1. Introduction

Portland cement has been around for almost 200 years; however, the Romans and Egyptians were using cement-like materials centuries before Joseph Aspdin would patent Portland cement [

1]. Nowadays, ordinary Portland cement (OPC) is the second most consumed product on Earth, second only to water, and is expected to increase from 2.55 billion tonnes in 2006 to 3.7–4.4 billion tonnes by 2050 [

2]. This gives rise to an increasing need to find an environmentally friendly alternative to Portland cement in order to reduce carbon dioxide emissions and promote green concrete technology by utilizing various by-product materials such as fly ash and blast furnace slag. However, many studies have indicated the potential benefits of fly-ash-based geopolymer concrete over the OPC concrete in the last few years [

3]. Hence, geopolymer concrete has shown the potential to replace OPC by reducing the amount of carbon emissions up to 80%, while still maintaining high strengths comparable to that of OPC [

4].

Geopolymer concrete, which is also known as alkali-activated or inorganic concrete, is a different kind of concrete, using different chemistry to that found in OPC concrete. The historical backdrop of geopolymer started with the first patented by German chemist and engineer Kűhl in 1908, where a combination of alumina and silica content (vitreous slag) with an alkali (alkali sulfate or carbonate) source led to the development of solid material comparable to OPC [

5]. The improvement of this binder was enhanced by Purdon where he published an important journal with respect to the achievement rates of strength and the final strength that is equivalent to the OPC activated by solution of sodium hydroxide and calcium hydroxide combined with different sodium sources tested under different types of blast furnace slags [

6,

7]. Purdon faced a problem with the handling of a high concentrated solution and the sensitivity of total water added from the activation conditions [

8]. Research on alkali-activated binders then broadened eastward for a couple of decades, including the Soviet Union and China, where a new alternative material as a substitution of OPC was needed [

9]. Glukhovsky [

10] from the Soviet Union presented a theoretical basis and development of alkaline cements that leads to the use of material called alkaline cement. Alkaline activation products in Western countries saw no advancement until the last development by Purdon in 1979 [

11]. Joseph Davidovits referred to an aluminosilicate-based material as a geopolymer, and he defined it as a three-dimensional, short range order inorganic polymer that forms when high concentrated aqueous alkali hydroxide-silicate solution is added to the alumino-silicate materials [

12]. By-product materials such as fly ash and slag are main sources of alumino-silicate materials. The properties of alkali-activated by-product rely on many factors such as the chemical composition of the binders, the type of alkali activators, the concentration of the activator, the curing condition, and the water content [

13].

According to British standards [

14], concrete is termed heavyweight when the density of the sample reaches an oven dry density of 2600 kg/m

3, as opposed to normal weight concrete, which has a density of 2400 kg/m

3. The typical aggregates used to achieve heavyweight concrete are magnetite, barite, hematite, limonite, and limenite [

15]. Due to the addition of such aggregates, concrete can achieve densities of up to 8,900 kg/m

3 depending on the type of material [

16]. However, magnetite seems the most practical since it is found abundantly in Western Australia alongside hematite, and, due to the higher iron content found within hematite, magnetite seems to be better suited in the use of heavyweight concrete [

17]. Heavyweight concrete has applications in the medical and nuclear industries, where radiation shielding is required. Furthermore, offshore applications have used heavyweight concrete to provide stability to pipelines and other underwater structures. Horszczaruk et al. [

15] found that cement mortars containing magnetite offered the highest thermal stability, further justifying the use of magnetite over other heavyweight aggregates in this study. Additionally, Horszczaruk et al. [

18] found that the use of magnetite in concrete resulted in a lower rate of deterioration of up to two times that of normal-weight coarse aggregate samples after exposure to high temperatures. The inclusion of heavyweight aggregates in concrete shows a reduction in the thickness required for sufficient radiation shielding of up to 40% compared to concrete with a normal aggregate [

18]. However, the tendency of aggregate to segregate in a concrete mixture increases with the increase in density of the aggregates. Therefore, chemical admixtures can be used to control the rheological behavior of heavyweight concrete to control segregation and bleeding.

Currently, the most common binder used in the formation of geopolymer is fly ash. Fly ash geopolymer has been shown to have better mechanical properties and durability compared to OPC [

3,

19]. In the geopolymerization process, the amount of calcium content in fly ash was found to possess a significant impact on the resulting hardened geopolymer [

20]. Oh et al. [

21] and Winnefeld et al. [

22] stated that class-C fly ash showed lower properties in terms of strength development and binder phase evolution compared to class-F fly ash. Meanwhile, some researchers have affirmed that class-F fly ash as a source material is preferable to class-C fly ash. However, Deventer et al. [

23] proved that the presence of higher CaO in class-C fly ash causes a disruption in the geopolymerization process and has the potential to change the existing microstructure of the geopolymer, further justifying the use of class-F fly ash over class-C fly ash in this study. Moreover, class-F fly ash has better resistance against sulfate attack and lowers the heat hydration and heat generation of concrete’s rate than class-C fly ash [

24].

Notable studies have been done on the fly ash geopolymer combined with some additional materials [

25]. The suitability of fly-ash-based geopolymer blended with ground granulated blast furnace slag has been reported by Dombrowski et al. [

26]. The inclusion of GGBFS into fly-ash-based geopolymers resulted in quicker setting times and higher strength, resulting in creating a concrete suitable for ambient curing conditions [

27]. Wardhono et al. [

28] found out that the mixes containing larger portions of ground granulated blast furnace slag ratios of up to 50% produced the best strength results under ambient curing, albeit providing a much lower setting time. Nath et al. [

20] investigated the properties of fly-ash-based geopolymer concrete with different proportions of additives such as GGBFS, OPC, and calcium hydroxide (CH). The maximum compressive strength was achieved with the 10% addition of GGBFS in fly-ash-based geopolymer after 28 days at ambient curing conditions. However, Somna et al. [

29] found out that the fly-ash-based geopolymer can be improved by increasing the reactivity of fly ash; i.e., by increasing fineness. Moreover, the addition of calcium oxide and calcium hydroxide as a replacement of fly ash improves the mechanical properties at ambient curing [

30].

