Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing

Abstract

:1. Introduction

2. Materials and Method

3. Intelligent Optimization Algorithms

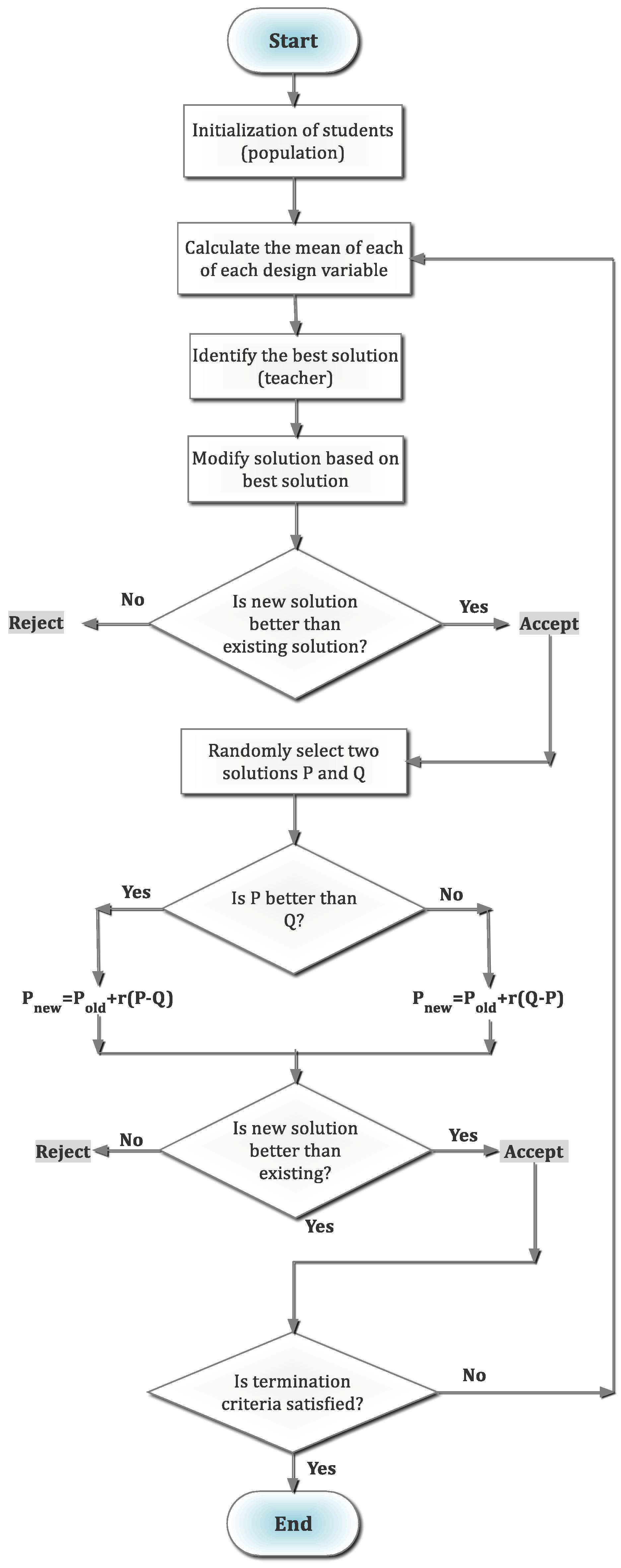

3.1. Teaching–Learning-Based Optimization (TLBO)

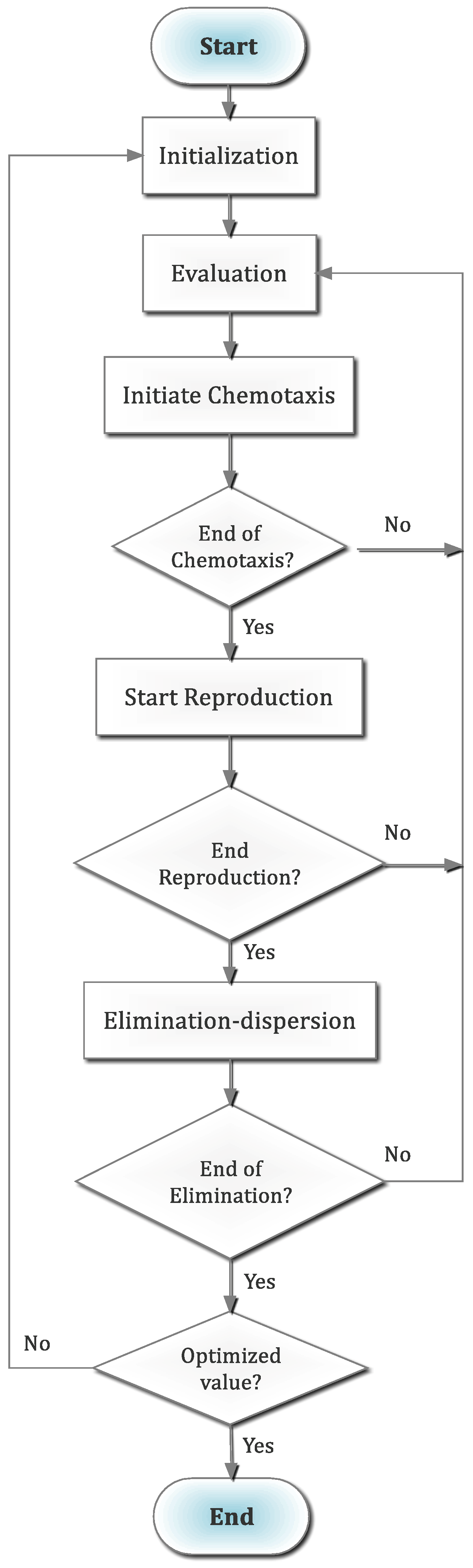

3.2. Bacteria Foraging Optimization (BFO)

4. Results and Discussion

4.1. Results

4.2. Optimization by TLBO and BFO

5. Conclusions

- Intelligent optimization is an important ingredient of smart manufacturing in which the learning capability of the method is required—which is present in both teaching–learning-based optimization and bacteria foraging optimization. Lack of implementation of these methods in hard turning motivated the current study, and eventually their successful implementation is shown here.

