Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls

Abstract

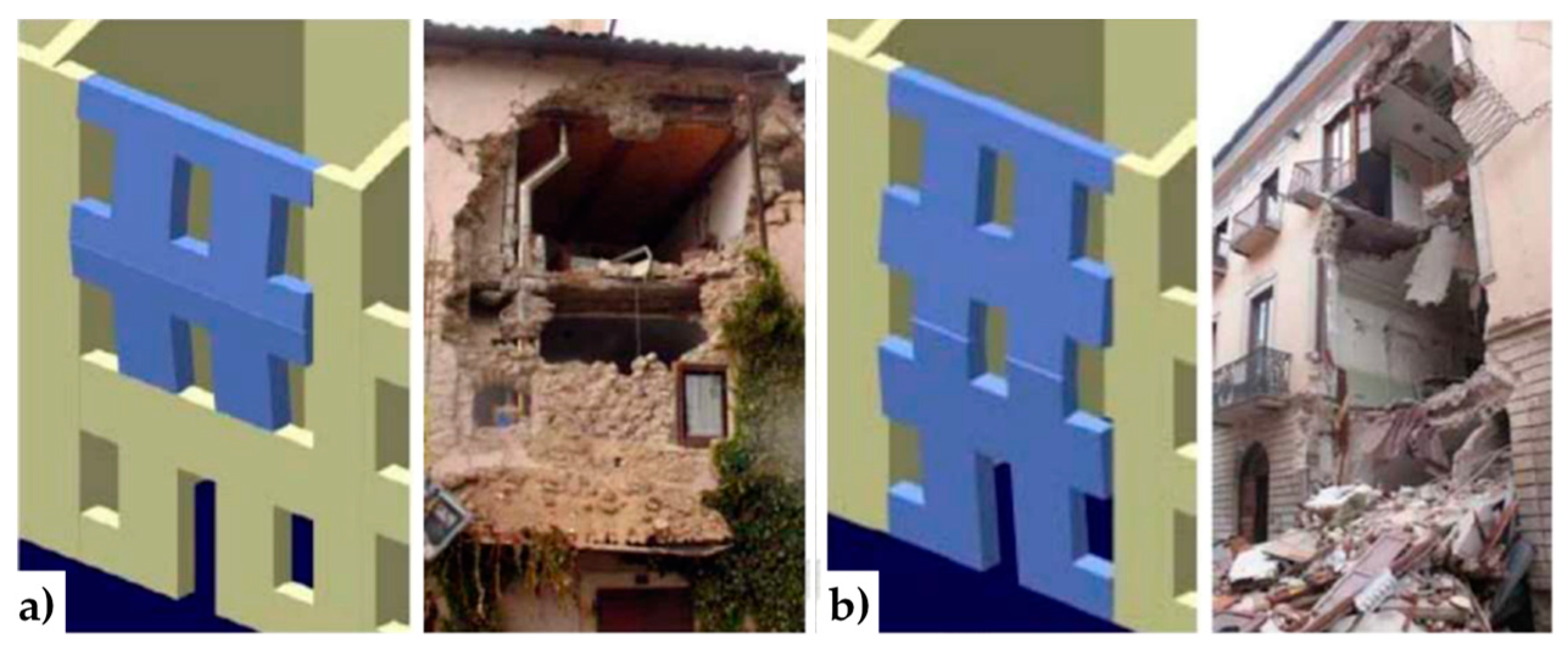

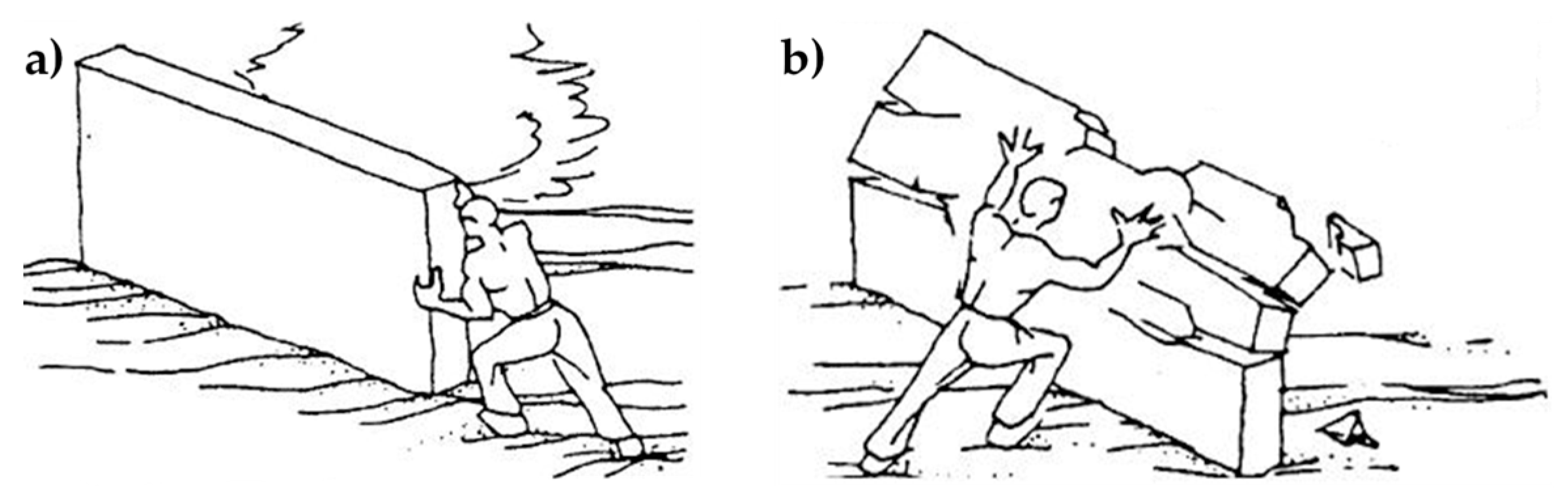

:1. Introduction

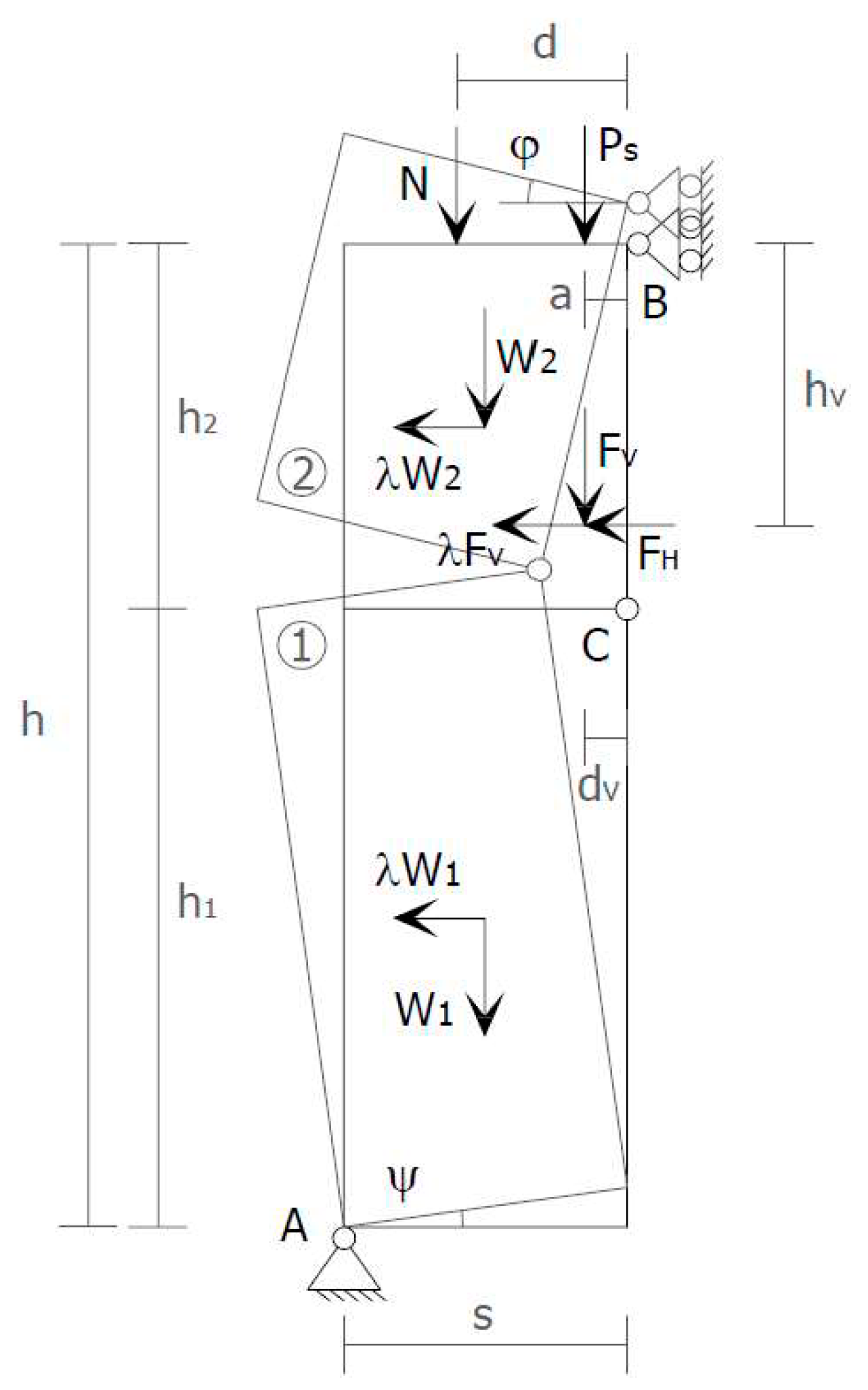

- s is the thickness of the wall;

- h is the height of the wall;

- W is the self-weight of the wall;

- is the weight transmitted to the wall by the floor;

- N is the weight of upper walls and floors;

- is the vertical component of the thrusts given to the wall by arches and vaults;

- is the horizontal component of the thrusts given to the wall by floors, arches, and vaults;

- a is the distance between and the hinge in B;

- d is the distance between N and the hinge in B;

- is the distance between and the hinge in B;

- is the distance between and the hinge in B.

