Study on the Properties of Vertical Carbon Nanotube Films Grown on Stainless Steel Bipolar Plates

Abstract

:1. Introduction

2. Experimental Details

2.1. Sample Preparation

2.2. Sample Test

3. Results and Discussions

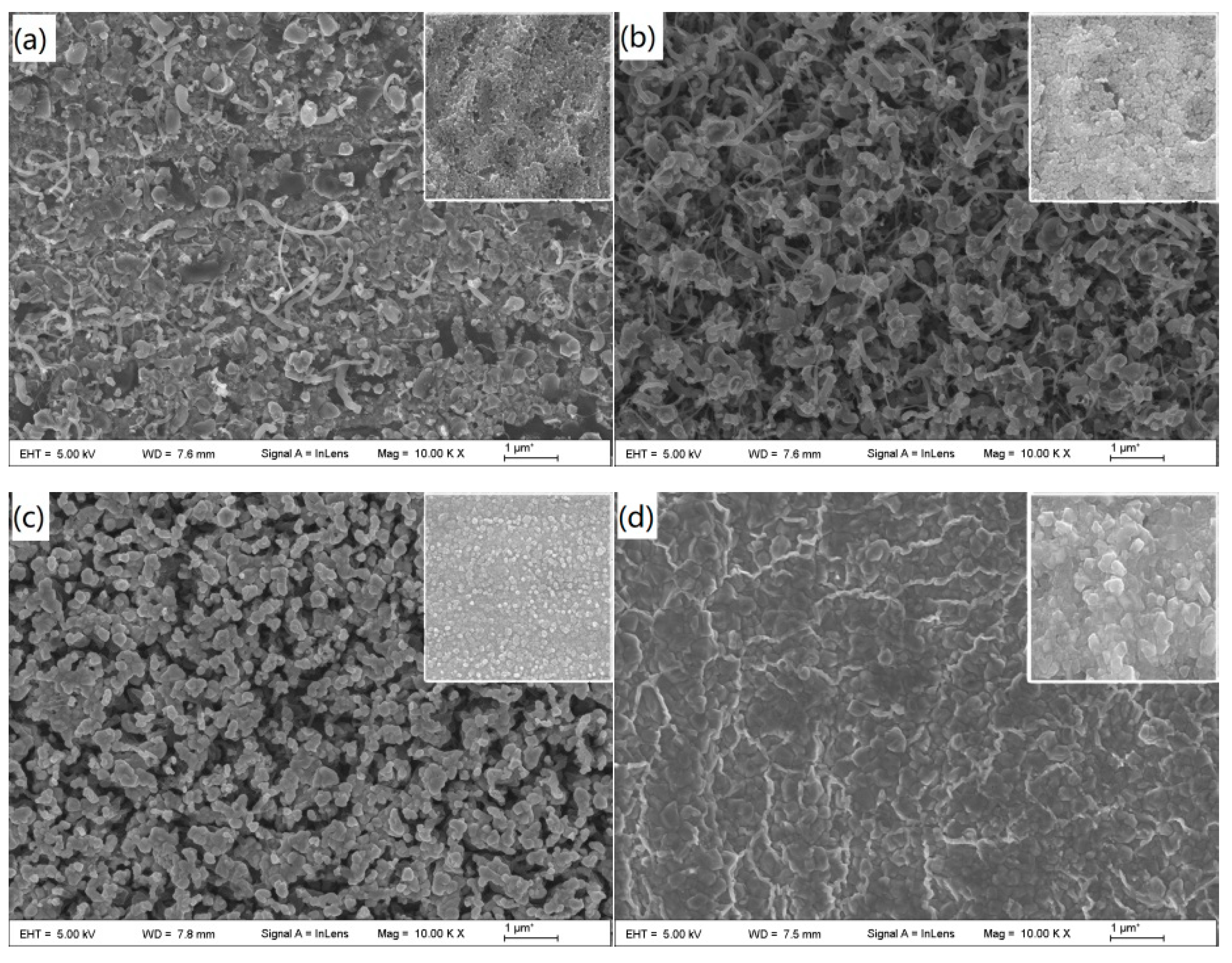

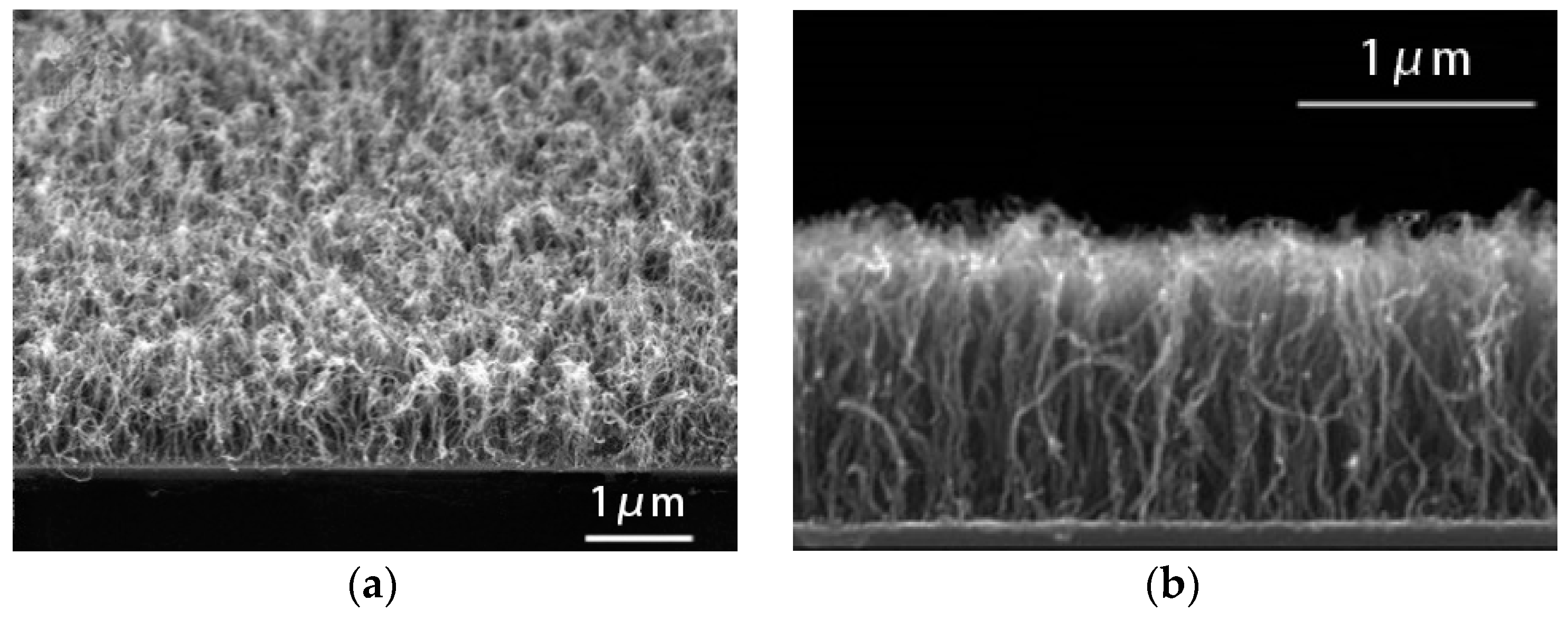