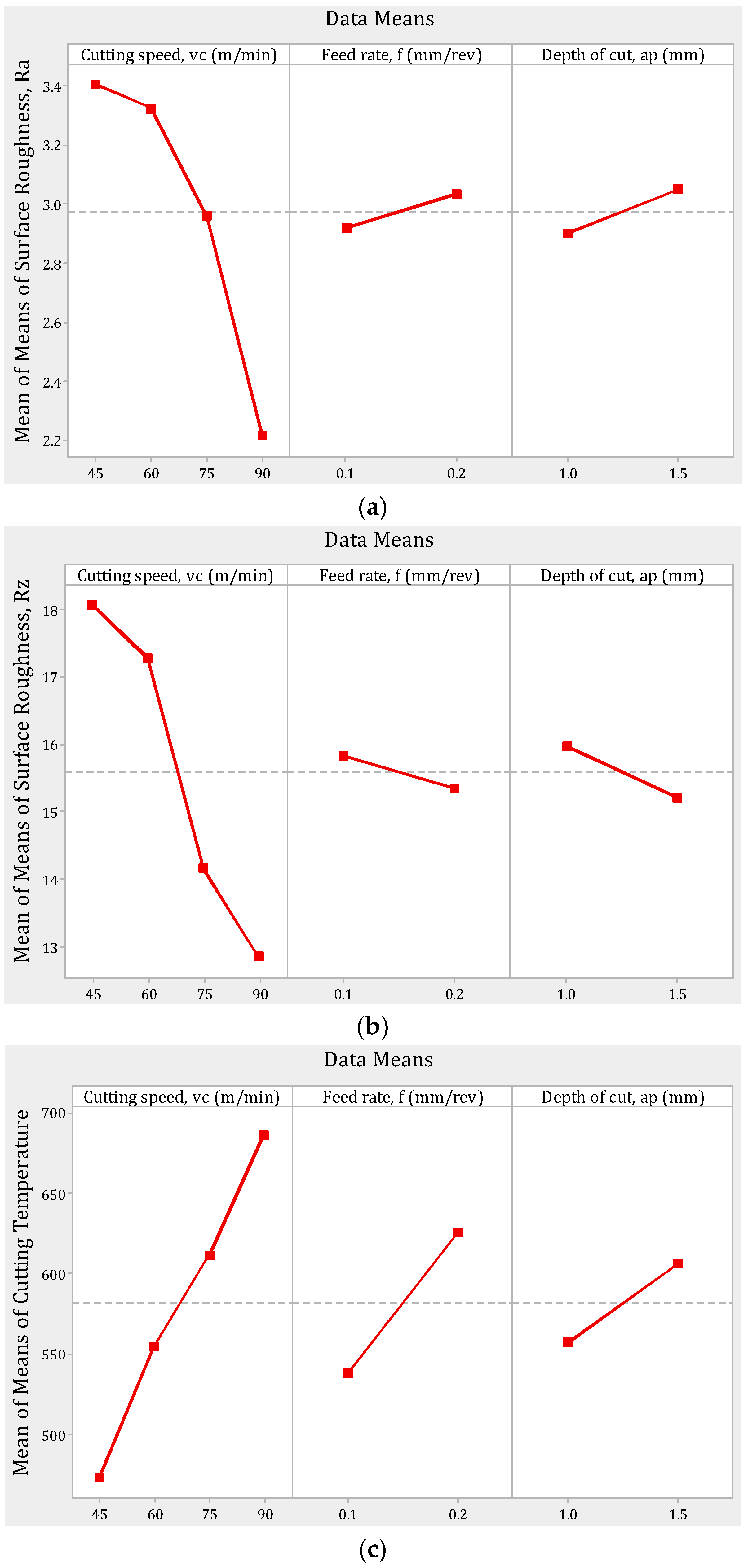

- The influences of cutting speed, feed rate, and cutting depth on the arithmetic mean deviation of surface roughness Ra, the maximum height of the profile of surface roughness Rz, and cutting temperature are investigated by portraying the main effects plot. It was found that the cutting speed played the most dominant role in defining the roughness parameter as well as the temperature. Moreover, an increase in cutting speed resulted in a decrease in the roughness values but an increase in the cutting temperature. This outcome necessitated a trade-off of factor values.

