Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production

Abstract

1. Introduction

- Achieving a uniform and homogeneous composition

- Producing complex geometries

- Low level of machinability (high elastic and abrasive nature of Ni-Ti)

- Purchasing of good Ni-Ti powder quality (free of oxides and inclusions)

- Provision of inert atmosphere (to avoid oxidation)

- Avoiding impurities (affects transformation temperatures, and crack propagation)

- Avoiding flaws and undesired porosity (reduces load, initiates crack nucleation/propagation)

1.1. Additive Manufacturing of Nitinol

1.2. Current Work

2. Materials and Methods

2.1. Effect of Operation Parameters

2.1.1. Process Parameters

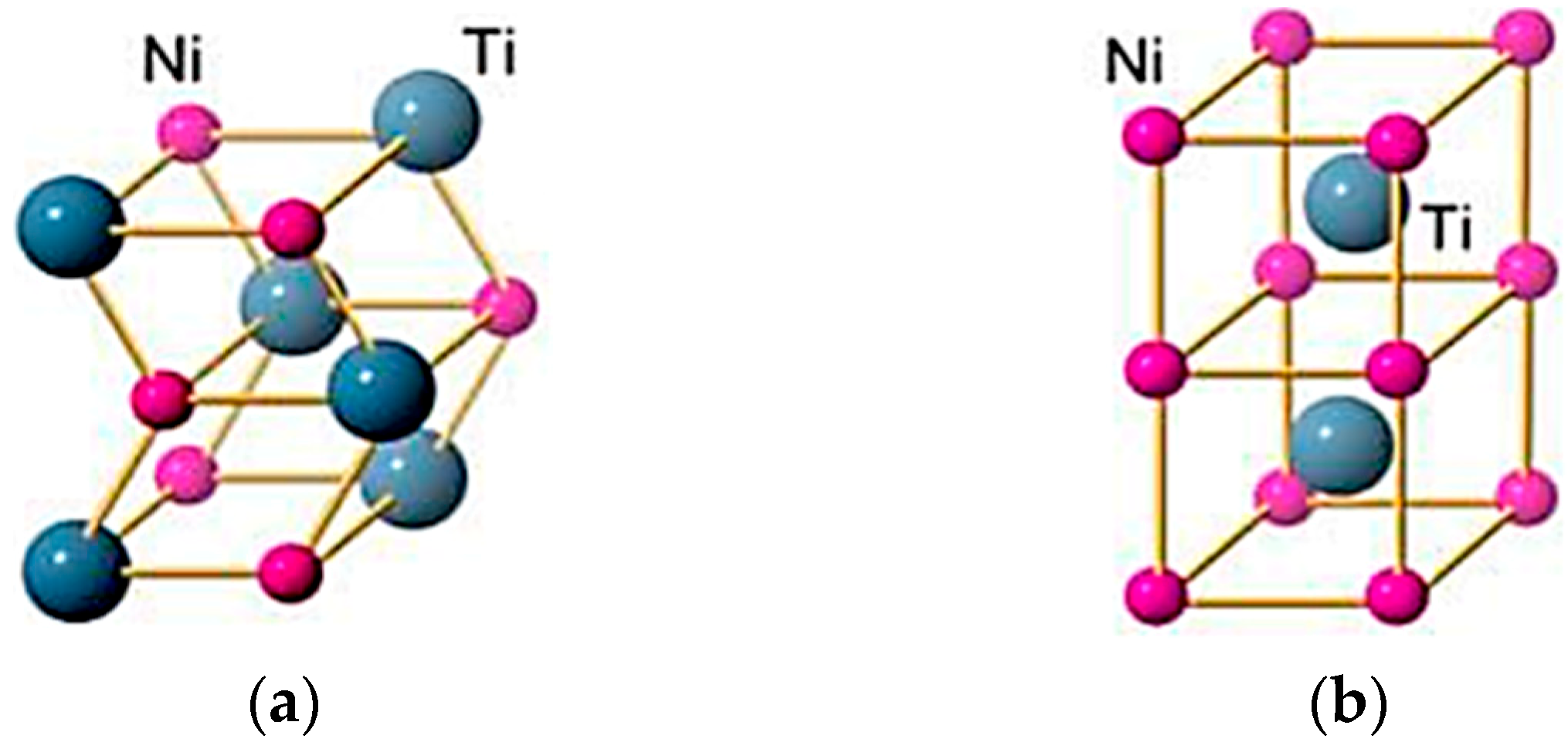

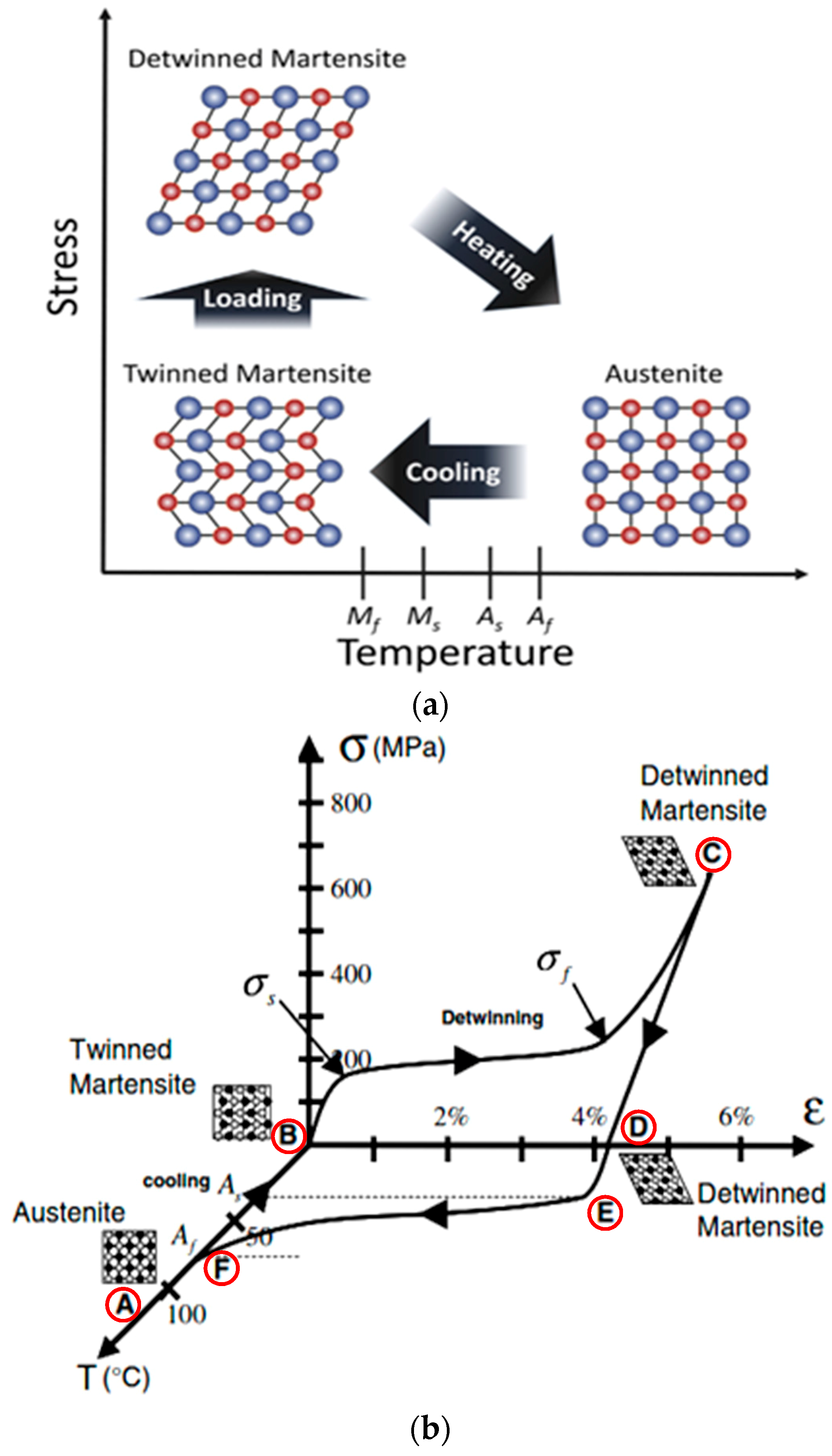

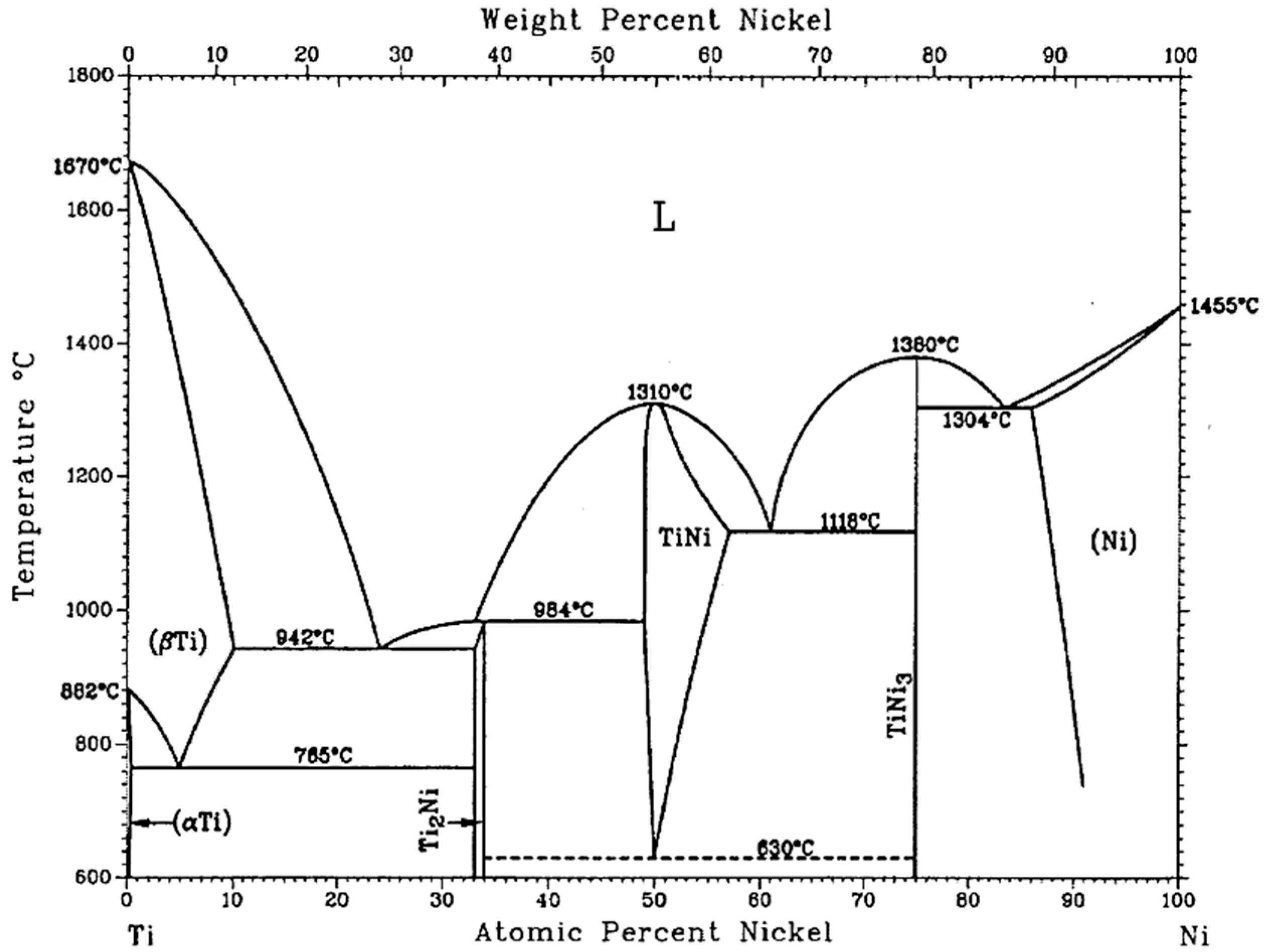

2.1.2. Phases and Crystal Structures of Nitinol

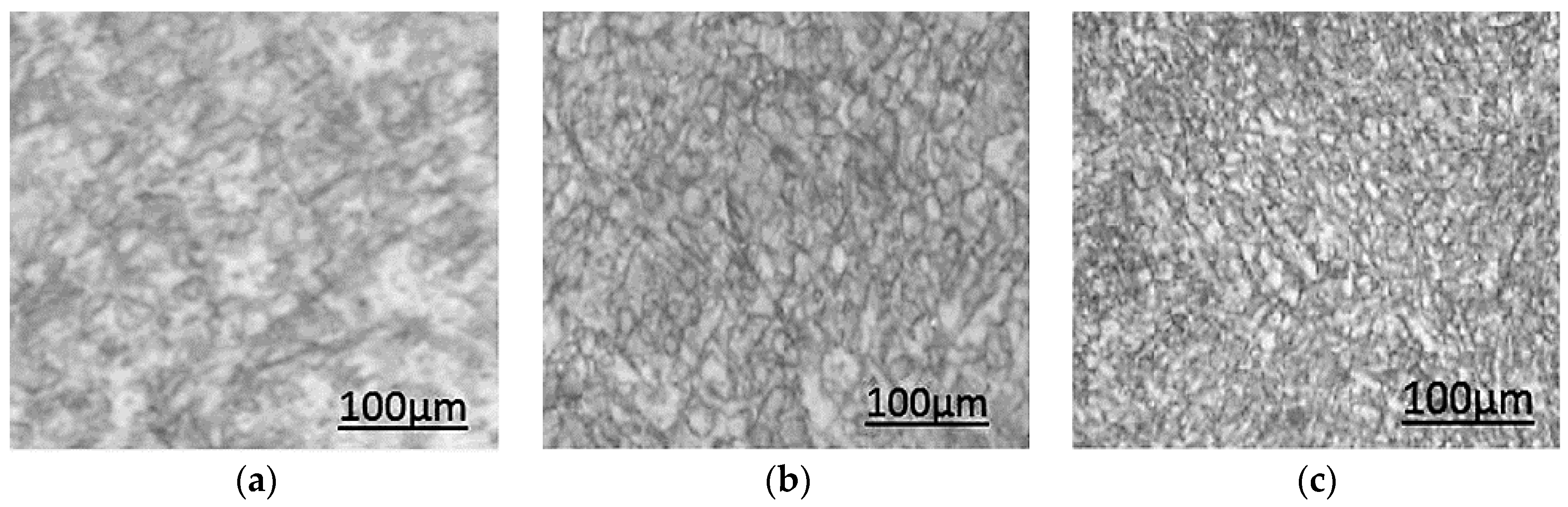

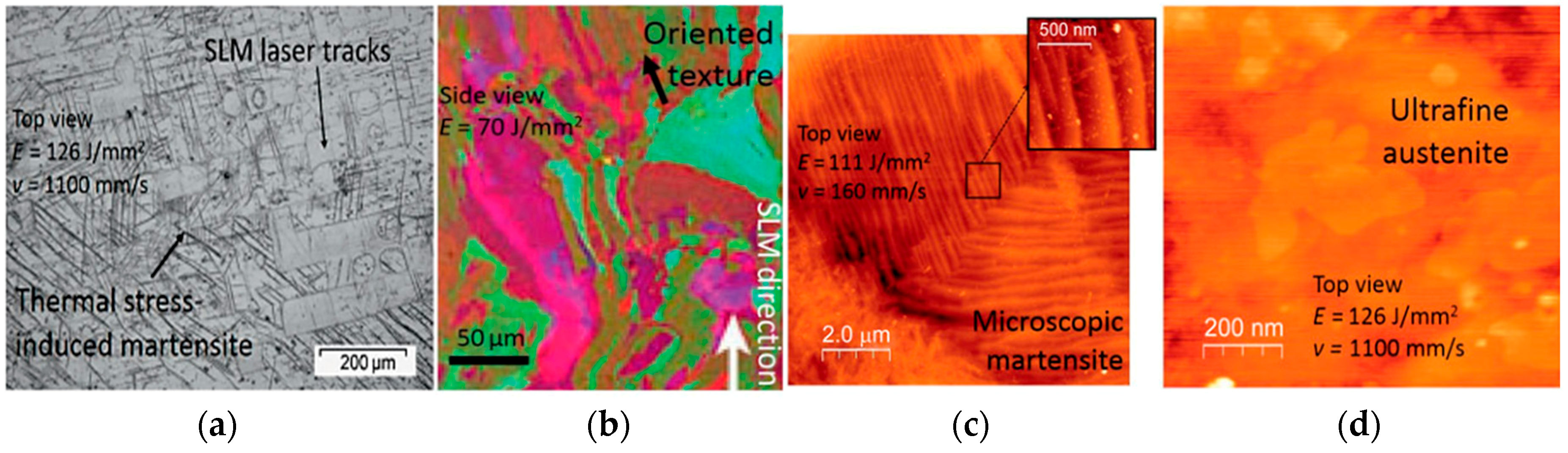

2.1.3. Metal AM Parameter Setting Effect on Microstructure

2.1.4. Effect on Transformation Temperatures

2.1.5. Effect on Corrosion Properties

2.2. Powder and Material Composition

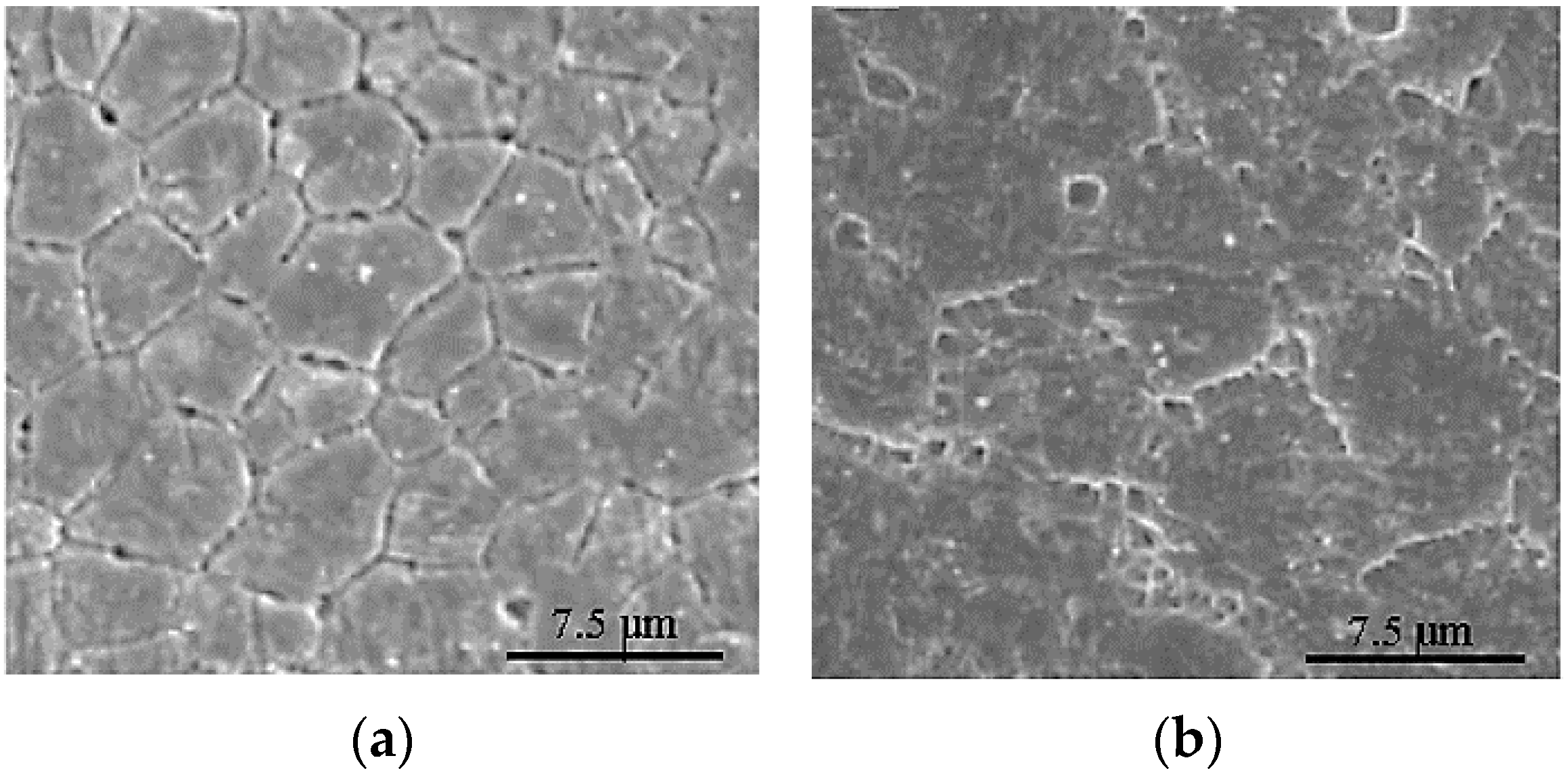

