Instrumented Indentation of Super-Insulating Silica Compacts

Abstract

1. Introduction

2. Materials and Methods

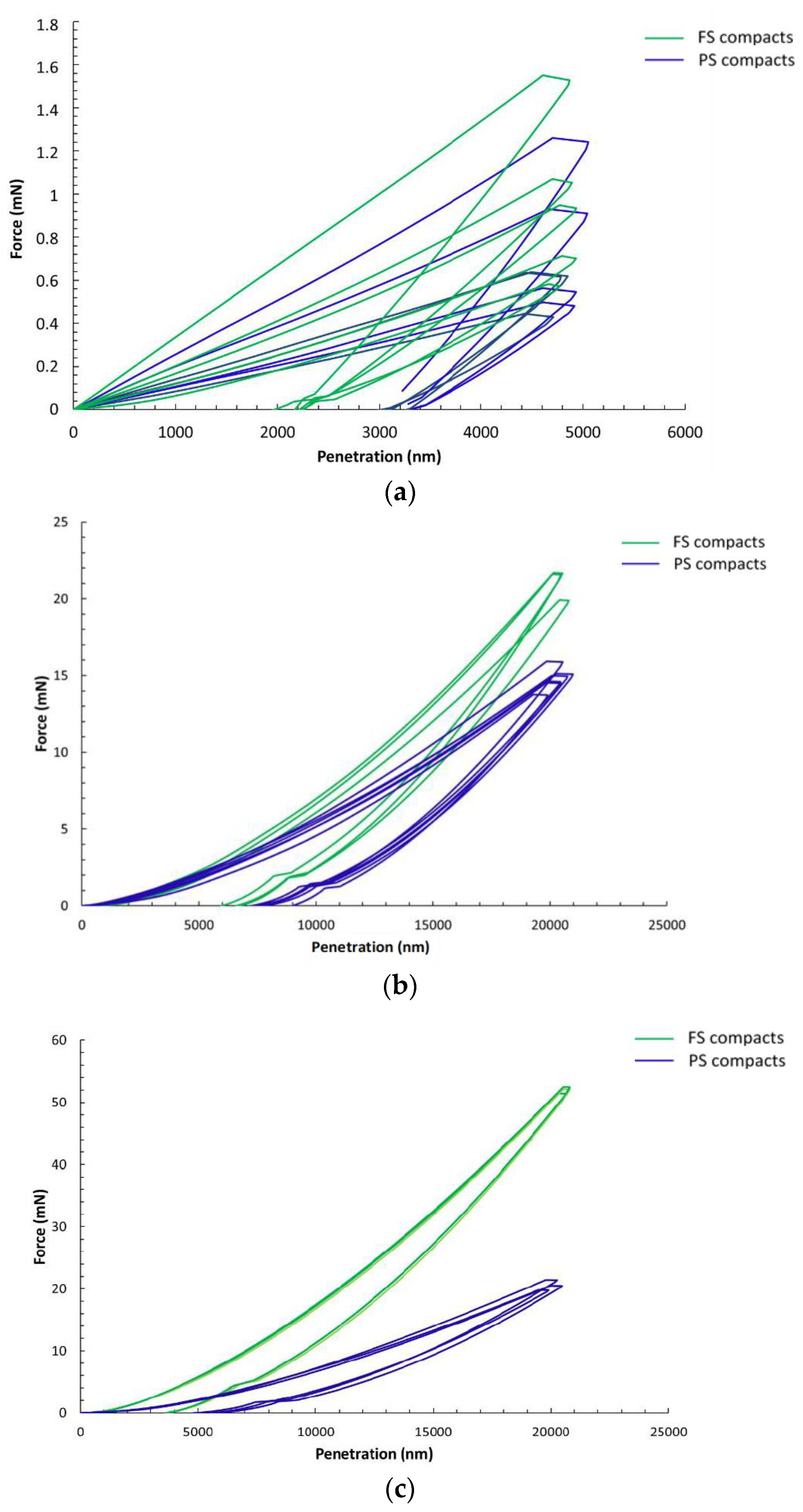

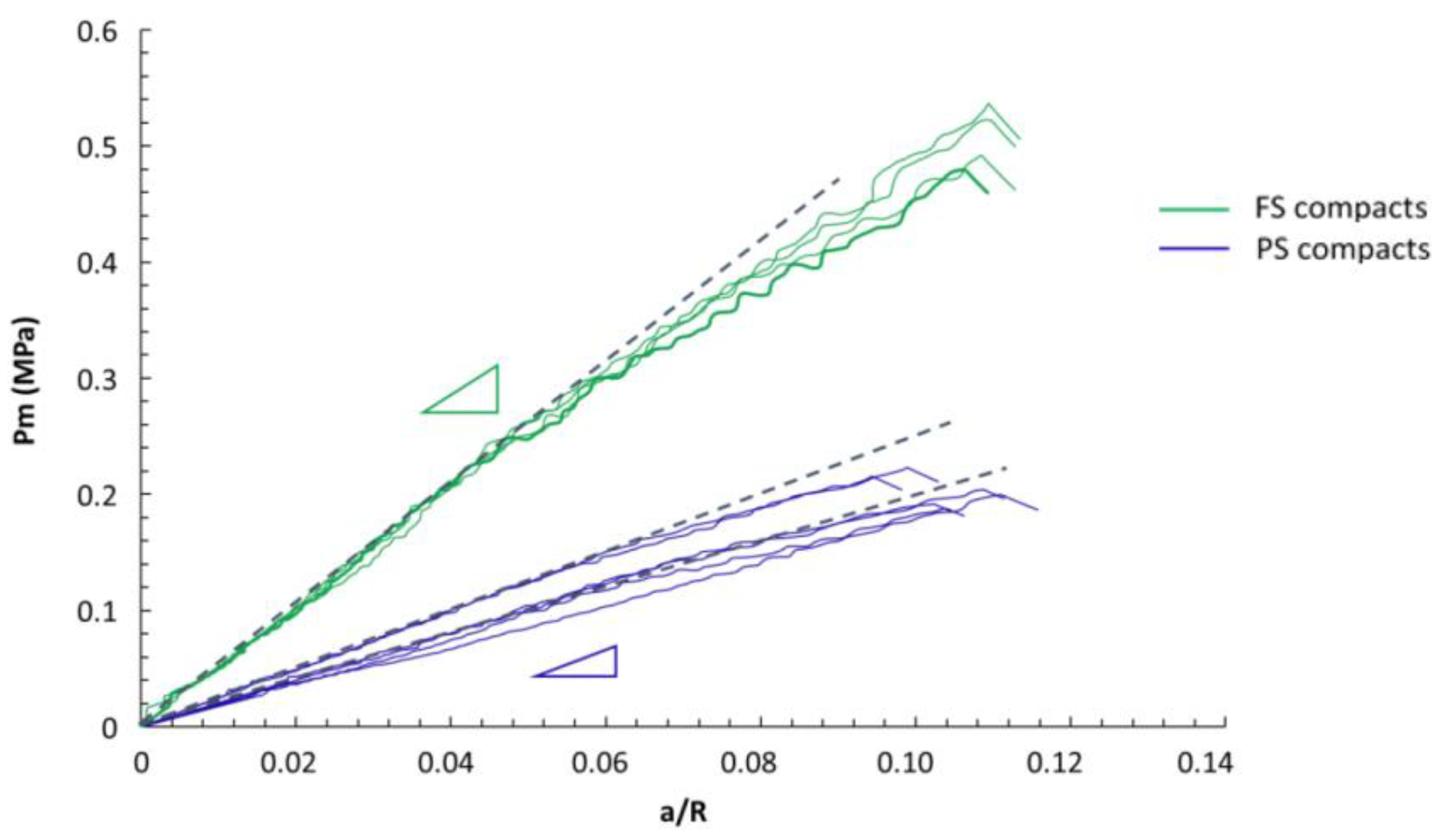

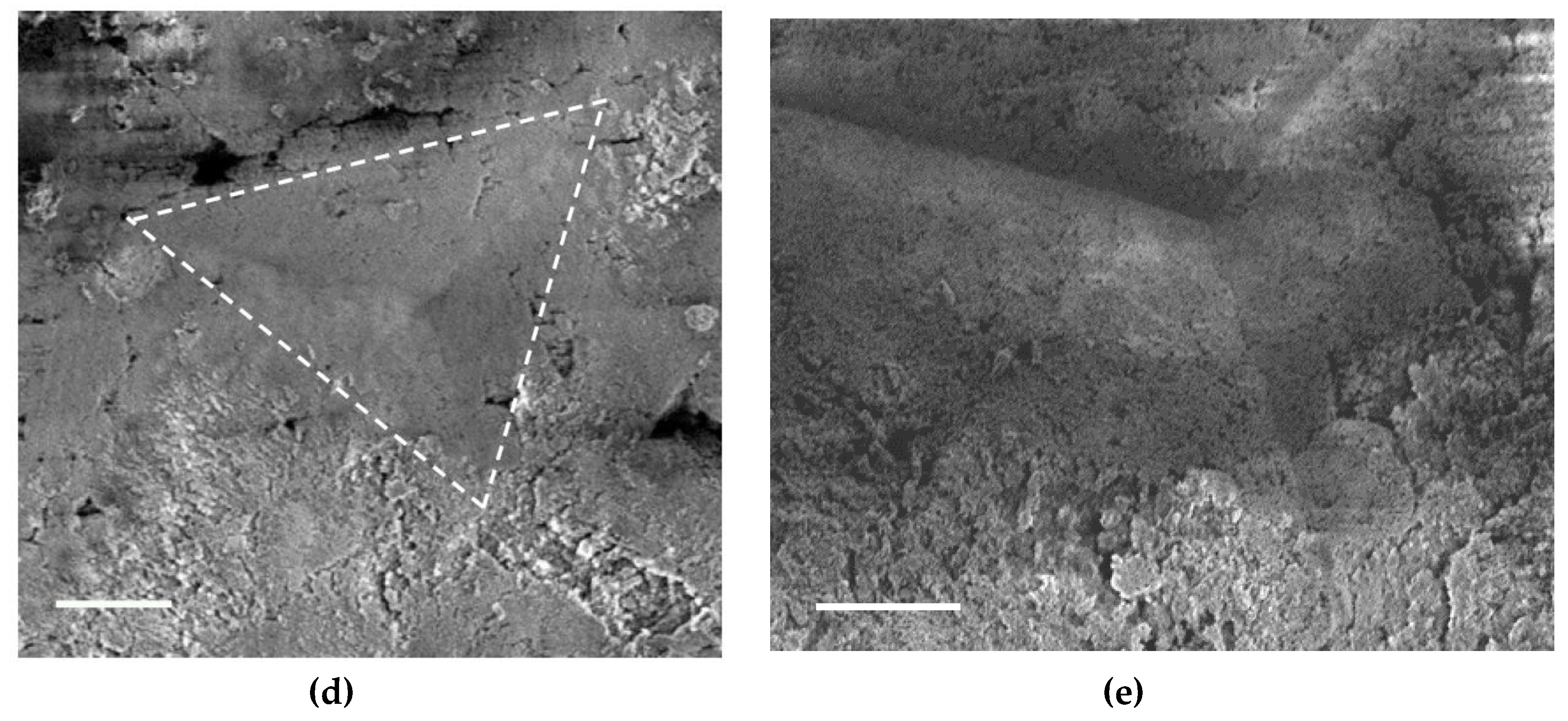

3. Results

4. Discussion

4.1. Porous Silica Compacts, A Peculiar Material

4.2. Influence of the Tip Geometry

4.3. Comparison between Fumed and Precipitated Silica

4.4. Comparison with Other Porous Silica Samples and Silica Aerogels

4.5. Final Remarks, Outlook

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bosseboeuf, D. Energy Efficiency Trends and Policies in the Household and Tertiary Sectors. 2015, p. 97. Available online: http://www.odyssee-mure.eu/publications/br/energy-efficiency-trends-policies-buildings.pdf (accessed on 11 March 2019).