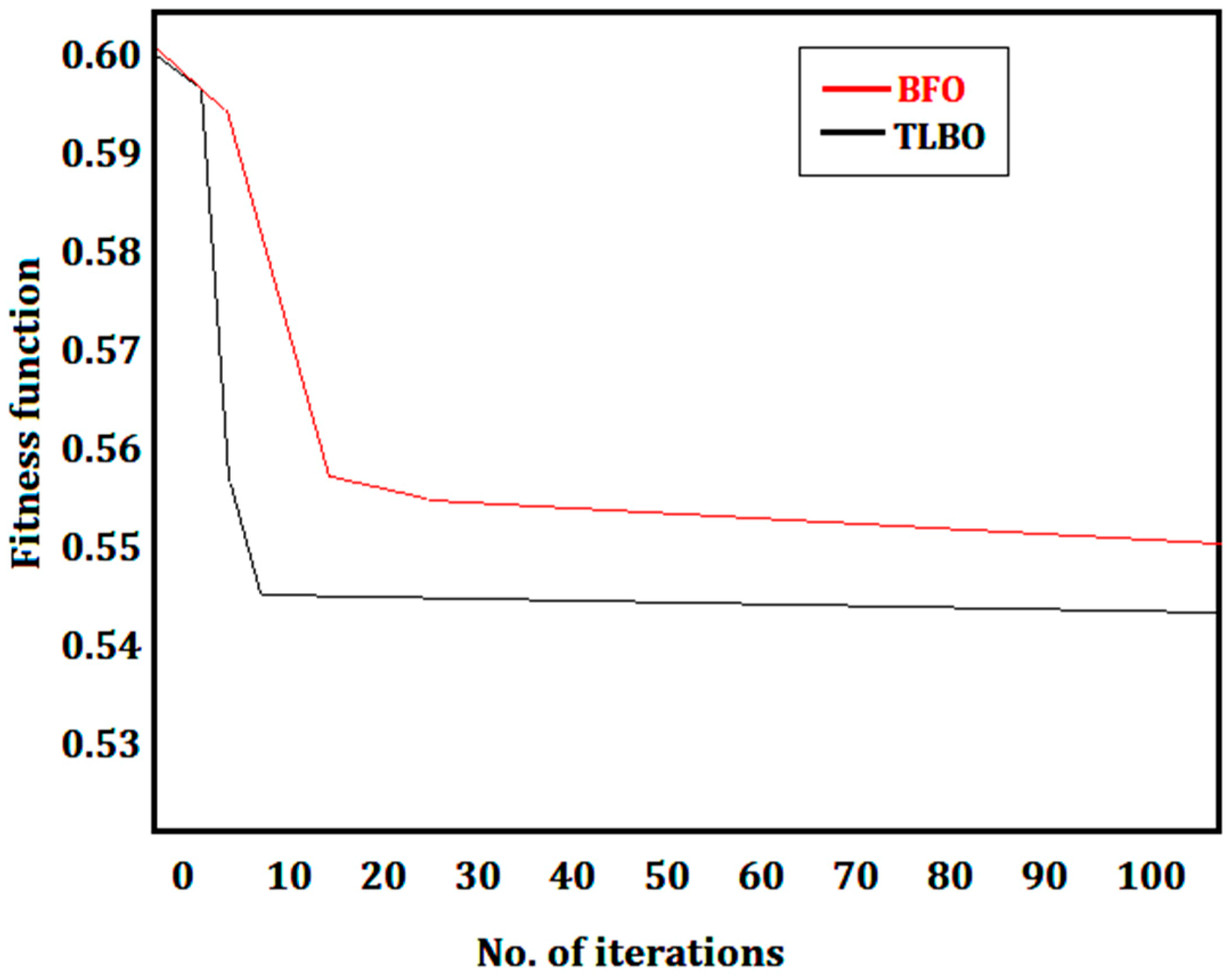

- Trade-off of the responses/factors was accomplished by employing the intelligent optimization method i.e., TLBO and BFO. Optimum results by the TLBO approach were a cutting speed of 80 m/min, feed rate of 0.13 mm/rev, and depth-of-cut of 1.5 mm; optimum parameter settings by BFO were a cutting speed of 70 m/min, feed rate of 0.10 mm/rev and depth-of-cut of 1.3 mm.

- The TLBO was found to be superior to the BFO in terms of better convergence and shorter time of computation—hence, the TLBO is recommended.

- Future research direction can be the adoption of evolutionary methods in the parametric optimization of additive manufacturing processes. Also, further research attention can be given to the integration of optimization methods with the real-time parameter optimization.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Patalas-Maliszewska, J.; Kłos, S. An intelligent system for core-competence identification for industry 4.0 based on research results from german and polish manufacturing companies. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Cham, Switzerland, 2017; pp. 131–139. [Google Scholar]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Kujawińska, A.; Diering, M.; Rogalewicz, M.; Żywicki, K.; Hetman, Ł. Soft modelling-based methodology of raw material waste estimation. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Cham, Switzerland, 2017; pp. 407–417. [Google Scholar]