2.2.1. Effect on Microstructure

2.2.2. Effect on Transformation Temperatures

2.3. Heat Treatment Processes

2.3.1. Effect on Phase Transformations

2.3.2. Effect on Mechanical Properties

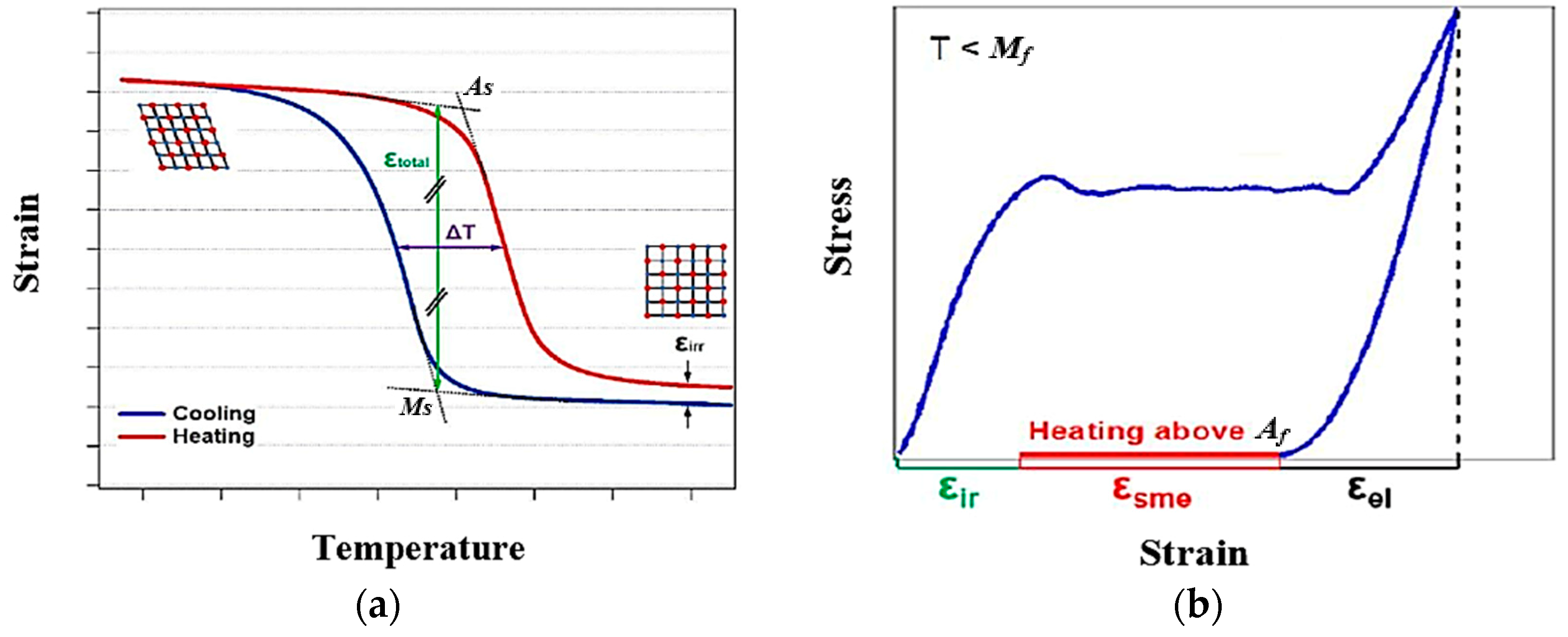

2.4. Challenges in Producing Shape Memory Effect

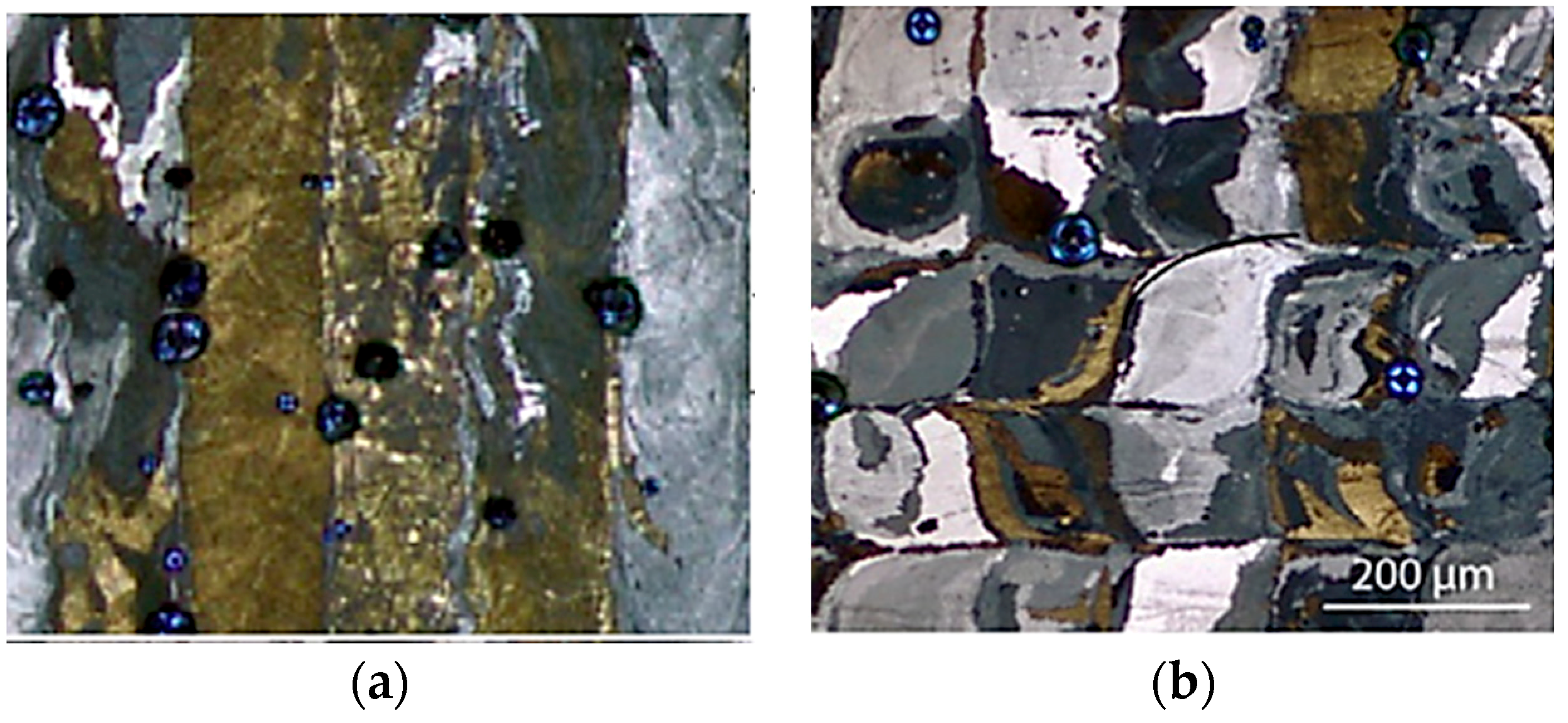

2.5. Defects in Fabricated Parts

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dadbakhsh, S.; Speirs, M.; van Humbeeck, J.; Kruth, J.P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P.; Stöver, D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Saedi, S. Shape