The Effect of Processing Route on Properties of HfNbTaTiZr High Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

- (i)

- elemental powders mixed in appropriate ratio in Turbula 2F device for 10 h at 45 rpm and subsequently pressed into green compacts (denoted here HEAP) using CIP under the pressure of 400 MPa;

- (ii)

- MA powder prepared from the elemental powders (granularity −325 mesh) by high energy ball milling in an Ar atmosphere for 42 h using tungsten carbide balls. The mean particle size of the MA powder was ≈3 μm and MA particles consisted of nanocrystalline grains

- (iii)

- atomized powder (AT) prepared from arc melted HfNbTaTiZr alloy by crucible-free electrode induction-melting gas atomization in a protective Ar atmosphere to suppress undesirable oxidation. The AT powder had a broad particle size distribution covering the range from 10 to 300 μm.

3. Results

3.1. Initial Powders

3.1.1. HEAP Green Compact

3.1.2. AT Powder

3.1.3. MA Powder

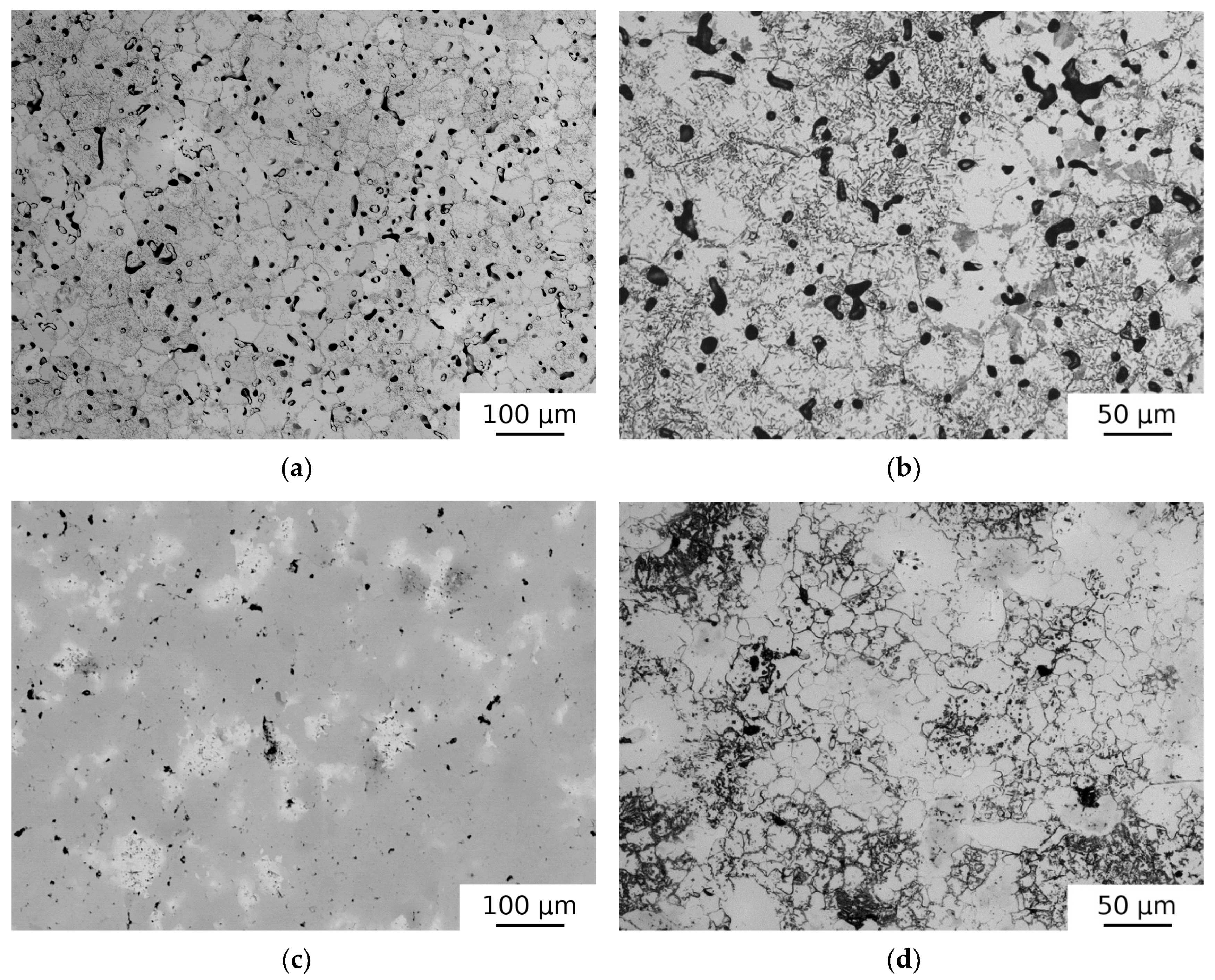

3.2. Effect of HIP and Sintering

3.3. Effect of Swaging

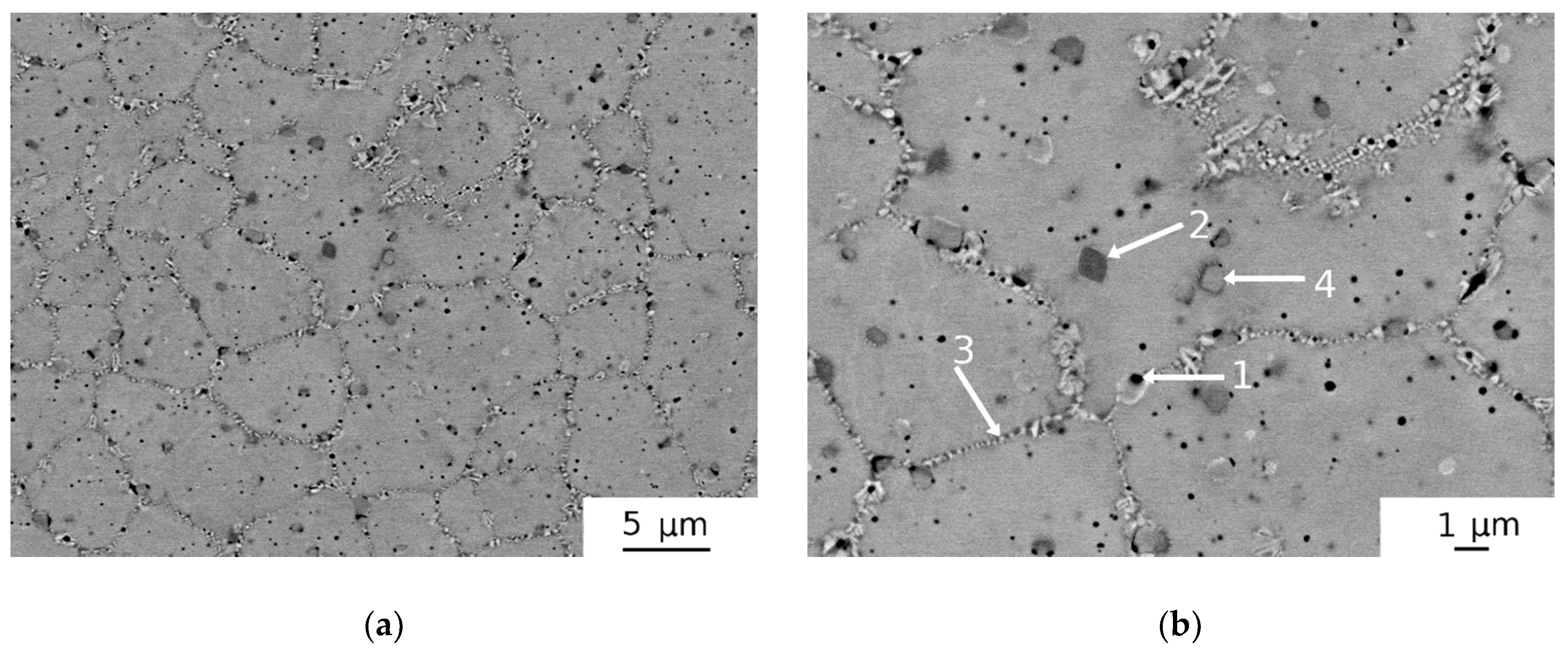

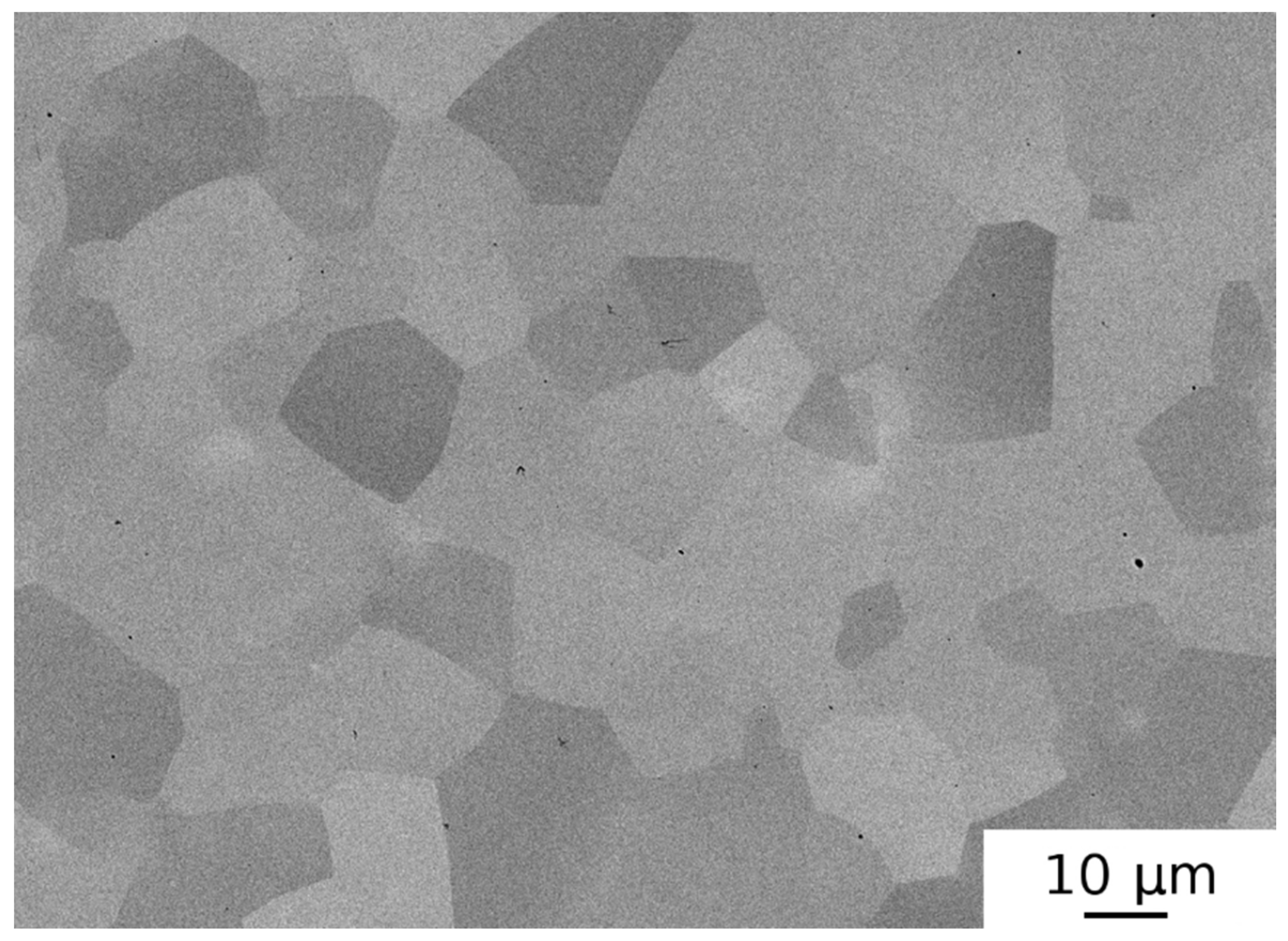

3.4. Effect of SPS and HPT Processing

4. Discussion

4.1. Residual Porosity

4.2. Oxygen Content

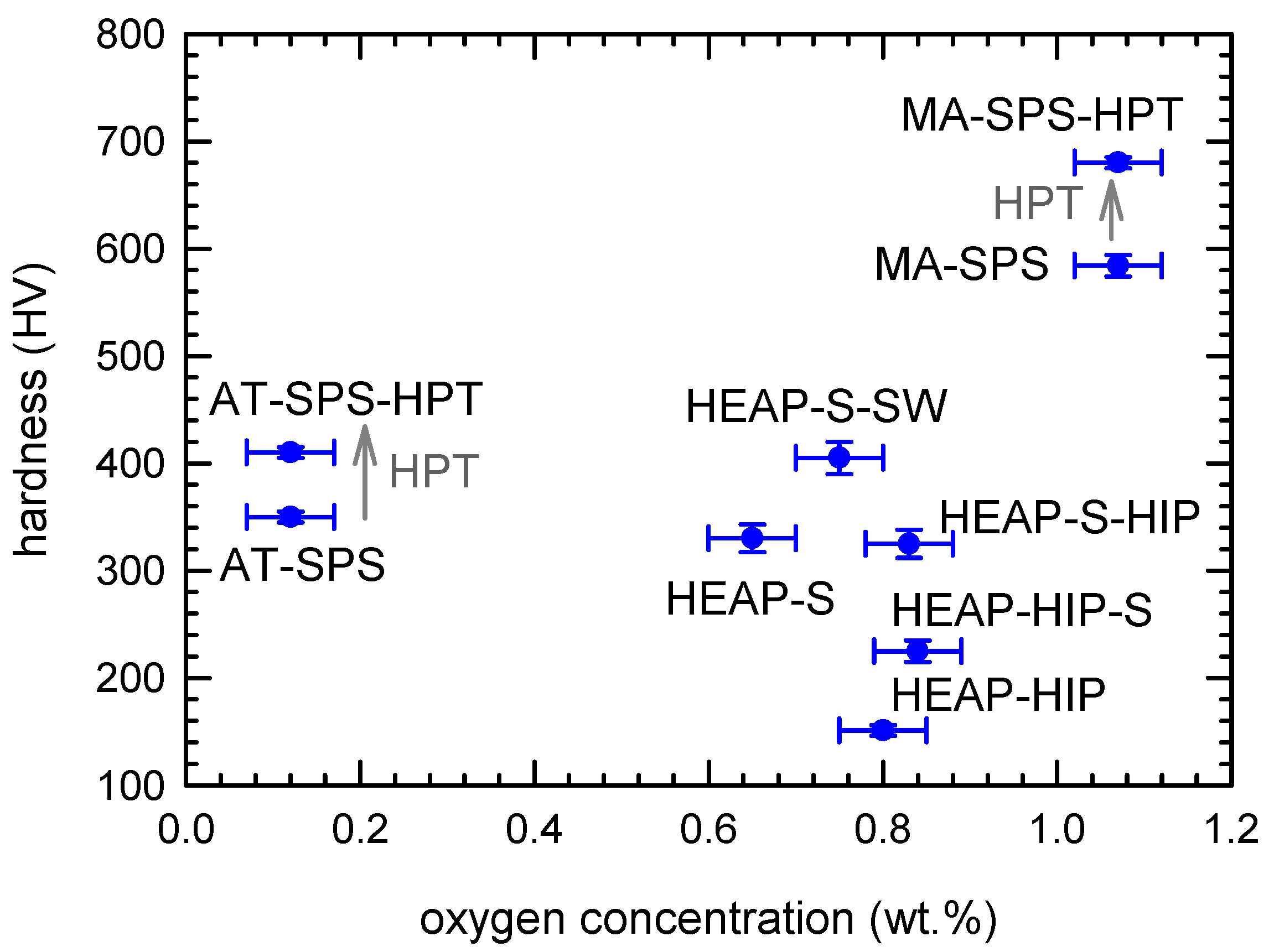

4.3. Hardness

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gorsse, S.; Miracle, D.B.; Senkov, O.N. Mapping the world of complex concentrated alloys. Acta Mater. 2017, 135, 177–187. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Lu, Z.P.; Wang, H.; Chen, M.W.; Baker, I.; Yeh, J.W.; Liu, C.T.; Nieh, T.G. An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 2015, 66, 67–76. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Yeh, B.J.