Defect Visualization of a Steel Structure Using a Piezoelectric Line Sensor Based on Laser Ultrasonic Guided Wave

Abstract

:1. Introduction

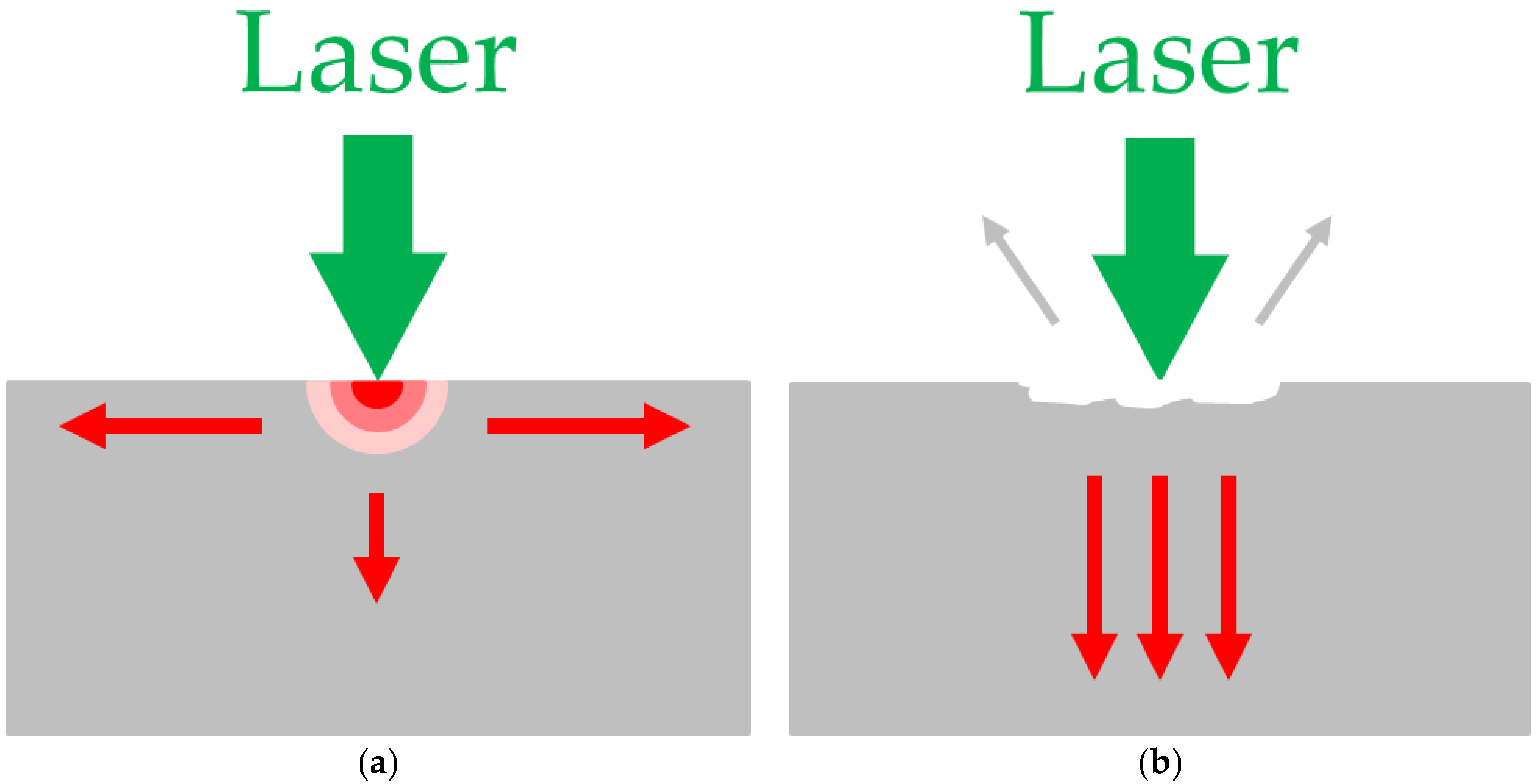

2. Principle of Laser Ultrasonic Generation

