Diffusion Mechanism of Rejuvenator and Its Effects on the Physical and Rheological Performance of Aged Asphalt Binder

Abstract

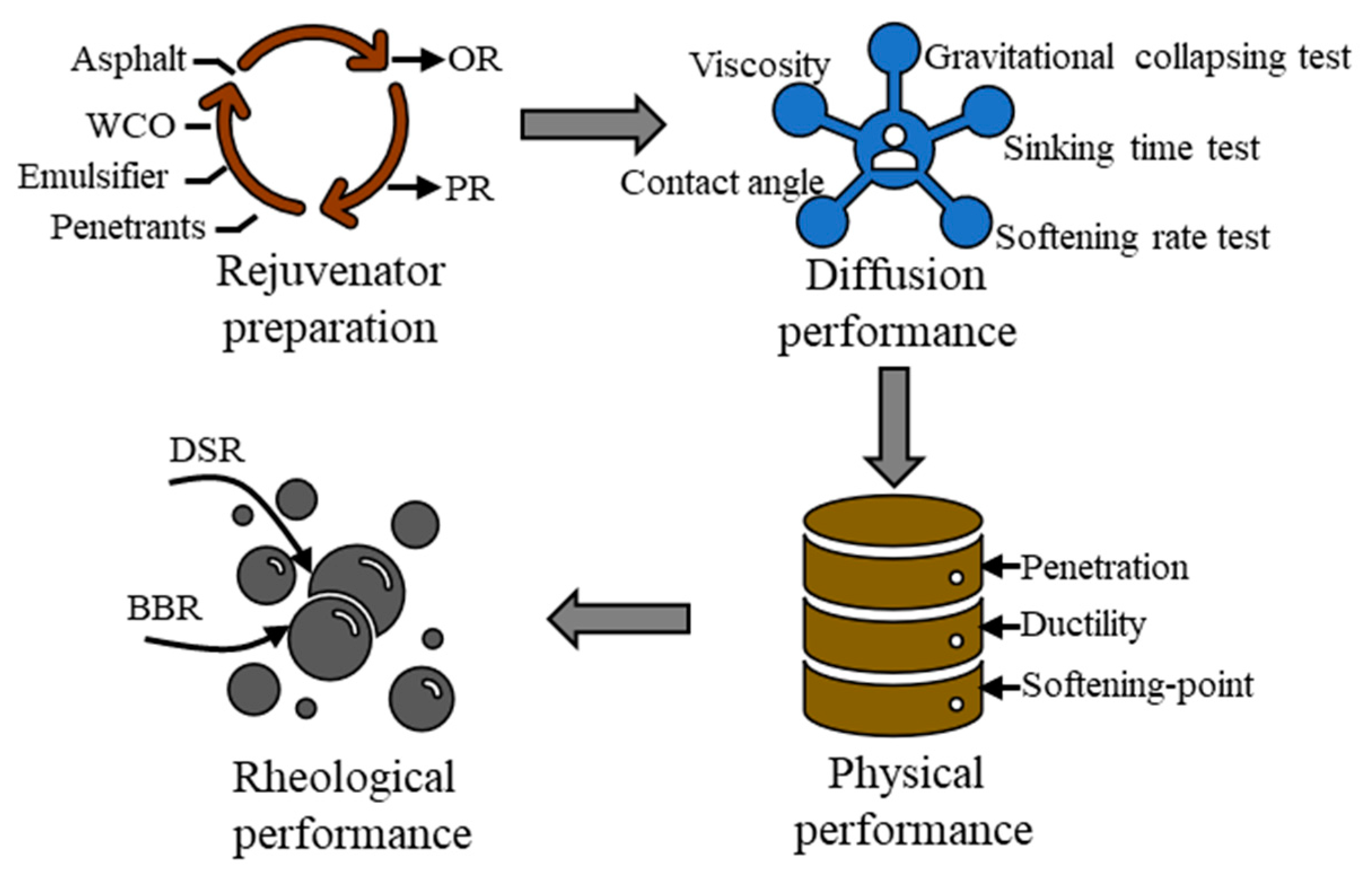

- Two rejuvenators were prepared with waste cooking oil and emulsified asphalt;

- Three self-designed tests were used to study the diffusion efficiency of the rejuvenators;

- Dosages of rejuvenators were optimized based on the rheological property of asphalt;

- Two rejuvenators improved the crack resistance of aged asphalt;

- Penetrative rejuvenator has a better permeability to penetrate in aged asphalt.

