An Energy-Based Unified Approach to Predict the Low-Cycle Fatigue Life of Type 316L Stainless Steel under Various Temperatures and Strain-Rates

Abstract

:1. Introduction

2. Materials and Methods

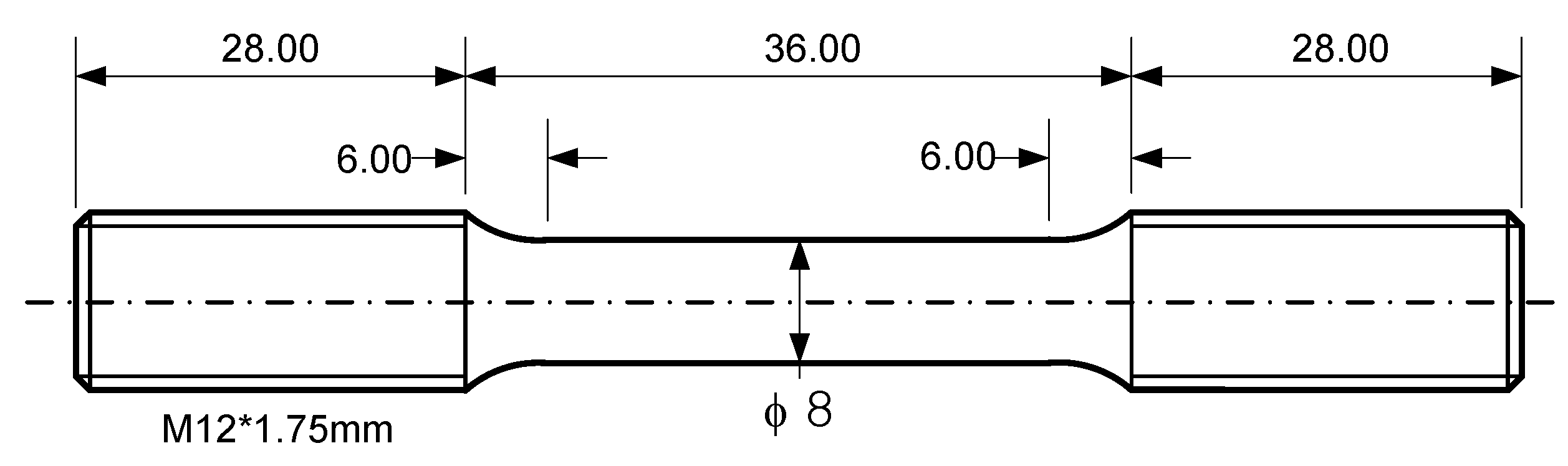