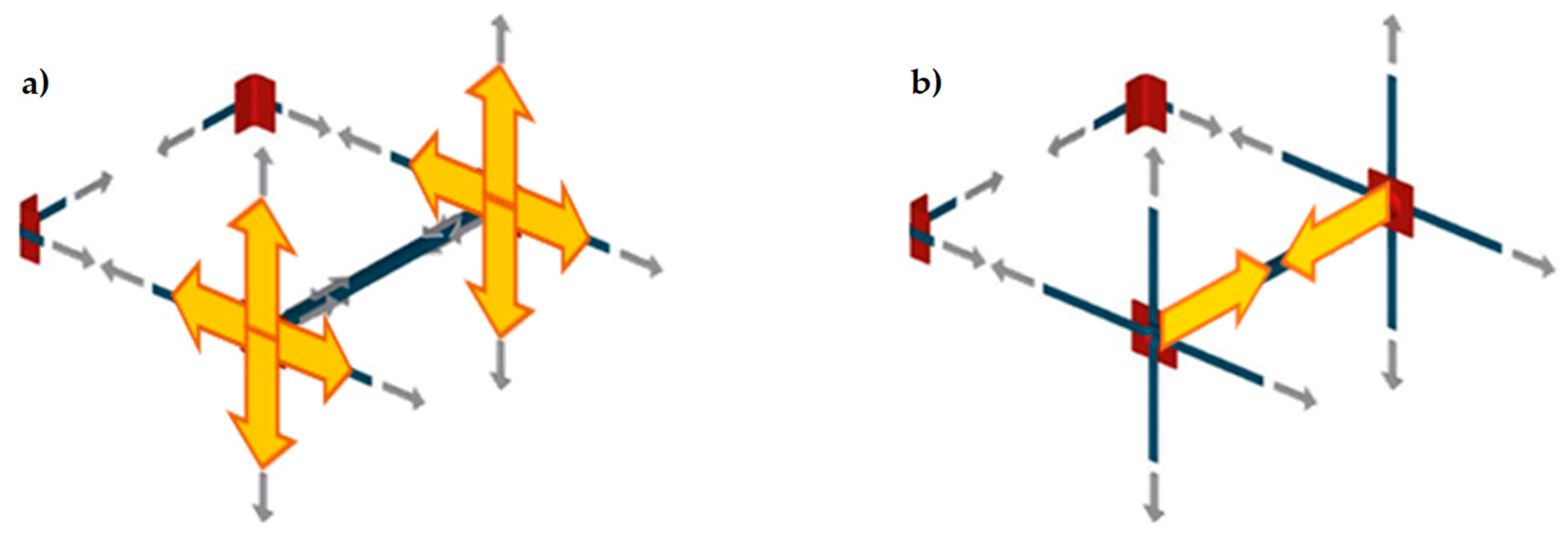

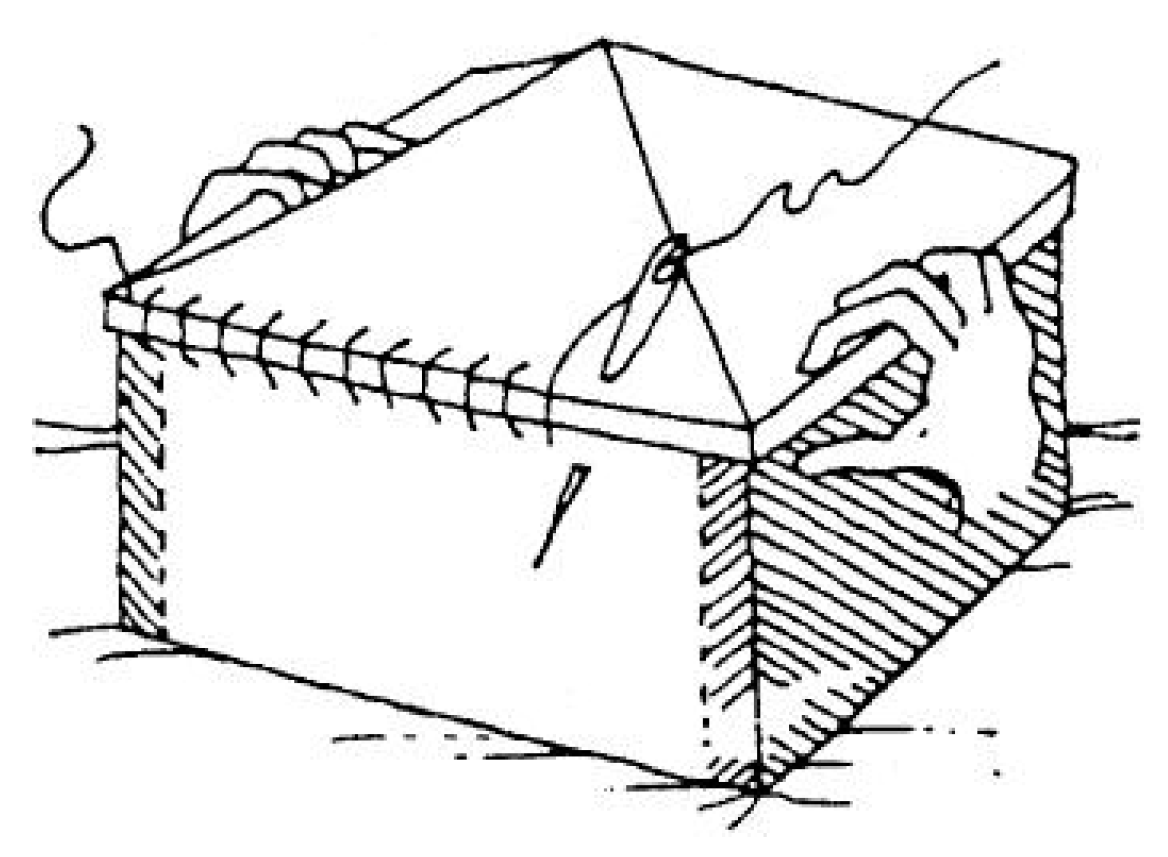

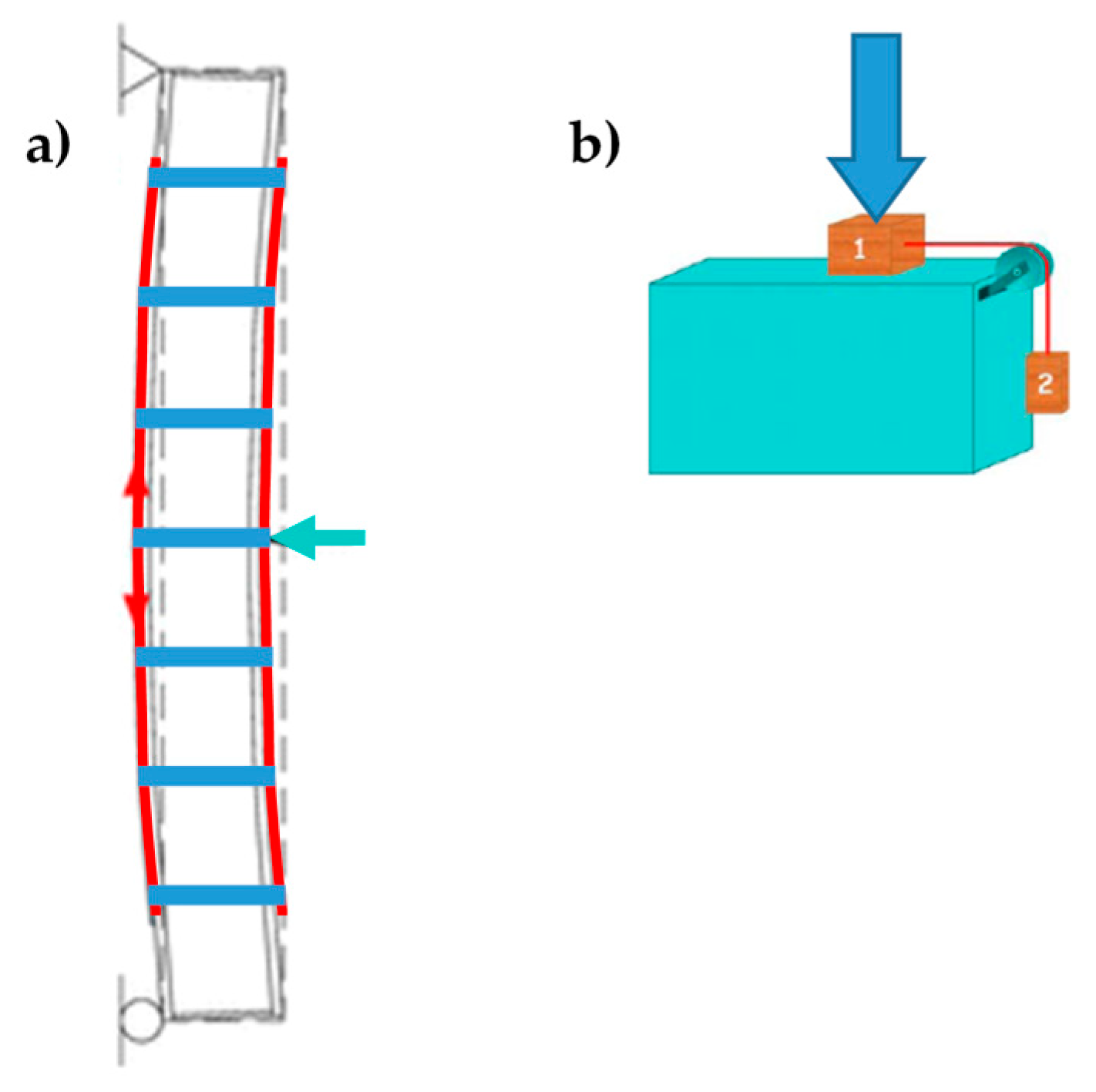

2. Some Basic Notions of the CAM System

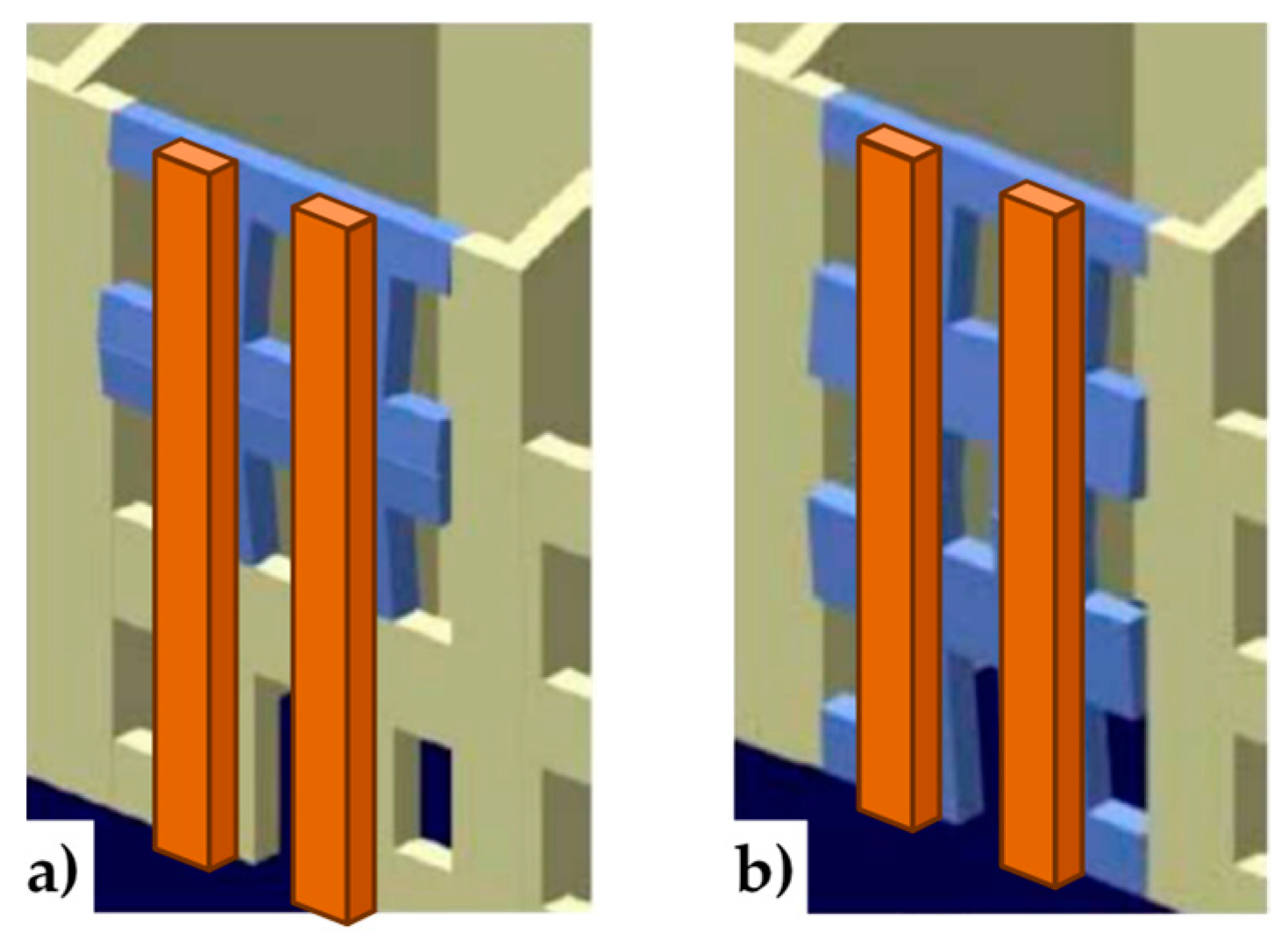

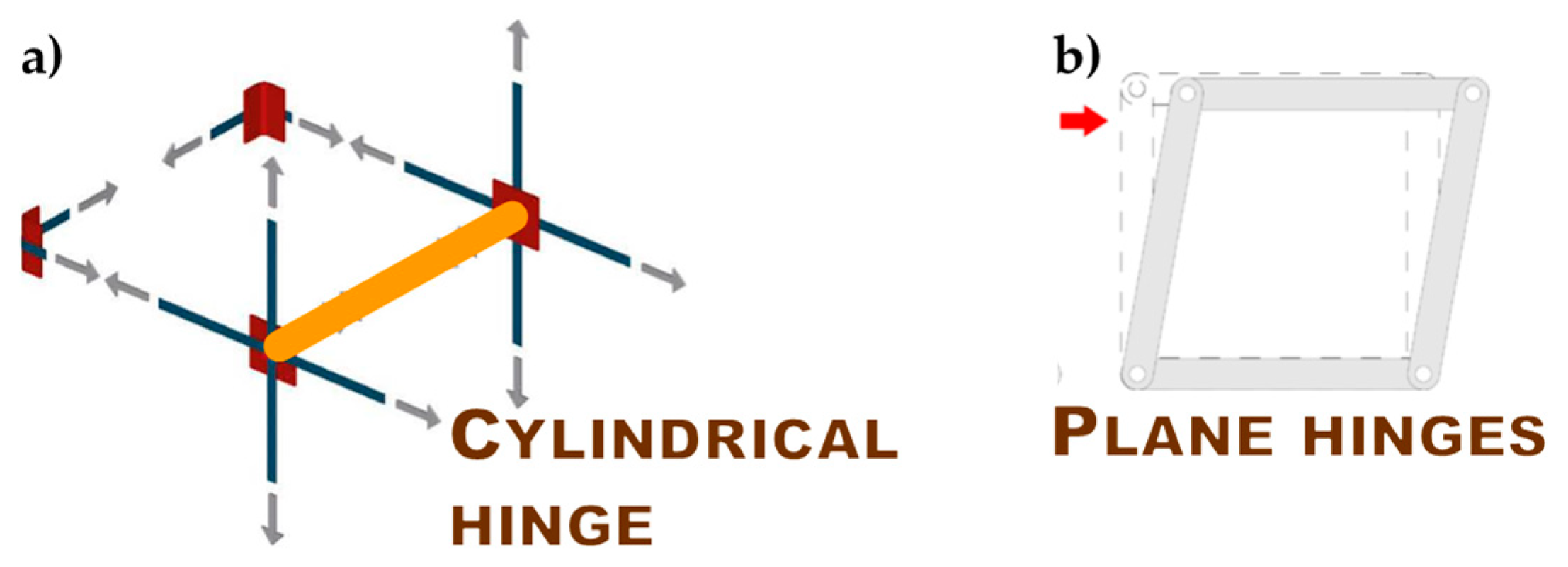

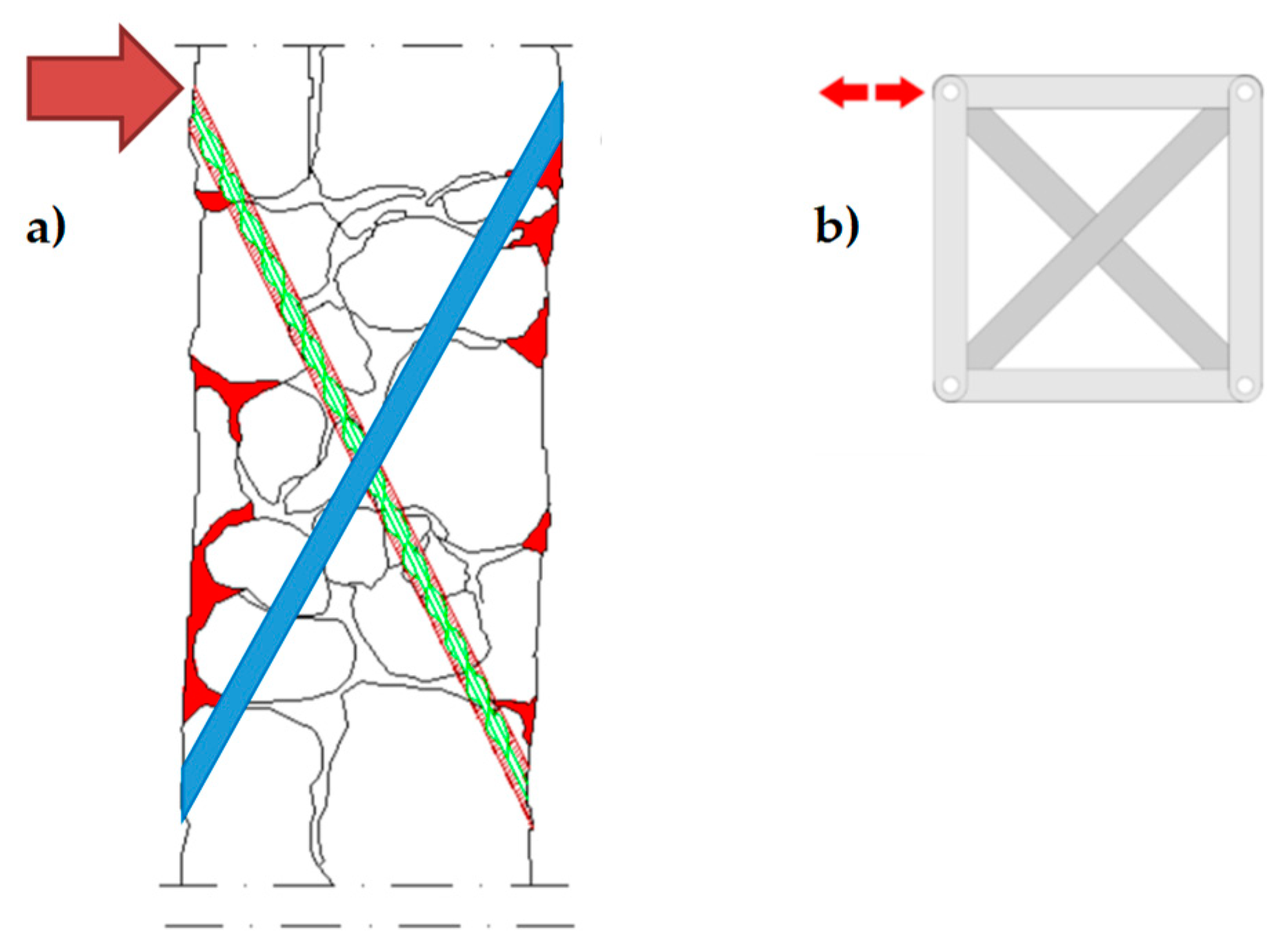

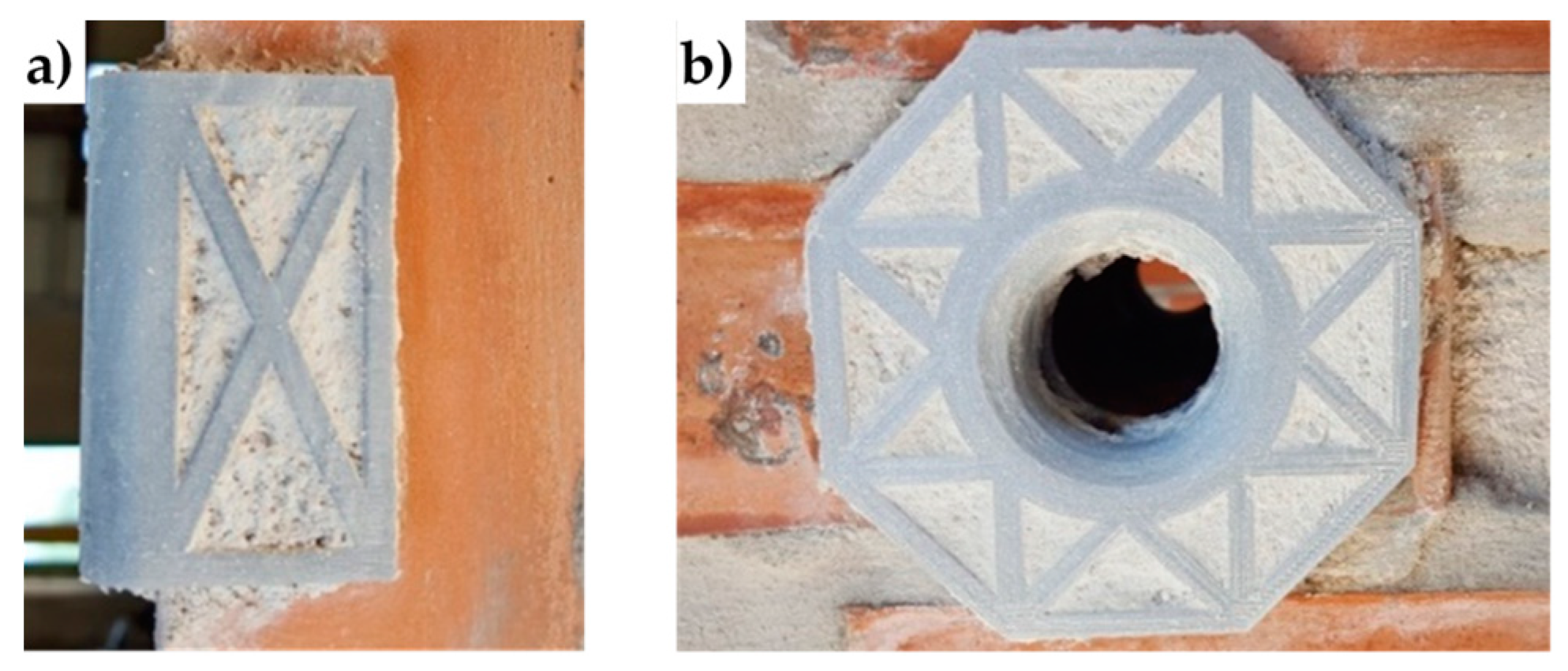

3. Techniques of Cross Bracing in the Thickness of the Wall

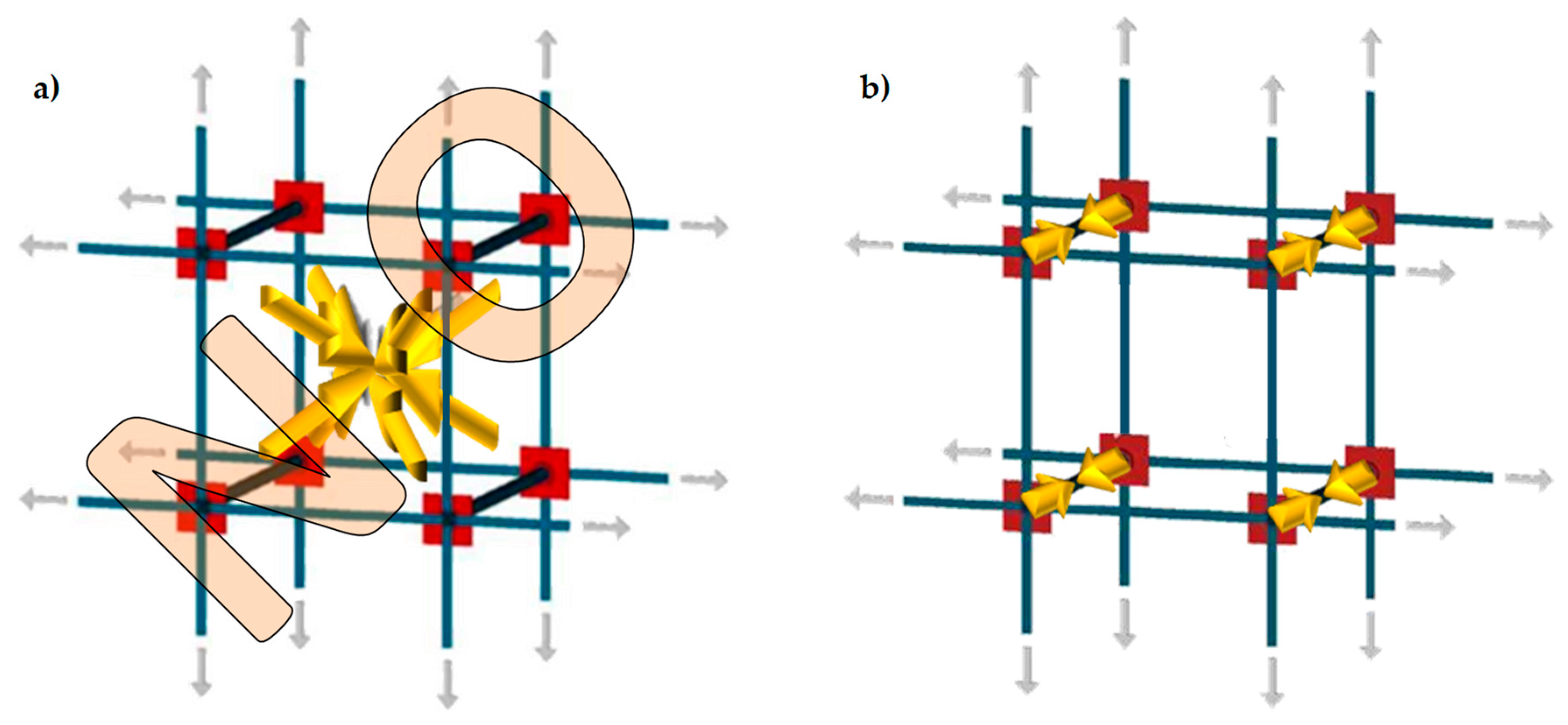

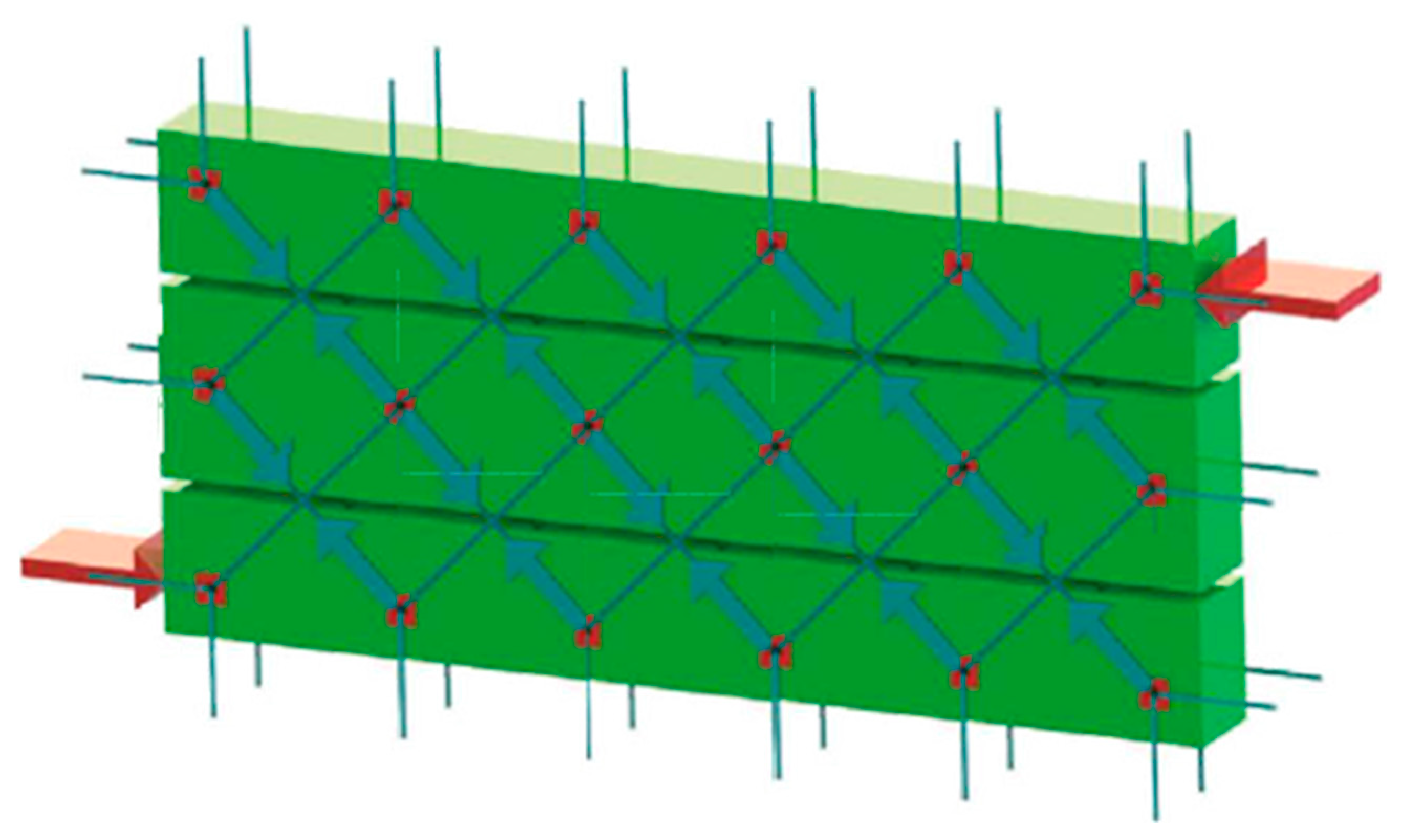

3.1. Re-Arrangement of the CAM Straps

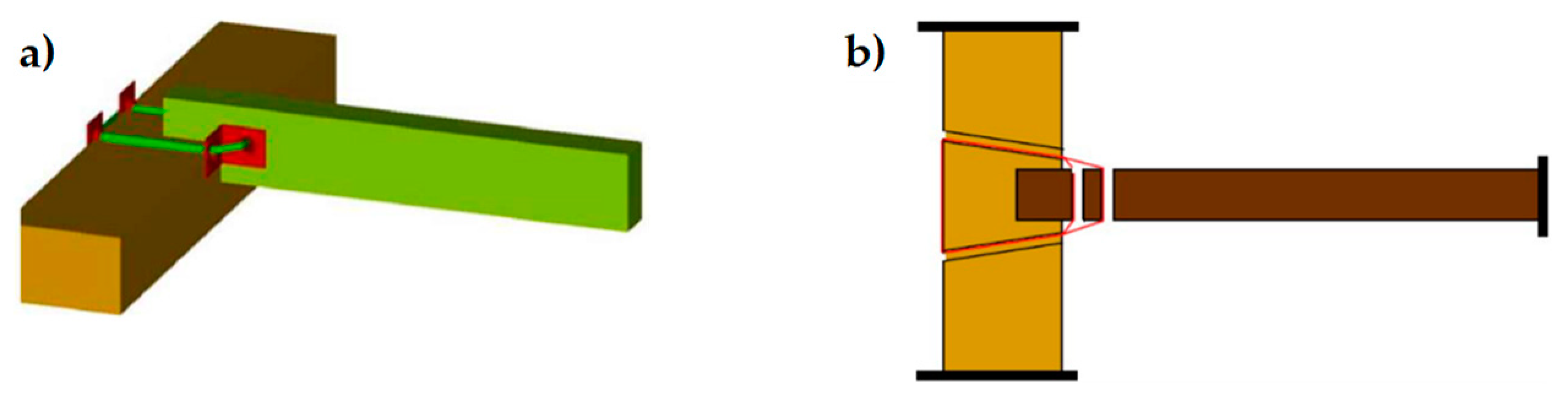

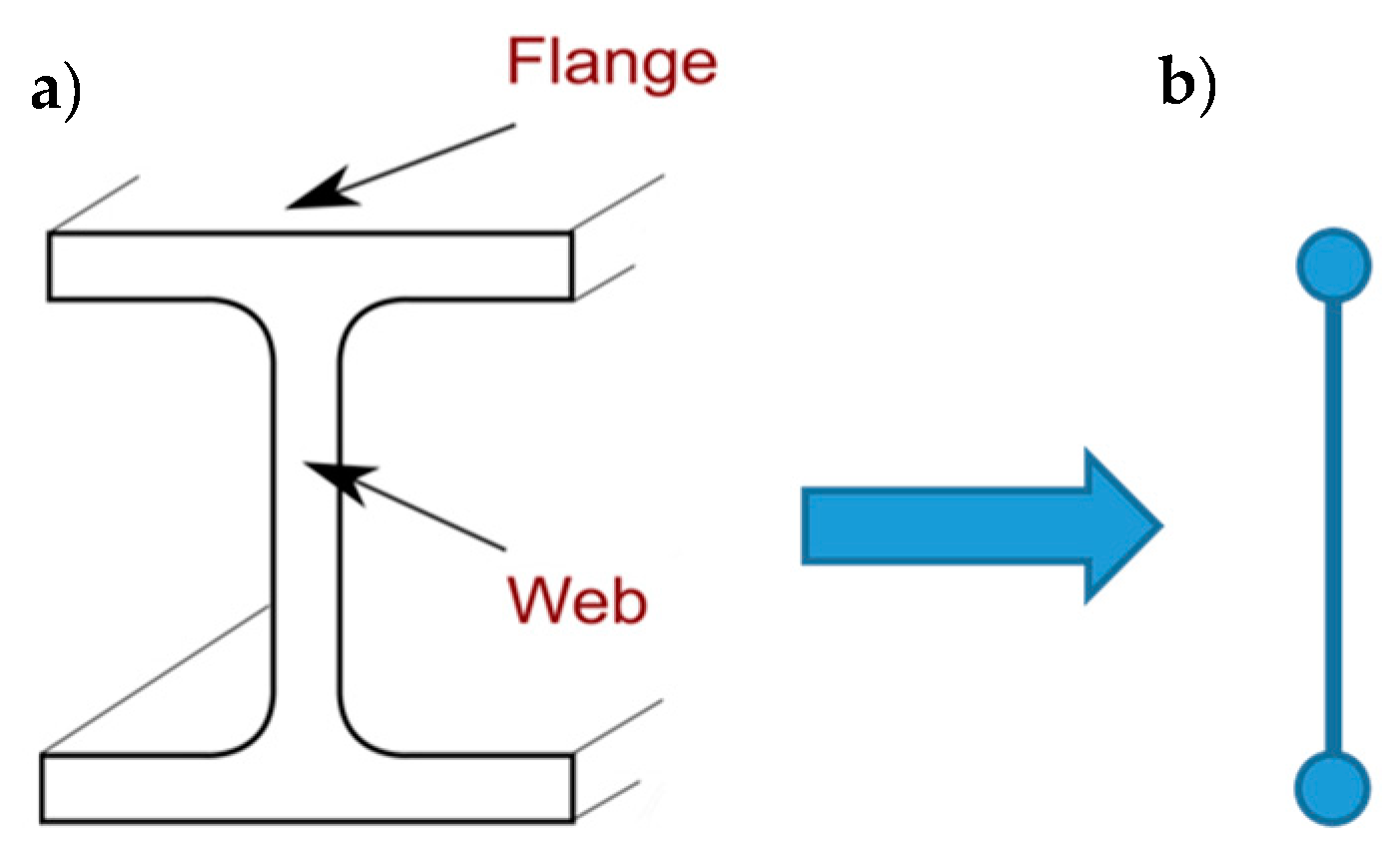

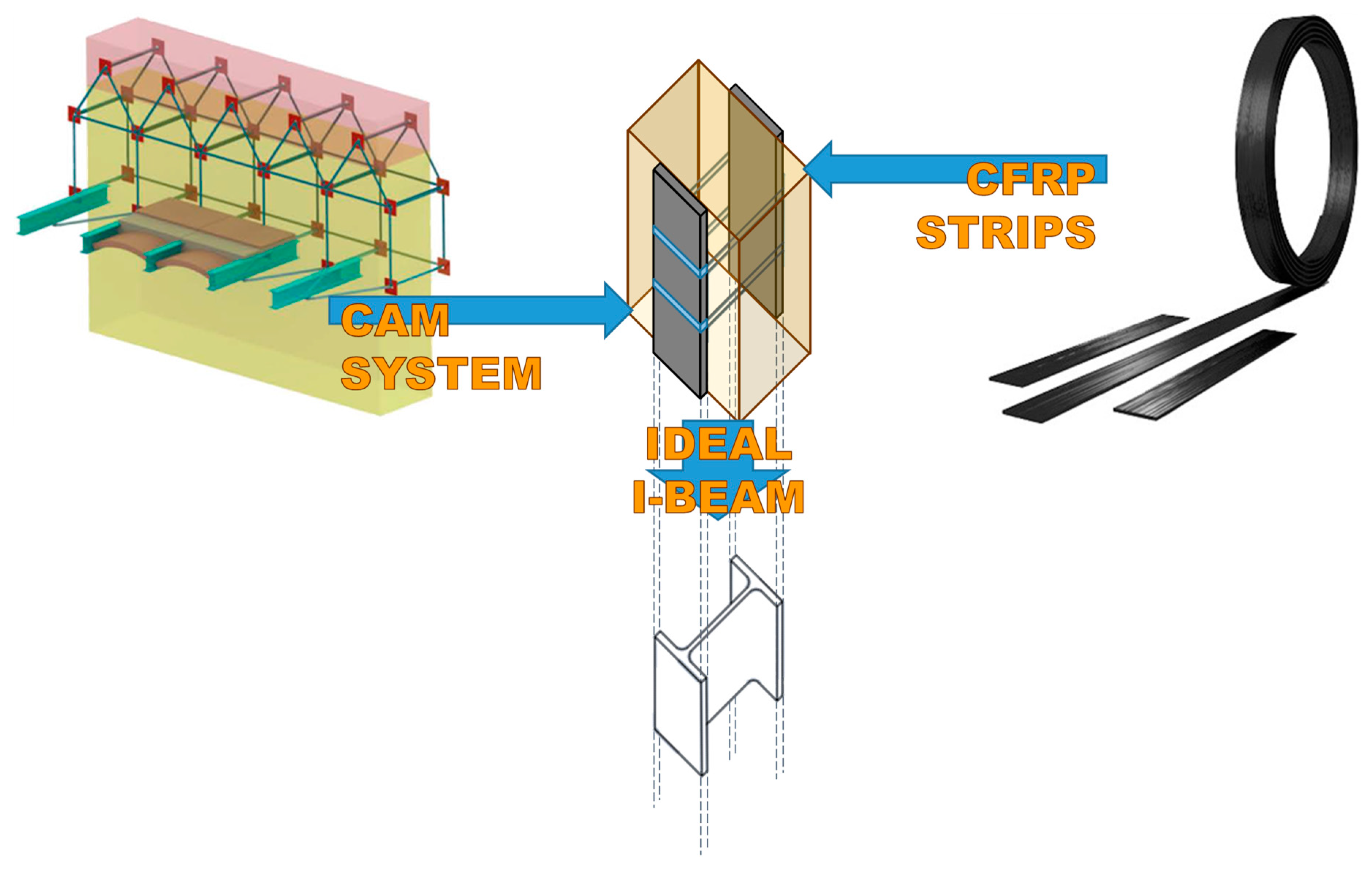

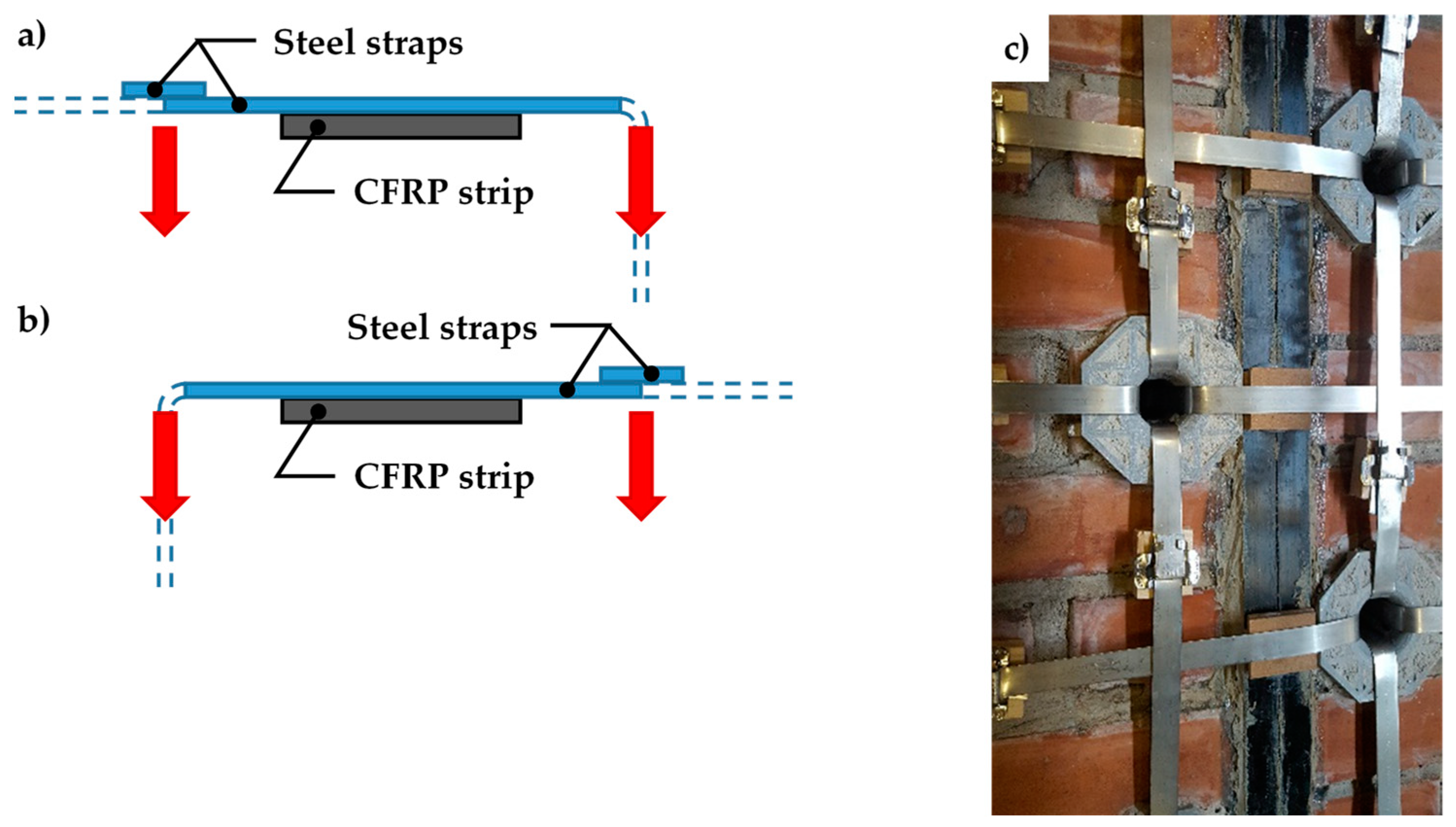

3.2. Application of the CAM System Together with CFRP Strips

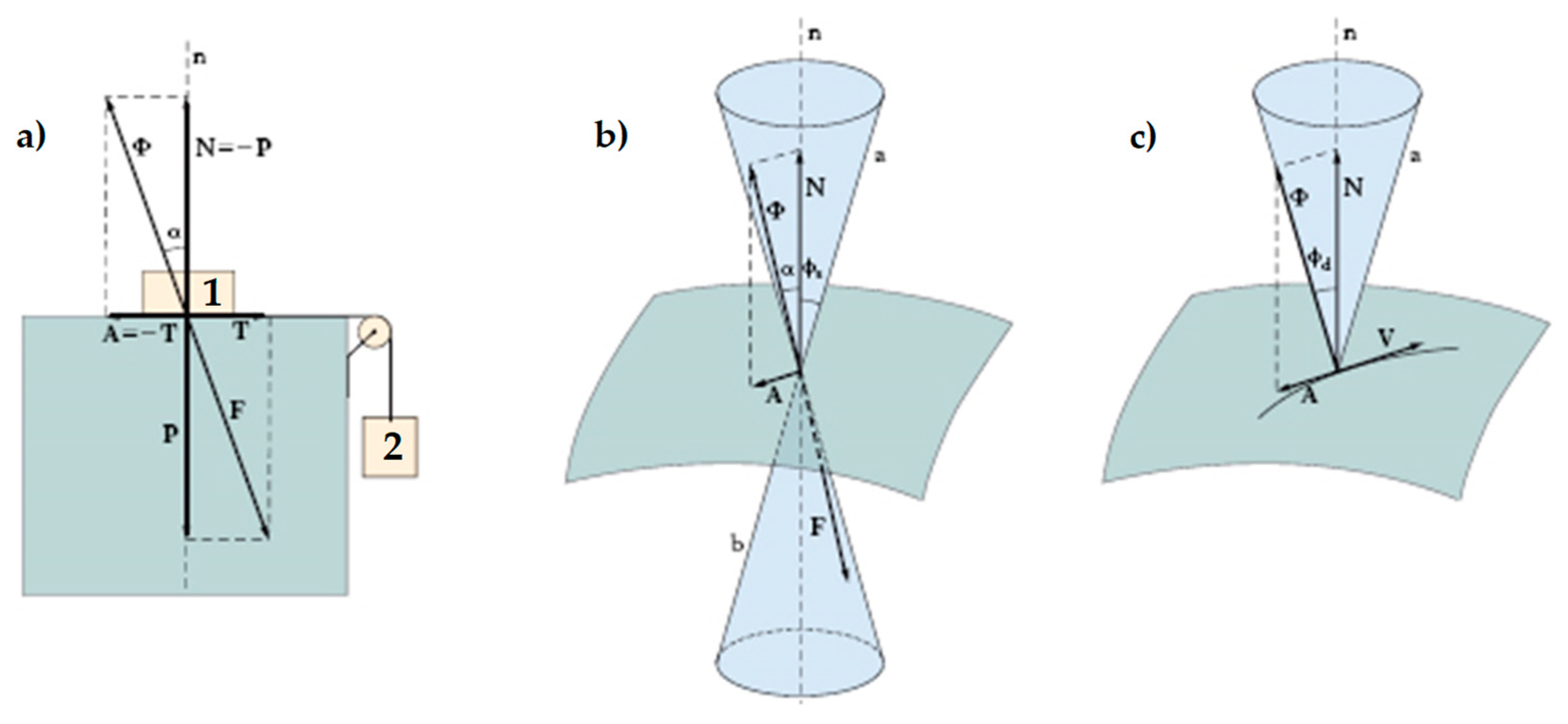

- P is the weight force, exerted by body 1 on the support plane;

- N is the normal reaction force, equal and opposite to P, exerted by the support plane on body 1;

- T is the shear force, exerted by the hanging body (body 2) on the support plane;

- A is the friction force, developed by the support plane as a reaction to T: in static conditions, A is equal and opposite to T;

- F is the resultant force acting on the support plane (the component vectors of F are P and T);

- Φ is the resultant force acting on body 1 (the component vectors of Φ are N and A);

