Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent

Abstract

:1. Introduction

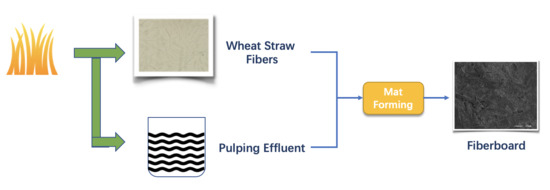

2. Materials and Methods

2.1. Materials

2.2. Main Chemical Components

2.3. Straw-Based Fiberboard Production

2.4. Fourier Transform Infrared (FT-IR)

2.5. Thermo Gravimetric Analyses (TGA)

2.6. Physical and Mechanical Characterization

3. Results and Discussion

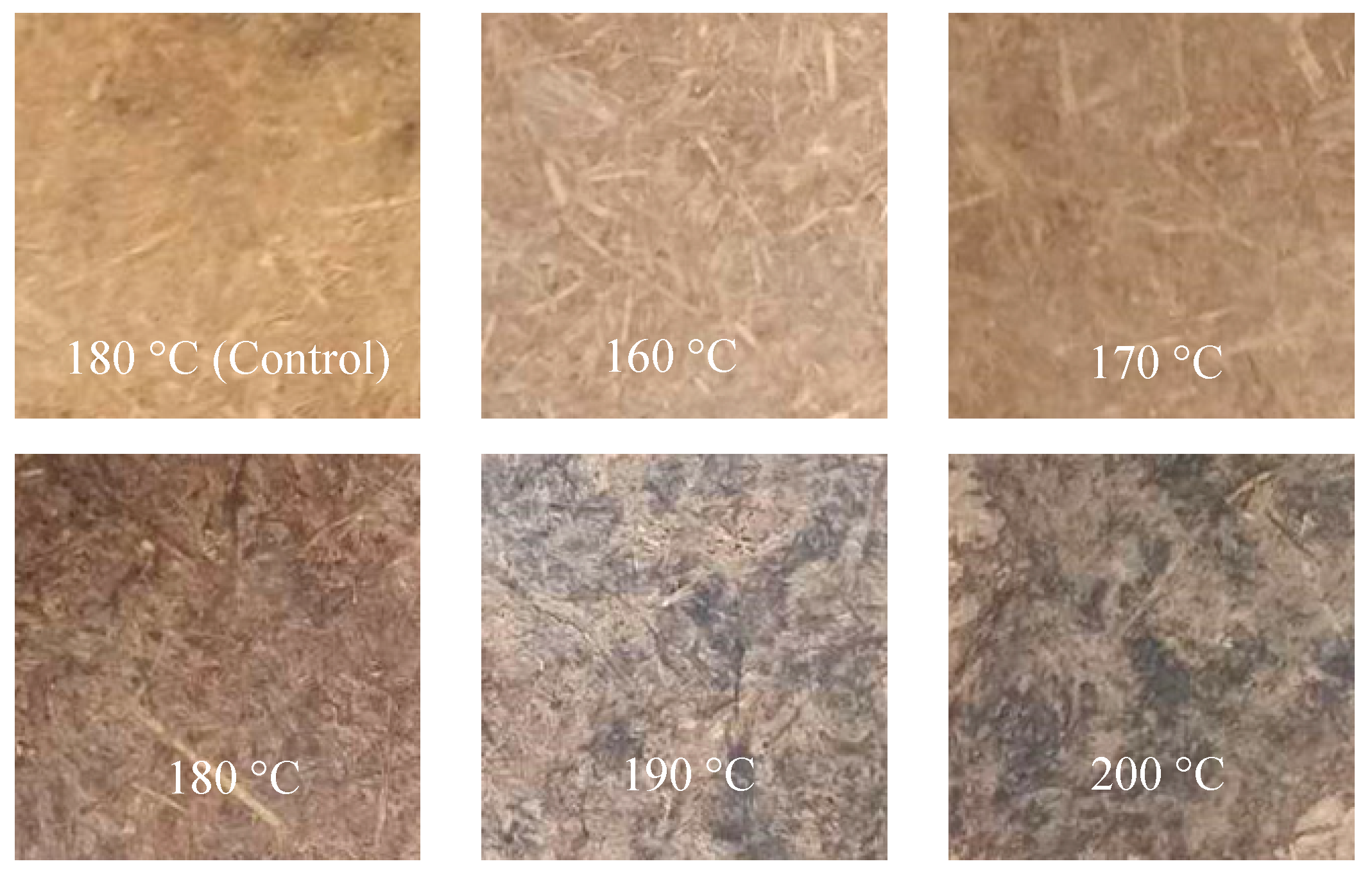

3.1. Surface Appearance

3.2. Chemical Characterization

3.3. Imaging FT-IR Spectra

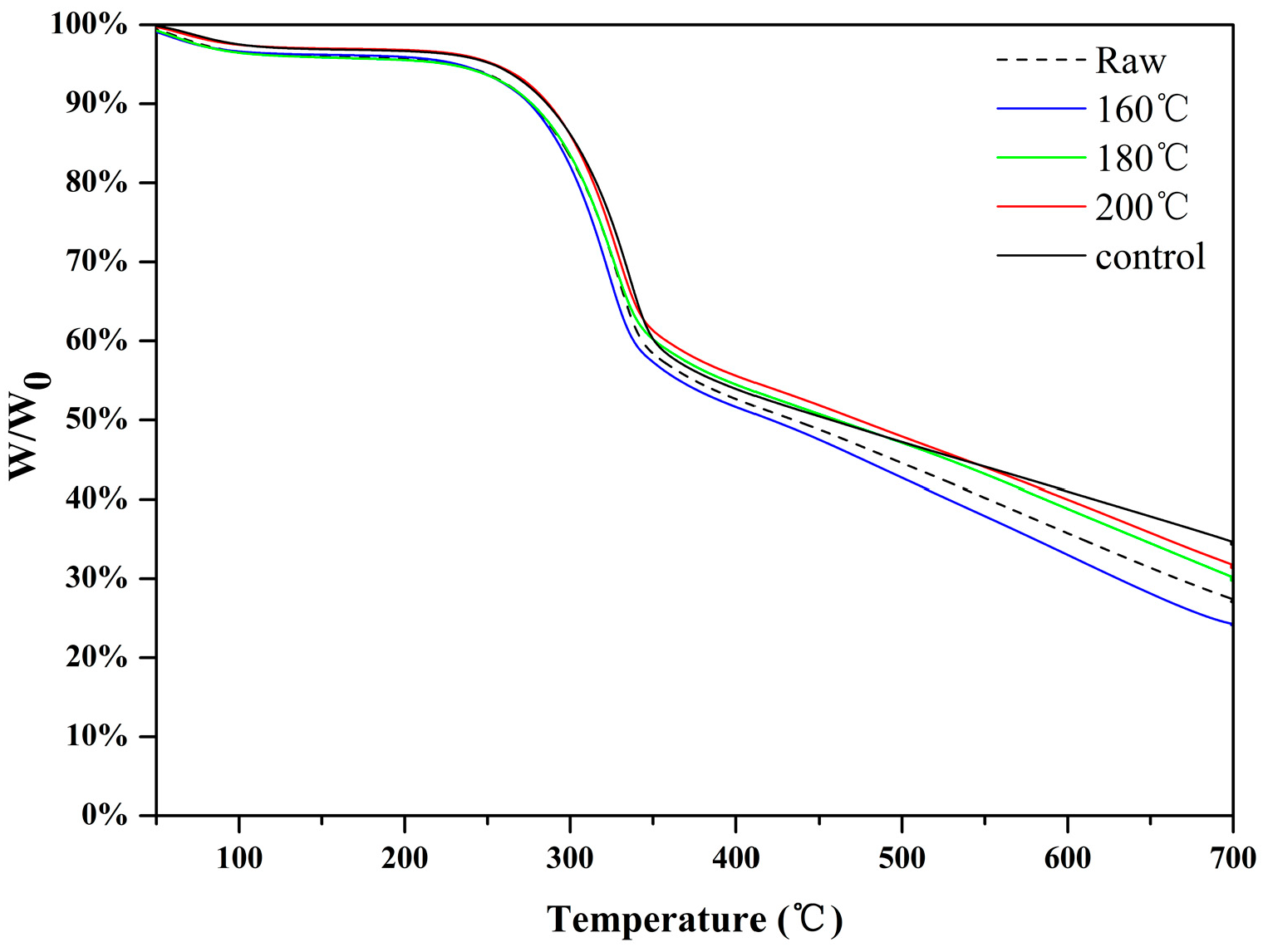

3.4. Thermal Stability

3.5. Physical-Technological Properties of Fiberboards

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, X.; Wang, F.; Hu, H.; Yang, L.; Guo, P.; Xiao, B. Assessment of sustainable biomass resource for energy use in China. Biomass Bioenerg. 2011, 35, 1–11. [Google Scholar] [CrossRef]

- Wang, X.; Yang, I.; Steinherger, Y.; Liu, Z.; Liao, S.; Xie, G. Field crop residue estimate and availability for biofuel production in China. Renew. Sust. Energ. Rev. 2013, 27, 864–875. [Google Scholar] [CrossRef]

- Doyle, C.J.; Mason, V.C.; Baker, R.D. Straw disposal and utilization: An economic evaluation of the alternative end-uses for wheat straw in the UK. Biol. Wastes 1988, 23, 39–56. [Google Scholar] [CrossRef]

