Melt-Processed Poly(Ether Ether Ketone)/Carbon Nanotubes/Montmorillonite Nanocomposites with Enhanced Mechanical and Thermomechanical Properties

Abstract

1. Introduction

2. Experimental

2.1. Materials

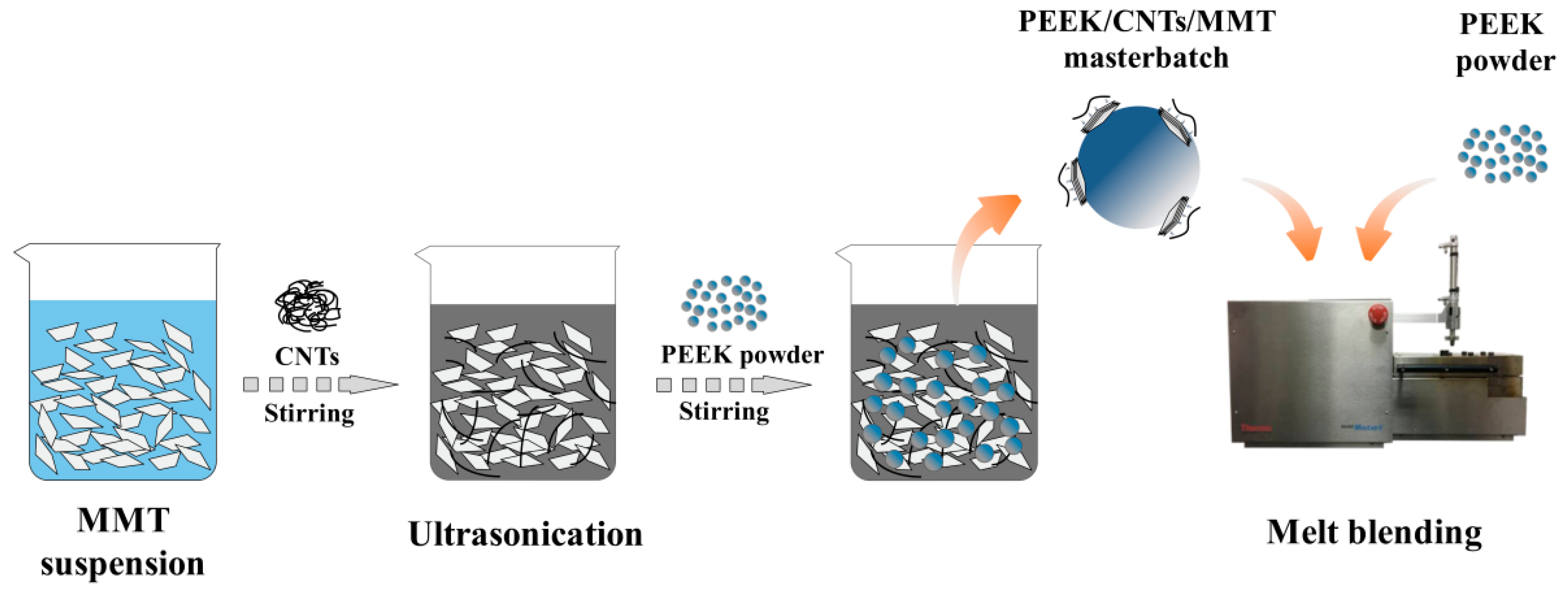

2.2. Materials and Sample Preparation

2.3. Characterization

3. Results and Discussion

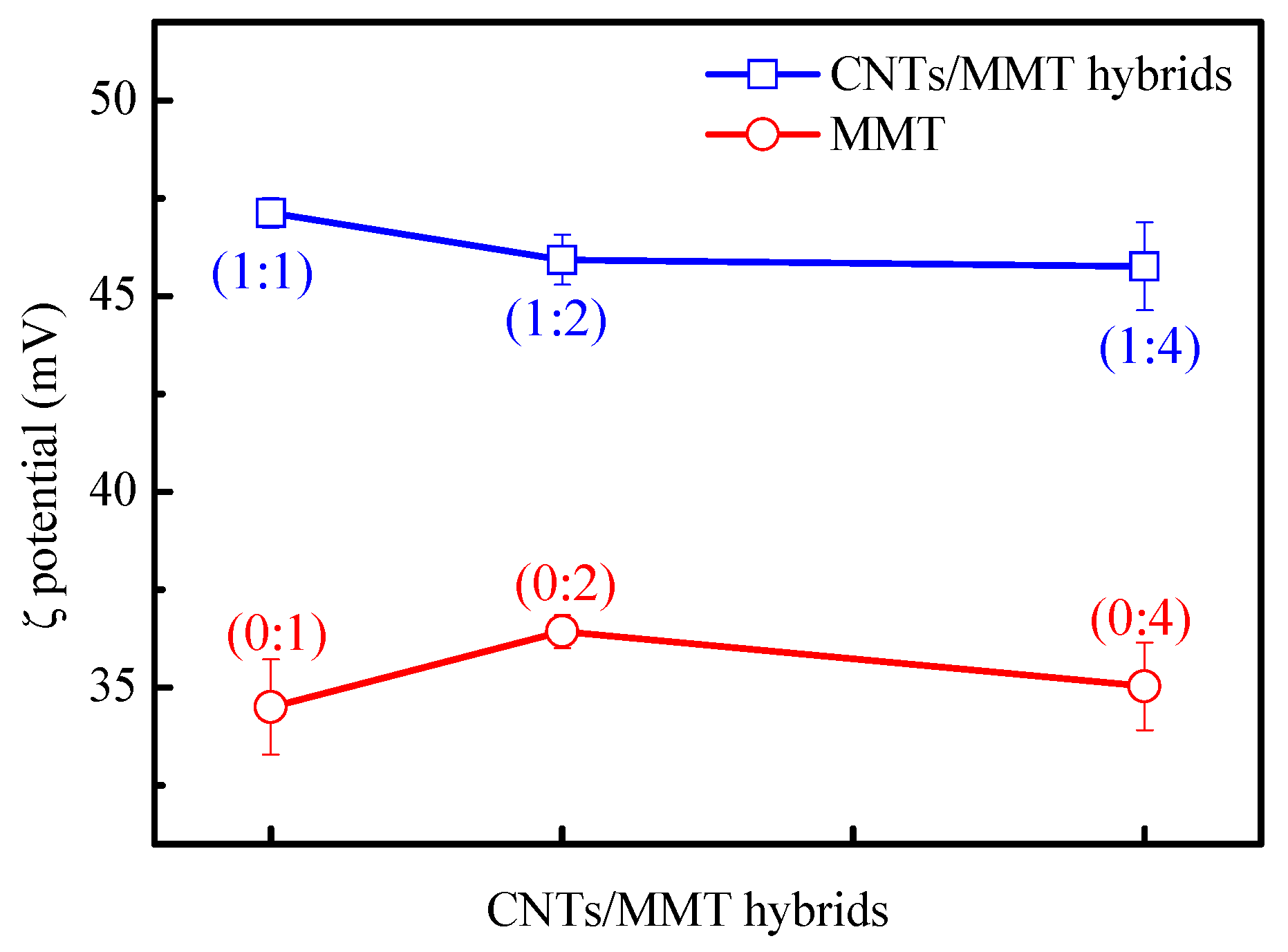

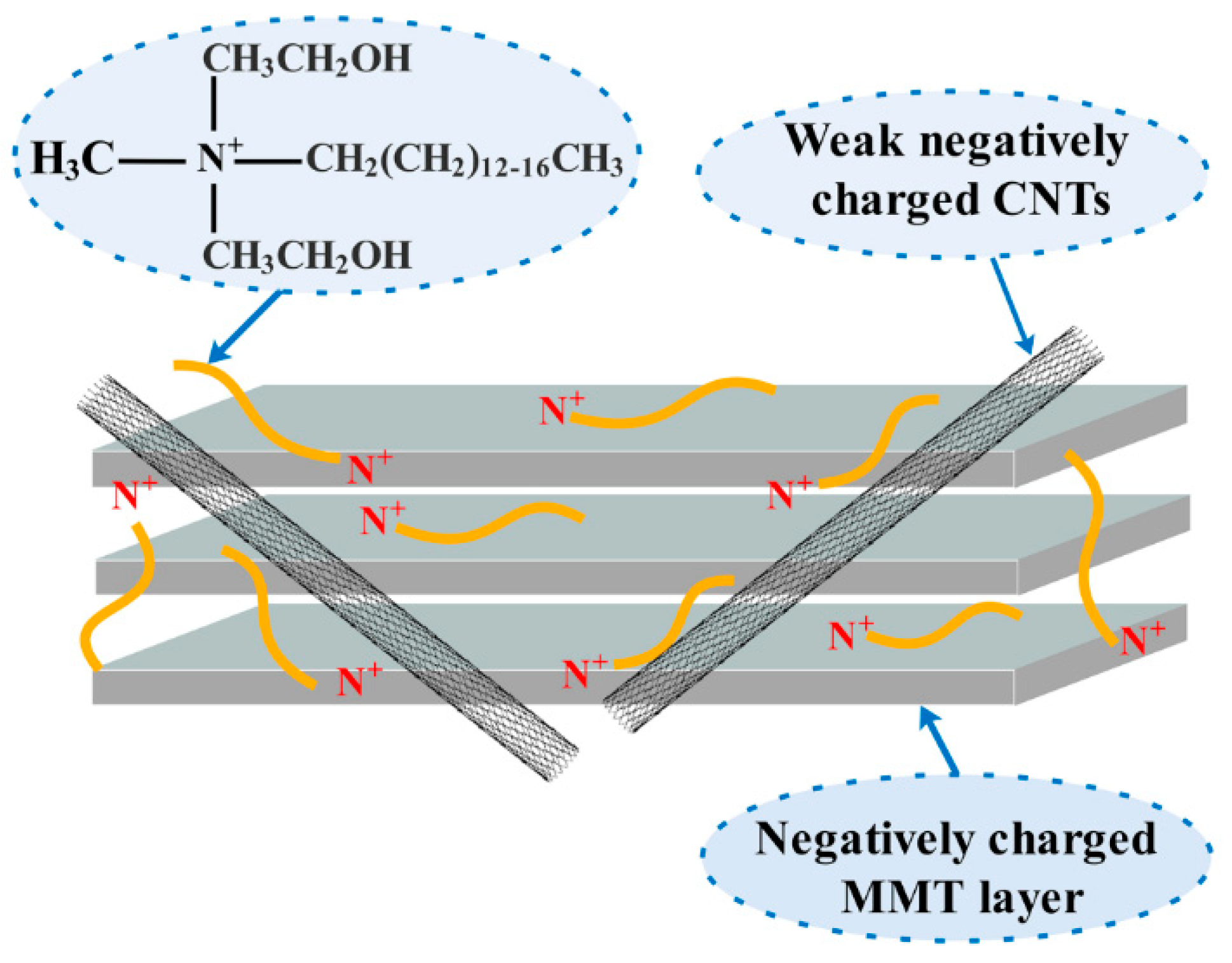

3.1. MMT-Assisted Dispersion of CNTs in Water

3.2. Morphologies of PEEK Nanocomposites

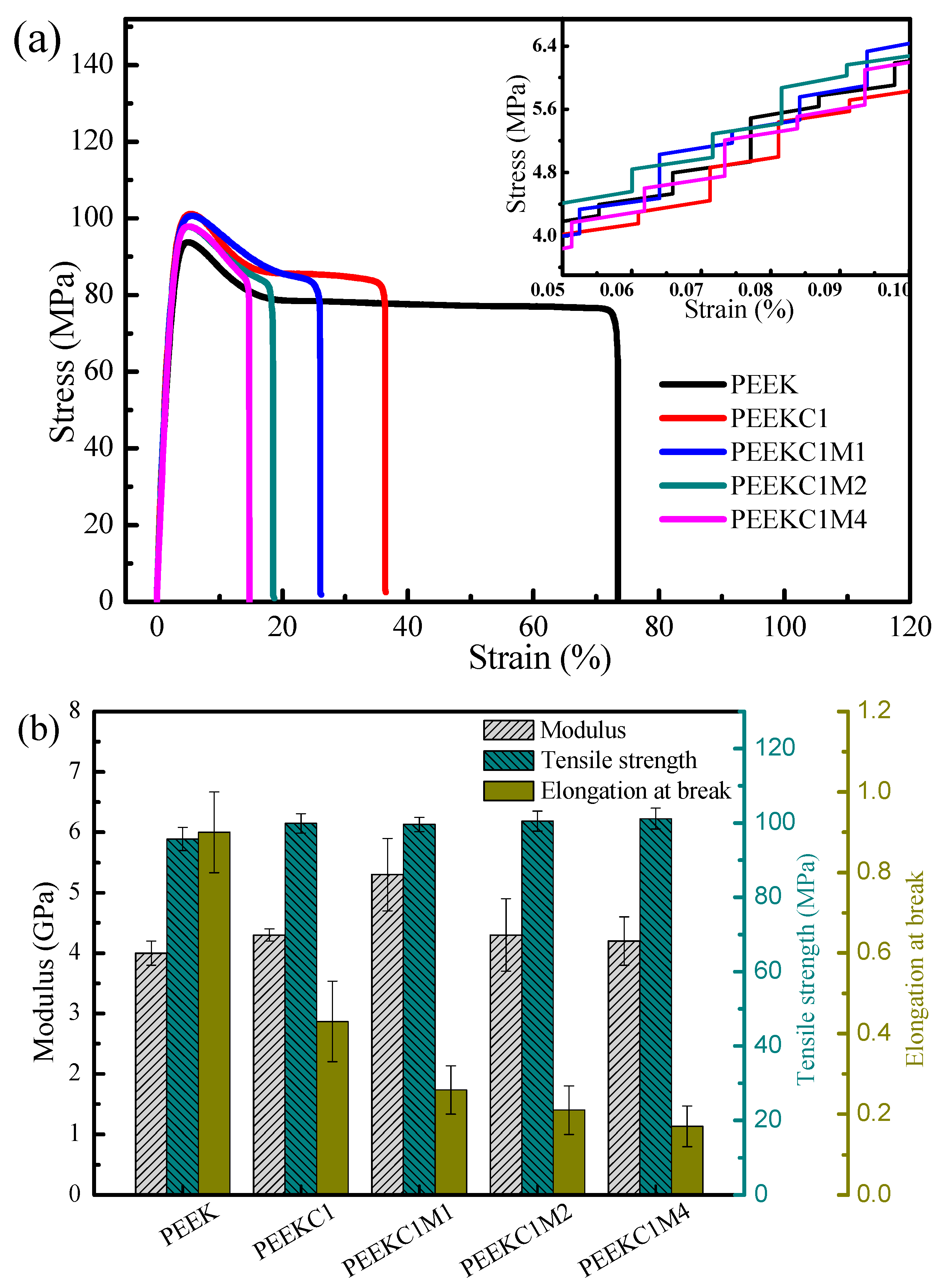

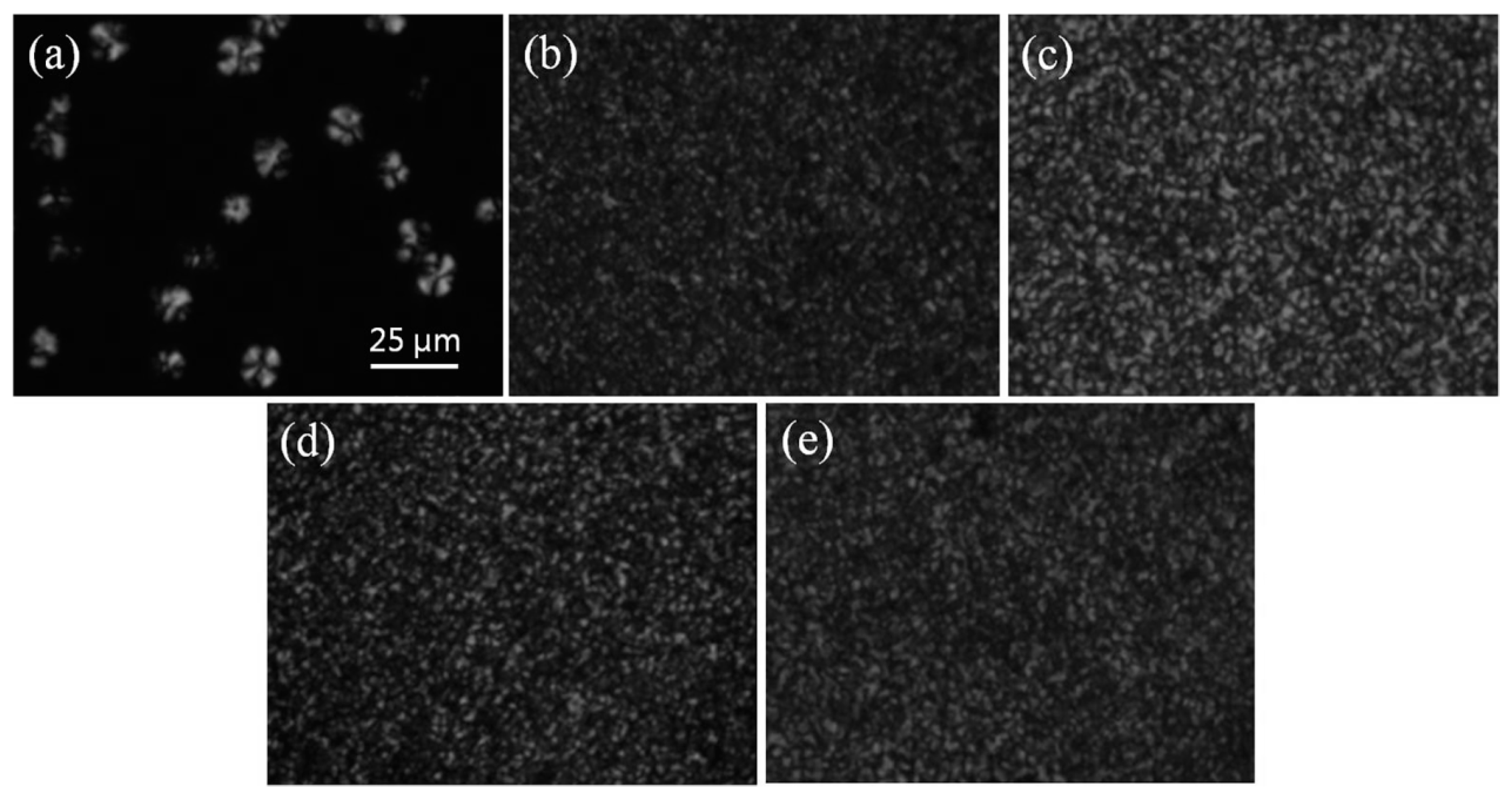

3.3. Tensile Behavior of PEEK Nanocomposites

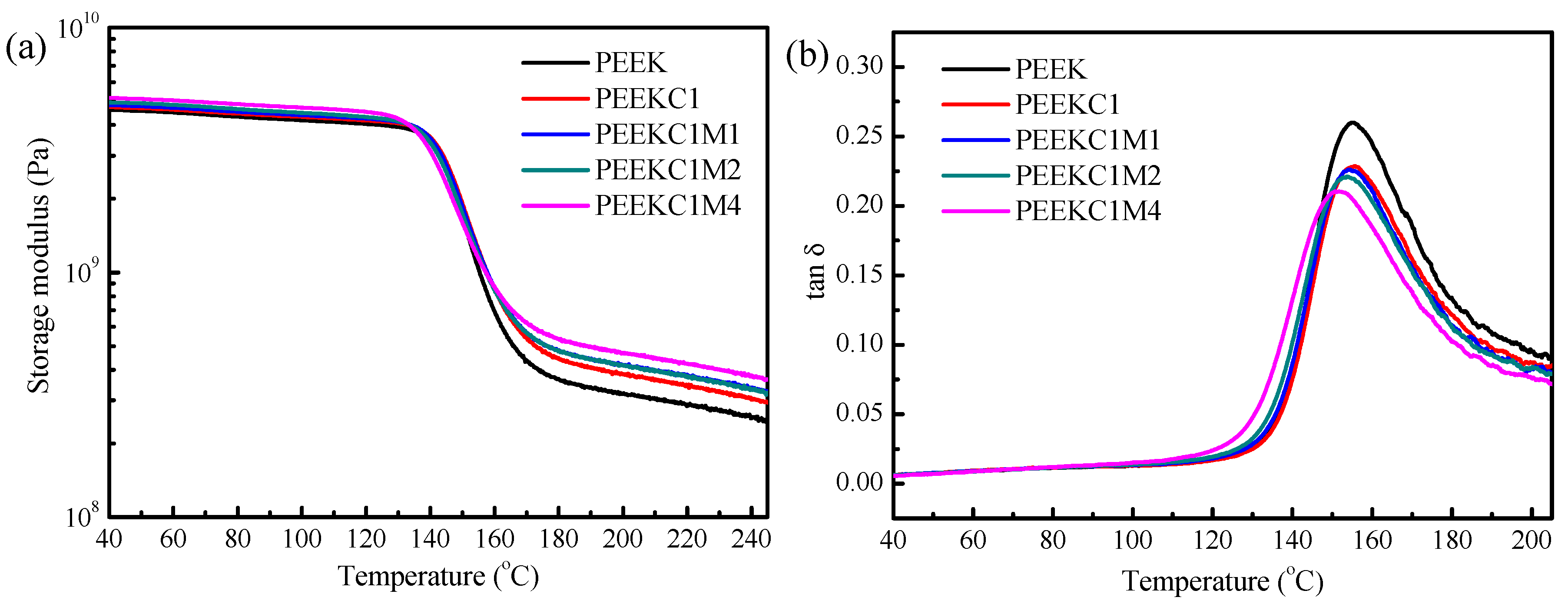

3.4. DMA Analysis of PEEK Nanocomposites

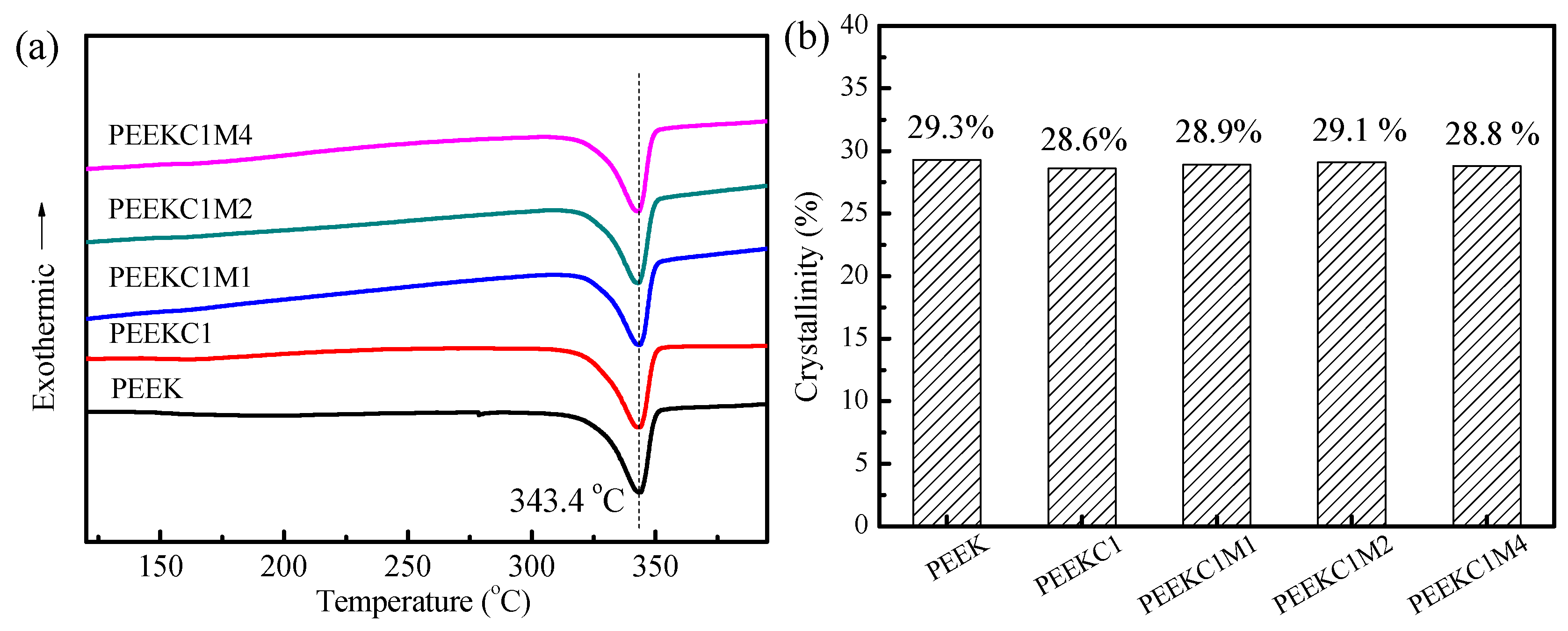

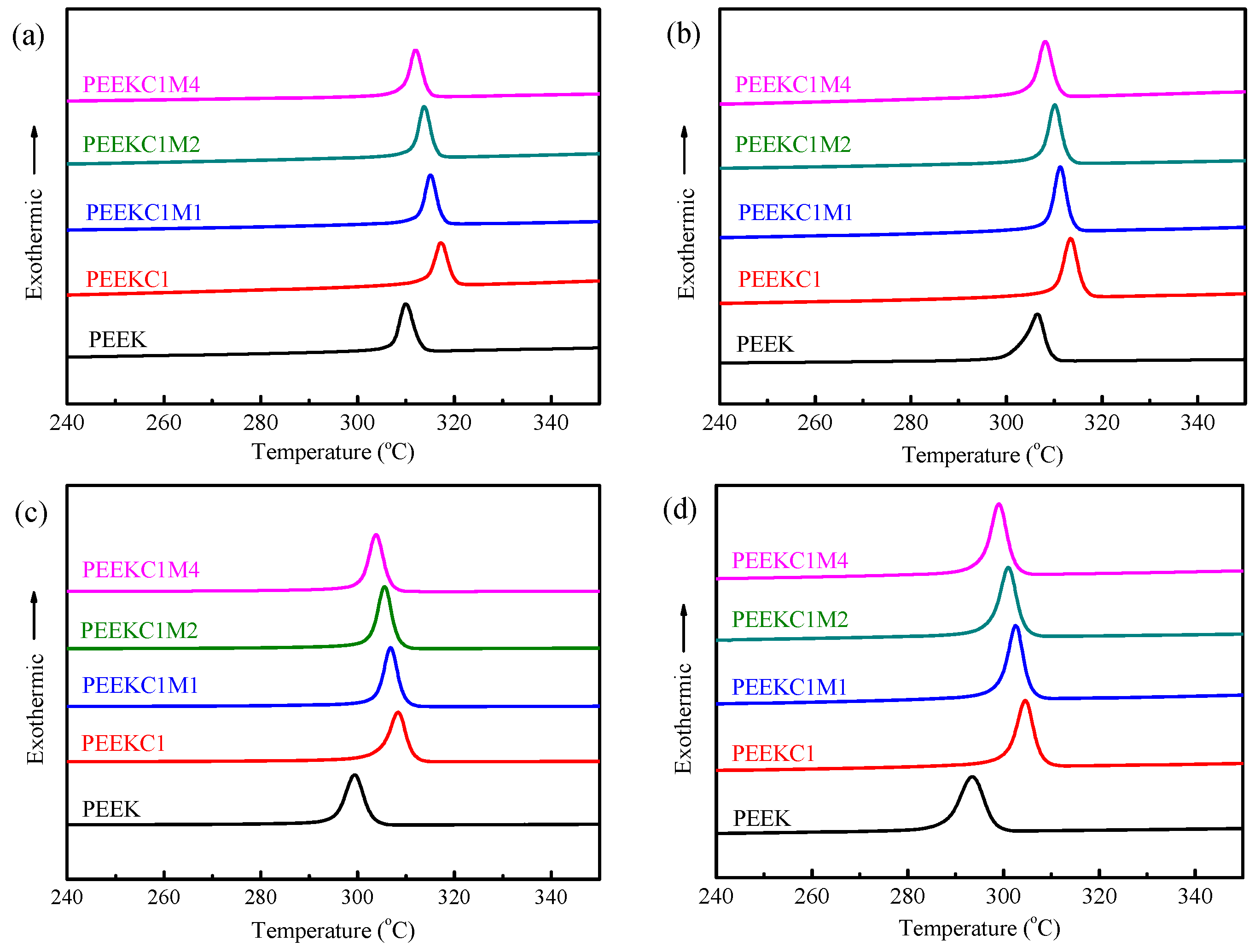