1. Introduction

2. Materials and Experiments

2.1. Raw Materials

2.2. Experiments

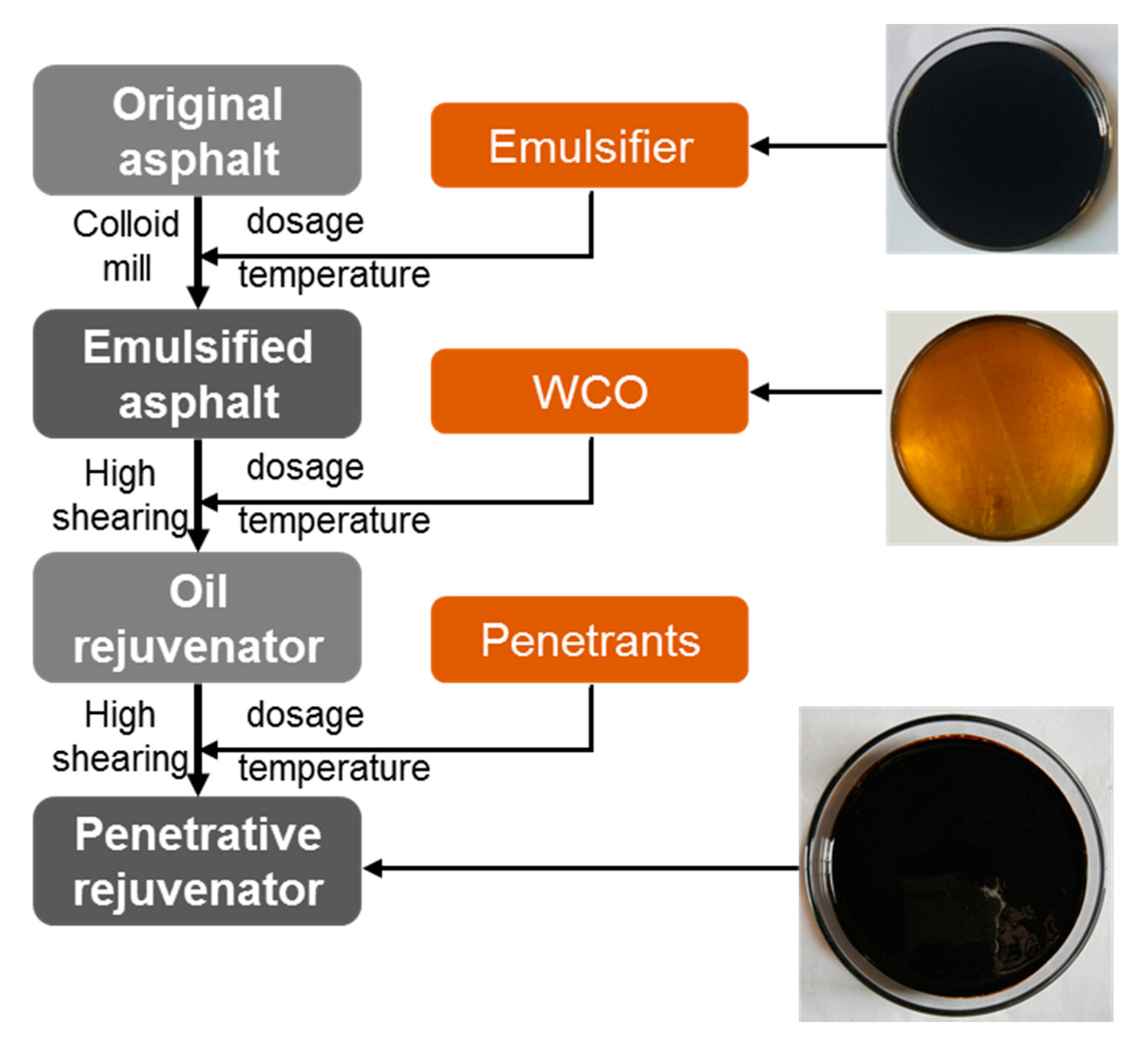

2.2.1. Preparation of Rejuvenators and Samples

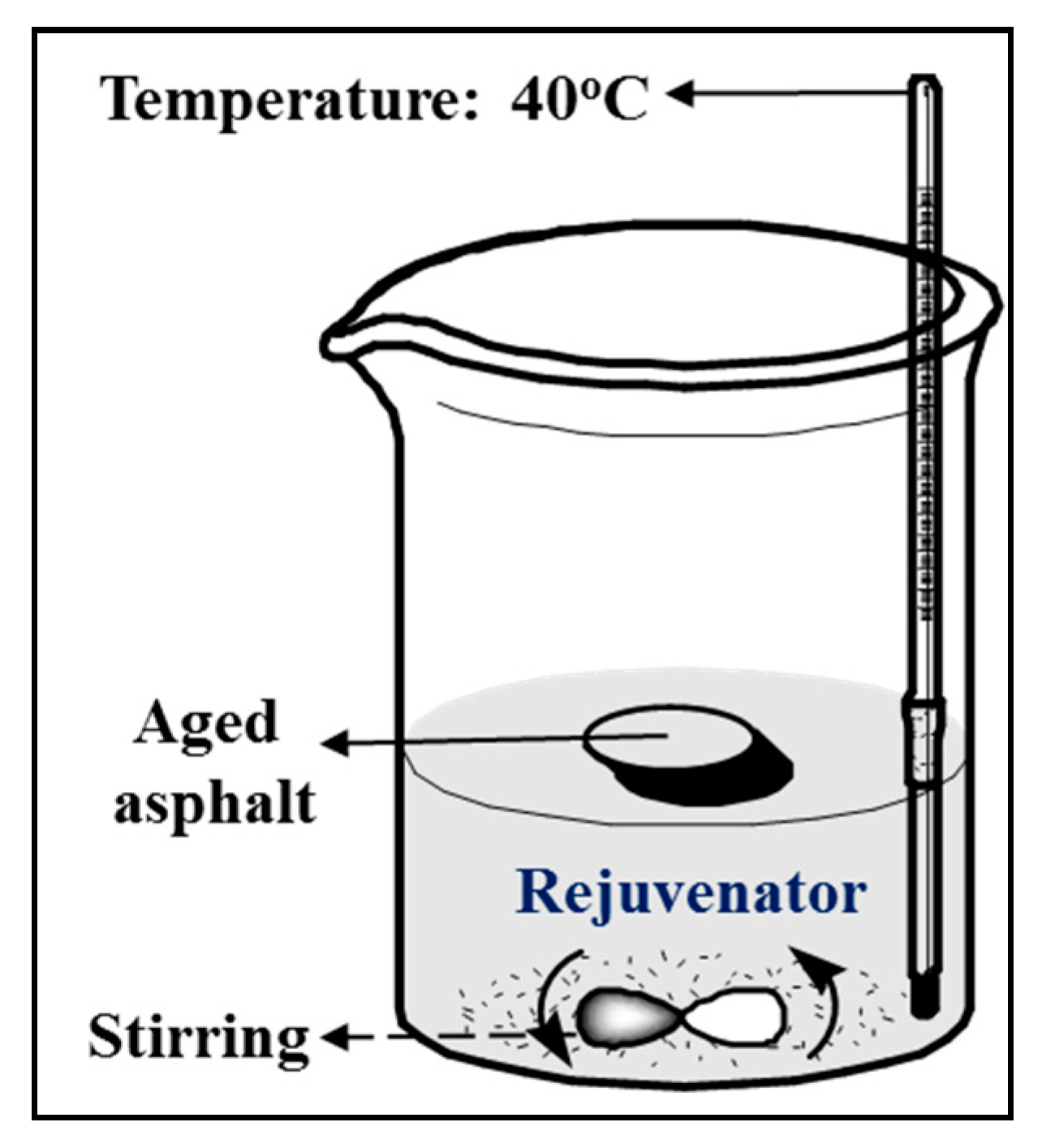

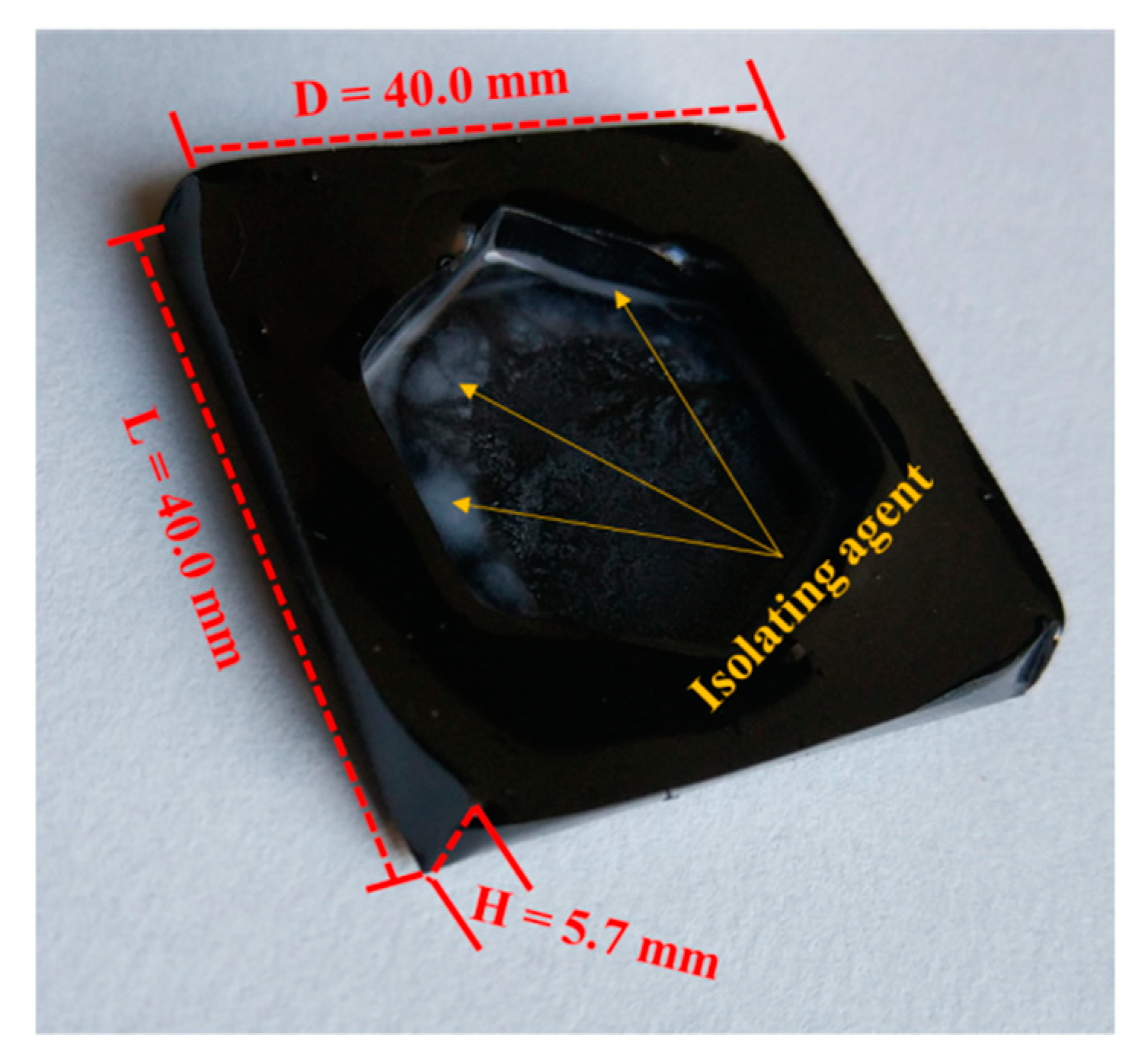