- Araújo, A.F.; Varela, M.L.; Gomes, M.S.; Barreto, R.C.; Trojanowska, J. Development of an Intelligent and Automated System for Lean Industrial Production, Adding Maximum Productivity and Efficiency in the Production Process. In Advances in Manufacturing; Springer: Cham, Switzerland, 2018; pp. 131–140. [Google Scholar]

- Mia, M.; Dhar, N.R. Prediction and optimization by using SVR, RSM and GA in hard turning of tempered AISI 1060 steel under effective cooling condition. In Neural Computing and Applications; Springer: London, UK, 2017. [Google Scholar]

- Rao, R.V.; Savsani, V.J.; Vakharia, D. Teaching–learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput.-Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Rao, R.V.; Kalyankar, V. Experimental investigation on submerged arc welding of Cr–Mo–V steel. Int. J. Adv. Manuf. Technol. 2013, 69, 93–106. [Google Scholar] [CrossRef]

- Pawar, P.; Rao, R.V. Parameter optimization of machining processes using teaching–learning-based optimization algorithm. Int. J. Adv. Manuf. Technol. 2013, 67, 995–1006. [Google Scholar] [CrossRef]

- Rao, R.V.; Kalyankar, V. Parameter optimization of modern machining processes using teaching–learning-based optimization algorithm. Eng. Appl. Artif. Intell. 2013, 26, 524–531. [Google Scholar]

