Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges

Abstract

:1. Introduction

2. Alternative Process Routes

2.1. CerAMfacturing of Single-Material Porous Ceramics

2.2. CerAM Replica of Single-Material Porous Ceramics

2.3. CerAMfacturing of Multiproperty Porous Ceramics

3. Materials and Methods

3.1. CerAMfacturing of Porous Ceramics by CerAM VPP

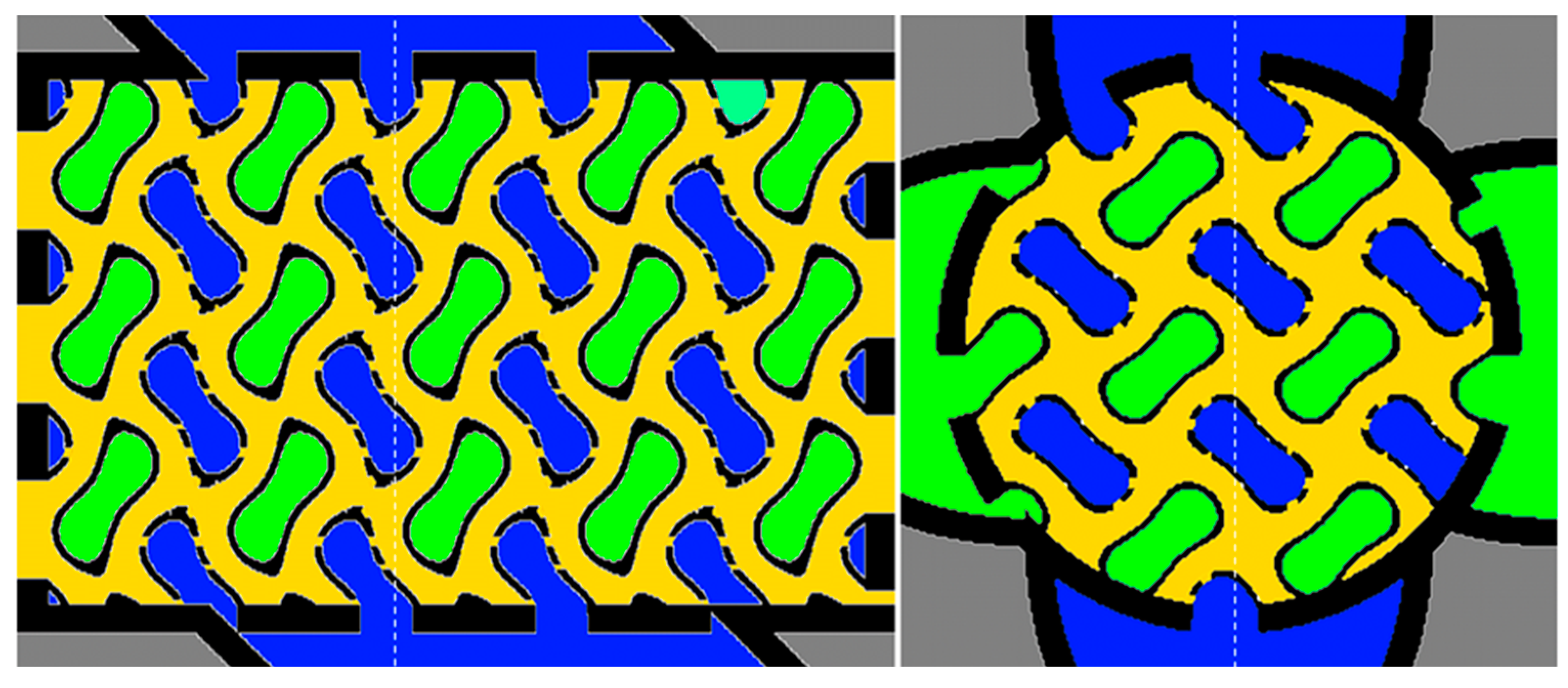

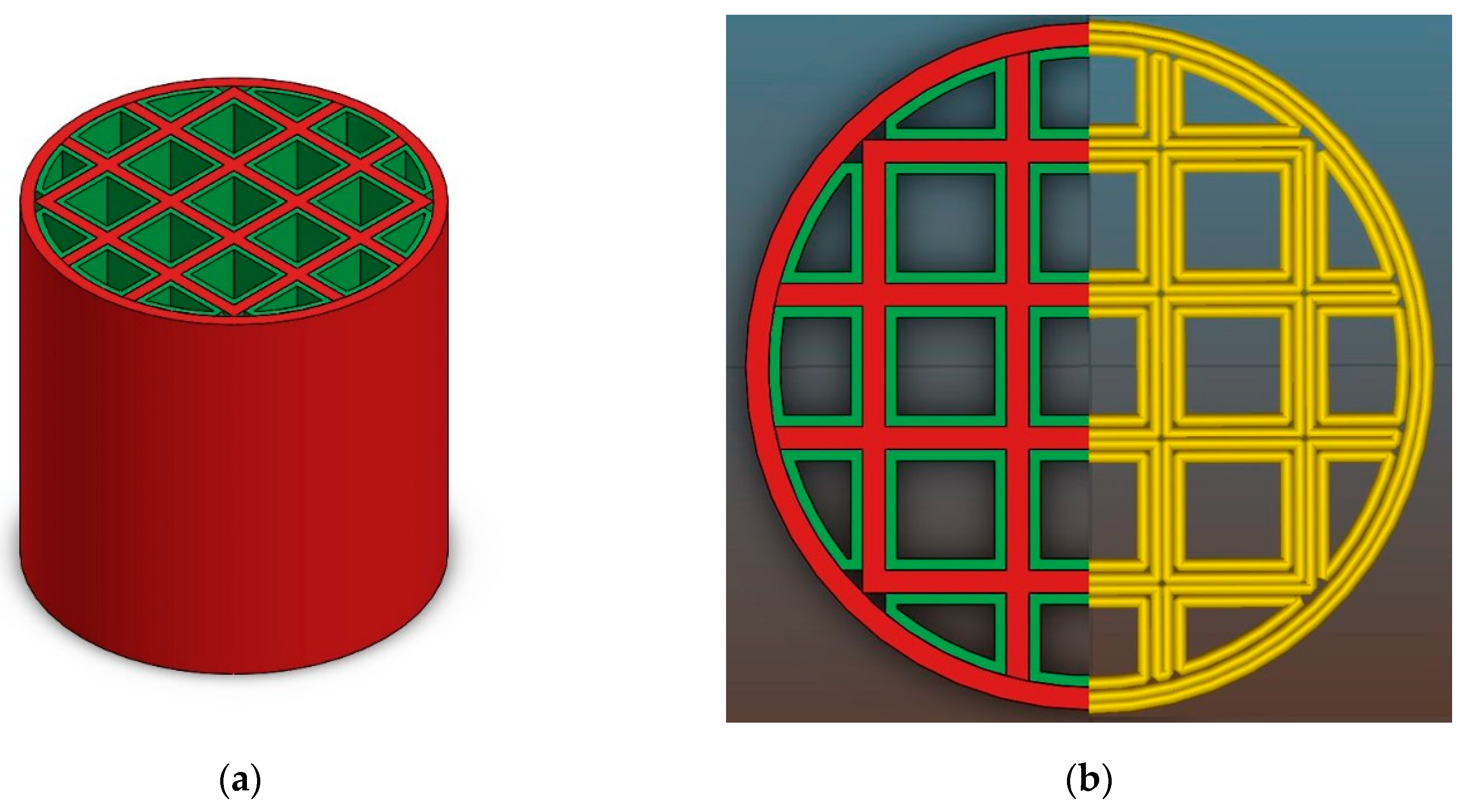

3.1.1. Generation of CAD Data by Voxel Based Geometry Generators

- fluid A: ;

- fluid B: ;

- fluid C: and

- period length of the gyroid selected as .