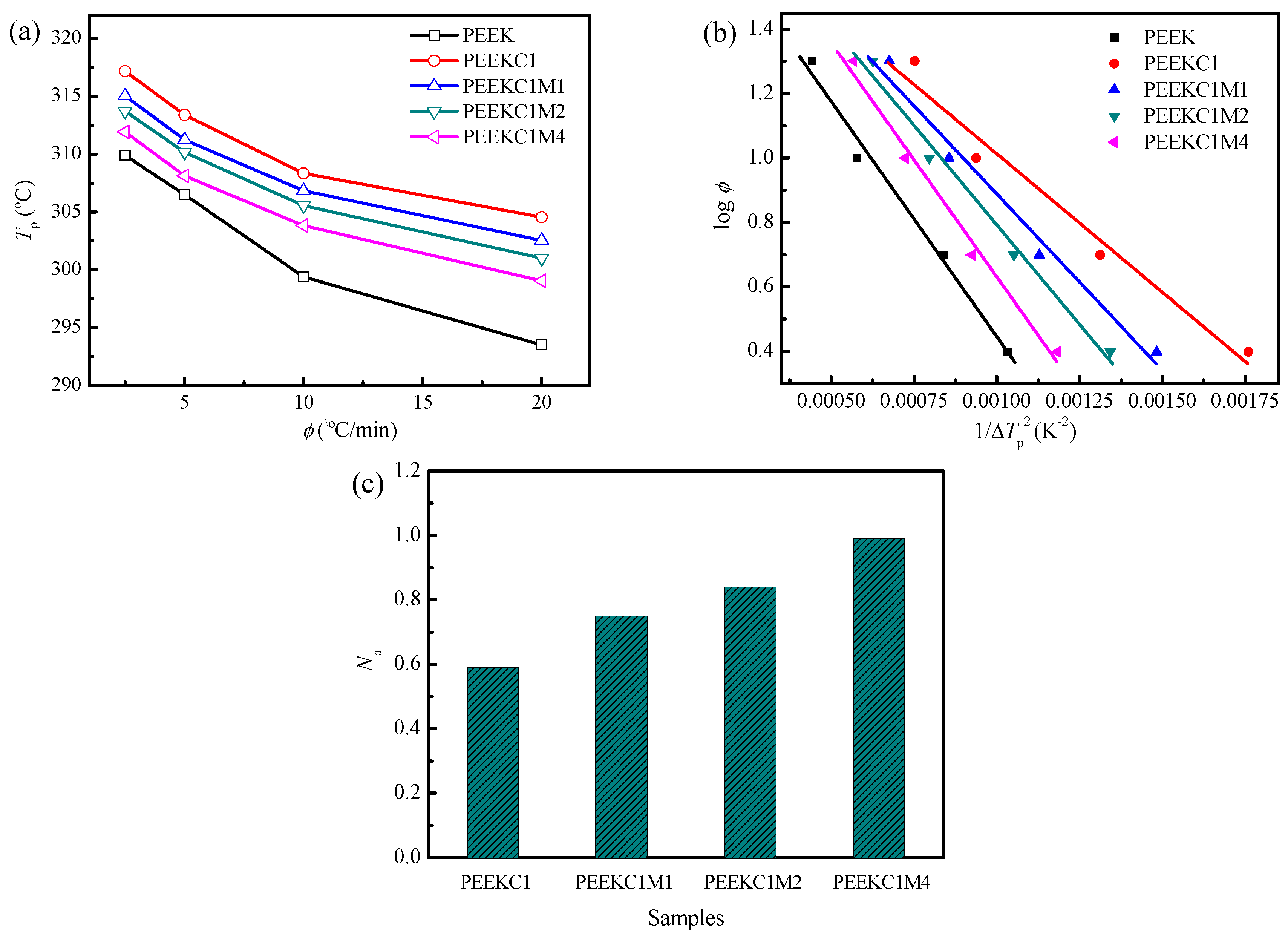

3.5. Melting and Crystallization Behavior of PEEK Nanocomposites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abbasnezhad, N.; Khavandi, A.; Fitoussi, J.; Arabi, H.; Shirinbayan, M.; Tcharkhtchi, A. Influence of loading conditions on the overall mechanical behavior of polyether-ether-ketone (PEEK). Int. J. Fatigue 2018, 109, 83–92. [Google Scholar] [CrossRef]

- Yuan, B.; Cheng, Q.; Zhao, R.; Zhu, X.; Yang, X.; Yang, X.; Zhang, K.; Song, Y.; Zhang, X. Comparison of osteointegration property between PEKK and PEEK: Effects of surface structure and chemistry. Biomaterials 2018, 170, 116–126. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Lin, Q.; Cao, W.; Liu, C.; Shen, C. Crystallization behavior of partially melted poly(ether ether ketone). J. Therm. Anal. Calorim. 2017, 129, 1021–1028. [Google Scholar]