Memory Behavior of Dense and Porous NiTi Alloys Fabricated by Selective Laser Melting. Ph.D. Thesis, University of Kentucky, Lexington, KT, USA, 2017. [Google Scholar]

- Jackson, C.M.; Wagner, H.J.; Wasilewski, R.J. 55 Nitinol—The Alloy with a Memory: Its Physical Metallurgy, Properties, and Applications; NASA SP-5110; NASA: Washington, DC, USA, 1972.

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Walker, J.M.; Haberland, C.; Andani, M.T.; Karaca, H.E.; Dean, D.; Elahinia, M. Process development and characterization of additively manufactured nickel-titanium shape memory parts. J. Intell. Mater. Syst. Struct. 2016, 27, 2653–2660. [Google Scholar] [CrossRef]

- Khanlari, K.; Ramezani, M.; Kelly, P. 60NiTi: A review of recent research findings, potential for structural and mechanical applications, and areas of continued investigations. Trans. Indian Inst. Met. 2018, 71, 781–799. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2018, 327, 128–151. [Google Scholar] [CrossRef]

- Baran, A.; Polanski, M. Microstructure and properties of LENS (laser engineered net shaping) manufactured Ni-Ti shape memory alloy. J. Alloys Compd. 2018, 750, 863–870. [Google Scholar] [CrossRef]