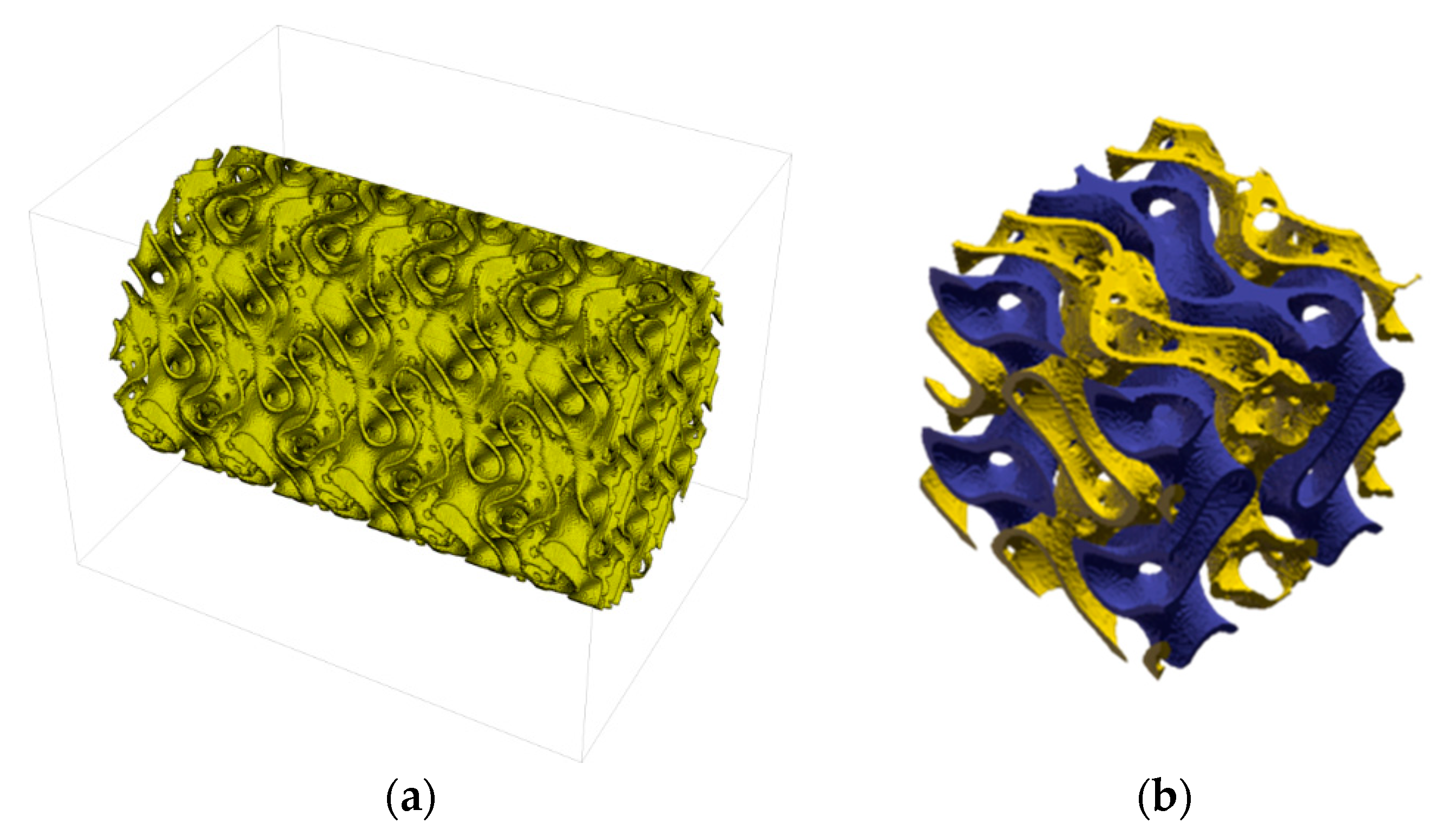

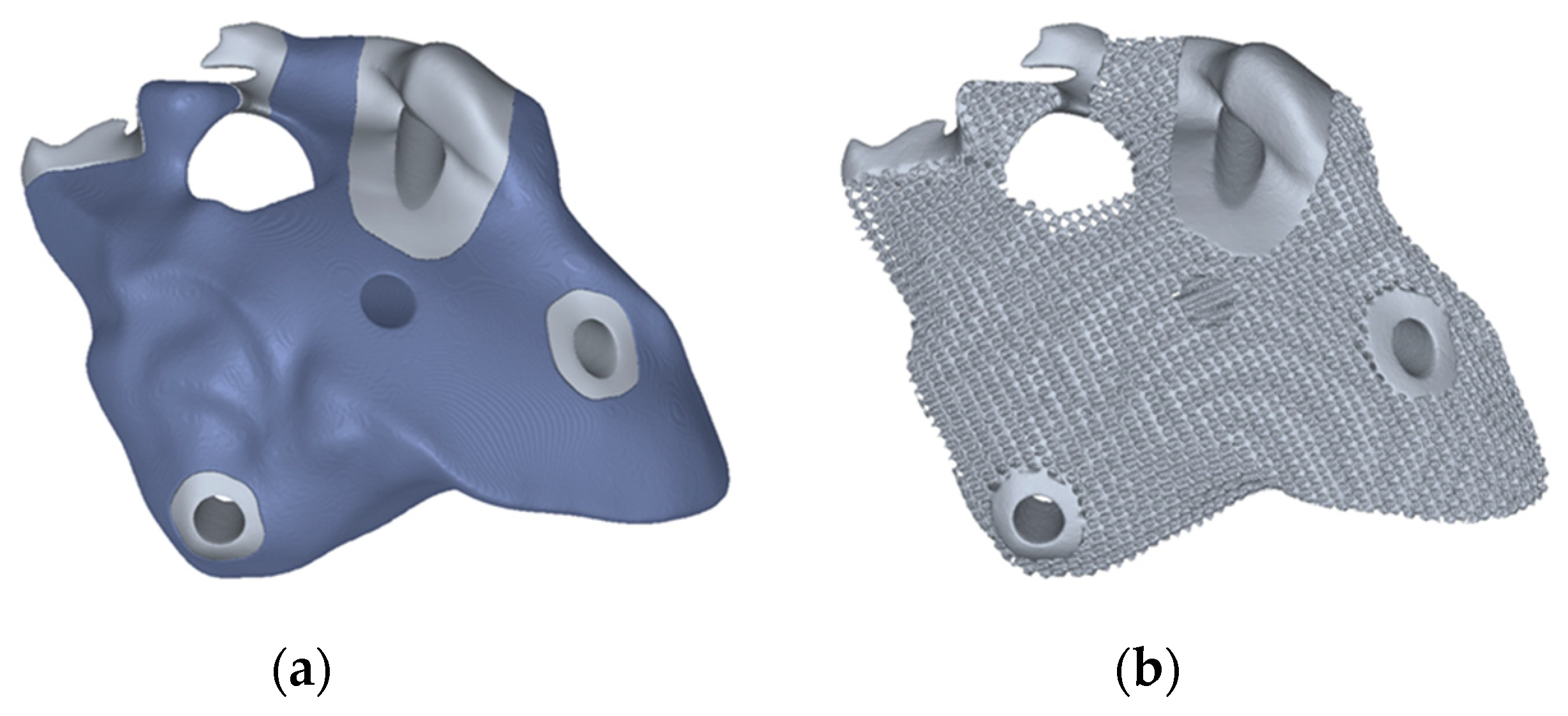

3.1.2. Generation of CAD Data based on Distance Fields

3.1.3. CerAM VPP

3.2. CerAMfacturing of Single-Material Porous Ceramics by CerAM Replica

3.3. CerAMfacturing of Multi-Properties Porous Ceramics by CerAM T3DP

4. Results

4.1. CerAM VPP

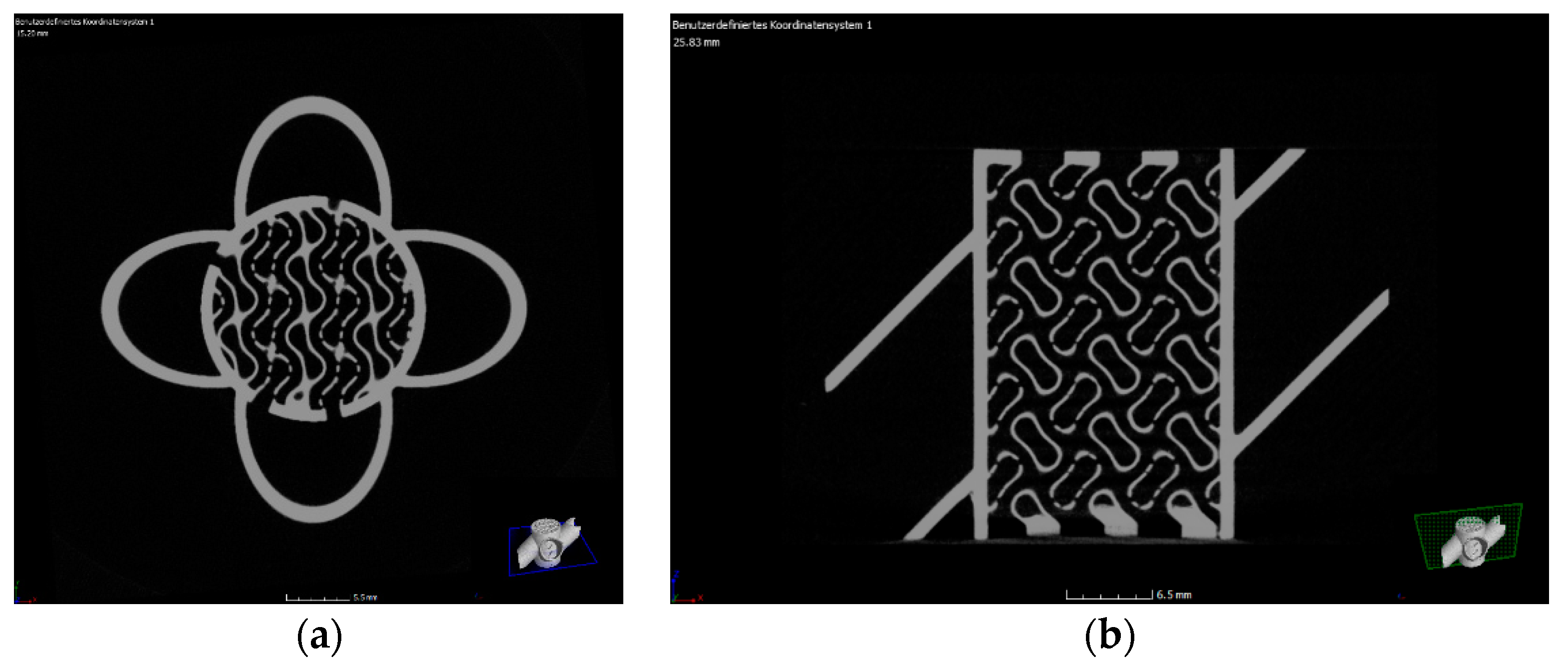

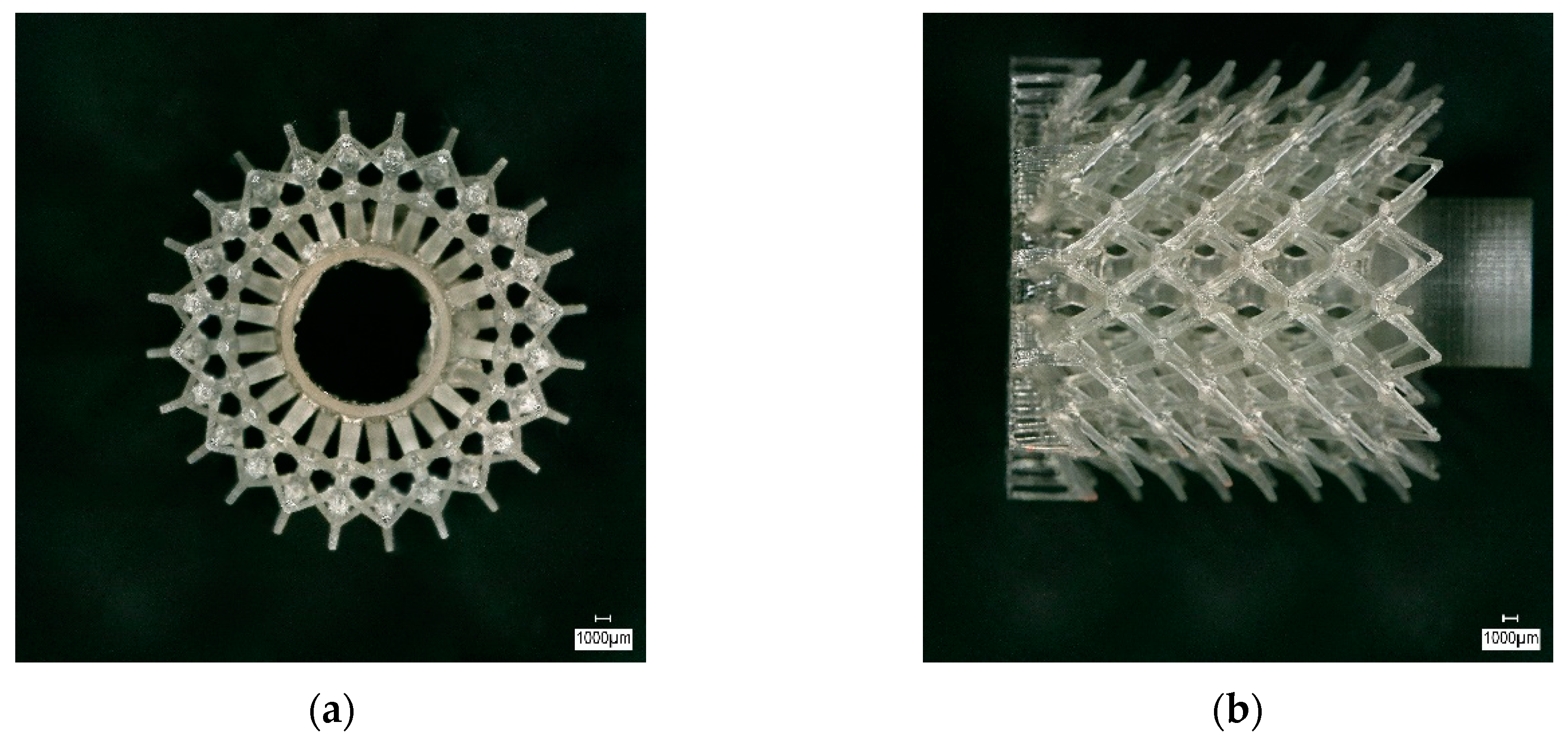

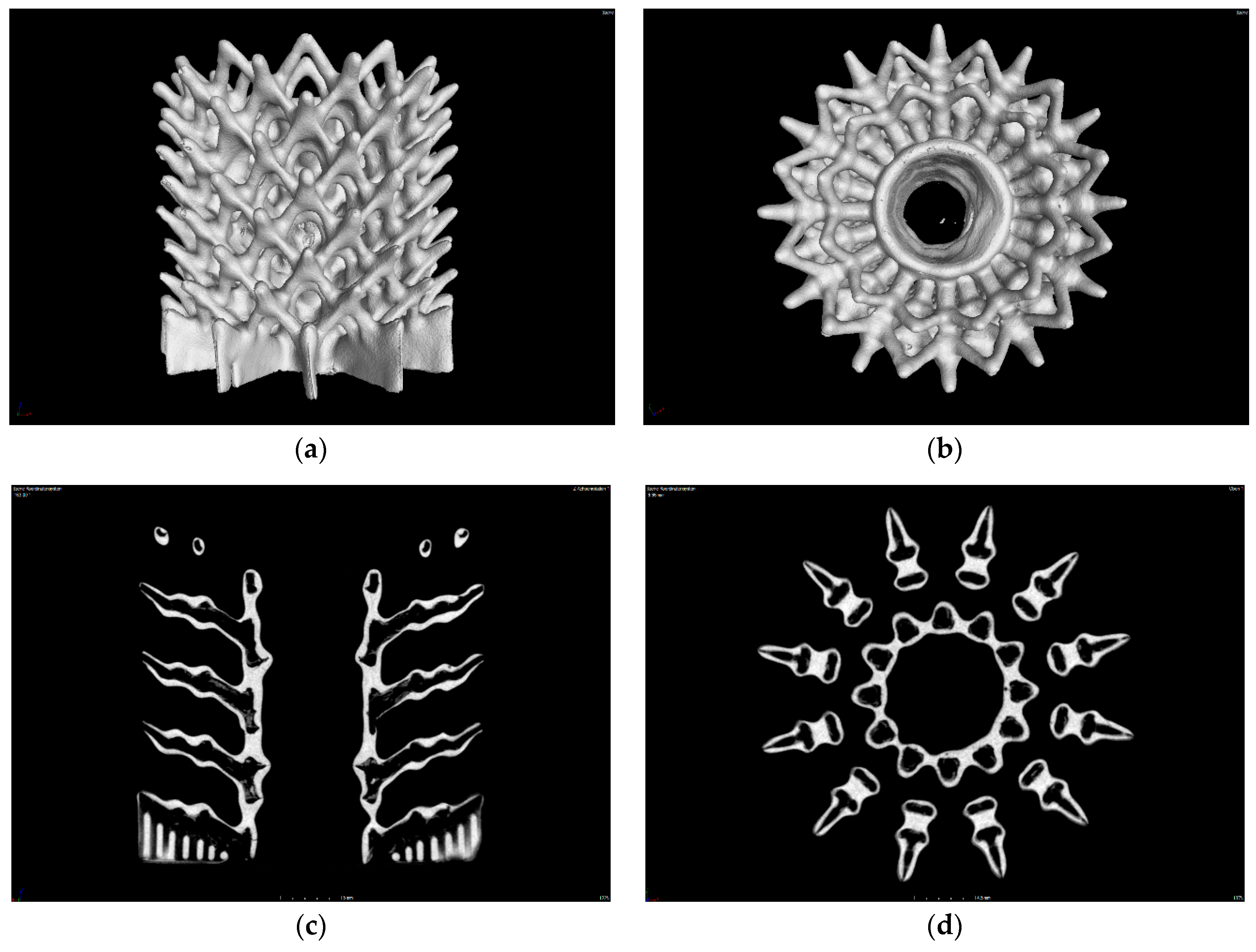

4.1.1. CerAM VPP—Machine Files

4.1.2. CerAM VPP—Sintered Components

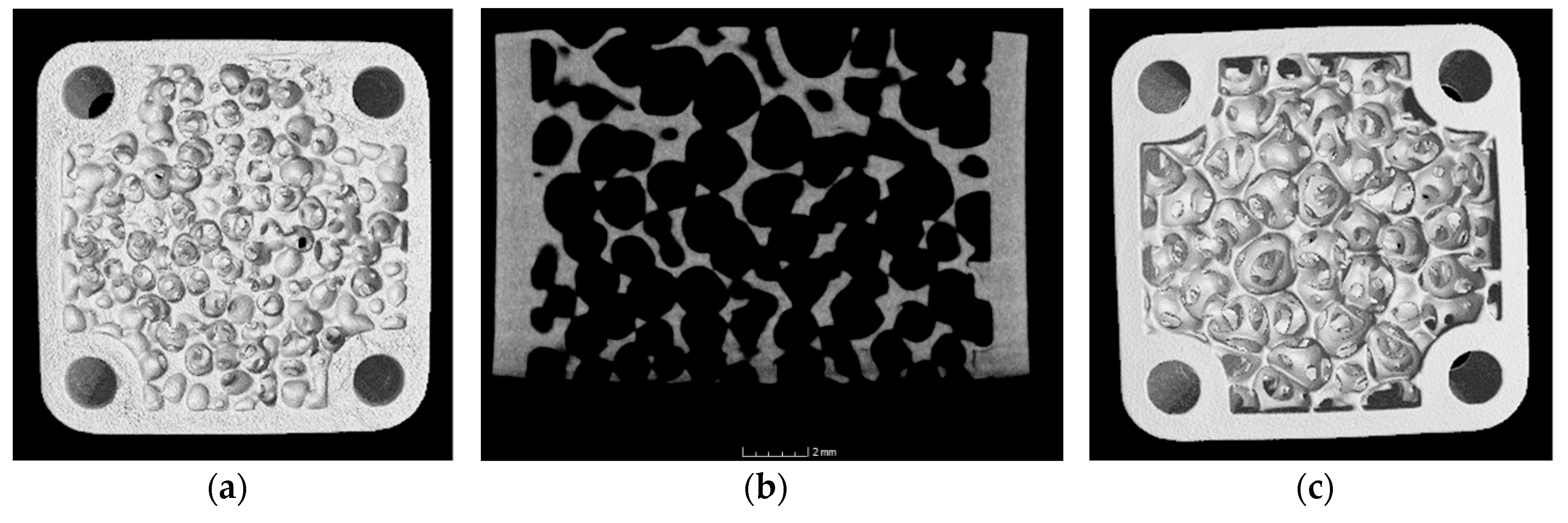

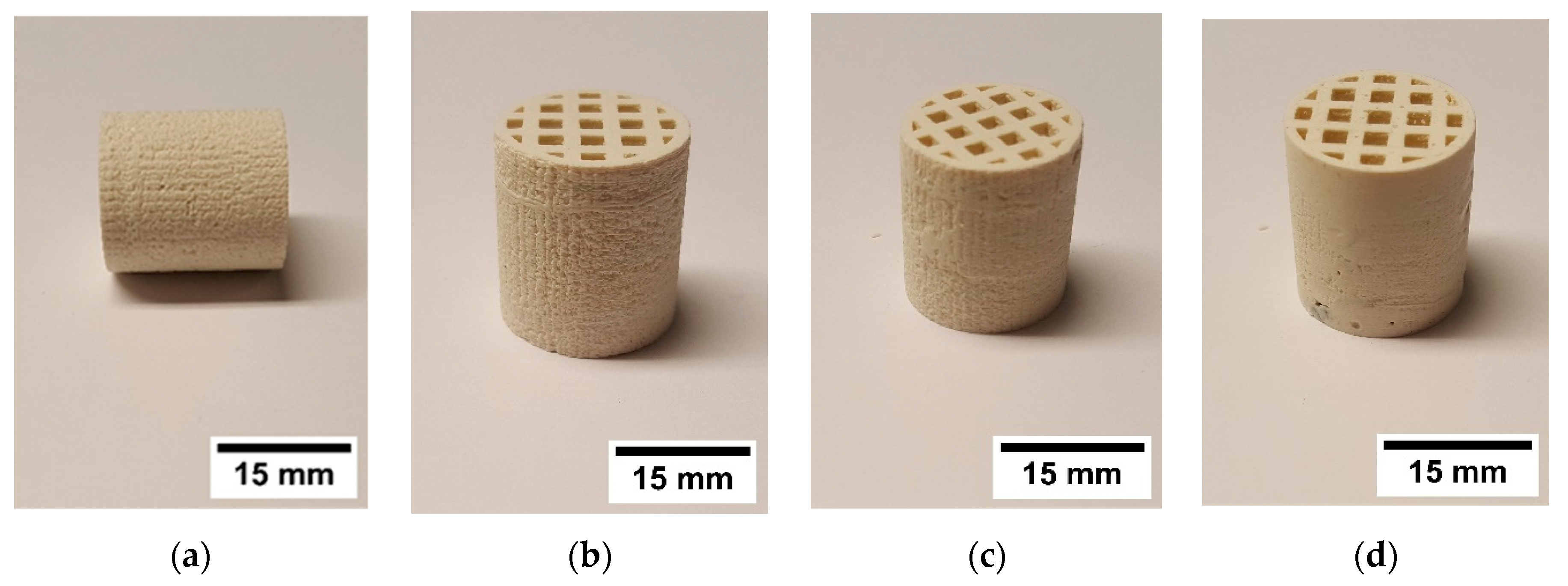

