Cell Bioprinting: The 3D-Bioplotter™ Case

Abstract

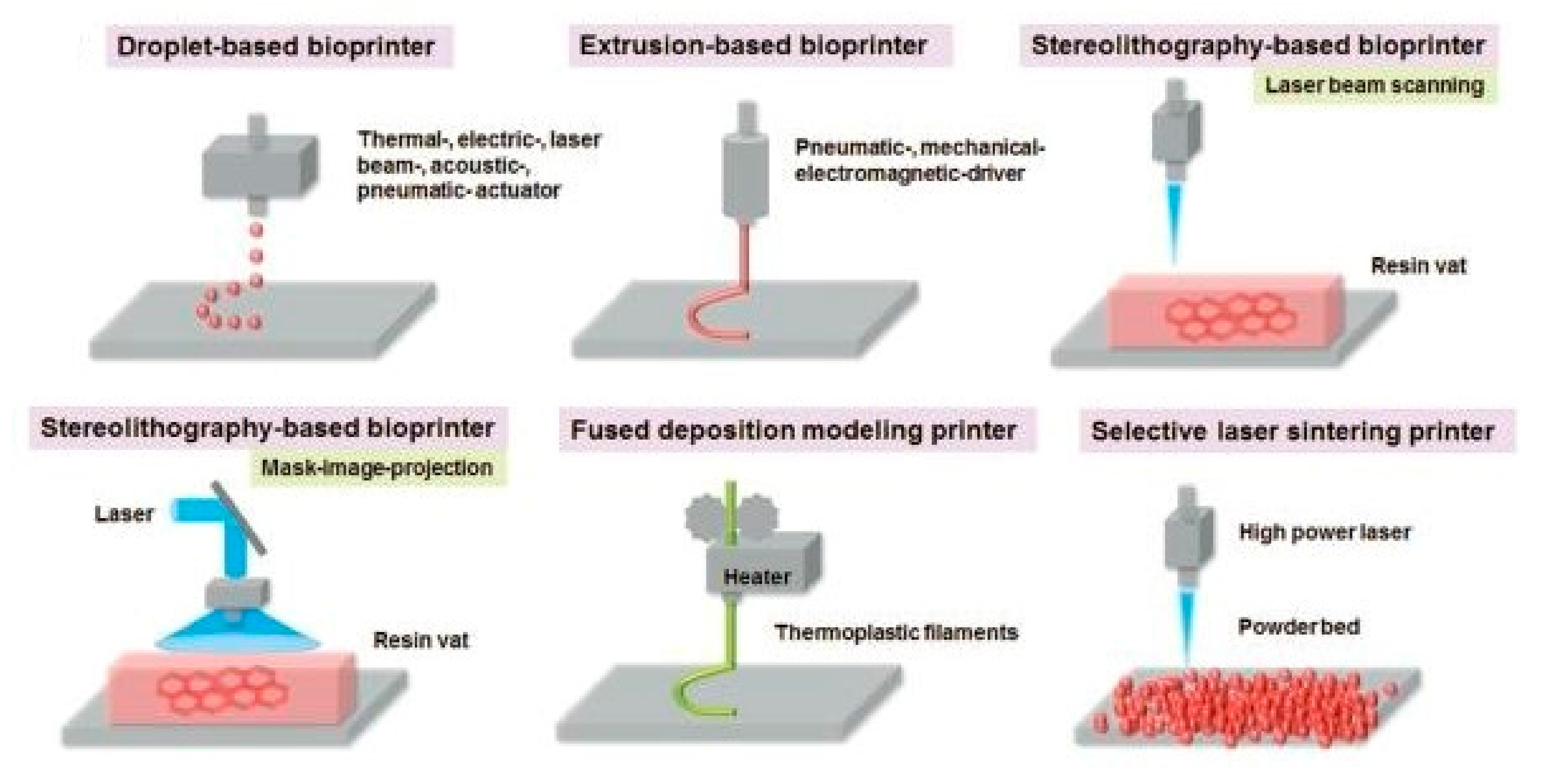

:1. Introduction

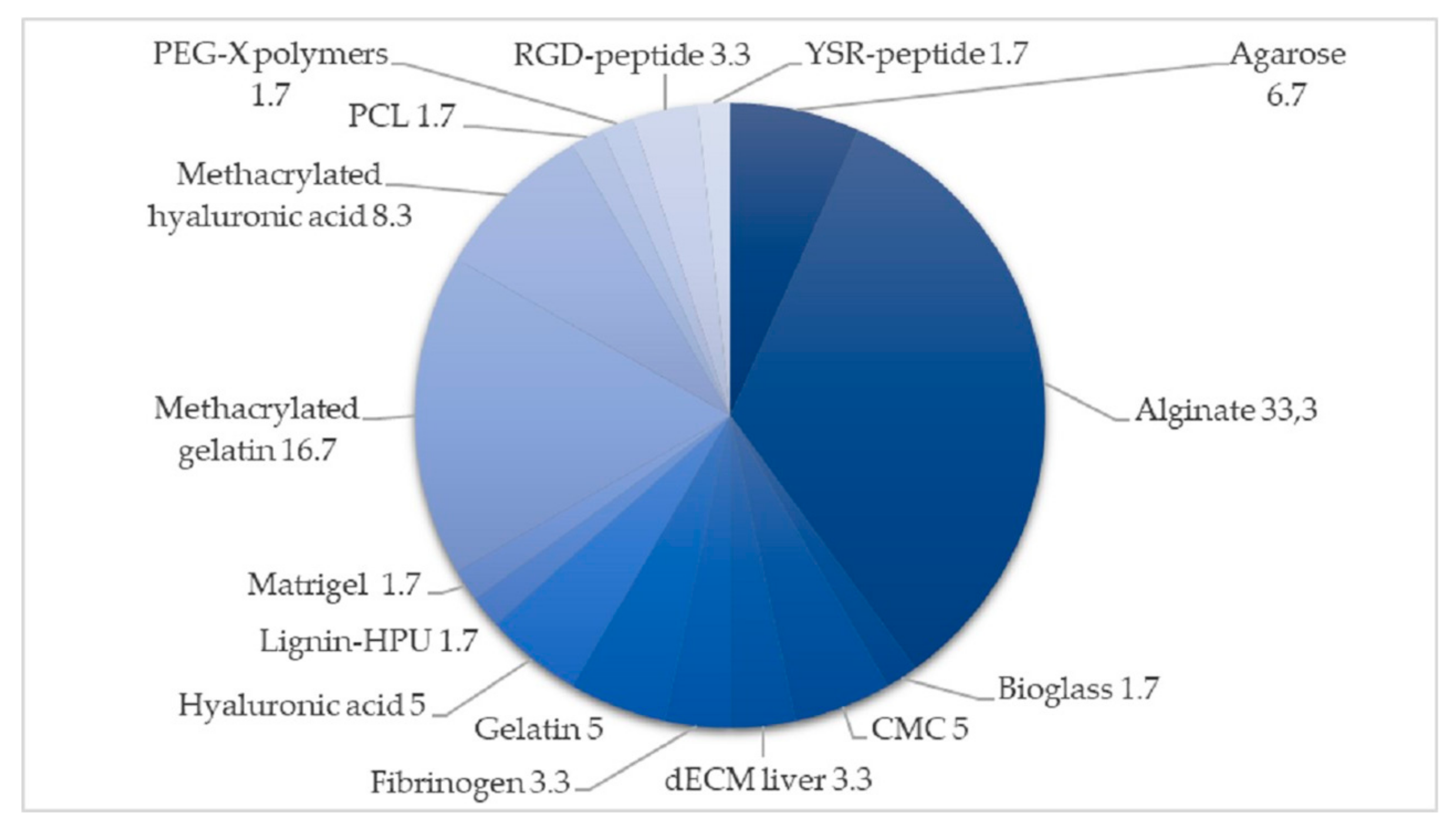

2. Materials for Bioprinting

2.1. Polymers

2.1.1. Natural Polymers

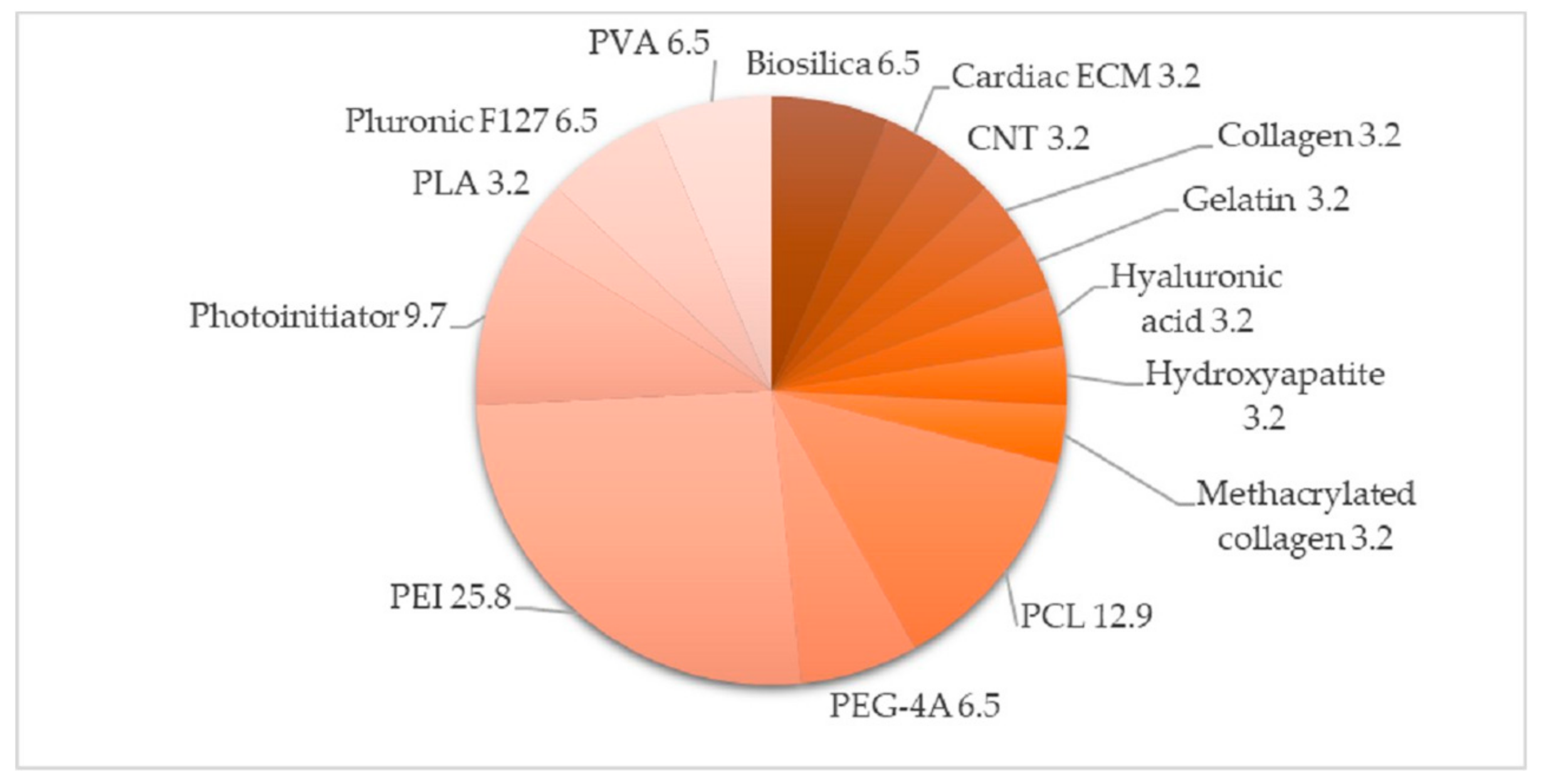

2.1.2. Synthetic Polymers

2.2. Cross-Linking Methods

2.3. Cellular Typologies

2.3.1. Vascular Tissues

2.3.2. Cartilage and Bone-Like Structures

2.3.3. Cardiac Tissues

2.3.4. Liver Tissues

2.3.5. Stem Cells

2.3.6. Cancer Cells

2.3.7. Adipose Tissues

2.3.8. Muscle Cells

2.3.9. Schwann Cells

2.3.10. Skin Tissues

2.4. General Summary

3. Manufacturing Parameters

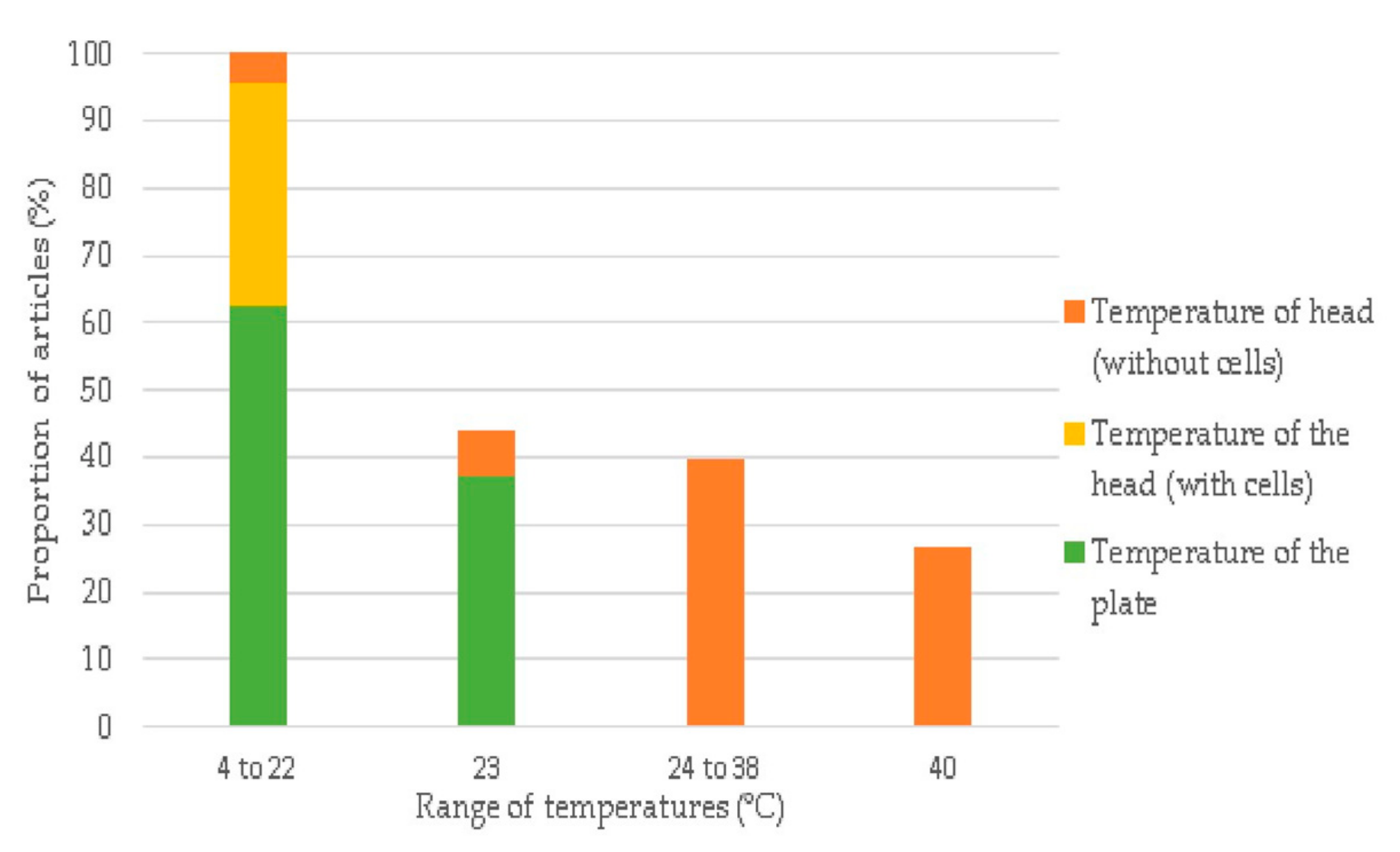

3.1. Temperature of the Head and Plate

3.2. Pressure

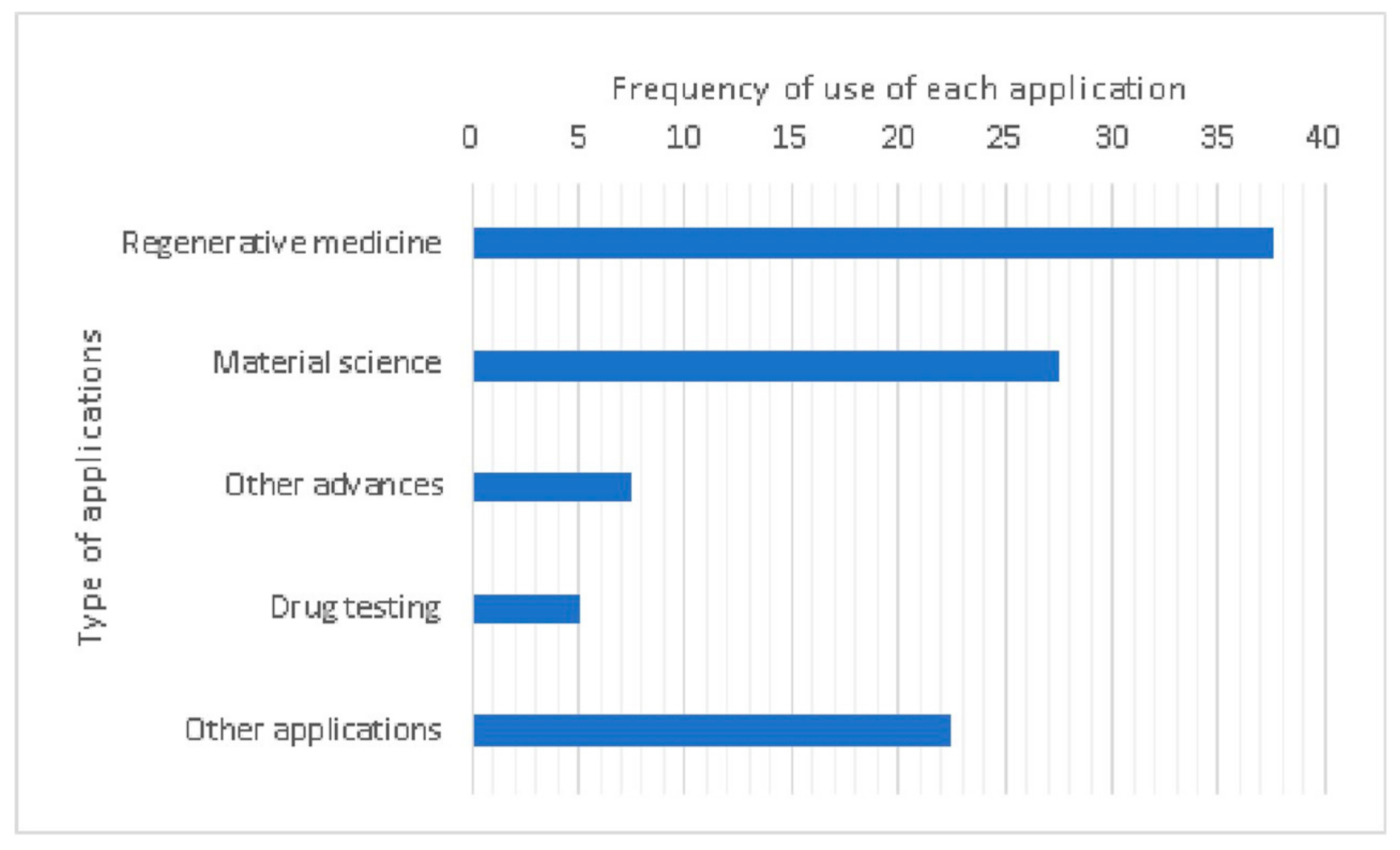

4. Applications of Bioprinting

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Gabriel, S.; Hull, C.W. Apparatus for production of three-dimensional objects by stereolithography. U.S. Patent 4575330, 8 August 1984. [Google Scholar]