2.1. Material and Specimen

2.2. Test Equipment

2.3. Tesile Test

2.4. LCF Test

3. Results and Discussion

3.1. Tensile Test Result

3.1.1. Test by Displacement Control

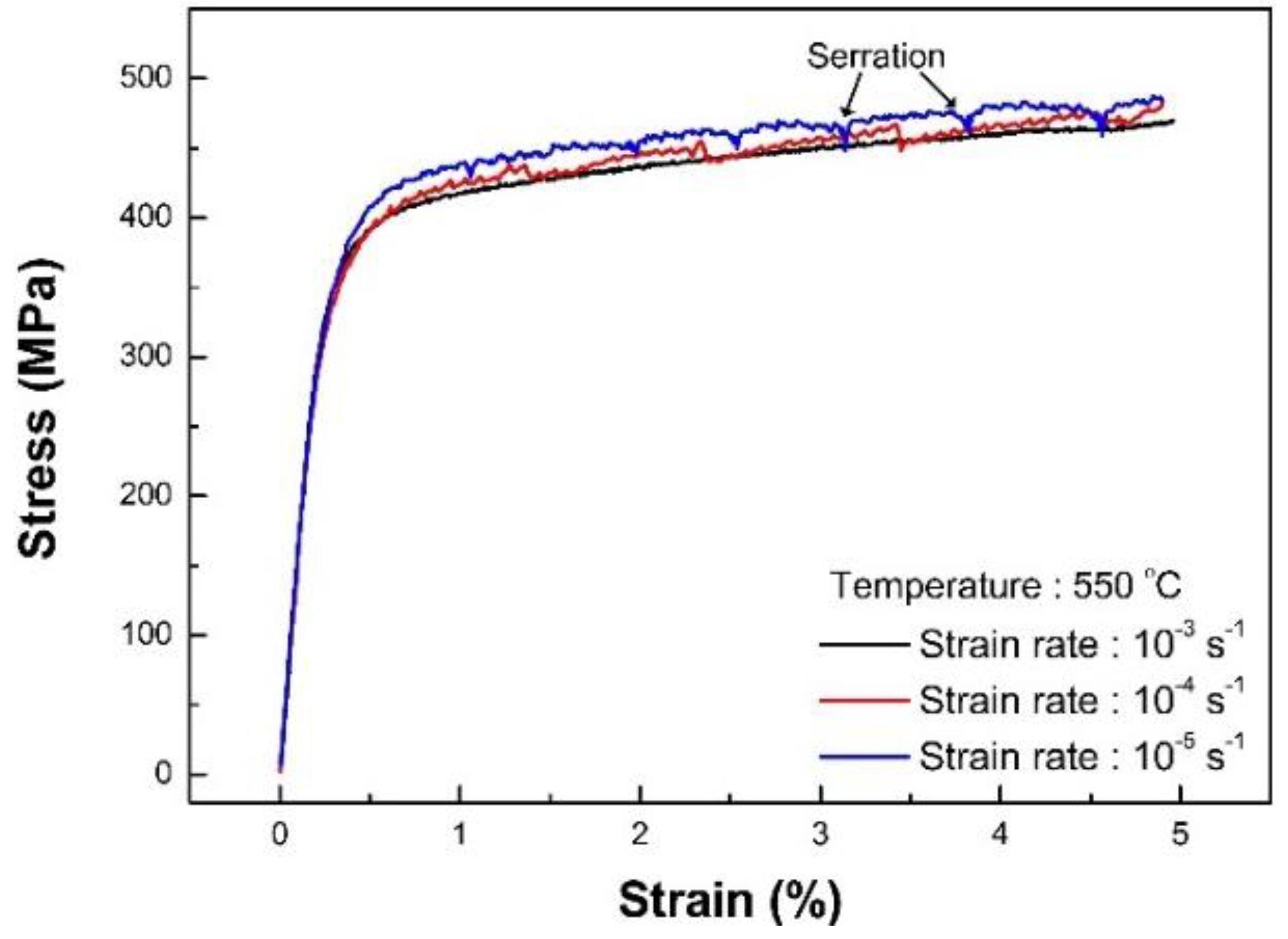