4.1.3. CerAM VPP—Characterization

4.2. CerAM Replica

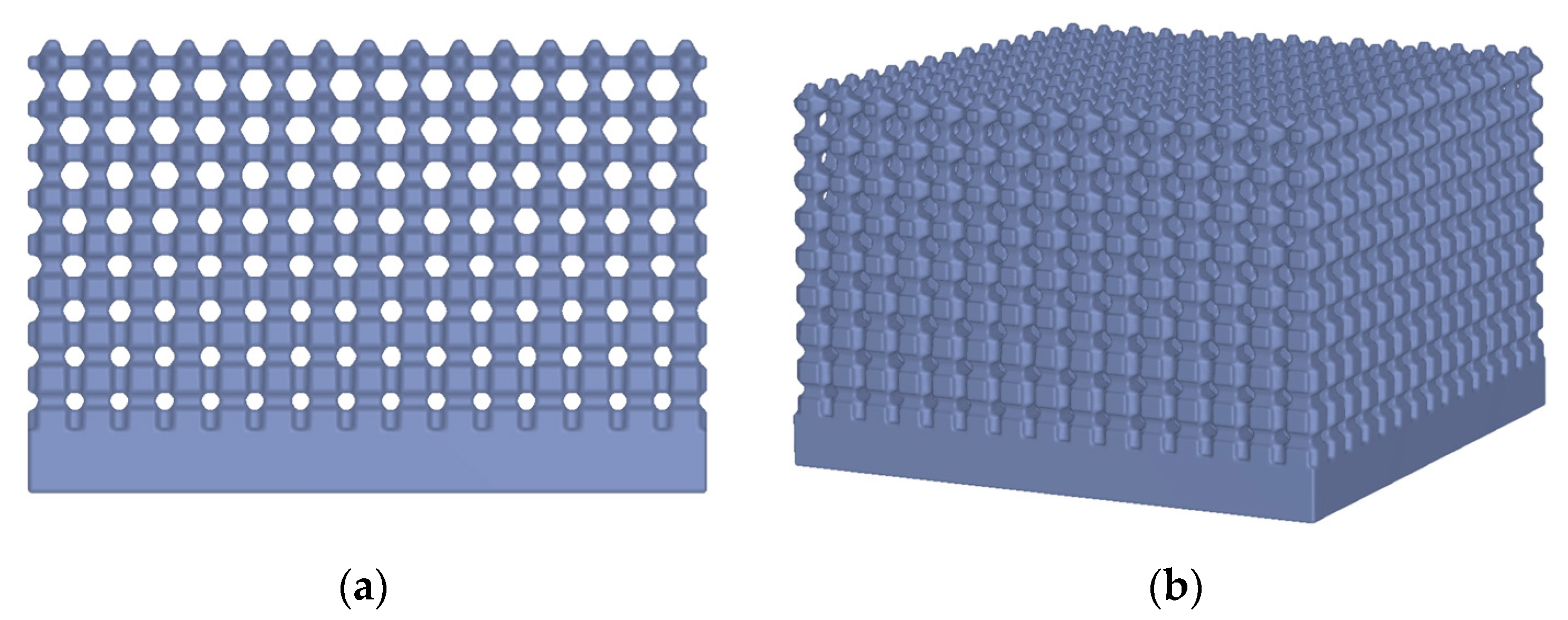

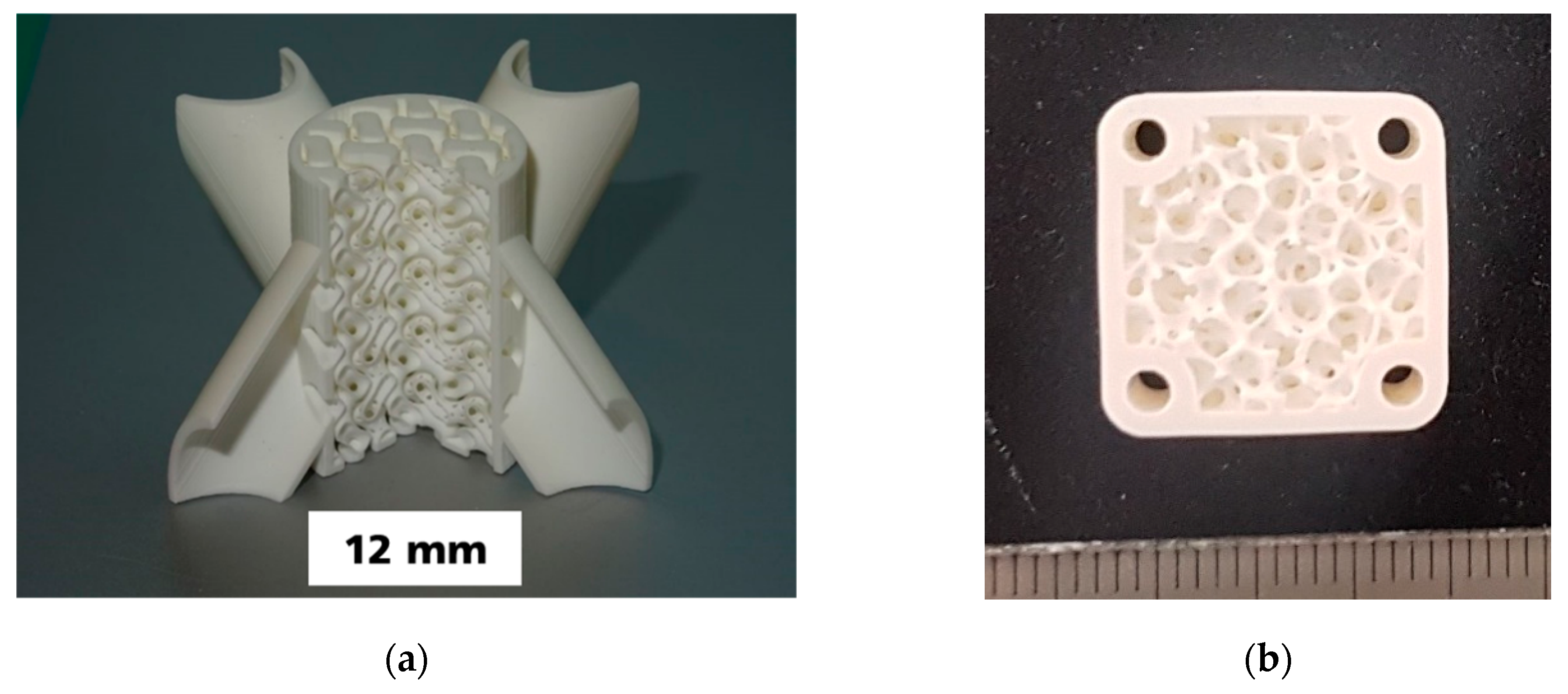

4.2.1. CerAM Replica—Final CAD Data and Polymeric Template

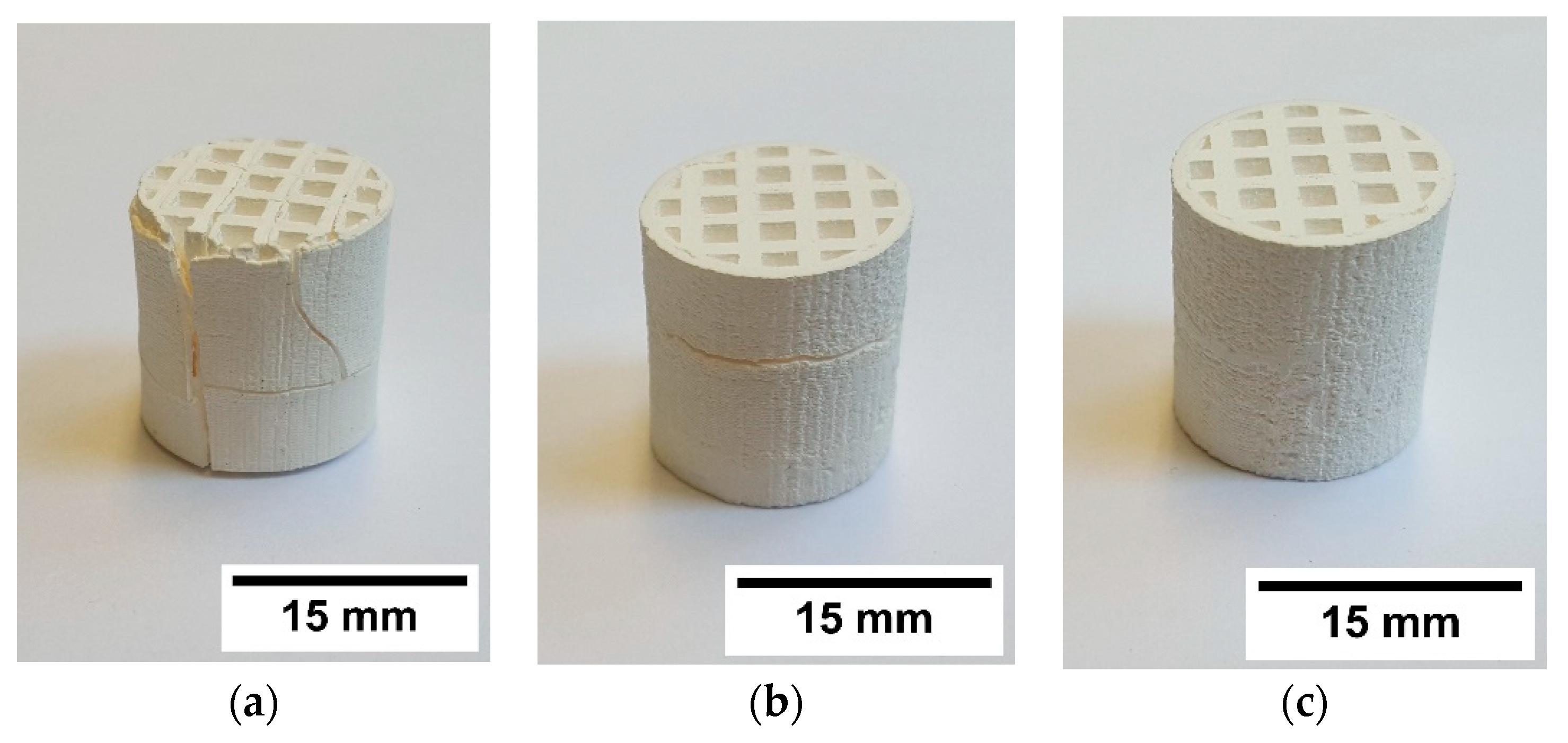

4.2.2. CerAM Replica—Green and Sintered Components

4.2.3. CerAM Replica—Characterization

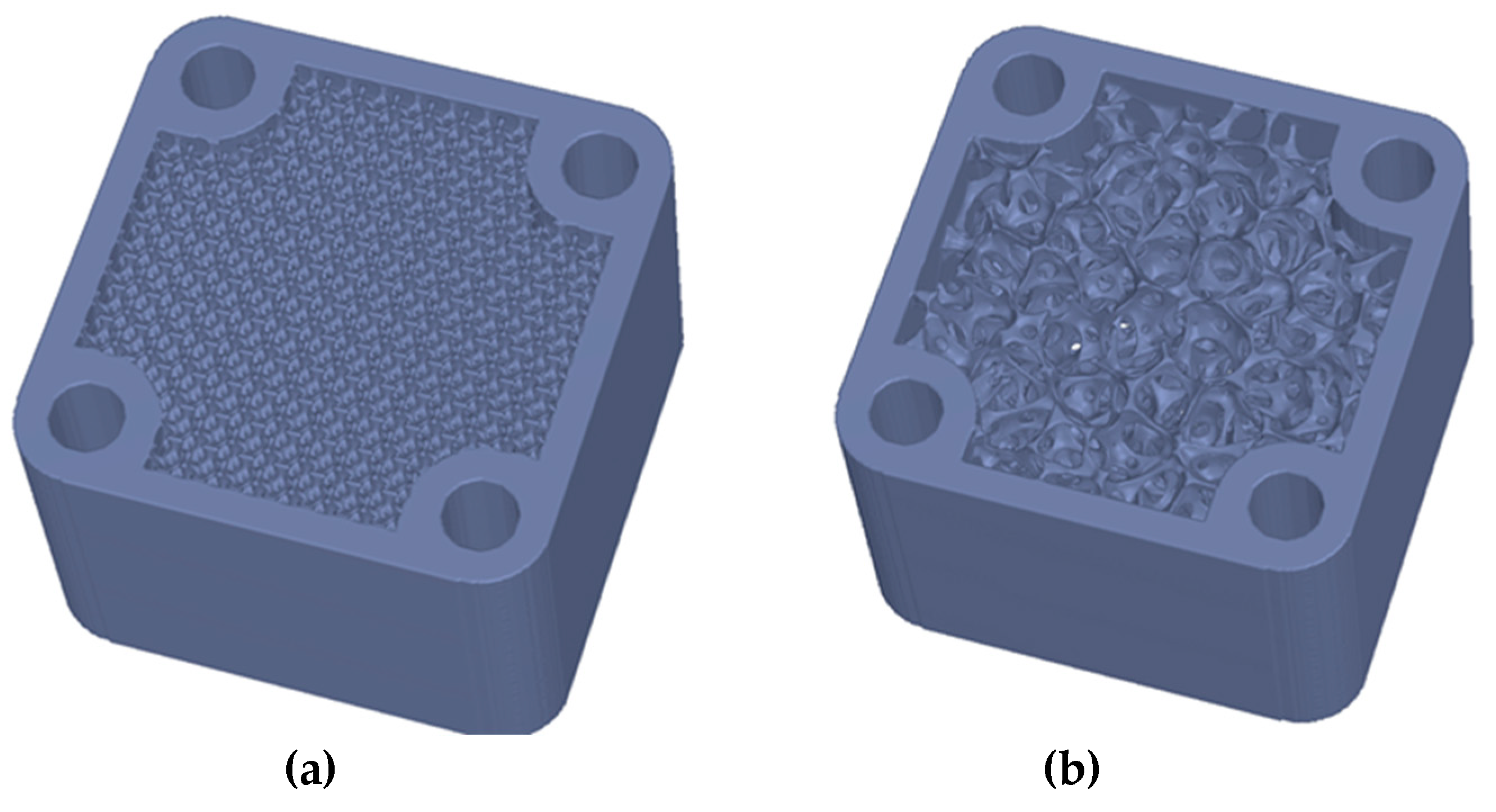

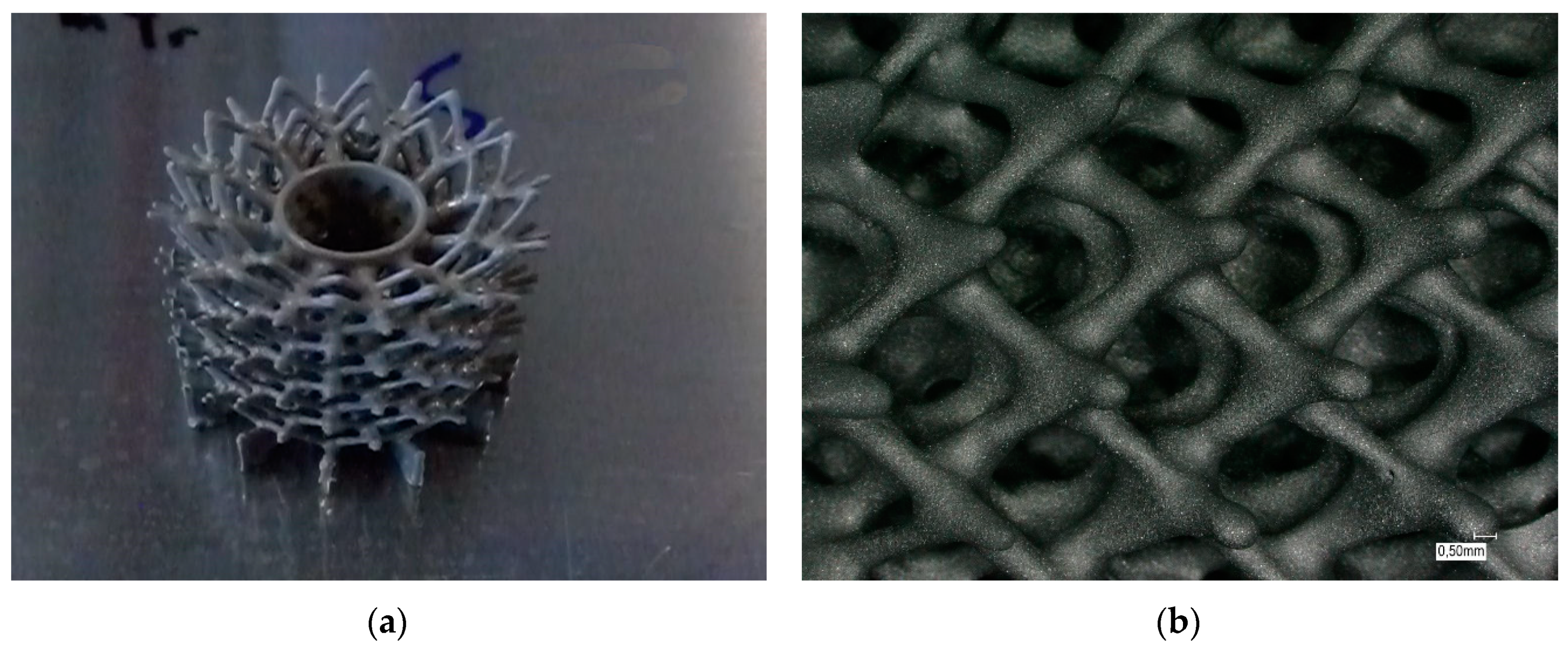

4.3. CerAM T3DP

4.3.1. CerAM T3DP—Characterization of the Suspensions

4.3.2. CerAM T3DP—Green and Sintered Components

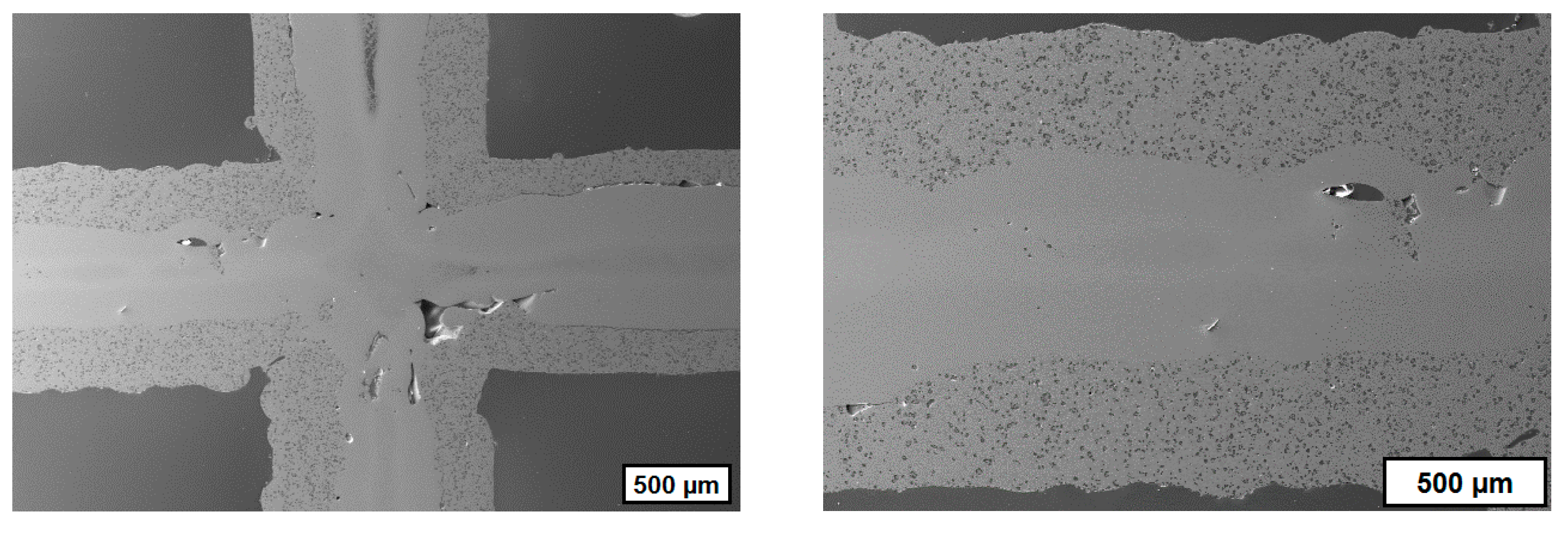

