Effects of Reactive MgO on the Reaction Process of Geopolymer

Abstract

1. Introduction

2. Materials and Methods

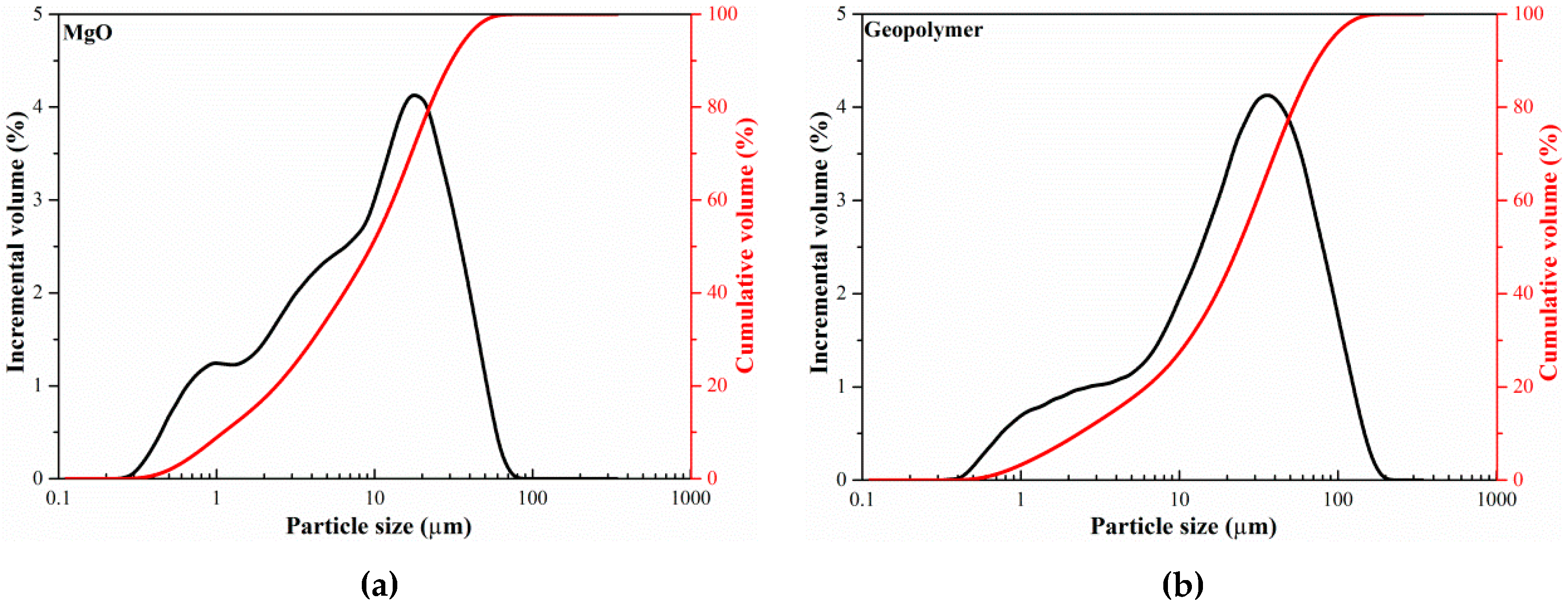

2.1. Raw Materials

2.2. Testing Methods

3. Results and Discussion

3.1. Effect of MgO on the Deformation of Geopolymer Paste

3.1.1. Effect of MgO on the Chemical Shrinkage of Geopolymer Paste

