Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

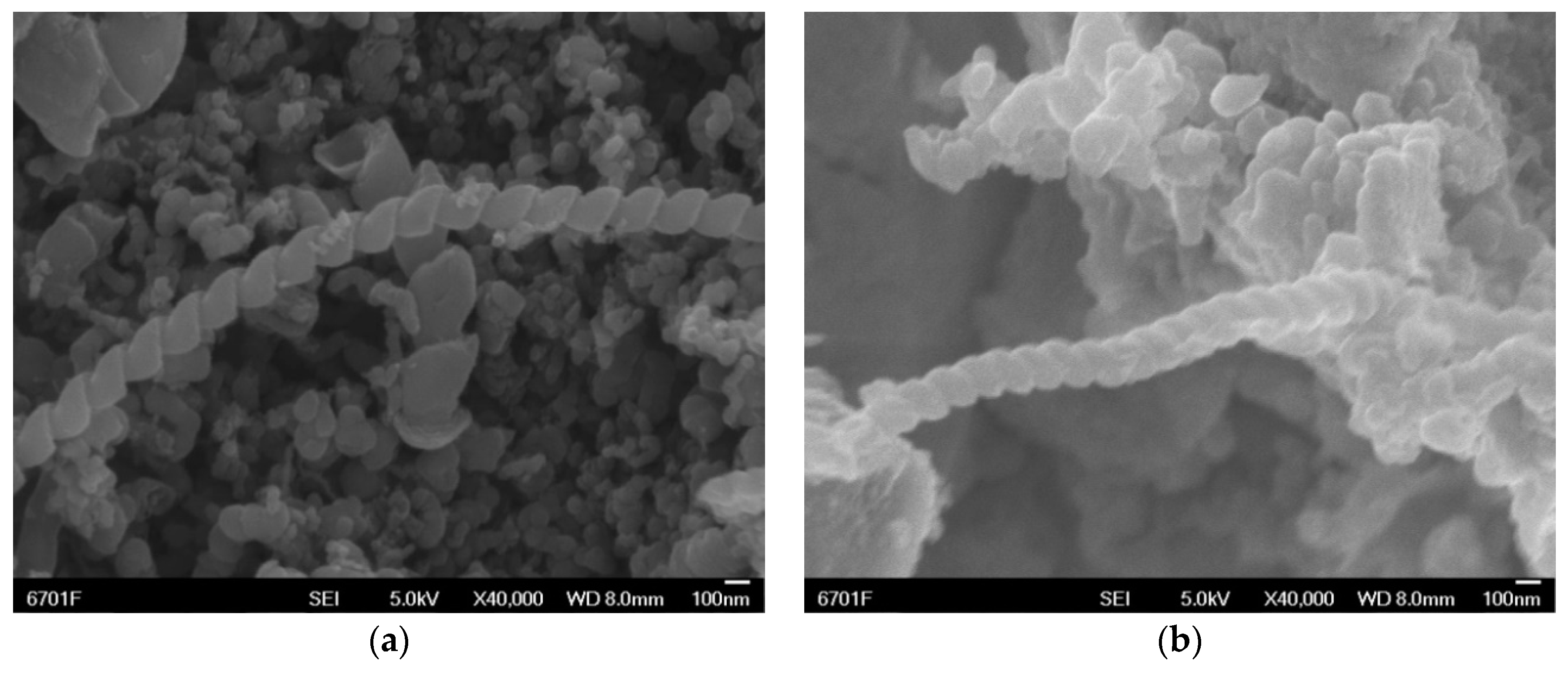

2.2.1. Pre-Treatment of H-CNTs

2.2.2. Synthetic Process

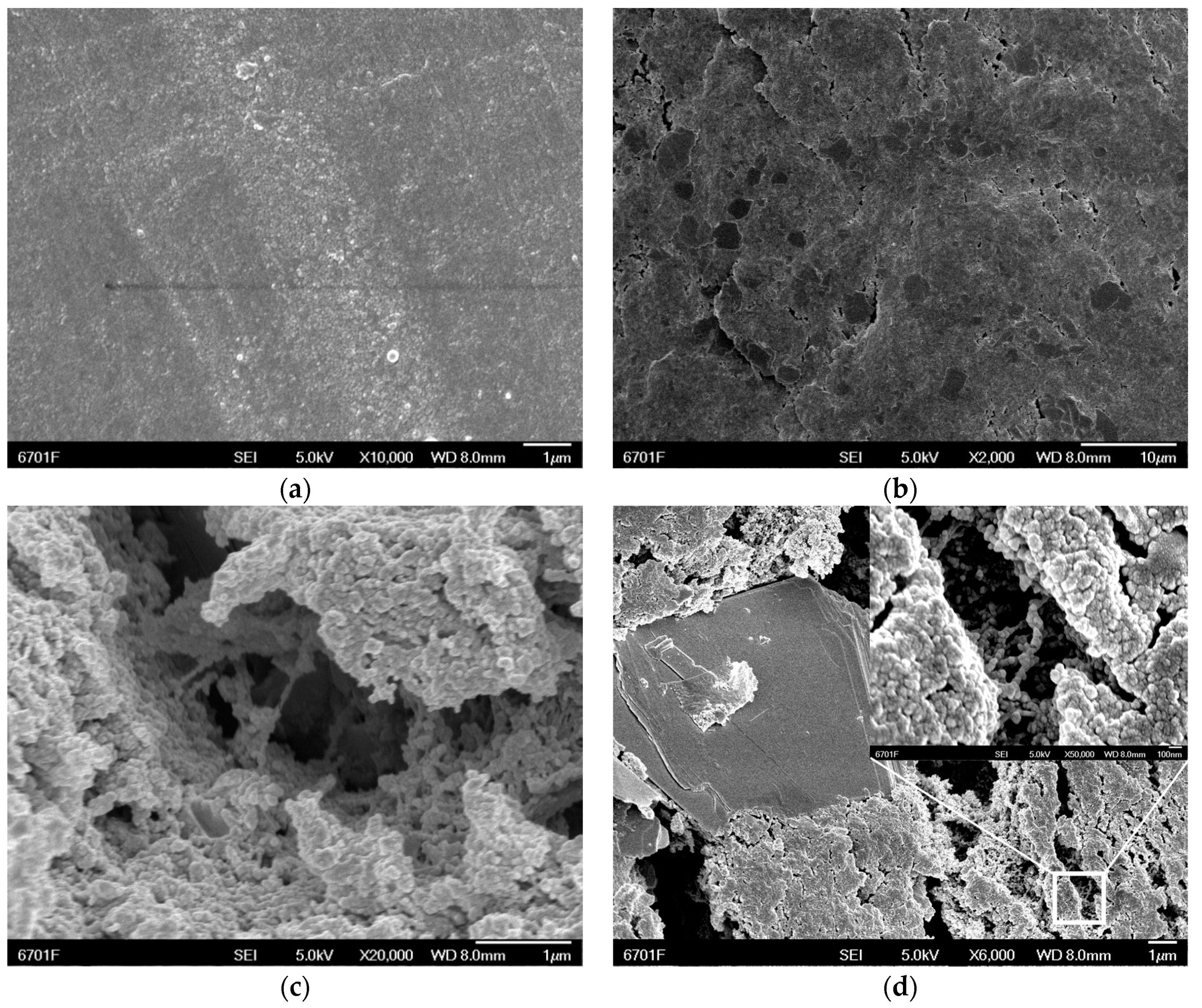

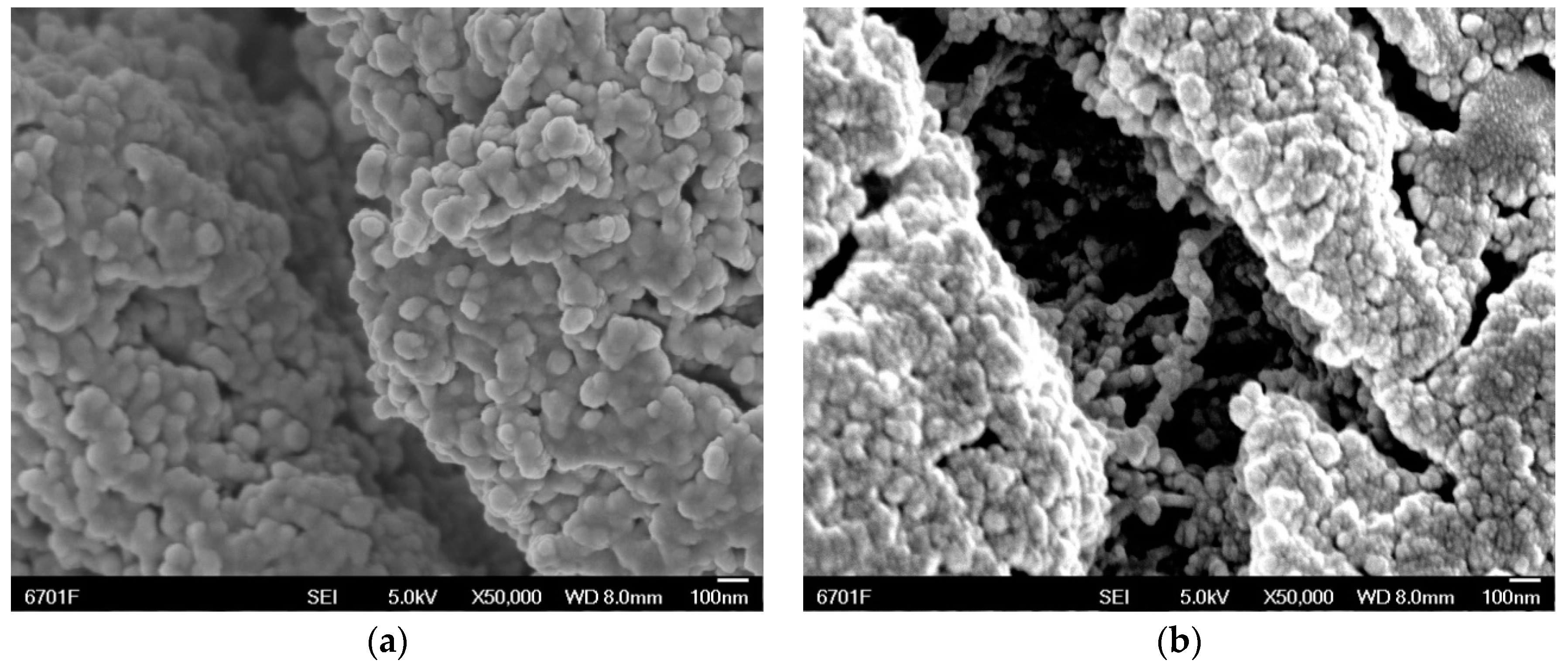