- is the angle formed by Φ with the direction orthogonal to the support plane;

- is the angle of static friction, that is, the maximum inclination angle of the support plane before which body 1 will begin sliding on it;

- is the coefficient of static friction, which is a dimensionless scalar value that describes the maximum ratio of the force of friction between two bodies at rest relative to each other and the force pressing them together;

- is the coefficient of kinetic friction, which is the ratio of the force of friction between two bodies in relative motion and the force pressing them together.

- On the compressed side, the straps prevent the buckling of the CFRP strip, which is the main cause of delamination on that side.

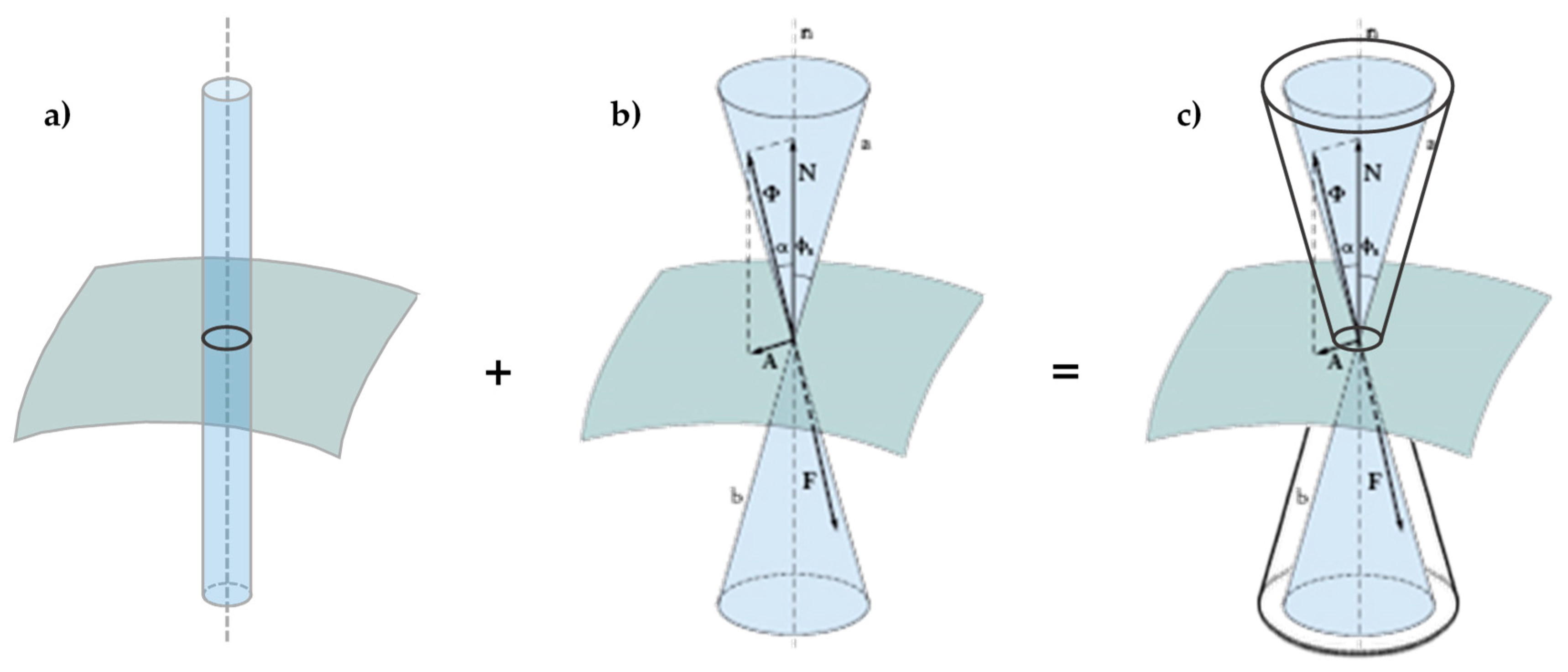

- On the stretched side, the compression forces exerted by the straps on the CFRP strip modify the shape of the limit surface, from the cylinder of Figure 21a to the double truncated cone of Figure 21c. As a result, the CFRP strip can withstand higher shear forces before the head of Φ touches the limit surface. Since the shear forces depend on the bending load linearly, this ultimately means that the stretched CFRP strip will undergo delamination for higher values of the bending load. Therefore, the strapping delays the delamination on the stretched side.