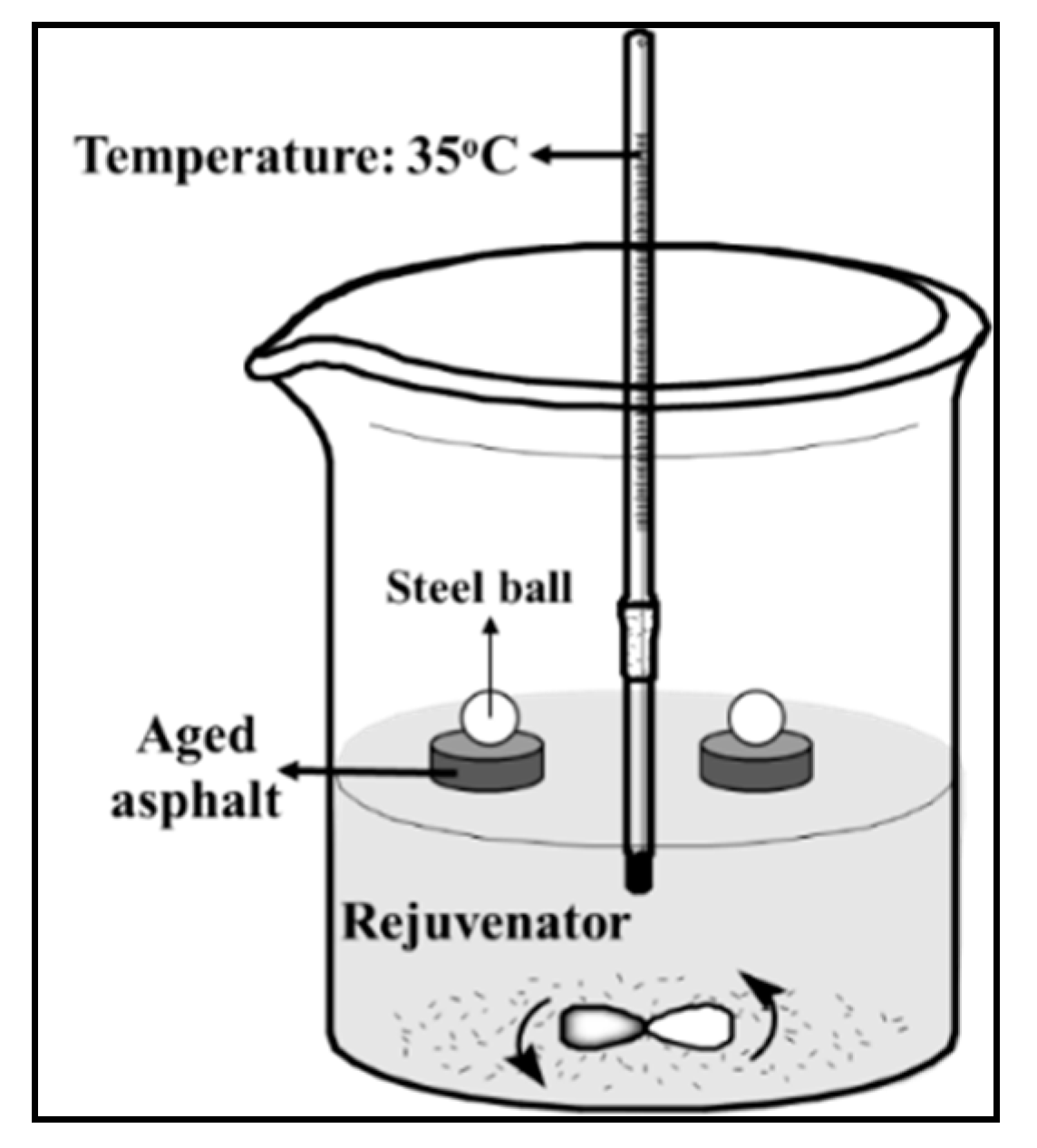

2.2.2. Diffused Performance Tests

2.2.3. Rheological Performance Tests

3. Results and Discussions

3.1. Diffusion Performance

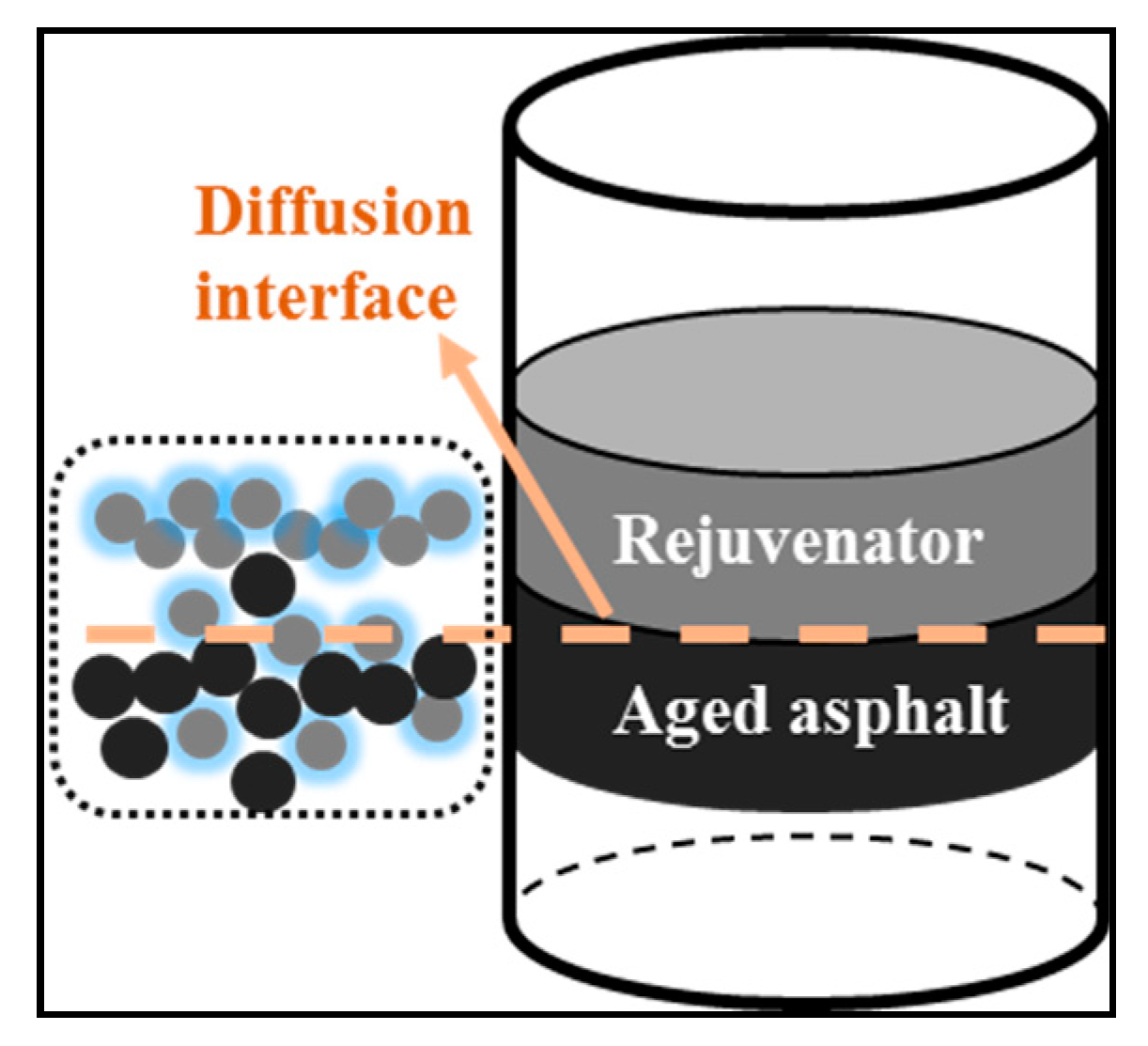

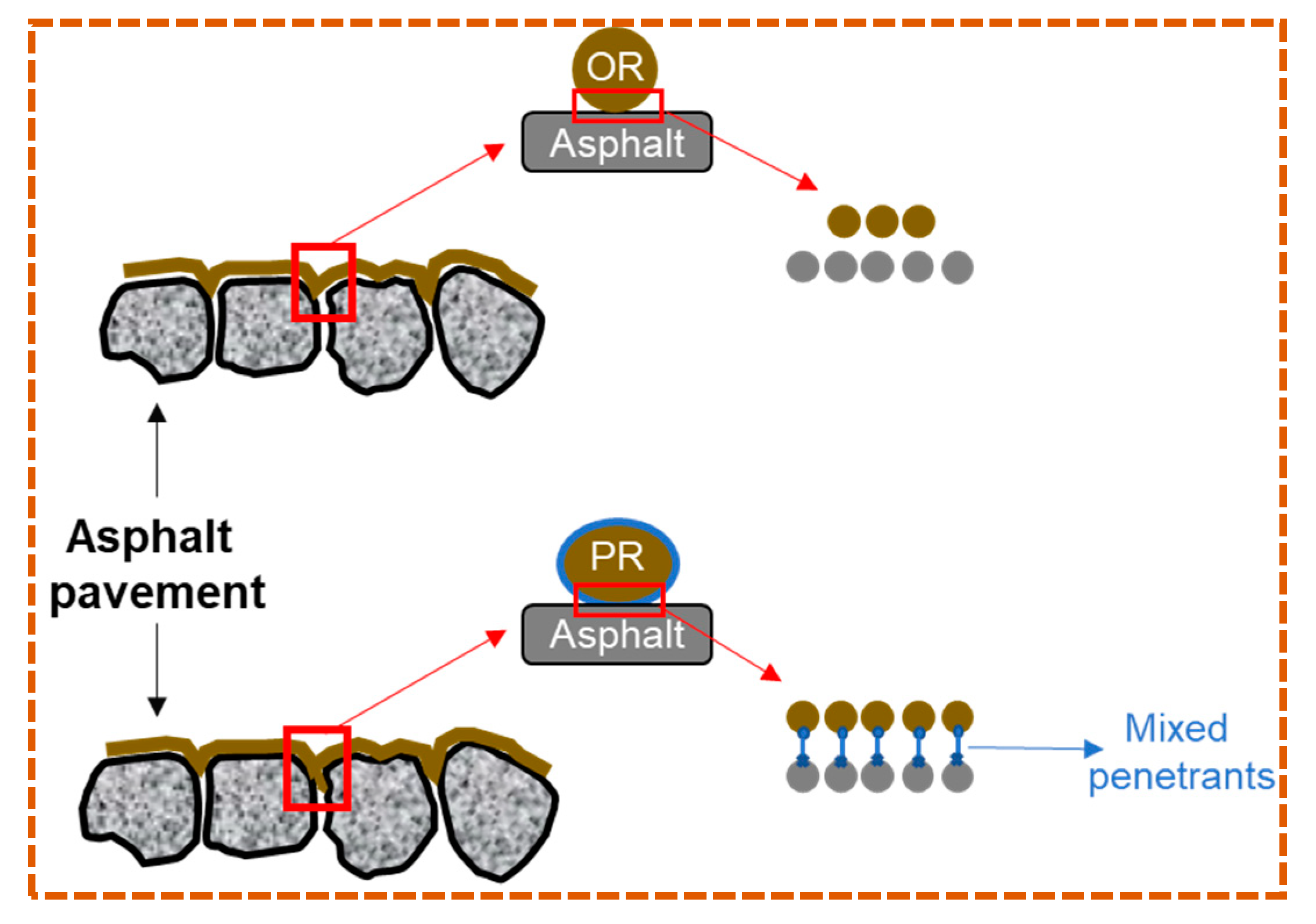

3.2. Diffusion Mechanisms

