Suppression of the Growth of Intermetallic Compound Layers with the Addition of Graphene Nano-Sheets to an Epoxy Sn–Ag–Cu Solder on a Cu Substrate

Abstract

:1. Introduction

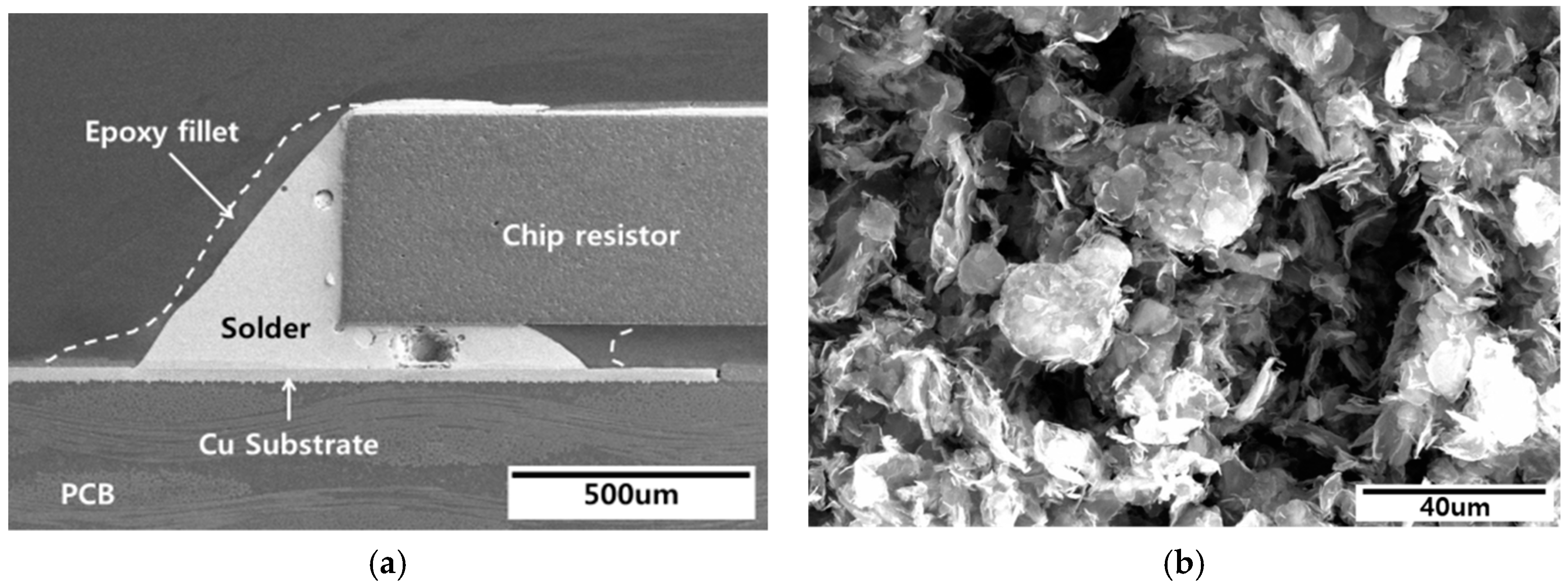

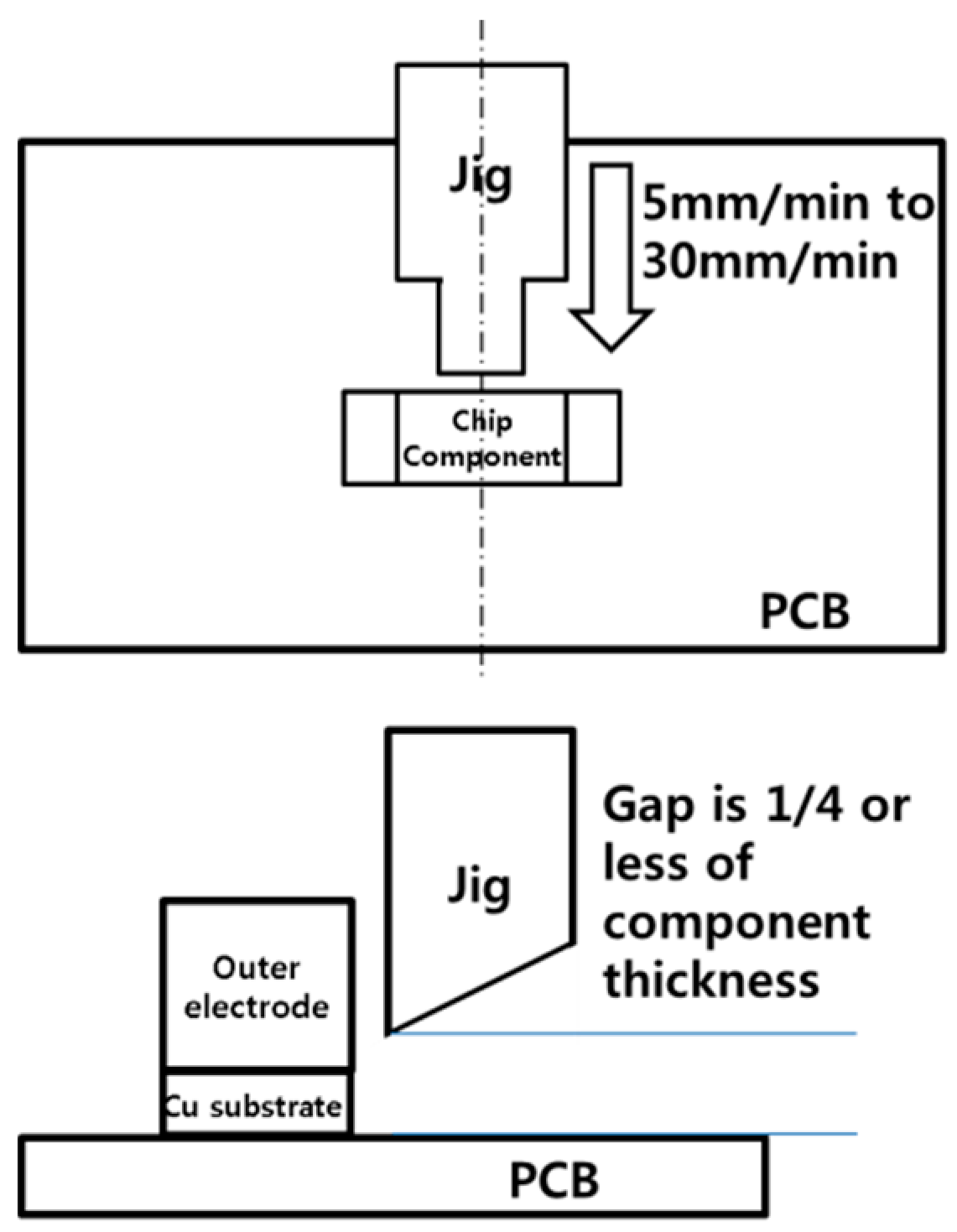