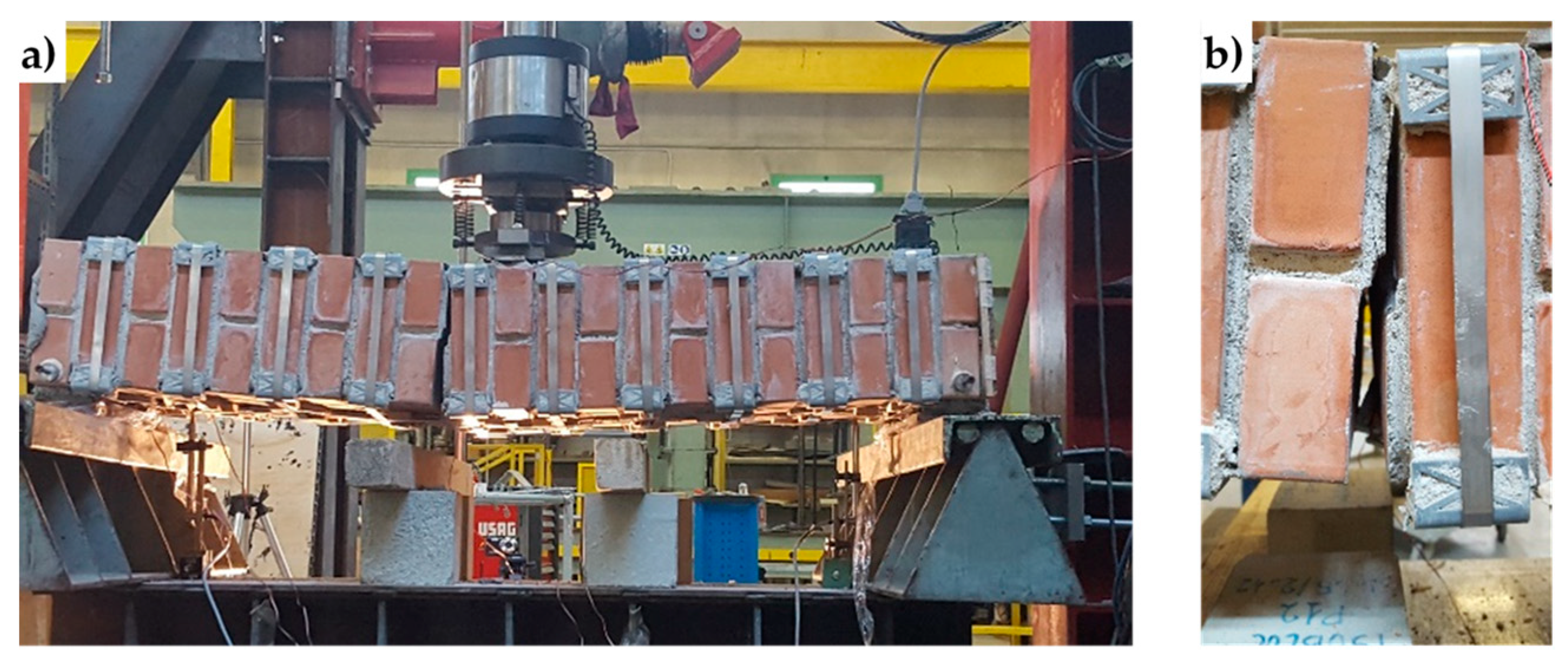

4. Experimental Program

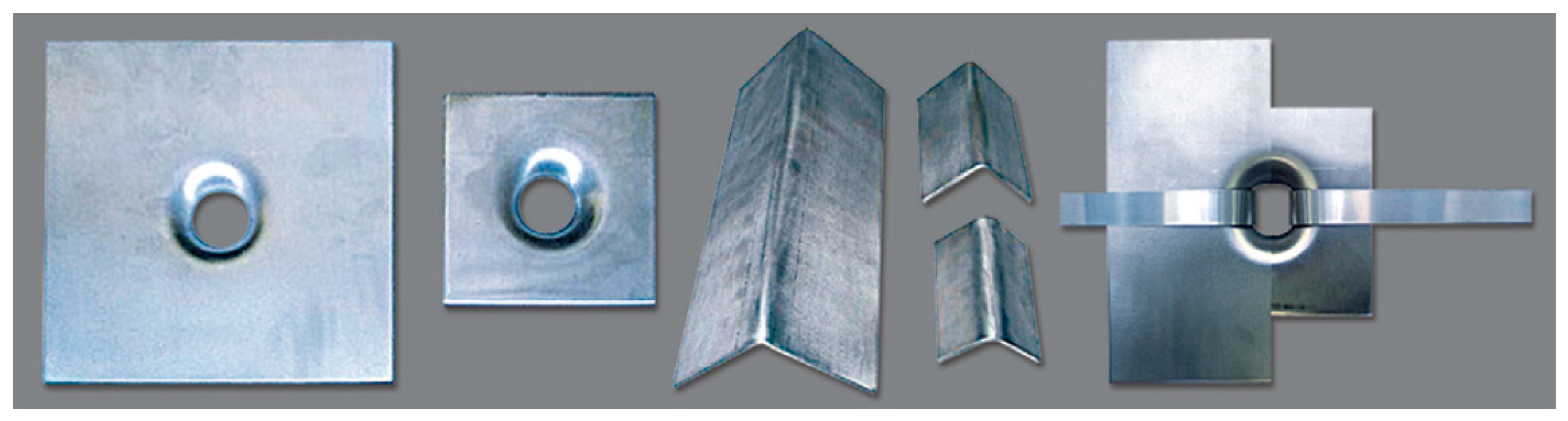

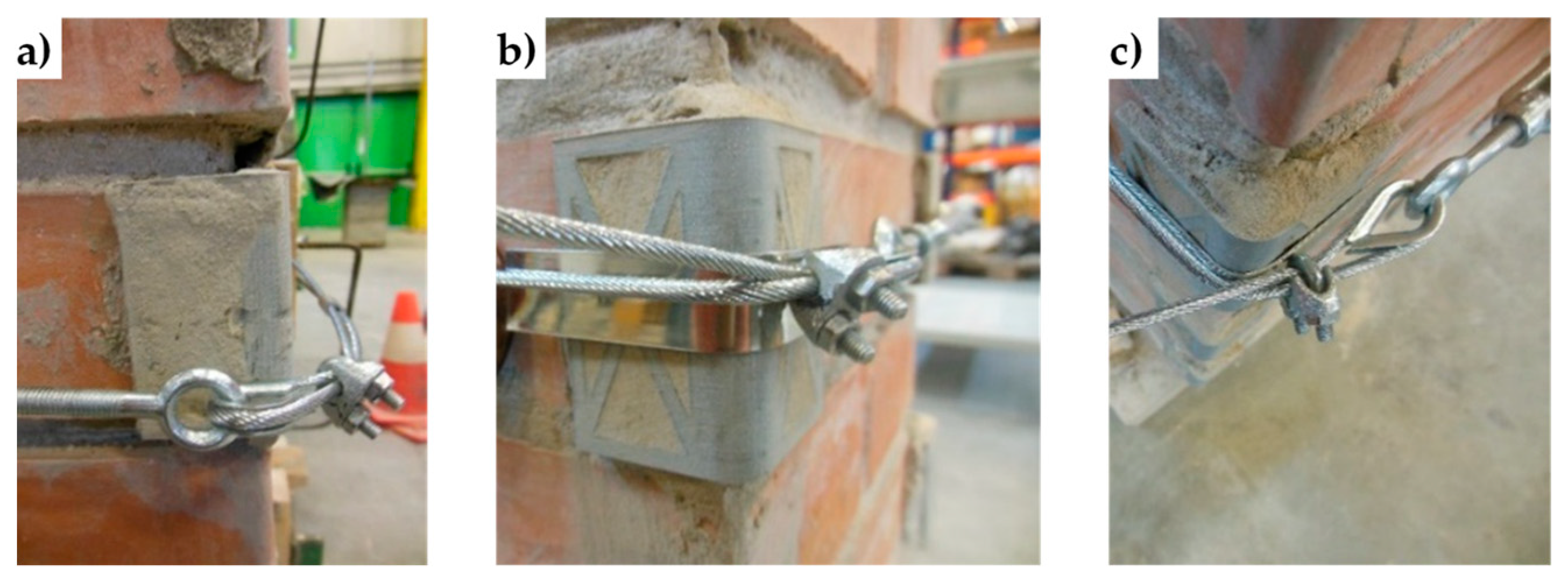

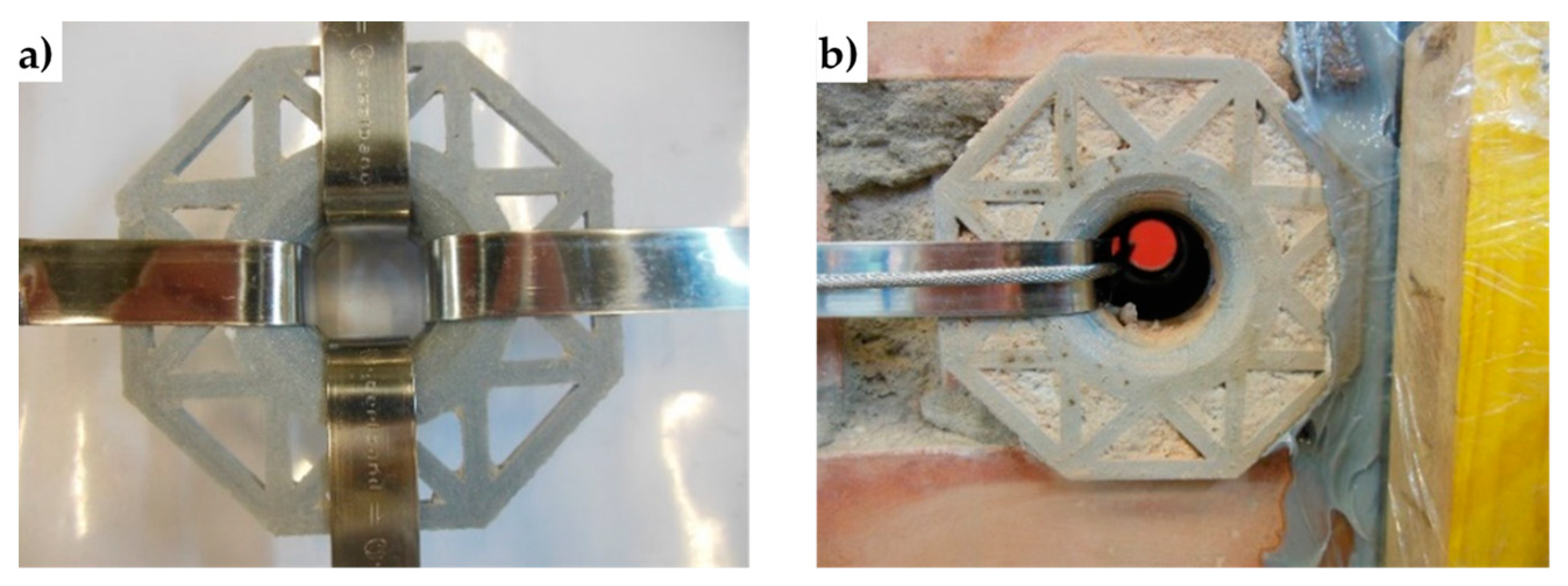

4.1. Funnel Plates and Rounded Angles

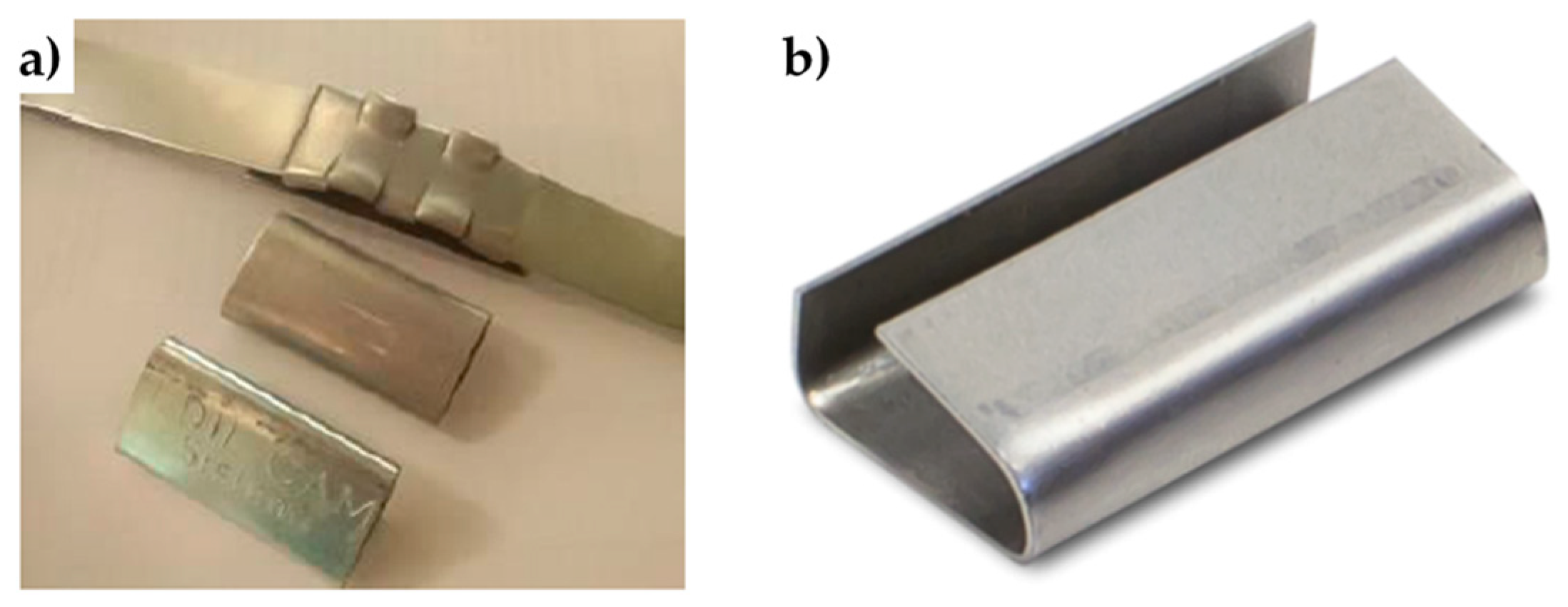

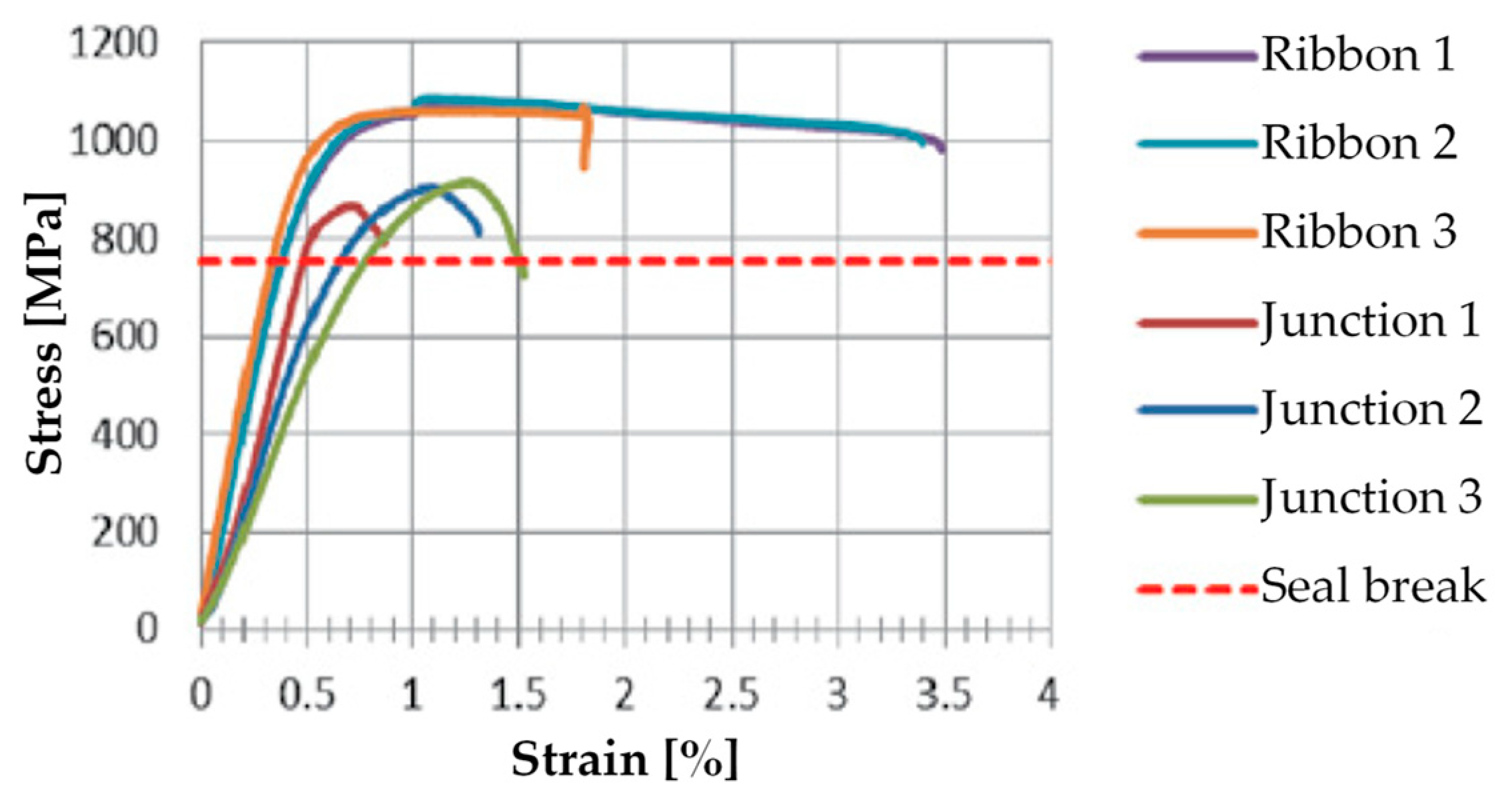

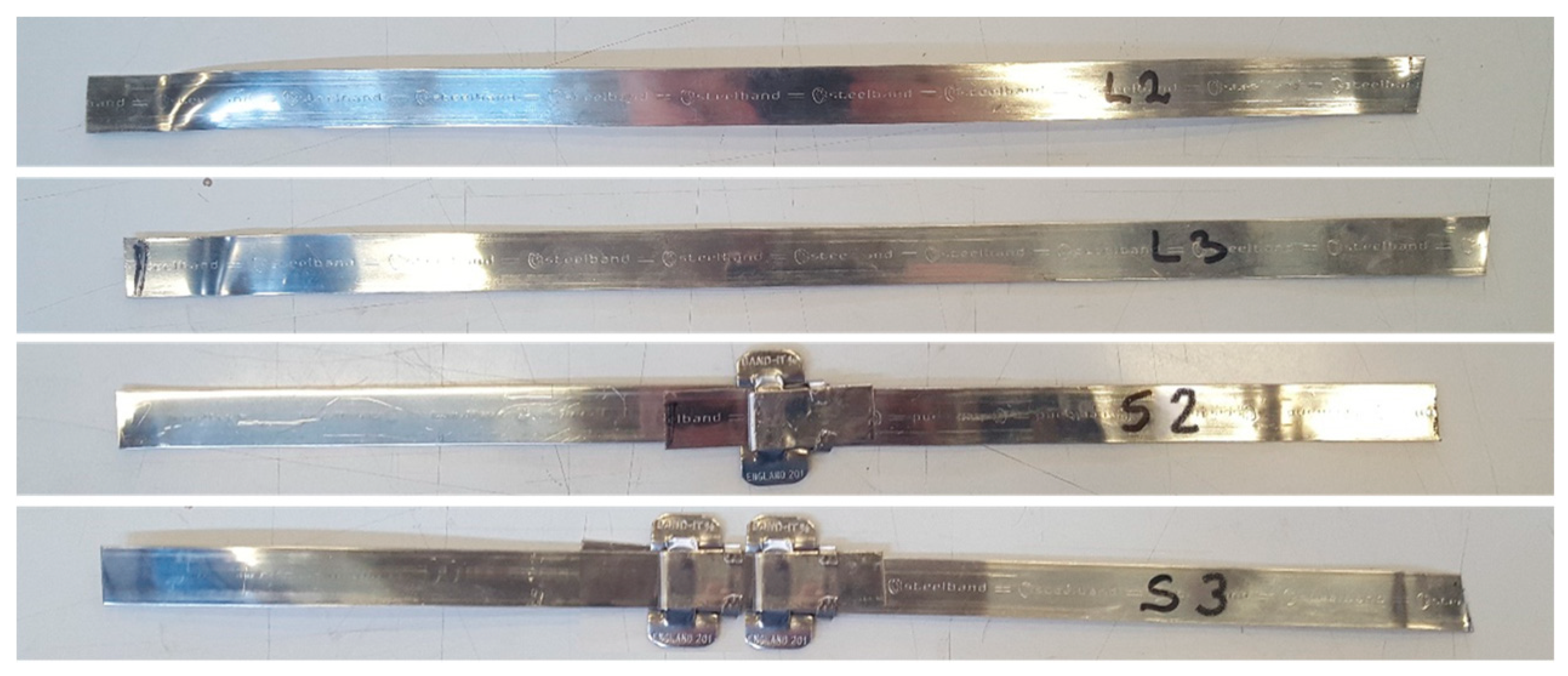

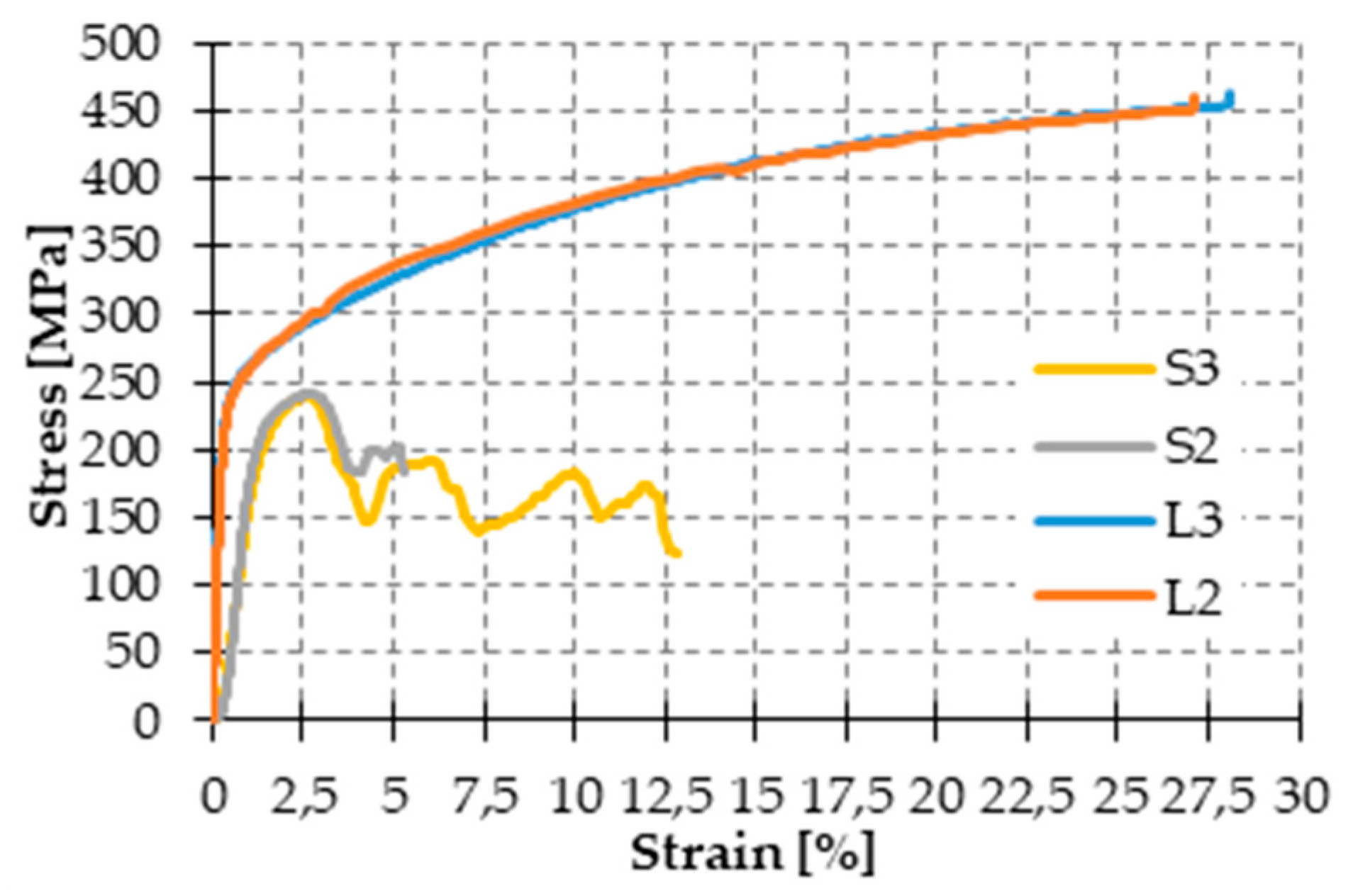

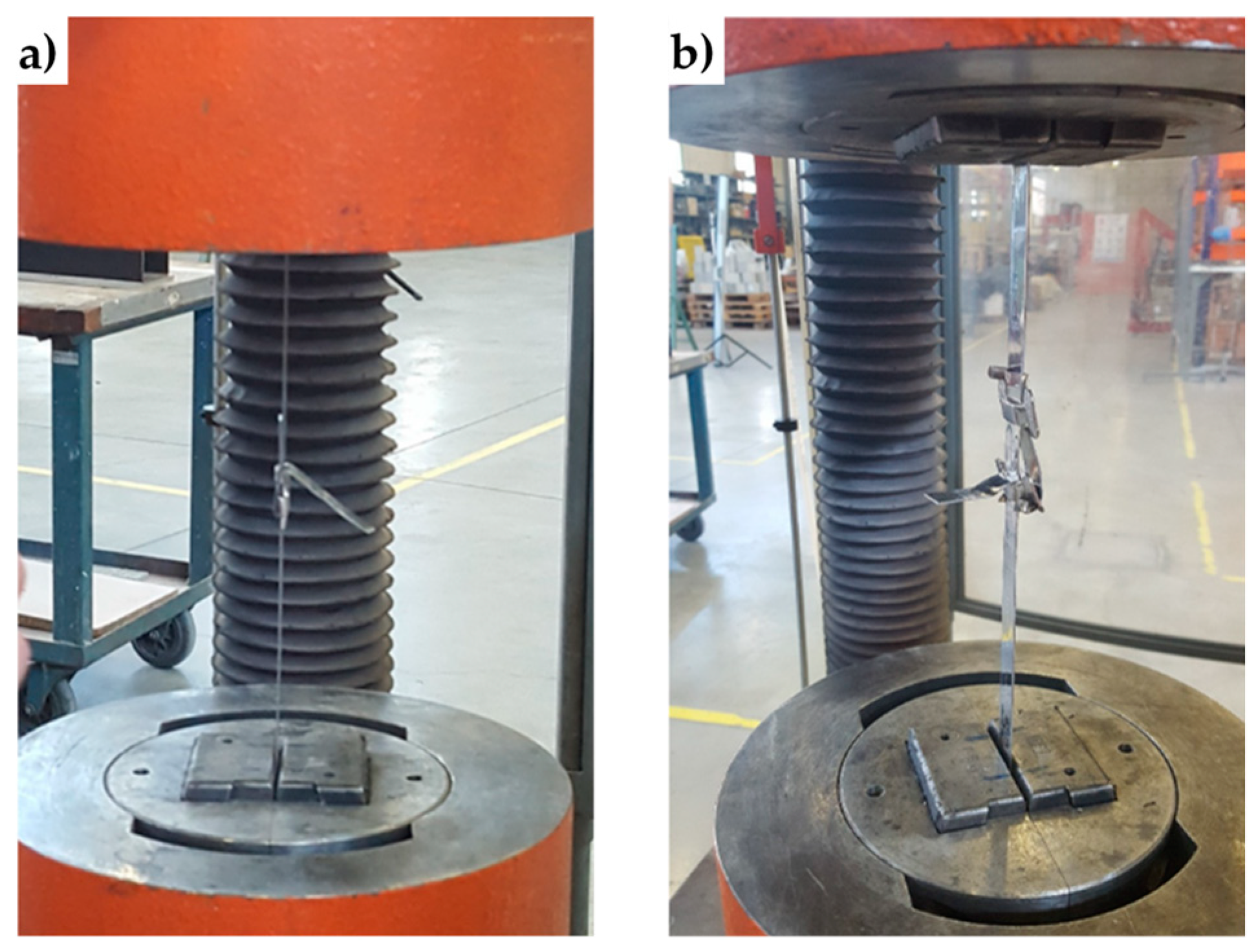