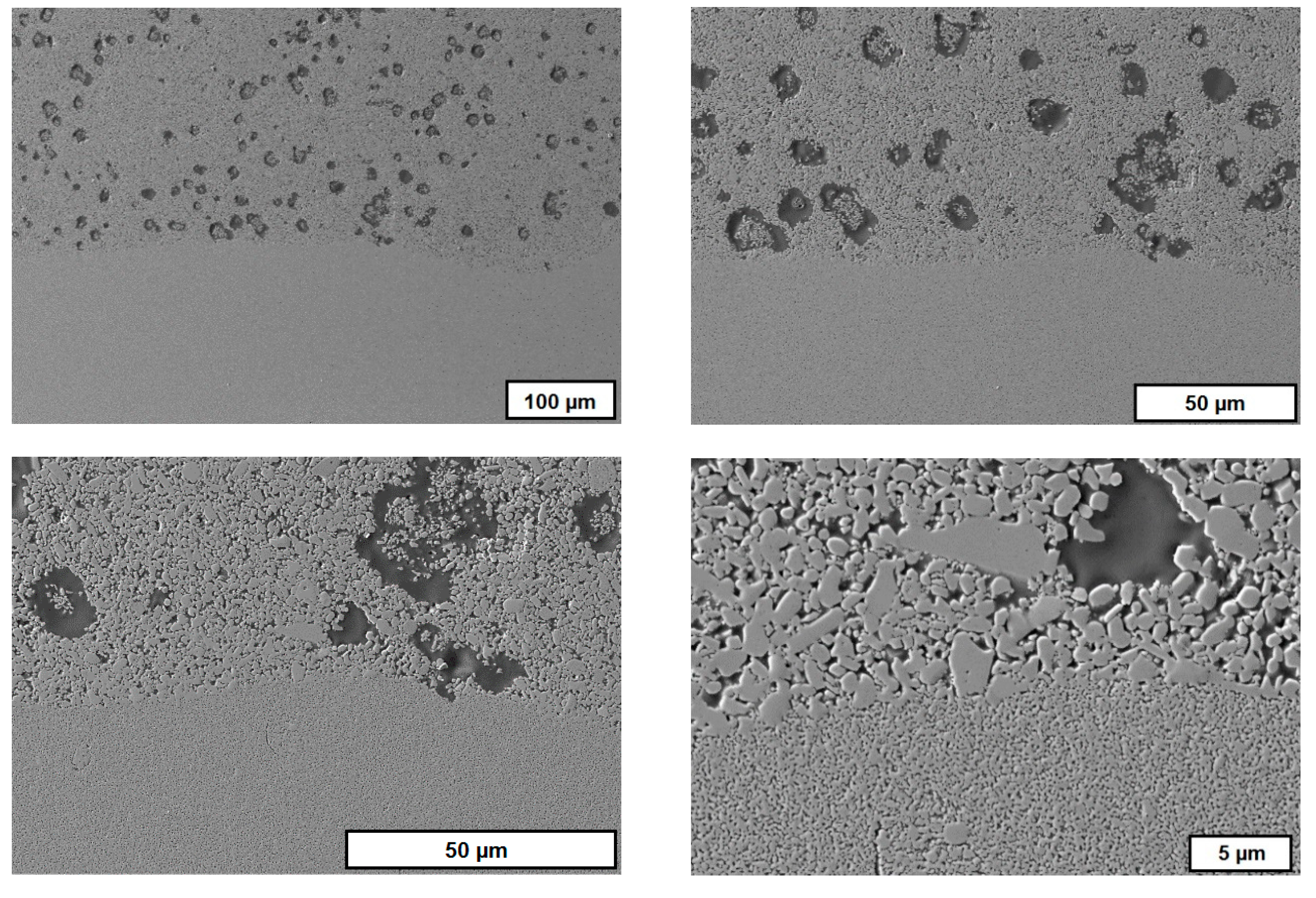

4.3.3. CerAM T3DP—Characterization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jean, G.; Sciamanna, V.; Demuynck, M.; Cambier, F.; Gonon, M. Macroporous ceramics: Novel route using partial sintering of alumina-powder agglomerates obtained by spray-drying. Ceram. Int. 2014, 40, 10197–10203. [Google Scholar] [CrossRef]

- Shan, S.Y.; Yang, J.F.; Gao, J.Q.; Zhang, W.H.; Jin, Z.H.; Janssen, R.; Ohji, T. orous Silicon Nitride Ceramics Prepared by Reduction–Nitridation of Silica. J. Am. Ceram. Soc. 2005, 88, 2594–2596. [Google Scholar] [CrossRef]