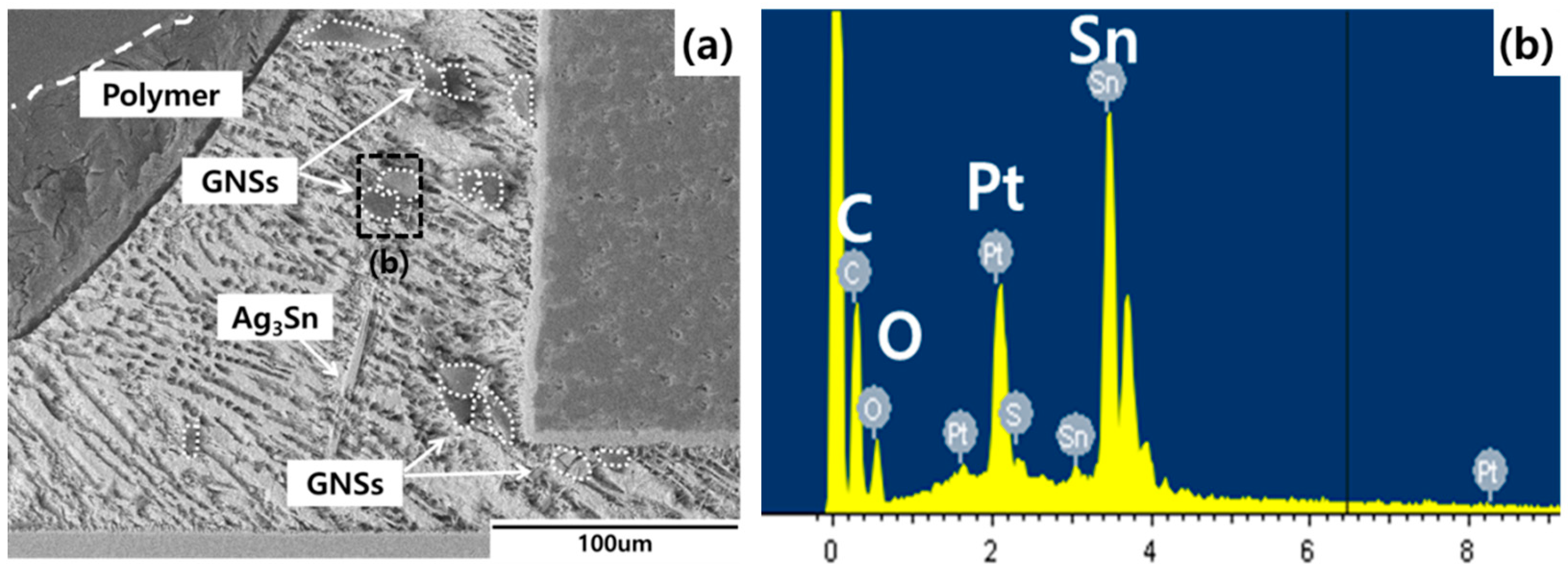

2. Experimental

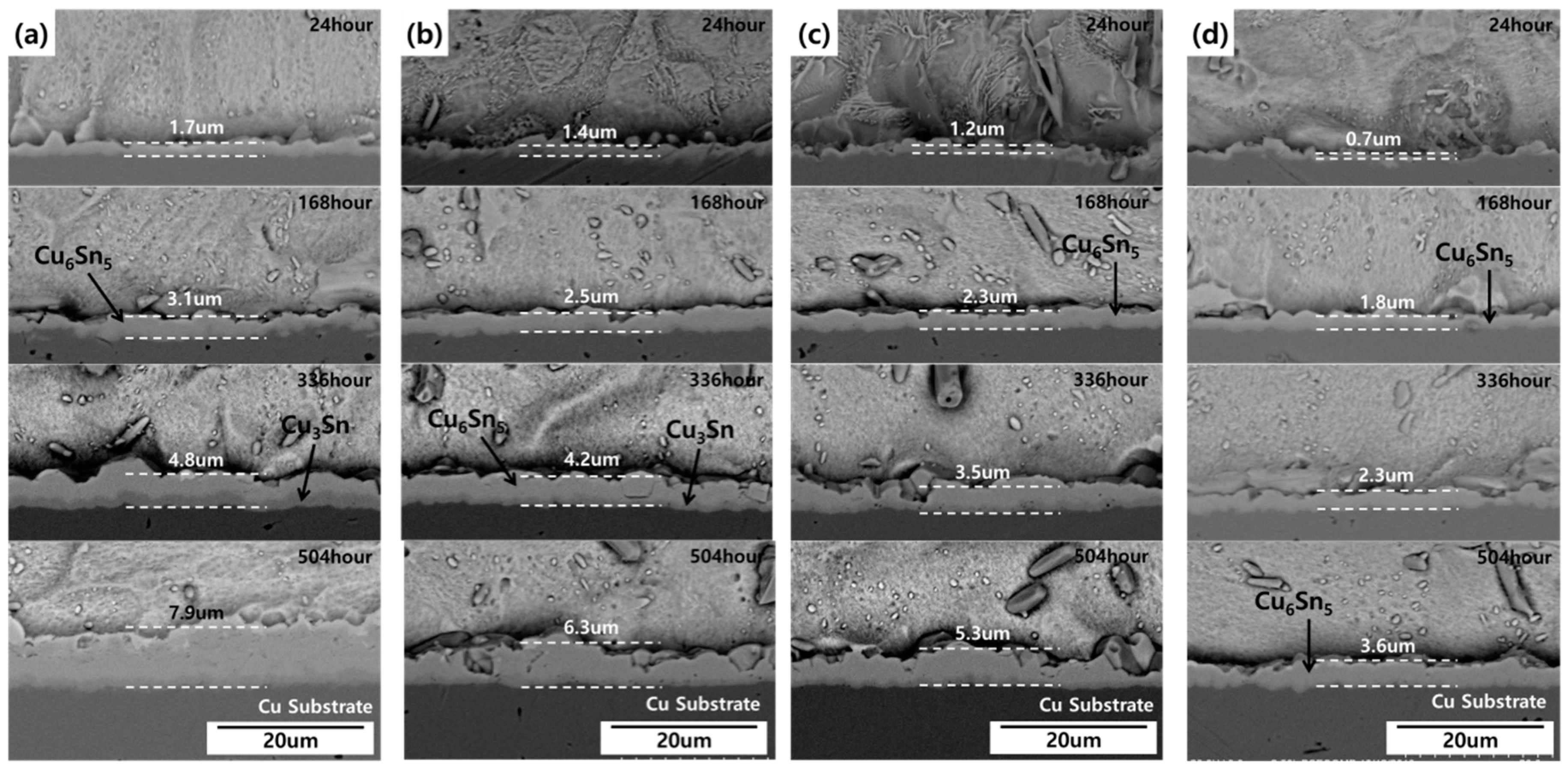

3. Results

4. Conclusions

- (1)

