Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting

Abstract

1. Introduction

2. Experimental Setup and Data Analysis

2.1. EBM Process and Material

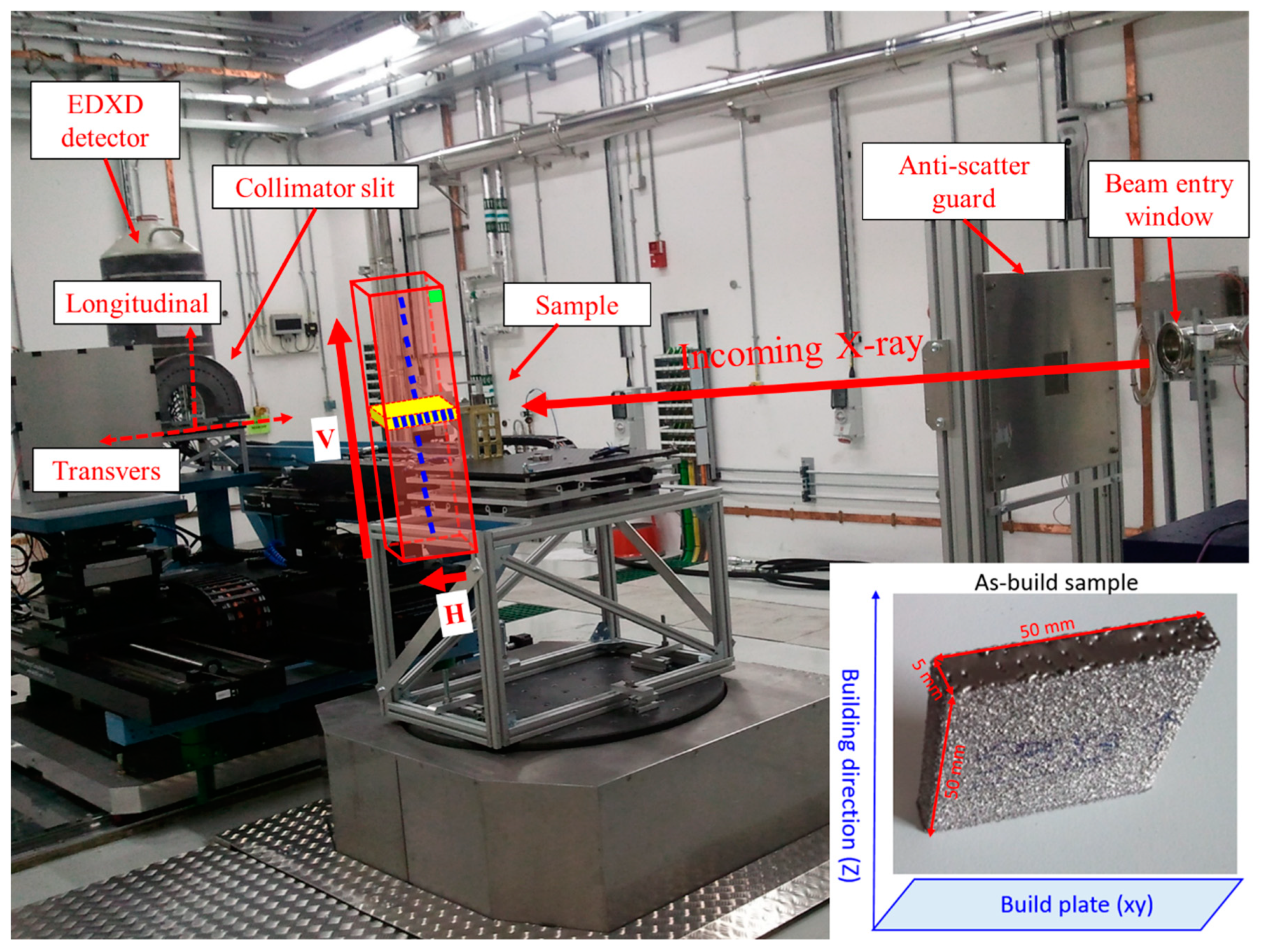

2.2. Synchrotron X-ray Measurements (EDXRD)

2.3. Neutron Diffraction Studies

2.4. Microstructure Studies

2.5. Diffraction Data Analysis

2.6. Strain Calculations

3. Results and Discussion

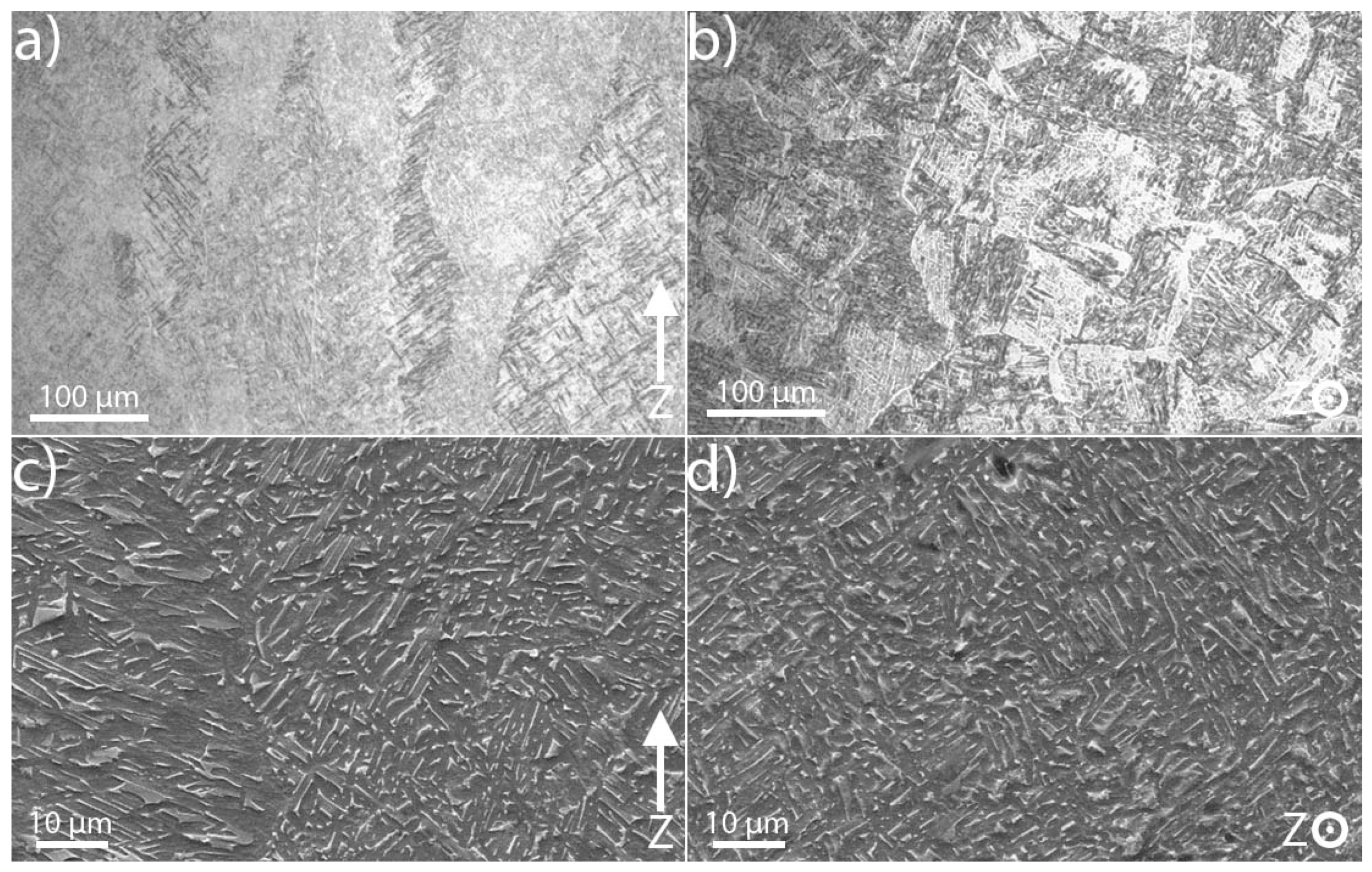

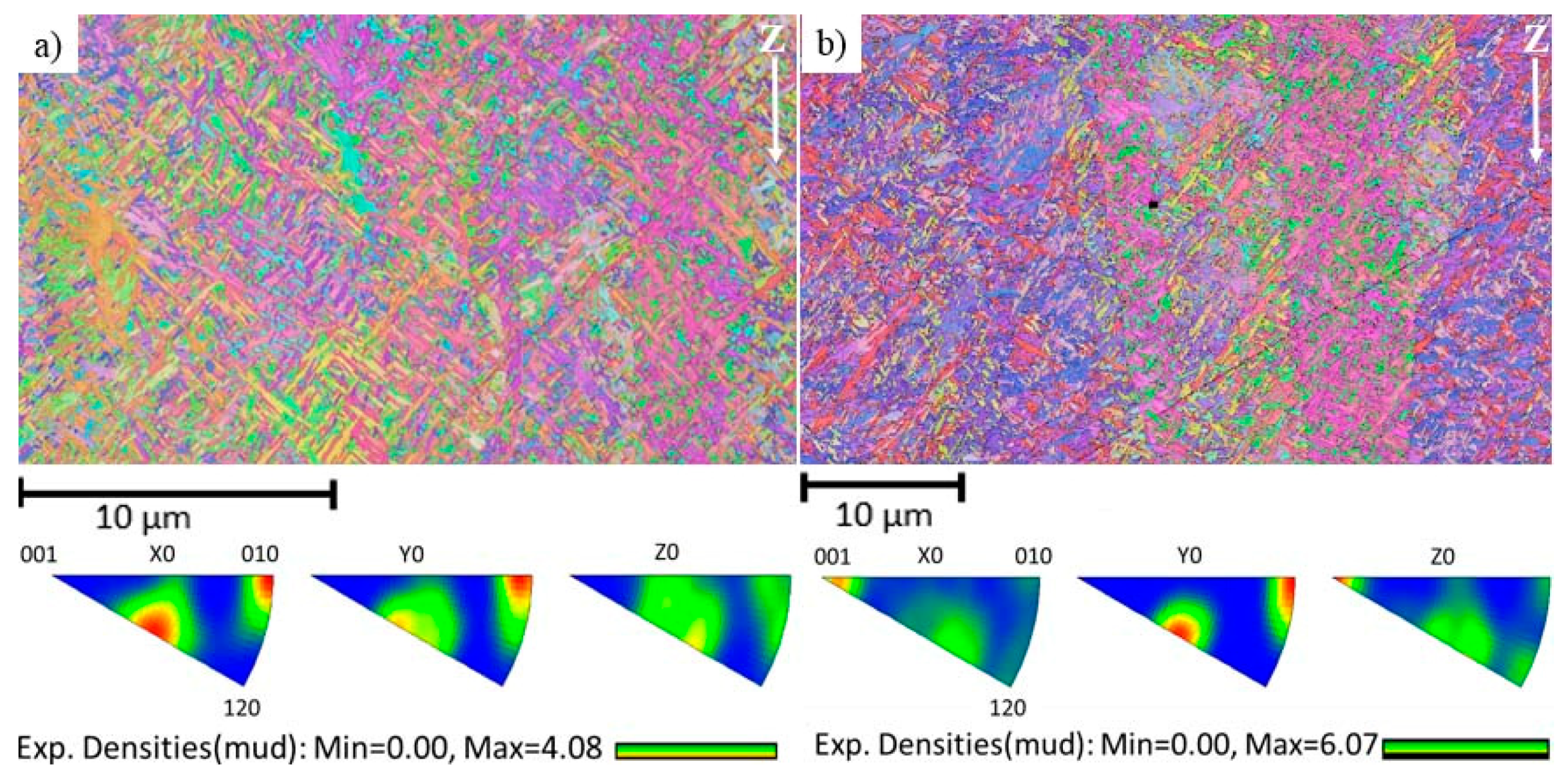

3.1. Microstructure

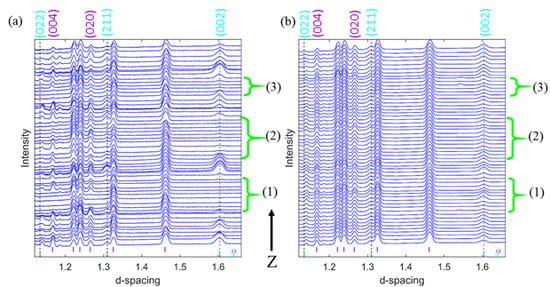

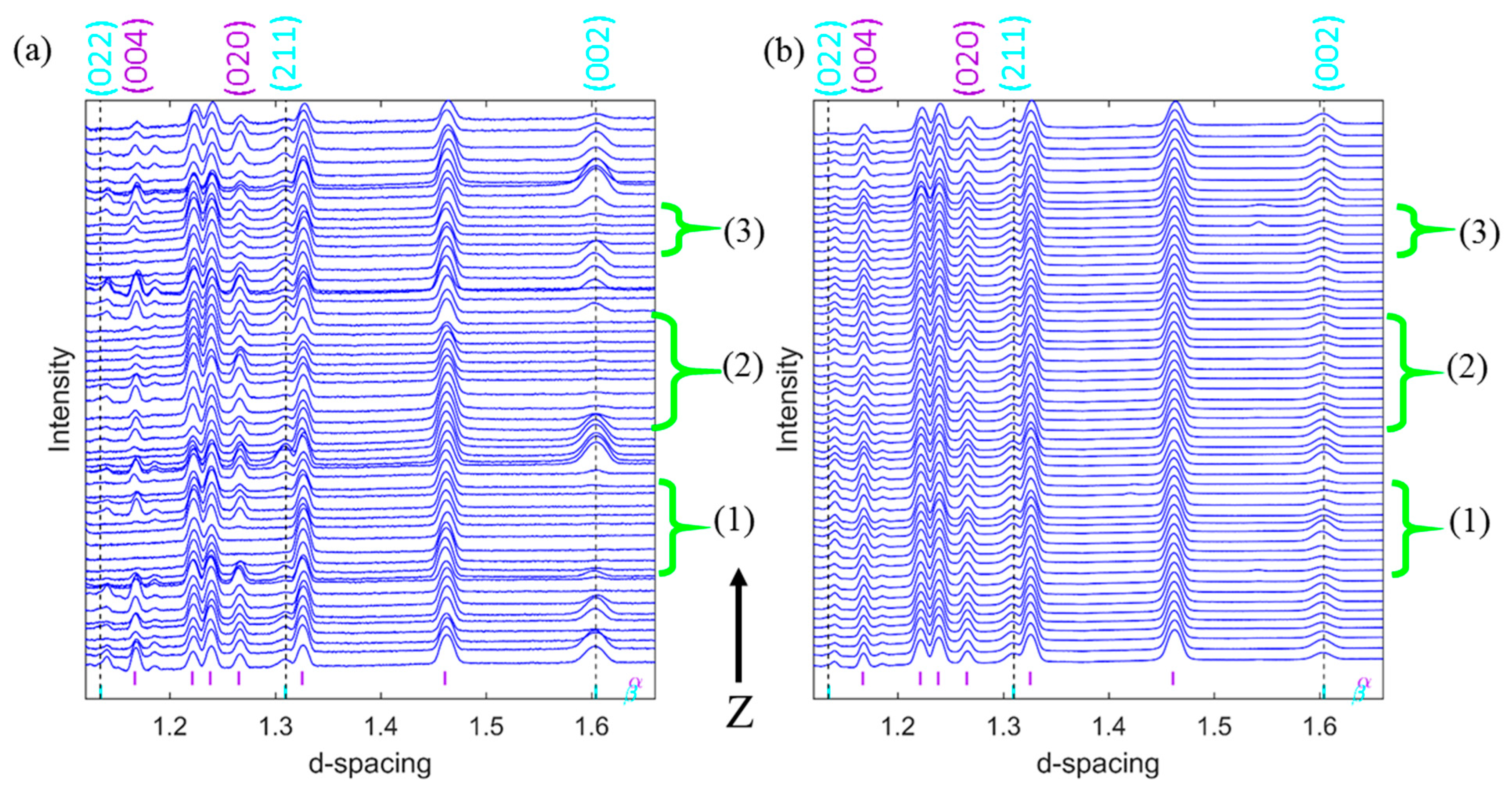

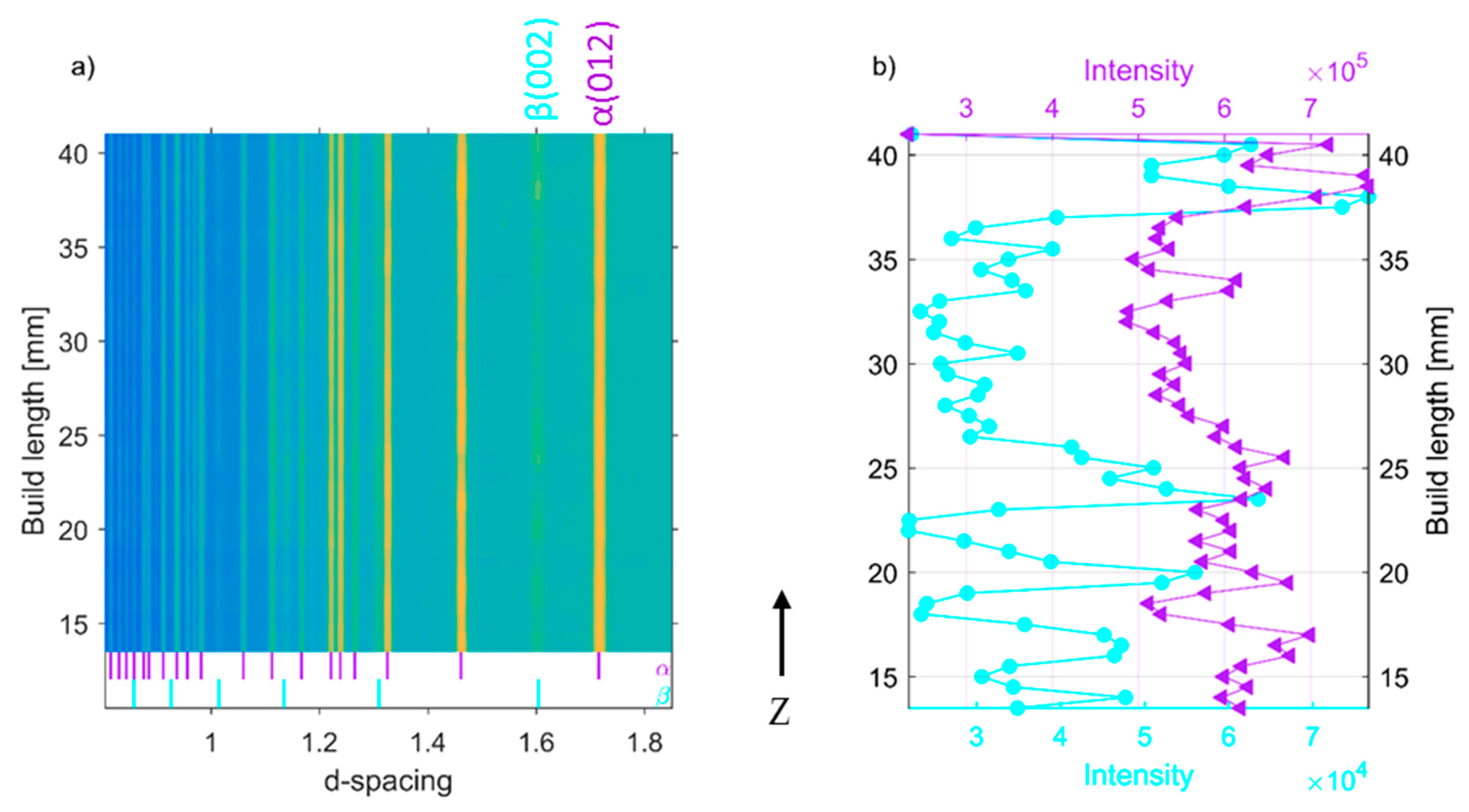

3.2. Peak Intensities and Phase Compositions

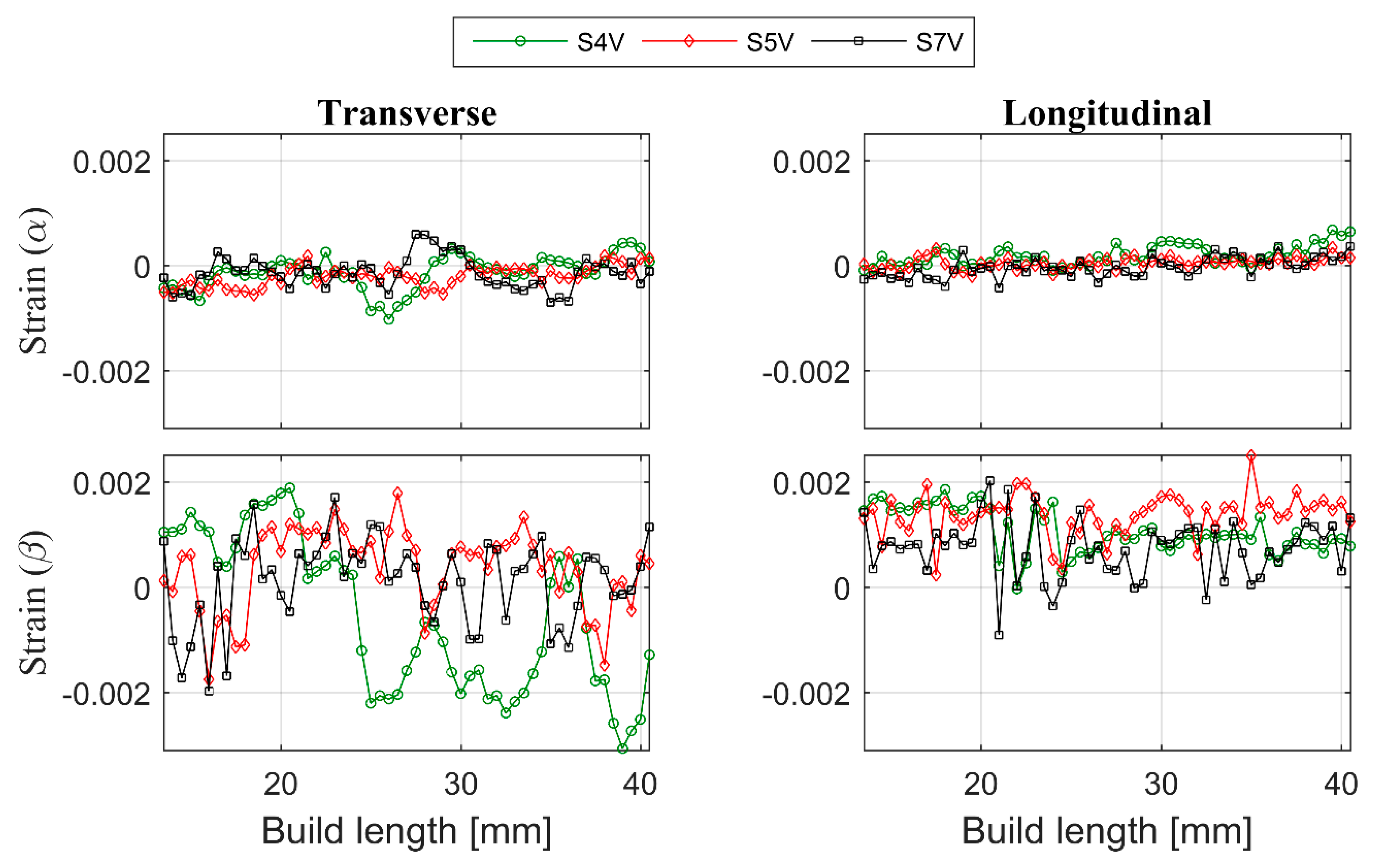

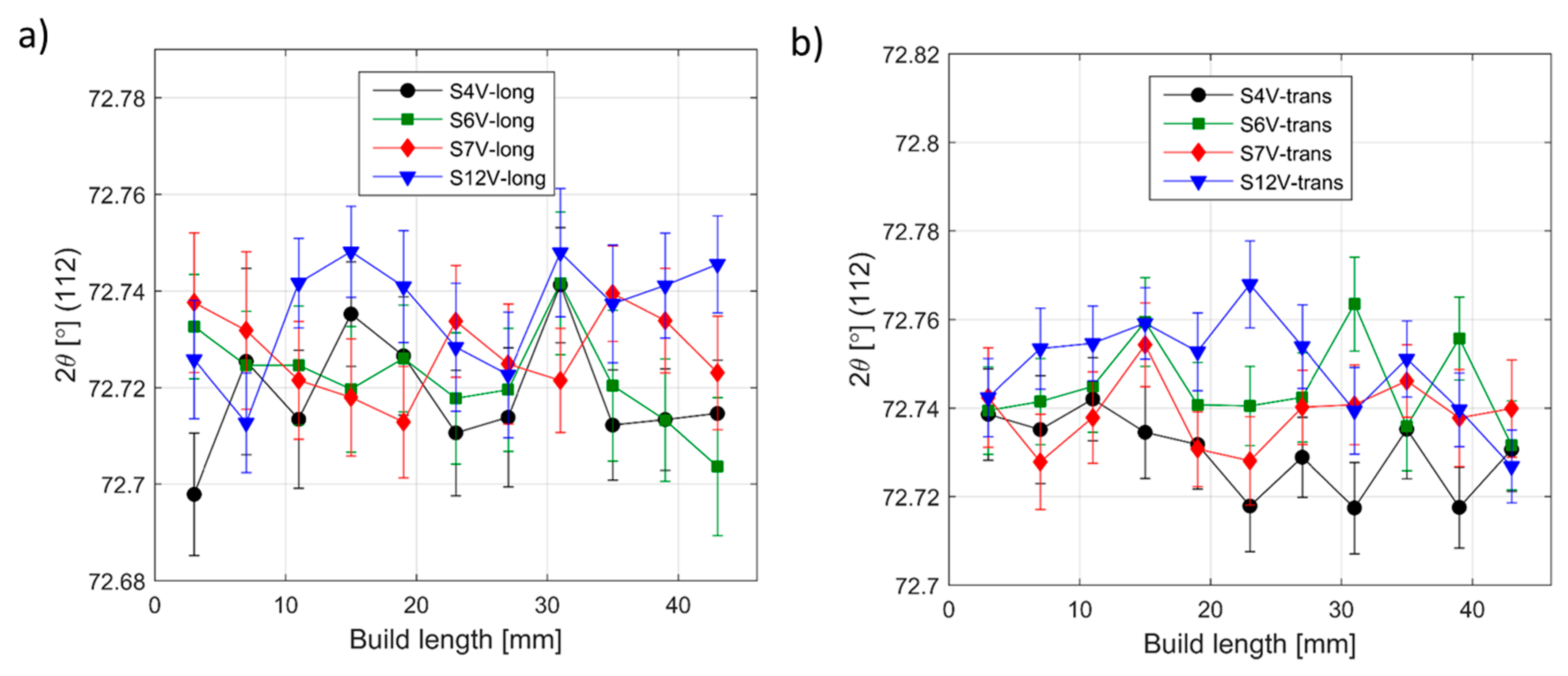

3.3. Residual Strain

4. Conclusions

- Despite strong texture and a columnar microstructure in the build direction, a fairly uniform phase distribution has been observed. The microstructure is mostly Widmanstätten type with majority are α-Ti phase with some amount of β phase (1.5–10 wt %).