- Melchels, F.P.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.P.; Cooper, G.J.T.; Hinkley, T.; Gibson, G.M.; Padgett, M.J.; Cronin, L. Development of a 3D printer using scanning projection stereolithography. Sci. Rep. 2015, 5, 9875. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D stereolithography printing of graphene oxide reinforced complex architectures. Nanotechnology 2015, 26, 434003. [Google Scholar] [CrossRef] [PubMed]

- Hutmacher, D.W.; Schantz, T.; Zein, I.; Ng, K.W.; Teoh, S.H.; Tan, K.C. Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J. Biomed. Mater. Res. 2001, 55, 203–216. [Google Scholar] [CrossRef]

- Hafezi, F.; Kucukgul, C.; Ozler, S.; Koc, B. Bioprinting: Application of Additive Manufacturing in Medicine. In Additive Manufacturing; CRC Press: Boca Rato, FL, USA, 2015; pp. 197–214. [Google Scholar]

- Gu, Q.; Hao, J.; Lu, Y.J.; Wang, L.; Wallace, G.G.; Zhou, Q. Three-dimensional bio-printing. Sci. China Life Sci. 2015, 58, 411–419. [Google Scholar] [CrossRef] [PubMed]

- Mullen, L.; Stamp, R.C.; Brooks, W.K.; Jones, E.; Sutcliffe, C.J. Selective laser melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 89, 325–334. [Google Scholar] [CrossRef]

- Nakamura, M.; Iwanaga, S.; Henmi, C.; Arai, K.; Nishiyama, Y. Biomatrices and biomaterials for future developments of bioprinting and biofabrication. Biofabrication 2010, 2, 6. [Google Scholar] [CrossRef]

- Mueller, B.; Kochan, D. Laminated object manufacturing for rapid tooling and patternmaking in foundry industry. Comput. Ind. 1999, 39, 47–53. [Google Scholar] [CrossRef]

- Tappa, K.; Jammalamadaka, U. Novel biomaterials used in medical 3D printing techniques. J. Funct. Biomater. 2018, 9, 17. [Google Scholar] [CrossRef]