3.1.2. Test by Strain Control

3.2. LCF Test Result

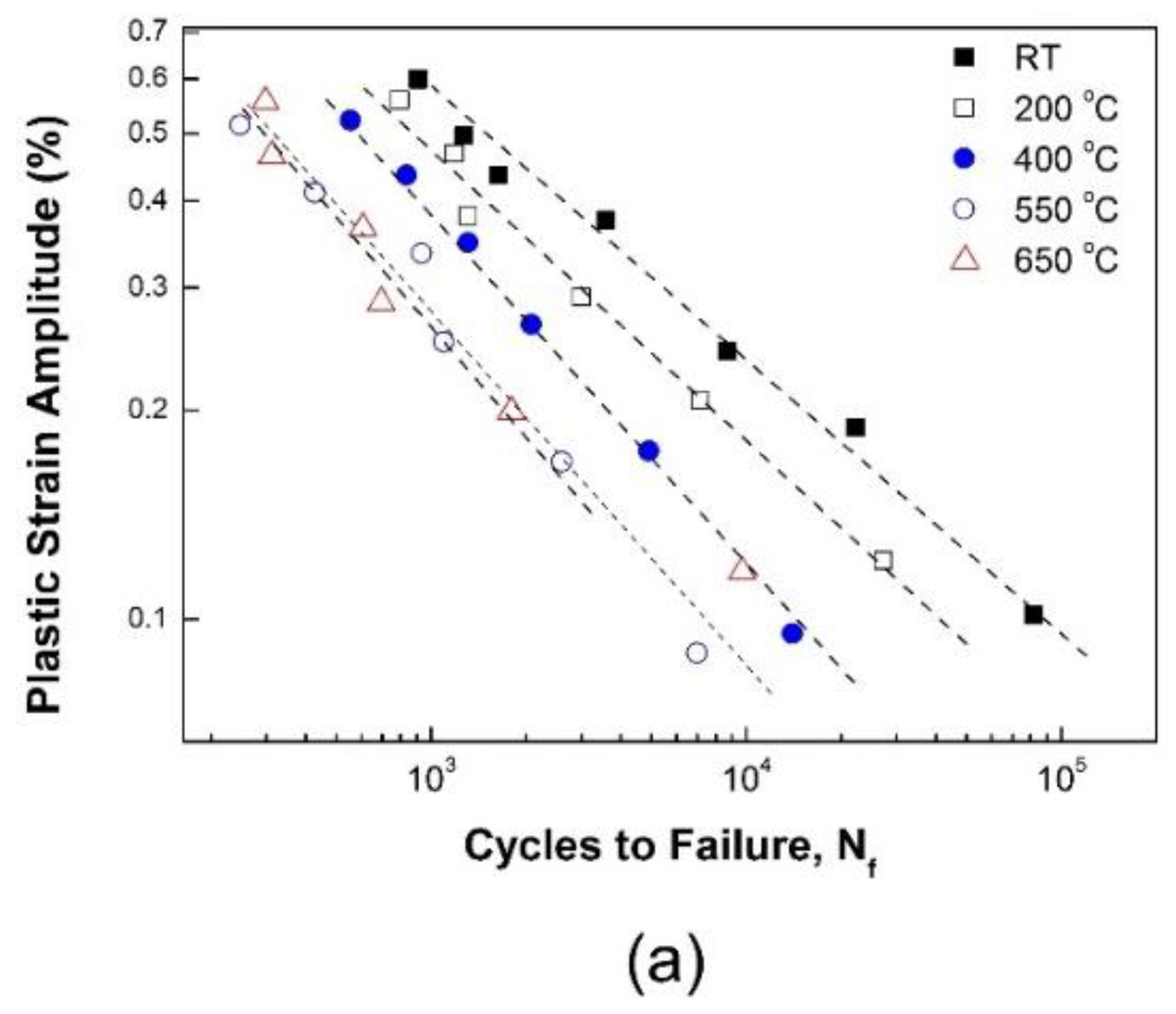

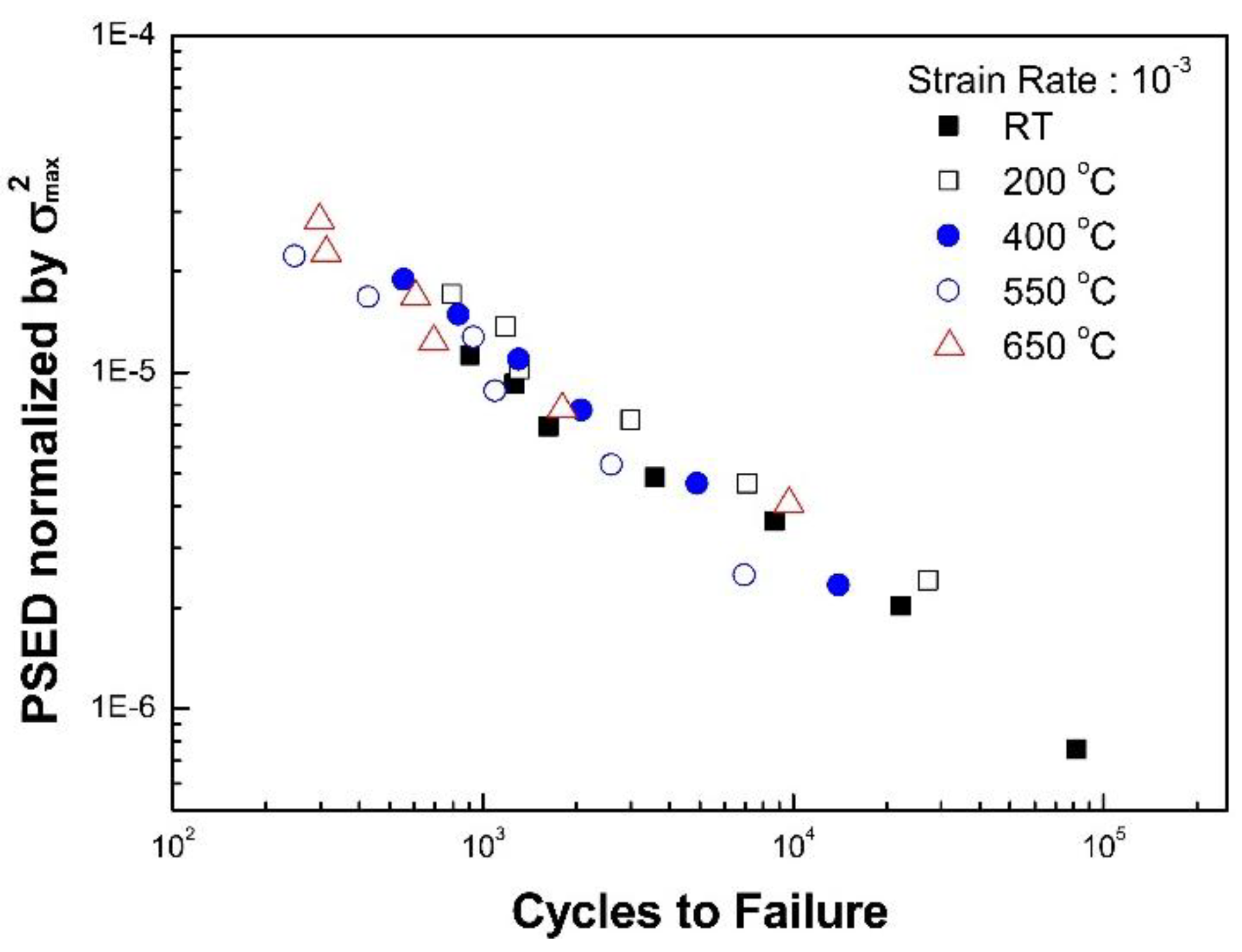

3.2.1. Effect of Temperature on Fatigue Life

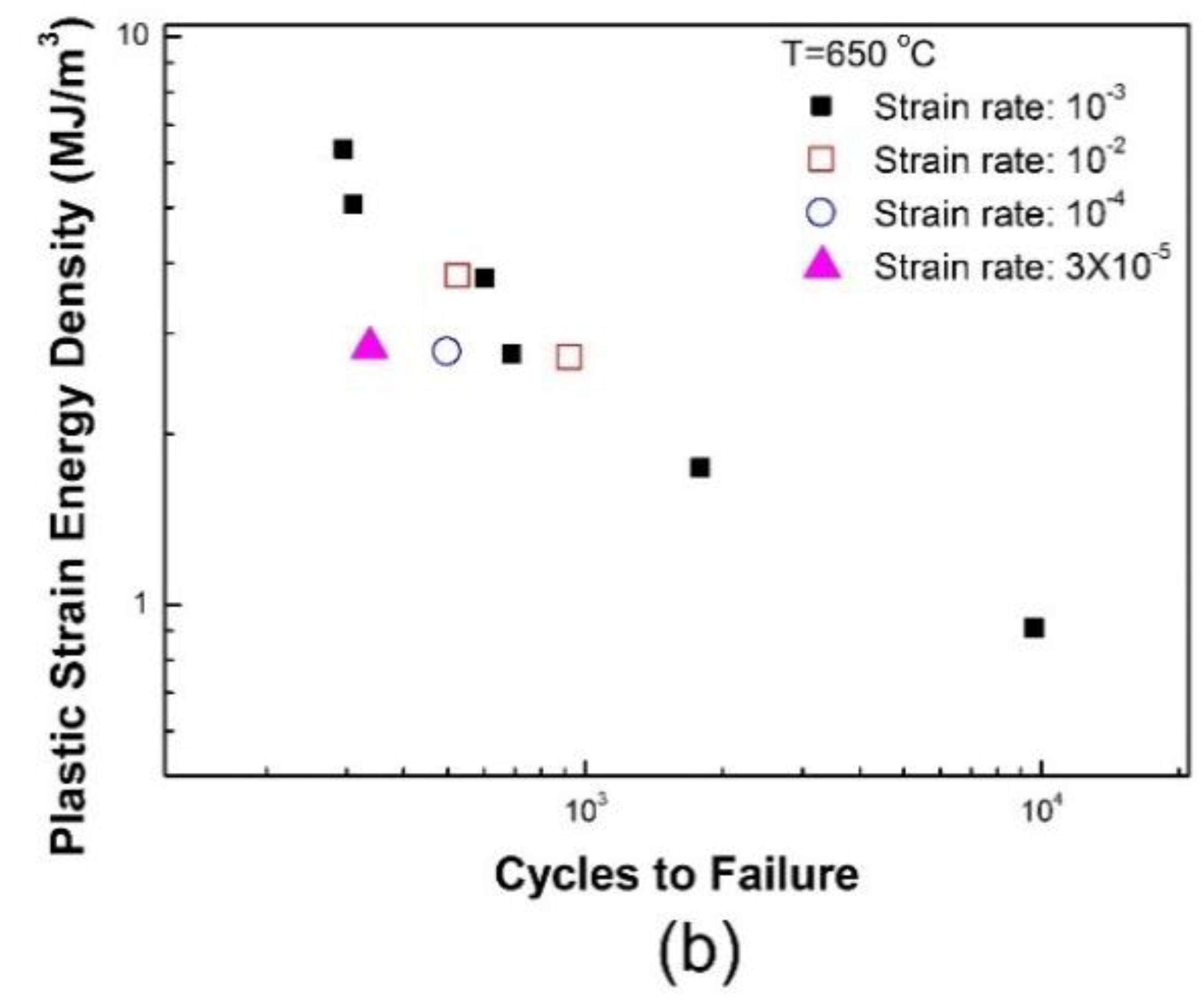