Alkali activator also significantly influences the geopolymerization process. Different alkali activators have been used in geopolymer concrete, such as alkali hydroxides, alkali silicates, alkali carbonates, and alkali sulfate [

5]. Currently, alkali silicate is an important chemical compound that has been used as a good activator to a binder in geopolymer concrete. Na silicates are the most often used activators because of their low cost compared to K-silicate solutions. Alkali concentration has been shown to be one of the main parameters in the contribution to the performance of geopolymer concrete [

5]. Many researchers have developed geopolymer concrete by combining an activator between alkali silicates and alkali hydroxides with appropriate ratios [

31,

32]. Furthermore, the ratio between alkali silicate and alkali hydroxide plays an important role in the mechanical properties of geopolymer concrete. Palomo et al. [

33] found that a compressive strength in the range 35–40 MPa will be produced from a reaction of different fly ash types with an alkali activator (NaOH) in the range 8–12 mol/L cured at 85 °C in 24 h, while the compressive strength (with the same conditions) will increase up to 90 MPa when alkali silicate (Na

2SiO

3) is added with a SiO

2/Na

2O ratio of 1.23. Similarly, Pradip et al. found significant compressive strength by using alkaline solution prepared where the Na

2SiO

3/NaOH ratio = 2.5 [

20], further justifying the use of NaOH with sodium silicate as an alkaline reactor in this study.

The polymerization reaction is highly influenced by curing conditions. Curing temperature impacts the microstructural and mechanical development of geopolymer concrete. Normally, the polymerization reactions in low calcium fly ash based geopolymer concrete are accelerated at high temperatures which enhances mechanical and durability properties of concrete, compared with geopolymerisation reactions at ambient curing conditions [

34]. However, the polymerization process and resulting products may also be affected by other factors such as the type and properties of alumino silicate sources and the composition of the alkaline solution [

9]. Class-F fly-ash-based geopolymers outperform the conventional concrete in fire, due to their ceramic-like properties [

35]. The mechanical strength of geopolymer changes due to high-temperature-induced structural and phase composition changes in the material [

36]. Structural changes include sintering, densification, melting, cracking, and pore size changes. Phase composition changes include crystal growth, crystal destruction, hydration, and geopolymer paste decomposition and release of free Si, Al, and alkali. However, thermal dilation of secondary phases such as crystalline impurities and aggregate during exposure also affects the mechanical strength [

37]. Moreover, the improvement in the interconnectivity through sintering could increase mechanical strength, which, in some cases, can be more than five times the strength at ambient temperature [

38]. According to Rickard et al. [

39], sintering can be defined as the “heal” of the crack induced during the dehydration phase (the phase in which water escaping caused the structural damage) and hence improve the mechanical properties of the materials.

The strength development of geopolymer concrete is heavily influenced by the water content. It is crucial to control the amount of moisture going into a mix [

27,

40]. A water-to-binder ratio in geopolymer is best kept around 0.2 to achieve the minimum needed for workability [

27,

41]. Compressive strengths were shown to decrease exponentially when the water-to-solid ratio increased from around 0.15 to 0.5 [

42]. Admixtures can be used to improve and manipulate the fresh properties of a concrete mix to better suit the concrete for a specific use [

43]. The use of superplasticizers and water reducing admixtures can cause a reduction in the amount of water in a mixture by up to 30 and 12%, respectively [

44]. Both types of admixtures can either show an increase or decrease in setting time depending on how it reacts to the mix with the water reducing admixture, causing an initial setting time to increase by 3 h, and the superplasticizer can either decrease or increase setting time by up to 1 h. The addition of superplasticizers can show an early concrete strength increase by 50–75% and an increase in workability on the fresh properties of concrete [

44].

It should be noted that numerous studies have been conducted on the thermal characteristics of standard geopolymer concrete [

27], but no study has examined the effects of prolonged exposure to high temperatures on the physical and mechanical properties of heavyweight geopolymer concrete in comparison with standard geopolymer concrete. The research presented here will explore the ability of materials to produce standard GC and HWGC, together with binders, fillers, sand, SP, and others, using locally available materials in Australia. This research will help in standardizing local materials and obtaining an idea of the strength it can generate and its durability when exposed to fire at high temperatures. Therefore, it will promote the sustainable use of GC and HWGC in Australia for radiation shielding purposes and other offshore structures.

4. Conclusions

This research may serve as a supporting article for developing GC and HWGC using normal-weight coarse and magnetite aggregates, respectively. The experimental study presented in this research could initially serve for developing and promoting the use of environmentally friendly GC and HWGC by eliminating the carbon emission through OPC in Australia. In addition, the residual strengths of these concretes were examined at high temperatures. All the mixes made with the replacement of magnetite aggregates satisfied the heavyweight concrete classifications and GC classifications. The results presented in this research show the following trends:

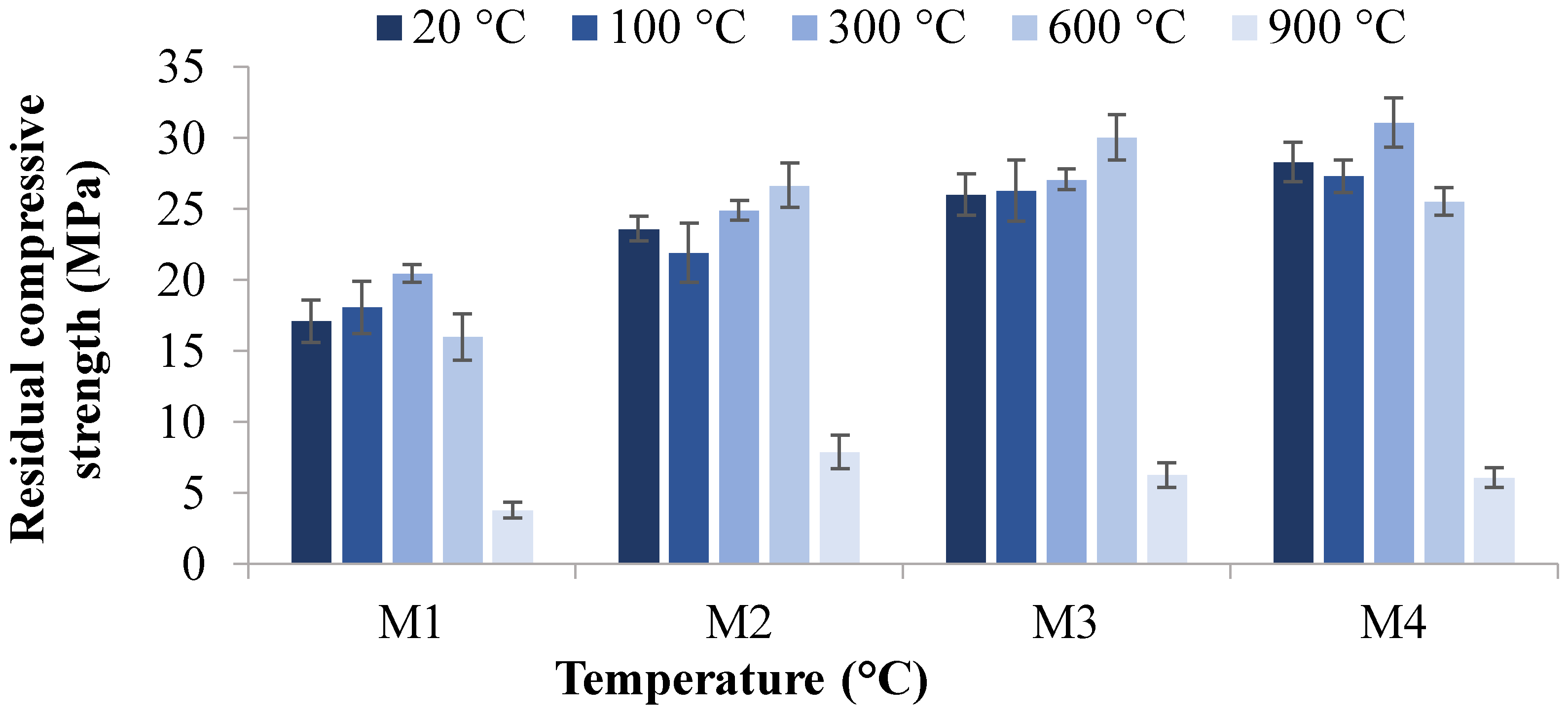

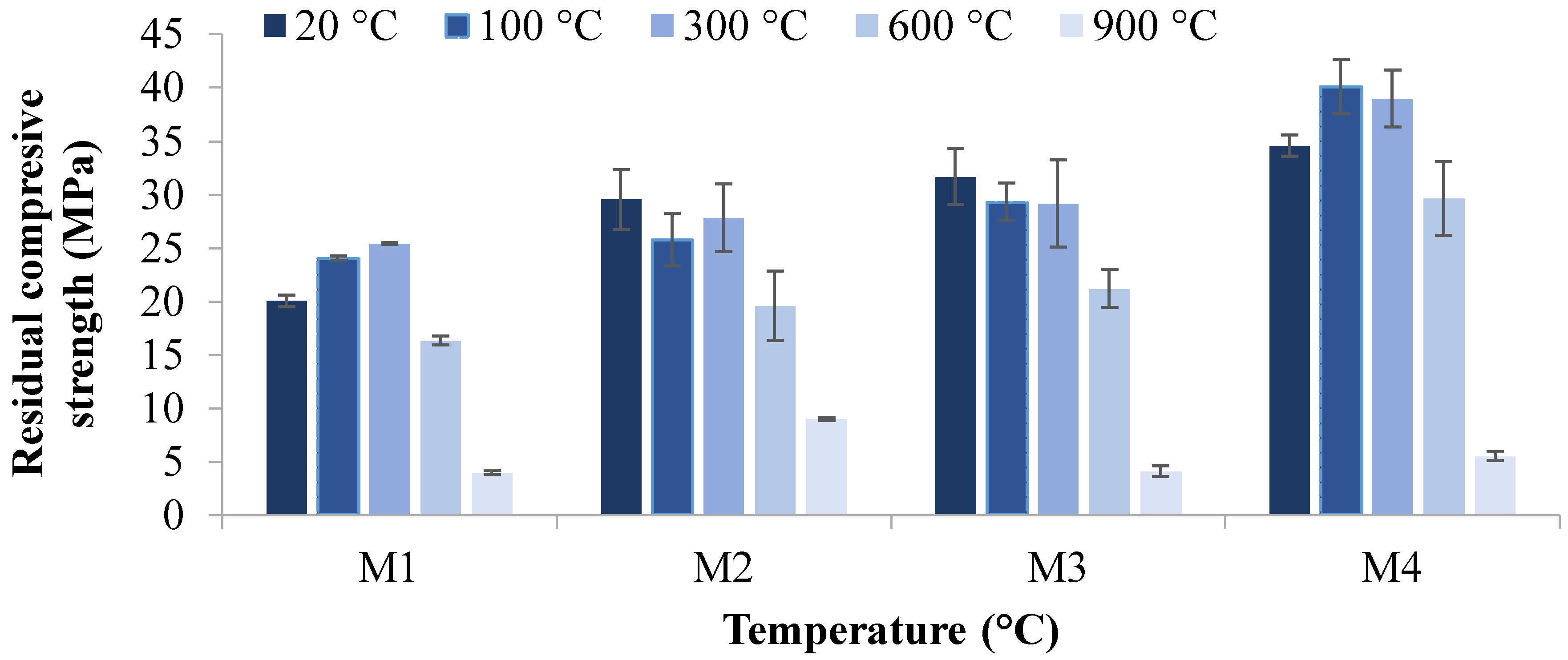

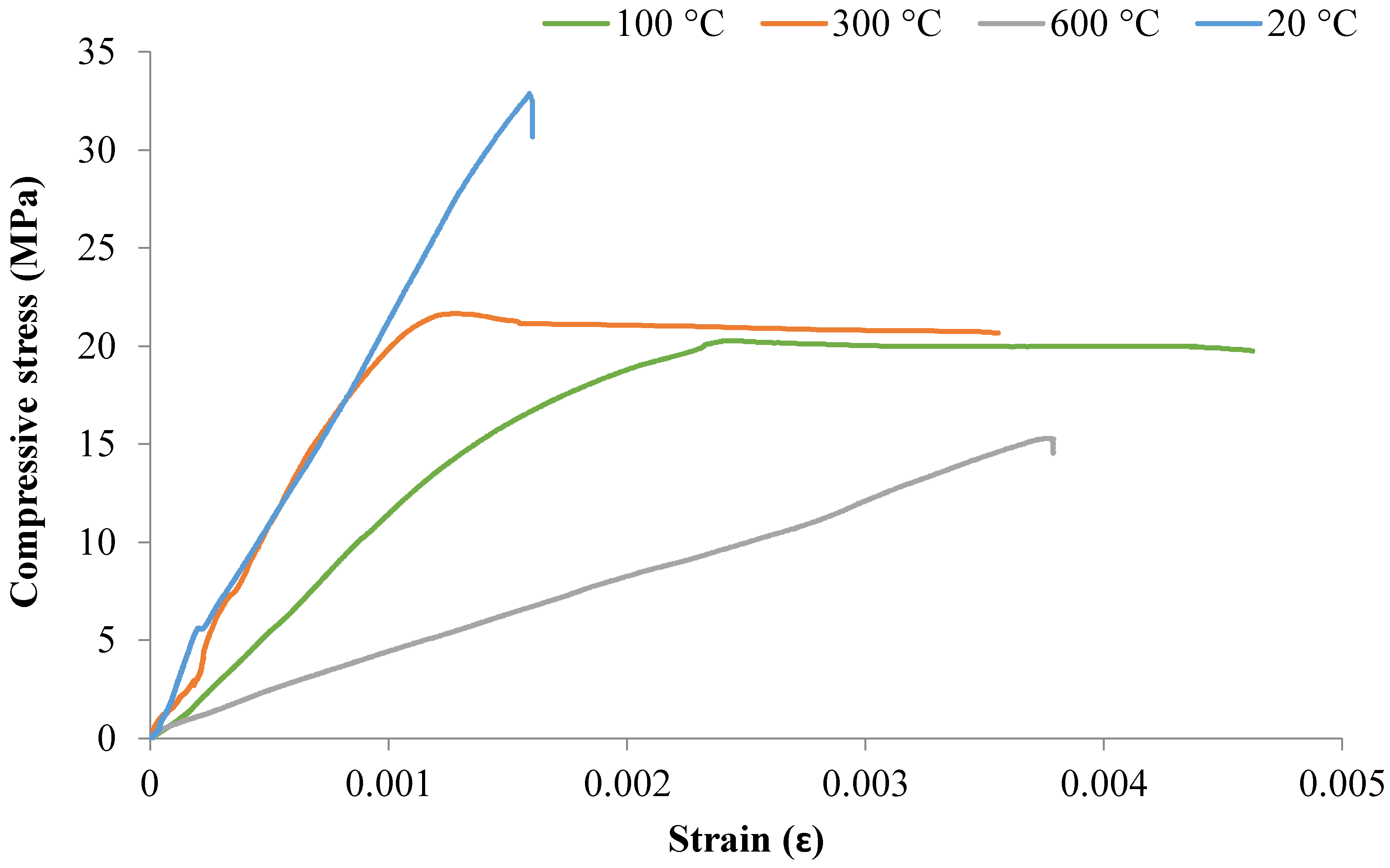

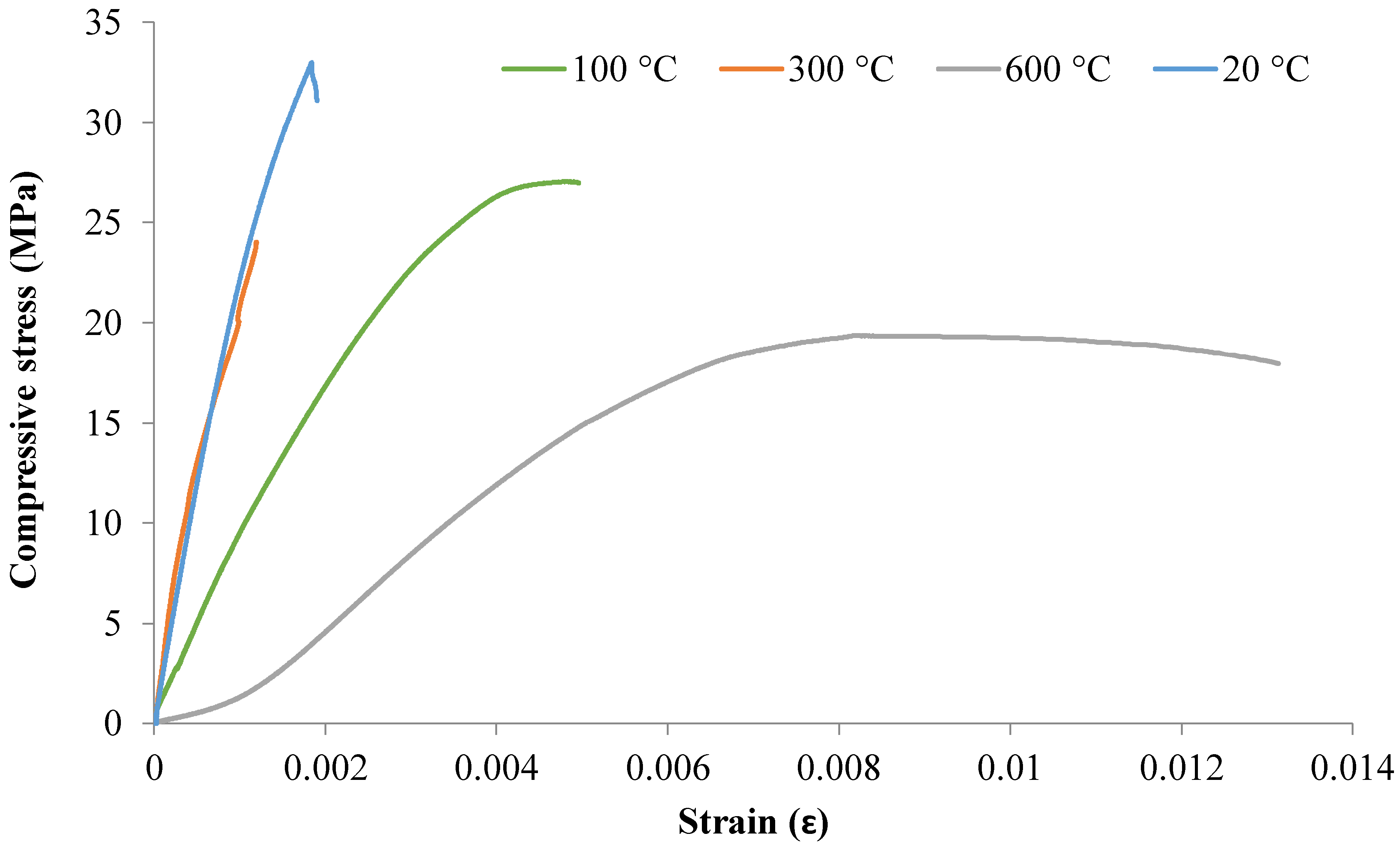

For all mixes at 28-day compressive testing, the strength of all samples increases when temperature rises from 100 to 300 °C. Thus, the densification of geopolymer appears to occur at 100 and 300 °C, resulting in an increase in compressive strength by forming larger geopolymer grains.

As the density increases with the replacement of magnetite aggregates, the slump flow diameter decreases. This decrease can be attributed to the difference in the rate of water absorption between normal-weight natural aggregates and magnetite aggregates, where the latter absorbs more water than the normal-weight aggregates.

A linear trend was observed in slump flow diameter decrements as normal aggregate was replaced by magnetite aggregates.