- Intergovernmental Panel on Climate Change. Summary for policymakers. In Climate Change 2014 Mitigation of Climate Change; Cambridge University Press: Cambridge, UK, 2015; pp. 1–30. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Thue, J.; Tenpierik, M.J.; Grynning, S.; Uvsløkk, S.; Gustavsen, A. Vacuum insulation panels for building applications: A review and beyond. Energy Build. 2010, 42, 147–172. [Google Scholar] [CrossRef]

- Quenard, S.H.D. Micro-nano porous materials for high performance thermal insulation. In Proceedings of the 2nd International Symposium on Nanotechnology in Construction, Bilbao, Spain, 13–16 November 2005. [Google Scholar]

- Chal, B.; Yrieix, B.; Roiban, L.; Masenelli-Varlot, K.; Chenal, J.-M.; Foray, G. Nanostructured silica used in super-insulation materials (SIM), hygrothermal ageing followed by sorption characterizations. Energy Build. 2019, 183, 626–638. [Google Scholar] [CrossRef]

- Caps, R.; Fricke, J. Thermal Conductivity of Opacified Powder Filler Materials for Vacuum Insulations1. Int. J. Thermophys. 2000, 21, 445–452. [Google Scholar] [CrossRef]

- Simmler, H.; Heinemann, U.; Kumaran, K.; Brunner, S. Vacuum Insulation Panels: Study on VIP-Components and Panels for Service Life Prediction of VIP in Building Applications Subtask A. Available online: http://www.iea-ebc.org/Data/publications/EBC_Annex_39_Report_Subtask-A.pdf (accessed on 11 March 2019).

- Baeza, G.P.; Genix, A.-C.; Paupy-Peyronnet, N.; Degrandcourt, C.; Couty, M.; Oberdisse, J. Revealing nanocomposite filler structures by swelling and small-angle X-ray scattering. Faraday Discuss. 2016, 186, 295–309. [Google Scholar] [CrossRef] [PubMed]

- Baeza, G.P.; Genix, A.-C.; Degrandcourt, C.; Petitjean, L.; Gummel, J.; Couty, M.; Oberdisse, J. Multiscale Filler Structure in Simplified Industrial Nanocomposite Silica/SBR Systems Studied by SAXS and TEM. Macromolecules 2013, 46, 317–329. [Google Scholar] [CrossRef]

- Roiban, L.; Foray, G.; Rong, Q.; Perret, A.; Ihiawakrim, D.; Masenelli-Varlot, K.; Mairea, E.; Yrieixb, B. Advanced three dimensional characterization of silica-based ultraporous materials. RSC Adv. 2016, 6, 10625–10632. [Google Scholar] [CrossRef]

- Benane, B.; Baeza, G.P.; Chal, B.; Roiban, L.; Meille, S.; Olagnon, C.; Yrieix, B.; Foray, G. Multiscale Structure of Super Insulation Nano-Fumed Silicas Studied by SAXS, Tomography and Porosimetry. Acta Mater. 2019, 168, 401–410. [Google Scholar] [CrossRef]

- Meille, S.; Garboczi, E.J. Linear elastic properties of 2D and 3D models of porous materials made from elongated objects. Model. Simul. Mater. Sci. Eng. 2001, 9, 371. [Google Scholar] [CrossRef]

- Meille, S.; Lombardi, M.; Chevalier, J.; Montanaro, L. Mechanical properties of porous ceramics in compression: On the transition between elastic, brittle, and cellular behavior. J. Eur. Ceram. Soc. 2012, 32, 3959–3967. [Google Scholar] [CrossRef]