3.2.2. Effect of Strain Rate on Fatigue Life

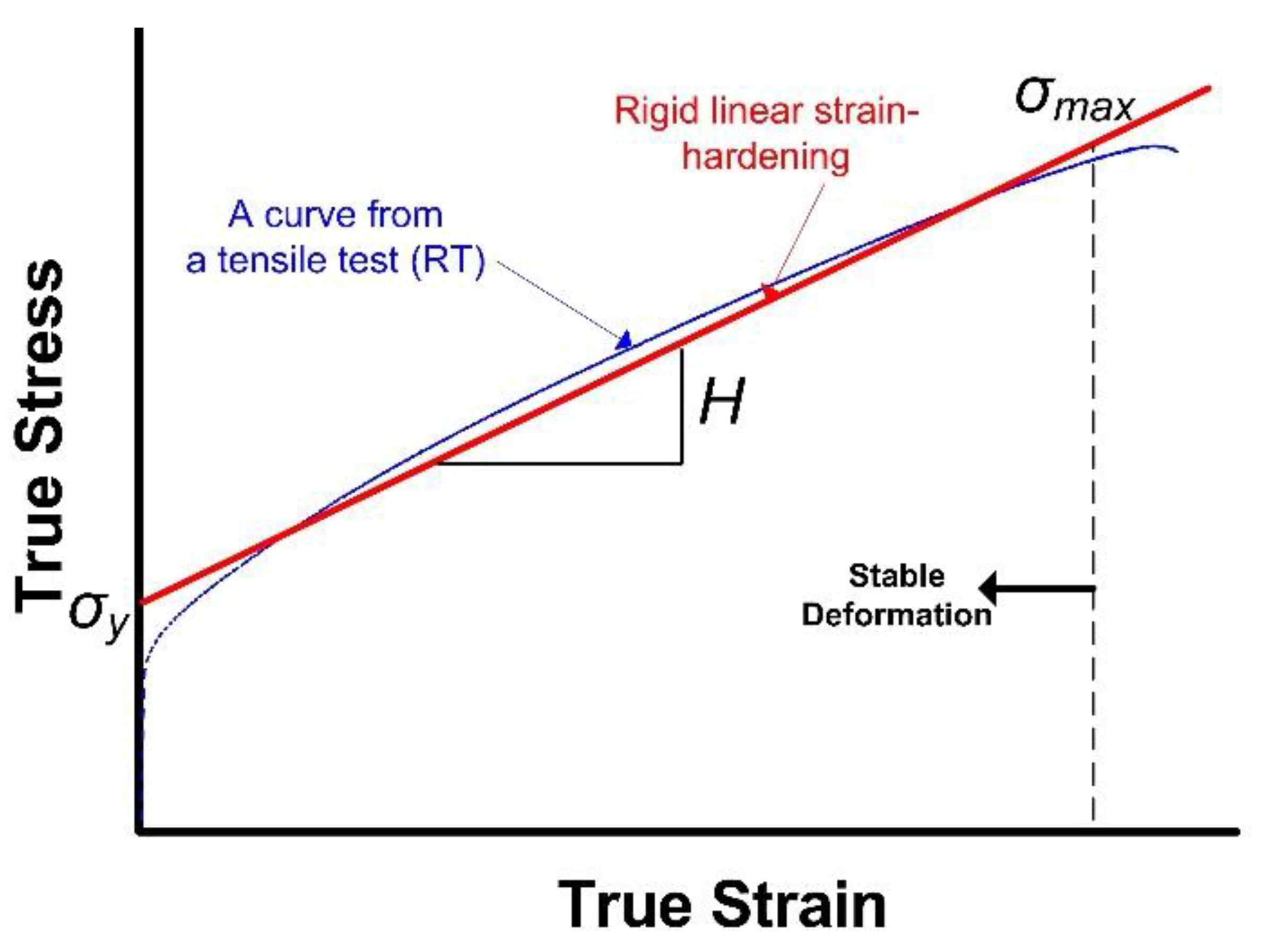

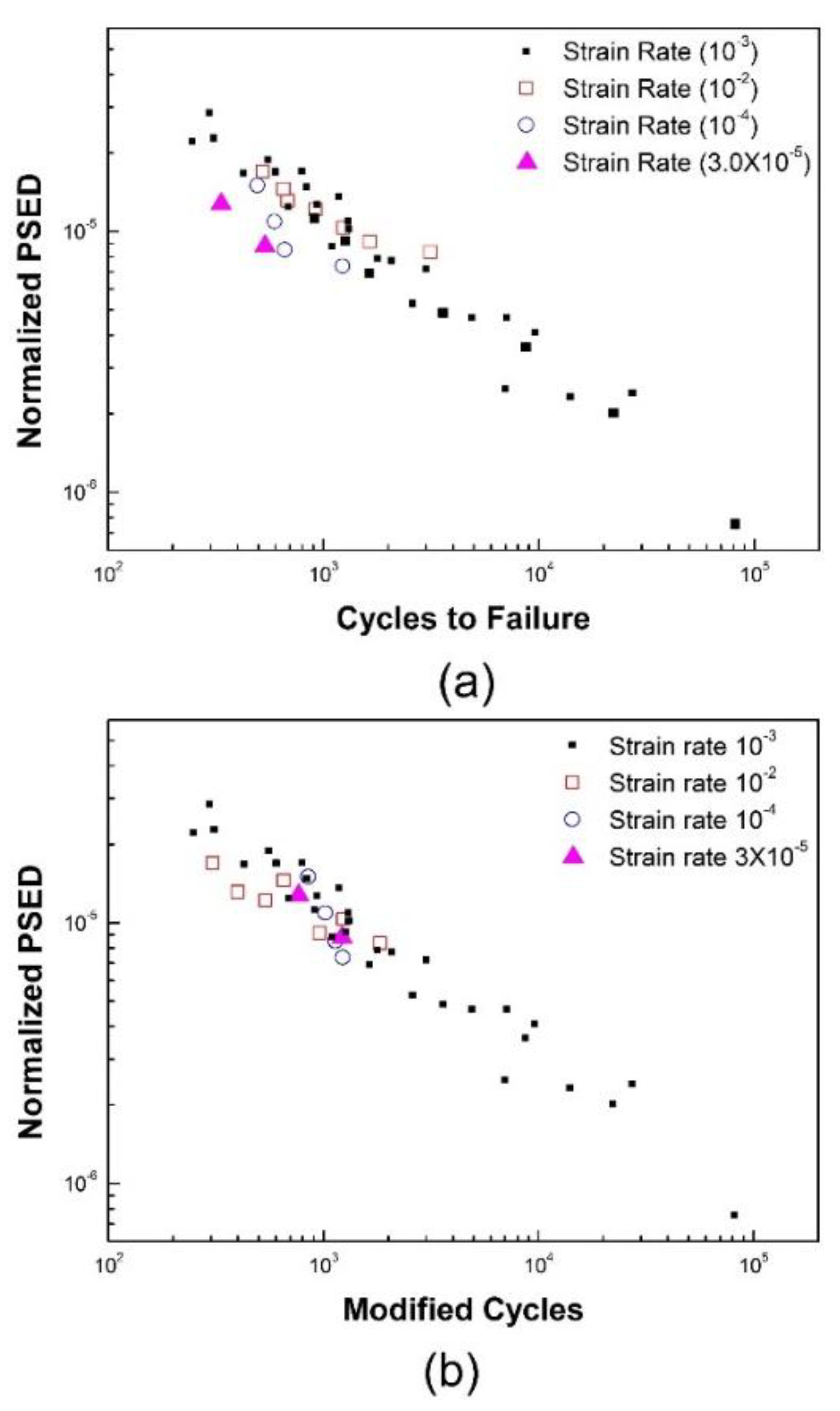

3.2.3. Proposed Energy-Based Fatigue Model

4. Conclusions

- The developed fatigue model successfully described the temperature and strain-dependent fatigue life. The developed model was a multiplicative form of the normalized plastic strain energy density and frequency modified fatigue life, resulting from a good correlation between the two parameters. Finally, the prediction capabilities were verified by comparing with the predicted life and experimental fatigue life. Consequently, most of experimental data were found to be between the factor-of-two lines.