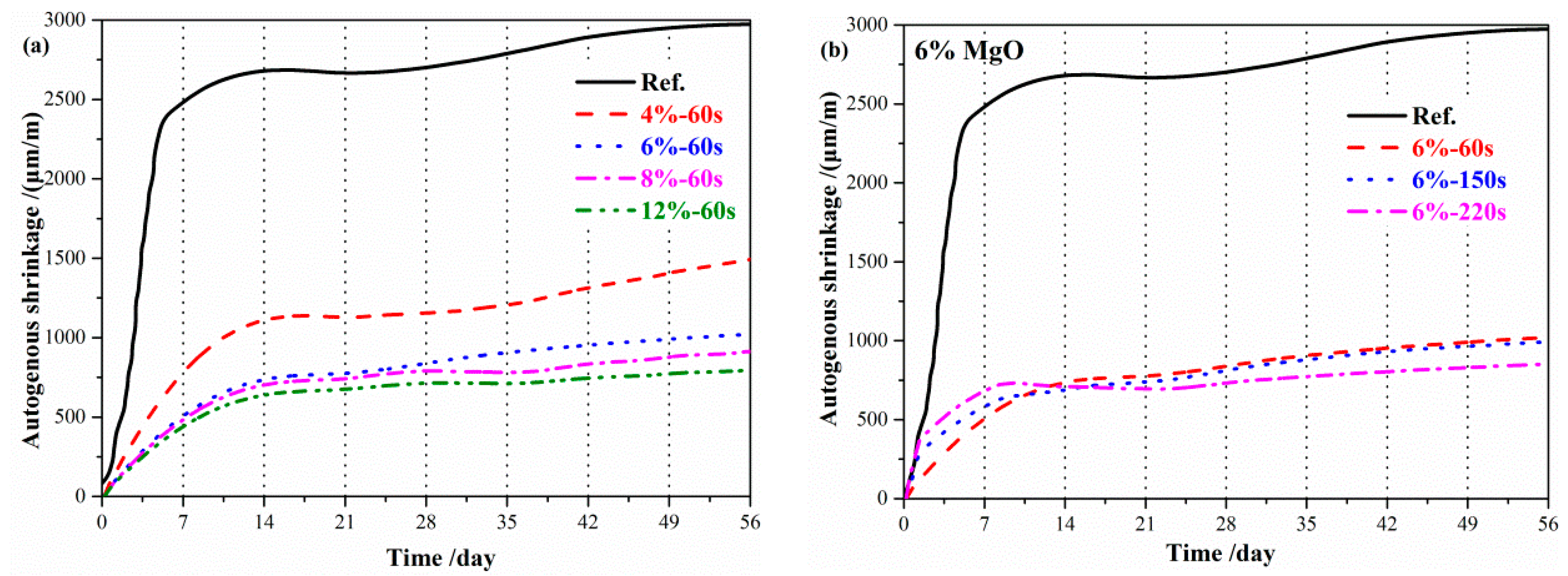

3.1.2. Effect of MgO on the Autogenous Shrinkage of Geopolymer Paste

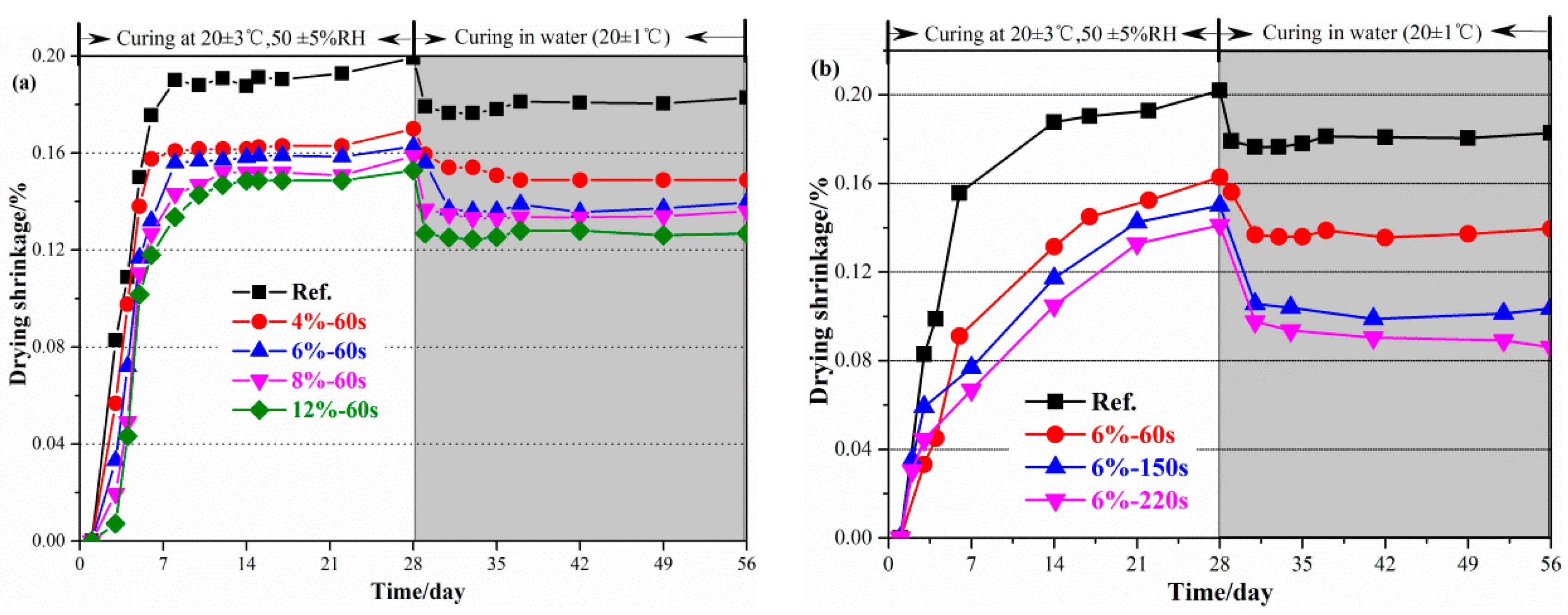

3.1.3. Effect of MgO on the Drying Shrinkage of Geopolymer Paste

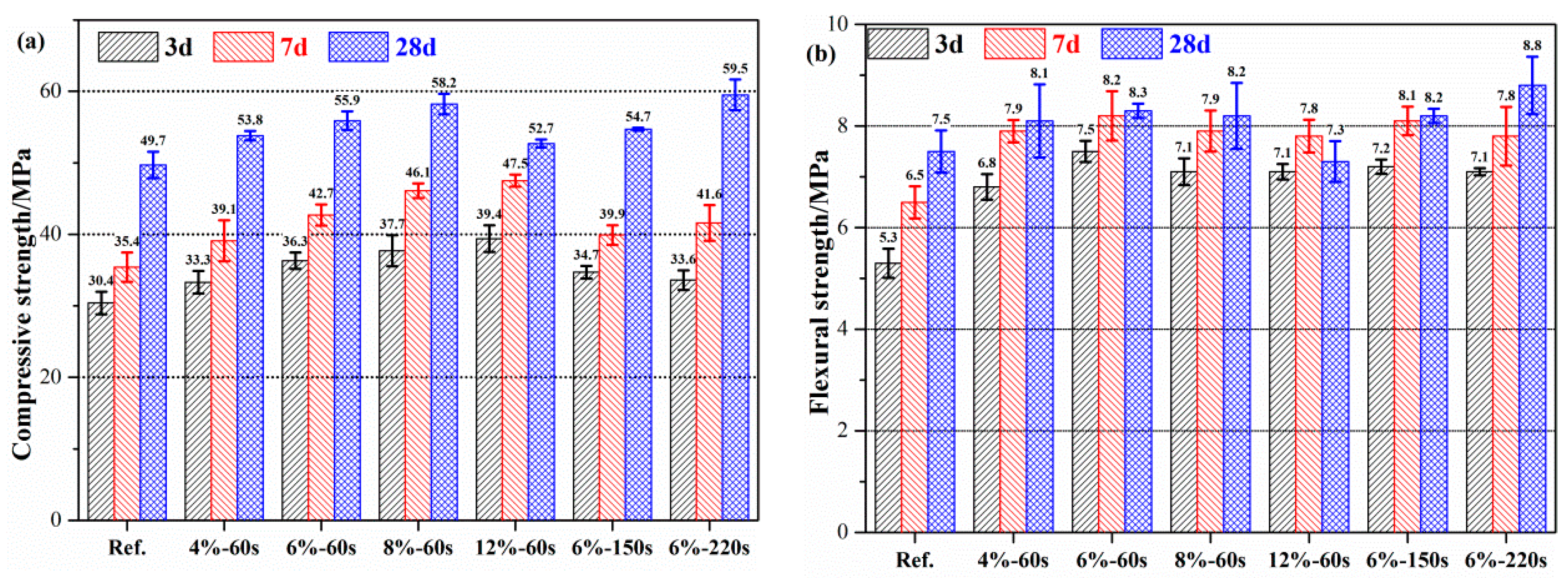

3.2. Effect of MgO on the Mechanical Properties of Geopolymer