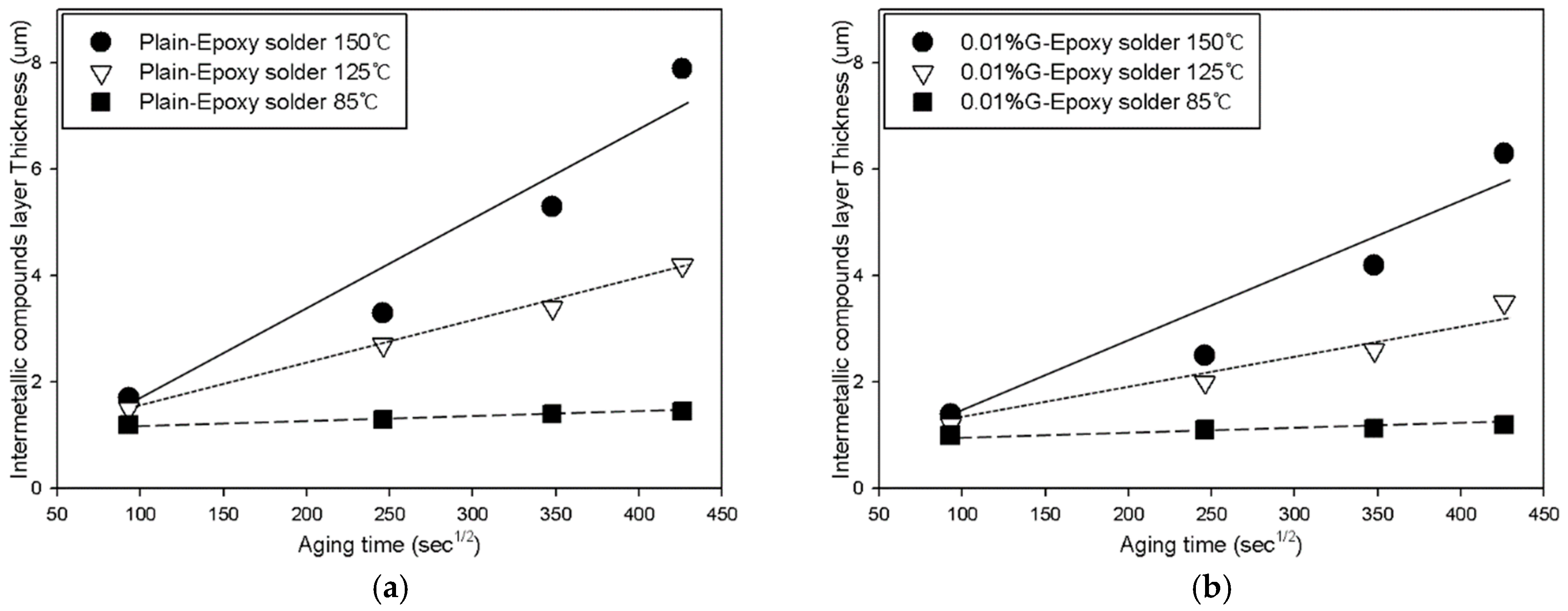

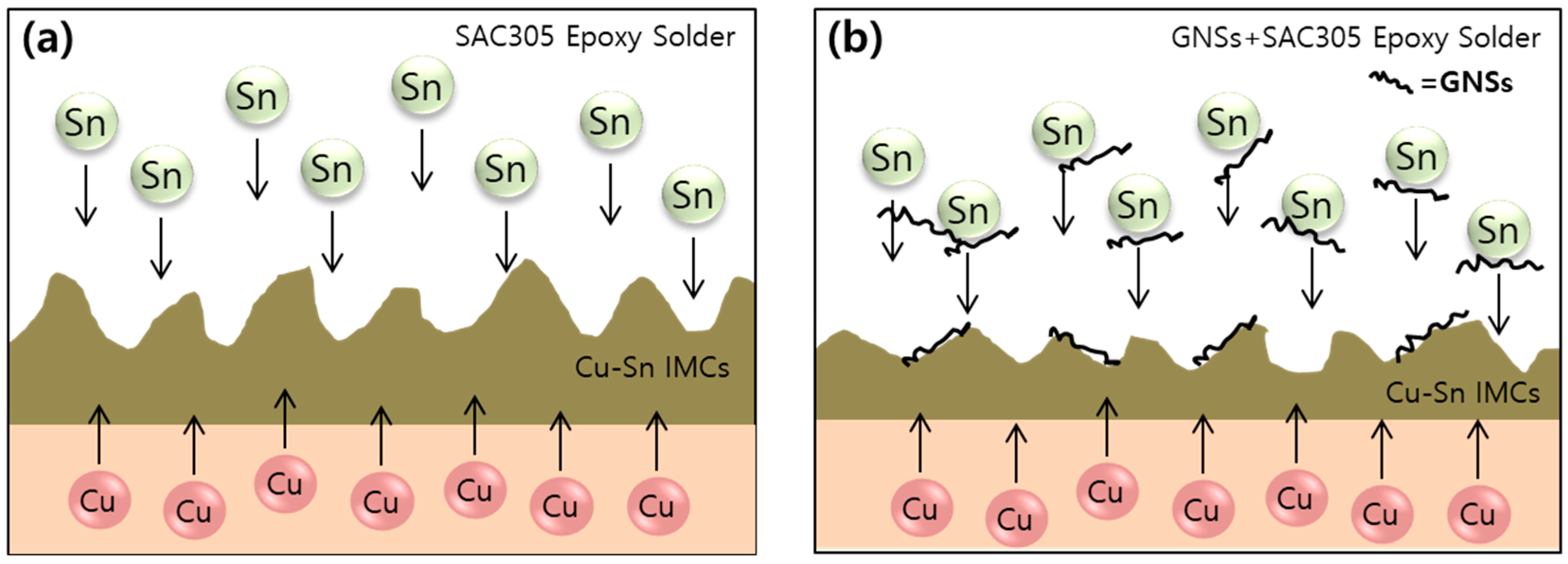

- Growth of the Cu–Sn IMC layer at the solder/Cu substrate interface due to Sn and Cu atomic diffusion was confirmed with aging tests at 150 °C, 125 °C, and 85 °C. It was found that the IMC layer was suppressed by the addition GNSs to the solder. Under the harshest conditions (isothermal 150 aging for 21 days), the thickness of the IMC layer was 7.9 µm in plain epoxy solder, 6.3 µm for the 0.01%-GNS solder, 5.3 um for the 0.05%-GNS solder, and 3.6 µm for the 0.1%-GNS solder.

