77–84. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Ferreira, J.; Soares, D. Dynamic characterization of full-scale structures made with recycled coarse aggregates. J. Clean. Prod. 2017, 142, 4195–4205. [Google Scholar] [CrossRef]

- Dong, S.; Hao, P.; Tighe, S.L. A diagnostic method for evaluating the condition index of cement-stabilised base using t-s fuzzy neural network. Int. J. Pavement Eng. 2017, 1–14. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in china: Part I. material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Liu, W.; Cao, W.; Zhang, J.; Wang, R.; Ren, L. Mechanical behavior of recycled aggregate concrete-filled steel tubular columns before and after fire. Materials 2017, 10, 274. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Tam, V.W.; Le, K.N. Aggregate testing using 2nd-, 7th-and 10th-order interpolation polynomials.Resources. Conserv. Recycl. 2007, 52, 39–57. [Google Scholar] [CrossRef][Green Version]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- López-Gayarre, F.; Serna, P.; Domingo-Cabo, A.; Serrano-López, M.A.; López-Colina, C. Influence of recycled aggregate quality and proportioning criteria on recycled concrete properties. Waste Manag. 2009, 29, 3022–3028. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Fournier, B.; Isgor, O.B.; Zavadil, R.; Razaqpur, A.G.; Foo, S. Quantification of the residual mortar content in recycled concrete aggregates by image analysis. Mater. Charact. 2009, 60, 716–728. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, J.; Dong, H.; Qiao, Q.; Zhou, Z. Experimental research on moderate strength recycled aggregate concrete floor slabs. J. Nat. Disasters 2015, 3, 112–119. [Google Scholar]

- Xiao, J.; Li, H.; Yang, Z. Fatigue behavior of recycled aggregate concrete under compression and bending cyclic loadings. Constr. Build. Mater. 2013, 38, 681–688. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Vegas, I.; Azkarate, I.; Juarrero, A.; Frías, M. Design and performance of masonry mortars made with recycled concrete aggregates. Mater. Constr. 2009, 59, 5–18. [Google Scholar] [CrossRef]

- Fernández-Ledesma, E.; Jiménez, J.R.; Ayuso, J.; Corinaldesi, V.; Iglesias-Godino, F.J. A proposal for the maximum use of recycled concrete sand in masonry mortar design. Mater. Constr. 2016, 66, 075. [Google Scholar]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Bouziadi, F.; Boulekbache, B.; Hamrat, M. The effects of fibres on the shrinkage of high-strength concrete under various curing temperatures. Constr. Build. Mater. 2016, 114, 40–48. [Google Scholar] [CrossRef]

- Saiz-Martínez, P.; Ferrández-Vega, D.; Morón-Fernández, C.; de Tejada-Alonso, A.P. Comparative study of the influence of three types of fibre in the shrinkage of recycled mortar. Mater. Constr. 2018, 68, 168. [Google Scholar] [CrossRef]

- Kim, H.; Kim, G.; Gucunski, N.; Nam, J.; Jeon, J. Assessment of flexural toughness and impact resistance of bundle-type polyamide fiber-reinforced concrete. Compos. Part B Eng. 2015, 78, 431–446. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Akça, K.R.; Çakır, Ö.; Ipek, M. Properties of polypropylene fiber reinforced concrete using recycled aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- Nam, J.; Kim, G.; Yoo, J.; Choe, G.; Kim, H.; Choi, H.; Kim, Y. Effectiveness of fiber reinforcement on the mechanical properties and shrinkage cracking of recycled fine aggregate concrete. Materials 2016, 9, 131. [Google Scholar] [CrossRef]

- Kim JH, J.; Park, C.G.; Lee, S.W.; Lee, S.W.; Won, J.P. Effects of the geometry of recycled PET fiber reinforcement on shrinkage cracking of cement-based composites. Compos. Part B Eng. 2008, 39, 442–450. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Shanghai Construction and Transportation Commission. Technical Code on the Application of Recycled Concrete; DG/TJ08-2018-2007; Shanghai Construction and Transportation Commission: Shanghai, China, 2007. (In Chinese)