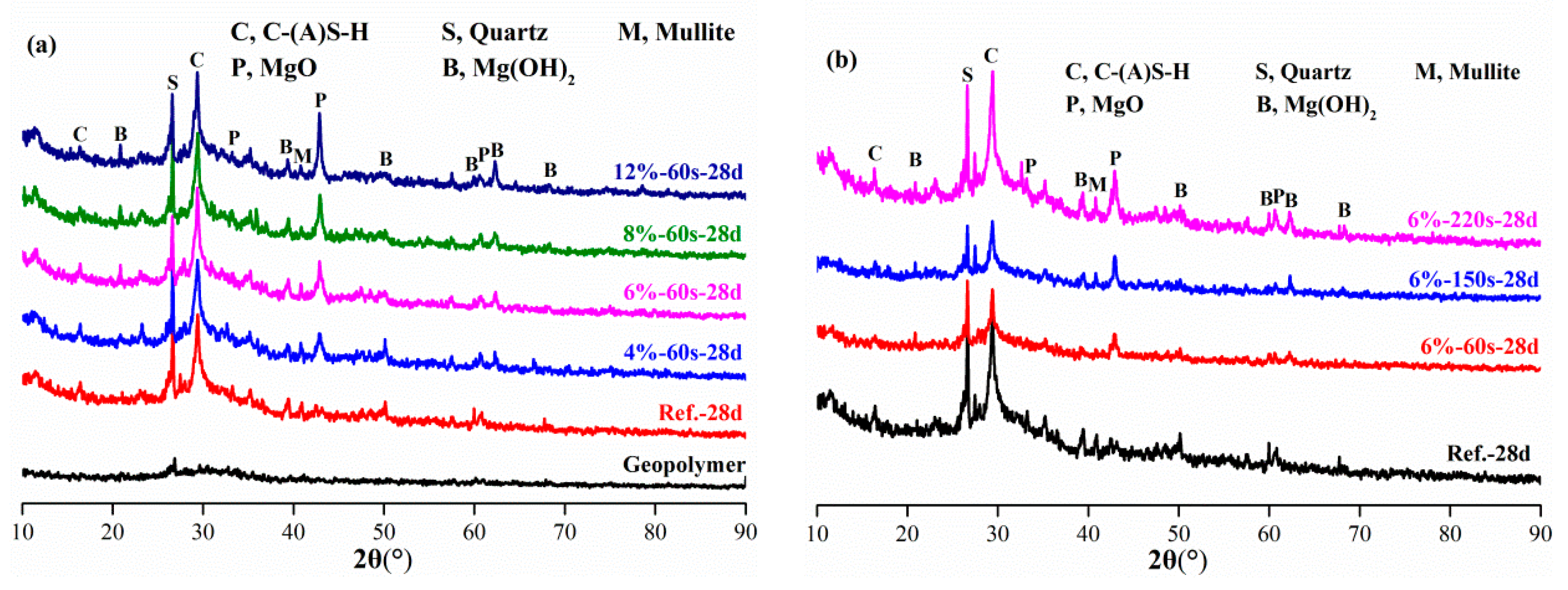

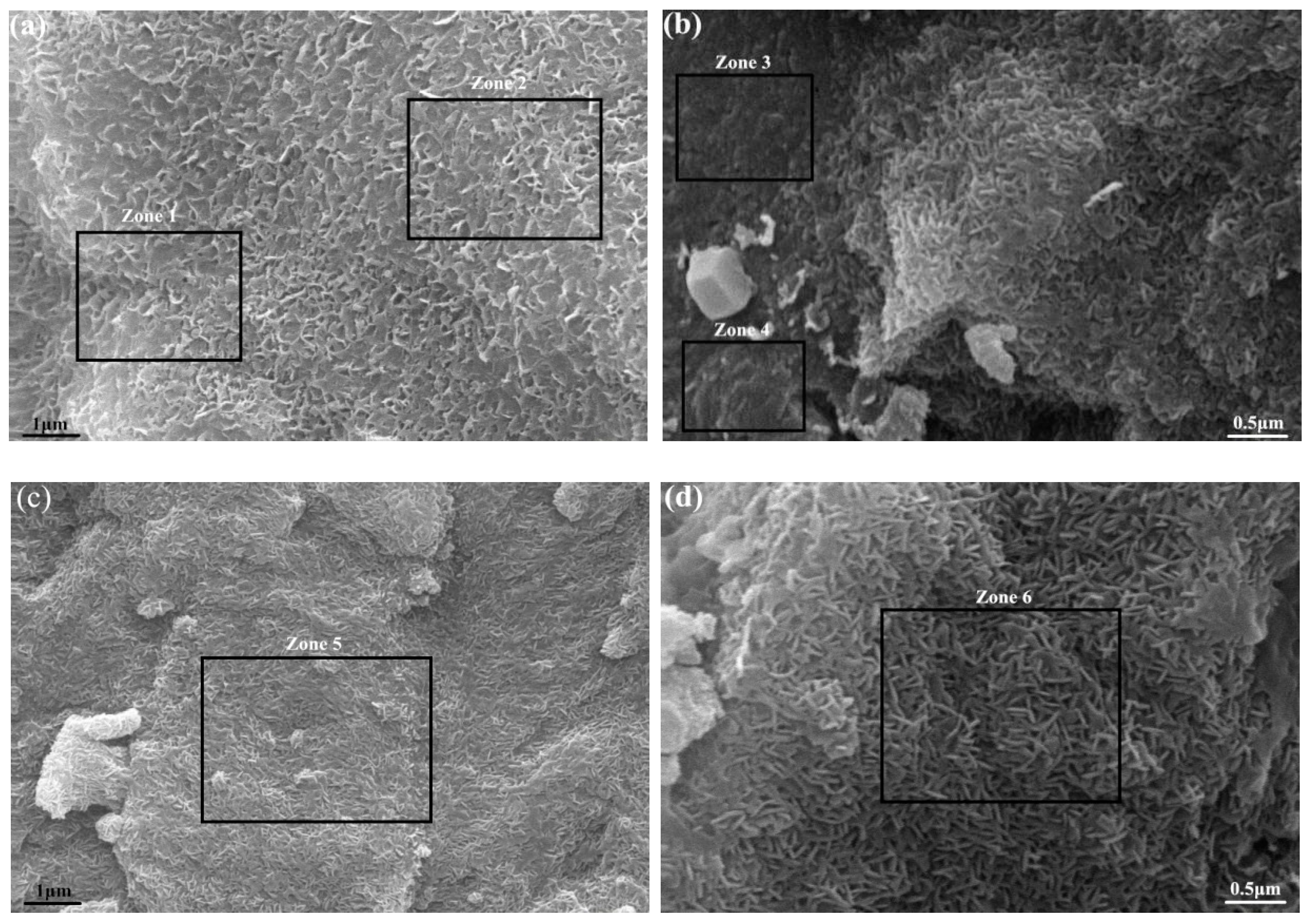

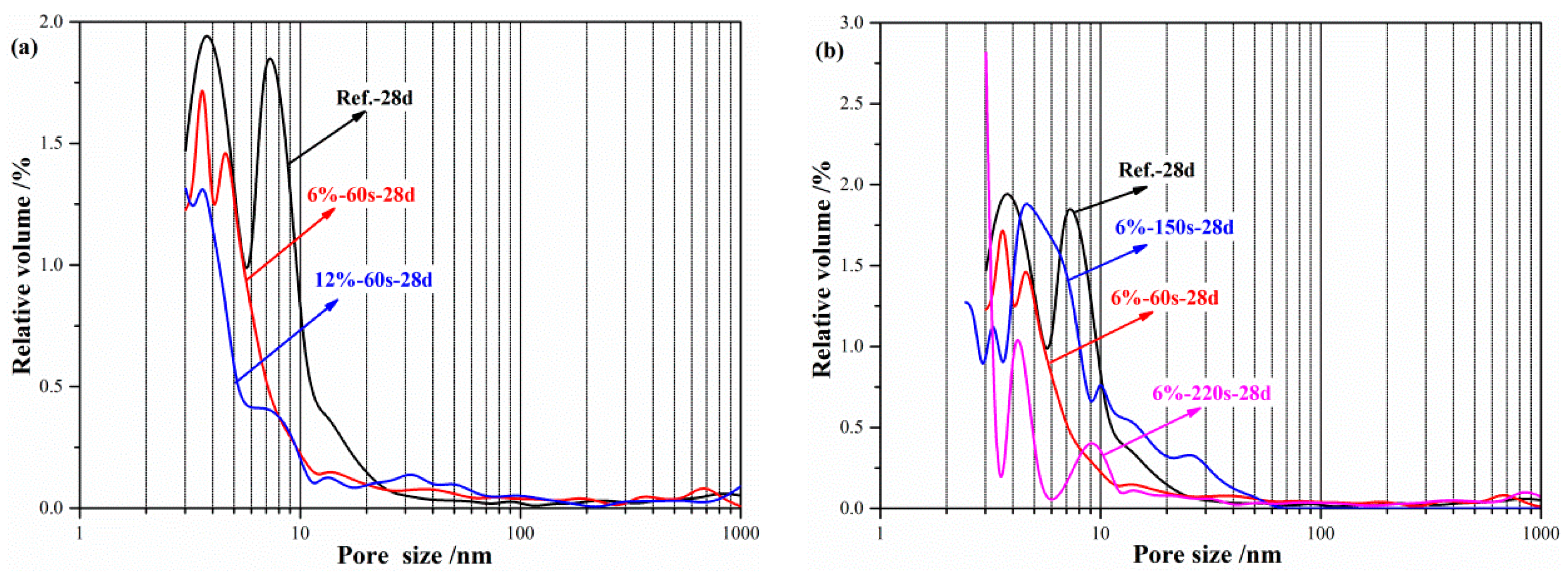

3.3. Composition and Structure of Geopolymer Paste

4. Conclusions

- (1)

- The geopolymer solidified quickly and generated a large number of C-S-H and C-A-S-H gels, which show large chemical shrinkage, autogenous shrinkage and drying shrinkage at the early stage.

- (2)

- Adding reactive MgO with fine particles into the geopolymer paste to generate a large number of fine worm-like Mg(OH)2 can result in uniform microexpansion, refine the pore size of pastes, increase the compressive strength, and effectively compensate the chemical shrinkage, autogenous shrinkage and drying shrinkage.

- (3)

- With an increase of MgO content, the autogenous shrinkage, chemical shrinkage and drying shrinkage of geopolymer paste decreases gradually. The shrinkage of hardened geopolymer paste at early stage is small when adding high-activity MgO. The volume shrinkage of hardened paste at a later stage can be compensated by adding low-activity MgO.

- (4)

- In the high alkalinity liquid phase environment of geopolymer, the generated Mg(OH)2 crystal is small and does not grow easily, which disperses in the geopolymer paste, resulting in uniform volume expansion, effectively compensating for volume shrinkage in the hardening process and matching the shrinkage process.