- Cui, H.; Nowicki, M.; Fisher, J.P.; Zhang, L.G. 3D Bioprinting for Organ Regeneration. Adv. Healthc. Mater. 2017, 6. [Google Scholar] [CrossRef]

- Huang, J.J.; Ren, J.A.; Wang, G.F.; Li, Z.A.; Wu, X.W.; Ren, H.J.; Liu, S. 3D-printed “fistula stent” designed for management of enterocutaneous fistula: An advanced strategy. World J. Gastroenterol. 2017, 23, 7489–7494. [Google Scholar] [CrossRef] [PubMed]

- Horvath, L.; Umehara, Y.; Jud, C.; Blank, F.; Petri-Fink, A.; Rothen-Rutishauser, B. Engineering an in vitro air-blood barrier by 3D bioprinting. Sci. Rep. 2015, 5, 7974. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Shukla, M.R.; Singh, A.S.; Piunno, K.; Saxena, P.K.; Jones, A.M.P. Application of 3D printing to prototype and develop novel plant tissue culture systems. Plant Methods 2017, 13, 6. [Google Scholar] [CrossRef]

- Shi, W.; He, R.; Liu, Y. 3D printing scaffolds with hydrogel materials for biomedical applications. Eur. J. Biomed. Res. 2015, 1, 3. [Google Scholar] [CrossRef]

- Almeida, C.R.; Serra, T.; Oliveira, M.I.; Planell, J.A.; Barbosa, M.A.; Navarro, M. Impact of 3-D printed PLA- and chitosan-based scaffolds on human monocyte/macrophage responses: Unraveling the effect of 3-D structures on inflammation. Acta Biomater. 2014, 10, 613–622. [Google Scholar] [CrossRef]

- Hollister, S.J. Porous scaffold design for tissue engineering. Nat. Mater. 2006, 5, 590. [Google Scholar] [CrossRef]

- Hospodiuk, M.; Dey, M.; Sosnoski, D.; Ozbolat, I.T. The bioink: A comprehensive review on bioprintable materials. Biotechnol. Adv. 2017, 35, 217–239. [Google Scholar] [CrossRef]

- Drury, J.L.; Mooney, D.J. Hydrogels for tissue engineering: Scaffold design variables and applications. Biomaterials 2003, 24, 4337–4351. [Google Scholar] [CrossRef]

- Campbell, J.; McGuinness, I.; Wirz, H.; Sharon, A.; Sauer-Budge, A.F. Multimaterial and Multiscale Three-Dimensional Bioprinter. J. Nanotechnol. Eng. Med. 2015, 6, 021005. [Google Scholar] [CrossRef]

- Colosi, C.; Shin, S.R.; Manoharan, V.; Massa, S.; Costantini, M.; Barbetta, A.; Dokmeci, M.R.; Dentini, M.; Khademhosseini, A. Microfluidic Bioprinting of Heterogeneous 3D Tissue Constructs Using Low-Viscosity Bioink. Adv. Mater. 2016, 28, 677–684. [Google Scholar] [CrossRef] [PubMed]

- Vukicevic, M.; Mosadegh, B.; Min, J.K.; Little, S.H. Cardiac 3D Printing and its Future Directions. JACC Cardiovasc. Imaging 2017, 10, 171–184. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.S.; Yue, K.; Aleman, J.; Mollazadeh-Moghaddam, K.; Bakht, S.M.; Yang, J.; Jia, W.; Dell’Erba, V.; Assawes, P.; Shin, S.R.; et al. 3D Bioprinting for Tissue and Organ Fabrication. Ann. Biomed. Eng. 2017, 45, 148–163. [Google Scholar] [CrossRef] [PubMed]

- Blaeser, A.; Duarte Campos, D.F.; Puster, U.; Richtering, W.; Stevens, M.M.; Fischer, H. Controlling Shear Stress in 3D Bioprinting is a Key Factor to Balance Printing Resolution and Stem Cell Integrity. Adv. Healthc. Mater. 2016, 5, 326–333. [Google Scholar] [CrossRef]

- Jakus, A.E.; Rutz, A.L.; Shah, R.N. Advancing the field of 3D biomaterial printing. Biomed. Mater. 2016, 11, 014102. [Google Scholar] [CrossRef]

- Skardal, A.; Atala, A. Biomaterials for Integration with 3-D Bioprinting. Ann. Biomed. Eng. 2015, 43, 730–746. [Google Scholar] [CrossRef]

- Chung, J.H.Y.; Naficy, S.; Yue, Z.; Kapsa, R.; Quigley, A.; Moulton, S.E.; Wallace, G.G. Bio-ink properties and printability for extrusion printing living cells. Biomater. Sci. 2013, 1, 763–773. [Google Scholar] [CrossRef]

- De Santis, R.; Gloria, A.; Russo, T.; D’Amora, U.; D’Antò, V.; Bollino, F.; Catauro, M.; Mollica, F.; Rengo, S.; Ambrosio, L. Advanced composites for hard-tissue engineering based on PCL/organic-inorganic hybrid fillers: From the design of 2D substrates to 3D rapid prototyped scaffolds. Polym. Compos. 2013, 34, 1413–1417. [Google Scholar] [CrossRef]

- Gurkan, U.A.; Tasoglu, S.; Kavaz, D.; Demirel, M.C.; Demirci, U. Emerging technologies for assembly of microscale hydrogels. Adv. Healthc. Mater. 2012, 1, 149–158. [Google Scholar] [CrossRef]

- Puppi, D.; Mota, C.; Gazzarri, M.; Dinucci, D.; Gloria, A.; Myrzabekova, M.; Ambrosio, L.; Chiellini, F. Additive manufacturing of wet-spun polymeric scaffolds for bone tissue engineering. Biomed. Microdevices 2012, 14, 1115–1127. [Google Scholar] [CrossRef]

- Guvendiren, M.; Burdick, J.A. Engineering synthetic hydrogel microenvironments to instruct stem cells. Curr. Opin. Biotechnol. 2013, 24, 841–846. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th anniversary article: Engineering hydrogels for biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef] [PubMed]

- Hunt, N.C.; Grover, L.M. Cell encapsulation using biopolymer gels for regenerative medicine. Biotechnol. Lett. 2010, 32, 733–742. [Google Scholar] [CrossRef] [PubMed]

- Walters, B.D.; Stegemann, J.P. Strategies for directing the structure and function of three-dimensional collagen biomaterials across length scales. Acta Biomater. 2014, 10, 1488–1501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tasoglu, S.; Diller, E.; Guven, S.; Sitti, M.; Demirci, U. Untethered micro-robotic coding of three-dimensional material composition. Nat. Commun. 2014, 5, 3124. [Google Scholar] [CrossRef] [PubMed]

- Bonino, C.A.; Efimenko, K.; Jeong, S.I.; Krebs, M.D.; Alsberg, E.; Khan, S.A. Three-dimensional electrospun alginate nanofiber mats via tailored charge repulsions. Small 2012, 8, 1928–1936. [Google Scholar] [CrossRef]

- Jeon, O.; Alsberg, E. Photofunctionalization of Alginate Hydrogels to Promote Adhesion and Proliferation of Human Mesenchymal Stem Cells. Tissue Eng. Part A 2013, 19, 1424–1432. [Google Scholar] [CrossRef]

- Kleinman, H.K.; Martin, G.R. Matrigel: Basement membrane matrix with biological activity. Semin. Cancer Biol. 2005, 15, 378–386. [Google Scholar] [CrossRef]