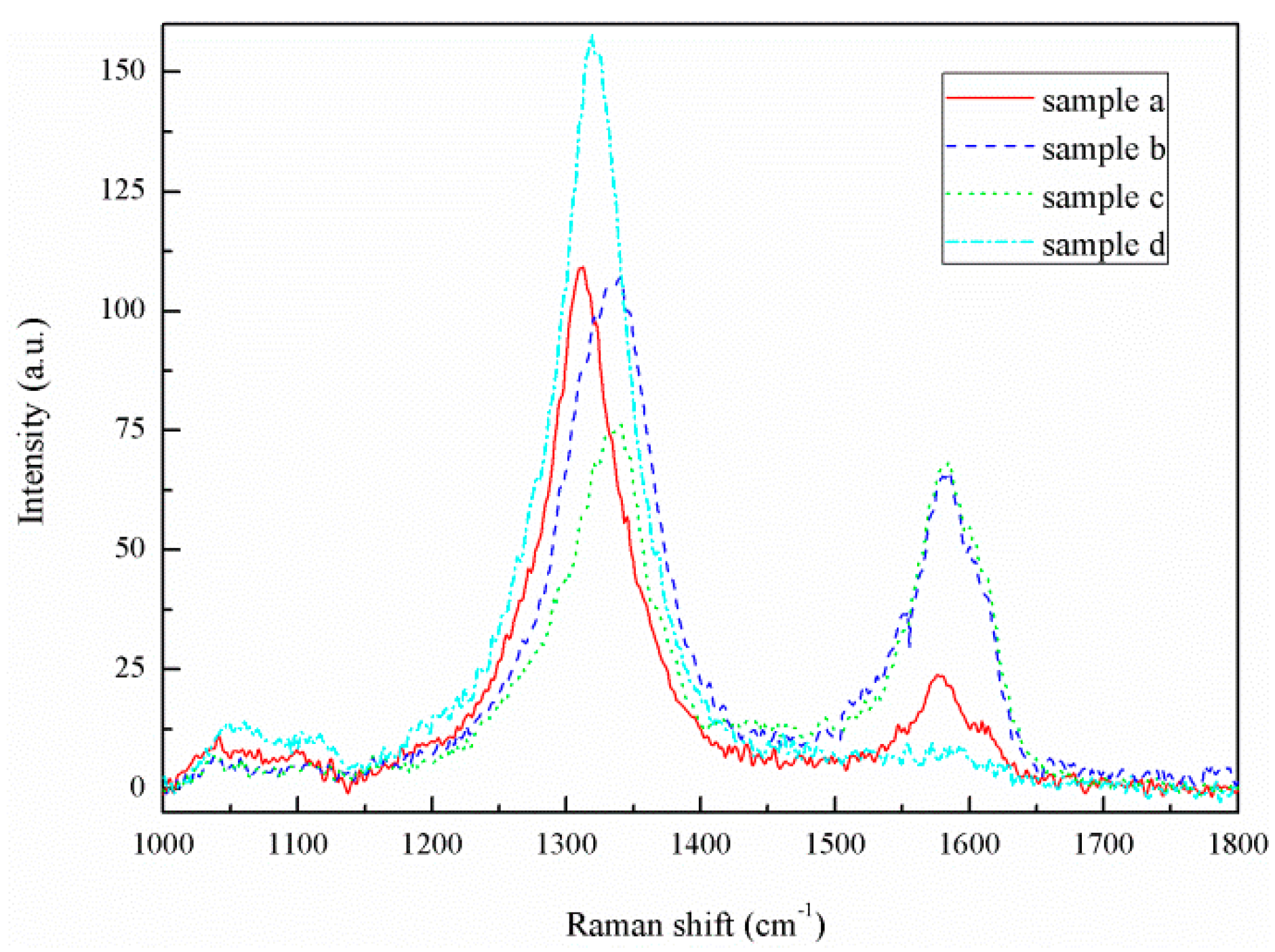

3.1. Sample Surface Topography

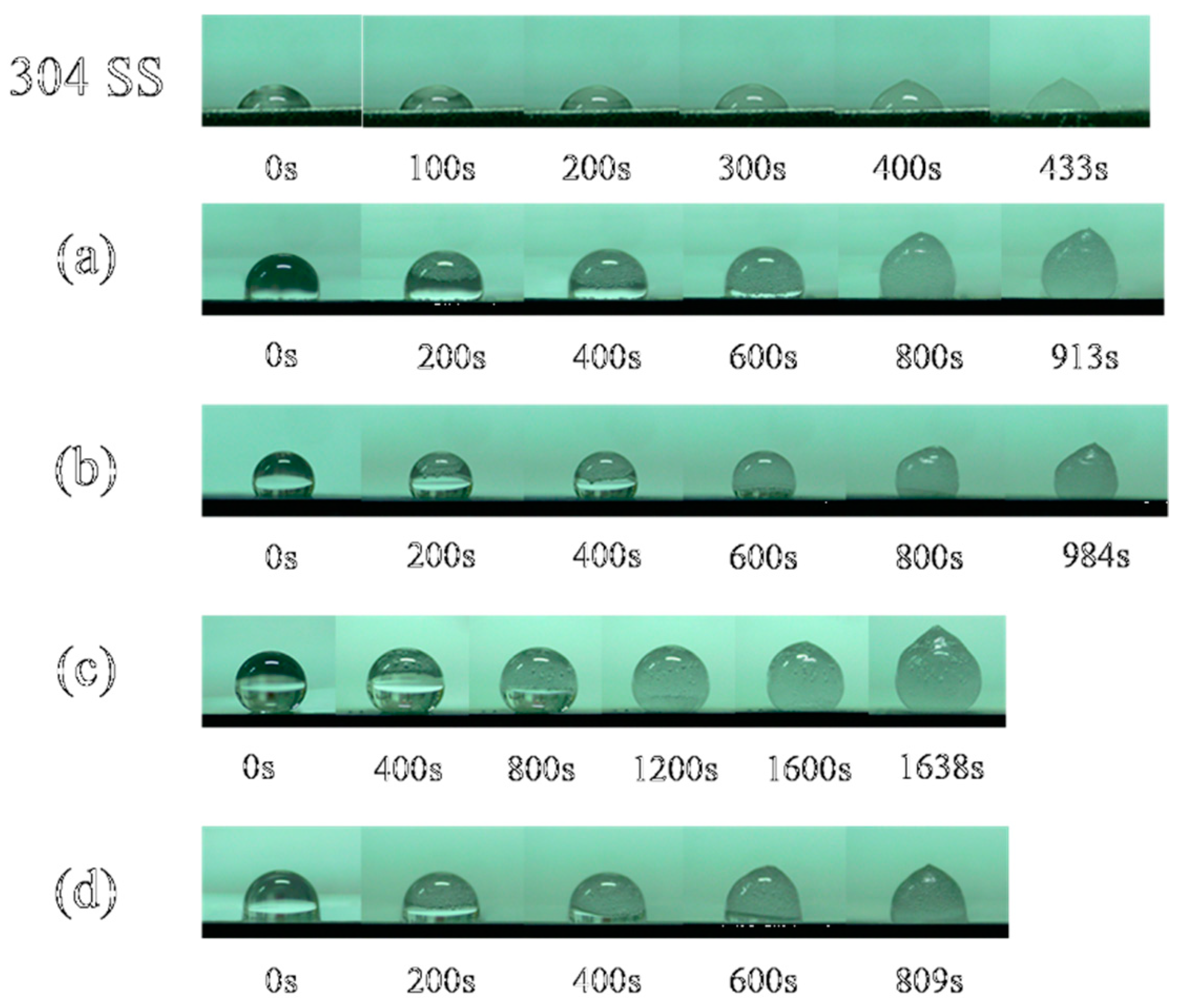

3.2. Hydrophobicity and Anti-Icing of the Surface of the Sample

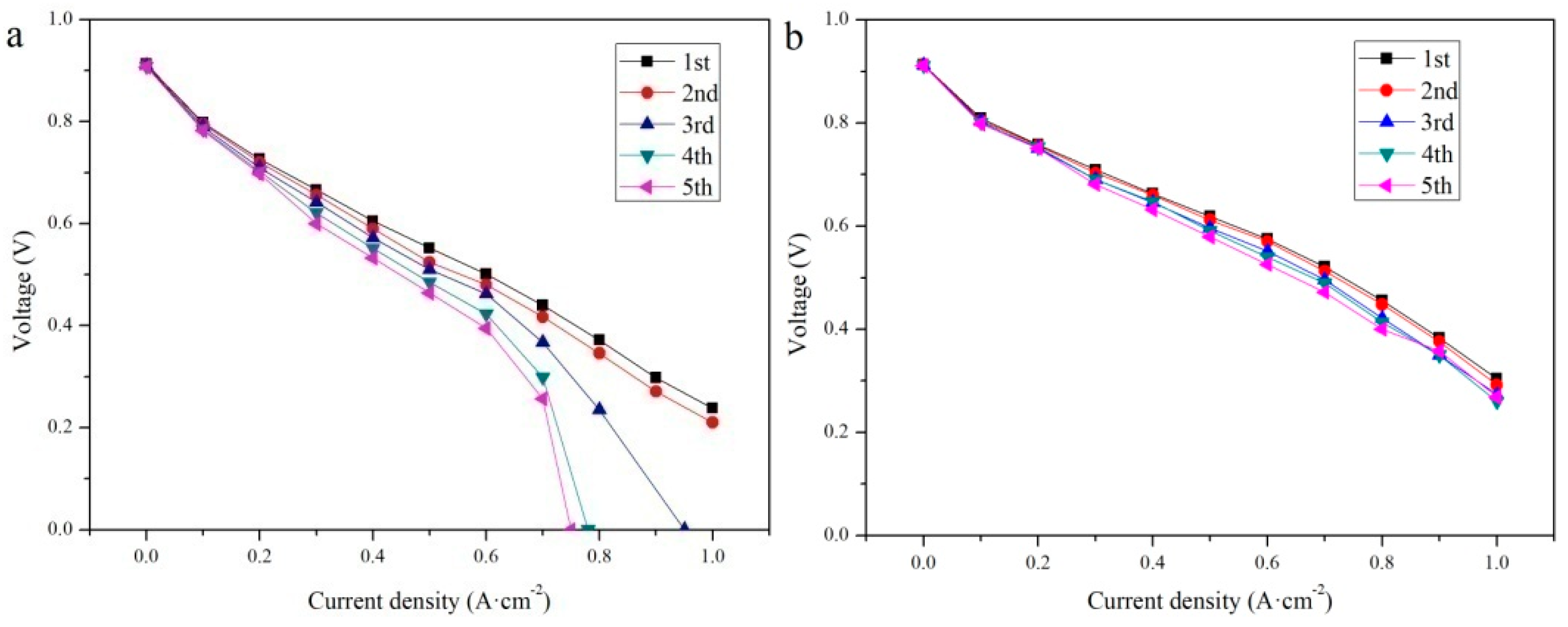

3.3. Analysis of the Contact Resistance of the Samples

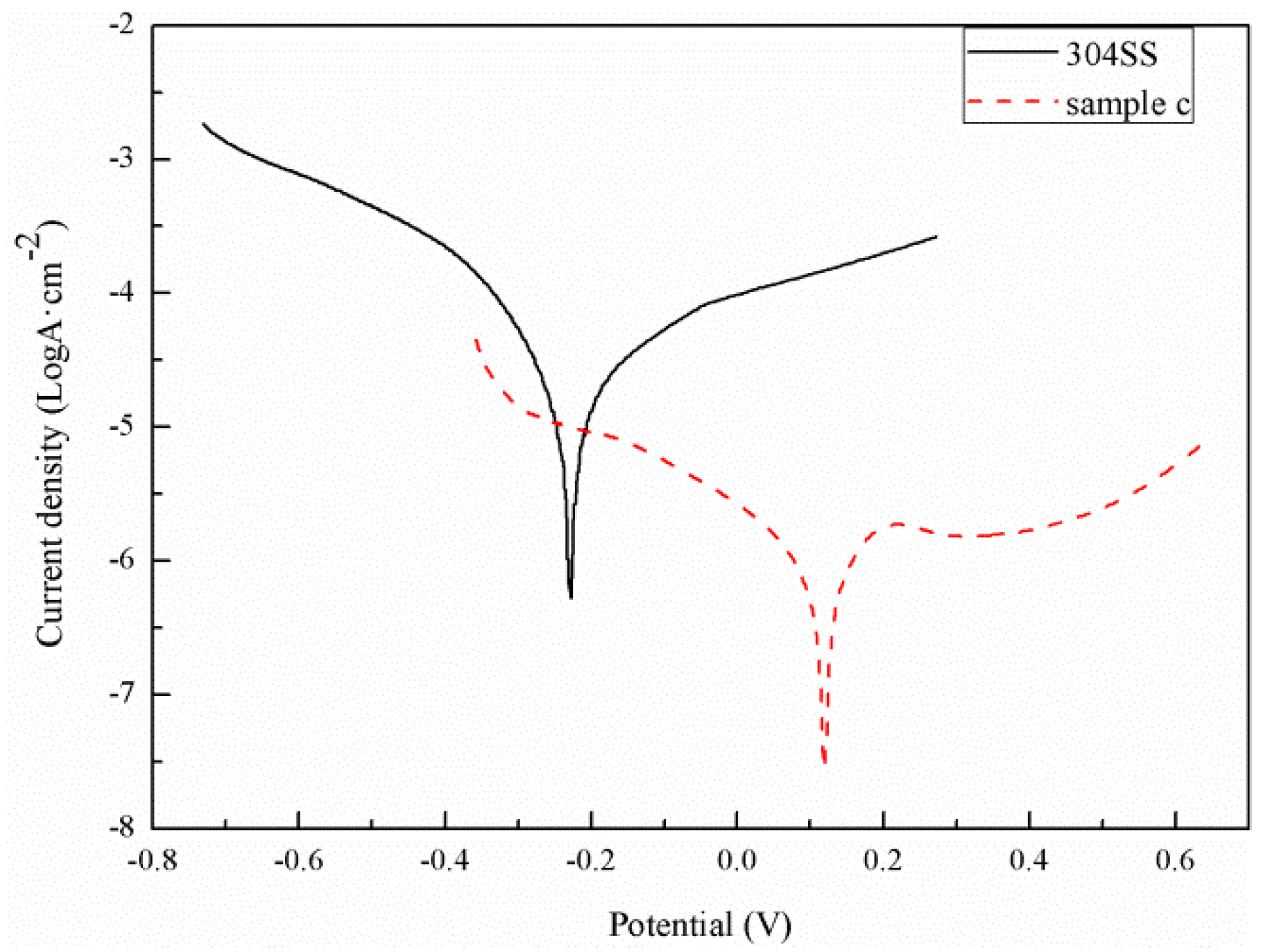

3.4. Analysis of the Corrosion Resistance Performance of Samples

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wee, J.H. Applications of proton exchange membrane fuel cell systems. Renew. Sust. Energy Rev. 2007, 11, 1720–1738. [Google Scholar] [CrossRef]

- Tu, Z.K.; Zhang, H.N.; Luo, Z.P.; Liu, J.; Wan, Z.M.; Pan, M. Evaluation of 5 kW proton exchange membrane fuel cell stack operated at 95 degrees C under ambient pressure. J. Power Sour. 2013, 222, 277–281. [Google Scholar] [CrossRef]

- Lee, S.; Woo, S.; Kakati, N.; Lee, Y.; Yoon, Y. Corrosion and electrical properties of carbon/ceramic multilayer coated on stainless steel bipolar plates. Surf. Coat. Tech. 2016, 303, 162–169. [Google Scholar] [CrossRef]

- Asri, N.F.; Husaini, T.; Sulong, A.; Majlan, E.H.; Daud, W.R.W. Coating of stainless steel and titanium bipolar plates for anticorrosion in PEMFC: A review. Int. J. Hydrog. Energy 2017, 42, 9135–9148. [Google Scholar] [CrossRef]