3.2.1. Diffusion Theory

3.2.2. Penetration Principle for Interface

3.3. Physical and Rheological Performance

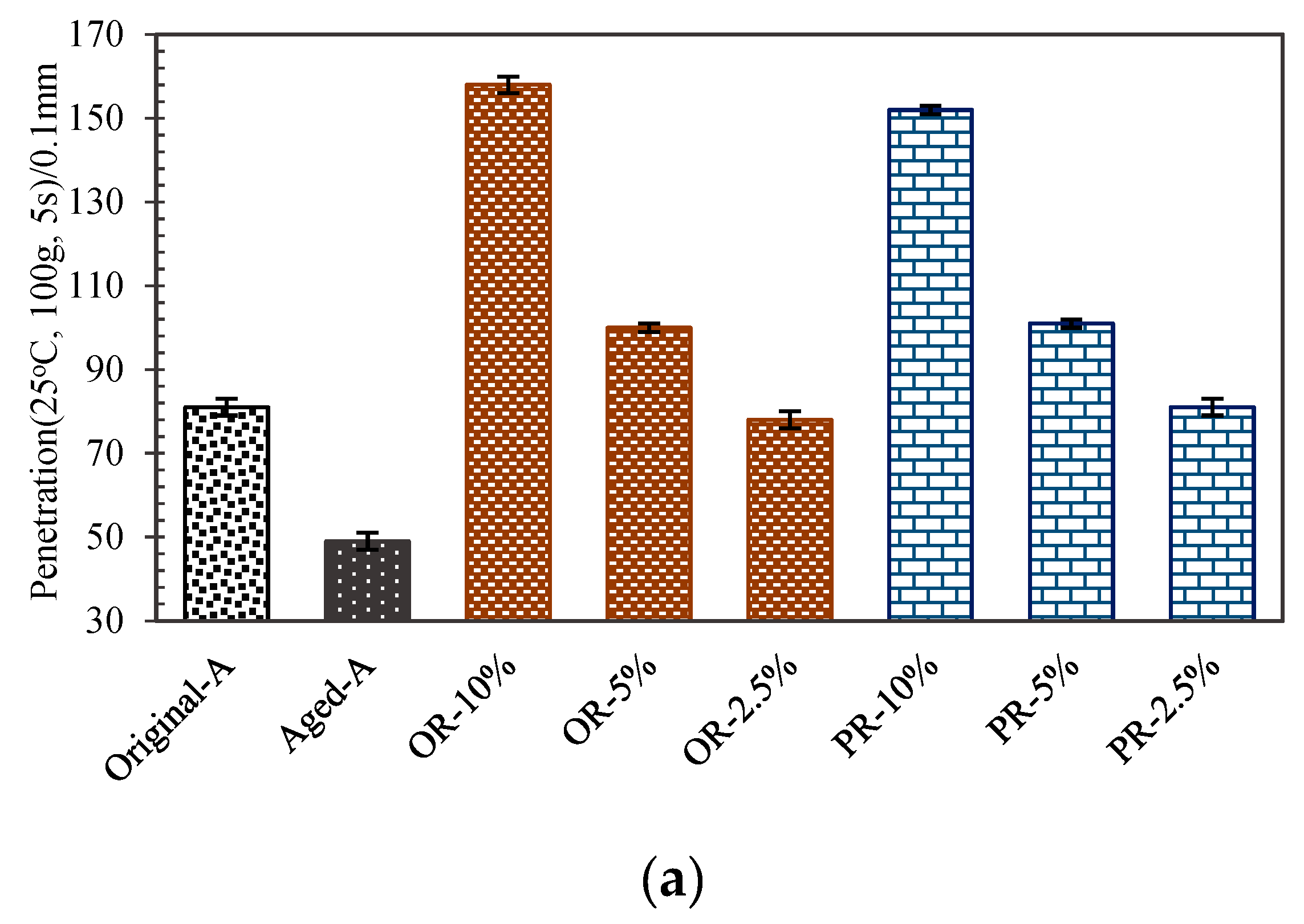

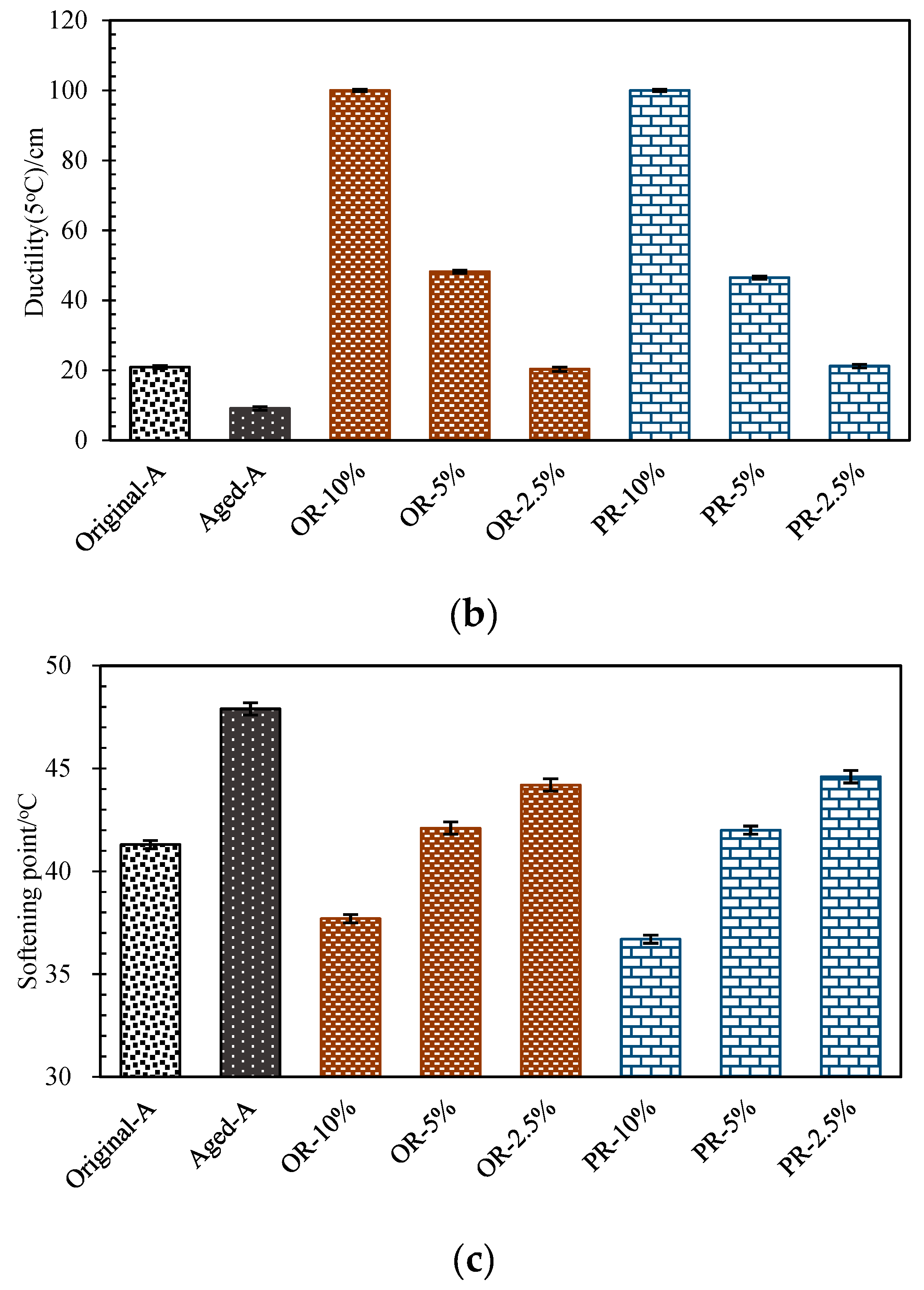

3.3.1. Physical Properties

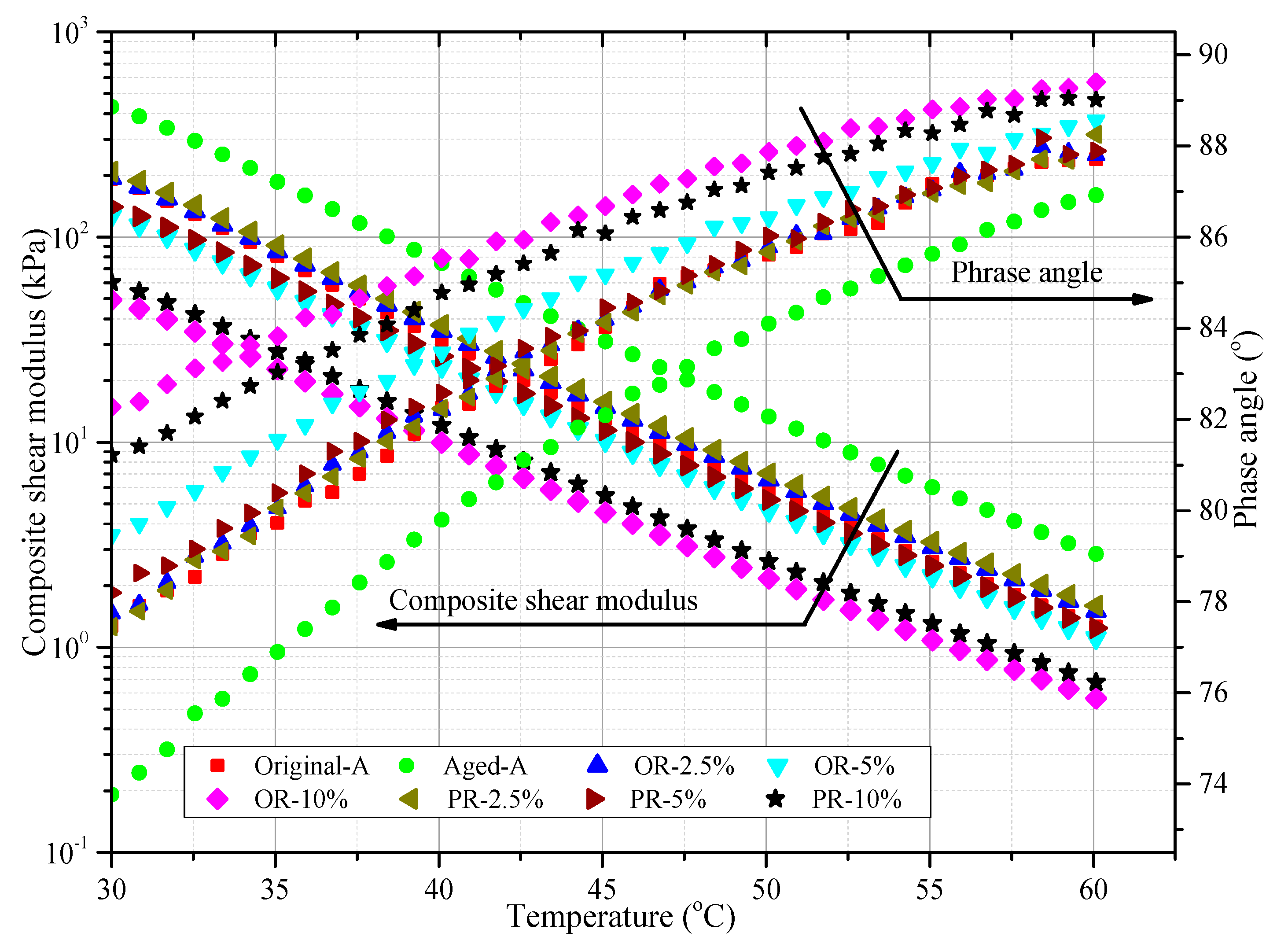