- (2)

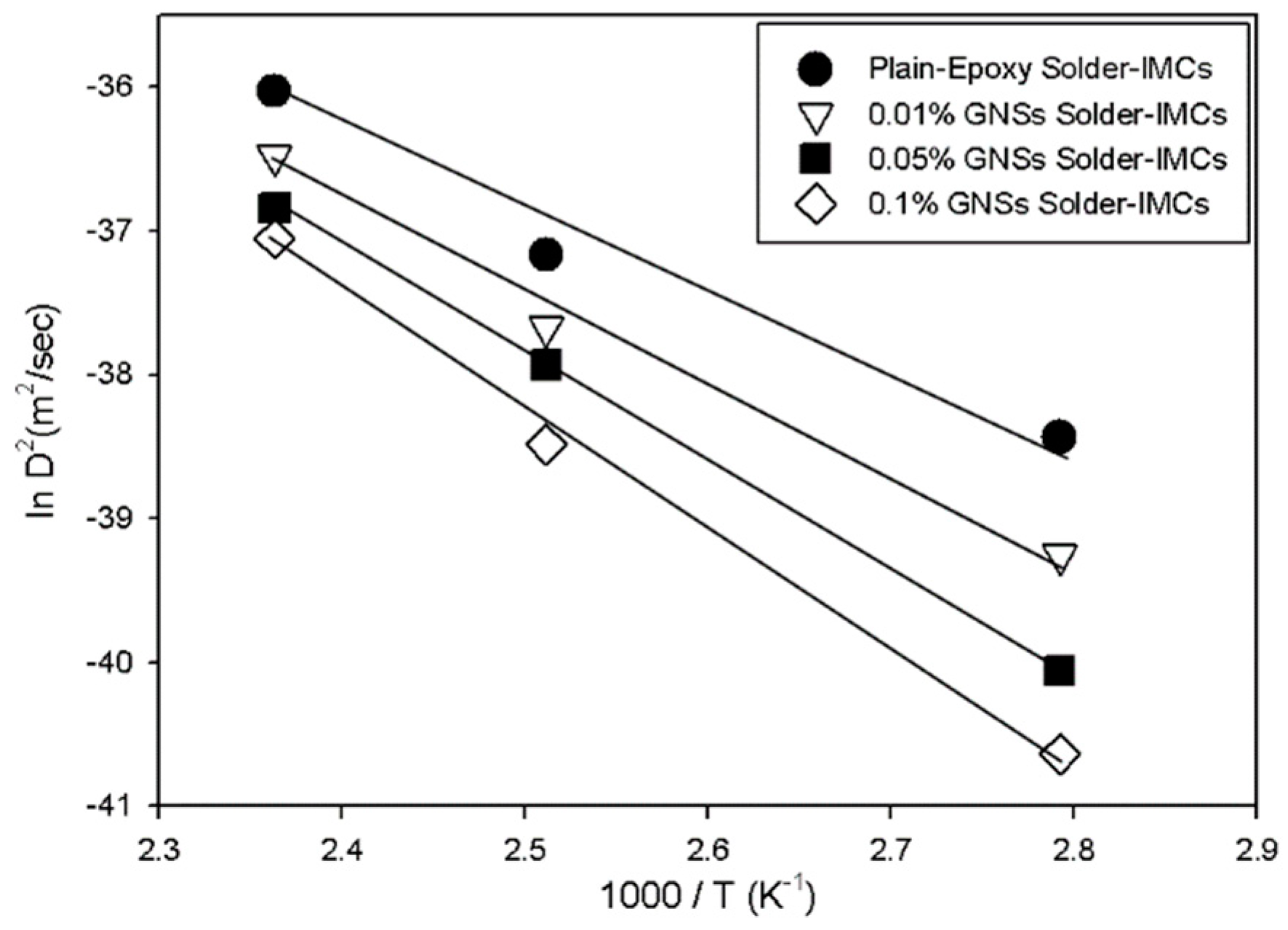

- The suppression of IMC growth was stronger with increasing GNS levels in the solder. The activation energy for the plain epoxy solder, 0.01%-GNS solder, 0.05%-GNS solder, and 0.1%-GNS solder was 45.5 KJ/mol, 52.8 KJ/mol, 62.5 KJ/mol, and 68.7 KJ/mol, respectively.