- Zhang, P.; Wei, T.; Jia, Z.; Han, Q.; Ren, X.; Li, Y. Effects of straw incorporation on soil organic matter and soil water-stable aggregates content in semiarid regions of Northwest China. PLoS ONE 2014, 9, e92839. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.; Liu, M.; Ni, B.; Wang, Y. Utilization of wheat straw for the preparation of coated controlled-release fertilizer with the function of water retention. J. Agric. Food Chem. 2012, 60, 6921–6928. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Zhang, Y.; Wu, T.; Wu, L.; Li, X.; Ouyang, Z. Effects of straw application on coastal saline topsoil salinity and wheat yield trend. Soil Tillage Res. 2017, 169, 1–6. [Google Scholar] [CrossRef]

- Galperin, A.S.; Kuleshov, G.G.; Tarashkevich, V.I.; Shutov, G.M. Manufacturing and properties of modified wood: A review of 25 years work. Holzforschung 1995, 49, 45–50. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Differential behavior of nodes and internodes of wheat straw with various pre-treatments. Biomass Bioenergy 2015, 83, 373–382. [Google Scholar] [CrossRef]

- Nitu, I.P.; Shams, M.; Islam, M.; Ratul, S.B.; Ashaduzzaman, M. Development of binderless composites from different nonwood lignocellulosic materials: Overview. In Handbook of Ecomaterials; Martínez, L., Kharissova, O., Kharisov, B., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Jain, S.K.; Handa, S.K. Press for producing binderless board from agricultural waste. Res. Ind. 1982, 27, 121–123. [Google Scholar]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of non-resin wheat straw fiberboards. Ind. Crop. Prod. 2009, 29, 437–445. [Google Scholar] [CrossRef]

