Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

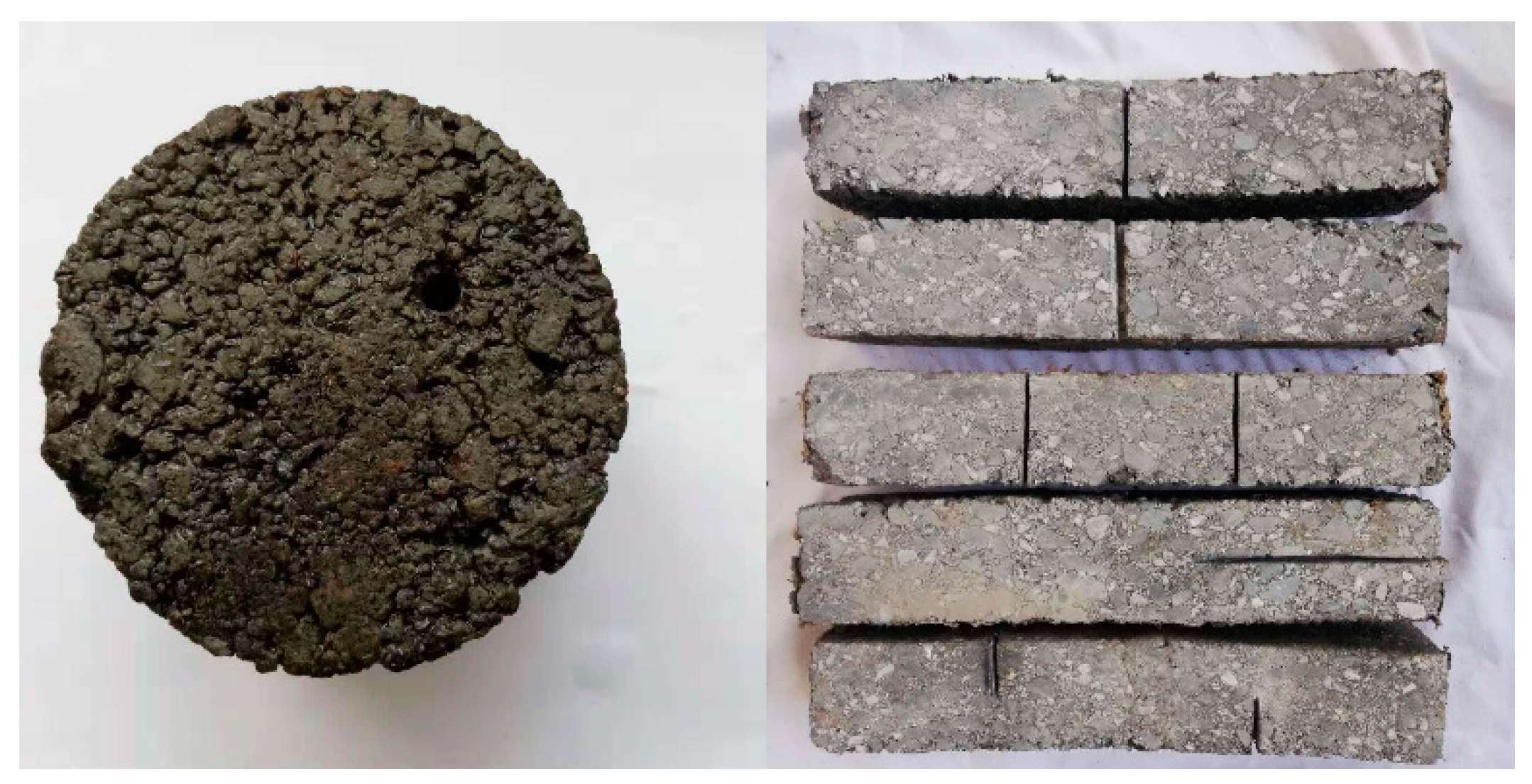

2.2. Preparation of Asphalt Concrete

2.3. Experimental Methods

3. Results and Discussion

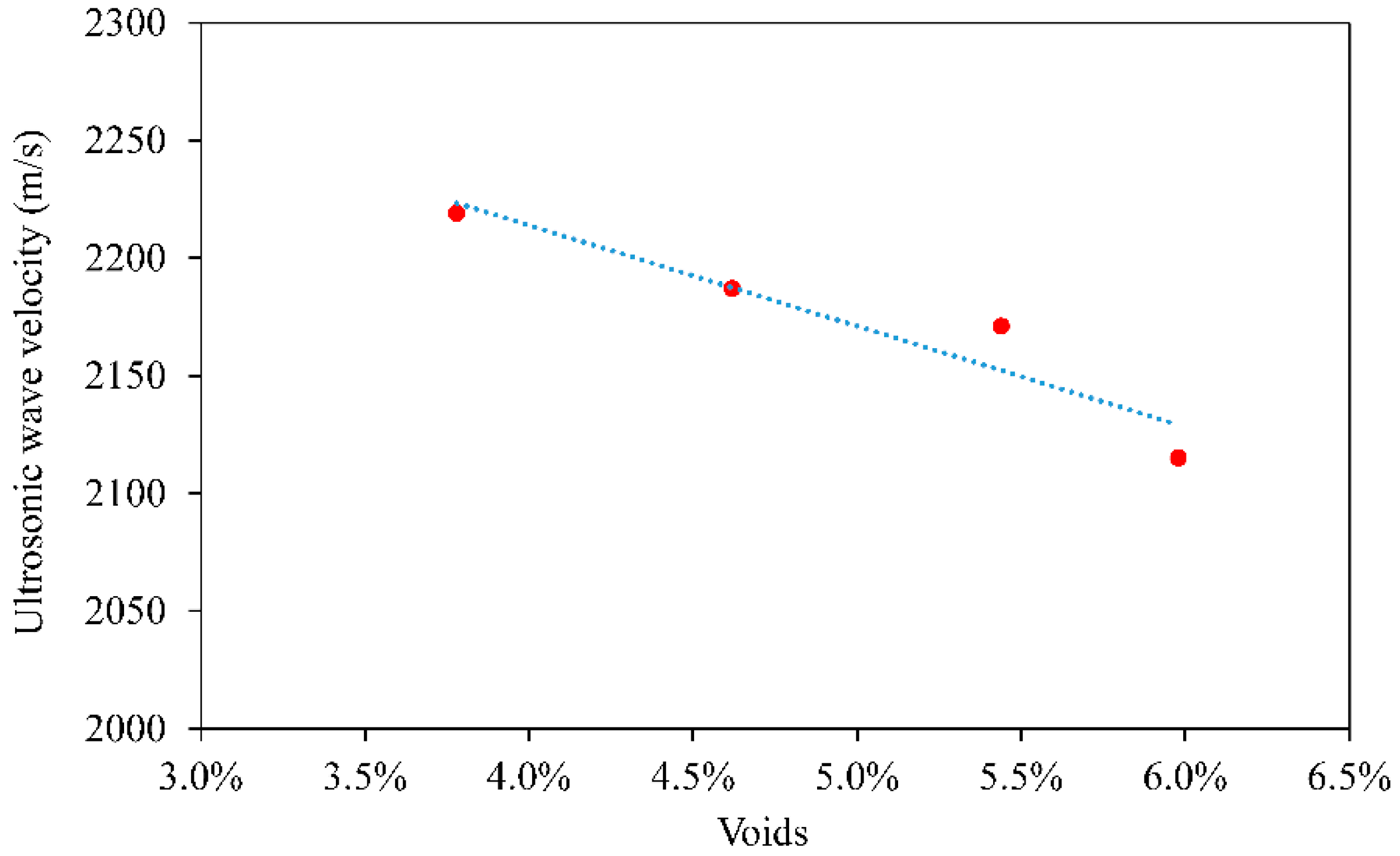

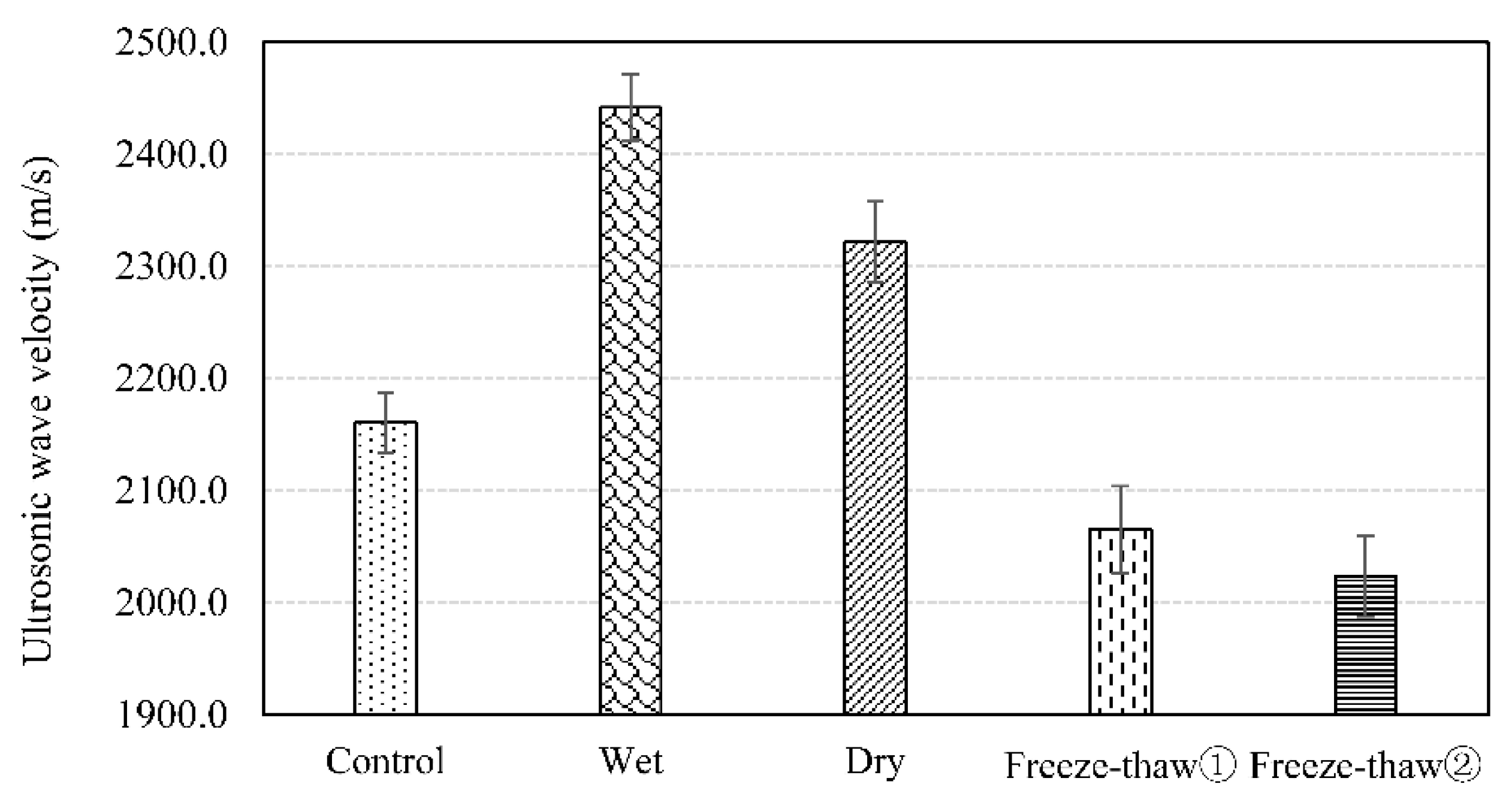

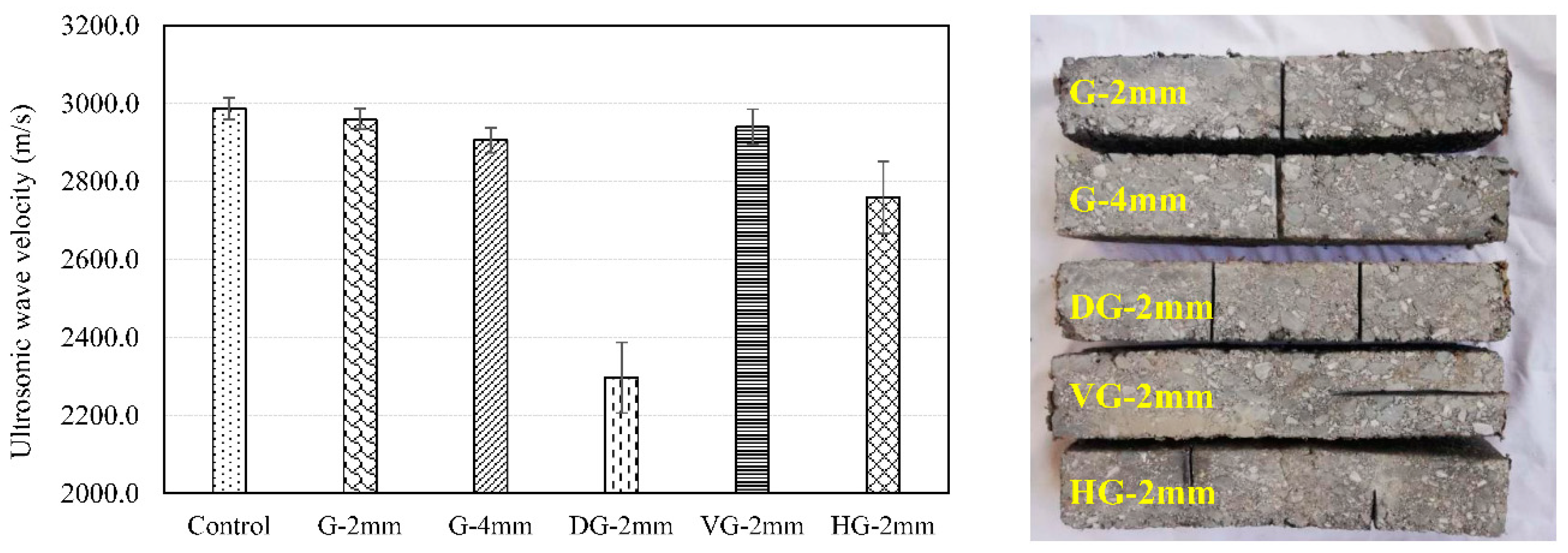

3.1. Ultrasonic Test

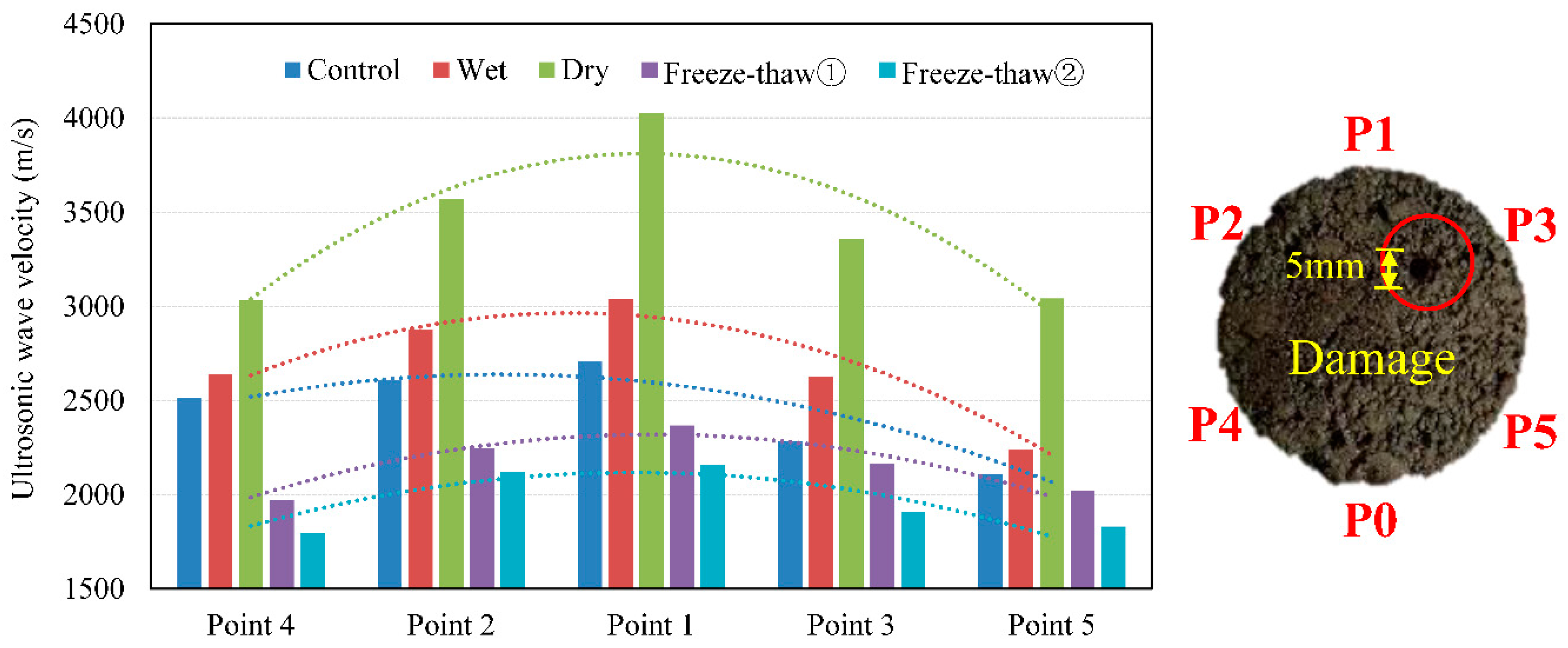

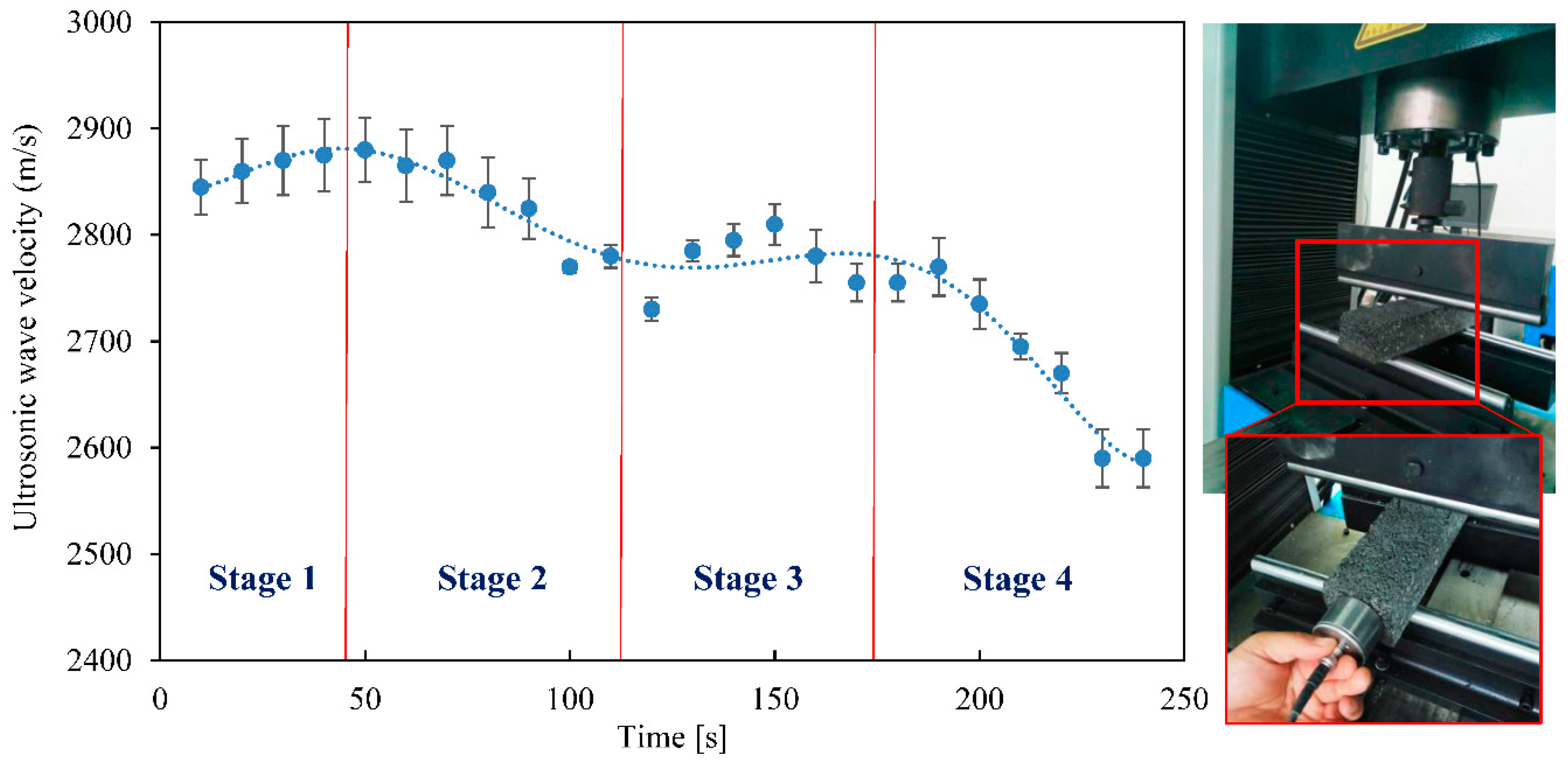

3.2. Damage Detection

3.3. Three Point Bending Test