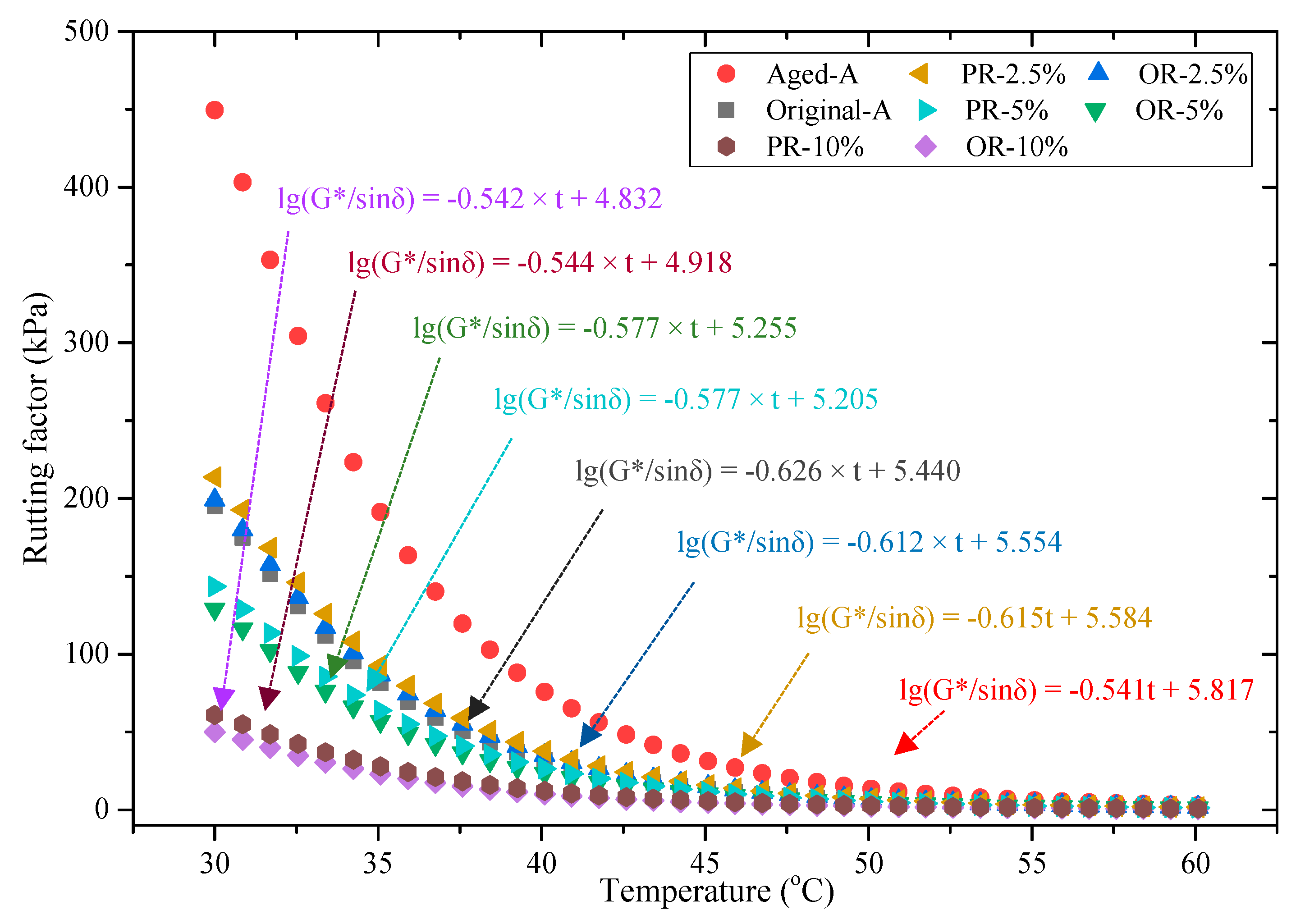

3.3.2. High-Temperature Rheological Properties

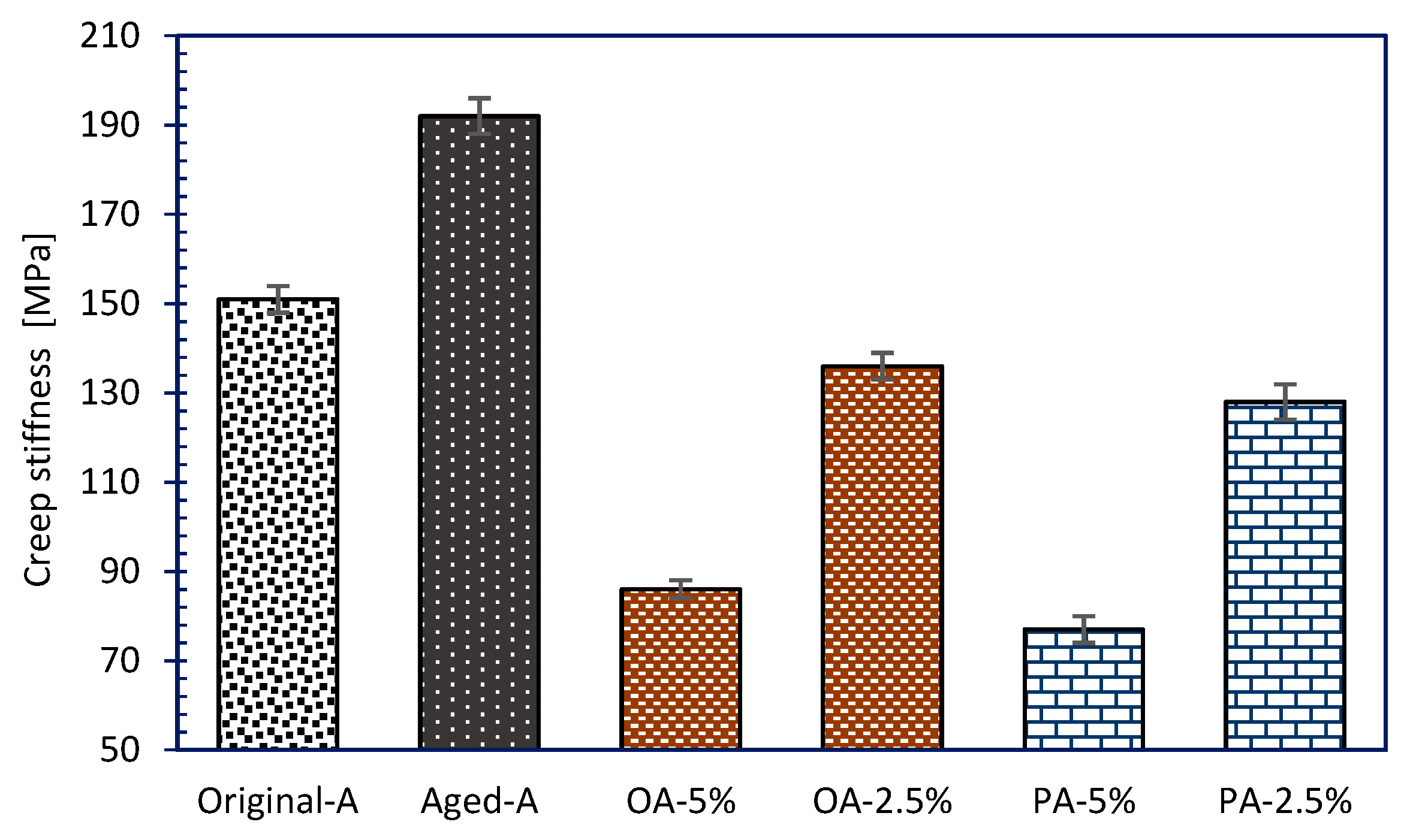

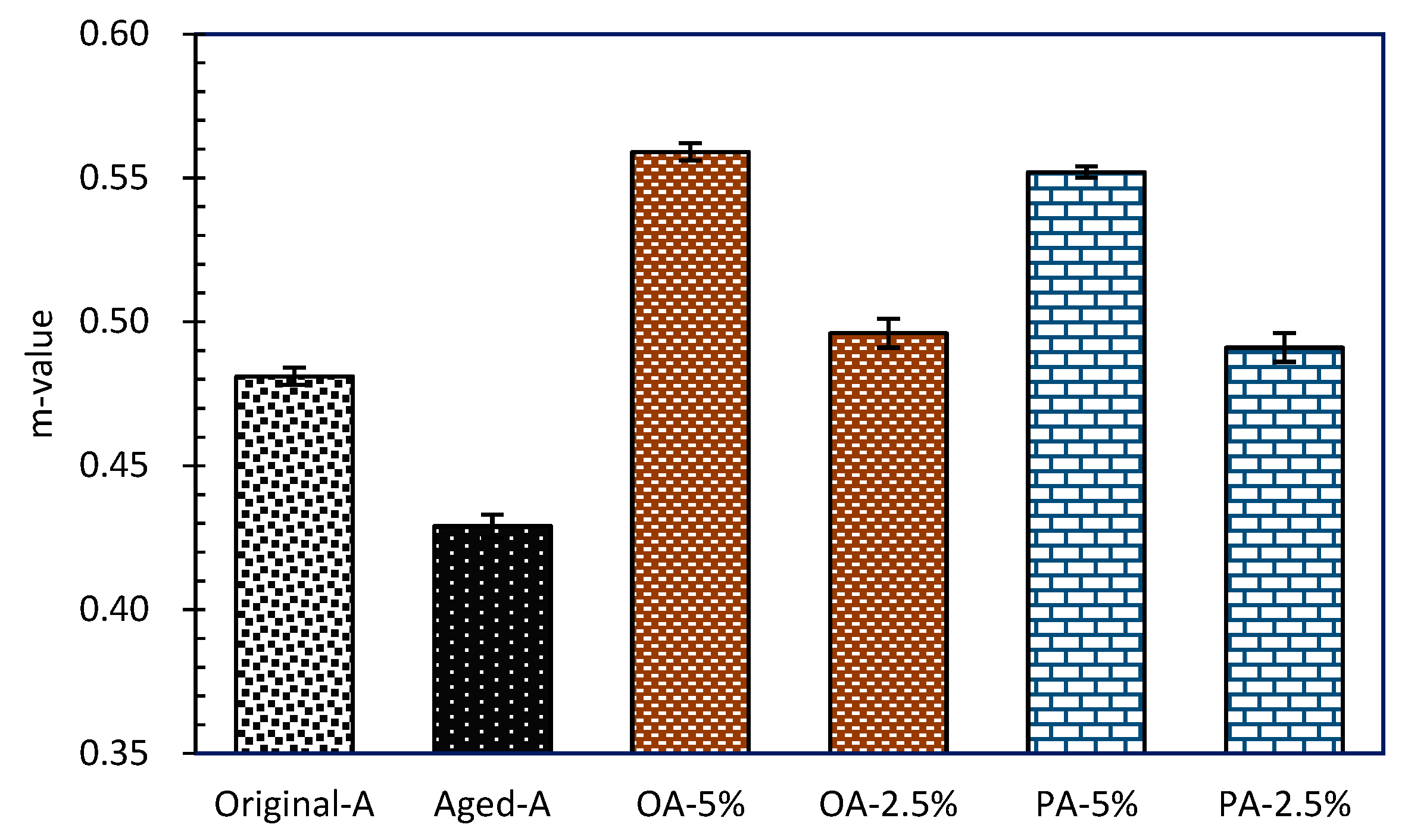

3.3.3. Low-Temperature Rheological Properties

4. Conclusions

- (1)

- The applied penetrants can reduce the contact angle between the liquid rejuvenator and the aged asphalt binder, because of the diffusion mechanism and its interface information. It improved the efficiency of diffusion and permeability between rejuvenators and aged asphalt binder.