- Enam, S. Substrates for clinical applicability of stem cells. World J. Stem Cells 2015, 7, 243–252. [Google Scholar] [CrossRef]

- Poldervaart, M.T.; Gremmels, H.; Van Deventer, K.; Fledderus, J.O.; Öner, F.C.; Verhaar, M.C.; Dhert, W.J.A.; Alblas, J. Prolonged presence of VEGF promotes vascularization in 3D bioprinted scaffolds with defined architecture. J. Control. Release 2014, 184, 58–66. [Google Scholar] [CrossRef]

- Bourgine, P.E.; Scotti, C.; Pigeot, S.; Tchang, L.A.; Todorov, A.; Martin, I. Osteoinductivity of engineered cartilaginous templates devitalized by inducible apoptosis. Proc. Natl. Acad. Sci. USA 2014, 111, 17426–17431. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tasoglu, S.; Kavaz, D.; Gurkan, U.A.; Guven, S.; Chen, P.; Zheng, R.; Demirci, U. Paramagnetic levitational assembly of hydrogels. Adv. Mater. 2013, 25, 1137–1143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, X.; Sarvestani, S.K.; Moeinzadeh, S.; He, X.; Jabbari, E. Three-Dimensional-Engineered Matrix to Study Cancer Stem Cells and Tumorsphere Formation: Effect of Matrix Modulus. Tissue Eng. Part A 2013, 19, 669–684. [Google Scholar] [CrossRef] [PubMed]

- Leung, G.K.K.; Wang, Y.C.; Wu, W. Peptide nanofiber scaffold for brain tissue reconstruction. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 2012; Volume 508, pp. 177–190. [Google Scholar]

- Cui, X.; Boland, T. Human microvasculature fabrication using thermal inkjet printing technology. Biomaterials 2009, 30, 6221–6227. [Google Scholar] [CrossRef] [Green Version]

- Miller, J.S.; Stevens, K.R.; Yang, M.T.; Baker, B.M.; Nguyen, D.H.T.; Cohen, D.M.; Toro, E.; Chen, A.A.; Galie, P.A.; Yu, X.; et al. Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues. Nat. Mater. 2012, 11, 768–774. [Google Scholar] [CrossRef]

- Rutz, A.L.; Hyland, K.E.; Jakus, A.E.; Burghardt, W.R.; Shah, R.N. A multimaterial bioink method for 3D printing tunable, cell-compatible hydrogels. Adv. Mater. 2015, 27, 1607–1614. [Google Scholar] [CrossRef] [Green Version]

- Qi, D.; Wu, S.; Kuss, M.A.; Shi, W.; Chung, S.; Deegan, P.T.; Kamenskiy, A.; He, Y.; Duan, B. Mechanically robust cryogels with injectability and bioprinting supportability for adipose tissue engineering. Acta Biomater. 2018, 74, 131–142. [Google Scholar] [CrossRef]

- Cui, X.; Breitenkamp, K.; Finn, M.G.; Lotz, M.; D’Lima, D.D. Direct Human Cartilage Repair Using Three-Dimensional Bioprinting Technology. Tissue Eng. Part A 2012, 18, 1304–1312. [Google Scholar] [CrossRef] [Green Version]

- Kundu, J.; Shim, J.H.; Jang, J.; Kim, S.W.; Cho, D.W. An additive manufacturing-based PCL-alginate-chondrocyte bioprinted scaffold for cartilage tissue engineering. J. Tissue Eng. Regen. Med. 2015, 9, 1286–1297. [Google Scholar] [CrossRef]

- Esposito, A.R.; Moda, M.; Cattani, S.M.; de Santana, G.M.; Barbieri, J.A.; Munhoz, M.M.; Cardoso, T.P.; Barbo, M.L.P.; Russo, T.; D’Amora, U.; et al. PLDLA/PCL-T Scaffold for Meniscus Tissue Engineering. Biores. Open Access 2013, 2, 138–147. [Google Scholar] [CrossRef]

- Calandrelli, L.; Immirzi, B.; Malinconico, M.; Luessenheide, S.; Passaro, I.; Di Pasquale, R.; Oliva, A. Natural and synthetic hydroxyapatite filled PCL: Mechanical properties and biocompatibility analysis. In Proceedings of the Journal of Bioactive and Compatible Polymers; SAGE PublicationsSage UK: London, UK, 2004; Volume 19, pp. 301–313. [Google Scholar]

- Catros, S.; Fricain, J.C.; Guillotin, B.; Pippenger, B.; Bareille, R.; Remy, M.; Lebraud, E.; Desbat, B.; Amédée, J.; Guillemot, F. Laser-assisted bioprinting for creating on-demand patterns of human osteoprogenitor cells and nano-hydroxyapatite. Biofabrication 2011, 3, 025001. [Google Scholar] [CrossRef] [PubMed]

- Fedorovich, N.E.; De Wijn, J.R.; Verbout, A.J.; Alblas, J.; Dhert, W.J.A. Three-dimensional fiber deposition of cell-laden, viable, patterned constructs for bone tissue printing. Tissue Eng. Part A 2008, 14, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Kuss, M.A.; Harms, R.; Wu, S.; Wang, Y.; Untrauer, J.B.; Carlson, M.A.; Duan, B. Short-term hypoxic preconditioning promotes prevascularization in 3D bioprinted bone constructs with stromal vascular fraction derived cells. RSC Adv. 2017, 7, 29312–29320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- You, F.; Wu, X.; Zhu, N.; Lei, M.; Eames, B.F.; Chen, X. 3D Printing of Porous Cell-Laden Hydrogel Constructs for Potential Applications in Cartilage Tissue Engineering. ACS Biomater. Sci. Eng. 2016, 2, 1200–1210. [Google Scholar] [CrossRef]

- You, F.; Chen, X.; Cooper, D.M.L.; Chang, T.; Eames, B.F. Homogeneous hydroxyapatite/alginate composite hydrogel promotes calcified cartilage matrix deposition with potential for three-dimensional bioprinting. Biofabrication 2019, 11, 015015. [Google Scholar] [CrossRef] [PubMed]

- Gu, Q.; Tomaskovic-Crook, E.; Wallace, G.G.; Crook, J.M. Engineering human neural tissue by 3D bioprinting. Methods Mol. Biol. 2018, 1758, 129–138. [Google Scholar]

- Jakab, K.; Norotte, C.; Damon, B.; Marga, F.; Neagu, A.; Besch-Williford, C.L.; Kachurin, A.; Church, K.H.; Park, H.; Mironov, V.; et al. Tissue Engineering by Self-Assembly of Cells Printed into Topologically Defined Structures. Tissue Eng. Part A 2008, 14, 413–421. [Google Scholar] [CrossRef]

- Bejleri, D.; Streeter, B.W.; Nachlas, A.L.Y.; Brown, M.E.; Gaetani, R.; Christman, K.L.; Davis, M.E. A Bioprinted Cardiac Patch Composed of Cardiac-Specific Extracellular Matrix and Progenitor Cells for Heart Repair. Adv. Healthc. Mater. 2018, 7, 1–13. [Google Scholar] [CrossRef]

- Izadifar, M.; Chapman, D.; Babyn, P.; Chen, X.; Kelly, M.E. UV-Assisted 3D Bioprinting of Nanoreinforced Hybrid Cardiac Patch for Myocardial Tissue Engineering. Tissue Eng. Part C Methods 2018, 24, 74–88. [Google Scholar] [CrossRef]

- Visk, D. Will Advances in Preclinical In Vitro Models Lower the Costs of Drug Development? Appl. Vitr. Toxicol. 2015, 1, 79–82. [Google Scholar] [CrossRef] [Green Version]