Author Contributions

Funding

Conflicts of Interest

References

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Davidovits, J. High-alkali cements for 21st century concretes. Spec. Pub. 1994, 144, 383–398. [Google Scholar]

- Pacheco-torgal, F.; Castro-gomes, J.; Jalali, S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef]

- Roy, D.M.; Silsbee, M.R. Alkali activated cementitious materials: An overview. MRS Proc. 1991, 245, 153. [Google Scholar] [CrossRef]

- Roy, D.M. Alkali-activated cements opportunities and challenges. Cem. Concr. Res. 1999, 29, 249–254. [Google Scholar] [CrossRef]

- Pacheco-torgal, F.; Castro-gomes, J.; Jalali, S. Alkali-activated binders: A review. Part 2. About materials and binders manufacture. Constr. Build. Mater. 2008, 22, 1315–1322. [Google Scholar] [CrossRef]

- Davidovits, J.; Comrie, D.C.; Paterson, J.H.; Ritcey, D.J. Geopolymeric concretes for environmental protection. Concr. Int. 1990, 12, 30–40. [Google Scholar]

- Zhao, R.; Sanjayan, J.G. Geopolymer and Portland cement concretes in simulated fire. Mag. Concr. Res. 2011, 63, 163–173. [Google Scholar] [CrossRef]

- Cheng, T.W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Wallah, S.E. Drying shrinkage of heat-cured fly ash-based geopolymer concrete. Mod. Appl. Sci. 2009, 3, 14. [Google Scholar] [CrossRef]

- He, P.; Jia, D.; Lin, T.; Wang, M.; Zhou, Y. Effects of high-temperature heat treatment on the mechanical properties of unidirectional carbon fiber reinforced geopolymer composites. Ceram. Int. 2010, 36, 1447–1453. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.Q.; Zhou, S.H.; Chen, E.; Tang, S.W. Mechanical properties, long-term hydration heat, shinkage behavior and crack resistance of dam concrete designed with low heat Portland (LHP) cement and fly ash. Constr. Build. Mater. 2018, 187, 1073–1091. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the development of fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar]

- Somna, K.; Jatyrapitakkul, C.; Kajtvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Temuujin, J.; Van, R.A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Wallah, S.E.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Research Report GC 2; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- Zosin, A.P.; Primak, T.I.; Avsaragov, K.B. Geopolymer materials based on magnesia-iron slags for normalization and storage of radioactive wastes. Atom. Energy 1998, 85, 510–514. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Qianli, C.; Lin, C. Synthesis and heavy metal immobilization behaviors of slag based geopolymer. J. Hazard. Mater. 2007, 143, 206–213. [Google Scholar] [CrossRef]

- Li, Z.; Liu, S. Influence of slag as additive on compressive strength of fly ash-based geopolymer. J. Mater. Civ. Eng. 2007, 19, 470–474. [Google Scholar] [CrossRef]

- Palumbo, G.; Ladicicco, A.; Messina, F.; Ferone, C.; Campopiano, S.; Cioffi, R.; Colangelo, F. Characterization of Early Age Curing and Shrinkage of Metakaolin-Based Inorganic Binders with Different Rheological Behavior by Fiber Bragg Grating Sensors. Materials 2018, 11, 10. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Dalvand, A. Comparative Study on the Effects of Recycled Glass–Fiber on Drying Shrinkage Rate and Mechanical Properties of the Self-Compacting Mortar and Fly Ash–Slag Geopolymer Mortar. J. Mater. Civ. Eng. 2017, 29, 04017076. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Firouz, R.; Illikainen, M. Drying shrinkage in alkali-activated binders—A critical review. Constr. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Kheradmand, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Shrinkage performance of fly ash alkali-activated cement based binder mortars. KSCE J. Civ. Eng. 2017, 22, 1854–1864. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, T.; Hu, J.; Tang, Y.; Niu, Y.; Wei, J.; Yu, Q. Characterization of reaction products and reaction process of MgO-SiO2-H2O system at room temperature. Constr. Build. Mater. 2014, 61, 252–259. [Google Scholar] [CrossRef]

- Li, Z.; Yu, Q.; Chen, X.; Liu, H.; Zhang, J.; Yang, Y.; Wei, J. The role of MgO in the thermal behavior of MgO-silica fume pastes. J. Therm. Anal. Calorim. 2017, 127, 1897–1909. [Google Scholar]