- Gutierrez, A.G.G.; Sebastian, P.J.; Cacho, L.M.; Arco, E.B.; Campos, I.; Baron, A. Surface Modification of Aluminum Alloy 6061 for Bipolar Plate Application: Adhesion Characteristics and Corrosion Resistance. Int. J. Electrochem. Sci. 2018, 13, 3958–3969. [Google Scholar] [CrossRef]

- Lu, C.E.; Lee, J.L.; Sheu, H.H.; Hou, K.H.; Tseng, C.C.; Ger, M.D. Preparation and Characterizations of High Carbon Content Cr-C Coatings Electroplated from a Trivalent Chromium-Based Bath. Int. J. Electrochem. Sci. 2015, 10, 5405–5419. [Google Scholar]

- Shimpalee, S.; Lilavivat, V.; McCrabb, H.; Khunatorn, Y.; Lee, H.K.; Lee, W.K.; Weidner, J.W. Investigation of bipolar plate materials for proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2016, 41, 13688–13696. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.P.; Lee, C.I.; Chen, C.C.; Chang, W.S.; Yang, C.C. Development of novel proton exchange membrane fuel cells using stamped metallic bipolar plates. J. Power Source 2015, 283, 429–442. [Google Scholar] [CrossRef]

- Papadias, D.D.; Ahluwalia, R.K.; Thomson, J.K.; Meyer, H.M.; Brady, M.P.; Wang, H.L.; Turner, J.A.; Mukundan, R.; Borup, R. Degradation of SS316L bipolar plates in simulated fuel cell environment: Corrosion rate, barrier film formation kinetics and contact resistance. J. Power Source 2015, 273, 1237–1249. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.F.; Franchi, D.; Leone, A.; Pilloni, L.; Masci, A.; Pozio, A. Surface conductivity and stability of metallic bipolar plate materials for polymer electrolyte fuel cells. Electrochim. Acta 2006, 51, 3592–3598. [Google Scholar] [CrossRef]

- Taherian, R. A review of composite and metallic bipolar plates in proton exchange membrane fuel cell: Materials, fabrication, and material selection. J. Power Source 2014, 265, 370–390. [Google Scholar] [CrossRef]

- Weil, K.S.; Xia, G.; Yang, Z.G.; Jin, Y.K. Development of a niobium clad PEM fuel cell bipolar plate material. Int. J. Hydrog. Energy 2007, 32, 3724–3733. [Google Scholar] [CrossRef]

- Feng, K.; Li, Z.; Cai, X.; Chu, P.K. Silver implanted 316L stainless steel as bipolar plates in polymer electrolyte membrane fuel cells. Mater. Chem. Phys. 2011, 126, 6–11. [Google Scholar] [CrossRef]

- Yang, L.H.; Qin, Z.L.; Pan, H.T.; Yun, H.; Min, Y.L.; Xu, Q.J. Corrosion Protection of 304 Stainless Steel Bipolar Plates of PEMFC by Coating SnO2 Film. Int. J. Electrochem. Sci. 2017, 12, 10946–10957. [Google Scholar] [CrossRef]

- Feng, K.; Kwok, D.T.K.; Liu, D.A.; Li, Z.G.; Cai, X.; Chu, P.K. Nitrogen plasma-implanted titanium as bipolar plates in polymer electrolyte membrane fuel cells. J. Power Source 2010, 195, 6798–6804. [Google Scholar] [CrossRef]

- Feng, K.; Wu, G.S.; Li, Z.G.; Cai, X.; Chu, P.K. Corrosion behavior of SS316L in simulated and accelerated PEMFC environments. Int. J. Hydrog. Energy 2011, 36, 13032–13042. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Ling, H.; Qiu, Y.; Lou, J.; Hou, X.; Bag, S.P.; Wang, J.; Wu, H.; Chai, G. Significant Enhancement of the Visible Light Photocatalytic Properties in 3D BiFeO(3)/Graphene Composites. Nanomaterials 2019, 9, 65. [Google Scholar] [CrossRef]

- Li, P.P.; Ding, X.A.; Yang, Z.Y.; Chen, M.; Wang, M.; Wang, X.D. Electrochemical synthesis and characterization of polyaniline-coated PEMFC metal bipolar plates with improved corrosion resistance. Ionics 2018, 24, 1129–1137. [Google Scholar] [CrossRef]

- Pan, T.J.; Zuo, X.W.; Wang, T.; Hu, J.; Chen, Z.D.; Ren, Y.J. Electrodeposited conductive polypyrrole/polyaniline composite film for the corrosion protection of copper bipolar plates in proton exchange membrane fuel cells. J. Power Sour. 2016, 302, 180–188. [Google Scholar] [CrossRef]

- Feng, K.; Cai, X.; Sun, H.L.; Li, Z.G.; Chu, P.K. Carbon coated stainless steel bipolar plates in polymer electrolyte membrane fuel cells. Diam. Relat. Mater. 2010, 19, 1354–1361. [Google Scholar] [CrossRef]