- Díez-Pascual, A.M.; Naffakh, M.; Marco, C.; Ellis, G.; Gómez-Fatou, M.A. High-performance nanocomposites based on polyetherketones. Prog. Mater. Sci. 2012, 57, 1106–1190. [Google Scholar] [CrossRef]

- Zhao, F.; Li, D.; Jin, Z. Preliminary investigation of poly-ether-ether-ketone based on fused deposition modeling for medical applications. Materials 2018, 11, 288. [Google Scholar] [CrossRef] [PubMed]

- Karsli, N.G.; Demirkol, S.; Yilmaz, T. Thermal aging and reinforcement type effects on the tribological, thermal, thermomechanical, physical and morphological properties of poly(ether ether ketone) composites. Compos. Part B Eng. 2016, 88, 253–263. [Google Scholar] [CrossRef]

- Regis, M.; Bellare, A.; Pascolini, T.; Bracco, P. Characterization of thermally annealed PEEK and CFR-PEEK composites: Structure-properties relationships. Polym. Degrad. Stab. 2017, 136, 121–130. [Google Scholar] [CrossRef]

- Ji, S.; Sun, C.; Zhao, J.; Liang, F. Comparison and analysis on mechanical property and machinability about polyetheretherketone and carbon-fibers reinforced polyetheretherketone. Materials 2015, 8, 4118–4130. [Google Scholar] [CrossRef]

- Gao, S.; Gao, S.; Xu, B.; Yu, H. Effects of different pH-values on the nanomechanical surface properties of PEEK and CFR-PEEK compared to dental resin-based materials. Materials 2015, 8, 4751–4767. [Google Scholar] [CrossRef]

- Wang, N.; Yang, Z.; Thummavichai, K.; Xu, F.; Hu, C.; Chen, H.; Xia, Y.; Zhu, Y. Novel graphitic carbon coated IF-WS2 reinforced poly(ether ether ketone) nanocomposites. RSC Adv. 2017, 7, 35265–35273. [Google Scholar] [CrossRef]