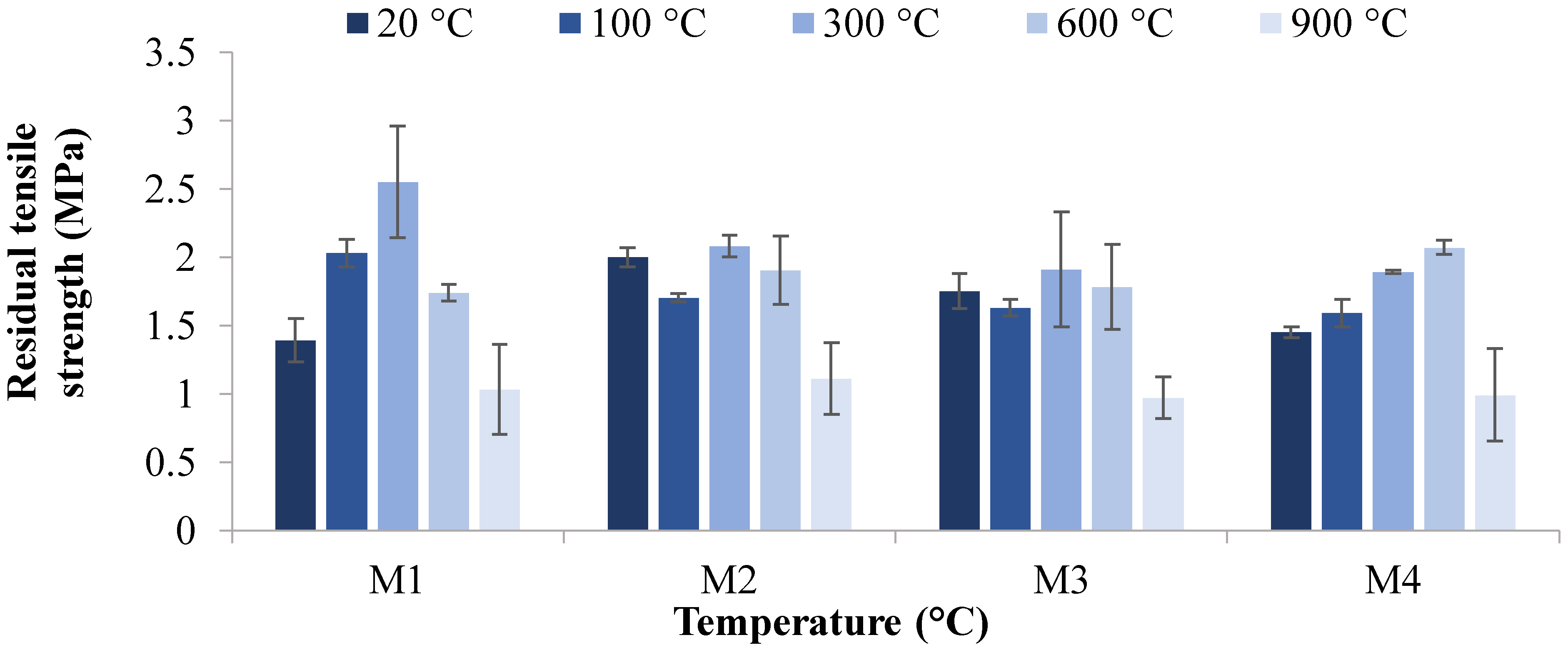

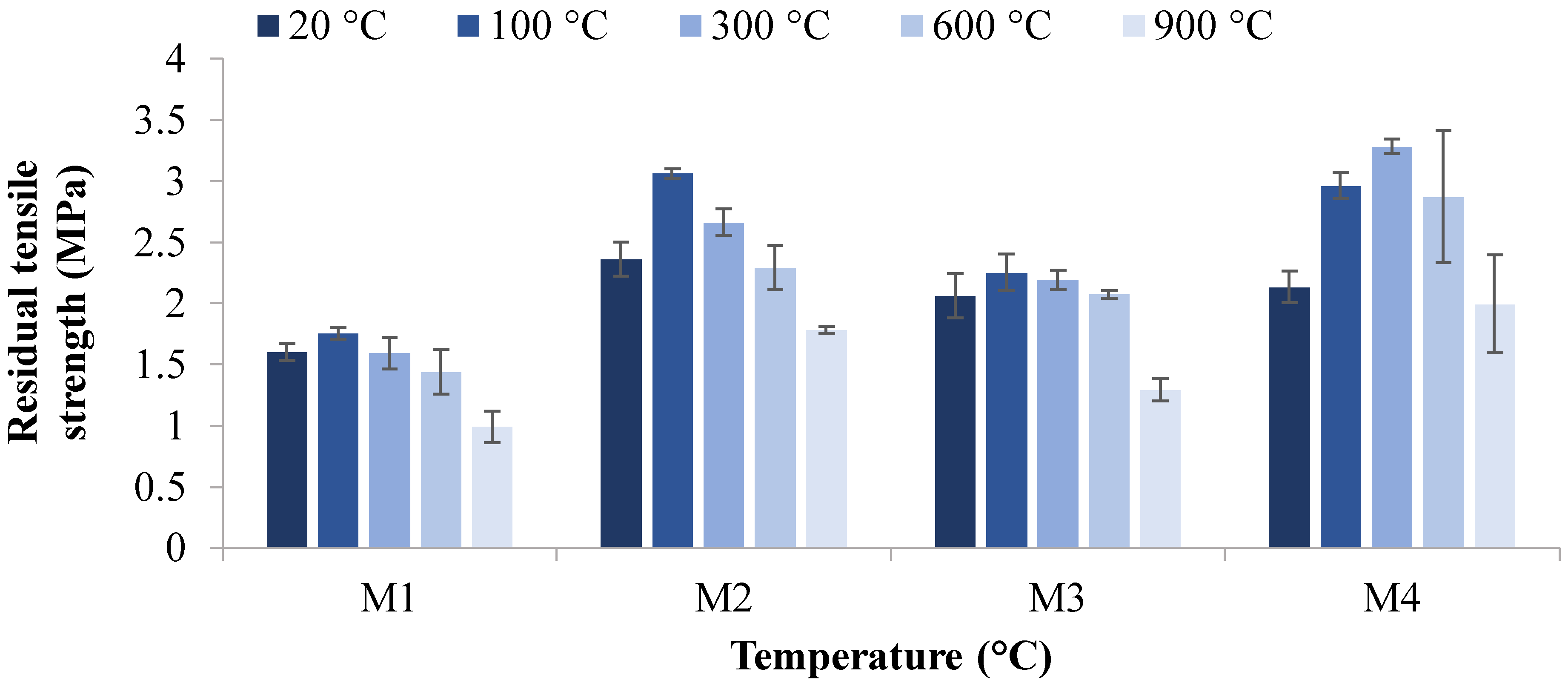

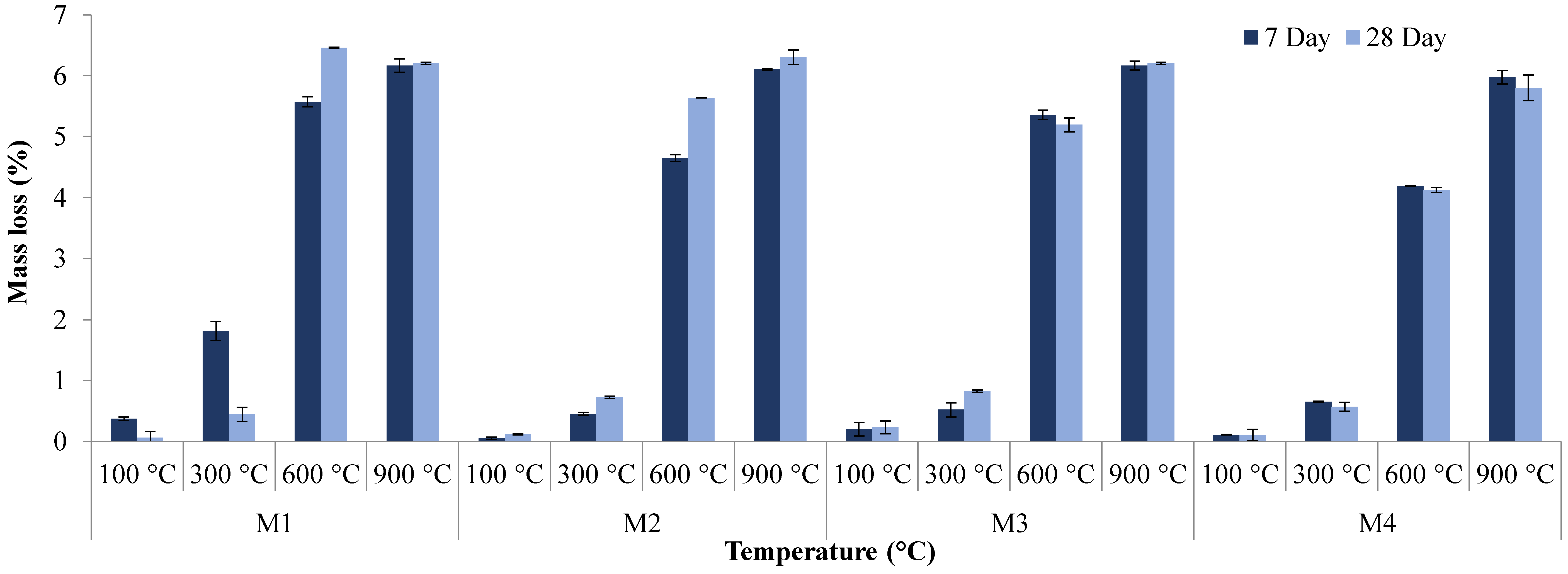

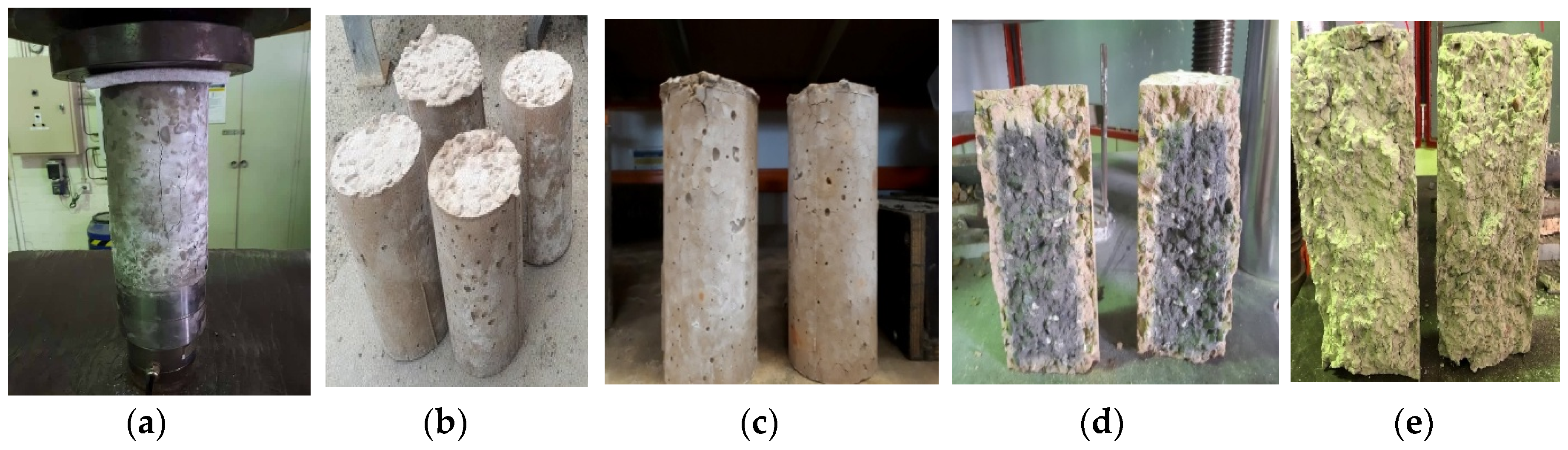

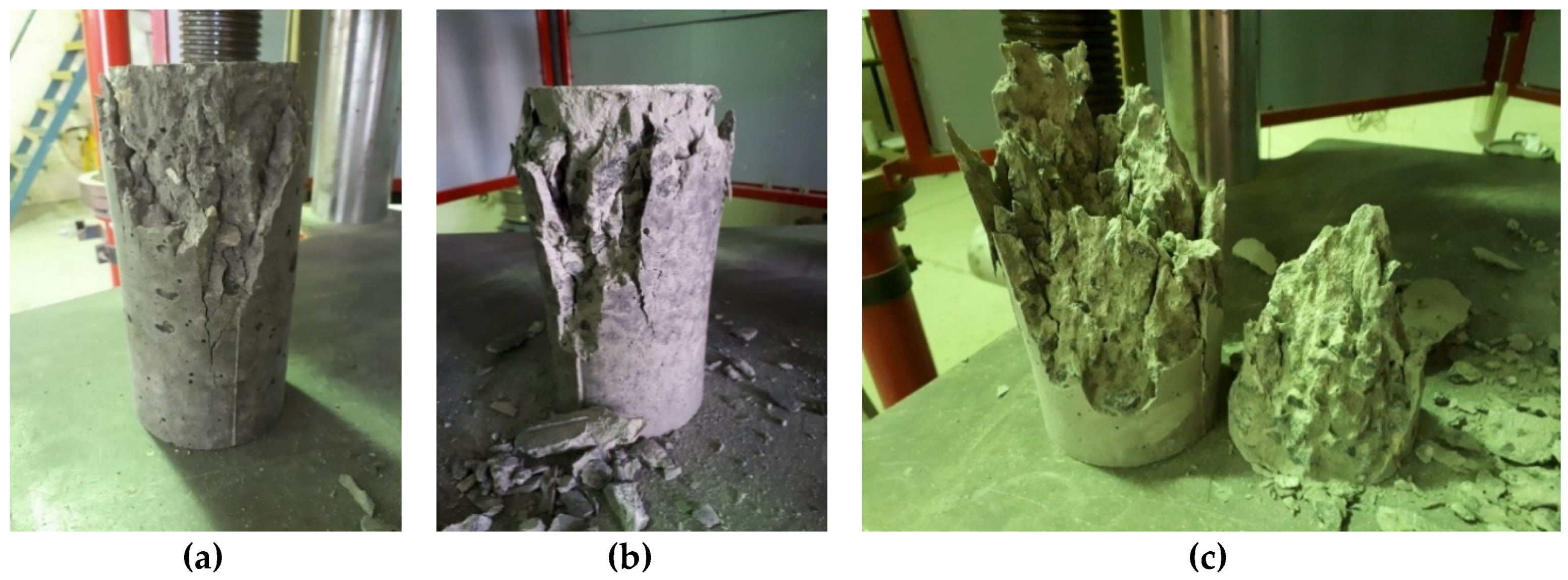