- Wu, M.; Lu, C.; Hong, T.; Chen, G.; Wen, D. Chromium interlayer amorphous carbon film for 304 stainless steel bipolar plate of proton exchange membrane fuel cell. Surf. Coat. Tech. 2016, 307, 374–381. [Google Scholar]

- Liu, A.P.; Liu, M.; Yu, J.C.; Qian, G.D.; Tang, W.H. Structural characteristics of surface-functionalized nitrogen-doped diamond-like carbon films and effective adjustment to cell attachment. Chin. Phys. 2015, 24. [Google Scholar] [CrossRef]

- Sharma, S.; Zhang, K.; Gupta, G.; Santamaria, D.G. Exploring PANI-TiN Nanoparticle Coatings in a PEFC Environment: Enhancing Corrosion Resistance and Conductivity of Stainless Steel Bipolar Plates. Energies 2017, 10, 1152. [Google Scholar] [CrossRef]

- Lin, K.J.; Li, X.Y.; Dong, H.S.; Du, S.F.; Lu, Y.X.; Ji, X.C.; Gu, D.D. Surface modification of 316 stainless steel with platinum for the application of bipolar plates in high performance proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2017, 42, 2338–2348. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Morita, T.; Nakata, K.; Yoshida, K.; Shiozawa, M. Behavior of water below the freezing point in PEFCs. J. Power Source 2007, 163, 708–712. [Google Scholar] [CrossRef]

- Jiao, K.; Alaefour, I.E.; Karimi, G.; Li, X.G. Cold start characteristics of proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2011, 36, 11832–11845. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

- Wu, H.P.; Zhu, K.; Cao, B.B.; Zhang, Z.; Wu, B.B.; Liang, L.H.; Chai, G.Z.; Liu, A.P. Smart design of wettability-patterned gradients on substrate-independent coated surfaces to control unidirectional spreading of droplets. Soft Matter 2017, 13, 2995–3002. [Google Scholar] [CrossRef]

- Kang, H.J.; Cheng, Z.J.; Lai, H.; Ma, H.X.; Liu, Y.Y.; Mai, X.M.; Wang, Y.S.; Shao, Q.; Xiang, L.C.; Guo, X.K.; et al. Superlyophobic anti-corrosive and self-cleaning titania robust mesh membrane with enhanced oil/water separation. Sep. Purif. Technol. 2018, 201, 193–204. [Google Scholar] [CrossRef]

- Cho, E.C.; Chang-Jian, C.W.; Chen, H.C.; Chuang, K.S.; Zheng, J.H.; Hsiao, Y.S.; Lee, K.C.; Huang, J.H. Robust multifunctional superhydrophobic coatings with enhanced water/oil separation, self-cleaning, anti-corrosion, and anti-biological adhesion. Chem. Eng. J. 2017, 314, 347–357. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, B.B.; Lu, C.D.; Wu, H.L.; Wu, H.P.; Jiang, S.F.; Chai, G.Z. A novel thermo-mechanical anti-icing/de-icing system using bi-stable laminate composite structures with superhydrophobic surface. Compos. Struct. 2017, 180, 933–943. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.N.; Huang, J.Y.; Tang, Y.X.; Li, S.H.; Ge, M.Z.; Chen, Z.; Zhang, K.Q.; Lai, Y.K. Understanding the Role of Dynamic Wettability for Condensate Microdrop Self-Propelling Based on Designed Superhydrophobic TiO2 Nanostructures. Small 2017, 13. [Google Scholar] [CrossRef]

- Selim, M.S.; Elmarakbi, A.; Azzam, A.M.; Shenashen, M.A.; EL-Saeed, A.M.; El-Safty, S.A. Eco-friendly design of superhydrophobic nano-magnetite/silicone composites for marine foul-release paints. Prog. Org. Coat. 2018, 116, 21–34. [Google Scholar] [CrossRef]

- Xuan, L.N.; Fu, Y.L.; Liu, Z.G.; Wei, P.L.; Wu, L.H. Hydrophobicity and Photocatalytic Activity of a Wood Surface Coated with a Fe3+-Doped SiO2/TiO2 Film. Materials 2018, 11, 2594. [Google Scholar] [CrossRef]

- Yongxin, W.; Al Shakhshir, S.; Xianguo, L.; Pu, C. Superhydrophobic flow channel surface and its impact on PEM fuel cell performance. Int. J. Low Carb. Technol. 2014, 9, 225–236. [Google Scholar] [CrossRef]

- Conde, J.J.; Ferreira-Aparicio, P.; Chaparro, A.M. Anti-corrosion coating for metal surfaces based on superhydrophobic electrosprayed carbon layers. Appl. Mater. Today 2018, 13, 100–106. [Google Scholar] [CrossRef]