- (3)

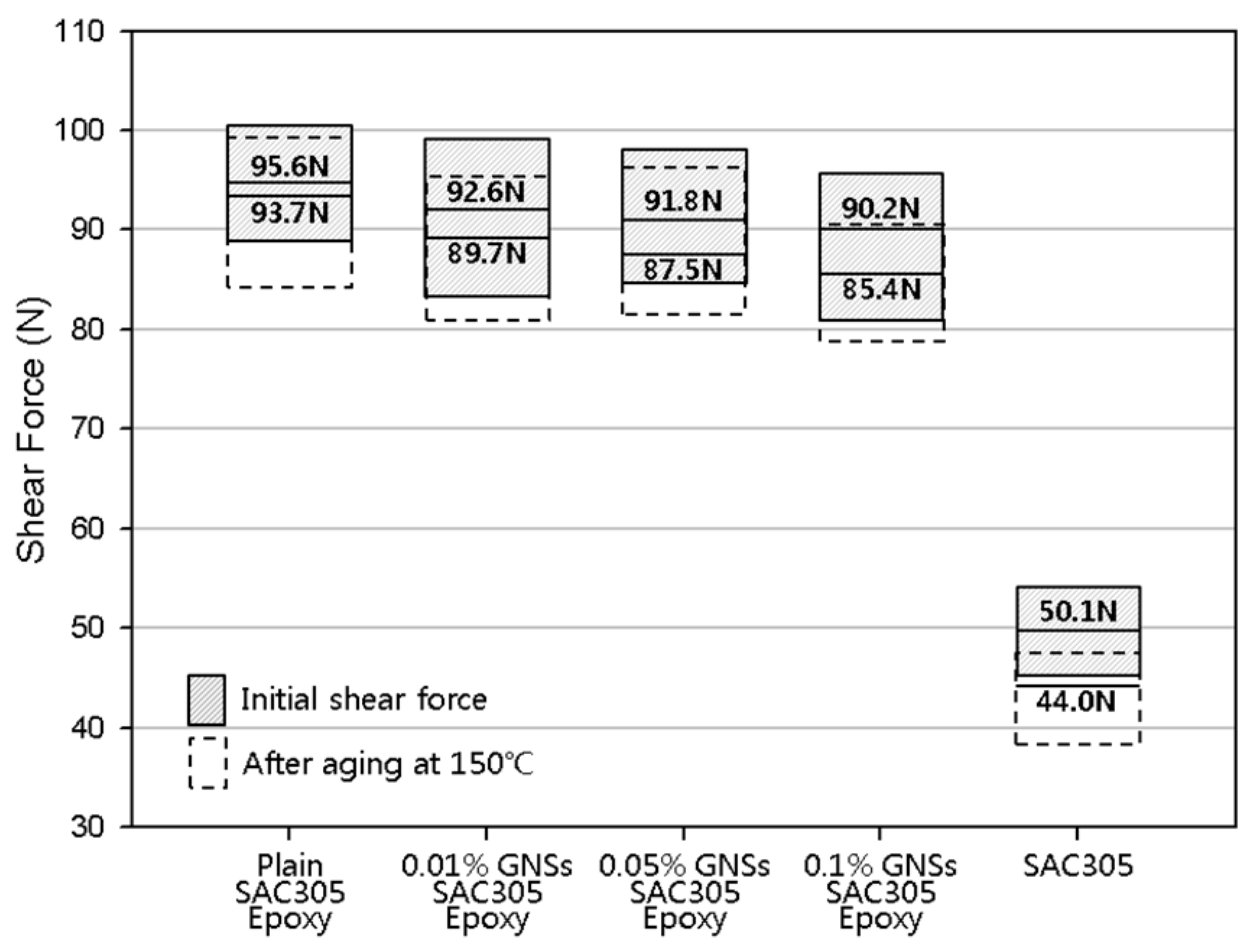

- The presence of GNSs in the epoxy solder paste had a slight negative effect on the bonding characteristics of the solder, but this was not critical to the function of the solder joint because the epoxy reinforced the bonding and mechanical characteristics of solder joints compared to conventional SAC305 solder joints.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, G.; Wu, F.; Liu, C.; Silberschmidt, V.V.; Chan, Y.C. Microstructures and properties of new Sn–Ag–Cu lead-free solder reinforced with Ni-coated graphene nanosheets. J. Alloys Compd. 2016, 656, 500–509. [Google Scholar] [CrossRef] [Green Version]

- Kang, M.S.; Jeon, Y.J.; Kim, D.S.; Shin, Y.E. Degradation characteristics and Ni3Sn4 IMC growth by a thermal shock test in SAC305 solder joints of MLCCs applied in automotive electronics. Int. J. Precis. Eng. Manuf. 2016, 17, 445–452. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Kim, D.S.; Shin, Y.E. Study of characteristics of solar cells through thermal shock and high-temperature and high-humidity testing. Int. J. Precis. Eng. Manuf. 2015, 15, 355–360. [Google Scholar] [CrossRef]