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.N. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Fuerbacher, M.; Heidelmann, M.; Carsten, T. Hexagonal High-Entropy Alloys. Mater. Res. Lett. 2014, 3, 1–9. [Google Scholar] [CrossRef]

- Yusenko, K.V.; Riva, S.; Carvalho, P.A.; Yusenko, M.V.; Arnaboldi, S.; Suknikh, A.S.; Hanfland, M.; Gromilov, S.A. First hexagonal close packed high-entropy alloy with outstanding stability under extreme conditions and electrocatalytic activity for methanol oxidation. Scr. Mater. 2017, 138, 22–27. [Google Scholar] [CrossRef]

- Sheikh, S.; Shafeie, S.; Hu, Q.; Ahlstrom, J.; Persson, C.; Veselý, J.; Zýka, J.; Klement, U.; Guo, S. Alloy design for intrinsically ductile refractory high-entropy alloys. J. Appl. Phys. 2016, 120, 164902. [Google Scholar] [CrossRef]

- Couzinié, J.; Dirras, G. Body-centered cubic high-entropy alloys: From processing to underlying deformation mechanisms. Mater. Charact. 2019, 147, 533–544. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high—Entropy dual—Phase alloys overcome the strength—Ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Fu, C.; Wu, Y.; Wang, Q.; Hui, X.; Wang, Y. Formation and toughening of metastable phases in TiZrHfAlNb medium entropy alloys. Mater. Sci. Eng. A 2019, 748, 441–452. [Google Scholar] [CrossRef]

- Wang, D.; Lu, X.; Wan, D.; Li, Z.; Barnoush, A. In-situ observation of martensitic transformation in an interstitial metastable high-entropy alloy during cathodic hydrogen charging. Scr. Mater. 2019, 173, 56–60. [Google Scholar] [CrossRef]

- Čapek, J.; Kyncl, J.; Kolařík, K.; Beránek, L.; Pitrmuc, Z.; Medřický, J.; Pala, Z. Grinding of Inconel 713 superalloy for gas turbines Grinding of Inconel 713 Superalloy for Gas Turbines. Manuf. Technol. 2016, 16, 38–45. [Google Scholar]

- Praveen, S.; Kim, H.S. High-Entropy Alloys: Potential Candidates for High-Temperature Applications—An Overview. Adv. Eng. Mater. 2018, 20, 1700645. [Google Scholar] [CrossRef]

- Couzinié, J.; Senkov, O.N.; Miracle, D.B.; Dirras, G. Comprehensive data compilation on the mechanical properties of refractory high-entropy alloys. Data Br. 2018, 21, 1622–1641. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Maisenkothen, F.; Micracle, D.B.; Woodward, C.F. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Wang, J.; Abdel-Hady Gepreel, M.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef]

- Donato, T.A.G.; Almeida, L.H.; Nogueira, R.A.; Niemeyer, T.C.; Grandini, C.R.; Caram, R.; Schneider, S.G.; Santos, A.R., Jr. Cytotoxicity study of some Ti alloys used as biomaterial. Mater. Sci. Eng. C 2009, 29, 1365–1369. [Google Scholar] [CrossRef]