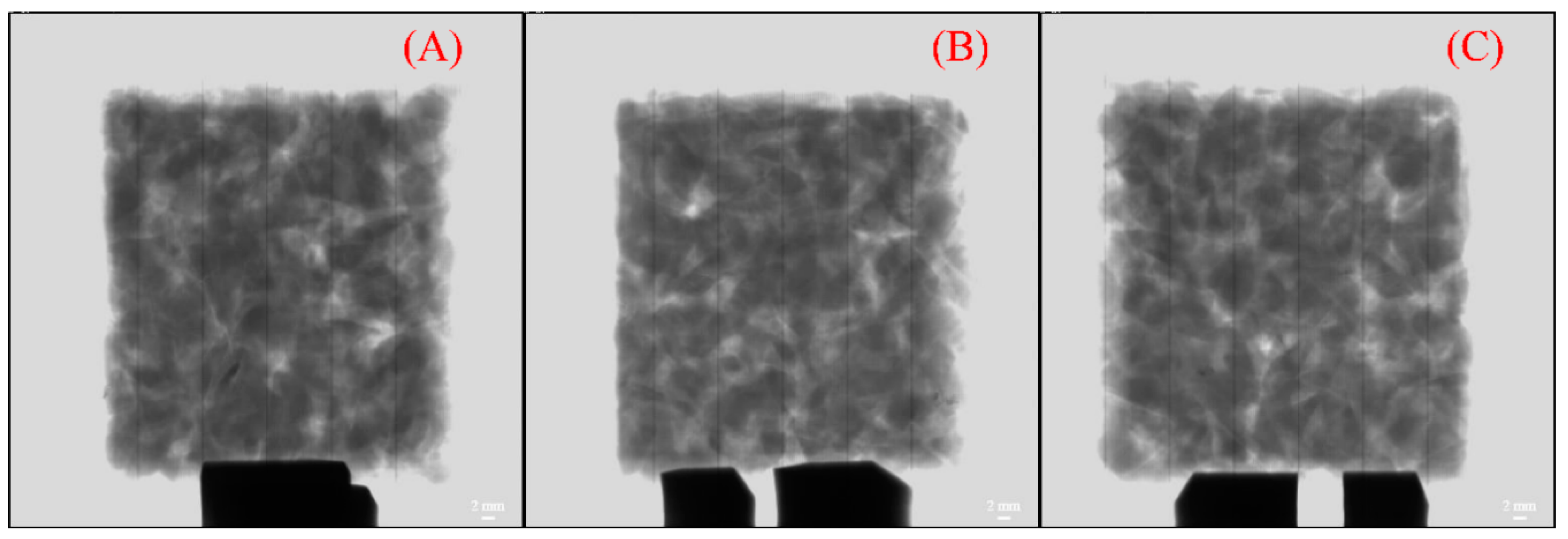

3.4. Impact Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peshkin, D.G.; Hoerner, T.E.; Zimmerman, K.A. Optimal timing of pavement preventive maintenance treatment applications. J. Transp. Res. Board 2004, 523, 10–15. [Google Scholar]

- Giustozzi, F.; Crispino, M.; Flintsch, G.W. Multi-attribute life cycle assessment of preventive maintenance treatments on road pavements for achieving environmental sustainability. Int. J. Life Cycle Assess. 