- Mejía, E.H.; Quintana, G.C.; Ogunsile, B.O. Development of binderless fiberboards from steam exploded and oxidized oil palm wastes. BioResources 2014, 9, 2922–2936. [Google Scholar] [CrossRef]

- Euring, M.; Trojanowski, J.; Horstmann, M.; Kharazipour, A. Studies of enzymatic oxidation of TMP fibers and lignin model compounds by a laccase-mediator-system using different 14C and 13C techniques. Wood Sci. Technol. 2011, 46, 699–708. [Google Scholar] [CrossRef]

- Kudanga, T.; Nyanhongo, G.S.; Guebitz, G.M.; Burton, S. Potential applications of laccase-mediated coupling and grafting reactions: A review. Enzyme Microb. Tech. 2011, 48, 195–208. [Google Scholar] [CrossRef] [PubMed]

- El Mansouri, N.E.; Pizzi, A.; Salvado, J. Lignin-based polycondensation resins for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of steam exploded residual softwood for the production of binderless panels. Effect of the pre-treatment severity and lignin addition. Biomass Bioenerg. 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, F.; Lv, C.; Tang, L.; Wei, K.; Liu, X.; Du, G.; Yong, Q.; Xue, G. Properties of formaldehyde-free environmentally friendly lignocellulosic composites made from poplar fibres and oxygen-plasma-treated enzymatic hydrolysis lignin. Compos. Part B Eng. 2013, 53, 369–375. [Google Scholar] [CrossRef]