- American Society for Testing Materials. Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage; ASTM C1581; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Length Change of Hardened Hydraulic-Cement, Mortar, and Concrete; ASTM C157; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- General Administration of Quality Inspection and Quarantine of the People’s Republic of China. Standard Test Methods for Drying Shrinkage Stress and Cracking Possibility of Cement Mortar Concrete; GB/T 29417-2012; General Administration of Quality Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2012. (In Chinese)

- General Administration of Quality Inspection and Quarantine of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; GB/T 50081-2002; General Administration of Quality Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2013. (In Chinese)

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Evangelista, L.; Brito, J.D. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Shen, L.; Poon, C.S. Compressive behaviour of recycled aggregate concrete under impact loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of recycled pet fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef]

| Length (mm) | Density (g/cm3) | Water Absorption (%) | Fusion Point (℃) | ||

|---|---|---|---|---|---|

| 12/19 | 0.91 | <0.1 | ≈165 | ||

| Elastic Modulus (MPa) | Breaking tensile strength (MPa) | Breaking Elongation (%) | |||

| 3.79 × 103 | 310 (CV = 16.5%) | 18.5 (CV = 17.1%) | |||

| Rate of Cement Clinker (%) | Mineral Composition (%) | |||||

|---|---|---|---|---|---|---|

| KH | SM | IM | C3S | C2S | C3A | C4AF |

| 0.893 | 2.66 | 1.7 | 55.91 | 20.53 | 7.12 | 10.32 |

| Chemical Composition (%) | ||||

|---|---|---|---|---|

| SO3 | MgO | Loss on Ignition | Insoluble Residue | Content of Alkali |

| 2.49 | 3.54 | 1.0 | 0.55 | 0.51 |

| SCA (m3/kg) | Normal Consistency (%) | Setting Time | Soundness | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 days | 28 days | 3 days | 28 days | |||

| 348 | 25.0 | 2 h 20 min | 3 h 50 min | Qualified | 25.9 | 43.6 | 5.9 | 9.1 |

| Group of Specimens | Water-Cement Ratio | Length of Fibers (mm) | Replacement Ratio of RAs | Volume Fraction of Fibers | Cement (kg/m3) | Sand (kg/m3) | RAC (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| FRC01 | 0.55 | 0 | 100% | 0 | 390 | 709 | 1156 | 215 |

| FRC02 | 0.55 | 12 | 100% | 0.08% | 390 | 709 | 1156 | 215 |

| FRC03 | 0.55 | 12 | 100% | 0.12% | 390 | 709 | 1156 | 215 |

| FRC04 | 0.55 | 12 | 100% | 0.16% | 390 | 709 | 1156 | 215 |

| FRC05 | 0.55 | 19 | 100% | 0.08% | 390 | 709 | 1156 | 215 |

| FRC06 | 0.55 | 19 | 100% | 0.12% | 390 | 709 | 1156 | 215 |

| FRC07 | 0.55 | 19 | 100% | 0.16% | 390 | 709 | 1156 | 215 |

| NC | 0.50 | 0 | 0 | 0 | 390 | 709 | 1156 | 195 |

| Group of Specimens | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

| FRC01 | 39.82 | 4.96 |

| FRC02 | 39.15 | 5.58 |

| FRC03 | 40.12 | 6.31 |

| FRC04 | 39.88 | 6.57 |

| FRC05 | 39.95 | 6.24 |

| FRC06 | 41.47 | 7.12 |

| FRC07 | 40.89 | 6.95 |

| NC | 44.52 | 5.87 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zhou, J.; Kang, T.; Wang, F.; Ding, X.; Wang, S. Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete. Materials 2019, 12, 1196. https://doi.org/10.3390/ma12081196

Wu X, Zhou J, Kang T, Wang F, Ding X, Wang S. Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete. Materials. 2019; 12(8):1196. https://doi.org/10.3390/ma12081196

Chicago/Turabian StyleWu, Xiaoxin, Jinghai Zhou, Tianbei Kang, Fengchi Wang, Xiangqun Ding, and Shanshan Wang. 2019. "Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete" Materials 12, no. 8: 1196. https://doi.org/10.3390/ma12081196

APA StyleWu, X., Zhou, J., Kang, T., Wang, F., Ding, X., & Wang, S. (2019). Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete. Materials, 12(8), 1196. https://doi.org/10.3390/ma12081196