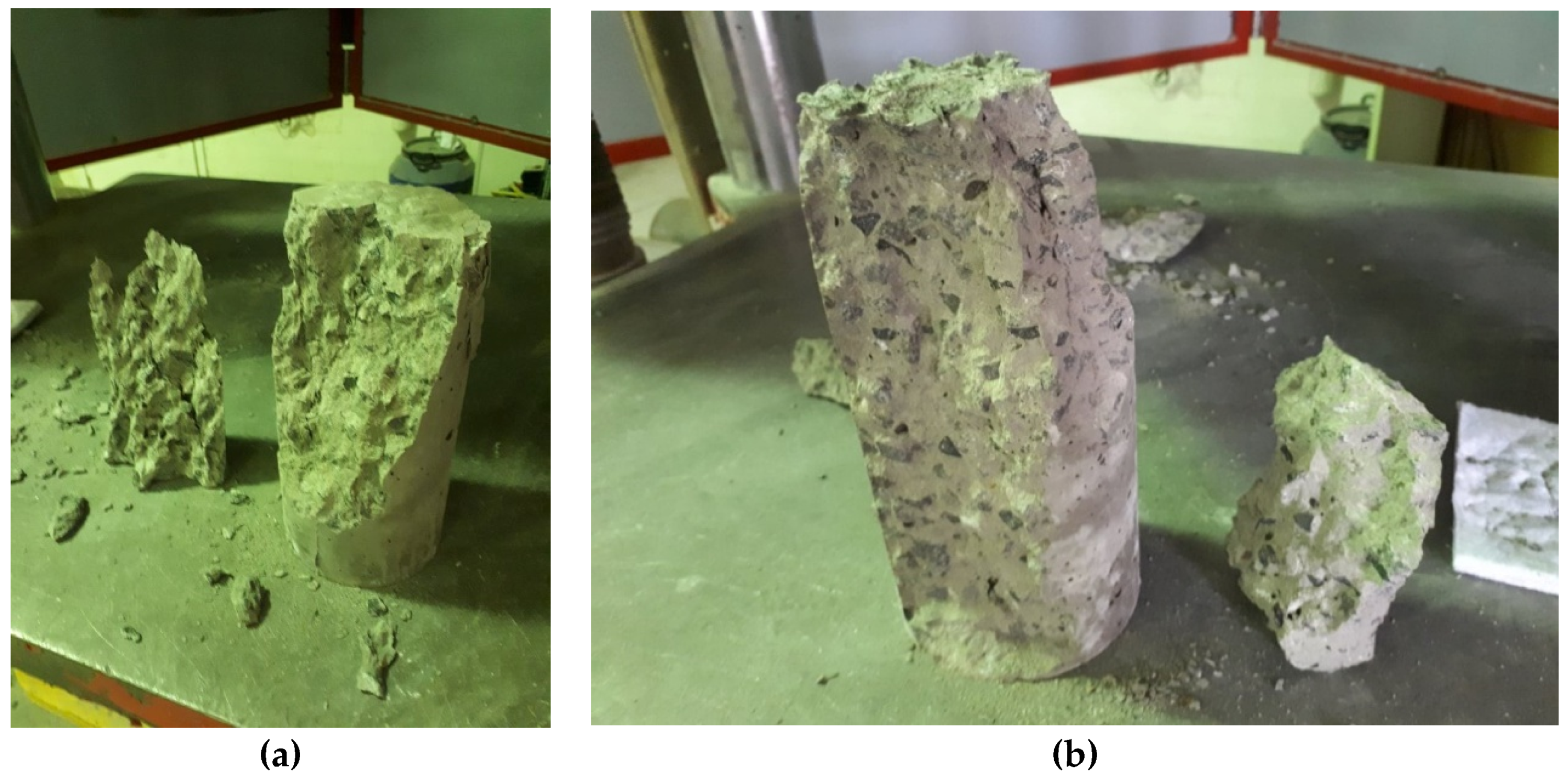

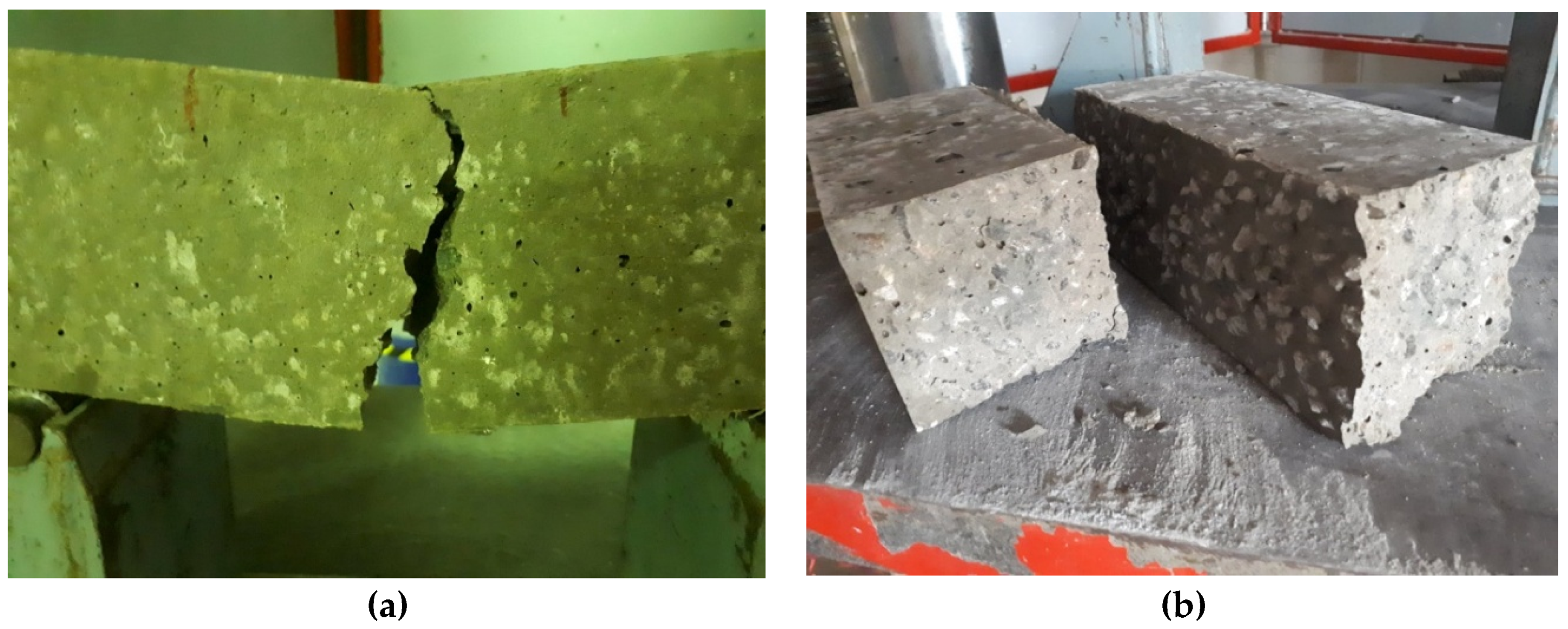

A significant change in appearance occurred (spalling) when all mix samples were exposed to 900 °C. Severe macro-cracks were observed for samples when the temperature was increased from 600 to 900 °C. This is attributed to the destruction of the cellular structure of geopolymer due to dehydration damage, dimensional instability, and sintering.

Samples at 600 °C exhibited enormous micro cracks on the surface but still retained significant compressive strengths. The sintering process may be considered the main reason for keeping the strength even with microcracking on the surface of samples at 600 °C.