- Eisenbarth, E.; Velten, D.; Müller, M.; Thull, R.; Breme, J. Biocompatibility of β-stabilizing elements of titanium alloys. Biomaterials 2004, 25, 5705–5713. [Google Scholar] [CrossRef] [PubMed]

- Senkov, O.N.; Semiatin, S.L. Microstructure and properties of a refractory high-entropy alloy after cold working. J. Alloys Compd. 2015, 649, 1110–1123. [Google Scholar] [CrossRef]

- Maiti, S.; Steurer, W. Structural-disorder and its effect on mechanical properties in single-phase TaNbHfZr high-entropy alloy. Acta Mater. 2016, 106, 87–97. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, M.H.; Tsai, C.W.; Lin, C.M.; Wang, W.R.; Yang, C.C.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics 2015, 62, 76–83. [Google Scholar] [CrossRef]

- Chen, S.; Tseng, K.K.; Tong, Y.; Li, W.; Tsai, C.W.; Yeh, J.W.; Liaw, P.K. Grain growth and Hall-Petch relationship in a refractory HfNbTaZrTi high-entropy alloy. J. Alloys Compd. 2019, 795, 19–26. [Google Scholar] [CrossRef]

- Senkov, O.N.; Pilchak, A.L.; Semiatin, S.L. Effect of Cold Deformation and Annealing on the Microstructure and Tensile Properties of a HfNbTaTiZr Refractory High Entropy Alloy. Metall. Mater. Trans. A 2018, 49, 2876–2892. [Google Scholar] [CrossRef]

- Lukac, F.; Dudr, M.; Mušálek, R.; Klečka, J.; Cinert, J.; Čížek, J.; Chráska, T.; Čížek, J.; Melikhova, O.; Kuriplach, J.; et al. Spark plasma sintering of gas atomized high-entropy alloy HfNbTaTiZr. J. Mater. Res. 2018, 33, 3247–3257. [Google Scholar] [CrossRef]

- Kang, B.; Lee, J.; Jin, H.; Hyung, S. Ultra-high strength WNbMoTaV high-entropy alloys with fi ne grain structure fabricated by powder metallurgical process. Mater. Sci. Eng. A 2018, 712, 616–624. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Liu, B.; Zhang, W. Precipitation behavior during hot deformation of powder metallurgy Ti-Nb-Ta-Zr-Al high entropy alloys. Intermetallics 2018, 100, 95–103. [Google Scholar] [CrossRef]

- Portnoi, V.K.; Leonov, A.V.; Gusakov, M.S.; Logachev, I.A.; Fedotov, S.A. Preparation of High-Temperature Multicomponent Alloys by Mechanochemical Synthesis from Refractory Elements. Inorg. Mater. 2019, 55, 219–223. [Google Scholar] [CrossRef]

- Wang, S.; Xu, J. (TiZrNbTa)—Mo high-entropy alloys: Dependence of microstructure and mechanical properties on Mo concentration and modeling of solid solution strengthening. Intermetallics 2018, 95, 59–72. [Google Scholar] [CrossRef]

- Lewis, G. Properties of open-cell porous metals and alloys for orthopaedic applications. J. Mater. Sci. Mater. Med. 2013, 24, 2293–2325. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Liu, B.; Liu, Y.; Li, T.; Fu, A.; Fang, Q.; Nie, Y. Microstructures and mechanical properties of ductile NbTaTiV refractory high entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2019, 776, 428–436. [Google Scholar] [CrossRef]

- Neslušan, M.; Minárik, P.; Čilliková, M.; Kolařík, K.; Rubešová, K. Barkhausen noise emission in tool steel X210Cr12 after semi-solid processing. Mater. Charact. 2019, 157, 109981. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Bečvář, F.; Čížek, J.; Procházka, I.; Janotová, J. The asset of ultra-fast digitizers for positron-lifetime spectroscopy. Nucl. Instrum. Methods Phys. Res. A 2005, 539, 372–385. [Google Scholar] [CrossRef]