2.3. Microstructure of the Composites

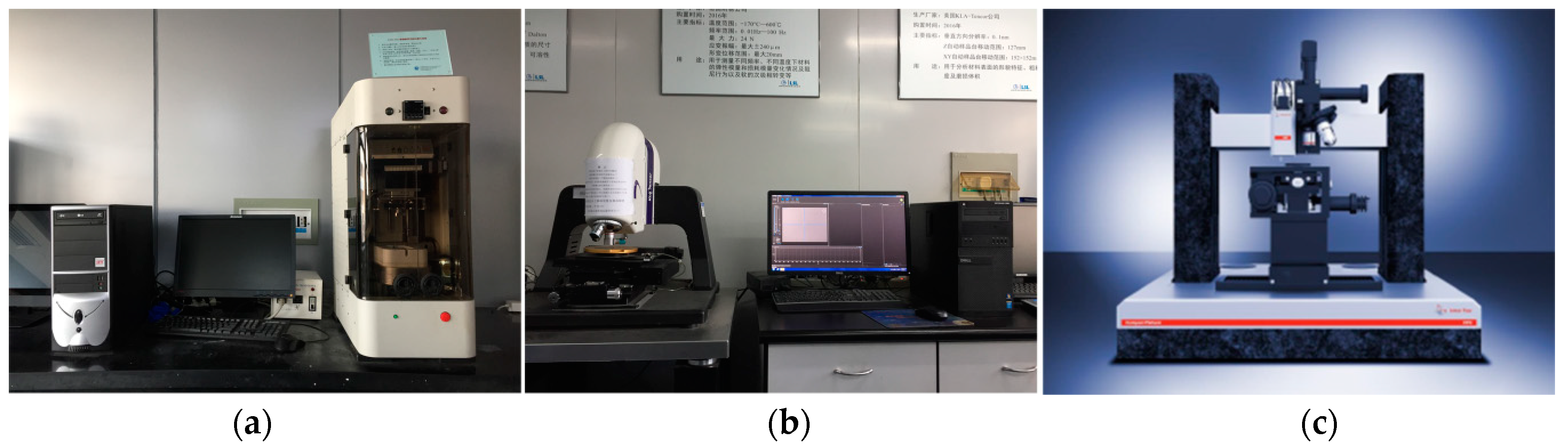

2.4. Test Method

3. Results

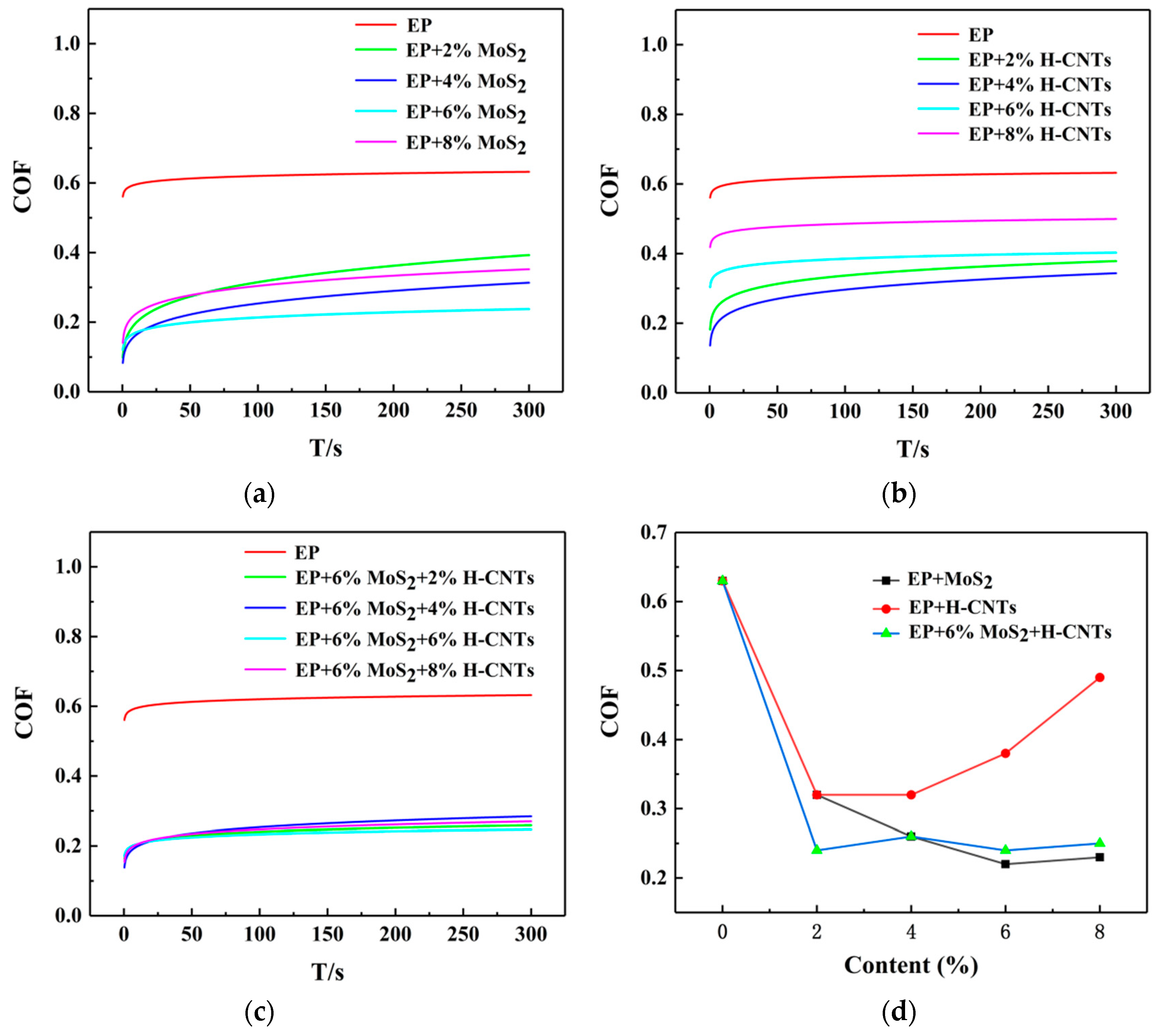

3.1. Friction Coefficient

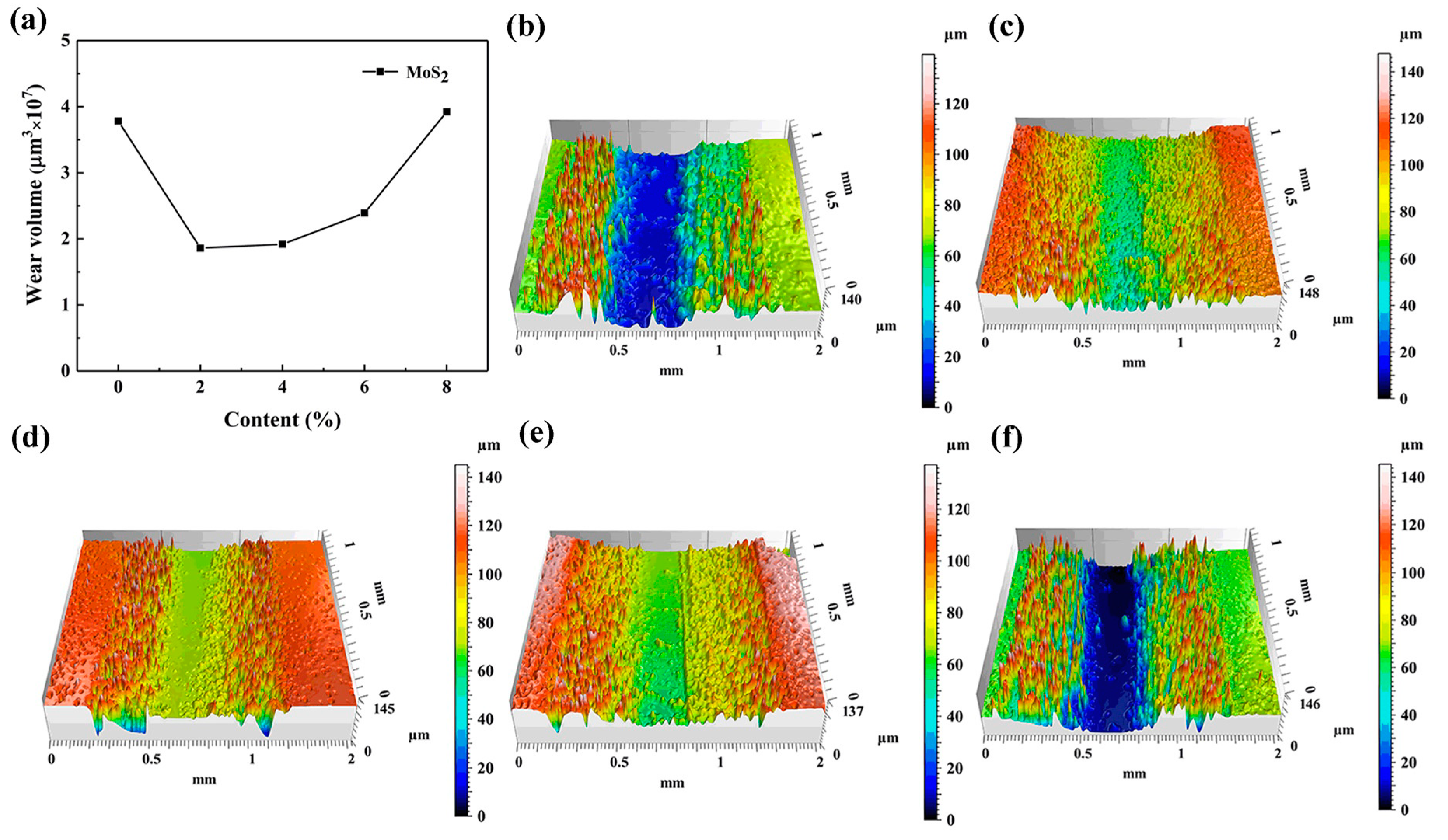

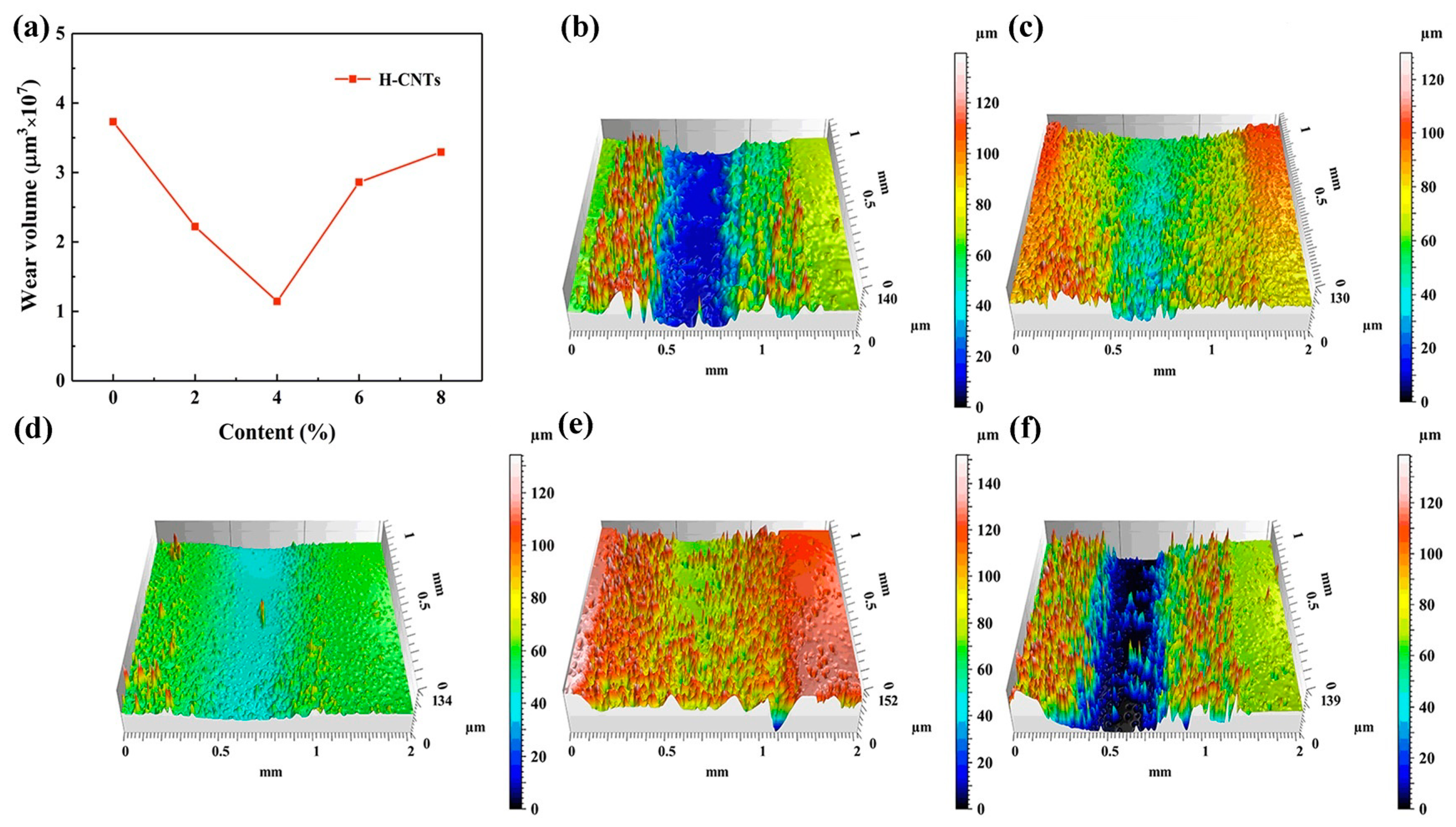