- Deville, S.; Meille, S.; Seuba, J. A meta-analysis of the mechanical properties of ice-templated ceramics and metals. Sci. Technol. Adv. Mater. 2015, 16, 043501. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Atkinson, A.; Brandon, N. Spherical indentation of porous ceramics: Elasticity and hardness. J. Eur. Ceram. Soc. 2016, 36, 1435–1445. [Google Scholar] [CrossRef]

- Johnson, A.J.W.; Herschler, B.A. A review of the mechanical behavior of CaP and CaP/polymer composites for applications in bone replacement and repair. Acta Biomater. 2011, 7, 16–30. [Google Scholar] [CrossRef]

- Gonzenbach, U.; Studart, A.R. Macroporous Ceramics from Particle-Stabilized Wet Foams. J. Am. Ceram. Soc. 2007, 90, 16–22. [Google Scholar] [CrossRef]

- Pecqueux, F.; Tancret, F.; Payraudeau, N.; Bouler, J.M. Influence of microporosity and macroporosity on the mechanical properties of biphasic calcium phosphate bioceramics: Modelling and experiment. J. Eur. Ceram. Soc. 2010, 30, 819–829. [Google Scholar] [CrossRef]

- Sanahuja, J.; Dormieux, L.; Meille, S.; Hellmich, C.; Fritsch, A. Micromechanical explanation of elasticity and strength of gypsum: From elongated anisotropic crystals to isotropic porous polycrystals. J. Eng. Mech. 2010, 136. [Google Scholar] [CrossRef]

- Moner-Girona, M.; Roig, A.; Molins, E. Micromechanical properties of silica aerogels. Appl. Phys. Lett. 1999, 75, 653. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Hamza, A.V.; Satcher, J.H.; Worsley, M.A. Depth-sensing indentation of low-density brittle nanoporous solids. Acta Mater. 2009, 57, 3472–3480. [Google Scholar] [CrossRef]

- Alaoui, A.H.; Woignier, T.; Scherer, G.W.; Phalippou, J. Comparison between flexural and uniaxial compression tests to measure the elastic modulus of silica aerogel. J. Non-Cryst. Solids 2008, 354, 4556–4561. [Google Scholar] [CrossRef]

- Woignier, T.; Primera, J.; Alaoui, A.; Etienne, P.; Despestis, F.; Calas-Etienne, S. Mechanical Properties and Brittle Behavior of Silica Aerogels. Gels 2015, 1, 256–275. [Google Scholar] [CrossRef]

- Tillotson, T.M.; Hrubesh, L.W. Transparent ultralow-density silica aerogels prepared by a two-step sol-gel process. J. Non-Cryst. Solids 1992, 145, 44–50. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Stadermann, M.; Shin, S.J.; Satcher, J.H., Jr.; Gammon, S.A.; Letts, S.A.; van Buuren, T.; Hamza, A.V. Super-compressibility of ultralow-density nanoporous silica. Adv. Mater. 2012, 24, 776–780. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Lord, K.A.; Hamza, A.V. Room-temperature creep of nanoporous silica. J. Mater. Res. 2011, 26, 781–784. [Google Scholar] [CrossRef]

- Hentzschel, C.M.; Alnaief, M.; Smirnova, I.; Sakmann, A.; Leopold, C.S. Tableting properties of silica aerogel and other silicates. Drug Dev. Ind. Pharm. 2012, 38, 462–467. [Google Scholar] [CrossRef]

- Clément, P.; Meille, S.; Chevalier, J.; Olagnon, C. Mechanical characterization of highly porous inorganic solids materials by instrumented micro-indentation. Acta Mater. 2013, 61, 6649–6660. [Google Scholar] [CrossRef]