- Li, Z.; Xu, Y.; Zhang, T.; Hu, J.; Wei, J.; Yu, Q. Effect of MgO calcination temperature on the reaction products and kinetics of MgO-SiO2-H2O system. Am. Ceram. Soc. 2018. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Liu, H.; Zhang, J.; Wei, J.; Yu, Q. Effect of the MgO/Silica Fume Ratio on the Reaction Process of the MgO-SiO2-H2O System. Materials 2019, 12, 80. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, S.H.; Shi, Y.; Tang, S.W.; Chen, E. Effect of silica fume and PVA fiber on the abrasion resistance and volume stability of concrete. Compos. Part. B Eng. 2017, 130, 28–37. [Google Scholar] [CrossRef]

- Tang, S.W.; Cai, X.H.; He, Z.; Shao, H.Y.; Li, Z.J.; Chen, E. Hydration process of fly ash blended cement pastes by impedance measurement. Constr. Build. Mater. 2016, 113, 939–950. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | SO3 | P2O5 | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Geopolymer | 30.56 | 19.56 | 2.22 | 0.85 | 34.40 | 3.23 | 1.23 | 0.05 | 2.09 | 4.88 | 0.93 |

| MgO | 2.02 | 1.24 | 0.94 | - | 2.40 | 92.26 | - | - | - | - | 1.14 |

| Standard Consistency Water Consumption | Specific Surface Area (m2/kg) | Density (g/cm3) | Soundness | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 28 d | 3 d | 7 d | 28 d | ||||

| 0.224 | 370 | 2.91 | Qualified | 29.6 | 40.2 | 49.8 | 7.2 | 7.5 | 7.8 |

| Number | Mass fraction of Geopolymer/% | Mass Fraction of Reactive MgO/% | Reactivity of MgO/s | Water-Solid Ratio |

|---|---|---|---|---|

| Ref. | 100 | 0 | / | 0.38 |

| 4%-60s | 96 | 4 | 60 | 0.38 |

| 6%-60s | 94 | 6 | 60 | 0.38 |

| 8%-60s | 92 | 8 | 60 | 0.38 |

| 12%-60s | 88 | 12 | 60 | 0.38 |

| 6%-150s | 94 | 6 | 150 | 0.38 |

| 6%-220s | 94 | 6 | 220 | 0.38 |

| Chemical Element | O | Na | Si | Ca | Al | Mg |

|---|---|---|---|---|---|---|

| Zone 1 | 69.91 | 3.66 | 8.46 | 11.30 | 4.69 | 1.98 |

| Zone 2 | 70.28 | 4.74 | 7.38 | 10.29 | 5.21 | 2.10 |

| Zone 3 | 69.71 | 3.86 | 8.16 | 11.60 | 4.99 | 1.68 |

| Zone 4 | 70.08 | 4.94 | 7.28 | 10.39 | 5.11 | 2.20 |

| Zone 5 | 42.10 | 3.30 | 6.47 | 2.51 | 3.64 | 41.98 |

| Zone 6 | 46.28 | 2.69 | 5.19 | 2.21 | 2.82 | 40.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, W.; Wang, R.; Chen, F.; Jia, X.; Cong, P. Effects of Reactive MgO on the Reaction Process of Geopolymer. Materials 2019, 12, 526. https://doi.org/10.3390/ma12030526

Li Z, Zhang W, Wang R, Chen F, Jia X, Cong P. Effects of Reactive MgO on the Reaction Process of Geopolymer. Materials. 2019; 12(3):526. https://doi.org/10.3390/ma12030526

Chicago/Turabian StyleLi, Zhaoheng, Wei Zhang, Ruilan Wang, Fangzhu Chen, Xichun Jia, and Peitong Cong. 2019. "Effects of Reactive MgO on the Reaction Process of Geopolymer" Materials 12, no. 3: 526. https://doi.org/10.3390/ma12030526

APA StyleLi, Z., Zhang, W., Wang, R., Chen, F., Jia, X., & Cong, P. (2019). Effects of Reactive MgO on the Reaction Process of Geopolymer. Materials, 12(3), 526. https://doi.org/10.3390/ma12030526