- Lewis, P.L.; Yan, M.; Su, J.; Shah, R.N. Directing the growth and alignment of biliary epithelium within extracellular matrix hydrogels. Acta Biomater. 2019, 85, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Gu, Q.; Tomaskovic-Crook, E.; Wallace, G.G.; Crook, J.M. 3D Bioprinting Human Induced Pluripotent Stem Cell Constructs for In Situ Cell Proliferation and Successive Multilineage Differentiation. Adv. Healthc. Mater. 2017, 6, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Shi, W.; Kuss, M.; Mirza, S.; Qi, D.; Krasnoslobodtsev, A.; Zeng, J.; Band, H.; Band, V.; Duan, B. 3D Bioprinting of Breast Cancer Models for Drug Resistance Study. ACS Biomater. Sci. Eng. 2018, 4, 4401–4411. [Google Scholar] [CrossRef]

- Narayanan, L.K.; Huebner, P.; Fisher, M.B.; Spang, J.T.; Starly, B.; Shirwaiker, R.A. 3D-Bioprinting of Polylactic Acid (PLA) Nanofiber-Alginate Hydrogel Bioink Containing Human Adipose-Derived Stem Cells. ACS Biomater. Sci. Eng. 2016, 2, 1732–1742. [Google Scholar] [CrossRef]

- Kuo, C.-Y.; Wilson, E.; Fuson, A.; Gandhi, N.; Monfaredi, R.; Jenkins, A.; Romero, M.; Santoro, M.; Fisher, J.P.; Cleary, K.; et al. Repair of Tympanic Membrane Perforations with Customized Bioprinted Ear Grafts Using Chinchilla Models. Tissue Eng. Part A 2018, 24, 527–535. [Google Scholar] [CrossRef]

- Tang, Q.; Piard, C.; Lin, J.; Nan, K.; Guo, T.; Caccamese, J.; Fisher, J.; Chen, Y. Imaging stem cell distribution, growth, migration, and differentiation in 3-D scaffolds for bone tissue engineering using mesoscopic fluorescence tomography. Biotechnol. Bioeng. 2018, 115, 257–265. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.-Y.; Ma, D.-D.; Wu, B.-L. Gelatin/alginate hydrogel scaffolds prepared by 3D bioprinting promotes cell adhesion and proliferation of human dental pulp cells in vitro. Nan Fang Yi Ke Da Xue Xue Bao 2017, 37, 668–672. [Google Scholar]

- Wang, X.; Tolba, E.; Der, H.C.S.; Neufurth, M.; Feng, Q.; Diehl-Seifert, B.R.; Mü Ller, W.E.G. Effect of bioglass on growth and biomineralization of saos-2 cells in hydrogel after 3d cell bioprinting. PLoS ONE 2014, 9, 1–7. [Google Scholar] [CrossRef]

- Neufurth, M.; Wang, X.; Schröder, H.C.; Feng, Q.; Diehl-Seifert, B.; Ziebart, T.; Steffen, R.; Wang, S.; Müller, W.E.G. Engineering a morphogenetically active hydrogel for bioprinting of bioartificial tissue derived from human osteoblast-like SaOS-2 cells. Biomaterials 2014, 35, 8810–8819. [Google Scholar] [CrossRef]

- Billiet, T.; Gevaert, E.; De Schryver, T.; Cornelissen, M.; Dubruel, P. The 3D printing of gelatin methacrylamide cell-laden tissue-engineered constructs with high cell viability. Biomaterials 2014, 35, 49–62. [Google Scholar] [CrossRef]

- Rajaram, A.; Schreyer, D.J.; Chen, D.X.B. Use of the polycation polyethyleneimine to improve the physical properties of alginate-hyaluronic acid hydrogel during fabrication of tissue repair scaffolds. J. Biomater. Sci. Polym. Ed. 2015, 26, 433–445. [Google Scholar] [CrossRef] [PubMed]

- Olubamiji, A.D.; Izadifar, Z.; Zhu, N.; Chang, T.; Chen, X.; Eames, B.F. Using synchrotron radiation inline phase-contrast imaging computed tomography to visualize three-dimensional printed hybrid constructs for cartilage tissue engineering. J. Synchrotron Radiat. 2016, 23, 802–812. [Google Scholar] [CrossRef] [PubMed]

- DaSilva-Arnold, S.; Kuo, C.; Davra, V.; Remache, Y.; Cw, P.; Fisher, J.P.; Zamudio, S.; Al-khan, A.; Birge, R.B.; Nicholas, P. ZEB2, a master regulator of the epithelial-mesenchymal transition, mediates trophoblast differentiation. Mol. Hum. Reprod. 2019, 25, 61–75. [Google Scholar] [CrossRef] [PubMed]

- Ning, L.; Sun, H.; Lelong, T.; Guilloteau, R.; Zhu, N.; Schreyere, D.J.; Chen, X. 3D bioprinting of scaffolds with living Schwann cells for potential nerve tissue engineering applications. Biofabrication 2019, 10, 035014. [Google Scholar] [CrossRef]

- Sarker, M.D.; Naghieh, S.; McInnes, A.D.; Ning, L.; Schreyer, D.J.; Chen, X. Bio-fabrication of peptide-modified alginate scaffolds: Printability, mechanical stability and neurite outgrowth assessments. Bioprinting 2019, 14, e00045. [Google Scholar] [CrossRef]

- Rajaram, A.; Schreyer, D.J.; Chen, X. Development of Schwann Cell-Encapsulated Alginate Scaffolds for the Repair of Peripheral Nerve Injury. CMBES 2012, 35, 3–6. [Google Scholar]

- Rajaram, A.; Schreyer, D.; Chen, D. Bioplotting Alginate/Hyaluronic Acid Hydrogel Scaffolds with Structural Integrity and Preserved Schwann Cell Viability. 3D Print. Addit. Manuf. 2016, 1, 194–203. [Google Scholar] [CrossRef]

- Oveissi, F.; Naficy, S.; Le, T.Y.L.; Fletcher, D.F.; Dehghani, F. Tough and Processable Hydrogels Based on Lignin and Hydrophilic Polyurethane. ACS Appl. Bio Mater. 2018, 1, 2073–2081. [Google Scholar] [CrossRef]

- Shi, Y.; Xing, T.L.; Zhang, H.B.; Yin, R.X.; Yang, S.M.; Wei, J.; Zhang, W.J. Tyrosinase-doped bioink for 3D bioprinting of living skin constructs. Biomed. Mater. 2018, 13, 035008. [Google Scholar] [CrossRef]

- Axpe, E.; Oyen, M.L. Applications of alginate-based bioinks in 3D bioprinting. Int. J. Mol. Sci. 2016, 17, 1976. [Google Scholar] [CrossRef] [Green Version]

- Jia, J.; Richards, D.J.; Pollard, S.; Tan, Y.; Rodriguez, J.; Visconti, R.P.; Trusk, T.C.; Yost, M.J.; Yao, H.; Markwald, R.R.; et al. Engineering alginate as bioink for bioprinting. Acta Biomater. 2014, 10, 4323–4331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cuadros, T.R.; Erices, A.A.; Aguilera, J.M. Porous matrix of calcium alginate/gelatin with enhanced properties as scaffold for cell culture. J. Mech. Behav. Biomed. Mater. 2015, 46, 331–342. [Google Scholar] [CrossRef] [PubMed]