2.1. Mechanism of Laser Ultrasonics

2.2. Thermoelastic Regime

2.3. Ablation Regime

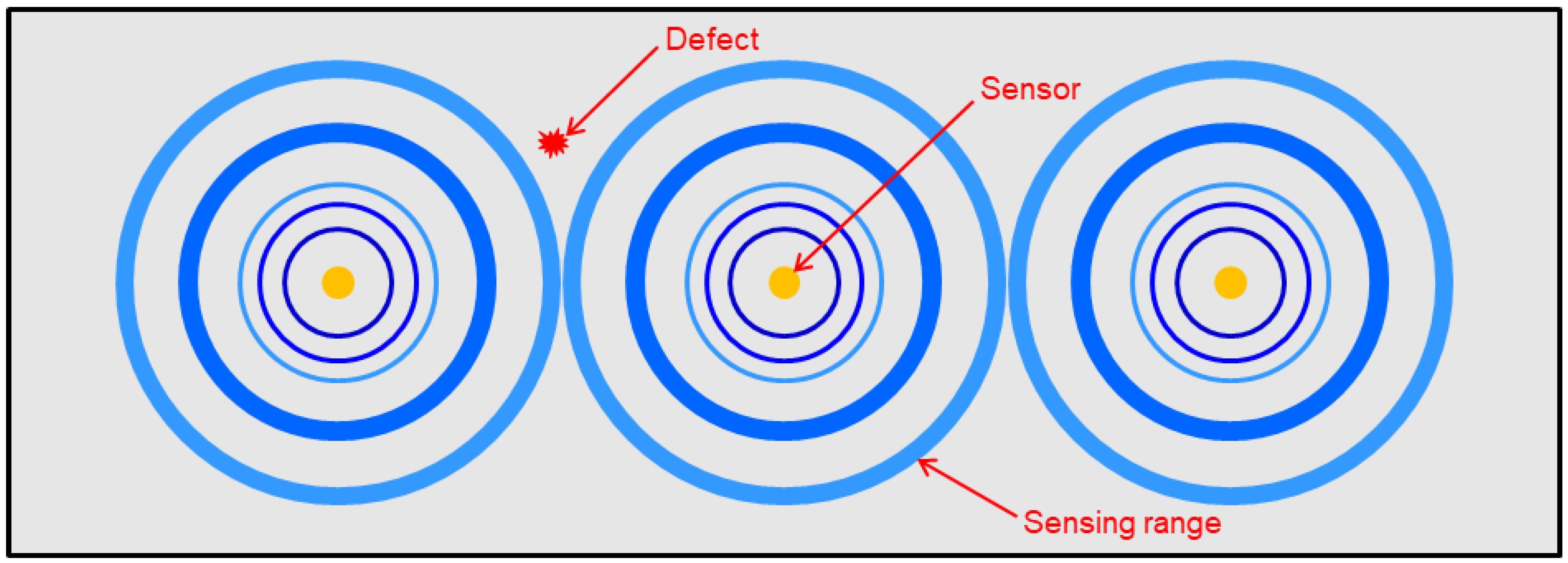