2012, 17, 409–419. [Google Scholar] [CrossRef]

- Haider, S.; Dwaikat, M. Estimating optimum timing for preventive maintenance treatment to mitigate pavement roughness. J. Transp. Res. Board 2011, 2235, 43–53. [Google Scholar] [CrossRef]

- Chou, J.S.; Le, T.S. Reliability-based performance simulation for optimized pavement maintenance. Reliab. Eng. Syst. Saf. 2011, 96, 1402–1410. [Google Scholar] [CrossRef]

- Maierhofer, C.; Arndt, R.; Röllig, M.; Rieck, C.; Walther, A.; Scheel, H.; Hillemeier, B. Application of impulse-thermography for non-destructive assessment of concrete structures. Cem. Concr. Compos. 2006, 28, 393–401. [Google Scholar] [CrossRef]

- Winston, R.J.; Al-Rubaei, A.M.; Blecken, G.T.; Viklander, M.; Hunt, W.F. Maintenance measures for preservation and recovery of permeable pavement surface infiltration rate–The effects of street sweeping, vacuum cleaning, high pressure washing, and milling. J. Environ. Manag. 2016, 169, 132–144. [Google Scholar] [CrossRef] [PubMed]

- Shah, Y.U.; Jain, S.S.; Parida, M. Evaluation of prioritization methods for effective pavement maintenance of urban roads. Int. J. Pavement Eng. 2014, 15, 238–250. [Google Scholar] [CrossRef]

- Meneses, S.; Ferreira, A. Pavement maintenance programming considering two objectives: Maintenance costs and user costs. Int. J. Pavement Eng. 2013, 14, 206–221. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Hoła, J.; Bień, J.; Schabowicz, K. Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Dumoulin, J.; Ibos, L.; Marchetti, M.; Mazioud, A. Detection of non-emergent defects in asphalt pavement samples by long pulse and pulse phase infrared thermography. Eur. J. Environ. Civ. Eng. 2011, 15, 557–574. [Google Scholar] [CrossRef]

- Fauchard, C.; Beaucamp, B.; Laguerre, L. Non-destructive assessment of hot mix asphalt compaction/density with a step-frequency radar: Case study on a newly paved road. Near Surf. Geophys. 2015, 13, 289–297. [Google Scholar] [CrossRef]

- Hunaidi, O. Evolution-based genetic algorithms for analysis of non-destructive surface wave tests on pavements. NDT E International 1998, 31, 273–280. [Google Scholar] [CrossRef]

- Liu, H.; Sato, M. In situ measurement of pavement thickness and dielectric permittivity by GPR using an antenna array. NDT E Int. 2014, 64, 65–71. [Google Scholar] [CrossRef]