- Based on synchrotron X-ray studies, longitudinal strain in α-Ti changes slightly from compression to tensile along the build direction, but no such trend is observed in β-Ti. Neutron studies showed no clear trend of RS in neither α- nor β-Ti.

- Neither transverse nor longitudinal strains in α- and β-Ti in the build plane change significantly. The longitudinal strains in both α- and β-Ti, however, showed a compressive nature close to the edges of the built materials.

- No clear residual strain differences between deposition layers was found.

- The strain variation along the build direction may be related to the elongated prior β-grains and should be considered in future experimentation and analysis.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gerd, L.; James, C.W. Titanium, 2nd ed.; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Safdar, A.; He, H.Z.; Wei, L.; Snis, A.; Chavez, d.P. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Martinez, J.L.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Neikter, M.; Åkerfeldt, P.; Pederson, R.; Antti, M.-L.; Sandell, V. Microstructural characterization and comparison of Ti-6Al-4V manufactured with different additive manufacturing processes. Mater. Charact. 2018, 143, 68–75. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Liu, Y.J.; Wang, H.L.; Li, S.J.; Wang, S.G.; Wang, W.J.; Hou, W.T.; Hao, Y.L.; Yang, R.; Zhang, L.C. Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting. Acta Mater. 2017, 126, 58–66. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, S.J.; Wang, H.L.; Hou, W.T.; Hao, Y.L.; Yang, R.; Sercombe, T.B.; Zhang, L.C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Zhao, S.; Li, S.J.; Wang, S.G.; Hou, W.T.; Li, Y.; Zhang, L.C.; Hao, Y.L.; Yang, R.; Misra, R.D.K.; Murr, L.E. Compressive and fatigue behavior of functionally graded Ti-6Al-4V meshes fabricated by electron beam melting. Acta Mater. 2018, 150, 1–15. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.-Y.; Snis, A.; Lai, Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 2012, 65, 8–15. [Google Scholar] [CrossRef]

- Neikter, M.; Woracek, R.; Maimaitiyili, T.; Scheffzük, C.; Strobl, M.; Antti, M.-L.; Åkerfeldt, P.; Pederson, R.; Bjerkén, C. Alpha texture variations in additive manufactured Ti-6Al-4V investigated with neutron diffraction. Addit. Manuf. 2018, 23, 225–234. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- de Formanoir, C.; Michotte, S.; Rigo, O.; Germain, L.; Godet, S. Electron beam melted Ti-6Al-4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater. Sci. Eng. A 2016, 652, 105–119. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Fitzpatrick, M.E.; Lodini, A. Analysis of Residual Stress by Diffraction using Neutron and Synchrotron Radiation; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Yang, X.; Richard Liu, C. Machining titanium and its alloys. Mach. Sci. Technol. 1999, 3, 107–139. [Google Scholar] [CrossRef]

- Hauk, V. Structural and Residual Stress Analysis by Nondestructive Methods. In Structural and Residual Stress Analysis by Nondestructive Methods; Hauk, V., Ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual stress. Part 2—Nature and origins. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Szost, B.A.; Terzi, S.; Martina, F.; Boisselier, D.; Prytuliak, A.; Pirling, T.; Hofmann, M.; Jarvis, D.J. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti–6Al–4V components. Mater. Des. 2016, 89, 559–567. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q.; Lu, J.; Liu, Y.; Shi, W. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti-6Al-4V alloy: Microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An Assessment of Subsurface Residual Stress Analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef] [PubMed]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Inter. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.-W. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Addit. Manuf. 2016, 12, 231–239. [Google Scholar] [CrossRef]

- Tiferet, E.; Rivin, O.; Ganor, M.; Ettedgui, H.; Ozeri, O.; Caspi, E.N.; Yeheskel, O. Structural investigation of selective laser melting and electron beam melting of Ti-6Al-4V using neutron diffraction. Addit. Manuf. 2016, 10, 43–46. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual stress. Part 1—Measurement techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Maimaitiyili, T.; Bjerken, C.; Steuwer, A.; Wang, Z.; Daniels, J.; Andrieux, J.; Blomqvist, J.; Zanellato, O. In situ observation of γ-ZrH formation by X-ray diffraction. J. Alloy. Compd. 2017, 695, 3124–3130. [Google Scholar] [CrossRef]

- Maimaitiyili, T.; Steuwer, A.; Blomqvist, J.; Bjerkén, C.; Blackmur, M.S.; Zanellato, O.; Andrieux, J.; Ribeiro, F. Observation of the δ to ε Zr-hydride transition by in-situ synchrotron X-ray diffraction. Cryst. Res. Technol. 2016, 51, 663–670. [Google Scholar] [CrossRef]