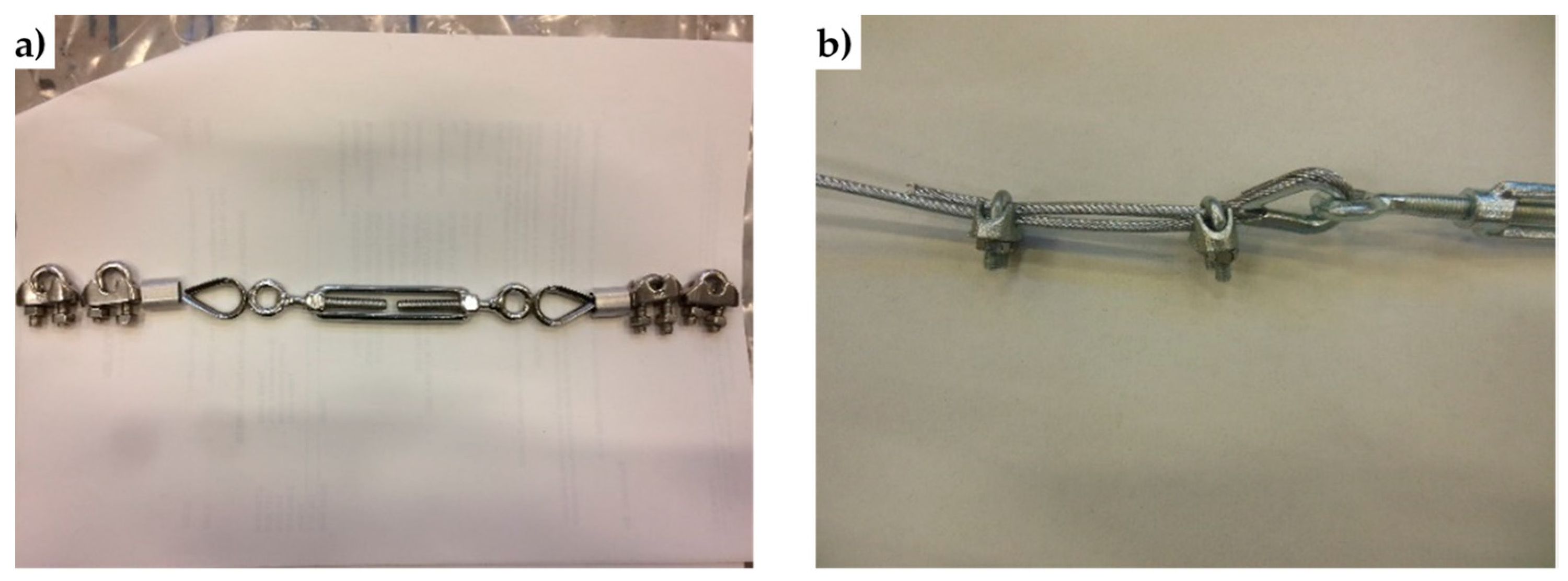

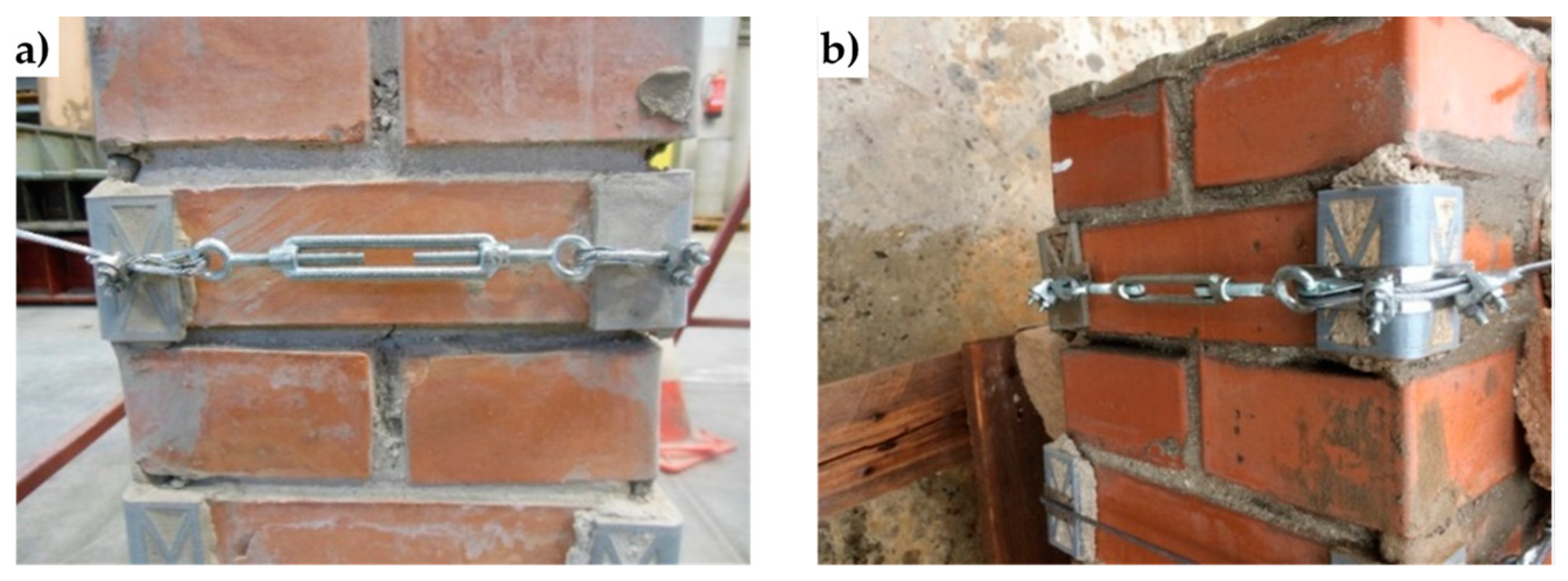

4.2. Straps and Seals

- Specimen L2, consisting of a steel ribbon without junction;

- Specimen L3, consisting of a steel ribbon without junction;

- Specimen S2, consisting of 2 pieces of steel ribbon, fastened together by 1 seal;

- Specimen S3, consisting of 2 pieces of steel ribbon, fastened together by 2 seals;