- Mai, T.C.; Razafindratsima, S.; Sbartaï, Z.M.; Demontoux, F.; Bos, F. Non-destructive evaluation of moisture content of wood material at GPR frequency. Construct. Build. Mater. 2015, 77, 213–217. [Google Scholar] [CrossRef]

- Kumar, J.; Rakaraddi, P.G. SASW evaluation of asphaltic and cement concrete pavements using different heights of fall for a spherical mass. Int. J. Pavement Eng. 2013, 14, 354–363. [Google Scholar] [CrossRef]

- Hazra, S.; Kumar, J. SASW testing of asphaltic pavement by dropping steel balls. Int. J. Geotech. Eng. 2014, 8, 34–45. [Google Scholar] [CrossRef]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental studies in Ultrasonic Pulse Velocity of roller compacted concrete pavement containing fly ash and M-sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef]

- Mandal, T.; Tinjum, J.M.; Edil, T.B. Non-destructive testing of cementitiously stabilized materials using ultrasonic pulse velocity test. Transp. Geotech. 2016, 6, 97–107. [Google Scholar] [CrossRef]

- Hoegh, K.; Khazanovich, L.; Maser, K.; Tran, N. Evaluation of ultrasonic technique for detecting delamination in asphalt pavements. J. Transp. Res. Board 2012, 2306, 105–110. [Google Scholar] [CrossRef]

- Van Velsor, J.K.; Premkumar, L.; Chehab, G.; Rose, J.L. Measuring the Complex Modulus of Asphalt Concrete Using Ultrasonic Testing. J. Eng. Sci. Technol. Rev. 2011, 4, 160–168. [Google Scholar] [CrossRef]

- Mounier, D.; Di Benedetto, H.; Sauzéat, C. Determination of bituminous mixtures linear properties using ultrasonic wave propagation. Construct. Build. Mater. 2012, 36, 638–647. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, P.; Jiao, Y. Damage Simulation and Ultrasonic Detection of Asphalt Mixture under the Coupling Effects of Water-Temperature-Radiation. Adv. Mater. Sci. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Tigdemir, M.; Kalyoncuoglu, S.F.; Kalyoncuoglu, U.Y. Application of ultrasonic method in asphalt concrete testing for fatigue life estimation. NDT E Int. 2004, 37, 597–602. [Google Scholar] [CrossRef]

- Norambuena, J.; Castro, D. Dynamic modulus of asphalt mixture by ultrasonic direct test. NDT E Int. 2010, 43, 629–634. [Google Scholar] [CrossRef]

- Ministry of Transport of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering: JTG E20-2011; Ministry of Transport of China: Beijing, China, 2011.

| Property | Unit | Results | Technical Requirements | Test [26] |

|---|---|---|---|---|

| Penetration | dmm | 88.2 | 80–100 | T0604 |

| Ductility | cm | 127 | ≥100 | T0605 |

| Softening point | °C | 49.1 | ≥45 | T0606 |

| Density | g/cm3 | 1.03 | – | T0603 |

| Sieve Size (mm) | 16 | 13 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Passing (%) | 100 | 94.8 | 77.1 | 48.6 | 30.3 | 22.8 | 16.2 | 11.4 | 7.6 | 6.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, W.-h.; Sun, X.-d.; Wu, L.-m.; Yang, K.-k.; Tang, N. Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology. Materials 2019, 12, 443. https://doi.org/10.3390/ma12030443

Pan W-h, Sun X-d, Wu L-m, Yang K-k, Tang N. Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology. Materials. 2019; 12(3):443. https://doi.org/10.3390/ma12030443

Chicago/Turabian StylePan, Wen-hao, Xu-dong Sun, Li-mei Wu, Kai-kai Yang, and Ning Tang. 2019. "Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology" Materials 12, no. 3: 443. https://doi.org/10.3390/ma12030443

APA StylePan, W.-h., Sun, X.-d., Wu, L.-m., Yang, K.-k., & Tang, N. (2019). Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology. Materials, 12(3), 443. https://doi.org/10.3390/ma12030443