3. Laser Ultrasonic Guided Wave

4. Defects Visualization Using I-Shaped Sensor

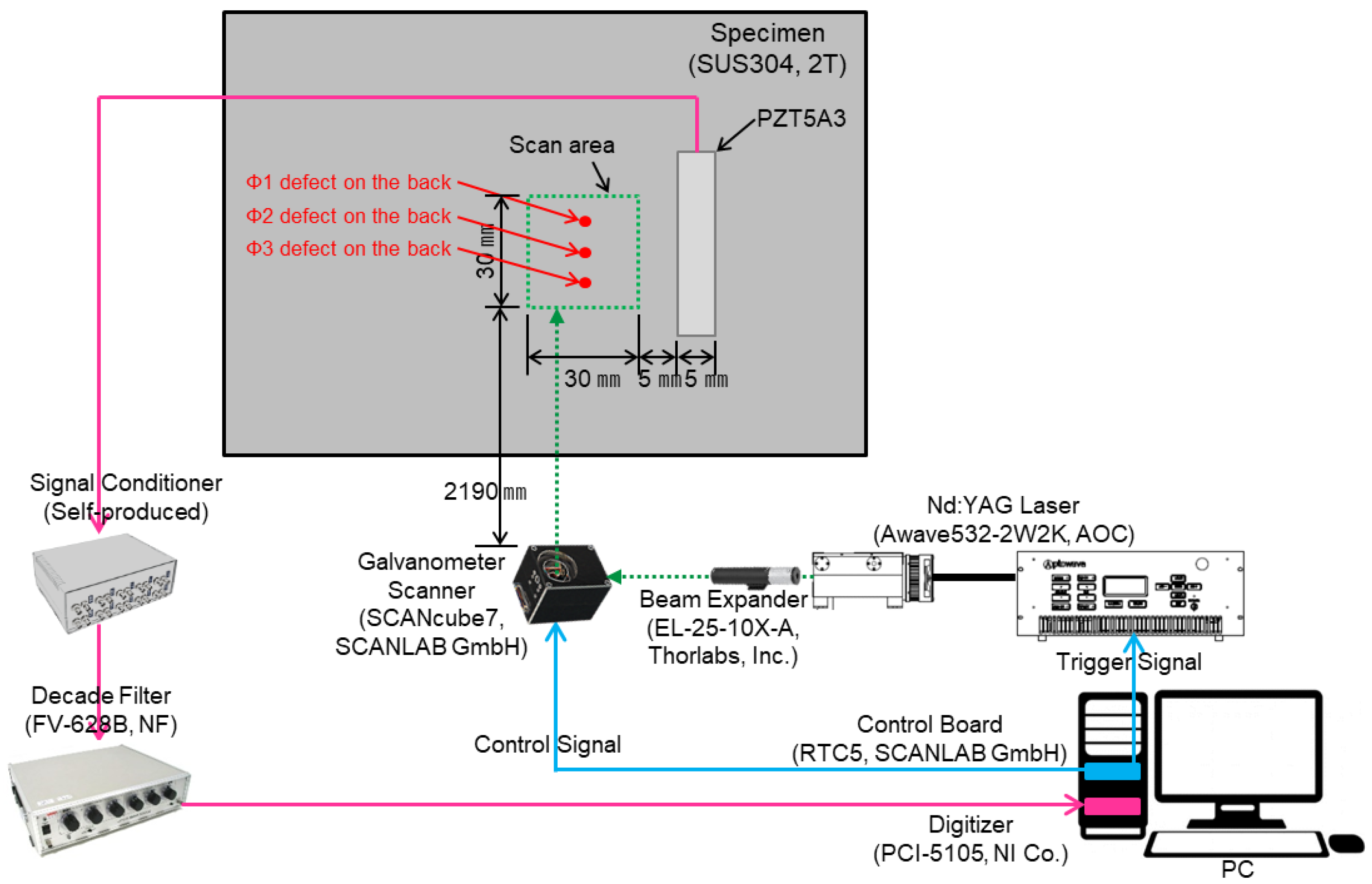

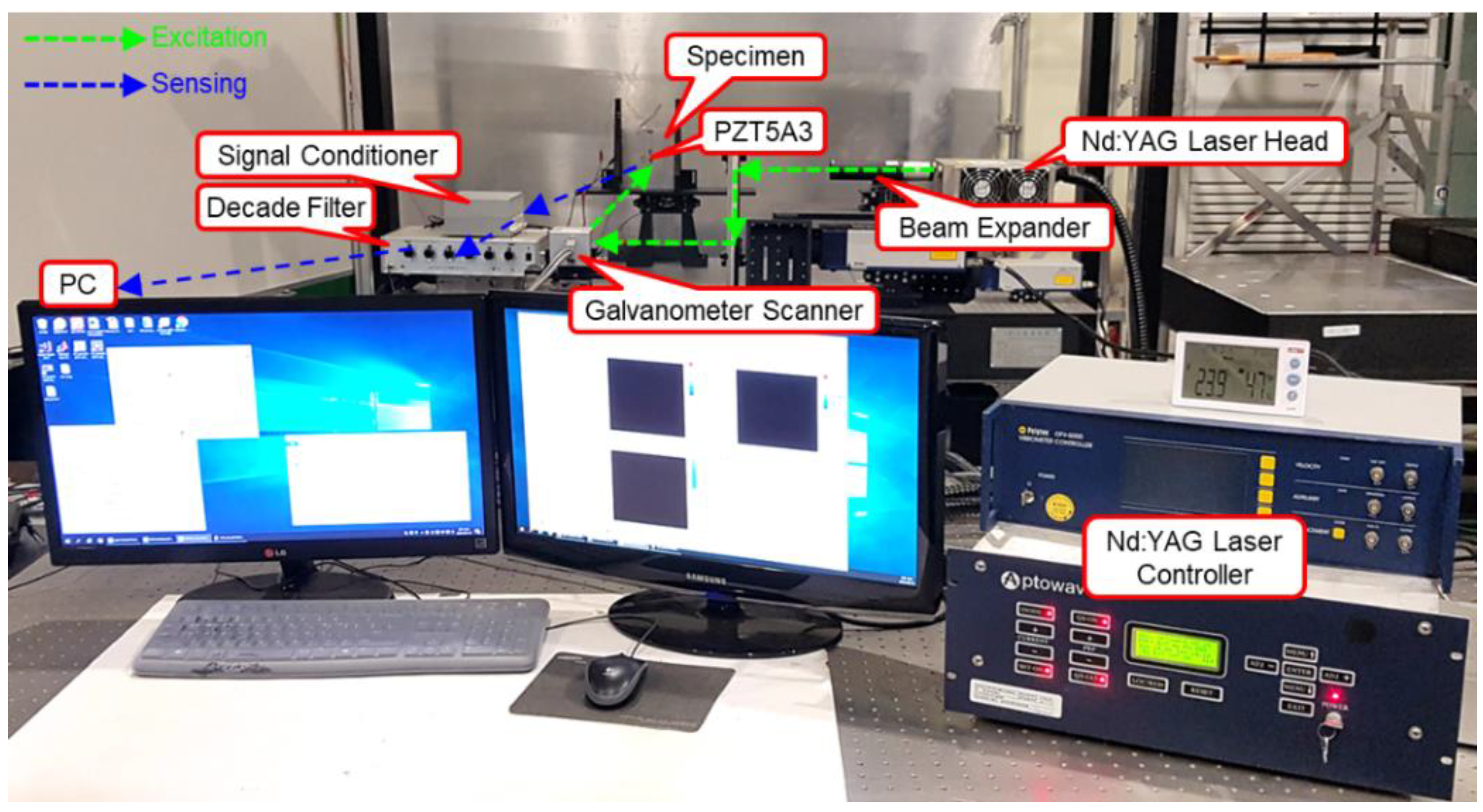

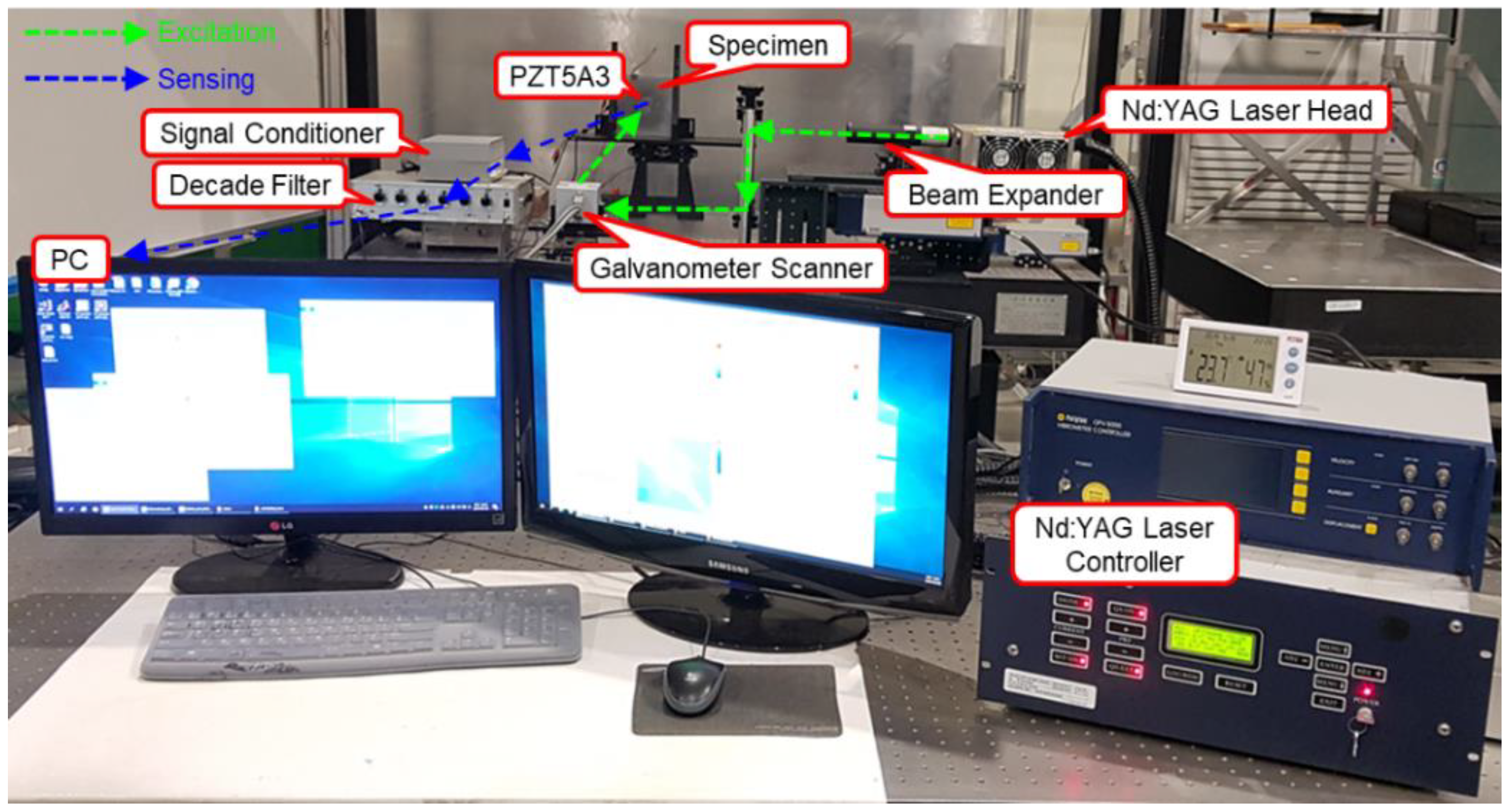