- Colombo, P. Conventional and novel processing methods for cellular ceramics. Phil. Trans. R. Soc. A 2006, 364, 109–124. [Google Scholar] [CrossRef] [PubMed]

- Khabas, T.A.; Vakalova, T.V.; Kamyshnaya, K.S.; D’yakonova, E.V.; Cherepanova, A.I.; Biryukova, A.A. Porous Cordierite Ceramic with pore formers of a different nature. Refract. Ind. Ceram. 2018, 59, 269–274. [Google Scholar] [CrossRef]

- Adler, J.; Standke, G. Open-celled foam ceramics, Part 1 and 2. Keram. Z. 2003, 55, 694–703. [Google Scholar]

- Pokhrel, A.; Deo, D.N.; Lee, S.T.; Kim, I.J. Processing of porous ceramics by direct foaming: A review. J. Korean Ceram. Soc. 2013, 50, 93–102. [Google Scholar] [CrossRef]

- Luthard, F.; Adler, J.; Michaelis, A. Characteristics of a Continuous Direct Foaming Technique. Int. J. Appl. Ceram. Technol. 2015, 12, 133–138. [Google Scholar] [CrossRef]

- Schwartzwalder, A.V. Method of making porous ceramic articles. U.S. Patent 3090094 A, 21 May 1963. [Google Scholar]

- Gauckler, L.J.; Waeber, M.M.; Conti, C.; Jacob-Duliere, M. Ceramic Foam for Molten Metal Filtration. J. Metals 1985, 37, 47–50. [Google Scholar] [CrossRef]

- Fuessel, A.; Boettge, D.; Adler, J.; Marschallek, F.; Michaelis, A. Cellular Ceramics in Combustion Environments. Adv. Eng. Mater. 2011, 11, 13. [Google Scholar] [CrossRef]

- Zaversky, F.; Aldaz, L.; Sánchez, M.; Ávila-Marín, A.L.; Roldán, M.I.; Fernández-Reche, J.; Füssel, A.; Beckert, W.; Adler, J. Numerical and experimental evaluation of ceramic foam solar absorber—single-layer vs multi-layer configuration. Appl. Energy 2018, 210, 351–375. [Google Scholar] [CrossRef]

- Buciuman, F.C.; Kraushaar-Czarnetzki, B. Ceramic Foam Monoliths as Catalyst Carriers. 1. Adjustment and Description of the Morphology. Ind. Eng. Chem. Res. 2003, 42, 1863–1869. [Google Scholar] [CrossRef]