3.2. Wear Volume

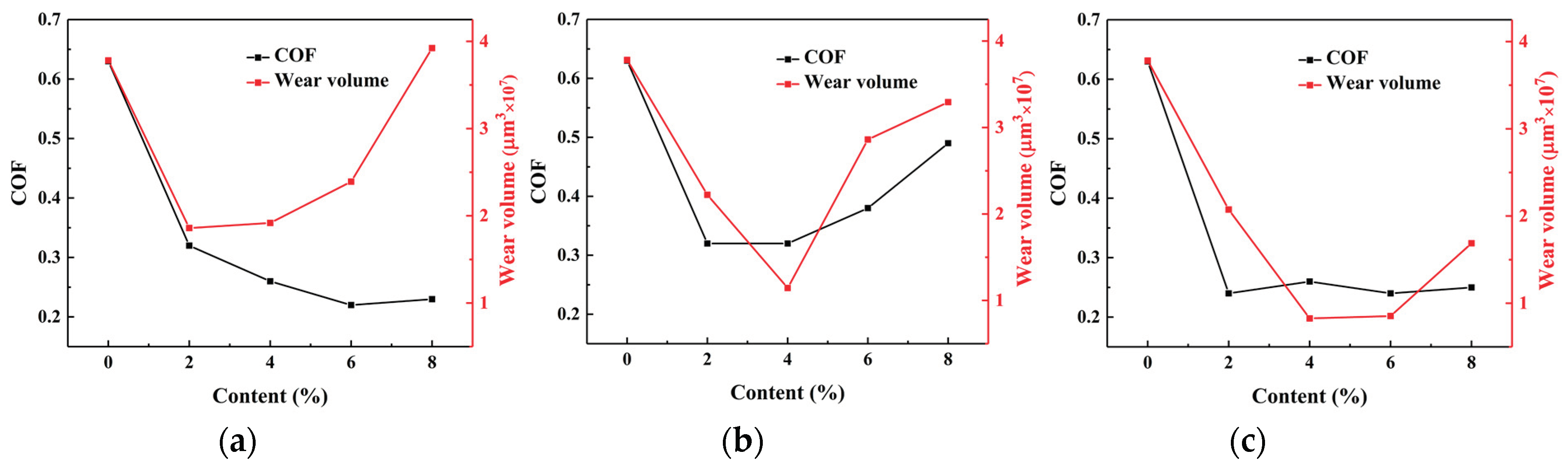

3.3. Comparison of Wear and Friction Coefficients of Composite Materials with Different Additives

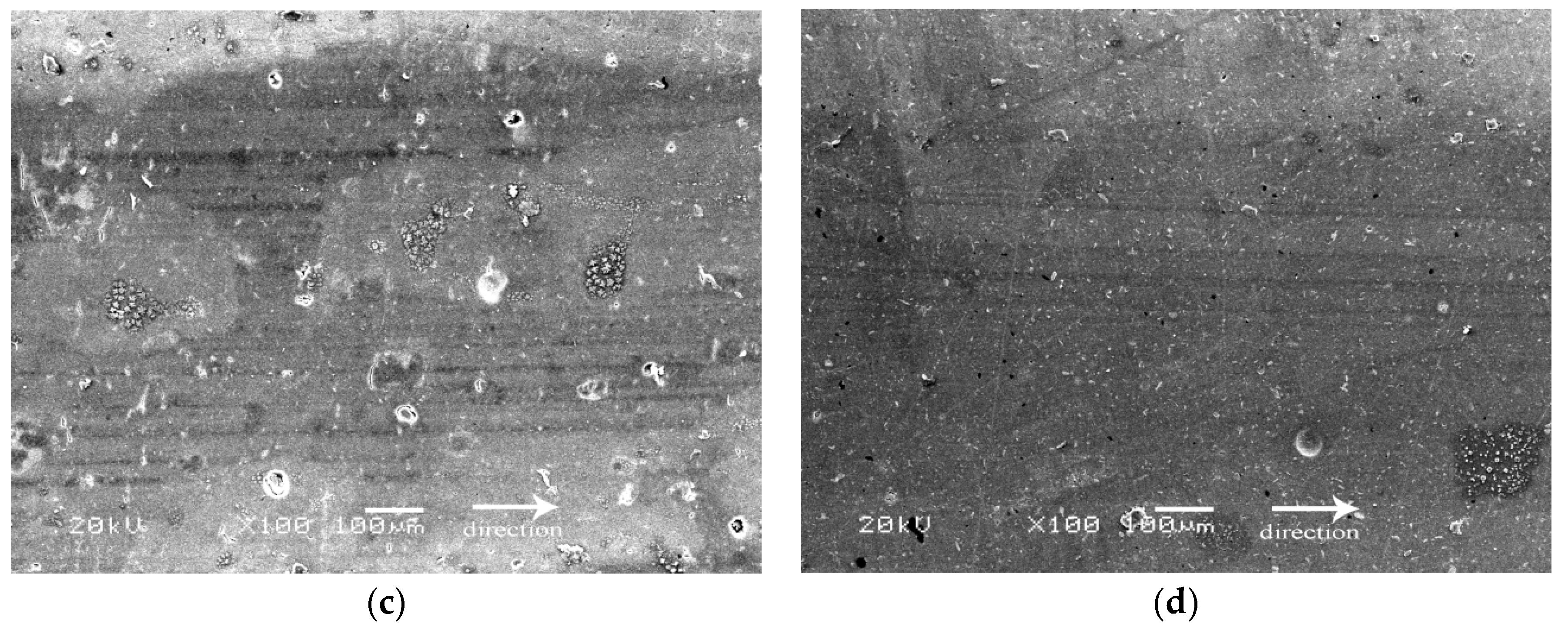

3.4. Wear Surface Analysis