- Sattari, M.; Molazemhosseini, A.; Naimi-Jamal, M.R.; Khavandi, A. Nonisothermal crystallization behavior and mechanical properties of PEEK/SCF/nano-SiO2 composites. Mater. Chem. Phys. 2014, 147, 942–953. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, S.L.; Zhang, C.F.; Zhou, Z.; Wang, G.B. Study on poly(ether ether ketone)/organically modified montmorillonite composites. Plast. Rubber Compos. 2013, 38, 279–283. [Google Scholar] [CrossRef]

- He, S.; Jia, H.; Lin, Y.; Qian, H.; Lin, J. Effect of clay modification on the structure and properties of sulfonated poly(ether ether ketone)/clay nanocomposites. Polym. Compos. 2016, 37, 2632–2638. [Google Scholar] [CrossRef]

- Tewatia, A.; Hendrix, J.; Dong, Z.; Taghon, M.; Tse, S.; Chiu, G.; Mayo, W.E.; Kear, B.; Nosker, T.; Lynch, J. Characterization of melt-blended graphene—poly(ether ether ketone) nanocomposite. Mater. Sci. Eng. B 2017, 216, 41–49. [Google Scholar] [CrossRef]

- Ajayan, P.M. Nanotubes from carbon. Chem. Rev. 1999, 99, 1787–1800. [Google Scholar] [CrossRef] [PubMed]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Van Hoa, S. Electrical resistance of CNT-PEEK composites under compression at different temperatures. Nanoscale Res. Lett. 2011, 6, 419. [Google Scholar] [CrossRef] [PubMed]

- Rinaldi, M.; Puglia, D.; Dominici, F.; Cherubini, V.; Torre, L.; Nanni, F. Melt processing and mechanical property characterization of high-performance poly(ether ether ketone)-carbon nanotube composite. Polym. Int. 2017, 66, 1731–1736. [Google Scholar] [CrossRef]