- Staub, D.; Meille, S.; Le Corre, V.; Rouleau, L.; Chevalier, J. Identification of a damage criterion of a highly porous alumina ceramic. Acta Mater. 2016, 107, 261–272. [Google Scholar] [CrossRef]

- Gallo, M.; Tadier, S.; Meille, S.; Gremillard, L.; Chevalier, J. The in vitro evolution of resorbable brushite cements: A physico-chemical, micro-structural and mechanical study. Acta Biomater. 2017, 53, 515–525. [Google Scholar] [CrossRef]

- Pathak, S.; Kalidindi, S.R. Spherical nanoindentation stress-strain curves. Mater. Sci. Eng. R Rep. 2015, 91, 1–36. [Google Scholar] [CrossRef]

- Bala, Y.; Depalle, B.; Douillard, T.; Meille, S.; Clément, P.; Follet, H.; Chevalier, J.; Boivin, G. Respective roles of organic and mineral components of human cortical bone matrix in micromechanical behavior: An instrumented indentation study. J. Mech. Behav. Biomed. Mater. 2011, 4, 7. [Google Scholar] [CrossRef]

- Moseson, A.J.; Basu, S.; Barsoum, M.W. Determination of the effective zero point of contact for spherical nanoindentation. J. Mater. Res. 2008, 23, 204–209. [Google Scholar] [CrossRef]

- Flamant, Q.; Caravaca, C.; Meille, S.; Gremillard, L.; Chevalier, J.; Biotteau-Deheuvels, K.; Kuntz, M.; Chandrawati, R.; Herrmann, I.K.; Spicer, C.D.; et al. Selective etching of injection molded zirconia-toughened alumina: Towards osseointegrated and antibacterial ceramic implants. Acta Biomater. 2016, 46, 308–322. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Lawn, B.R. Indentation of Ceramics with Spheres: A Century after Hertz. J. Am. Ceram. Soc. 1998, 81, 1977–1994. [Google Scholar] [CrossRef]

- Benane, B. Mechanics of Compacted Silica for Use as VIP (Vacuum Insulation Panels) Core Material; INSA Lyon: Villeurbanne, France, 2018. [Google Scholar]

- Chen, Z.; Wang, X.; Atkinson, A.; Brandon, N. Spherical indentation of porous ceramics: Cracking and toughness. J. Eur. Ceram. Soc. 2016, 36, 3473–3480. [Google Scholar] [CrossRef]

- Schwiedrzik, J.J.; Zysset, P.K. The influence of yield surface shape and damage in the depth-dependent response of bone tissue to nanoindentation using spherical and Berkovich indenters. Comput. Methods Biomech. Biomed. Eng. 2013, 18, 492–505. [Google Scholar] [CrossRef]

- Colombo, P. Materials Science: In Praise of Pores. Science 2008, 322, 381–383. [Google Scholar] [CrossRef]

- Garboczi, E.J.; Snyder, K.A.; Douglas, J.F.; Thorpe, M.F. Geometrical percolation threshold of overlapping ellipsoids. Phys. Rev. E 1995, 52, 819–828. [Google Scholar] [CrossRef]

- Toivola, Y.; Stein, A.; Cook, R.F. Depth-sensing indentation response of ordered silica foam. J. Mater. Res. 2004, 19, 260–271. [Google Scholar] [CrossRef]

- Guesnet, E.; Dendievel, R.; Jauffrès, D.; Martin, C.L.; Yrieix, B. A growth model for the generation of particle aggregates with tunable fractal dimension. Phys. A Stat. Mech. Appl. 2019, 513, 63–73. [Google Scholar] [CrossRef]

- Gonçalves, W.; Amodeo, J.; Morthomas, J.; Chantrenne, P.; Perez, M.; Foray, G.; Martin, C.L. Nanocompression of secondary particles of silica aerogel. Scr. Mater. 2018, 157, 157–161. [Google Scholar] [CrossRef]