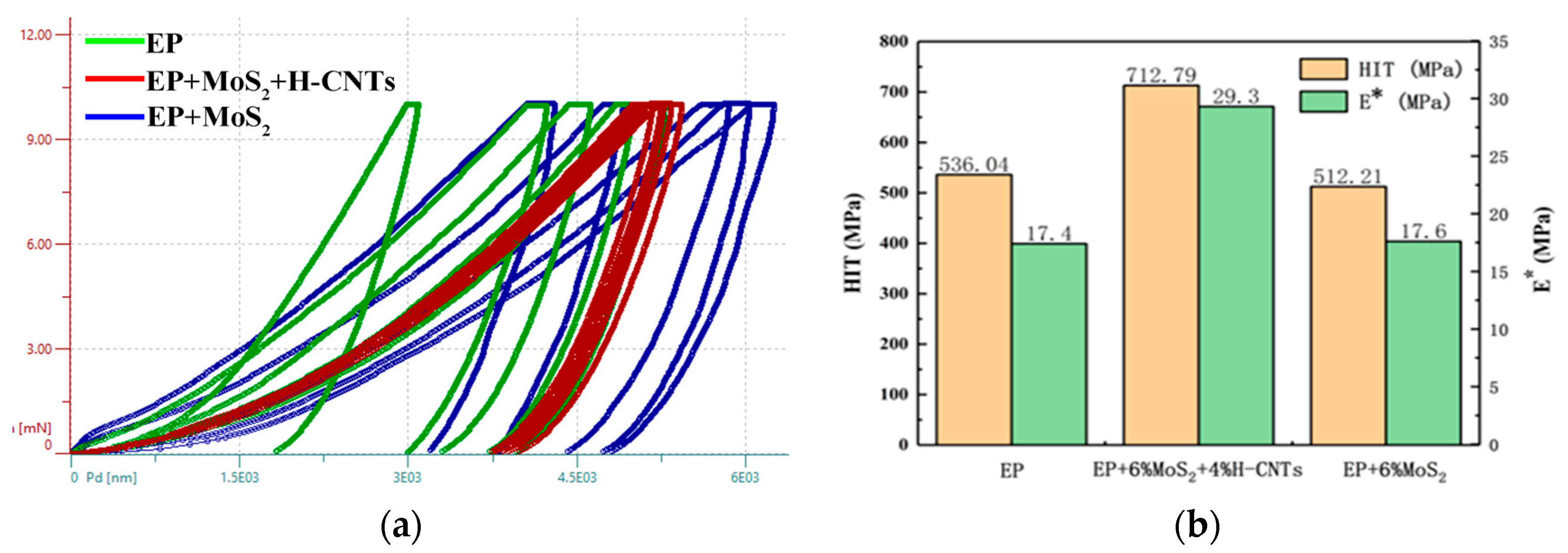

3.5. Modulus of Elasticity and Hardness

4. Conclusions

- (1)

- When only MoS2 was added, the friction coefficient decreased gradually with the increasing content of MoS2. When the content of MoS2 reached 6%, the friction coefficient was the smallest, but the wear rate decreased with 2% of MoS2 and then increased. The wear rate was the smallest when the content of MoS2 was 2%, and close to that of the original epoxy resin for 8% MoS2 content. When only H-CNTs were added, and with the increasing content of H-CNTs, friction coefficient of the composites decreased first (for 2%), then stabilized, and subsequently increased rapidly (for more than 4%), while the wear rate decreased up to 4% of H-CNTs and then increased.