- Shimpalee, S.; Lilavivat, V. Study of Water Droplet Removal on Etched-Metal Surfaces for Proton Exchange Membrane Fuel Cell Flow Channel. J. Electrochem. Energy Convers. Storage 2016, 13. [Google Scholar] [CrossRef]

- Balram, A.; Santhanagopalan, S.; Hao, B.Y.; Yap, Y.K.; Meng, D.D. Electrophoretically-Deposited Metal-Decorated CNT Nanoforests with High Thermal/Electric Conductivity and Wettability Tunable from Hydrophilic to Superhydrophobic. Adv. Funct. Mater. 2016, 26, 2571–2579. [Google Scholar] [CrossRef]

- Ogihara, H.; Xie, J.; Saji, T. Spraying carbon nanotube dispersions to prepare superhydrophobic films. J. Mater. Sci. 2014, 49, 3183–3188. [Google Scholar] [CrossRef]

- Lau, K.K.S.; Bico, J.; Teo, K.B.K.; Chhowalla, M.; Amaratunga, G.A.J.; Milne, W.I.; McKinley, G.H.; Gleason, K.K. Superhydrophobic carbon nanotube forests. Nano Lett. 2003, 3, 1701–1705. [Google Scholar] [CrossRef]

- Sethi, S.; Dhinojwala, A. Superhydrophobic Conductive Carbon Nanotube Coatings for Steel. Langmuir ACS J. Surf. Colloids 2009, 25, 4311–4313. [Google Scholar] [CrossRef]

- Talapatra, S.; Kar, S.; Pal, S.K.; Vajtai, R.; Ci, L.; Victor, P.; Shaijumon, M.M.; Kaur, S.; Nalamasu, O.; Ajayan, P.M. Direct growth of aligned carbon nanotubes on bulk metals. Nat. Nanotechnol. 2006, 1, 112–116. [Google Scholar] [CrossRef]

- Park, D.; Kim, Y.H.; Lee, J.K. Pretreatment of stainless steel substrate surface for the growth of carbon nanotubes by PECVD. J. Mater. Sci. 2003, 38, 4933–4939. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.L.; Jin, J.F.; Liu, J.A.; Yan, Y.Y.; Han, Z.W.; Ren, L.Q. Anti-icing property of bio-inspired micro-structure superhydrophobic surfaces and heat transfer model. Appl. Surf. Sci. 2017, 400, 498–505. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.L.; Sweikart, M.A.; Turner, J.A. Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J. Power Source 2003, 115, 243–251. [Google Scholar] [CrossRef]

- Turan, C.; Cora, O.N.; Koc, M. Investigation of the effects of process sequence on the contact resistance characteristics of coated metallic bipolar plates for polymer electrolyte membrane fuel cells. J. Power Source 2013, 243, 925–934. [Google Scholar] [CrossRef]

- Wang, Y.; Northwood, D.O. An investigation into TiN-coated 316L stainless steel as a bipolar plate material for PEM fuel cells. J. Power Source 2007, 165, 293–298. [Google Scholar] [CrossRef]

- Tawfik, H.; Hung, Y.; Mahajan, D. Metal bipolar plates for PEM fuel cell—A review. J. Power Source 2007, 163, 755–767. [Google Scholar] [CrossRef]

| Samples | Plasma Etching Time/min | Growth Pressure/mT | Growth Time/min | Growth Temperature/°C | |

|---|---|---|---|---|---|

| a | 0 | 214–256 | 20 | 6:14 | 700 |

| b | 5 | 223–263 | 20 | 6:14 | 700 |

| c | 10 | 198–236 | 20 | 6:14 | 700 |

| d | 20 | 226–269 | 20 | 6:14 | 700 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Shi, F.; Jin, J.; Peng, X. Study on the Properties of Vertical Carbon Nanotube Films Grown on Stainless Steel Bipolar Plates. Materials 2019, 12, 899. https://doi.org/10.3390/ma12060899

Lu C, Shi F, Jin J, Peng X. Study on the Properties of Vertical Carbon Nanotube Films Grown on Stainless Steel Bipolar Plates. Materials. 2019; 12(6):899. https://doi.org/10.3390/ma12060899

Chicago/Turabian StyleLu, Congda, Fengye Shi, Jing Jin, and Xiang Peng. 2019. "Study on the Properties of Vertical Carbon Nanotube Films Grown on Stainless Steel Bipolar Plates" Materials 12, no. 6: 899. https://doi.org/10.3390/ma12060899

APA StyleLu, C., Shi, F., Jin, J., & Peng, X. (2019). Study on the Properties of Vertical Carbon Nanotube Films Grown on Stainless Steel Bipolar Plates. Materials, 12(6), 899. https://doi.org/10.3390/ma12060899