- Kermouche, G.; Barthel, E.; Vandembroucq, D.; Dubujet, P. Mechanical modelling of indentation-induced densification in amorphous silica. Acta Mater. 2008, 56, 3222–3228. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Brandon, N.; Atkinson, A. Analysis of spherical indentation of porous ceramic films. J. Eur. Ceram. Soc. 2016, 37, 1031–1038. [Google Scholar] [CrossRef]

- Hamdi, B.; Gottschalk-Gaudig, T.; Balard, H.; Brendlé, E.; Nedjari, N.; Donnet, J.-B. Ageing process of some pyrogenic silica samples exposed to controlled relative humidities: Part I: Kinetic of water sorption and evolution of the surface silanol density. Colloids Surf. A Physicochem. Eng. Asp. 2016, 491, 62–69. [Google Scholar] [CrossRef]

- Morel, B.; Autissier, L.; Autissier, D.; Lemordant, D.; Yrieix, B.; Quenard, D. Pyrogenic silica ageing under humid atmosphere. Powder Technol. 2009, 190, 225–229. [Google Scholar] [CrossRef]

- Yrieix, B.; Morel, B.; Pons, E. VIP service life assessment: Interactions between barrier laminates and core material, and significance of silica core ageing. Energy Build. 2014, 85, 617–630. [Google Scholar] [CrossRef]

| Silica | Solid Fraction | Specific Surface | Skeletal Density | Apparent Density | Water Uptake (wt %) |

|---|---|---|---|---|---|

| % | g/m2 | kg/m3 | kg/m3 | 24 °C 45% RH | |

| FS | 9.9 | 187 15 | 2200 | 218 2 | 0.5 0.1 |

| PS | 9.4 | 207 20 | 2100 | 198 2 | 6.0 0.4 |

| E (MPa) | Sphere | Berkovich | |||||

|---|---|---|---|---|---|---|---|

| D2000 | D600 | ||||||

| CSM | OP | Hertz | CSM | OP | Hertz | CSM | |

| FS | 11.8 0.6 | 12.6 0.6 | 12.3 1.0 | 10.0 0.6 | 10.7 0.6 | 10.6 1.0 | 21 10 |

| PS | 5.5 0.4 | 6.1 0.4 | 5.7 1.0 | 8.2 0.3 | 9.1 0.3 | 7.1 1.0 | 24 10 |

| Property | Sample | Sphere | Berkovich | |

|---|---|---|---|---|

| D2000 | D600 | |||

| E (MPa) | FS | 11.8 0.6 | 10.0 0.6 | 21 10 |

| PS | 5.5 0.4 | 8.2 0.3 | 24 10 | |

| H (MPa) | FS | 0.35 0.01 | 0.35 0.02 | 5.2 2.4 |

| PS | 0.15 0.01 | 0.25 0.02 | 3.8 1.8 | |

| We/Wtot | FS | 0.77 0.02 | 0.65 0.03 | 0.45 0.08 |

| PS | 0.65 0.02 | 0.55 0.03 | 0.33 0.06 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benane, B.; Meille, S.; Foray, G.; Yrieix, B.; Olagnon, C. Instrumented Indentation of Super-Insulating Silica Compacts. Materials 2019, 12, 830. https://doi.org/10.3390/ma12050830

Benane B, Meille S, Foray G, Yrieix B, Olagnon C. Instrumented Indentation of Super-Insulating Silica Compacts. Materials. 2019; 12(5):830. https://doi.org/10.3390/ma12050830

Chicago/Turabian StyleBenane, Belynda, Sylvain Meille, Geneviève Foray, Bernard Yrieix, and Christian Olagnon. 2019. "Instrumented Indentation of Super-Insulating Silica Compacts" Materials 12, no. 5: 830. https://doi.org/10.3390/ma12050830

APA StyleBenane, B., Meille, S., Foray, G., Yrieix, B., & Olagnon, C. (2019). Instrumented Indentation of Super-Insulating Silica Compacts. Materials, 12(5), 830. https://doi.org/10.3390/ma12050830