- (2)

- The self-designed sinking time test, softening rate test, and gravitational collapsing test had been approved as effective ways to compare the diffusion efficiency between different rejuvenators. All these three tests agreed with each other quite well. PR has a better permeability into aged asphalt than that of OR. It has shorter sinking time, softening time, and collapsing time.

- (3)

- Rejuvenators increased the penetration and ductility values, while decreased the softening point. The addition of 2.5 wt% rejuvenator could result in the most effective regeneration performance on aged asphalt, according to both physical and rheological tests results.

- (4)

- Both modulus and phase angle indicated that adding rejuvenators can recover viscosity of aging asphalt partially. Moreover, BBR test demonstrated that the addition of rejuvenators can restore the rheology and temperature sensitivity of aged asphalt in cold condition. But excessive dosage of rejuvenator may cause a worse stiffness modulus, increasing the rutting possibility.

Author Contributions

Funding

Conflicts of Interest

References

- Pan, P.; Wu, S.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Xiao, Y.; Wan, M.; Jenkins, K.J.; Wu, S.P.; Cui, P.Q. Using activated carbon to reduce the volatile organic compounds from bituminous materials. J. Mater. Civil. Eng. 2017, 29, 040171661–040171668. [Google Scholar] [CrossRef]

- Liu, Z.B. Asphalt pavement preventive maintenance technology overview. Appl. Mech. Mater. 2014, 638, 1135–1138. [Google Scholar] [CrossRef]

- Johnson, A.M. Best Practices Handbook on Asphalt Pavement Maintenance; Technical Report MN/RC-2000-04; University of Minnesota: Minneapolis, MN, USA, February 2000. [Google Scholar]

- Patil, M.S.B.; Patil, D.S. Evaluation of cost effective material for maintenance of flexible pavement. Int. J. Sci. Eng. Res. 2013, 4, 72–78. [Google Scholar]

- Lin, J.; Hong, J.; Huang, C.; Liu, J.; Wu, S. Effectiveness of rejuvenator seal materials on performance of asphalt pavement. Constr. Build. Mater. 2014, 55, 63–68. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of fine aggregate morphology by image method and its effect on skid-resistance of micro-surfacing. Materials 2018, 11, 920. [Google Scholar] [CrossRef]

- Lin, J.; Guo, P.; Xie, J.; Wu, S.; Chen, M. Effect of rejuvenator sealer materials on the properties of aged asphalt binder. J. Mater. Civil Eng. 2013, 25, 829–835. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Li, C.; Xiao, Y.; Wu, S.; Pan, P. The rejuvenating effect in hot asphalt recycling by mortar transfer ratio and image analysis. Materials 2017, 10, 574. [Google Scholar] [CrossRef]

- García, Á.; Schlangen, E.; van de Ven, M.; Sierra-Beltrán, G. Preparation of capsules containing rejuvenators for their use in asphalt concrete. J. Hazard. Mater. 2010, 184, 603–611. [Google Scholar] [CrossRef]

- Lin, J.; Huo, L.; Xu, F.; Xiao, Y.; Hong, J. Development of microstructure and early-stage strength for 100% cold recycled asphalt mixture treated with emulsion and cement. Constr. Build. Mater. 2018, 189, 924–933. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Im, S.; Zhou, F.; Lee, R.; Scullion, T. Impacts of rejuvenators on performance and engineering properties of asphalt mixtures containing recycled materials. Constr. Build. Mater. 2014, 53, 596–603. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Impact of rejuvenators on aging properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Zhang, W.; Zhang, D. Experimental study of stable crumb rubber asphalt and asphalt mixture. Constr. Build. Mater. 2017, 157, 975–981. [Google Scholar] [CrossRef]

- Zaumanis, M.; Boesiger, L.; Kunz, B.; Cavalli, M.C.; Poulikakos, L. Determining optimum rejuvenator addition location in asphalt production plant. Constr. Build. Mater. 2019, 198, 368–378. [Google Scholar] [CrossRef]

- Mirhosseini, A.F.; Tahami, S.A.; Hoff, I.; Dessouky, S.; Ho, C.H. Performance evaluation of asphalt mixtures containing high-RAP binder content and bio-oil rejuvenator. Constr. Build. Mater. 2019, 227, 116465. [Google Scholar] [CrossRef]

- Saleh, M.; Nguyen, N.H. Effect of rejuvenator and mixing methods on behaviour of warm mix asphalt containing high RAP content. Constr. Build. Mater. 2019, 197, 792–802. [Google Scholar]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Ržek, L.; Turk, M.R.; Tušar, M. Increasing the rate of reclaimed asphalt in asphalt mixture by using alternative rejuvenator produced by tire pyrolysis. Constr. Build. Mater. 2020, 232, 117177. [Google Scholar] [CrossRef]

- Haghshenas, H.; Nsengiyumva, G.; Kim, Y.R.; Santosh, K.; Amelian, S. Research on High-RAP Asphalt Mixtures with Rejuvenators-Phase II; Technical Report SPR-(18) M070; University of Nebraska-Lincoln: Nebraska, NE, USA, August 2019. [Google Scholar]

- Mansourkhaki, A.; Ameri, M.; Daryaee, D. Application of different modifiers for improvement of chemical characterization and physical-rheological parameters of reclaimed asphalt binder. Constr. Build. Mater. 2019, 203, 83–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Van de Ven, M.F.C.; Molenaar, A.A.A.; Wu, S. Increasing the Service Life of Porous Asphalt with Rejuvenators. Sustain. Constr. Mater. 2013, 28, 318–330. [Google Scholar]

- Cui, P.; Wu, S.; Xu, H.; Lv, Y. Silicone Resin Polymer Used in Preventive Maintenance of Asphalt Mixture Based on Fog Seal. Polymers 2019, 11, 1814. [Google Scholar] [CrossRef] [PubMed]

- Feng, P.; Wang, H.; Zhang, X.; Hasan, M.R.M.; You, Z.; Gao, J. Study on workability and skid resistance of bio-oil–modified fog seal with sand. J. Test. Eval. 2019, in press. [Google Scholar] [CrossRef]

- Wan, L.; Wu, S.P.; Lei, M.; Jenkins, K. The Rej uvenating and Aging Performances of Aged SBS Modified Asphalt Treated by Different Rejuvenator Sealer Materials. Adv. Mater. Res. 2013, 753, 734–740. [Google Scholar] [CrossRef]

- O’Connell, J.; Rampersad, A.; Lavelle, R. The evaluation of asphalt mix surface rejuvenators in South Africa. In Proceedings of the Southern African Transport Conference, Pretoria, South Africa, 10–13 July 2017. [Google Scholar]

- Kurth, T.L.; Nivens, S.; Stevermer, C.P.; Tabatabaee, H.A. Emulsions with Polymerized Oils & Methods of Manufacturing the Same. U.S. Patent Application No. 15/715,741, 28 March 2019. [Google Scholar]

- Kurth, T.L.; Nivens, S.; Stevermer, C.P.; Tabatabaee, H.A. Rejuvenating Compositions for Asphalt Applications & Methods of Manufacturing the Same. U.S. Patent Application No. 15/553,711, 25 January 2018. [Google Scholar]

- Xiao, Y.; Li, C.; Wan, M.; Zhou, X.; Wang, Y.; Wu, S. Study of the diffusion of rejuvenators and its effect on aged bitumen binder. Appl. Sci. 2017, 7, 397. [Google Scholar] [CrossRef]

- Mićić, R.; Tomić, M.; Martinović, F.; Kiss, F.; Simikić, M.; Aleksic, A. Reduction of free fatty acids in waste oil for biodiesel production by glycerolysis: Investigation and optimization of process parameters. Green Process. Synth. 2018, 8, 15–23. [Google Scholar] [CrossRef]