- Hammel, E.C.; Ighodaro, O.L.-R.; Okoli, O.I. Processing and properties of advanced porous ceramics: An application based review. Ceram. Int. 2014, 40, 15351–15370. [Google Scholar] [CrossRef]

- Scheithauer, U.; Weingarten, S.; Abel, J.; Schwarzer, E.; Beckert, B.; Richter, H.-J.; Moritz, T.; Michaelis, A. Additive Manufacturing of Ceramic—Based Functionally Graded Materials. Ceram. Appl. 2018, 6, 2. [Google Scholar]

- Homa, J. Rapid Prototyping of high-performance ceramics opens new opportunities for the CIM industry. Powder Injection Moulding Int. 2012, 6, 65–68. [Google Scholar]

- Schwentenwein, M.; Homa, J. Additive Manufacturing of Dense Alumina Ceramics. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Ganzer, G.; Körnig, A.; Beckert, W.; Reichelt, E.; Jahn, M.; Härtel, A.; Richter, H.-J.; Moritz, T.; Michaelis, A. Micro-reactors made by Lithography-based Ceramic Manufacturing (LCM). In Additive Manufacturing and Strategic Technologies in Advanced Ceramics; John Wiley & Sons: Hoboken, NJ, USA, 2016; Volume 258. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Moritz, T.; Michaelis, A. Additive Manufacturing of ceramic heat exchanger —Opportunities and limits of the Lithography-based Ceramic Manufacturing (LCM). J. Mater. Eng. Perform. 2018, 27, 14–20. [Google Scholar] [CrossRef]

- Frisken, S.F.; Perry, R.N. Designing with distance fields. In Proceedings of the SIGGRAPH ’06 ACM SIGGRAPH 2006 Courses, Boston, MA, USA, 30 July–03 August 2006; ACM Press: New York, NY, USA; pp. 60–66. [Google Scholar]

- Bærentzen, J.A.; Aanæs, H. Generating Signed Distance Fields From Triangle Meshes. Inform. Math. Model. Tech. Univ. Den. 2002, 20, 23. [Google Scholar]

- Lorensen, W.E.; Cline, H.E. Marching cubes: A high resolution 3D surface construction algorithm. In Proceedings of the SIGGRAPH ’87—The 14th Annual Conference on Computer Graphics and Interactive Techniques, Anaheim, CA, USA, 27–31 July 1987; ACM Press: New York, NY, USA; pp. 163–169. [Google Scholar]

- Boettge, D.; Standke, G.; Fuessel, A.; Adler, J. Functionalization of open-celled foams by homogeneous slurry-based coatings. J. Mater. Res. 2013, 28, 2220–2233. [Google Scholar] [CrossRef]

- Balzarotti, R.; Ciurlia, M.; Cristiani, C.; Paparella, F. Washcoat deposition of Ni- and CoZrO2 Low Sureface Area Powders onto Ceramic Open-Cell Foams: Influence of Slurry Formulation and Rheology. Catalysts 2015, 5, 2271–2286. [Google Scholar] [CrossRef]

- Gómez, S.Y.; Alvarez, O.A.; Escobar, J.A.; Rodrigues Neto, J.B.; Rambo, C.R.; Hotza, D. Relationship between Rheological Behavior and Final Structure of Al2O3 and YSZ Foams Produced by Replica. Adv. Mater. Sci. Eng. 2012. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Richter, H.J.; Moritz, T. Thermoplastic 3D Printing—An Additive Manufacturing Method for Producing Dense Ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 26–31. [Google Scholar] [CrossRef]

- Scheithauer, U.; Johne, R.; Weingarten, S.; Schwarzer, E.; Abel, J.; Richter, H.; Moritz, T.; Michaelis, A. Investigation of Droplet Deposition for Suspensions Usable for Thermoplastic 3D Printing (T3DP). J. Mater. Eng. Perform. 2018, 27, 44–51. [Google Scholar] [CrossRef]

- Scheithauer, U.; Pötschke, J.; Weingarten, S.; Schwarzer, E.; Vornberger, A.; Moritz, T.; Michaelis, A. Droplet-based additive manufacturing of hard metal components by thermoplastic 3D printing (T3DP). J. Ceram. Sci. Technol. 2017, 8, 155–160. [Google Scholar]

- Scheithauer, U.; Bergner, A.; Schwarzer, E.; Richter, H.-J.; Moritz, T. Studies on thermoplastic 3D printing of steel–zirconia composites. J. Mater. Res. 2014, 29, 1931–1940. [Google Scholar] [CrossRef]

- Scheithauer, U.; Slawik, T.; Schwarzer, E.; Richter, H.-J.; Moritz, T.; Michaelis, A. Additive Manufacturing of Metal-Ceramic-Composites by Thermoplastic 3D-Printing. J. Ceram. Sci. Technol. 2015, 6, 125–132. [Google Scholar]

- Weingarten, S.; Scheithauer, U.; Johne, R.; Abel, J.; Schwarzer, E.; Moritz, T.; Michaelis, A. Multi-material Ceramic-Based Components—Additive Manufacturing of Black-and-white Zirconia Components by Thermoplastic 3D-Printing (CerAM-T3DP). J. Vis. Exp. 2019, 143, e57538. [Google Scholar]

- Scheithauer, U.; Weingarten, S.; Johne, R.; Schwarzer, E.; Abel, J.; Richter, H.-J.; Moritz, T.; Michaelis, A. Ceramic-Based 4D Components: Additive Manufacturing (AM) of Ceramic-Based Functionally Graded Materials (FGM) by Thermoplastic 3D Printing (T3DP). Materials 2017, 10, 19. [Google Scholar] [CrossRef] [PubMed]

- Mitteramskogler, G.; Gmeiner, R.; Felzmann, R.; Gruber, S.; Hofstetter, C.; Stampfl, J. Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 2014, 1, 110–118. [Google Scholar] [CrossRef]

- Johansson, E.; Lidström, O.; Johansson, J.; Lyckfeldt, O.; Adolfsson, E. Influence of Resin Composition on the Defect Formation in Alumina Manufactured by Stereolithography. Materials 2017, 10, 138. [Google Scholar] [CrossRef] [PubMed]

| Name | Company | d50 in µm | d90 in µm | Fired Density in g/cm³ |

|---|---|---|---|---|

| CT 1200 SG | Almatis | 1.734 | 3.14 | 3.99 |

| Baikalox SMA6 | Baikowski | 0.251 | 0.671 | 3.96 |

| MR52 | Martinswerk | 1.836 | 4.856 | - |

| Component | Content in vol.% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | |

| CT1200 SG | 50 | 50 | 45 | ||||||

| SMA6 | 35 | 35 | 45 | 55 | |||||

| MR52 | 50 | 50 | |||||||

| binder system | 45 | 35 | 40 | 60 | 50 | 50 | 40 | 45 | 35 |

| dispersant | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| PFA | 0 | 10 | 10 | 0 | 10 | 0 | 0 | 0 | 10 |

| Suspension | CT1200 SG | SMA6 | MR52 | PFA (10 vol.%) | Open Porosity [%] (After Sintering at 1250 °C) | Open Porosity [%] (After Sintering at 1600 °C) |

|---|---|---|---|---|---|---|

| A | x | 28.85 | 0.46 | |||

| B | x | x | 30.22 | 4.45 | ||

| C | x | x | 24.05 | |||

| D | x | 20.64 | 0.18 | |||

| E | x | x | 24.44 | 2.93 | ||

| F | x | 16.83 | ||||

| G | x | 8.49 | ||||

| H | x | 23.03 | 0.09 | |||

| I | x | x | 25.25 | 0.51 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheithauer, U.; Kerber, F.; Füssel, A.; Holtzhausen, S.; Beckert, W.; Schwarzer, E.; Weingarten, S.; Michaelis, A. Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges. Materials 2019, 12, 663. https://doi.org/10.3390/ma12040663

Scheithauer U, Kerber F, Füssel A, Holtzhausen S, Beckert W, Schwarzer E, Weingarten S, Michaelis A. Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges. Materials. 2019; 12(4):663. https://doi.org/10.3390/ma12040663

Chicago/Turabian StyleScheithauer, Uwe, Florian Kerber, Alexander Füssel, Stefan Holtzhausen, Wieland Beckert, Eric Schwarzer, Steven Weingarten, and Alexander Michaelis. 2019. "Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges" Materials 12, no. 4: 663. https://doi.org/10.3390/ma12040663

APA StyleScheithauer, U., Kerber, F., Füssel, A., Holtzhausen, S., Beckert, W., Schwarzer, E., Weingarten, S., & Michaelis, A. (2019). Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges. Materials, 12(4), 663. https://doi.org/10.3390/ma12040663