- Maimaitiyili, T.; Blomqvist, J.; Steuwer, A.; Bjerkén, C.; Zanellato, O.; Blackmur, M.S.; Andrieux, J.; Ribeiro, F. In situ hydrogen loading on zirconium powder. J. Synchrotron Radiat. 2015, 22, 995–1000. [Google Scholar] [CrossRef] [PubMed]

- Withers, P.J.; Preuss, M.; Steuwer, A.; Pang, J.W.L. Methods for obtaining the strain-free lattice parameter when using diffraction to determine residual stress. J. Appl. Crystallogr. 2007, 40, 891–904. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Song, X.; Hofmann, F.; Abbey, B.; Xie, M.; Connolley, T.; Reinhard, C.; Atwood, R.C.; Connor, L.; Drakopoulos, M. Polycrystal deformation analysis by high energy synchrotron X-ray diffraction on the I12 JEEP beamline at Diamond Light Source. Mater. Lett. 2010, 64, 1724–1727. [Google Scholar] [CrossRef]

- Wimpory, R.C.; Mikula, P.; Šaroun, J.; Poeste, T.; Li, J.; Hofmann, M.; Schneider, R. Efficiency Boost of the Materials Science Diffractometer E3 at BENSC: One Order of Magnitude Due to a Horizontally and Vertically Focusing Monochromator. Neutron News 2008, 19, 16–19. [Google Scholar] [CrossRef]

- Coelho, A. TOPAS Academic: Technical Reference. TOPAS Academic: Technical Reference 2004, V4.1. Available online: http://www.TOPAS-academic.net/ (accessed on 1 January 2017).

- Neikter, M. Microstructure and Texture of Additive Manufactured Ti-6Al-4V. Licentiate Thesis, Lulea University of Technology, Luleå, Sweden, 31 January 2018. [Google Scholar]

- Cansizoglu, O.; Harrysson, O.L.A.; West, H.A.; Cormier, D.R.; Mahale, T. Applications of structural optimization in direct metal fabrication. Rapid Prototyp. J. 2008, 14, 114–122. [Google Scholar] [CrossRef]

- Algardh, J.K.; Horn, T.; West, H.; Aman, R.; Snis, A.; Engqvist, H.; Lausmaa, J.; Harrysson, O. Thickness dependency of mechanical properties for thin-walled titanium parts manufactured by Electron Beam Melting (EBM)®. Addit. Manuf. 2016, 12, 45–50. [Google Scholar] [CrossRef]

- Karlsson, J.; Snis, A.; Engqvist, H.; Lausmaa, J. Characterization and comparison of materials produced by Electron Beam Melting (EBM) of two different Ti–6Al–4V powder fractions. J. Mater. Process. Technol. 2013, 213, 2109–2118. [Google Scholar] [CrossRef]

- Electron Beam Melting. Available online: http://www.arcam.com/technology/electron-beam-melting/2016 (accessed on 1 October 2016).

- Wang, X.; Gong, X.; Chou, K. Scanning Speed Effect on Mechanical Properties of Ti-6Al-4V Alloy Processed by Electron Beam Additive Manufacturing. Procedia Manuf. 2015, 1, 287–295. [Google Scholar] [CrossRef]

- Qian, L.; Mei, J.; Liang, J.; Wu, X. Influence of position and laser power on thermal history and microstructure of direct laser fabricated Ti–6Al–4V samples. Mater. Sci. Technol. 2005, 21, 597–605. [Google Scholar] [CrossRef]

- Klingbeil, N.W.; Beuth, J.L.; Chin, R.K.; Amon, C.H. Residual stress-induced warping in direct metal solid freeform fabrication. Inter. J. Mech. Sci. 2002, 44, 57–77. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Pearson Education Limited: London, UK, 2013. [Google Scholar]

- Strobl, M.; Bulat, M.; Habicht, K. The wavelength frame multiplication chopper system for the ESS test beamline at the BER II reactor—A concept study of a fundamental ESS instrument principle. Nucl. Instrum. Methods Phys. Res. A 2013, 705, 74–84. [Google Scholar] [CrossRef]

- Woracek, R.; Hofmann, T.; Bulat, M.; Sales, M.; Habicht, K.; Andersen, K.; Strobl, M. The test beamline of the European Spallation Source—Instrumentation development and wavelength frame multiplication. Nucl. Instrum. Methods Phys. Res. A 2016, 839, 102–116. [Google Scholar] [CrossRef]

- Belsky, A.; Hellenbrandt, M.; Karen, V.L.; Luksch, P. New developments in the Inorganic Crystal Structure Database (ICSD): Accessibility in support of materials research and design. Acta Crystallogr. B Struct. Sci. 2002, 58, 364–369. [Google Scholar] [CrossRef]

- Daymond, M.R.; Bourke, M.A.M.; Dreele, R.B.V. Use of Rietveld refinement to fit a hexagonal crystal structure in the presence of elastic and plastic anisotropy. J. Appl. Phys. 1999, 85, 739–747. [Google Scholar] [CrossRef]