- Wan, G.; Chen, M.; Liu, J.; Liu, S.; Lin, H. Comparative study of waste cooking oil and waste lubricating oil on physical and rheological properties of aged asphalt. J. Wuhan Univ. Technol. 2018, 42, 7–11. [Google Scholar]

- Doughty, J.B. Lignin Amines as Asphalt Emulsifiers. U.S. Patent No. 3,871,893, 18 March 1975. [Google Scholar]

- Tao, X.; Shi, L.S.; Sun, M.J.; Li, N. Synthesis of lignin amine asphalt emulsifier and its investigation by online FTIR spectrophotometry. Adv. Mater. Res. 2014, 909, 72–76. [Google Scholar]

- Klint, A. Amphiphilic Surface Modification of Colloidal Silica Sols; Chalmers University of Technology: Göteborg, Sweden, 2011. [Google Scholar]

- Cong, P.; Hao, H.; Zhang, Y.; Luo, W.; Yao, D. Investigation of diffusion of rejuvenator in aged asphalt. Int. J. Pavement Res. Technol. 2016, 9, 280–288. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, T.; Ding, X.; Chen, T.; Huang, X.; Xu, G. Impacts of air-void structures on the rutting tests of asphalt concrete based on discretized emulation. Constr. Build. Mater. 2018, 166, 334–344. [Google Scholar] [CrossRef]

- Yan, J.; Leng, Z.; Li, F.; Zhu, H.; Bao, S. Early-age strength and long-term performance of asphalt emulsion cold recycled mixes with various cement contents. Constr. Build. Mater. 2017, 137, 153–159. [Google Scholar] [CrossRef]

- Koc, M.; Bulut, R. Characterization of warm mix asphalt additives using direct contact angle measurements and surface free energies. In Proceedings of the Transportation Research Board Annual Meeting, Washington, DC, USA, 12–16 January 2014. [Google Scholar]

- Chen, J.S.; Huang, C.C.; Chu, P.Y.; Lin, K.Y. Engineering characterization of recycled asphalt concrete and aged bitumen mixed recycling agent. J. Mater. Sci. 2007, 42, 9867–9876. [Google Scholar] [CrossRef]

- Cussler, E.L. Diffusion: Mass Transfer in Fluid Systems; Cambridge university press: Cambridge, UK, 2009. [Google Scholar]

- Karlsson, R.; Isacsson, U. Application of FTIR-ATR to characterization of bitumen rejuvenator diffusion. J. Mater. Civil Eng. 2003, 15, 157–165. [Google Scholar] [CrossRef]

- Oliver, J.W. Diffusion of oils in asphalts. Ind. Eng. Chem. Prod. Res. Dev. 1974, 13, 65–70. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Finite element modeling of rejuvenator diffusion in RAP binder film–simulation of plant mixing process. In Multi-Scale Modeling and Characterization of Infrastructure Materials; Springer: Berlin, Germany, 2013; pp. 407–419. [Google Scholar]

- Sullivan, D.E. Surface tension and contact angle of a liquid–solid interface. J. Chem. Phys. 1981, 74, 2604–2615. [Google Scholar] [CrossRef]

- Daugherty, R.L.; Ingersoll, A.C. Fluid Mechanics: With Engineering Applications; McGraw-Hill: New York, NY, USA, 1954. [Google Scholar]

- Wu, S.; Pang, L.; Yu, J.; Qiu, J.; Ma, L. Research progress on photooxidation aging of asphalt. Pet. Asph. 2007, 21, 1–6. [Google Scholar]

- Luo, W.; Zhang, Y.; Cong, P. Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr. Build. Mater. 2017, 144, 13–24. [Google Scholar] [CrossRef]

- Guo, Y.M.; Chen, W. Dynamic viscoelastic properties of SBS modified asphalt based on DSR testing. Adv. Mater. Res. 2012, 598, 473–476. [Google Scholar] [CrossRef]

- Yang, X.; Shen, A.; Guo, Y.; Lyu, Z. Effect of process parameters on the high temperature performance and reaction mechanism of CRMA. Pet. Sci. Technol. 2018, 36, 1537–1543. [Google Scholar] [CrossRef]

- Han, S.; Zhang, Z.; Zhang, Y.; Cheng, X.; Ren, W. Changes in rheological properties during asphalt aging. Pet. Sci. Technol. 2019, 37, 1539–1547. [Google Scholar] [CrossRef]

- Zofka, A.; Marasteanu, M.; Turos, M. Investigation of asphalt mixture creep compliance at low temperatures. Road Mater. Pavement Des. 2008, 9 (Suppl. 1), 269–285. [Google Scholar] [CrossRef]

- Cubuk, M.; Gürü, M.; Çubuk, M.K. Improvement of bitumen performance with epoxy resin. Fuel 2009, 88, 1324–1328. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Amirkhanian, S. Investigation of the graphene oxide and asphalt interaction and its effect on asphalt pavement performance. Constr. Build. Mater. 2018, 165, 572–584. [Google Scholar] [CrossRef]

| Items | Parameter | Results |

|---|---|---|

| Physical properties | 25 °C Penetration (0.1 mm) | 80.5 |

| 10 °C Ductility (cm) | >100 | |

| Softening point [°C] | 41.3 | |

| 135 °C Viscosity (Pa·s) | 0.533 | |

| Chemical compositions | Saturates (%) | 15.7 |

| Aromatics (%) | 31.3 | |

| Resins (%) | 41.8 | |

| Asphaltenes (%) | 11.2 |

| Items | Parameter | Results |

|---|---|---|

| Physical properties | pH values | 4.2 |

| Density (g/mL) | 0.920 | |

| 25 °C Viscosity (cP) | 57.0 | |

| Chemical compositions | Saturates (%) | 26.5 |

| Aromatics (%) | 28.1 | |

| Resins (%) | 45.4 | |

| Asphaltenes (%) | N/A |

| Rejuvenators and Dosages | Oil Rejuvenator | Penetrative Rejuvenator | ||||

|---|---|---|---|---|---|---|

| 10% | 5% | 2.5% | 10% | 5% | 2.5% | |

| Labels | OA-10% | OA-5% | OA-2.5% | PA-10% | PA-5% | PA-2.5% |

| Rejuvenators | 25 °C Viscosity (Pa·s) | Contact Angle (°) | Sinking Time (s) | Softening Time (s) | Collapsing Time (s) | |

|---|---|---|---|---|---|---|

| Aged Asphalt | Original Asphalt | |||||

| OR | 1.278 | 53.1 | 51.6 | 2660 | 1974 | 2873 |

| PR | 0.478 | 34.8 | 34.6 | 1557 | 1356 | 1926 |

| Samples | GTS | K1 | R2 |

|---|---|---|---|

| Original-A | 0.626 | 5.440 | 0.998 |

| Aged-A | 0.541 | 5.817 | 0.999 |

| OA-10% | 0.542 | 4.832 | 0.998 |

| OA-5% | 0.577 | 5.255 | 0.998 |

| OA-2.5% | 0.612 | 5.554 | 0.998 |

| PA-10% | 0.544 | 4.918 | 0.998 |

| PA-5% | 0.577 | 5.205 | 0.998 |

| PA-2.5% | 0.615 | 5.584 | 0.998 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhang, L.; Yan, B.; Kong, D.; Li, Y.; Wu, S. Diffusion Mechanism of Rejuvenator and Its Effects on the Physical and Rheological Performance of Aged Asphalt Binder. Materials 2019, 12, 4130. https://doi.org/10.3390/ma12244130

Wang F, Zhang L, Yan B, Kong D, Li Y, Wu S. Diffusion Mechanism of Rejuvenator and Its Effects on the Physical and Rheological Performance of Aged Asphalt Binder. Materials. 2019; 12(24):4130. https://doi.org/10.3390/ma12244130

Chicago/Turabian StyleWang, Fusong, Lei Zhang, Boxiang Yan, Dezhi Kong, Yuanyuan Li, and Shaopeng Wu. 2019. "Diffusion Mechanism of Rejuvenator and Its Effects on the Physical and Rheological Performance of Aged Asphalt Binder" Materials 12, no. 24: 4130. https://doi.org/10.3390/ma12244130

APA StyleWang, F., Zhang, L., Yan, B., Kong, D., Li, Y., & Wu, S. (2019). Diffusion Mechanism of Rejuvenator and Its Effects on the Physical and Rheological Performance of Aged Asphalt Binder. Materials, 12(24), 4130. https://doi.org/10.3390/ma12244130