- Álvarez, C.; Rojano, B.; Almaza, O.; Rojas, O.J.; Gañán, P. Self-bonding boards from plantain fiber bundles after enzymatic treatment: Adhesion improvement of lignocellulosic products by enzymatic pre-treatment. J. Polym. Environ. 2011, 19, 182–188. [Google Scholar] [CrossRef]

- Fahmy, T.Y.A.; Mobarak, F. Advanced self-bonded board-like green nanocomposites from undebarked cotton stalks and mechanism of self-bonding. Cellulose 2013, 20, 1453–1457. [Google Scholar] [CrossRef]

- Cao, Z.; Yan, H.; Guo, W. Study on bonding mechanism of dry-process self-bonded fiberboards part I. Chemical changes and effects in self-bonded fiberboard manufacture. China Wood Ind. 1996, 5, 3–6. (In Chinese) [Google Scholar]

- Okuda, N.; Sato, M. Manufacture and mechanical properties of self-bonded boards from kenaf core. J. Wood Sci. 2004, 50, 53–61. [Google Scholar] [CrossRef]

- Chow, S. Bark boards without synthetic resins. Forest Prod. J. 1974, 25, 32–37. [Google Scholar]

- Wang, J.; Liu, J.; Ni, L.; Li, J. Thermopressed binderless fiberboards from wheat straw by adding black liquor. Wood Res. 2018, 63, 1021–1032. [Google Scholar]

- Rastegarfar, N.; Behrooz, R.; Bahramifar, N. Electrocoagulation treatment of black liquor from soda-AQ pulping of wheat straw. Environ. Monit. Assess. 2015, 187, 1–9. [Google Scholar] [CrossRef]

- Ghatak, H.R.; Kumar, S.; Kundu, P.P. Electrode processes in black liquor electrolysis and their significance for hydrogen production. Int. J. Hydrogen Energ. 2008, 33, 2904–2911. [Google Scholar] [CrossRef]

- Geng, X.; Deng, J.; Zhang, S. Paper mill sludge as a component of wood adhesive formulation. Holzforschung 2007, 61, 688–692. [Google Scholar] [CrossRef]

- Larson, E.D.; Consonni, S.; Katofsk, R.E.; Frederic, W.J.A. Cost-Benefit Assessment of Gasification-Based Biorefining in the Kraft Pulp and Paper Industry; American Forest and Paper Association: Washington, DC, USA, 2006. [Google Scholar]

- Wang, K. The Timber Industry Practical Encyclopedia (Fiberboards); China Forestry Press: Beijing, China, 2002.

- GB/T 742−2008 Fibrous Raw Material, Pulp, Paper and Board-Determination of Ash; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 2677.4−1993 Fibrous Raw Material-Determination of Water Solubility; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 1993.

- GB/T 2677.5−1993 Fibrous Raw Material-Determination of one Percent Sodium Hydroxide Solubility; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 1993.

- GB/T 10741−2008 Pulps-Determination of Alcohol-Benzene Solubles; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 747−2003 Pulps-Determination of Acid-Insoluble Lignin; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 2003.

- Waddle, W.J. A simple ultraviolet spectrophotometric method for the determination of protein. J. Lab Clin. Med. 1956, 48, 311. [Google Scholar]

- GB/T 17657−2013 Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Bekhta, P.; Niemz, P.; Sedliacik, J. Effect of pre-pressing of veneer on the glueability and properties of veneer-based products. Eur. J. Wood Wood Prod. 2012, 70, 99–106. [Google Scholar] [CrossRef]

- de Cademartori, P.H.G.; Missio, A.L.; Mattos, B.D.; Schneid, E.; Gatto, D.A. Physical and mechanical properties and color changes of fast-growing Gympie messmate wood subjected to two-step steam-heat treatments. Wood Mat. Sci. Eng. 2014, 9, 40–48. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical propertied of stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Araújo Junior, C.P.; Coaquira, C.A.C.; Mattos, A.L.A.; de Souza Filho, M.d.S.M.; de Andrade Feitosa, J.P.; de Morais, J.P.S.; de Fitas Rosa, M. Binderless fiberboards made from unripe coconut husks. Waste Biomass Valoriz. 2018, 9, 2245–2254. [Google Scholar] [CrossRef]