- Kulseng, B.; Skjåk-Braek, G.; Ryan, L.; Andersson, A.; King, A.; Faxvaag, A.; Espevik, T. Transplantation of alginate microcapsules: Generation of antibodies against alginates and encapsulated porcine islet-like cell clusters. Transplantation 1999, 67, 978–984. [Google Scholar] [CrossRef] [PubMed]

- Pawar, S.N.; Edgar, K.J. Alginate derivatization: A review of chemistry, properties and applications. Biomaterials 2012, 33, 3279–3305. [Google Scholar] [CrossRef] [PubMed]

- Schuurman, W.; Levett, P.A.; Pot, M.W.; van Weeren, P.R.; Dhert, W.J.A.; Hutmacher, D.W.; Melchels, F.P.W.; Klein, T.J.; Malda, J. Gelatin-Methacrylamide Hydrogels as Potential Biomaterials for Fabrication of Tissue-Engineered Cartilage Constructs. Macromol. Biosci. 2013, 13, 551–561. [Google Scholar] [CrossRef] [PubMed]

- Derby, B. Bioprinting: Inkjet printing proteins and hybrid cell-containing materials and structures. J. Mater. Chem. 2008, 18, 5717–5721. [Google Scholar] [CrossRef]

- Owens, C.M.; Marga, F.; Forgacs, G.; Heesch, C.M. Biofabrication and testing of a fully cellular nerve graft. Biofabrication 2013, 5, 045007. [Google Scholar] [CrossRef] [Green Version]

- Larocca, R.A.; Moraes-Vieira, P.M.; Bassi, Ê.J.; Semedo, P.; de Almeida, D.C.; da Silva, M.B.; Thornley, T.; Pacheco-Silva, A.; Câmara, N.O.S. Adipose Tissue-Derived Mesenchymal Stem Cells Increase Skin Allograft Survival and Inhibit Th-17 Immune Response. PLoS ONE 2013, 8, e76396. [Google Scholar] [CrossRef]

- Izadifar, Z.; Chang, T.; Kulyk, W.; Chen, X.; Eames, B.F. Analyzing Biological Performance of 3D-Printed, Cell-Impregnated Hybrid Constructs for Cartilage Tissue Engineering. Tissue Eng. Part C Methods 2015, 22, 173–188. [Google Scholar] [CrossRef] [Green Version]

- Ning, L.; Betancourt, N.; Schreyer, D.J.; Chen, X. Characterization of Cell Damage and Proliferative Ability during and after Bioprinting. ACS Biomater. Sci. Eng. 2018, 4, 3906–3918. [Google Scholar] [CrossRef]

- Nair, K.; Gandhi, M.; Khalil, S.; Yan, K.C.; Marcolongo, M.; Barbee, K.; Sun, W. Characterization of cell viability during bioprinting processes. Biotechnol. J. 2009, 4, 1168–1177. [Google Scholar] [CrossRef] [PubMed]

- Kwok, T.-H.; Wang, C.C.L.; Deng, D.; Zhang, Y.; Chen, Y. Four-Dimensional Printing for Freeform Surfaces: Design Optimization of Origami and Kirigami Structures. J. Mech. Des. 2015, 137, 111413. [Google Scholar] [CrossRef]

- Castro, N.J.; Meinert, C.; Levett, P.; Hutmacher, D.W. Current developments in multifunctional smart materials for 3D/4D bioprinting. Curr. Opin. Biomed. Eng. 2017, 2, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Yang, G.H.; Yeo, M.; Koo, Y.W.; Kim, G.H. 4D Bioprinting: Technological Advances in Biofabrication. Macromol. Biosci. 2019, 19, 1–10. [Google Scholar] [CrossRef] [PubMed]

| 3D Printer Used | Cell Line (s) Used | Materials Used | Application | Reference |

|---|---|---|---|---|

| Modified thermal inkjet printer from HP® and Canon® | Not specified | Sacrificial material (carbohydrate glass filament networks) | Microvascular networks | [47,48] |

| 3D-Bioplotter™ | HUVEC 1 | Gelatin ink completed with PEG-SVA | Cell-compatible hydrogels | [49] |

| 3D-Bioplotter™ | HUVEC and HWA 2 | Methacrylated gelatin, methacrylated hyaluronic acid, and PEG-4A 3 | Robust cryogel for adipose tissue engineering | [50] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| Modified HP® Deskjet 500 printer | Human chondrocytes | PEGDA 1 hydrogel | Ambiguous | [51] |

| Multihead deposition system (MHDS) printer from AM technology | Not specified | Alginate-based ink completed with PCL 2 | Strength improvement on bioprinted cartilage | [52] |

| 3D printer | Not specified | PCL/hydroxyapatite hydrogel | Orthopaedic applications | [32,34,53,54] |

| Biological laser (BioLP) printer designed in the laboratory | Not specified | Alginate/hydroxyapatite hydrogel | Orthopedic applications | [55] |

| 3D-Bioplotter™ | BMSCs 3 | Non-medical alginate hydrogel and calcium chloride/Lutrol F127/Matrigel/Agarose and methylcellulose | Patterned constructs for bone tissue bioprinting | [56] |

| 3D-Bioplotter™ | SVFC 4 | PCL/hydroxyapatite hydrogel | Prevascularization in 3D bioprinted bone constructs | [57] |

| 3D-Bioplotter™ | Primary chondrocytes, other cells | Alginate hydrogel, PCL and calcium chloride | Cartilage tissue engineering | [58] |

| 3D-Bioplotter™ | Primary chondrocytes | Alginate/hydroxyapatite hydrogel | Cartilage tissue engineering | [59] |

| 3D-Bioplotter™ | Primary chondrocytes, Mesenchymal stem cells, Cartilage derived progenitor cells | Gelatin methacryloyl hydrogel, with a photoinitiator | Reversible cross-linking strategy on cartilage tissue engineering | [60] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| Printer designed by nScrypt Inc. | Cardiac cells and HUVEC 1 | Not specified | Tissue spheroids | [61] |

| 3D-Bioplotter™ | hCPCs 2 | Gelatin methacrylate hydrogel and cardiac ECM 3 | Cardiac patches | [62] |

| 3D-Bioplotter™ | Human coronary artery endothelial tissues | Alginate hydrogel and calcium chloride/PEI 4 | Cardiac implants | [63] |

| 3D-Bioplotter™ | Human coronary artery endothelial cells | Alginate hydrogel and methacrylated collagen and CNTs 5 | Nano-reinforced cardiac patches | [63] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| Organovo 3D-bioprinter | Not specified | Not specified (with problems) | Microliver tissues for in vitro drug testing | [64] |

| 3D-Bioplotter™ | Immortalized mouse small cholangiocytes and HUH7 1 | dECM 2 of the liver and sacrificial material (Pluronic F-127) | 3D-Bioprinting for liver tissues | [65] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | iPSCs 1 and/or hNSCs 2 | Alginate-CMC 3 hydrogel | Tissue bioprinting | [60] |

| 3D-Bioplotter™ | iPSCs | Alginate-CMC-agarose hydrogel and calcium chloride | In situ cell proliferation and successive multilineage differentiation | [66] |

| 3D-Bioplotter™ | ASMCs 4 | Complex hydrogel (methacrylated hyaluronic acid, methacrylated gelatin, hyaluronic acid and gelatin | Breast cancer model for drug resistance study | [67] |

| 3D-Bioplotter™ | Human mesenchymal stem cells | Methacrylated gelatin hydrogel | Placenta model for preeclampsia | [69] |