- West, R.N. Positron studies of condensed matter. Adv. Phys. 1973, 22, 263–383. [Google Scholar] [CrossRef]

- Čížek, J.; Haušild, P.; Cieslar, M.; Melikhova, O.; Vlasák, T.; Janeček, M.; Král, R.; Harcuba, P.; Lukáč, F.; Zýka, J.; et al. Strength enhancement of high entropy alloy HfNbTaTiZr by severe plastic deformation. J. Alloys Compd. 2018, 768, 924–937. [Google Scholar] [CrossRef]

- Couzinie, J.P.; Dirras, G.; Perriere, L.; Chauveau, T.; Leroy, E.; Champion, Y.; Guillot, I. Microstructure of a near-equimolar refractory high-entropy alloy. Mater. Lett. 2014, 126, 285–287. [Google Scholar] [CrossRef]

- Cichy, H.; Fromm, E. Oxidation kinetics of metal films at 300 K studied by the piezoelectric quartz crystal microbalance technique. Thin Solid Films 1991, 195, 147–158. [Google Scholar] [CrossRef]

- Málek, J.; Zýka, J.; Lukáč, F.; Čížek, J.; Kunčická, L.; Kocich, R. Microstructure and mechanical properties of sintered and heat treated HfNbTaTiZr high entropy alloy. Metals 2019, in press. [Google Scholar]

- Piluso, P.; Ferrier, M.; Chaput, C.; Claus, J.; Bonnet, J. Hafnium dioxide for porous and dense high-temperature refractories (2600 °C). J. Eur. Ceram. Soc. 2009, 29, 961–968. [Google Scholar] [CrossRef]

- Durov, A.V. Wetting oF Hafnium Dioxide by Pure Metals. Powder Metall. Met. Ceram. 2011, 50, 552–556. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, N.H.; Tsai, C.W.; Hsu, W.L.; Lin, C.M.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 2016, 184, 200–203. [Google Scholar] [CrossRef]

- Schuh, B.; Volker, B.; Todt, J.; Schnell, N.; Perriere, L.; Li, J.; Couzinie, J.P.; Hohenwarter, A. Thermodynamic instability of a nanocrystalline, single-phase TiZrNbHfTa alloy and its impact on the mechanical properties. Acta Mater. 2018, 142, 201–212. [Google Scholar] [CrossRef]

- Chen, S.Y.; Tong, Y.; Tseng, K.K.; Yeh, J.W.; Poplawsky, J.D.; Wen, J.G.; Gao, M.C.; Kim, G.; Chen, W.; Ren, Y.; et al. Phase transformations of HfNbTaTiZr high-entropy alloy at intermediate temperatures. Scr. Mater. 2019, 158, 50–56. [Google Scholar] [CrossRef]

- Yao, J.Q.; Liu, X.W.; Gao, N.; Jiang, Q.H.; Li, N.; Liu, G.; Zhang, W.B.; Fan, Z.T. Phase stability of a ductile single-phase BCC Hf0.5Nb0.5Ta0.5Ti1.5Zr refractory high-entropy alloy. Intermetallics 2018, 98, 79–88. [Google Scholar] [CrossRef]