- Gupta, M.K.; Sood, P.K.; Sharma, V.S. Machining Parameters Optimization of Titanium Alloy using Response Surface Methodology and Particle Swarm Optimization under Minimum-Quantity Lubrication Environment. Mater. Manuf. Process. 2016, 31, 1671–1682. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Barman, K.T.; Sahoo, P.; Davim, P.J. Modeling and Optimization of Fractal Dimension in Wire Electrical Discharge Machining of EN 31 Steel Using the ANN-GA Approach. Materials 2019, 12, 454. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.E.; Lee, M.C. A Study on the Optimal Machining Parameters of the Induction Assisted Milling with Inconel 718. Materials 2019, 12, 233. [Google Scholar] [CrossRef] [PubMed]

- Matras, A.; Zębala, W.; Machno, M. Research and Method of Roughness Prediction of a Curvilinear Surface after Titanium Alloy Turning. Materials 2019, 12, 502. [Google Scholar] [CrossRef] [PubMed]

- Raju, M.; Gupta, M.K.; Bhanot, N.; Sharma, V.S. A hybrid PSO–BFO evolutionary algorithm for optimization of fused deposition modelling process parameters. J. Intell. Manuf. 2018, 1–16. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 88, 739–753. [Google Scholar] [CrossRef]

- Passino, K.M. Bacterial foraging optimization. Int. J. Swarm Intell. Res. 2010, 1, 1–16. [Google Scholar] [CrossRef]

- Astakhov, V.P. Machining of hard materials: Definitions and industrial applications. In Machining of Hard Materials; Davim, J.P., Ed.; Springer Science & Business Media: Berlin, Germany, 2011; pp. 1–32. [Google Scholar]

| Experiment Number | Cutting Speed, vc (m/min) | Feed Rate, f (mm/rev) | Depth of Cut, ap (mm) | Surface Roughness, Ra (µm) | Surface Roughness, Rz (µm) | Cutting Temperature, θ (°C) |

|---|---|---|---|---|---|---|

| 1 | 45 | 0.1 | 1.0 | 2.60 | 14.36 | 404 |

| 2 | 45 | 0.2 | 1.5 | 4.21 | 21.75 | 543 |

| 3 | 60 | 0.1 | 1.0 | 3.87 | 22.20 | 488 |

| 4 | 60 | 0.2 | 1.5 | 2.78 | 12.35 | 622 |

| 5 | 75 | 0.1 | 1.5 | 3.51 | 16.48 | 585 |

| 6 | 75 | 0.2 | 1.0 | 2.41 | 11.85 | 638 |

| 7 | 90 | 0.1 | 1.5 | 1.70 | 10.26 | 674 |

| 8 | 90 | 0.2 | 1.0 | 2.73 | 15.45 | 699 |

| Parameters | Values |

|---|---|

| Number of bacterial elements considered, S | 50 |

| Max defined chemotactic steps, Nc | 50 |

| Max defined reproduction steps, Nre | 4 |

| Total elimination–dispersal event, Ned | 2 |

| Max allowed swim steps, Ns | 4 |

| Elimination–dispersal probability, Ped | 0.1 |

| Parameters | TLBO | BFO |

|---|---|---|

| Cutting speed (m/min) | 80 | 75 |

| Feed rate (mm/rev) | 0.13 | 0.10 |

| Depth of cut (mm) | 1.5 | 1.3 |

| Best solution (minimum of Z) | 0.54326 | 0.55262 |

| Worst solution | 0.56592 | 0.57854 |

| Average time (s) | 4 s | 16 s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mia, M.; Królczyk, G.; Maruda, R.; Wojciechowski, S. Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing. Materials 2019, 12, 879. https://doi.org/10.3390/ma12060879

Mia M, Królczyk G, Maruda R, Wojciechowski S. Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing. Materials. 2019; 12(6):879. https://doi.org/10.3390/ma12060879

Chicago/Turabian StyleMia, Mozammel, Grzegorz Królczyk, Radosław Maruda, and Szymon Wojciechowski. 2019. "Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing" Materials 12, no. 6: 879. https://doi.org/10.3390/ma12060879

APA StyleMia, M., Królczyk, G., Maruda, R., & Wojciechowski, S. (2019). Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing. Materials, 12(6), 879. https://doi.org/10.3390/ma12060879