| 3D-Bioplotter™ | Frontal cortical human neural stem cells | Alginate-CMC-agarose hydrogel and calcium chloride | Human neural tissues’ applications | [60] |

| 3D-Bioplotter™ | Frontal cortical human neural stem cells | Alginate-CMC-agarose hydrogel and calcium chloride | Production of neural mini-tissues | [60] |

| 3D-Bioplotter™ | Human mesenchymal stem cells and L929 fibroblasts | Gelatin methacrylate hydrogel/alginate hydrogel and calcium chloride | Mesoscopic fluorescence tomography for bone tissue engineering | [70] |

| 3D-Bioplotter™ | hASCs 5 | Alginate hydrogel and calcium chloride | Monitoring of 3D constructs via dielectric impedance spectroscopy technique | [68] |

| 3D-Bioplotter™ | Human adipose-derived mesenchymal stem cells | Sodium alginate-gelatin hydrogel | Osteogenesis’ applications on in vivo studies | [71] |

| 3D Printer Used | Cell line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | 21PT cell line 1 | Complex hydrogel (methacrylated hyaluronic acid, methacrylated gelatin, hyaluronic acid and gelatin | Breast cancer model for drug resistance study | [67] |

| 3D-Bioplotter™ | SaOS-2 cell line 2 | Biocalcite hydrogel (alginate and biosilica) | Synthesis of calcium phosphate-bone | [72] |

| 3D-Bioplotter™ | HUH7 3 and immortalized mouse small cholangiocytes | dECM 4 of the liver and sacrificial material (Pluronic F-127) | 3D-Bioprinting for liver tissues | [65] |

| 3D-Bioplotter™ | SaOS-2 cell line | Alginate-gelatin-bioglass hydrogel, polyP/calcium chloride, and silica/biosilica | Growth and biomineralization of SaOS-2 cells on bioglass | [72] |

| 3D-Bioplotter™ | SaOS-2 cell line | Alginate-gelatin-agarose hydrogel and calcium chloride | Bioprinting of bioartificial tissue | [73] |

| 3D-Bioplotter™ | MG63 cell line 5 and hASCs 6 | Alginate hydrogel and calcium chloride | Monitoring of 3D constructs via dielectric impedance spectroscopy technique | [68] |

| 3D-Bioplotter™ | HepG2 7 | Methacrylated gelatin B-type photocurable with UV-light | Constructs with high cell viability | [74] |

| 3D-Bioplotter™ | ATDC5 8 | Alginate hydrogel and PCL 9 | Cartilage tissue engineering | [58] |

| 3D-Bioplotter™ | ATDC5 | Alginate-hyaluronic acid hydrogel and calcium chloride or PVA 10 or PEI 11 | Tissue reparation | [75] |

| 3D-Bioplotter™ | ATDC5 | Alginate hydrogel and PCL and calcium chloride | Cartilage tissues’ applications | [76] |

| 3D-Bioplotter™ | JEG3 cell line 12 and trophoblast cells | Methacrylated gelatin hydrogel and EGF 13 | Testing on ZEB2, a master regulator of EMT 14 | [77] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | WAP 1 and BAP 2 | Methacrylated hyaluronic acid-methacrylated gelatin and hyaluronic acid and gelatin | Checking behaviour and metabolic function on human brown adipocyte | [57] |

| 3D-Bioplotter™ | HWA 3 and HUVEC 4 | Methacrylated gelatin, methacrylated hyaluronic acid, and PEG-4A 5 | Robust cryogel for adipose tissue engineering | [50] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | L8 myoblasts and Schwann cells | Alginate hydrogel and DMEM 1 | Characterization of cell damage and proliferative ability during and after bioprinting | [78] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | Living Schwann cells | Alginate/RGD 1-alginate hydrogel, hyaluronic acid, fibrinogen, and calcium chloride | Potential nerve tissue engineering applications | [78] |

| 3D-Bioplotter™ | Rat primary Schwann cells | Alginate hydrogel, RGD/YIGSR 2 peptides, and calcium chloride/PEI 3 | Peptide-modified alginate scaffolds | [79] |

| 3D-Bioplotter™ | RSC96 cell line 4 | Alginate hydrogel, hyaluronic acid, and calcium chloride | Scaffolds with high integrity and cell viability | [81] |

| 3D-Bioplotter™ | RSC96 cell line and L8 myoblasts | Alginate hydrogel and DMEM 5 | Characterization of cell damage and proliferative ability during and after bioprinting | [78] |

| 3D-Bioplotter™ | RSC96 cell line | Alginate hydrogel and calcium chloride/PEI | Repair of peripheral nerve injury | [80] |

| 3D-Bioplotter™ | Rat Schwann cells and ATDC5 6 | Alginate-hyaluronic acid hydrogel and calcium chloride/PVA 7 or PEI 8 | Tissue reparation | [75] |

| 3D Printer Used | Cell Line (s) Used | Materials Used | Applications | Reference |

|---|---|---|---|---|

| 3D-Bioplotter™ | HDF 1 and HUVEC 2 | 35 formulations of PEG 3-X polymers | Cell-compatible hydrogels | [49] |

| 3D-Bioplotter™ | L929 fibroblasts and Human mesenchymal stem cells | Gelatin methacrylate hydrogel/alginate hydrogel and calcium chloride | Mesoscopic fluorescence tomography for bone tissue engineering | [70] |

| 3D-Bioplotter™ | NIH/3T3 cell line 4 | Methacrylated gelatin hydrogel and EGF 5 | Regenerative medicine for tympanic membrane perforations | [69] |

| 3D-Bioplotter™ | Primary human dermal fibroblast cells | Lignin—HPU 6 hydrogel | A new concept for fibroblasts bioprinting | [82] |

| 3D-Bioplotter™ | HEM 7, HaCat 8, and HDF | Gelatin methacrylamide hydrogel, collagen, and photoinitiator (and tyrosinase) | Bioprinting of living skin constructs | [83] |

| Cell Line (s) | Pressure (kPa) | References |

|---|---|---|

| BMSCs 1 | 30–300 | [56] |

| Primary chondrocytes (cartilage tissue) | 10 | [59] |

| hCPCs 2 | 70–80 | [62] |

| Human iPSCs 3 | 5 | [66] |

| ASMCs 4 | 300–350 | [67] |

| hNSCs 5 | 150–200 | [60] |

| ATDC5 6 | 30 | [58] |

| SaOS-2 cell line 7 | 90 | [72,73] |

| 21PT cell line 8 | 300–350 | [67] |

| HWA 9 (+HUVEC 10) | 300–350 | [50] |

| Living Schwann cells | 30 | [78] |

| HDF 11 (+HUVEC) | 100–250 | [49] |

| Primary human dermal fibroblasts | 200 | [82] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angelats Lobo, D.; Ginestra, P. Cell Bioprinting: The 3D-Bioplotter™ Case. Materials 2019, 12, 4005. https://doi.org/10.3390/ma12234005

Angelats Lobo D, Ginestra P. Cell Bioprinting: The 3D-Bioplotter™ Case. Materials. 2019; 12(23):4005. https://doi.org/10.3390/ma12234005

Chicago/Turabian StyleAngelats Lobo, David, and Paola Ginestra. 2019. "Cell Bioprinting: The 3D-Bioplotter™ Case" Materials 12, no. 23: 4005. https://doi.org/10.3390/ma12234005

APA StyleAngelats Lobo, D., & Ginestra, P. (2019). Cell Bioprinting: The 3D-Bioplotter™ Case. Materials, 12(23), 4005. https://doi.org/10.3390/ma12234005