- Lundbäck, A.; Pederson, R.; Colliander, M.H.; Brice, C.; Steuwer, A.; Heralic, A.; Buslaps, T.; Lindgren, L. Modeling And Experimental Measurement with Synchrotron Radiation of Residual Stresses in Laser Metal Deposited Ti-6Al-4V. In Proceedings of the 13th World Conference on Titanium; Venkatesh, V., Pilchak, A.L., Allison, J.E., Ankem, S., Boyer, R., Christodoulou, J., Fraser, H.L., Imam, M.A., Kosaka, Y., Rack, H.J., et al., Eds.; Wiley: Hoboken, NJ, USA, 2016; pp. 1279–1282. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Kelly, S.M.; Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part I. Microstructural characterization. Metall. Mater. Trans. A 2004, 35, 1861–1867. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Da Silva, S.L.R.; Kerber, L.O.; Amaral, L.; dos Santos, C.A. X-ray diffraction measurements of plasma-nitrided Ti–6Al–4V. Surf. Coat. Technol. 1999, 116–119, 342–346. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Nayan, N.; Kumar, P.; Narayanan, P.R.; Sharma, S.C.; George, K.M. Microstructure–texture–mechanical properties relationship in multi-pass warm rolled Ti–6Al–4V Alloy. Mater. Sci. Eng. A 2014, 589, 174–181. [Google Scholar] [CrossRef]

- Chen, L.Y.; Huang, J.C.; Lin, C.H.; Pan, C.T.; Chen, S.Y.; Yang, T.L.; Lin, D.Y.; Lin, H.K.; Jang, J.S.C. Anisotropic response of Ti-6Al-4V alloy fabricated by 3D printing selective laser melting. Mater. Sci. Eng. A 2017, 682, 389–395. [Google Scholar] [CrossRef]

- Muguruma, T.; Iijima, M.; Brantley, W.A.; Yuasa, T.; Ohno, H.; Mizoguchi, I. Relationship between the metallurgical structure of experimental titanium miniscrew implants and their torsional properties. Eur. J. Orthod. 2011, 33, 293–297. [Google Scholar] [CrossRef] [PubMed]

- Mercelis, P.; Kruth, J.-P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

| Specimen ID | Contour Scan Speed (mm/s) | Scan Speed (mm/s) | Current (mA) | Contour Current (mA) | Offset Focus (mA) | Specimen Thickness (mm) |

|---|---|---|---|---|---|---|

| S4 | 180 | 575 | 8 | 9 | 15 | 2.47/5 * |

| S5 | 180 | 650 | 8 | 9 | 15 | 2.68 |

| S6 | 180 | 651 | 8 | 9 | 15 | 2.70/5 * |

| S7 | 180 | 652 | 8 | 9 | 15 | 1.99/5 * |

| S8 | 180 | 575 | 8 | 9 | 30 | 3.02 |

| S9 | 180 | 652 | 8 | 9 | 30 | 2.93 |

| S10 | 180 | 653 | 8 | 9 | 30 | 2.77 |

| S11 | 180 | 650 | 8 | 9 | 30 | 2.97 |

| S12 | 180 | 700 | 8 | 9 | 12 | 2.50/5 * |

| Phase | Structure | Space Group | a(Å) | c(Å) | (°C) | Atomic Site | Reference (ICSD) |

|---|---|---|---|---|---|---|---|

| α(Ti) | HCP | P63/mmc | 2.9511 | 4.6843 | 25 | 0.3333 0.6667 0.25 | 43416 |

| 2.9508 | 4.6855 | - | 52522 | ||||

| 2.9064 | 4.6667 | 20 | 99778 | ||||

| 2.951 | 4.682 | - | 43614 | ||||

| 2.916 | 4.631 | - | 168830 | ||||

| 2.9232(7) | 4.6700(4) | 25 | Polycrystal | ||||

| 2.9230(6) | 4.6697(6) | 25 | Polycrystal corner | ||||

| 2.9210(6) | 4.6644(8) | 25 | Powder | ||||

| β(Ti) | BCC | 3.2765 | 3.2765 | - | 000 | 653278 | |

| 3.2068(7) | 3.2068(7) | 25 | Polycrystal | ||||

| 3.2082(7) | 3.2082(7) | 25 | Polycrystal corner | ||||

| 3.2023(8) | 3.2023(8) | 25 | Powder | ||||

| Omega Ti | Loose HCP | P6/mmm | 4.6 | 2.82 | High pressure | Ti1 000; Ti2 0.3333 0.6667 0.5 | 52521 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maimaitiyili, T.; Woracek, R.; Neikter, M.; Boin, M.; Wimpory, R.C.; Pederson, R.; Strobl, M.; Drakopoulos, M.; Schäfer, N.; Bjerkén, C. Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting. Materials 2019, 12, 667. https://doi.org/10.3390/ma12040667

Maimaitiyili T, Woracek R, Neikter M, Boin M, Wimpory RC, Pederson R, Strobl M, Drakopoulos M, Schäfer N, Bjerkén C. Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting. Materials. 2019; 12(4):667. https://doi.org/10.3390/ma12040667

Chicago/Turabian StyleMaimaitiyili, Tuerdi, Robin Woracek, Magnus Neikter, Mirko Boin, Robert C. Wimpory, Robert Pederson, Markus Strobl, Michael Drakopoulos, Norbert Schäfer, and Christina Bjerkén. 2019. "Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting" Materials 12, no. 4: 667. https://doi.org/10.3390/ma12040667

APA StyleMaimaitiyili, T., Woracek, R., Neikter, M., Boin, M., Wimpory, R. C., Pederson, R., Strobl, M., Drakopoulos, M., Schäfer, N., & Bjerkén, C. (2019). Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting. Materials, 12(4), 667. https://doi.org/10.3390/ma12040667