- The conventional Coffin-Manson model and Morrow model were recommended at one isothermal temperature for a life prediction model. However, they were not applicable over the specified temperature range, or, the fatigue ductility coefficient, C, and exponent, m, must be provided with respect to temperature.

- At the temperature range of 300—550 °C, DSA occurred, causing abnormal features in the deformation behavior (a serrated flow and negative strain-rate sensitivity) and mechanical properties (a plateau in the variation of strength and ductility with temperature), and this led to the deterioration of the fatigue resistance. Despite the DSA-induced complicated nature of fatigue life behavior, the capability of the developed fatigue model could be proven over a range of temperature and strain rate.

Author Contributions

Funding

Conflicts of Interest

References

- Kamal, M.; Rahman, M.M. Advances in fatigue life modeling: A review. Renew. Sustain. Energy Rev. 2018, 82, 940–949. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, E.; Zalnezhad, E.; Cabibbo, M.; El Mehtedi, M.; Spigarelli, S. A review on fatigue life prediction methods for metals. Adv. Mater. Sci. Eng. 2016, 2016, 9573524. [Google Scholar] [CrossRef]

- Bezazi, A.; Pierce, S.G.; Worden, K.; Harkati, E. Fatigue life prediction of sandwich composite materials under flexural tests using a Bayesian trained artificial neural network. Int. J. Fatigue 2007, 29, 738–747. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, J.; Wu, X.; Han, E.; Ke, W.; Rao, J. Effect of temperature on corrosion fatigue behavior of 316LN stainless steel in high temperature pressurized water. Corros. Sci. 2019, 146, 80–89. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, X.; Tu, S.; Mannan, S.; Xuan, F.; Lin, Y. Review of creep-fatigue endurance and life prediction of 316 stainless steels. Int. J. Press Vessels Piping 2015, 126–127, 17–28. [Google Scholar] [CrossRef]

- Suazay, M.; Mottot, M.; Allais, L.; Noblecourt, M.; Monnet, I.; Perinet, J. Creep fatigue behavior of an AISI stainless steel at 550 °C. Nucl. Eng. Des. 2004, 232, 219–236. [Google Scholar] [CrossRef]

- Qiu, Y.; Pang, J.C.; Li, S.X.; Zhang, M.X.; Zhang, Z.F. Influence of temperature on the low-cycle fatigue properties of compacted graphite iron. Int. J. Fatigue 2018, 117, 450–460. [Google Scholar] [CrossRef]

- Hong, J.; Jang, C.; Kim, T. Effects of mixed strain rates on low cycle fatigue behaviors of austenitic stainless steels in a simulated PWR environment. Int. J. Fatigue 2016, 82, 292–299. [Google Scholar] [CrossRef]

- Srinivasan, V.S.; Valsan, M.; Rao, K.B.S.; Mannan, S.L.; Raj, B. Low cycle fatigue and creep-fatigue interaction behavior of 316L(N) stainless steel and life prediction by artificial neural network approach. Int. J. Fatigue 2003, 25, 1327–1338. [Google Scholar] [CrossRef]

- Sharkar, P.P.; De, P.S.; Dhua, S.K.; Chakraborti, P.C. Strain energy based low cycle fatigue damage analysis in a plain C–Mn rail steel. Mater. Sci. Eng. A Struct. Mater. 2017, 707, 125–135. [Google Scholar] [CrossRef]

- Coffin, L.F., Jr. A study of the effects of cyclic thermal stresses on a ductile metal. Trans. ASME 1954, 76, 931–950. [Google Scholar]

- Feltner, C.E.; Morrow, J.D. Microplastic strain hysteresis energy as a criterion for fatigue fracture. J. Basic Eng. 1961, 83, 15–22. [Google Scholar] [CrossRef]

- Shi, X.Q.; Pang, H.L.J.; Zhou, W.; Wang, Z.P. Low cycle fatigue analysis of temperature and frequency effects in eutectic solder alloy. Int. J. Fatigue 2000, 22, 217–228. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeong, H.Y. Fatigue life prediction of solder joints with consideration of frequency, temperature and cracking energy density. Int. J. Fatigue 2004, 61, 264–270. [Google Scholar] [CrossRef]

- ASTM E606-92 Standard Practice for Strain-Controlled Fatigue Testing; ASTM International: West Conshohocken, PA, USA, 2004.