- Wang, M.; Lin, X.; Huang, W. Laser additive manufacture of titanium alloys. Mater. Technol. 2016, 31, 90–97. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.G.; Lee, J.H.; Zhang, J. Additive manufacturing of metallic materials: A review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Bimber, B.A.; Andani, M.T.; Elahinia, M. Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. J. Mater. Process. Technol. 2017, 250, 55–64. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of selective laser melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef] [PubMed]

- Meier, H.; Haberland, C. Experimental studies on selective laser melting of metallic parts. Mater. Werk. 2008, 39, 665–670. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Bormann, T.; Muller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; de Wild, M. Microstructure of selective laser melted nickel-titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.P.; Schrooten, J.; Luyten, J.; Humbeeck, J.V. Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv. Eng. Mater. 2014, 16, 1140–1146. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.P.; van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. Manuf. Technol. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Yadroitsev, I.A.; Smurov, I.Y. Manufacturing three-dimensional nickel titanium articles using layer-by-layer laser-melting technology. Tech. Phy. Lett. 2013, 39, 1081–1084. [Google Scholar] [CrossRef]

- Ou, S.F.; Peng, B.Y.; Chen, Y.C.; Tsai, M.H. Manufacturing and characterization of NiTi alloy with functional properties by selective laser melting. Metals 2018, 8, 342. [Google Scholar] [CrossRef]

- Zhao, Y.; Taya, M.; Kang, Y.; Kawasaki, A. Compression behavior of porous NiTi shape memory alloy. Acta Mater. 2005, 53, 337–343. [Google Scholar] [CrossRef]

- Andani, M.T.; Moghaddam, N.S.; Haberland, C.; Dean, D.; Miller, M.J.; Elahinia, M. Metals for bone implants—Part 1: Powder metallurgy and implant rendering. Acta Biomater. 2014, 10, 4058–4070. [Google Scholar] [CrossRef] [PubMed]

- Johansen, K.; Voggenreiter, H.; Eggeler, G. On the effect of TiC particles on the tensile properties and on the intrinsic two-way effect of NiTi shape memory alloys produced by powder metallurgy. Mater. Sci. Eng. 1999, 27, 410–414. [Google Scholar] [CrossRef]

- Mentz, J.; Bram, M.; Buchkremer, H.P.; Stover, D. Improvement of mechanical properties of powder metallurgical NiTi shape memory alloys. Adv. Eng. Mater. 2006, 8, 247–252. [Google Scholar] [CrossRef]

- Ibrahim, H.; Jahadakbar, A.R.; Dehghan, A.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M. In vitro corrosion assessment of additively manufactured porous NiTi structures for bone fixation applications. Metals 2018, 8, 164. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Vrancken, B.; Buls, S.; van Humbeeck, J.; Kruth, J.P. Producing crack-free, high density M2 HSS parts by selective laser melting: Pre-heating the baseplate. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013; pp. 131–139. [Google Scholar]

- Vora, P.; Mumtaz, K.; Todd, I.; Hopkinson, N. AlSi12 in-situ alloy formation and residual stress reduction using anchorless selective laser melting. Addit. Manuf. 2015, 7, 12–19. [Google Scholar] [CrossRef]

- Aggarangsi, P.; Beuth, J.L. Localized preheating approaches for reducing residual stress in additive manufacturing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006. [Google Scholar]

- Srivatsan, T.; Sudarshan, T. Additive Manufacturing: Innovations, Advances, and Applications; CRC Press: Baca Raton, FL, USA, 2015. [Google Scholar]

- Machado, L.; Savi, M. Medical applications of shape memory alloys. Braz. J. Med. Biol. Res. 2003, 36, 683–691. [Google Scholar] [CrossRef] [PubMed]

- Morgan, N. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants; ASTM F2063-05; ASTM International: West Conshohocken, PA, USA, 2005.

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Contardo, L.; Guenin, G. Training and two-way memory effect in Cu-Zn-Al alloy. Acta Metall. Mater. 1990, 38, 1267–1272. [Google Scholar] [CrossRef]

- Weafer, F.M.; Guo, Y.; Bruzzi, M.S. The effect of crystallographic texture on stress-induced martensitic transformation in NiTi: A computational analysis. J. Mech. Behav. Biomed. Mater. 2016, 53, 210–217. [Google Scholar] [CrossRef]

- Eaton-Evans, J.; Dulieu-Barton, J.M.; Little, E.G.; Brown, I.A. Observations during mechanical testing of Nitinol. J. Mech. Eng. Sci. 2008, 222, 97–105. [Google Scholar] [CrossRef]

- Yang, S.Y.; Dui, G.S. Temperature analysis of one-dimensional NiTi shape memory alloys under different loading rates and boundary conditions. Int. J. Solids Struct. 2013, 50, 3254–3265. [Google Scholar] [CrossRef]

- Laeng, J.; Xiu, Z.; Xu, X.; Sun, X.; Ru, H.; Liu, Y. Phase formation of Ni–Ti via solid state reaction. Phys. Scr. 2007, T129, 250–254. [Google Scholar] [CrossRef]

- Barbarino, S.; Saavedra-Flores, E.I.; Ajaj, R.M.; Dayyani, I.; Friswell, M.I. A review on shape memory alloys with applications to morphing aircraft. Smart Mater. Struct. 2014, 23, 063001. [Google Scholar] [CrossRef]

- Han, M.W.; Rodrigue, H.; Cho, S.; Song, S.H.; Wang, W.; Chu, W.S.; Ahn, S.H. Woven type smart soft composite for soft morphing car spoiler. Comp. Pt. B Eng. 2016, 86, 285–298. [Google Scholar] [CrossRef]

- Kumar, P.K.; Lagoudlas, D.C. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Texas, TX, USA, 2008. [Google Scholar]

- Bormann, T.; Schumacher, R.; Muller, B.; Mertmann, M.; de Wild, M. Tailoring selective laser melting process parameters for NiTi implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef]

- Bormann, T.; de Wild, M.; Beckmann, F.; Muller, B. Assessing the morphology of selective laser melted NiTi scaffolds for a three-dimensional quantification of the one-way shape memory effect. In Proceedings of the SPIE, San Diego, CA, USA, 25–29 August 2013. [Google Scholar]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Gu, D. Laser Additive Manufacturing of High-Performance Materials; Springer: New York, NY, USA, 2015. [Google Scholar]