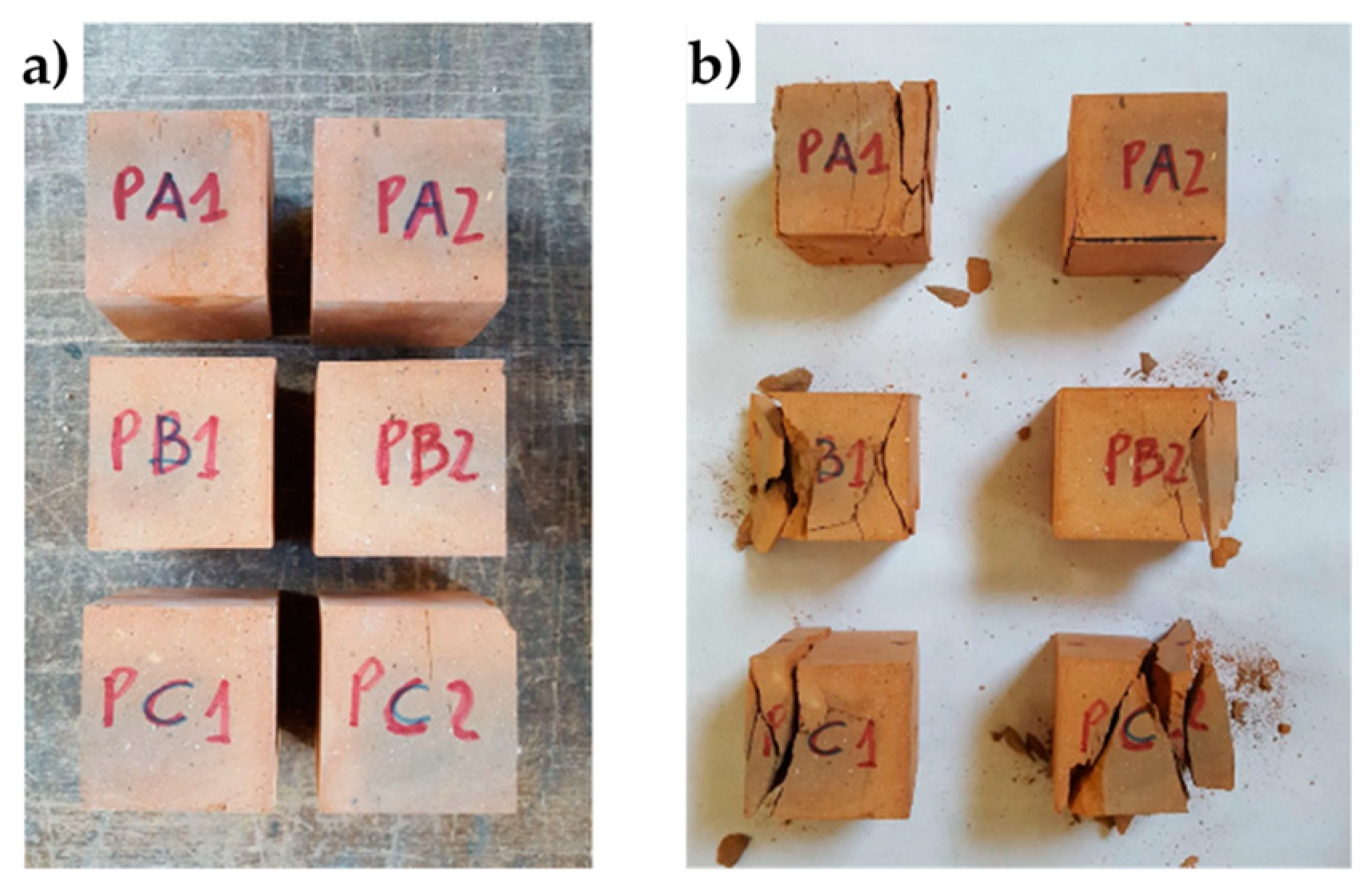

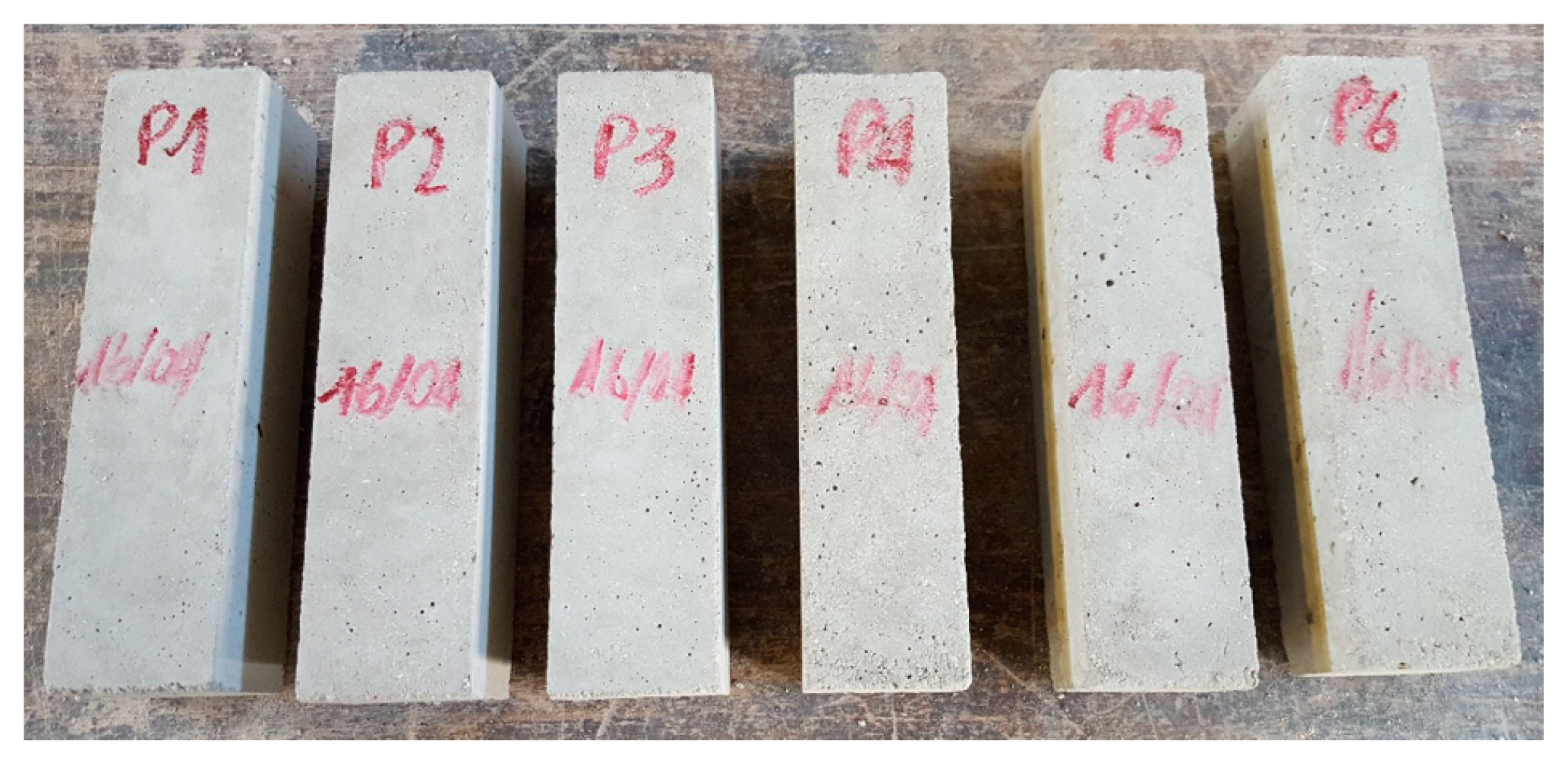

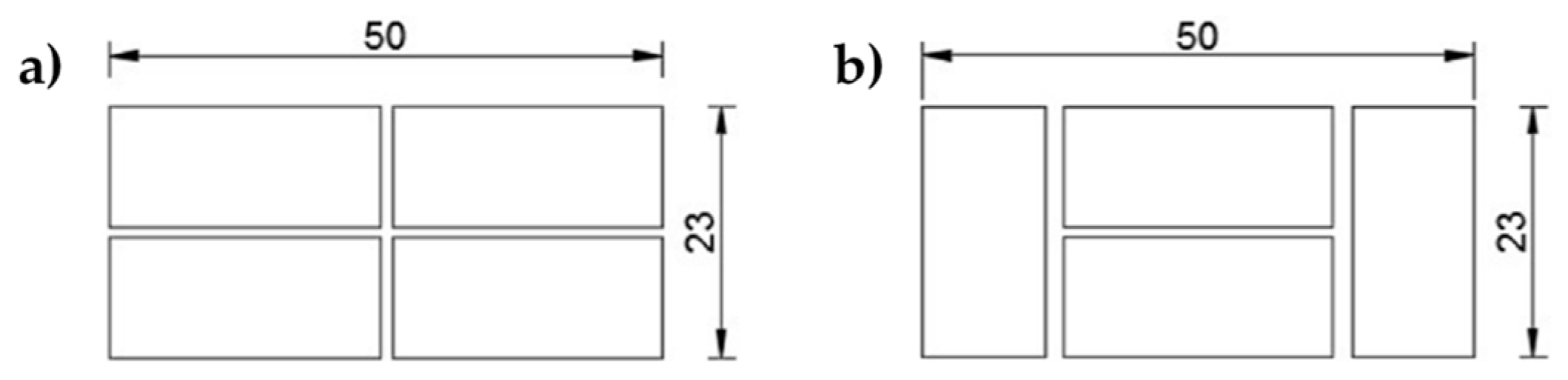

4.3. Mechanical Characterization of Bricks and Mortar

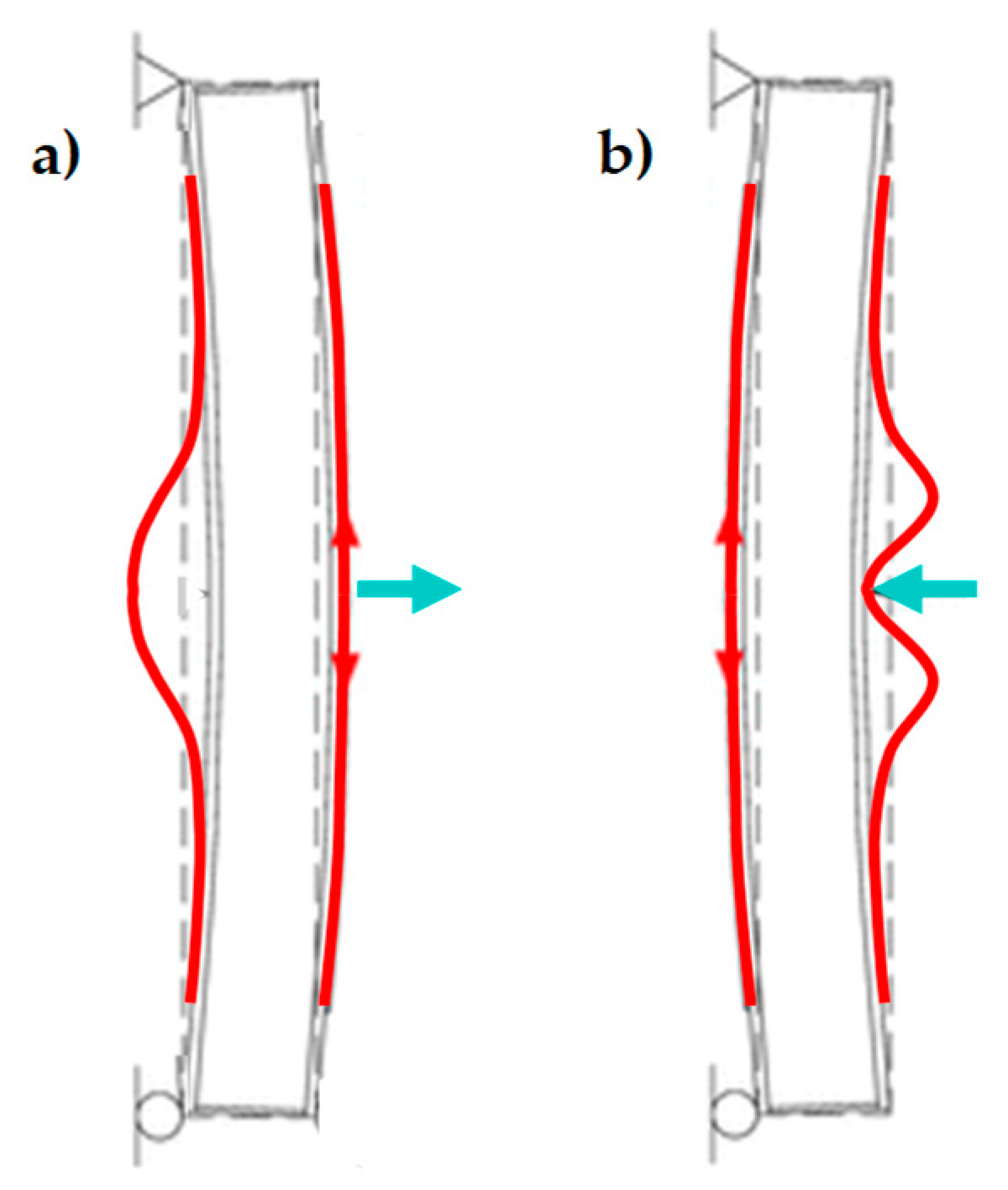

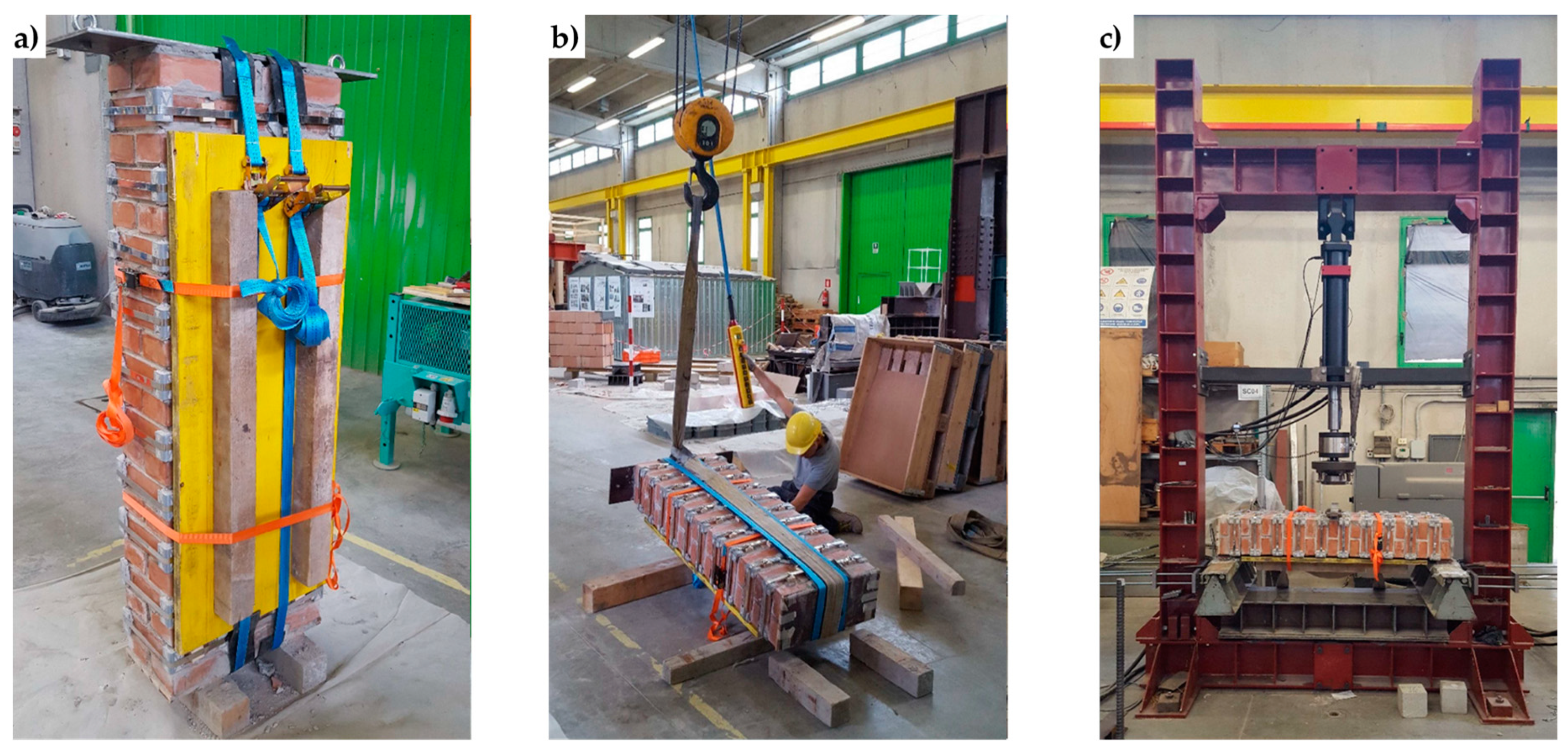

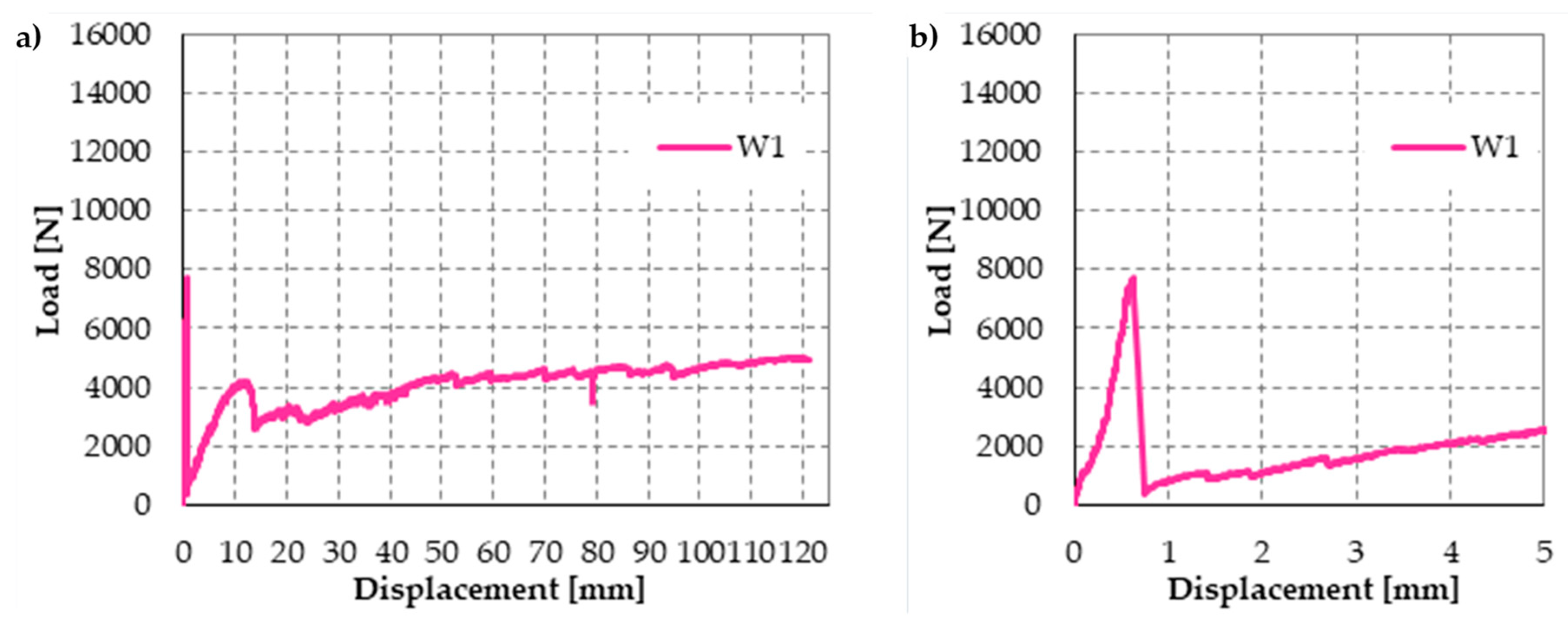

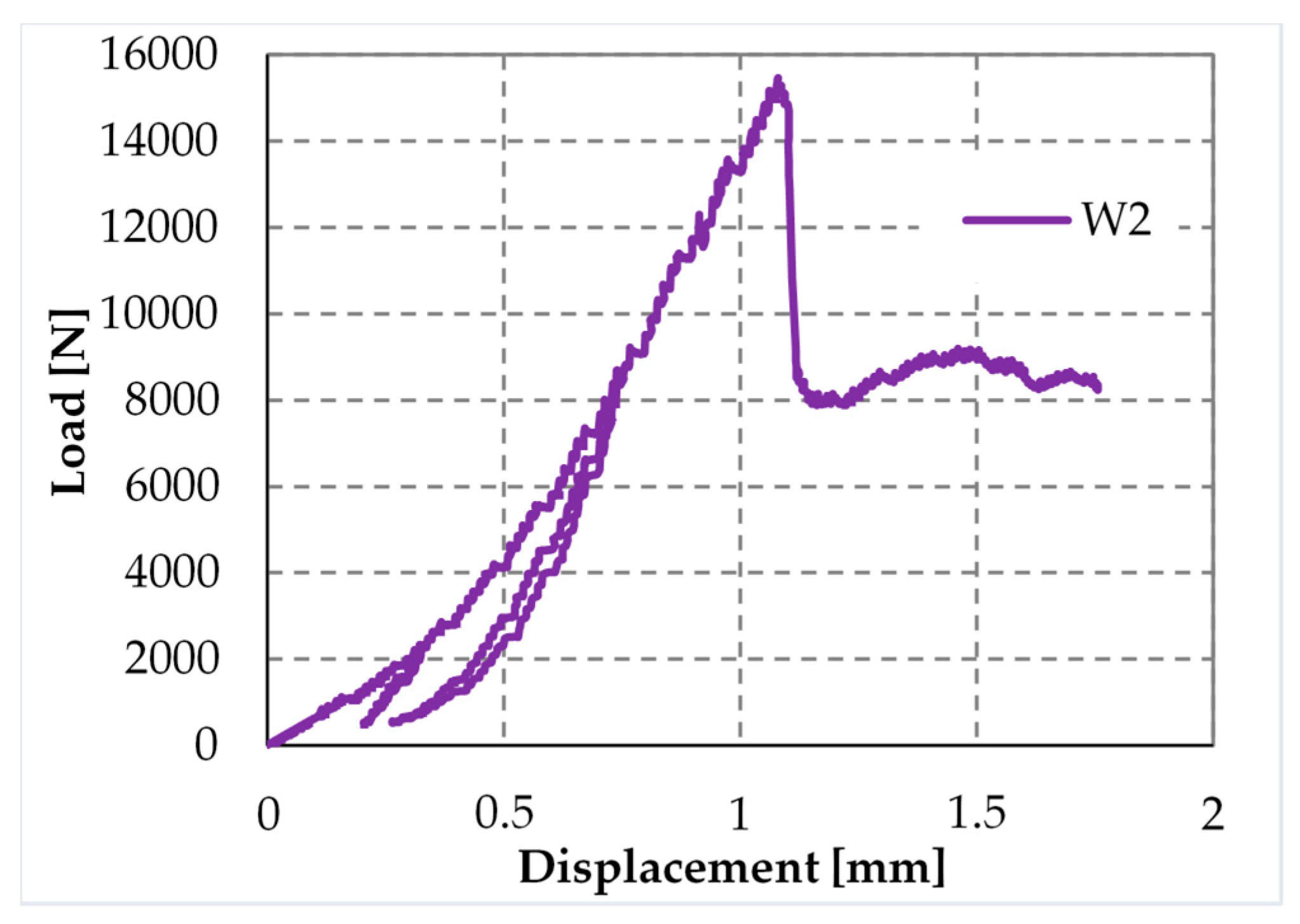

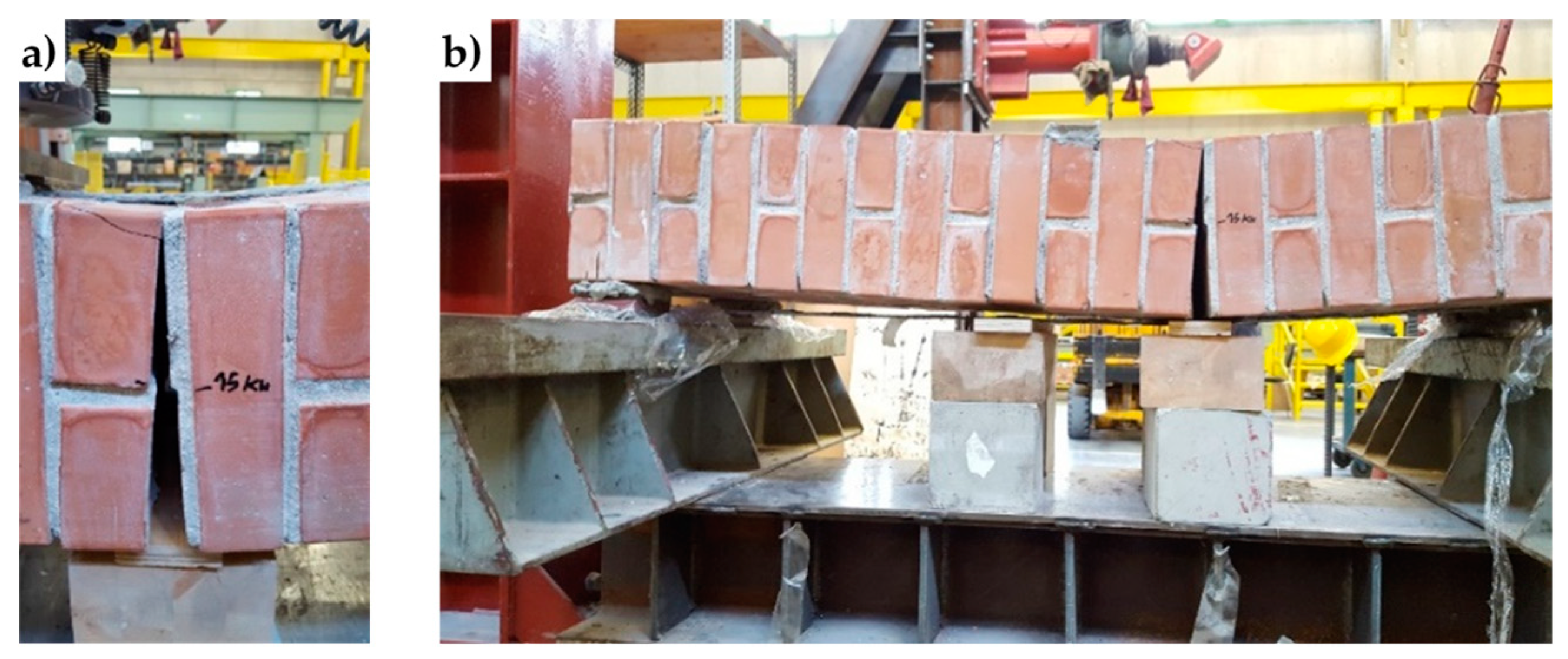

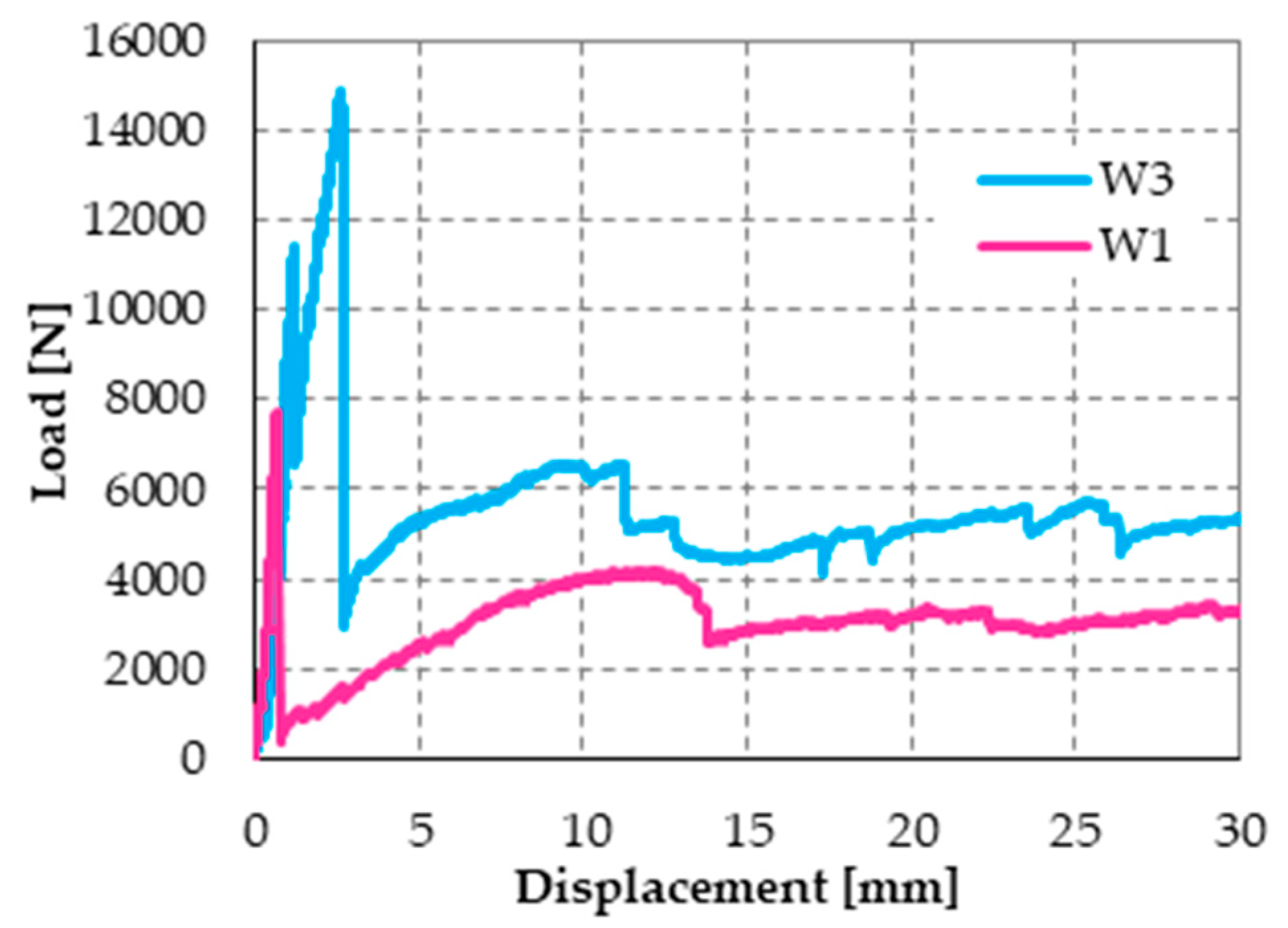

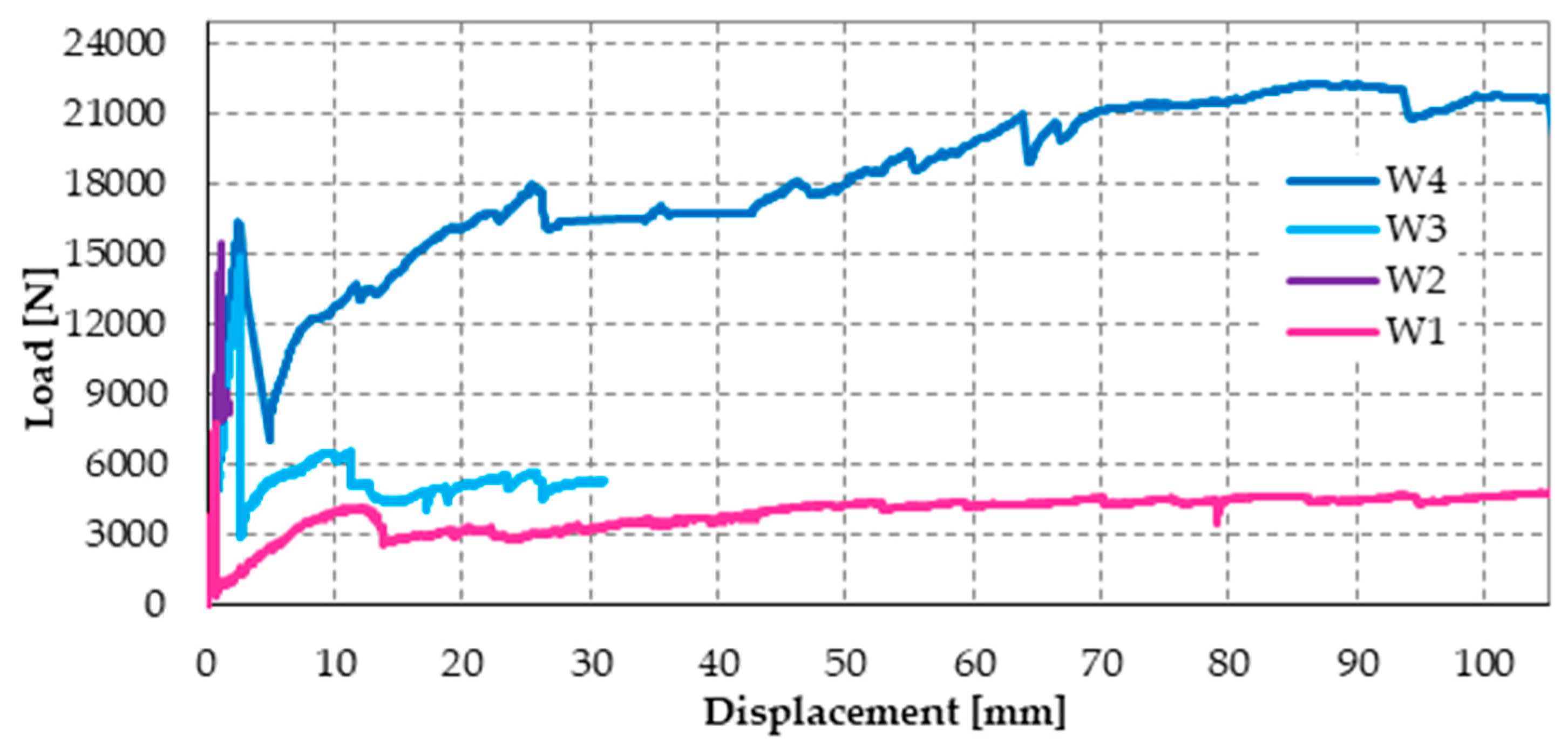

4.4. Specimens W1, W2, and W3

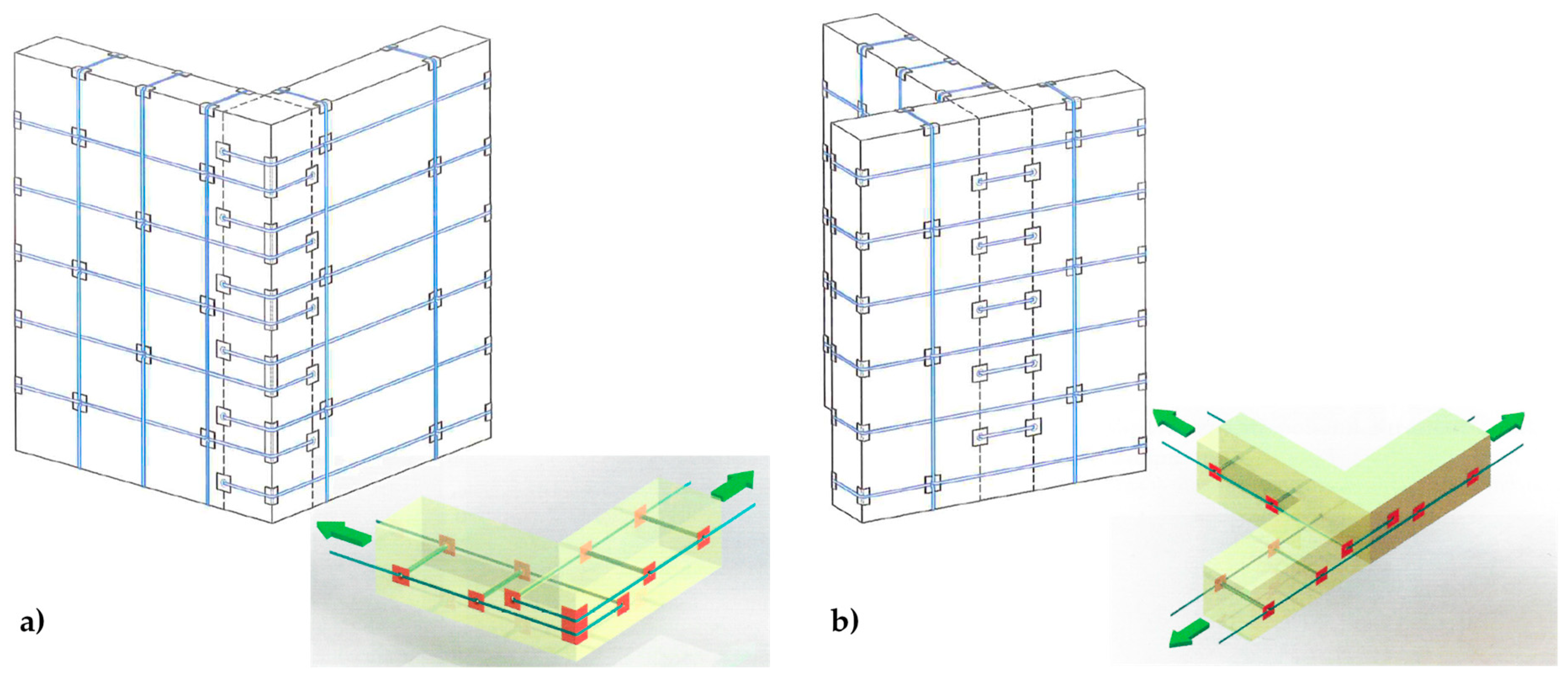

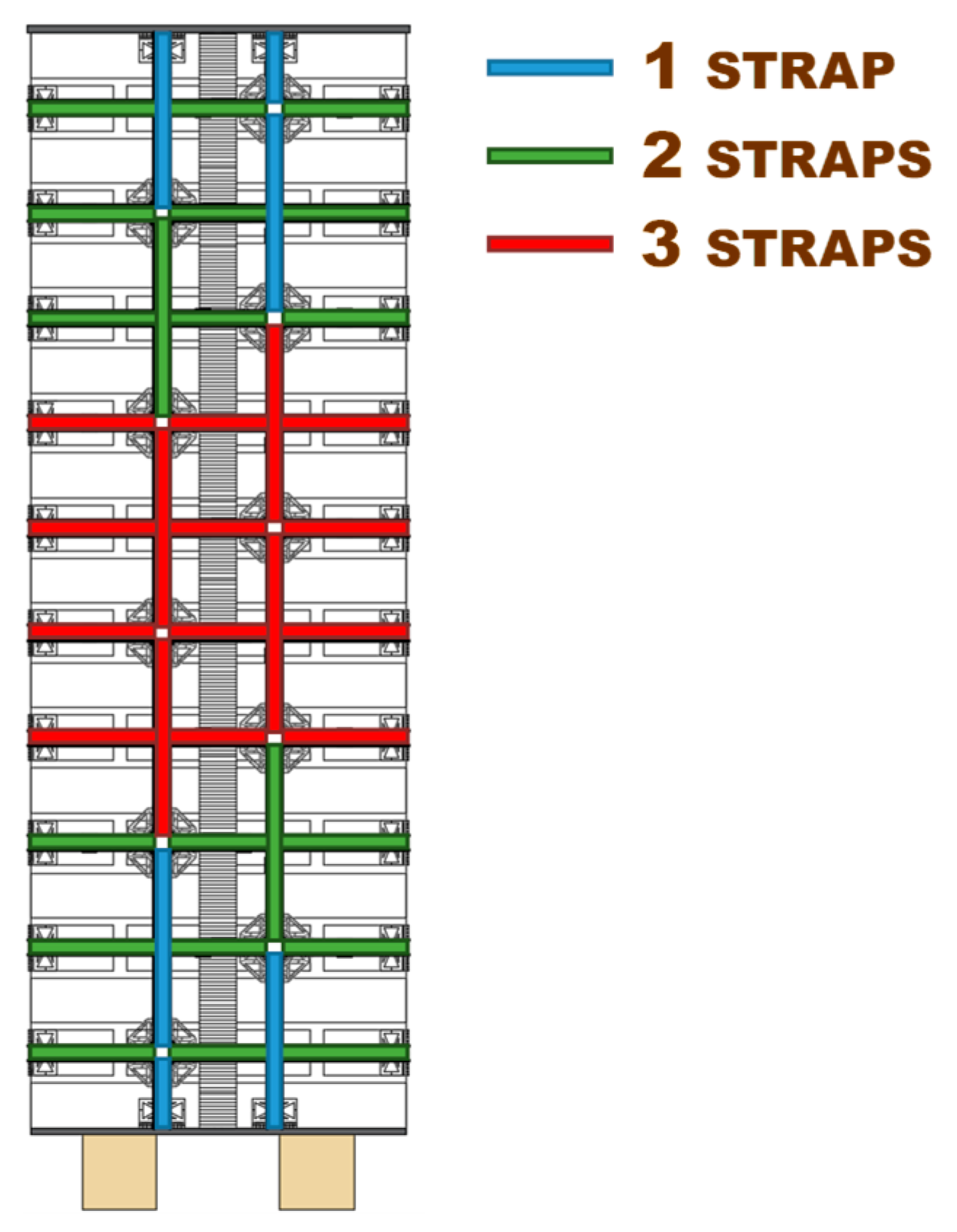

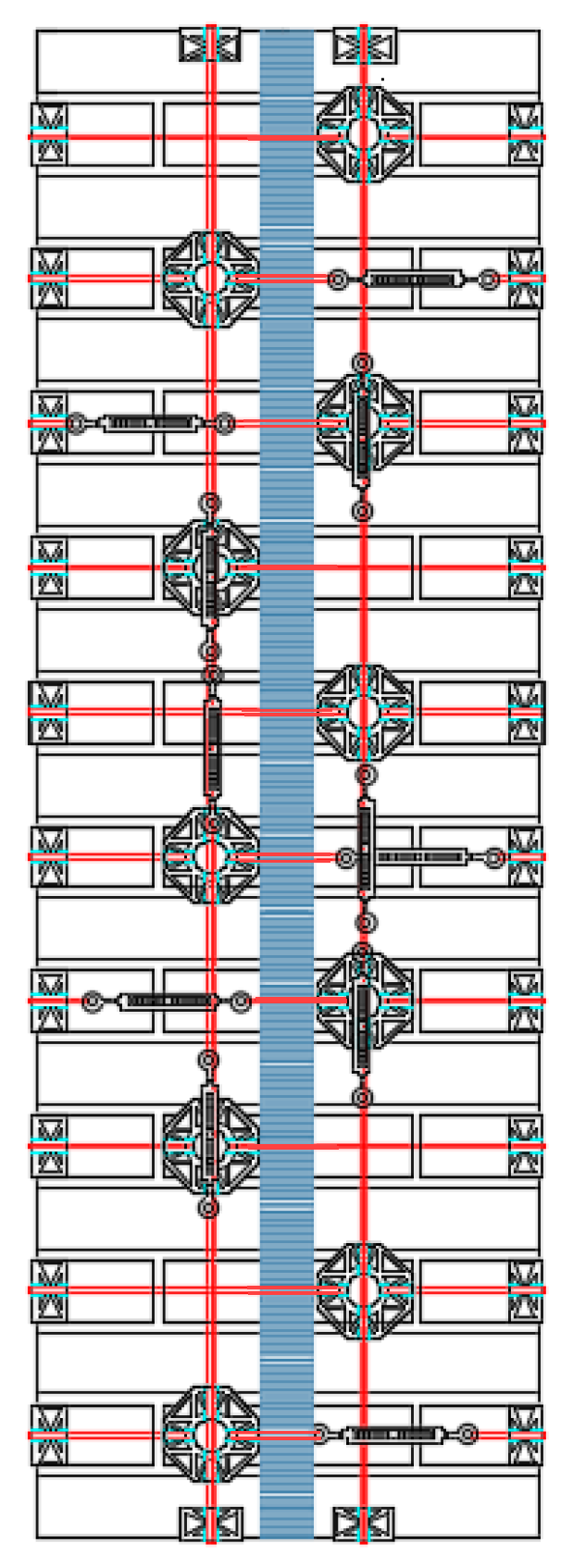

- Specimen W1 is a drilled masonry wall, with the holes arranged in quincunxes. This choice minimizes the number of holes and gives rise to two three-dimensional nets of straps, staggered along the horizontal and vertical directions.

- Specimen W2 is an undrilled wall, with two CFRP strips placed side by side for each vertical centerline of the two main faces. The CFRP strips are 25 mm wide and 1.2 mm thick.

- Specimen W3 is a drilled wall, with the holes arranged in quincunxes, where some straps of both three-dimensional nets tie the side-by-side CFRP strips together, along the vertical centerlines.