- (2)

- MoS2 and H-CNTs were added simultaneously to prepare the epoxy resin composites, which can reduce the friction coefficient and wear rate. By testing different contents of various additives, it became evident that the friction coefficient and wear amount of the composites reached the minimum when the contents of MoS2 and H-CNTs were 6% and 4%, respectively.

- (3)

- The hardness and modulus of the elasticity of three typical specimens were measured at five different locations by using the linear loading mode and O&P theory to obtain the average value. It was observed that the addition of H-CNTs enhanced the hardness and modulus of elasticity of the composites. The hardness changed from 530 MPa to 712 MPa, and the modulus of elasticity changed from 17.4 MPa to 29.3 MPa.

Author Contributions

Funding

Conflicts of Interest

References

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Odegard, G.M.; Bandyopadhyay, A. Physical aging of epoxy polymers and their composites. J. Polym. Sci. Polym. Phys. 2011, 49, 1695–1716. [Google Scholar] [CrossRef]

- Shen, X.J.; Pei, X.Q.; Liu, Y.; Fu, S.Y. Tribological performance of carbon nanotube–graphene oxide hybrid/epoxy composites. Compos. Part B Eng. 2004, 57, 120–125. [Google Scholar] [CrossRef]

- Zeng, C.; Lu, S.; Xiao, X.; Gao, J.; Pan, L.; He, Z.; Yu, J. Enhanced thermal and mechanical properties of epoxy composites by mixing noncovalently functionalized graphene sheets. Polym. Bull. 2015, 72, 453–472. [Google Scholar] [CrossRef]

- Qi, B.; Lu, S.R.; Xiao, X.E.; Pan, L.L.; Tan, F.Z.; Yu, J.H. Enhanced thermal and mechanical properties of epoxy composites by mixing thermotropic liquid crystalline epoxy grafted graphene oxide. Express Polym. Lett. 2014, 8, 467–479. [Google Scholar] [CrossRef]

- Fernandus, M.J.; Senthilkumar, T.; Balasubramanian, V.; Rajakumar, S. Optimising diffusion bonding parameters to maximize the strength of AA6061 aluminium and AZ31B magnesium alloy joints. Mater. Des. 2015, 33, 31–41. [Google Scholar] [CrossRef]

- Luming, L.; Songling, H.; Xiaofeng, W.; Keren, S.; Su, W. Magnetic field abnormality caused by welding residual stress. J. Magn. Magn. Mater. 2003, 261, 385–391. [Google Scholar] [CrossRef]

- Chhetri, S.; Adak, N.C.; Samanta, P. Investigation of mechanical and thermal properties of the cetyltrimethylammonium bromide functionalized molybdenum disulfide (MoS2)/epoxy composites. Polym. Bull. 2018, 75, 327–343. [Google Scholar] [CrossRef]

- Desai, A.V.; Haque, M.A. Mechanics of the interface for carbon nanotube–polymer composites. Thin Wall Struct. 2005, 43, 1787–1803. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M. Effect of multi-walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy-based nanocomposites. Polym. Test. 2011, 30, 548–556. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Materials: Introduction and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Gong, Z.; Jia, X.; Ma, W.; Zhang, B.; Zhang, J. Hierarchical structure graphitic-like/MoS2 film as superlubricity material. Appl. Surf. Sci. 2017, 413, 381–386. [Google Scholar] [CrossRef]

- Barboza, A.P.M.; Chacham, H.; Oliveira, C.K.; Fernandes, T.F.; Ferreira, E.H.M.; Archanjo, B.S.; Neves, B.R. Dynamic negative compressibility of few-layer graphene, h-BN, and MoS2. Nano Lett. 2012, 12, 2313–2317. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Zheng, D.; Pang, H.; Tang, J.H.; Li, Z.M. The effect of molecular chain polarity on electric field-induced aligned conductive carbon nanotube network formation in polymer melt. Compos. Sci. Technol. 2012, 72, 1875–1881. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Aniskevich, A.; Zarrelli, M.; Martone, A.; Giordano, M. Effect of filler on the creep characteristics of epoxy and epoxy-based CFRPs containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2014, 100, 198–203. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Sahoo, A.K.; Bindumadhavan, K.; Manu, S.K.; Nayak, B.B. Reinforcement of Ball Shaped MoS2 Nanoparticles in Epoxy Resin. J. Nanosci. Nanotechnol. 2010, 10, 8171–8179. [Google Scholar] [CrossRef]

- Ranjbar, M.; Feli, S. Mechanical and low-velocity impact properties of epoxy-composite beams reinforced by MWCNTs. J. Compos. Mater. 2018, 5, 693–705. [Google Scholar] [CrossRef]

- Luangtriratana, P.; Kandola, B.K.; Myler, P. Ceramic particulate thermal barrier surface coatings for glass fibre-reinforced epoxy composites. Mater. Des. 2015, 68, 232–244. [Google Scholar] [CrossRef]

- Kadhim, N.; Mei, Y.; Wang, Y.; Li, Y.; Meng, F.; Jiang, M.; Zhou, Z. Remarkable Improvement in the Mechanical Properties of Epoxy Composites Achieved by a Small Amount of Modified Helical Carbon Nanotubes. Polymers 2018, 10, 1103. [Google Scholar] [CrossRef]