- Hashim, R.; Saari, N.; Sulaiman, O.; Sugimoto, T.; Hiziroglu, S.; Sato, M.; Tanaka, R. Effect of particle geometry on the properties of binderless particleboard manufactured from oil palm trunk. Mater. Design 2010, 31, 4251–4257. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Riedl, B.; Nadji, H.; Deng, J.; Zhang, S.Y. Binderless fiberboard made from primary and secondary pulp and paper sludge. Wood Fiber Sci. 2011, 43, 180–193. [Google Scholar]

- Mancera, C.; Ferrando, F.; Salvado, J.; El Mansouri, N.E. Kraft lignin behavior during reaction in an alkaline medium. Biomass Bioenerg. 2011, 35, 2072–2079. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Handbook of Adhesive Technology; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Rowell, R.M. Handbook of Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Zhu, H.; Li, Y.; Pettersson, B.; Zhang, L.; Lindström, M.; Henriksson, G. Technical soda lignin dissolved in urea as an environmental friendly binder in wood fiberboard. J. Adhes. Sci. Technol. 2014, 28, 490–498. [Google Scholar] [CrossRef]

- Olsen, P.O.; Plackett, D.V. Perspectives on the performance of natural plant fibers presented at natural fibres performance forum. Copenhagen 1999, 5, 27–28. [Google Scholar]

- George, W.O.; McIntyre, P.S. Infrared Spectroscopy: Analytical Chemistry by Open Learning; John Wiley and Sons Inc.: London, UK, 1987. [Google Scholar]

- Abdul Khalil, H.P.S.; Nur Firdaus, M.Y.; Jawaid, M.; Anis, M.; Ridzuan, R.; Mohamed, A.R. Development and material properties of new hybrid medium density fiberboard from empty fruit bunch and rubberwood. Mater. Design 2010, 31, 4229–4236. [Google Scholar] [CrossRef]

- Velasquez, J.A.; Ferrando, F.; Salvado, J. Binderless fiberboard from steam exploded Miscanthus sinensis: The effect of a grinding process. Holz Roh. Werkst. 2002, 60, 297–302. [Google Scholar] [CrossRef]

- Velasquez, J.A.; Ferrando, F.; Salvado, J. Effects of kraft lignin addition in the production of binderless fiberboard from steam exploded Miscanthus sinensis. Ind. Crop. Prod. 2003, 18, 17–23. [Google Scholar] [CrossRef]

- Van Dam, J.E.G.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk. Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crop. Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogues, F.; Garriga, P. Structural analysis of photodegraded woodby means of FTIR spectroscopy. Polym. Degrad. Stabil. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Haris, P.I.; Chapman, D. Analysis of polypeptide and protein structures using Fourier transform infrared spectroscopy. In Methods Molecular Biology: Microscopy, Optical Spectroscopy, and Macroscopic Techniques; Humana Press: Totowa, NJ, USA, 1994. [Google Scholar]

- Lee, N.; Kwon, O.J.; Chun, B.C.; Park, J.S. Characterization of castor oil/polycaprolactone polyurethane biocomposites reinforced with hemp fibers. Fibers Polym. 2009, 10, 154–160. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Gérardin, P.; Zoulalian, A. Investigations of the reasons for fungal durability of heat-treated beech wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Goring, D.A.I. Thermal softening of lignin, hemicellulose and cellulose. Pulp Paper Mag. Can. 1963, 64, 517–527. [Google Scholar]