4.1. Experimental Setup Using I-Shaped Sensor

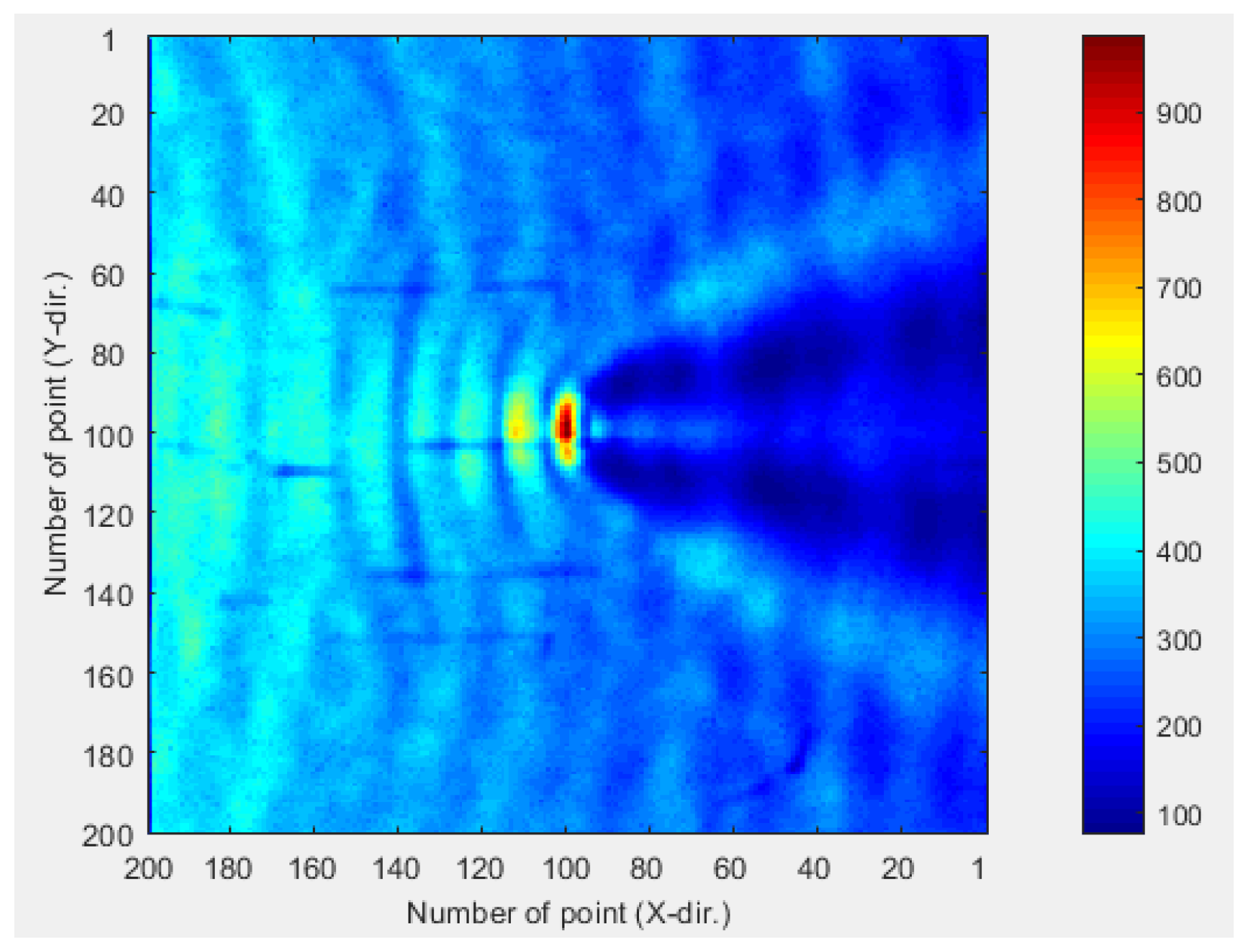

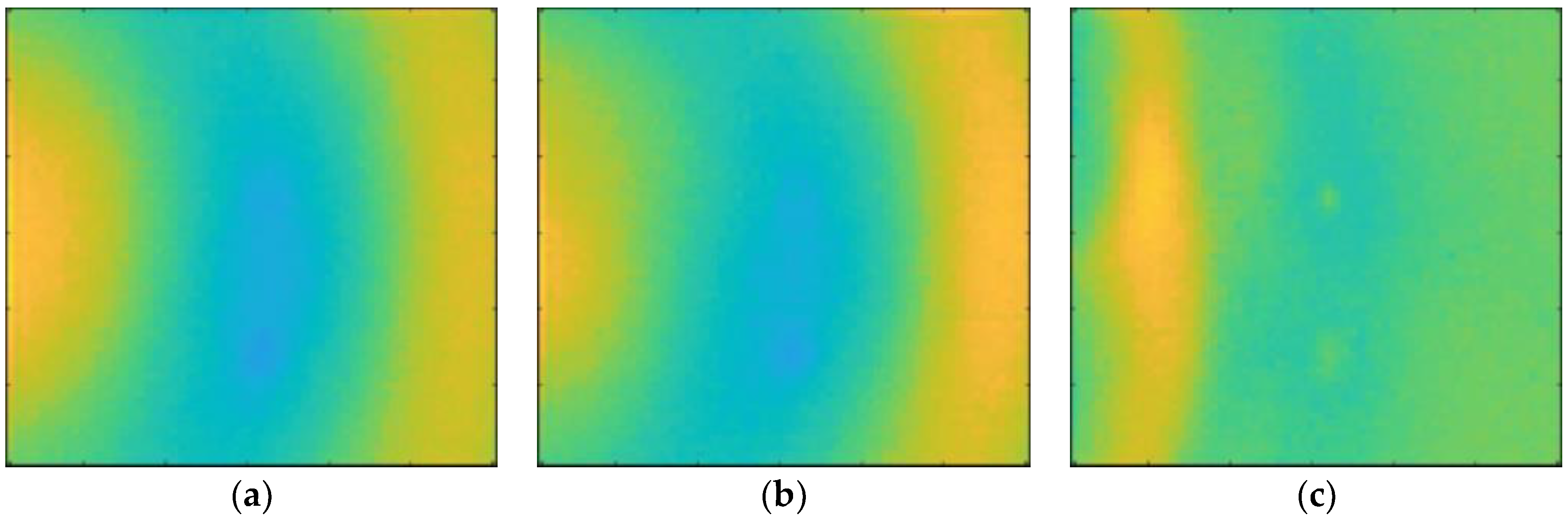