| Specimen | Process Route |

|---|---|

| HEAP | CIP |

| HEAP-S | CIP + sintering |

| HEAP-S-HIP | CIP + sintering + HIP |

| HEAP-HIP | CIP + HIP |

| HEAP-HIP-S | CIP + HIP + sintering |

| HEAP-S-SW | CIP + sintering + hot swaging |

| MA-SPS | mechanical alloying + SPS |

| AT-SPS | atomized powder + SPS |

| MA-SPS-HPT | mechanical alloying + SPS + HPT |

| AT-SPS-HPT | atomized powder + SPS + HPT |

| Specimen | Porosity (%) | Grain Size (μm) | Hardness (HV10) | Oxygen (wt %) |

|---|---|---|---|---|

| HEAP | N/A | N/A | N/A | 0.55 ± 0.05 |

| HEAP-S | 6.5 ± 1 | ~35 | 330 ± 13 | 0.65 ± 0.07 |

| HEAP-S-HIP | 4.5 ± 0.5 | ~45 | 325 ± 13 | 0.83 ± 0.02 |

| HEAP-HIP | 5 ± 0.5 | ~20 | 151 ± 7 | 0.80 ± 0.05 |

| HEAP-HIP-S | 5 ± 1 | ~25 | 225 ± 10 | 0.84 ± 0.06 |

| HEAP-S-SW | N/A1 | N/A | 405 ± 152 | 0.75 ± 0.03 |

| MA-SPS | 0.9 ± 0.3 | ~10 | 584 ± 10 | 1.07 ± 0.10 |

| AT-SPS | 0 | ~50 | 350 ± 5 | 0.12 ± 0.02 |

| MA-SPS-HPT | N/A1 | ~4 | 680 ± 52 | 1.07 ± 0.03 |

| AT-SPS-HPT | 0 | ~0.5 | 410 ± 5 | 0.12 ± 0.02 |

| Specimen | τ1 (ps) | I1 (%) | τ2 (ps) | I2 (%) | ρD (1014 m−2) |

|---|---|---|---|---|---|

| HEAP | 69(2) | 12(1) | 165(2) | 88(1) | 1.48(8) |

| HEAP-S | 85(2) | 22(2) | 175(4) | 78(2) | 0.94(9) |

| HEAP-S-HIP | 81(4) | 20(2) | 178(3) | 80(2) | 1.1(1) |

| HEAP-HIP | 81(3) | 17(3) | 168(3) | 83(3) | 1.1(1) |

| HEAP-HIP-S | 86(4) | 23(2) | 176(4) | 77(2) | 0.9(1) |

| HEAP-S-SW | 45(4) | 9(1) | 181(2) | 91(2) | 3.0(1) |

| AT | - | - | 165(2) | 100 | <0.1 |

| MA-SPS | 80(6) | 8(1) | 150(2) | 92(1) | 1.1(1) |

| AT-SPS | 148(1) | 100 | - | - | <0.01 |

| MA-SPS-HPT | - | - | 180(1) | 100 | >5 |

| AT-SPS-HPT | - | - | 183(1) | 100 | >5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Málek, J.; Zýka, J.; Lukáč, F.; Vilémová, M.; Vlasák, T.; Čížek, J.; Melikhova, O.; Macháčková, A.; Kim, H.-S. The Effect of Processing Route on Properties of HfNbTaTiZr High Entropy Alloy. Materials 2019, 12, 4022. https://doi.org/10.3390/ma12234022

Málek J, Zýka J, Lukáč F, Vilémová M, Vlasák T, Čížek J, Melikhova O, Macháčková A, Kim H-S. The Effect of Processing Route on Properties of HfNbTaTiZr High Entropy Alloy. Materials. 2019; 12(23):4022. https://doi.org/10.3390/ma12234022

Chicago/Turabian StyleMálek, Jaroslav, Jiří Zýka, František Lukáč, Monika Vilémová, Tomáš Vlasák, Jakub Čížek, Oksana Melikhova, Adéla Macháčková, and Hyoung-Seop Kim. 2019. "The Effect of Processing Route on Properties of HfNbTaTiZr High Entropy Alloy" Materials 12, no. 23: 4022. https://doi.org/10.3390/ma12234022

APA StyleMálek, J., Zýka, J., Lukáč, F., Vilémová, M., Vlasák, T., Čížek, J., Melikhova, O., Macháčková, A., & Kim, H.-S. (2019). The Effect of Processing Route on Properties of HfNbTaTiZr High Entropy Alloy. Materials, 12(23), 4022. https://doi.org/10.3390/ma12234022