- Yang, Z.J.; Yang, S.M.; Yu, H.S.; Kang, S.J.; Song, J.H.; Kim, K.J. IMC and creep behavior in lead-free solder joints of Sn-Ag and Sn-Ag-Cu alloy system by SP method. Int. J. Autom. Technol. 2014, 15, 1137–1142. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L.; Chan, Y.C. Microstructure, elastic modulus and shear strength of alumina (Al2O3) nanoparticles-doped tin–silver–copper (Sn–Ag–Cu) solders on copper (Cu) and gold/nickel (Au/Ni)-plated Cu substrates. J. Mater. Sci. Mater. Electron. 2015, 26, 7039–7048. [Google Scholar] [CrossRef]

- Gnecco, F.; Ricci, E.; Amore, S.; Giuranno, D.; Borzone, G.; Zanicchi, G.; Novakovic, R. Wetting behaviour and reactivity of lead free Au–In–Sn and Bi–In–Sn alloys on copper substrates. Int. J. Adhes. Adhes. 2007, 27, 409–416. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L.; Quadir, M.Z. Thermal aging effects on microstructures and mechanical properties of an environmentally friendly eutectic tin-copper solder alloy. Mater. Des. 2016, 110, 275–283. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Howes, P.D.; Mannan, S.H. A review: On the development of low melting temperature Pb-free solders. Microelectron. Reliab. 2014, 54, 1253–1273. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Microstructure, thermal analysis and damping properties of Ag and Ni nano-particles doped Sn–8Zn–3Bi solder on OSP–Cu substrate. J. Alloys Compd. 2014, 617, 779–786. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Growth mechanism of intermetallic compound and mechanical properties of nickel (Ni) nanoparticle doped low melting temperature tin–bismuth (Sn–Bi) solder. J. Mater. Sci. Mater. Electron. 2016, 27, 781–794. [Google Scholar] [CrossRef]

- Kumar, K.M.; Kripesh, V.; Tay, A.A. Single-wall carbon nanotube (SWCNT) functionalized Sn–Ag–Cu lead-free composite solders. J. Alloys Compd. 2008, 450, 229–237. [Google Scholar] [CrossRef]

- Hu, X.; Chan, Y.C.; Zhang, K.; Yung, K.C. Effect of graphene doping on microstructural and mechanical properties of Sn–8Zn–3Bi solder joints together with electromigration analysis. J. Alloys Compd. 2013, 580, 162–171. [Google Scholar] [CrossRef]

- Gao, F.; Nishikawa, H.; Takemoto, T.; Qu, J. Mechanical properties versus temperature relation of individual phases in Sn–3.0Ag–0.5Cu lead-free solder alloy. Microelectron. Reliab. 2009, 49, 296–302. [Google Scholar] [CrossRef]

- Cheng, F.; Nishikawa, H.; Takemoto, T. Microstructural and mechanical properties of Sn–Ag–Cu lead-free solders with minor addition of Ni and/or Co. J. Mater. Sci. 2008, 43, 3643–3648. [Google Scholar] [CrossRef]

- Kim, K.S.; Huh, S.H.; Suganuma, K. Effects of intermetallic compounds on properties of Sn–Ag–Cu lead-free soldered joints. J. Alloys Compd. 2003, 352, 226–236. [Google Scholar] [CrossRef]

- Myung, W.-R.; Kim, Y.; Jung, S.-B. Mechanical property of the epoxy-contained Sn–58Bi solder with OSP surface finish. J. Alloys Compd. 2014, 615, S411–S417. [Google Scholar] [CrossRef]

- Kim, J.; Myung, W.R.; Jung, S.B. Effect of aging treatment and epoxy on bonding strength of Sn-58Bi solder and OSP-finished PCB. J. Microelectron. Packag. Soc. 2014, 21, 97–103. [Google Scholar] [CrossRef]

- Cho, I.; Ahn, J.H.; Yoon, J.W.; Shin, Y.E.; Jung, S.B. Mechanical strength and fracture mode transition of Sn-58Bi epoxy solder joints under high-speed shear test. J. Mater. Sci. Mater. Electron. 2012, 23, 1515–1520. [Google Scholar] [CrossRef]

- Chen, B.L.; Li, G.Y. Influence of Sb on IMC growth in Sn–Ag–Cu–Sb Pb-free solder joints in reflow process. Thin Solid Films 2004, 462, 395–401. [Google Scholar] [CrossRef]

- Li, G.-Y.; Shi, X.Q. Effects of bismuth on growth of intermetallic compounds in Sn-Ag-Cu Pb-free solder joints. Trans. Nonferrous Met. Soc. China 2006, 16, s739–s743. [Google Scholar] [CrossRef]

- Lee, T.Y.; Choi, W.J.; Tu, K.N.; Jang, J.W.; Kuo, S.M.; Lin, J.K.; Frear, D.R.; Zeng, K.; Kivilahti, J.K. Morphology, kinetics, and thermodynamics of solid-state aging of eutectic SnPb and Pb-free solders (Sn–3.5 Ag, Sn–3.8 Ag–0.7 Cu and Sn–0.7 Cu) on Cu. J. Mater. Res. 2002, 17, 291–301. [Google Scholar] [CrossRef]