- Kandil, F.A. Potential ambiguity in the determination of the plastic strain range component in LCF testing. Int. J. Fatigue 1999, 21, 1013–1018. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, F. Plastic behavior and constitutive modeling of armor steel over wide temperature and strain rate ranges. Acta Mech. Solida Sin. 2012, 25, 598–608. [Google Scholar] [CrossRef]

- Hong, S.G.; Lee, S.B. Dynamic strain aging under tensile and LCF loading conditions and their comparison in cold worked 316L stainless steel. J. Nucl. Mater. 2004, 328, 232–242. [Google Scholar] [CrossRef]

- Hong, S.G.; Lee, S.B. Mechanism of dynamic strain aging and characterization of its effect on the low-cycle fatigue behavior in type 316L stainless steel. J. Nucl. Mater. 2005, 340, 307–314. [Google Scholar] [CrossRef]

- Ellyn, F. Fatigue Damage, Crack Growth and Life Prediction; Chapman & Hall: London, UK, 1997; pp. 87–90. [Google Scholar]

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| 0.025 | 0.41 | 1.41 | 0.025 | 0.025 | 10.22 | 16.16 | 2.09 | – | 0.043 |

| Temperature (°C) | Strain Rate (s−1) | σy (MPa) | σu (MPa) | EL (%) | σmax (MPa) |

|---|---|---|---|---|---|

| 20 | 9.34 × 10−4 | 489 | 684 | 50.90 | 985 |

| 200 | 1.01 × 10−3 | 419 | 546 | 28.80 | 638 |

| 300 | 1.01 × 10−3 | 409 | 510 | 24.80 | 583 |

| 400 | 9.11 × 10−4 | 389 | 512 | 24.14 | 591 |

| 550 | 9.42 × 10−4 | 368 | 487 | 24.00 | 554 |

| 600 | 9.09 × 10−4 | 346 | 457 | 25.32 | 528 |

| 650 | 9.68 × 10−4 | 315 | 403 | 33.65 | 472 |

| Temperature (°C) | Coffin-Manson Model (Equation (1)) | Morrow Model (Equation (2)) | ||

|---|---|---|---|---|

| mC | CC | mE | CE | |

| RT | 0.395 | 8.95 | 0.580 | 552.33 |

| 200 | 0.418 | 8.51 | 0.535 | 221.38 |

| 400 | 0.501 | 12.20 | 0.610 | 301.30 |

| 550 | 0.510 | 9.38 | 0.635 | 247.07 |

| 650 | 0.526 | 9.96 | 0.651 | 221.31 |

| Strain Rate (s−1) | WP (MJ/m3) | ||

|---|---|---|---|

| 400 °C | 500 °C | 650 °C | |

| 1 × 10−2 | 2.768 | 2.610 | 2.701 |

| 1 × 10−3 | 2.748 | 2.662 | 2.739 |

| 1 × 10−4 | 2.828 | 2.825 | 2.780 |

| 3.2 × 10−5 | – | 2.952 | 2.837 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tak, N.H.; Kim, J.-S.; Lim, J.-Y. An Energy-Based Unified Approach to Predict the Low-Cycle Fatigue Life of Type 316L Stainless Steel under Various Temperatures and Strain-Rates. Materials 2019, 12, 1090. https://doi.org/10.3390/ma12071090

Tak NH, Kim J-S, Lim J-Y. An Energy-Based Unified Approach to Predict the Low-Cycle Fatigue Life of Type 316L Stainless Steel under Various Temperatures and Strain-Rates. Materials. 2019; 12(7):1090. https://doi.org/10.3390/ma12071090

Chicago/Turabian StyleTak, Nae Hyung, Jung-Seok Kim, and Jae-Yong Lim. 2019. "An Energy-Based Unified Approach to Predict the Low-Cycle Fatigue Life of Type 316L Stainless Steel under Various Temperatures and Strain-Rates" Materials 12, no. 7: 1090. https://doi.org/10.3390/ma12071090

APA StyleTak, N. H., Kim, J.-S., & Lim, J.-Y. (2019). An Energy-Based Unified Approach to Predict the Low-Cycle Fatigue Life of Type 316L Stainless Steel under Various Temperatures and Strain-Rates. Materials, 12(7), 1090. https://doi.org/10.3390/ma12071090