- Khoo, Z.X.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N.; Liu, Y. Effect of heat treatment on repetitively scanned SLM NiTi shape memory alloy. Materials 2018, 12, 77. [Google Scholar] [CrossRef] [PubMed]

- Dadbakhsh, S.; Vrancken, B.; Kruth, J.P.; Luyten, J.; van Humbeeck, J. Texture and anisotropy in selective laser melting of NiTi alloy. Mater. Sci. Eng. 2016, 650, 225–232. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Moghaddam, N.S.; Elahinia, M.H.; Karaca, H.E. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater. Sci. Eng. 2017, 686, 1–10. [Google Scholar] [CrossRef]

- Wada, K.; Liu, Y. Shape recovery of NiTi shape memory alloy under various pre-strain and constraint conditions. Smart Mater. Struct. 2005, 14, 273–286. [Google Scholar] [CrossRef]

- Walker, J.M. Additive Manufacturing towards the Realization of Porous and Stiffness-Tailored NiTi Implants. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2014. [Google Scholar]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Fabrication of porous NiTi shape memory alloy structures using laser engineered net shaping. J. Biomed. Mater. Res. 2009, 89, 481–490. [Google Scholar] [CrossRef] [PubMed]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Laser processing of net-shape NiTi shape memory alloy. Phys. Metall. Mater. Sci. 2007, 38, 1096–1103. [Google Scholar] [CrossRef]

- Olakanmi, E.; Cochrane, R.; Dalgarno, K. Densifification mechanism and microstructural evolution in selective laser sintering of Al–12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Singh, A.K.; Datta, S.; Das, M.; Balla, V.K.; Bontha, S.; Kalpathya, S.K. Microstructure and corrosion behavior of laser processed NiTi alloy. Mater. Sci. Eng. 2015, 57, 309–313. [Google Scholar] [CrossRef]

- Hsu, T.I.; Wei, C.M.; Wu, L.D.; Li, Y.P.; Chiba, A.; Tsai, M.H. Nitinol powders generate from plasma rotation electrode process provide clean powder for biomedical devices used with suitable size, spheroid surface and pure composition. Sci. Rep. 2018, 8, 13776. [Google Scholar] [CrossRef]

- Morgan, R.H.; Papworth, A.J.; Sutcliffe, C.; Fox, P.; O’Neill, W. High density net shape components by direct laser re-melting of single-phase powders. J. Mater. Sci. 2002, 37, 3093–3100. [Google Scholar] [CrossRef]

- Andani, M.T.; Haberland, C.; Walker, J.; Elahinia, M. An investigation of effective process parameters on phase transformation temperature of Nitinol manufactured by selective laser melting. In Proceedings of the ASME Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Newport, RI, USA, 8–10 September 2014. [Google Scholar]

- Mathew Speirs, M.; Wang, X.; Van Baelen, S.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.P.; Van Humbeeck, J. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shape Mem. Superelast. 2016, 2, 310–316. [Google Scholar] [CrossRef]

- Andani, M.T. Modeling, Simulation, Additive Manufacturing, and Experimental Evaluation of Solid and Porous NiTi. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2015. [Google Scholar]

- Eliaz, N. Corrosion of metallic biomaterials: A review. Materials 2019, 12, 407. [Google Scholar] [CrossRef]

- Ma, C.; Andani, M.T.; Qin, H.; Moghaddam, N.S.; Ibrahim, H.; Jahadakbar, A.; Amerinatanzi, A.; Ren, Z.; Zhang, H.; Doll, G.L. Improving surface fifinish and wear resistance of additive manufactured nickel-titanium by ultrasonic nano-crystal surface modifification. J. Mater. Process. Technol. 2017, 249, 433–440. [Google Scholar] [CrossRef]

- Chan, C.W.; Man, H.C. Laser welding of thin foil nickel-titanium shape memory alloy. Opt. Lasers Eng. 2011, 49, 121–126. [Google Scholar] [CrossRef]

- Karaji, Z.G.; Speirs, M.; Dadbakhsh, S.; Kruth, J.P.; Weinans, H.; Zadpoor, A.A.; Yavari, S.A. Additively Manufactured and Surface Biofunctionalized Porous Nitinol. ACS Appl. Mater. Interfaces 2016, 9, 1293–1304. [Google Scholar] [CrossRef] [PubMed]

- Man, H.C.; Cui, Z.D.; Yue, T.M. Corrosion properties of laser surface melted NiTi shape memory alloy. Scr. Mater. 2001, 45, 1447–1453. [Google Scholar] [CrossRef]

- Landolt, D. Corrosion and Surface Chemistry of Metals; CRC Press: Baca Raton, FL, USA, 2007. [Google Scholar]

- Hedberg, Y.; Karlsson, M.E.; Blomberg, E.; Wallinder, I.O.; Hedberg, J. Correlation between surface physicochemical properties and the release of iron from stainless steel AISI 304 in biological media. Colloids Surf. B Biointerfaces 2014, 122, 216–222. [Google Scholar] [CrossRef] [PubMed]

- Wedian, F.; Al-Qudah, M.A.; Abu-Baker, A.N. The effect of Capparis spinosa L. extract as a green inhibitor on the corrosion rate of copper in a strong alkaline solution. Port. Electrochim. Acta 2016, 34, 39–51. [Google Scholar] [CrossRef]

- Rizvi, S.A.; Khan, T.I. A novel fabrication method for Nitinol shape memory alloys. Key Eng. Mater. 2010, 442, 309–315. [Google Scholar] [CrossRef]

- Meier, H.; Haberland, C.; Frenzel, J.; Zarnetta, R. Selective laser melting of NiTi shape memory components. In Proceedings of the International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 6–10 October 2009; pp. 233–238. [Google Scholar]