- Rong, C.; Ma, G.; Zhang, S.; Song, L.; Chen, Z.; Wang, G.; Ajayan, P.M. Effect of carbon nanotubes on the mechanical properties and crystallization behavior of poly(ether ether ketone). Compos. Sci. Technol. 2010, 70, 380–386. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Abraham, M.; Choudhary, V. Electromagnetic shielding and mechanical properties of thermally stable poly(ether ketone)/multi-walled carbon nanotube composites prepared using a twin-screw extruder equipped with novel fractional mixing elements. RSC Adv. 2016, 6, 113781–113790. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M.; Naffakh, M.; Gomez, M.A.; Marco, C.; Ellis, G.; Gonzalez-Dominguez, J.M.; Anson, A.; Martinez, M.T.; Martinez-Rubi, Y.; Simard, B.; et al. The influence of a compatibilizer on the thermal and dynamic mechanical properties of PEEK/carbon nanotube composites. Nanotechnology 2009, 20, 315707–315719. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M.; Naffakh, M.; González-Domínguez, J.M.; Ansón, A.; Martínez-Rubi, Y.; Martínez, M.T.; Simard, B.; Gómez, M.A. High performance PEEK/carbon nanotube composites compatibilized with polysulfones-II. Mechanical and electrical properties. Carbon 2010, 48, 3500–3511. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer nanocomposites-a comparison between carbon nanotubes, graphene, and clay as nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.; Qiu, L.; Yang, Y.; Chen, Y.; Liu, X. The surface modifications of multi-walled carbon nanotubes for multi-walled carbon nanotube/poly(ether ether ketone) composites. Appl. Surf. Sci. 2015, 353, 873–881. [Google Scholar] [CrossRef]

- Song, Z.; Liu, Y.; Shi, J.; Ma, T.; Zhang, Z.; Ma, H.; Cao, S. Hydroxyapatite/mesoporous silica coated gold nanorods with improved degradability as a multi-responsive drug delivery platform. Mater. Sci. Eng. C Mater. Biol. Appl. 2018, 83, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Shi, J.; Song, Z.; Zhu, X.; Zhu, Y.; Cao, S. A synergistically enhanced photothermal transition effect from mesoporous silica nanoparticles with gold nanorods wrapped in reduced graphene oxide. J. Mater. Sci. 2017, 53, 1810–1823. [Google Scholar] [CrossRef]

- Alsaleh, M.H. Clay/carbon nanotube hybrid mixture to reduce the electrical percolation threshold of polymer nanocomposites. Compos. Sci. Technol. 2017, 149, 34–40. [Google Scholar] [CrossRef]

- Levchenko, V.; Mamunya, Y.; Boiteux, G.; Lebovka, M.; Alcouffe, P.; Seytre, G.; Lebedev, E. Influence of organo-clay on electrical and mechanical properties of PP/MWCNT/OC nanocomposites. Eur. Polym. J. 2011, 47, 1351–1360. [Google Scholar] [CrossRef]

- Chiu, F.-C. Poly(vinylidene fluoride)/polycarbonate blend-based nanocomposites with enhanced rigidity—Selective localization of carbon nanofillers and organoclay. Polym. Test. 2017, 62, 115–123. [Google Scholar]

- Zhang, C.; Tjiu, W.W.; Liu, T.; Lui, W.Y.; Phang, I.Y.; Zhang, W.D. Dramatically enhanced mechanical performance of nylon-6 magnetic composites with nanostructured hybrid one-dimensional carbon nanotube-two-dimensional clay nanoplatelet heterostructures. J. Phys. Chem. B 2011, 115, 3392–3399. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Bikiaris, D.N.; Triantafyllidis, K.S.; Potsi, G.; Gournis, D.; Papageorgiou, G.Z.; Rudolf, P. Mechanical, thermal and decomposition behavior of poly(ε-caprolactone) nanocomposites with clay-supported carbon nanotube hybrids. Thermochim. Acta 2016, 642, 67–80. [Google Scholar] [CrossRef]

- Bakandritsos, A.; Simopoulos, A.; Petridis, D. Carbon nanotube growth on a swellable clay matrix. Chem. Mater. 2005, 17, 3468–3474. [Google Scholar] [CrossRef]

- Destrée, A.; Long, G.J.; Vatovez, B.; Grandjean, F.; Fonseca, A.; Nagy, J.B.; Fransolet, A.M. Synthesis and characterization of carbon nanotubes grown on montmorillonite clay catalysts. J. Mater. Sci. 2007, 42, 8671–8689. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, X.; Li, J.; Du, X.; Li, S.; Jiang, Z.; Tang, T. A simple method for preparing carbon nanotubes/clay hybrids in water. J. Phys. Chem. C 2009, 113, 8058–8064. [Google Scholar] [CrossRef]

- Georgakilas, V.; Bourlinos, A.; Gournis, D.; Tsoufis, T.; Trapalis, C.; Mateo-Alonso, A.; Prato, M. Multipurpose organically modified carbon nanotubes: From functionalization to nanotube composites. J. Am. Chem. Soc. 2008, 130, 8733–8740. [Google Scholar] [CrossRef] [PubMed]

- White, B.; Banerjee, S.; O’Brien, S.; Turro, N.J.; Herman, I.P. Zeta-potential measurements of surfactant-wrapped individual single-walled carbon nanotubes. J. Phys. Chem. C 2007, 111, 13684–13690. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, F.; Lin, D.; Xing, B. Clay minerals affect the stability of surfactant-facilitated carbon nanotube suspensions. Environ. Sci. Technol. 2008, 42, 6869–6875. [Google Scholar] [CrossRef]

- Zhu, J.; Yudasaka, M.; Zhang, M.; Iijima, S. Dispersing carbon nanotubes in water: A noncovalent and nonorganic way. J. Phys.Chem. B 2004, 108, 11317–11320. [Google Scholar] [CrossRef]

- Qiao, R.; Aluru, N.R. Atypical dependence of electroosmotic transport on surface charge in a dingle-wall carbon nanotube. Nano Lett. 2003, 3, 1013–1017. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, L.; Fang, J.; Dai, K. Influence of diameter of carbon nanotubes mounted in flow-through capacitors on removal of NaCl from salt water. J. Mater. Sci. 2006, 42, 2471–2475. [Google Scholar] [CrossRef]