- Tsao, L.C. Suppressing effect of 0.5 wt.% nano-TiO2 addition into Sn–3.5 Ag–0.5 Cu solder alloy on the intermetallic growth with Cu substrate during isothermal aging. J. Alloys Compd. 2011, 509, 8441–8448. [Google Scholar] [CrossRef]

- Noh, B.I.; Koo, J.M.; Kim, J.W.; Kim, D.G.; Nam, J.D.; Joo, J.; Jung, S.B. Effects of number of reflows on the mechanical and electrical properties of BGA package. Intermetallics 2006, 14, 1375–1378. [Google Scholar] [CrossRef]

- Huang, Y.; Xiu, Z.; Wu, G.; Tian, Y.; He, P.; Gu, X.; Long, W. Improving shear strength of Sn-3.0 Ag-0.5 Cu/Cu joints and suppressing intermetallic compounds layer growth by adding graphene nanosheets. Mater. Lett. 2016, 169, 262–264. [Google Scholar] [CrossRef]

- High Temperature Storage Life, JESD22A-103C; JEDEC Solid State Technology Association: Arlington, VA, USA, 2004.

- Mayappan, R.; Salleh, A. Intermetallic growth retardation with the addition of graphene in the Sn-3.5 Ag lead-free solder. IOP Conf. Ser. Mater. Sci. Eng. 2017, 205, 012017. [Google Scholar] [CrossRef]

- Flanders, D.R.; Jacobs, E.G.; Pinizzotto, R.F. Activation energies of intermetallic growth of Sn-Ag eutectic solder on copper substrates. J. Electron. Mater. 1997, 26, 883–887. [Google Scholar] [CrossRef]

- Liu, B.; Tian, Y.; Wang, C.; An, R.; Liu, Y. Extremely fast formation of CuSn intermetallic compounds in Cu/Sn/Cu system via a micro-resistance spot welding process. J. Alloys Compd. 2016, 687, 667–673. [Google Scholar] [CrossRef]

- Vianco, P.T.; Rejent, J.A.; Hlava, P.F. Solid-state intermetallic compound layer growth between copper and 95.5 Sn-3.9 Ag-0.6 Cu solder. J. Electron. Mater. 2004, 33, 991–1004. [Google Scholar] [CrossRef]

- Madeni, J.C.; Liu, S. Effect of thermal aging on the interfacial reactions of tin-based solder alloys and copper substrates and kinetics of formation and growth of intermetallic compounds. Soldagem Inspeção 2011, 16, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Mayappan, R.; Ahmad, Z.A. Effect of Bi addition on the activation energy for the growth of Cu5Zn8 intermetallic in the Sn–Zn lead-free solder. Intermetallics 2010, 18, 730–735. [Google Scholar] [CrossRef]

- Ghosh, G. Interfacial microstructure and the kinetics of interfacial reaction in diffusion couples between Sn–Pb solder and Cu/Ni/Pd metallization. Acta Mater. 2000, 48, 3719–3738. [Google Scholar] [CrossRef]

- El-Daly, A.A.; El-Taher, A.M.; Dalloul, T.R. Enhanced ductility and mechanical strength of Ni-doped Sn–3.0 Ag–0.5 Cu lead-free solders. Mater. Des. 2014, 55, 309–318. [Google Scholar] [CrossRef]

- Kim, S.H.; Tabuchi, H.; Kakegawa, C.; Park, H. IMC growth mechanisms of SAC305 lead-free solder on different surface finishes and their effects on solder joint reliability of FCBGA packages. J. Microelectron. Electron. Packag. 2009, 6, 119–124. [Google Scholar] [CrossRef]

- Ma, D.; Wu, P. Improved microstructure and mechanical properties for Sn58Bi0. 7Zn solder joint by addition of graphene nanosheets. J. Alloys Compd. 2016, 671, 127–136. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.-S.; Kim, D.-S.; Shin, Y.-E. Suppression of the Growth of Intermetallic Compound Layers with the Addition of Graphene Nano-Sheets to an Epoxy Sn–Ag–Cu Solder on a Cu Substrate. Materials 2019, 12, 936. https://doi.org/10.3390/ma12060936

Kang M-S, Kim D-S, Shin Y-E. Suppression of the Growth of Intermetallic Compound Layers with the Addition of Graphene Nano-Sheets to an Epoxy Sn–Ag–Cu Solder on a Cu Substrate. Materials. 2019; 12(6):936. https://doi.org/10.3390/ma12060936

Chicago/Turabian StyleKang, Min-Soo, Do-Seok Kim, and Young-Eui Shin. 2019. "Suppression of the Growth of Intermetallic Compound Layers with the Addition of Graphene Nano-Sheets to an Epoxy Sn–Ag–Cu Solder on a Cu Substrate" Materials 12, no. 6: 936. https://doi.org/10.3390/ma12060936

APA StyleKang, M.-S., Kim, D.-S., & Shin, Y.-E. (2019). Suppression of the Growth of Intermetallic Compound Layers with the Addition of Graphene Nano-Sheets to an Epoxy Sn–Ag–Cu Solder on a Cu Substrate. Materials, 12(6), 936. https://doi.org/10.3390/ma12060936