- Shiva, S.; Palani, I.A.; Mishra, S.K.; Paul, C.P.; Kukreja, L.M. Investigations on the inflfluence of composition in the development of Ni–Ti shape memory alloy using laser based additive manufacturing. Opt. Laser Technol. 2015, 69, 44–51. [Google Scholar] [CrossRef]

- Kalman, L.; Meszaros, I. Analysis of a NiTi shape memory alloy. Mater. Sci. Forum 2015, 812, 89–93. [Google Scholar] [CrossRef]

- Tang, W.; Sandstrom, Z.; Wei, G.; Miyazaki, S. Experimental investigation and thermodynamic calculation of the Ti-Ni-Cu shape memory alloys. Metall. Mater. Trans. A 2000, 31, 2423–2430. [Google Scholar] [CrossRef]

- Habijan, T.; Haberland, C.; Meier, H.; Frenzel, J.; Wittsiepe, J.; Wuwer, C.; Greulich, C.; Schildhauer, T.A.; Köller, M. The biocompatibility of dense and porous nickel–titanium produced by selective laser melting. Mater. Sci. Eng. C 2013, 33, 419–426. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.; Meier, H. Visions, concepts and strategies for smart Nitinol actuators and complex Nitinol structures produced by additive manufacturing. In Proceedings of the ASME Conference on Smart Materials, Adaptive Structures and Intelligent Systems—SMASIS 2013, Snowbird, UT, USA, 16–18 September 2013. [Google Scholar]

- Turabi, A.S.; Saedi, S.; Saghaian, S.M.; Karaca, H.E.; Elahinia, M.H. Experimental characterization of shape memory alloys. In Shape Memory Alloy Actuators: Design, Fabrication, and Experimental Evaluation; Elahinia, M.H., Ed.; John Wiley & Sons: New York, NY, USA, 2015; pp. 239–277. [Google Scholar]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Karaca, H.; Elahinia, M. The inflfluence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloy Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Frenzel, J.; Zhang, Z.; Somsen, C.; Neuking, K.; Eggeler, G. Inflfluence of carbon on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2007, 55, 1331–1341. [Google Scholar] [CrossRef]

- Firstov, G.S.; Vitchev, R.G.; Kumar, H.; Blanpain, B.; Humbeeck, J.V. Surface oxidation of NiTi shape memory alloy. Biomaterials 2002, 23, 4863–4871. [Google Scholar] [CrossRef]

- Slough, C.G. A Study of the Nitinol Solid-Solid Transition by DSC; TA Instruments: New Castle, DE, USA, 2007. [Google Scholar]

- Haberland, C.; Meier, H.; Frenzel, J. On the properties of Ni-rich NiTi shape memory parts produced by selective laser melting. In Proceedings of the ASME Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Stone Mountain, GA, USA, 19–21 September 2012. [Google Scholar]

- Mohd-Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal alloys for fusion-based additive manufacturing. Adv. Eng. Mater. 2018, 20, 1700952. [Google Scholar] [CrossRef]

- Walker, J.; Andani, M.T.; Haberland, C.; Elahinia, M. Additive manufacturing of Nitinol shape memory alloys to overcome challenges in conventional Nitinol fabrication. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Andani, M.T.; Haberland, C.; Walker, J.M.; Karamooz, M.; Turabi, A.S.; Saedi, S.; Rahmanian, R.; Karaca, H.; Dean, D.; Kadkhodaei, M.; et al. Achieving biocompatible stiffness in NiTi through additive manufacturing. J. Intell. Mater. Syst. Struct. 2016, 27, 2661–2671. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Gao, N. Influence of energy density on metallurgy and properties in metal additive manufacturing. Mater. Sci. Technol. 2017, 33, 1269–1289. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging features and the SLM/DMLS residual stresses problem: Review and future research need. Technologies 2017, 5, 15. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, Y.; Wu, W. One-Step Shaping of NiTi Biomaterial by Selective Laser Melting; Photonics Asia; International Society for Optics and Photonics: Bellingham, WA, USA, 2007. [Google Scholar]

- Hamilton, R.F.; Palmer, T.A.; Bimber, B.A. Spatial characterization of the thermal-induced phase transformation throughout as-deposited additive manufactured NiTi bulk builds. Scr. Mater. 2015, 101, 56–59. [Google Scholar] [CrossRef]

- Li, S.; Hassanin, H.; Attallah, M.M.; Adkins, N.J.E.; Essa, K. The development of TiNi-based negative Poisson’s ratio structure using selective laser melting. Acta Mater. 2016, 105, 75–83. [Google Scholar] [CrossRef]

| SLM | LENS |

|---|---|

| • Fabricates homogenous composition equivalent to the composition of the feedstock | • Composition varies spatially and may differ from the powder feedstock composition. |

| • Exhibits high aspect columnar grains extending over multiple layers, due to orientation in the build direction (along largest thermal gradient). | • Equiaxial grains are created with dimensions corresponding to the layer thickness (has smaller minor axis). |

| • Strain accumulation is more uniform, as material microstructure is more homogeneous. • The stress-strain curve shows a plateau as per the response when critical stress is exceeded. | • Due to heterogeneity, strain accumulation varies. The stress-strain curve exhibits a strain-hardening like response once the critical stress was crossed. |

| • Shape recovery requires a temperature increase. • Detwinned martensite is more stable. | • Residual martensite in the fabricated microstructure recovers on heating, hence, detwinned martensite is less stable in LENS-fabricated components. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chekotu, J.C.; Groarke, R.; O’Toole, K.; Brabazon, D. Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production. Materials 2019, 12, 809. https://doi.org/10.3390/ma12050809

Chekotu JC, Groarke R, O’Toole K, Brabazon D. Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production. Materials. 2019; 12(5):809. https://doi.org/10.3390/ma12050809

Chicago/Turabian StyleChekotu, Josiah Cherian, Robert Groarke, Kevin O’Toole, and Dermot Brabazon. 2019. "Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production" Materials 12, no. 5: 809. https://doi.org/10.3390/ma12050809

APA StyleChekotu, J. C., Groarke, R., O’Toole, K., & Brabazon, D. (2019). Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production. Materials, 12(5), 809. https://doi.org/10.3390/ma12050809