- Wang, P.; Yang, J.; Sun, G.; Zhang, X.; Zhang, H.; Zheng, Y.; Xu, S. Twist induced plasticity and failure mechanism of helical carbon nanotube fibers under different strain rates. Int. J. Plast. 2018, 110, 74–94. [Google Scholar] [CrossRef]

- Jacobs, O.; Xu, W.; Schädel, B.; Wu, W. Wear behaviour of carbon nanotube reinforced epoxy resin composites. Tribol. Lett. 2006, 23, 65–75. [Google Scholar] [CrossRef]

- Zhang, H.J.; Zhang, Z.Z.; Guo, F. Tribological behaviors of hybrid PTFE/Nomex fabric/phenolic composite reinforced with multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2012, 124, 235–241. [Google Scholar] [CrossRef]

- Kumar, A.M.; Gasem, Z.M. Effect of functionalization of carbon nanotubes on mechanical and electrochemical behavior of polyaniline nanocomposite coatings. Surf. Coat. Technol. 2015, 276, 416–423. [Google Scholar] [CrossRef]

- Yan, L.; Wang, H.; Wang, C.; Sun, L.; Liu, D.; Zhu, Y. Friction and wear properties of aligned carbon nanotubes reinforced epoxy composites under water lubricated condition. Wear 2013, 308, 105–112. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zarudi, I.; Xiao, K.Q. Novel behaviour of friction and wear of epoxy composites reinforced by carbon nanotubes. Wear 2006, 26, 806–811. [Google Scholar] [CrossRef]

- Li, X.; Chen, B.; Jia, Y.; Li, X.; Yang, J.; Li, C.; Yan, F. Enhanced tribological properties of epoxy-based lubricating coatings using carbon nanotubes-ZnS hybrid. Surf. Coat. Technol. 2018, 344, 154–162. [Google Scholar] [CrossRef]

- Martone, A.; Formicola, C.; Giordano, M.; Zarrelli, M. Reinforcement efficiency of multi-walled carbon nanotube/epoxy nano composites. Compos. Sci. Technol. 2010, 70, 1154–1160. [Google Scholar] [CrossRef]

- Cai, H.; Yan, F.; Xue, Q. Investigation of tribological properties of polyimide/carbon nanotube nanocomposites. Mater. Sci. Eng. A 2004, 364, 94–100. [Google Scholar] [CrossRef]

- Uzun, O.; Güçlü, N.; Kölemen, U.; Şahin, O. Analysis of data on indentation load against penetration depth for bulk MgB2 crystal using indentation work and Oliver–Pharr approaches. Mater. Chem. Phys. 2008, 112, 5–10. [Google Scholar] [CrossRef]

- Legocka, I.; Wierzbicka, E.; Al-Zahari, T.; Osawaru, O. Modified halloysite as a filler for epoxy resins. Pol. J. Chem. Technol. 2011, 13, 47–52. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

| Component | Requirement |

|---|---|

| Epoxy resin | Diglicidyl ether |

| Curing agent | Ethylenediamine |

| H-CNTs | Diameter 100–200 nm, length 1–10 μm, carbon content more than 95%, ignition point 560–600 ℃. |

| MoS2 | The content should be more than or equal to 98%. |

| COF | 0 | 2% | 4% | 6% | 8% |

|---|---|---|---|---|---|

| EP + MoS2 | 0.63 | 0.32 | 0.26 | 0.22 | 0.23 |

| EP + H-CNTs | 0.63 | 0.32 | 0.32 | 0.38 | 0.49 |

| EP + 6%MoS2 + H-CNTs | 0.63 | 0.24 | 0.26 | 0.24 | 0.25 |

| HIT(O&P) (MPa) | E*(O&P) (MPa) | |||||

|---|---|---|---|---|---|---|

| EP | EP + 6% MoS2 + H-CNTs | EP + 6% MoS2 | EP | EP + 6% MoS2 + H-CNTs | EP + 6% MoS2 | |

| Data: 1 | 12.7 | 17.2 | 16.5 | 366.6 | 587.9 | 517.3 |

| Data: 2 | 14.5 | 58.1 | 18.6 | 402.0 | 1034.1 | 518.9 |

| Data: 3 | 26.8 | 23.3 | 17.5 | 756.5 | 642.4 | 487.2 |

| Data: 4 | 12.7 | 28.6 | 18.0 | 566.0 | 681.3 | 508.5 |

| Data: 5 | 20.5 | 19.4 | 17.7 | 589.1 | 618.2 | 529.1 |

| Mean | 17.4 | 29.3 | 17.6 | 536.0 | 712.8 | 512.2 |

| Std Dev | 6.1 | 16.6 | 0.8 | 157.3 | 182.8 | 15.8 |

| Median | 14.5 | 23.3 | 17.7 | 566.0 | 642.4 | 517.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Z.; Yang, Y.; Lin, Y.; Guo, Z. Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin. Materials 2019, 12, 903. https://doi.org/10.3390/ma12060903

Ren Z, Yang Y, Lin Y, Guo Z. Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin. Materials. 2019; 12(6):903. https://doi.org/10.3390/ma12060903

Chicago/Turabian StyleRen, Zhiying, Yu Yang, Youxi Lin, and Zhiguang Guo. 2019. "Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin" Materials 12, no. 6: 903. https://doi.org/10.3390/ma12060903

APA StyleRen, Z., Yang, Y., Lin, Y., & Guo, Z. (2019). Tribological Properties of Molybdenum Disulfide and Helical Carbon Nanotube Modified Epoxy Resin. Materials, 12(6), 903. https://doi.org/10.3390/ma12060903