- Bouajila, J.; Limare, A.; Joly, C.; Dole, P. Lignin plasticization to improve binderless fiberboard mechanical properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood Handbook. Wood as an Engineering Material; General Technical Report FPL-GTR-190; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- GB/T 21723−2008 Wheat/Rice-Straw Particleboard; Inspection and Quarantine of the People’s Republic of China/Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Luo, P.; Yang, C. Self-bonded particleboard from steam exploded wheat straw. In Advanced Materials Research; Trans Tech Publications: Zürich, Switzerland, 2011. [Google Scholar]

| Characteristics | Ash (%) | α-Cellulose (%) | Holocellulose (%) | Lignin (%) | Extractives (%) | |||

|---|---|---|---|---|---|---|---|---|

| Cold Water | Hot Water | 1% NaOH | Alcohol–Benzene | |||||

| Wheat straw | 8.32 | 55.68 | 60.00 | 12.80 | 14.22 | 15.84 | 37.84 | 1.49 |

| Pulping fibers | 5.97 | 35.71 | 36.75 | 11.18 | 40.78 | 49.54 | 51.43 | 3.97 |

| Characteristics | pH | Density (g/mL) | Dissolved Solids Concentration (g/L) | Extractive (Alcohol–Benzene) (%) | Ash (mg/mL) | Lignin (mg/mL) | Protein (mg/mL) |

|---|---|---|---|---|---|---|---|

| Values | 9.17 | 1.00 | 17.50 | 0.09 | 752 | 190 | 2.95 |

| Specimens | Onset Mass (mg) | Temperature for the Mass Loss of 10% (°C) | Mass Loss at T ≤ 500 °C (%) | Final Mass (mg) | Total Mass Loss (%) |

|---|---|---|---|---|---|

| Raw | 8.38669 | 270.34 | 55.96 | 2.26536 | 72.99 |

| 160 °C | 6.59972 | 271.31 | 59.23 | 1.59229 | 75.87 |

| 180 °C | 8.92963 | 270.01 | 53.40 | 2.64878 | 70.34 |

| 200 °C | 8.61852 | 277.82 | 52.79 | 2.68206 | 68.88 |

| Control (180 °C) | 13.75989 | 277.32 | 53.33 | 4.69269 | 65.90 |

| Groups | Modulus of Rupture (MOR) (MPa) | Modulus of Elasticity MOE (MPa) | Thickness Swelling (TS) (%) | Water Absorption (WA) (%) | Internal Bonding Strength (IB) (MPa) |

|---|---|---|---|---|---|

| Control (180 °C) | 16.4 ± 2.0 | 1914 ± 158 | 33.3 ± 3.2 | 95.0 ± 5.1 | 0.84 ± 0.07 |

| 160 °C | 15.9 ± 1.5 b | 1747 ± 124 b | 33.9 ± 2.7 a | 99.1 ± 4.7 a | 0.79 ± 0.04 c |

| 170 °C | 17.5 ± 1.2 b | 2046 ± 480 b | 32.8 ± 1.5 ab | 95.3 ± 5.9 a | 0.81 ± 0.06 c |

| 180 °C | 21.2 ± 1.6 b | 2892 ± 207 a | 31.1 ± 1.0 abc | 91.4 ± 6.4 ab | 0.90 ± 0.03 bc |

| 190 °C | 24.9 ± 0.9 a | 2994 ± 554 a | 29.5 ± 2.4 bc | 86.5 ± 2.7 bc | 1.02 ± 0.11 ab |

| 200 °C | 24.0 ± 1.4 a | 2907 ± 292 a | 28.0 ± 2.6 c | 80.2 ± 4.2c | 1.11 ± 0.08 a |

| p-level | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Straw-based wood [60] | 18.10 | – | – | 63.7 | 0.24 |

| Spruce and pine residues [16] | 22.5 | 5000 | 18 | 45 | 0.75 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, B.; Liu, J.; Ni, L.; Li, J. Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent. Materials 2019, 12, 922. https://doi.org/10.3390/ma12060922

Wang J, Wang B, Liu J, Ni L, Li J. Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent. Materials. 2019; 12(6):922. https://doi.org/10.3390/ma12060922

Chicago/Turabian StyleWang, Jiajun, Bo Wang, Junliang Liu, Lin Ni, and Jianzhang Li. 2019. "Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent" Materials 12, no. 6: 922. https://doi.org/10.3390/ma12060922

APA StyleWang, J., Wang, B., Liu, J., Ni, L., & Li, J. (2019). Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent. Materials, 12(6), 922. https://doi.org/10.3390/ma12060922