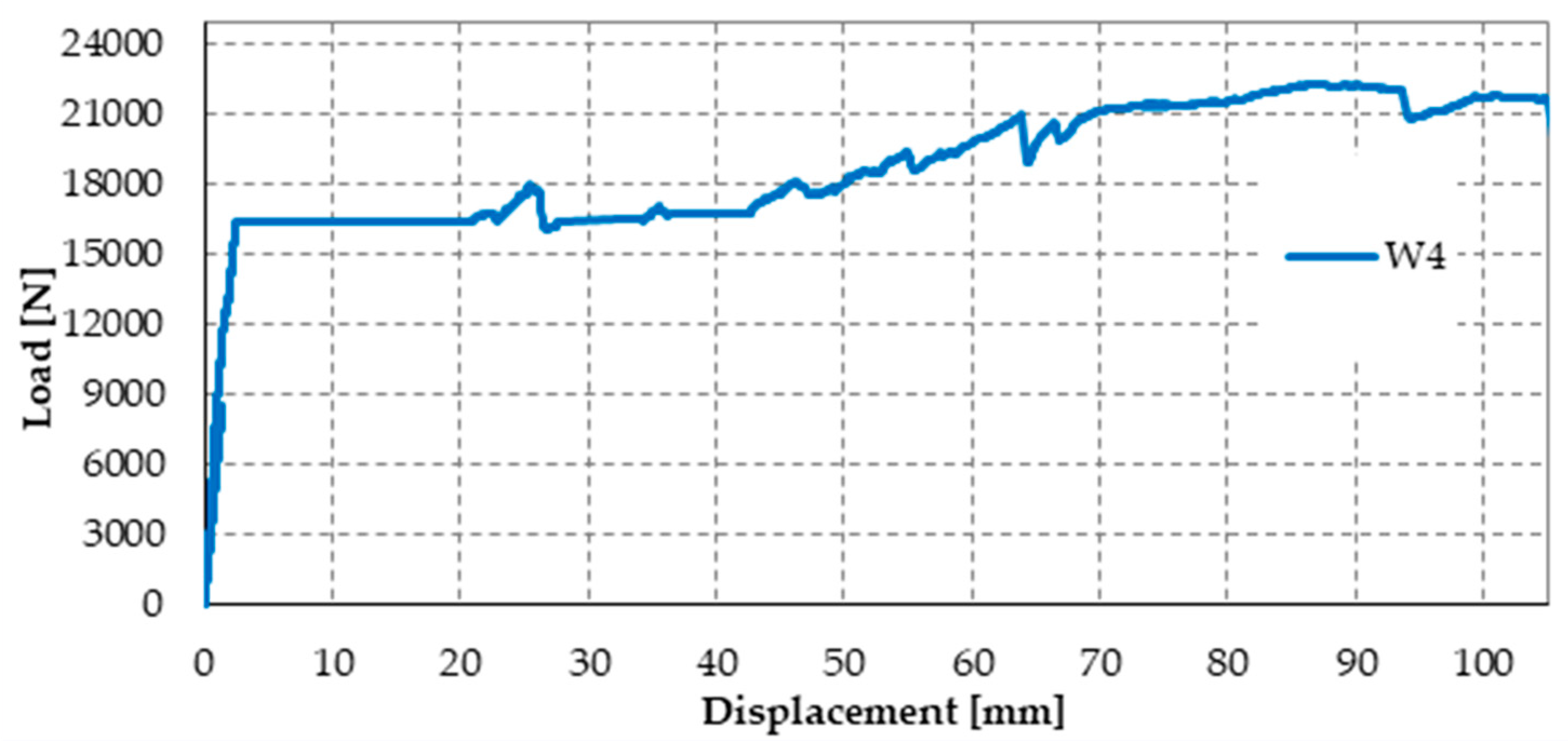

4.5. Specimen W4

- Removal of all damaged straps of Specimen W3;

- Cleaning of the specimen surface, in correspondence of the delaminated CFRP strips;

- Removal of the mortar on the cross-section where Specimen W3 opened into two parts;

- Restoration of the specimen integrity, by walling together the two parts of Specimen W3;

- Curing of the mortar on the restored cross-section;

- Bonding of new CFRP strips on both sides of the specimen;

- Strapping of the specimen, according to the scheme of Figure 47, by positioning the longitudinal straps over the transverse straps (like for Specimens W1 and W3).

- The pre-tension of the transverse straps delays the delamination of the CFRP strips, by pushing the straps against the wall, as shown in Figure 36a,b, which blocks the CFRP strips. Since the (low) pre-tension is provided by imposing a relative displacement between the free ends of the straps, with the relative displacement set by the strapping tool, the pre-tension value and the consequent action on the CFRP strips depend on the stiffness of the straps (the greater the stiffness, the greater the pre-tension).

- The ductility of the longitudinal straps delays the failure of the retrofitted masonry wall, which allows the formation of multiple plastic hinges without ever reaching a labile configuration.

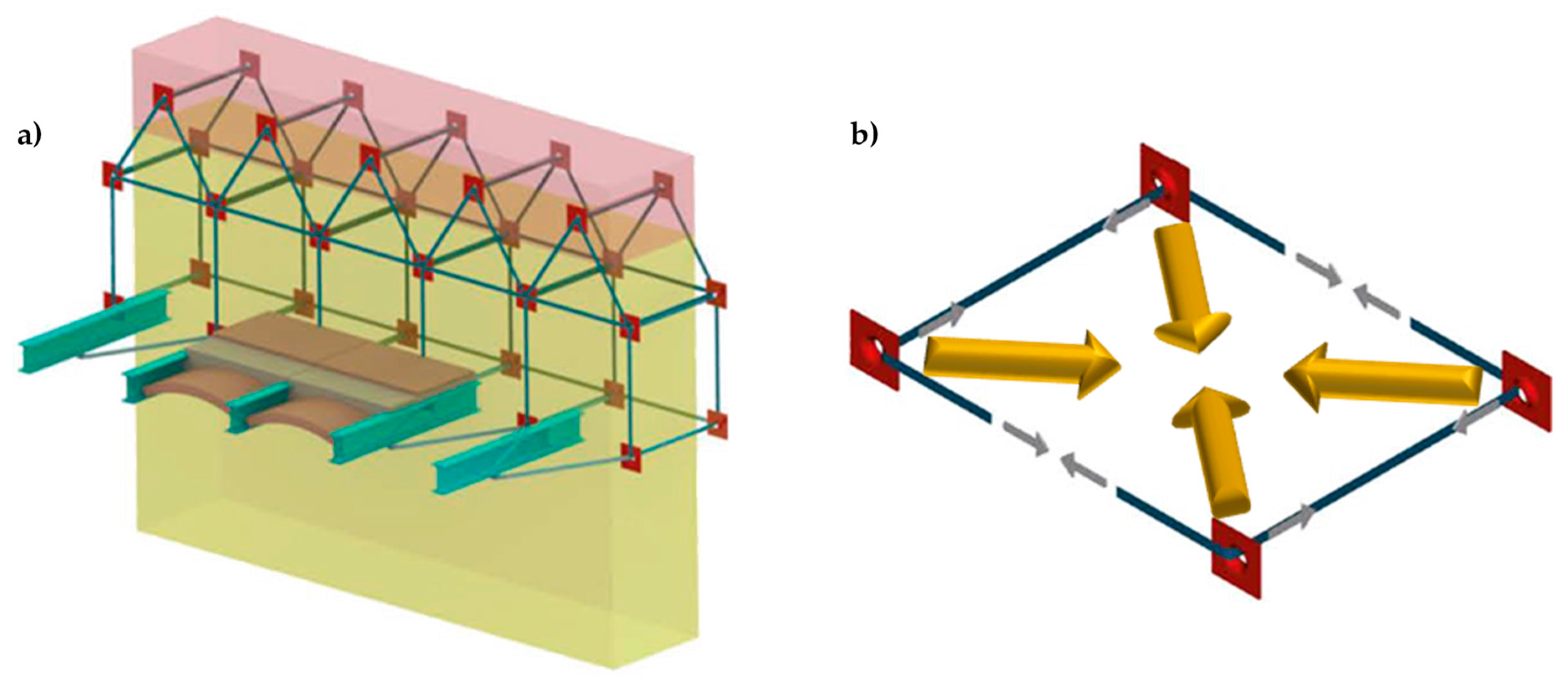

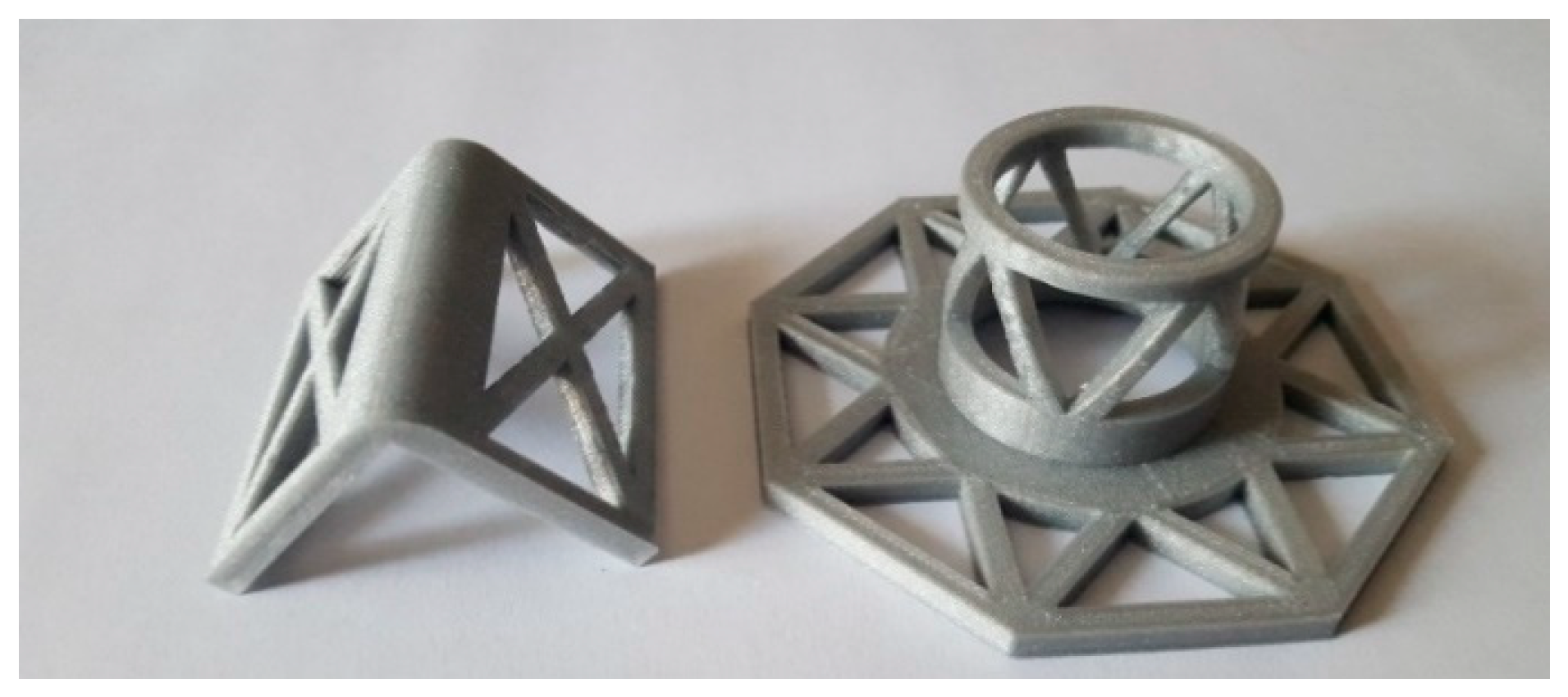

5. A Further Combined Technique

6. Conclusions

- The three-dimensional net of straps provides the building with a box-type behavior;

- Retrofitting does not excessively increase the total mass of the building, which limits the attraction of seismic forces;

- Once the masonry wall has cracked, the straps have exhausted their strengthening function but find a second use, starting to work as a device of safeguarding life.

7. Future Developments

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akhoundi, F.; Vasconcelos, G.; Lourenço, P.B. Experimental Out-Of-Plane Behavior of Brick Masonry Infilled Frames. Int. J. Archit. Herit. 2018. [Google Scholar] [CrossRef]

- Csikai, B.; Ramos, L.F.; Basto, P.; Moreira, S.; Lourenço, P.B. Flexural out-of-plane retrofitting technique for masonry walls in historical constructions. In Proceedings of the SAHC2014 9th International Conference on Structural Analysis of Historical Constructions, Mexico City, Mexico, 14–17 October 2014; Meli, R., Peña, F., Chávez, M., Eds.; 2014. [Google Scholar]

- Lourenço, P.B. Technologies for Seismic Retrofitting and Strengthening of Earthen and Masonry Structures: Assessment and Application. In Recent Advances in Earthquake Engineering in Europe, ECEE 2018, Geotechnical, Geological and Earthquake Engineering; Pitilakis, K., Ed.; Springer: Cham, Switzerland, 2018; Volume 46, pp. 501–518. [Google Scholar]

- Wang, C.; Sarhosis, V.; Nikitas, N. Strengthening/Retrofitting Techniques on Unreinforced Masonry Structure/Element Subjected to Seismic Loads: A Literature Review. Open Construct. Build. Tech. J. 2018, 12, 251–268. [Google Scholar] [CrossRef]

- Ferretti, E.; Pascale, G. Some of the Latest Active Strengthening Techniques for Masonry Buildings: A Critical Analysis. Materials 2019, 12, 1151. [Google Scholar] [CrossRef]

- Corradi, M.; Di Schino, A.; Borri, A.; Rufini, R. A review of the use of stainless steel for masonry repair and reinforcement. Constr. Build. Mater. 2018, 181, 335–346. [Google Scholar] [CrossRef]

- Cilia, M.; Cipolla, I.; Colajanni, P.; Marnetto, R.; Recupero, A.; Spinella, N. Prove sperimentali su travi in c.a. rinforzate con metodo CAM®: Valutazione del comportamento a taglio. Progettazione Sismica 2015, VII, 93–108. [Google Scholar]

- Dolce, M.; Nigro, D.; Ponzo, F.C.; Marnetto, R. The CAM system for the retrofit of masonry structures. In Proceedings of the 7th International Seminar on Seismic Isolation, Passive Energy Dissipation and Active Control of Vibrations of Structures, Assisi, Italy, 2–5 October 2001. [Google Scholar]

- Dolce, M.; Ponzo, F.C.; Di Croce, M.; Moroni, C.; Giordano, F.; Nigro, D.; Marnetto, R. Experimental assessment of the CAM and DIS-CAM systems for the seismic upgrading of monumental masonry buildings. In Proceedings of the PROHITECH 2009 1st International Conference on Protection of Historical Constructions, Rome, Italy, 21–24 June 2009; CRC Press/Balkema: Leiden, the Netherlands, 2009; pp. 1021–1028. [Google Scholar]

- Dolce, M.; Ponzo, F.C.; Goretti, A.; Moroni, C.; Giordano, F.; De Canio, G.; Marnetto, R. 3d dynamic tests on 2/3 scale masonry buildings retrofitted with different systems. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Leonori, M.; Vari, A. L’influenza della tipologia di terreno sui meccanismi locali di collasso degli edifici in muratura e miglioramento sismico con il sistema CAM®. In Dynamic Interaction of Soil and Structure (DISS_15); Proceedings of the 4th International Workshop on Archaeology, Cryptoportici, Hypogea, Geology, Geotechnics, Geophysics, Rome, Italy, 12–13 November 2015; Monti, G., Valente, G., Eds.; Università dell’Aquila, Dipartimento DICEAA—Sapienza, Università di Roma: Rome, Italy, 2015; pp. 1–15. [Google Scholar]

- Marnetto, R. Sviluppo ed applicazioni delle tecniche antisismiche presso la società TIS SpA di Roma. In Proceedings of the Seminario di Studi sui Sistemi e Tecnologie Antisismici, Rome, CNR, Italy, 12 September 2007; pp. 2–27. [Google Scholar]

- Marnetto, R.; Vari, A. Linee Guida—Cuciture Attive per la Muratura: Procedura Generale per la Progettazione, Modellazione, Calcolo e Verifica di Edifici in Muratura Rinforzati con il Sistema di Cucitura attiva CAM; EDIL CAM Sistemi S.r.l.: Rome, Italy, October 2015. [Google Scholar]

- Marnetto, R.; Vari, A.; Marnetto, L.; Leonori, M. Conservare L’edilizia in Muratura: Il Sistema CAM—Cuciture Attive dei Manufatti; Edizioni PREprogetti: Rome, Italy, 2014. [Google Scholar]

- Ferretti, E. Effectiveness of Active Confinement Techniques with Steel Ribbons: Masonry Buildings. Eur. J. Eng. Form. Sci. 2018, 2, 17–29. [Google Scholar] [CrossRef]

- Ferretti, E.; Casadio, E.; Di Leo, A. Masonry Walls under Shear Test: A CM Modeling. CMES-Comp. Model. Eng. 2008, 30, 163–189. [Google Scholar]

- Ferretti, E. Attaining a Beam-Like Behavior with FRP Strips and CAM Ribbons. Eur. J. Eng. Form. Sci. 2018, 2, 6–16. [Google Scholar] [CrossRef]

- Ferretti, E.; Di Leo, A. Cracking and creep role in displacements at constant load: Concrete solids in compression. CMC-Comput. Mater. Con. 2008, 7, 59–79. [Google Scholar]

- Rousakis, T.C.; Panagiotakis, G.D.; Archontaki, E.E.; Kostopoulos, A.K. Prismatic RC columns externally confined with FRP sheets and pretensioned basalt fiber ropes under cyclic axial load. Compos. B Eng. 2019, 163, 96–106. [Google Scholar] [CrossRef]

- Marques, R.; Lamego, P.; Lourenço, P.B.; Sousa, M.L. Efficiency and Cost-Benefit Analysis of Seismic Strengthening Techniques for Old Residential Buildings in Lisbon. J. Earthq. Eng. 2018, 22, 1590–1625. [Google Scholar] [CrossRef]

| Specimen | Dimensions [mm] | Weight [g] | Breaking Load [N] | Compressive Strength [N/mm2] | Normalized Compressive Strength [N/mm2] |

|---|---|---|---|---|---|

| PA1 | 55 × 54 × 55 | 296.1 | 116436 | 39.63165 | 34.47953 |

| PA2 | 57 × 57 × 55 | 317.8 | 165730 | 50.91128 | 44.29281 |

| PB1 | 55 × 53 × 55 | 297.5 | 146733 | 49.62439 | 43.17322 |

| PB2 | 56 × 55 × 57 | 319.2 | 142681 | 46.09916 | 40.10627 |

| PC1 | 56 × 53 × 56 | 310.5 | 144933 | 47.77687 | 41.56587 |

| PC2 | 56 × 55 × 56 | 317.1 | 149422 | 48.14767 | 41.88848 |

| Specimens of the Flexural Tests | Dimensions [mm] | Weight [g] | Breaking Load in Bending [N] | Flexural Strength [N/mm2] | Specimens of the Compression Tests | Breaking Load in Compression [N] | Compressive Strength [N/mm2] |

|---|---|---|---|---|---|---|---|

| P1 | 40 × 40 × 160 | 466.42 | 1758 | 4.12 | P1A | 30530 | 19.08 |

| P1B | 36730 | 22.96 | |||||

| P2 | 40 × 40 × 160 | 469.81 | 1838 | 4.31 | P2A | 30980 | 19.36 |

| P2B | 30930 | 19.33 | |||||

| P3 | 40 × 40 × 160 | 470.42 | 1443 | 3.38 | P3A | 27500 | 17.19 |

| P3B | 28530 | 17.83 | |||||

| P4 | 40 × 40 × 160 | 459.63 | 1885 | 4.42 | P4A | 34544 | 21.59 |

| P4B | 27730 | 17.33 | |||||

| P5 | 40 × 40 × 160 | 463.81 | 1990 | 4.66 | P5A | 33880 | 21.18 |

| P5B | 35200 | 22.00 | |||||

| P6 | 40 × 40 × 160 | 462.01 | 1598 | 3.75 | P6A | 30400 | 19.00 |

| P6B | 30450 | 19.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferretti, E.; Pascale, G. Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls. Materials 2019, 12, 1171. https://doi.org/10.3390/ma12071171

Ferretti E, Pascale G. Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls. Materials. 2019; 12(7):1171. https://doi.org/10.3390/ma12071171

Chicago/Turabian StyleFerretti, Elena, and Giovanni Pascale. 2019. "Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls" Materials 12, no. 7: 1171. https://doi.org/10.3390/ma12071171

APA StyleFerretti, E., & Pascale, G. (2019). Combined Strengthening Techniques to Improve the Out-of-Plane Performance of Masonry Walls. Materials, 12(7), 1171. https://doi.org/10.3390/ma12071171