- Silva, B.L.; Nack, F.C.; Lepienski, C.M.; Coelho, L.A.F.; Becker, D. Influence of intercalation methods in properties of clay and carbon nanotube and high density polyethylene nanocomposites. Mater. Res. 2014, 17, 1628–1636. [Google Scholar] [CrossRef]

- Lee, M.; Kim, W.; Ku, J.; Kim, Y.D.; Min, B.H.; Kim, J.H. Influence of nanoclays on electrical and morphological properties of thermoplastic polyurethane/multiwalled carbon nanotube/clay nanocomposites. J. Appl. Polym. Sci. 2013, 127, 4233–4240. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Zhang, R.; Li, Q.; Shen, C. Preparation and characterization of microbial biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate)/organoclay nanocomposites. Polym. Compos. 2012, 33, 838–842. [Google Scholar] [CrossRef]

- Khan, A.N.; Hong, P.-D.; Chaung, W.-T. Relaxation behavior of poly(trimethylene 2,6-naphthalate) in nanoclay confinement. J. Polym. Res. 2013, 20, 280–288. [Google Scholar] [CrossRef]

- Blundell, D.J.; Osborn, B.N. The morphology of poly(aryl-ether-ether-ketone). Polymer 1983, 24, 953–958. [Google Scholar] [CrossRef]

- Yang, X.; Wu, Y.; Wei, K.; Fang, W.; Sun, H. Non-Isothermal crystallization kinetics of short glass fiber reinforced poly (ether ether ketone) composites. Materials 2018, 11, 2094. [Google Scholar] [CrossRef]

- Li, M.; Hu, D.; Wang, Y.; Shen, C. Nonisothermal crystallization kinetics of poly(lactic acid) formulations comprising talc with poly(ethylene glycol). Polym. Eng. Sci. 2010, 50, 2298–2305. [Google Scholar] [CrossRef]

- Han, Q.; Wang, Y.; Shao, C.; Zheng, G.; Li, Q.; Shen, C. Nonisothermal crystallization kinetics of biodegradable poly(lactic acid)/zinc phenylphosphonate composites. J. Compos. Mater. 2013, 48, 2737–2746. [Google Scholar] [CrossRef]

- Xu, T.; Wang, Y.; Han, Q.; He, D.; Li, Q.; Shen, C. Nonisothermal crystallization kinetics of poly(lactic acid) nucleated with a multiamide nucleating agent. J. Macromol. Sci. Part B Phys. 2014, 53, 1680–1694. [Google Scholar] [CrossRef]

- He, D.; Wang, Y.; Shao, C.; Zheng, G.; Li, Q.; Shen, C. Effect of phthalimide as an efficient nucleating agent on the crystallization kinetics of poly(lactic acid). Polym. Test. 2013, 32, 1088–1093. [Google Scholar] [CrossRef]

- Dobreva, A.; Gutzow, I. Activity of substrates in the catalyzed nucleation of glass-forming melts. I. Theory. J. Non-Cryst. Solids 1993, 162, 1–12. [Google Scholar] [CrossRef]

- Dobreva, A.; Gutzow, I. Activity of substrates in the catalyzed nucleation of glass-forming melts. II. Experimental evidence. J. Non-Cryst. Solids 1993, 162, 13–25. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Achilias, D.S.; Bikiaris, D.N.; Karayannidis, G.P. Crystallization kinetics and nucleation activity of filler in polypropylene/surface-treated SiO2 nanocomposites. Thermochim. Acta 2005, 427, 117–128. [Google Scholar] [CrossRef]

- Hao, W.; Yang, W.; Cai, H.; Huang, Y. Non-isothermal crystallization kinetics of polypropylene/silicon nitride nanocomposites. Polym. Test. 2010, 29, 527–533. [Google Scholar] [CrossRef]

| Sample Code | PEEK (wt%) | CNTs (wt%) | MMT (wt%) |

|---|---|---|---|

| PEEK | 100 | - | - |

| PEEKC1 | 99.5 | 0.5 | - |

| PEEKC1M1 | 99.0 | 0.5 | 0.5 |

| PEEKC1M2 | 98.5 | 0.5 | 1.0 |

| PEEKC1M4 | 97.5 | 0.5 | 2.0 |

| Samples | E’40 °C (GPa) | E’240°C (MPa) | Tg (°C) |

|---|---|---|---|

| PEEK | 4.6 | 255.1 | 147.1 |

| PEEKC1 | 4.7 | 301.9 | 147.1 |

| PEEKC1M1 | 4.8 | 337.0 | 146.5 |

| PEEKC1M2 | 5.0 | 334.0 | 145.4 |

| PEEKC1M4 | 5.2 | 377.8 | 142.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Zhu, B.; Zeng, Q.; Wang, P.; Wang, Y.; Liu, C.; Shen, C. Melt-Processed Poly(Ether Ether Ketone)/Carbon Nanotubes/Montmorillonite Nanocomposites with Enhanced Mechanical and Thermomechanical Properties. Materials 2019, 12, 525. https://doi.org/10.3390/ma12030525

Ma R, Zhu B, Zeng Q, Wang P, Wang Y, Liu C, Shen C. Melt-Processed Poly(Ether Ether Ketone)/Carbon Nanotubes/Montmorillonite Nanocomposites with Enhanced Mechanical and Thermomechanical Properties. Materials. 2019; 12(3):525. https://doi.org/10.3390/ma12030525

Chicago/Turabian StyleMa, Ruixue, Bo Zhu, Qianqian Zeng, Pan Wang, Yaming Wang, Chuntai Liu, and Changyu Shen. 2019. "Melt-Processed Poly(Ether Ether Ketone)/Carbon Nanotubes/Montmorillonite Nanocomposites with Enhanced Mechanical and Thermomechanical Properties" Materials 12, no. 3: 525. https://doi.org/10.3390/ma12030525

APA StyleMa, R., Zhu, B., Zeng, Q., Wang, P., Wang, Y., Liu, C., & Shen, C. (2019). Melt-Processed Poly(Ether Ether Ketone)/Carbon Nanotubes/Montmorillonite Nanocomposites with Enhanced Mechanical and Thermomechanical Properties. Materials, 12(3), 525. https://doi.org/10.3390/ma12030525