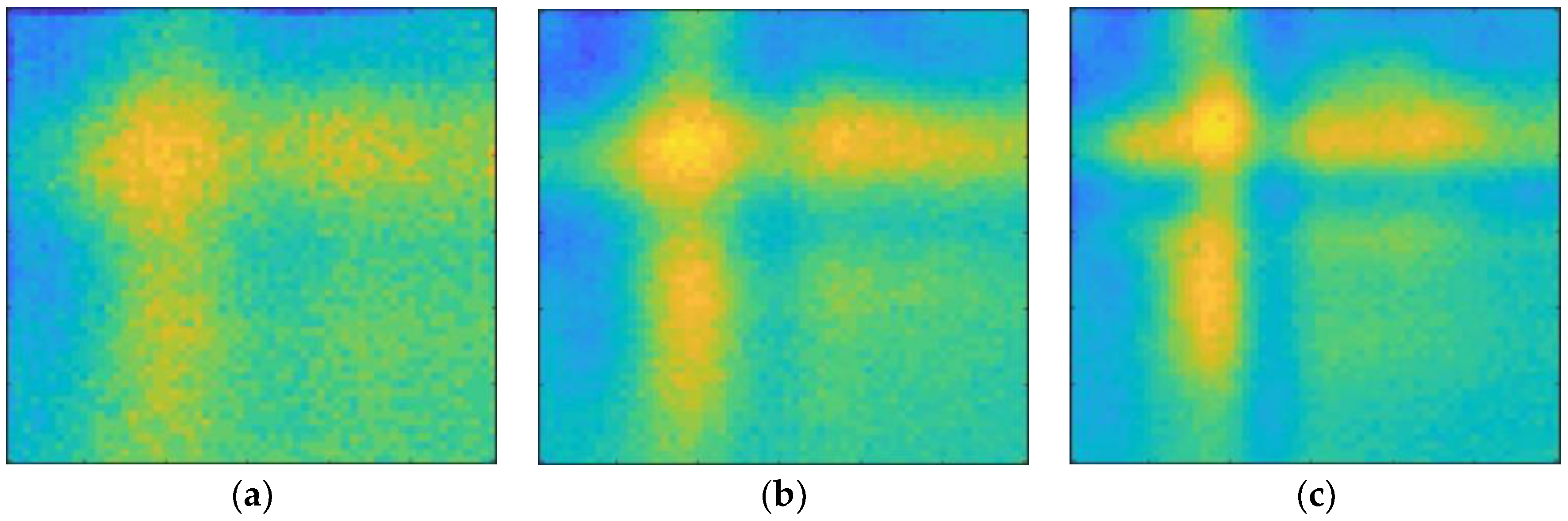

4.2. Experimental Results Using the I-Shaped Sensor

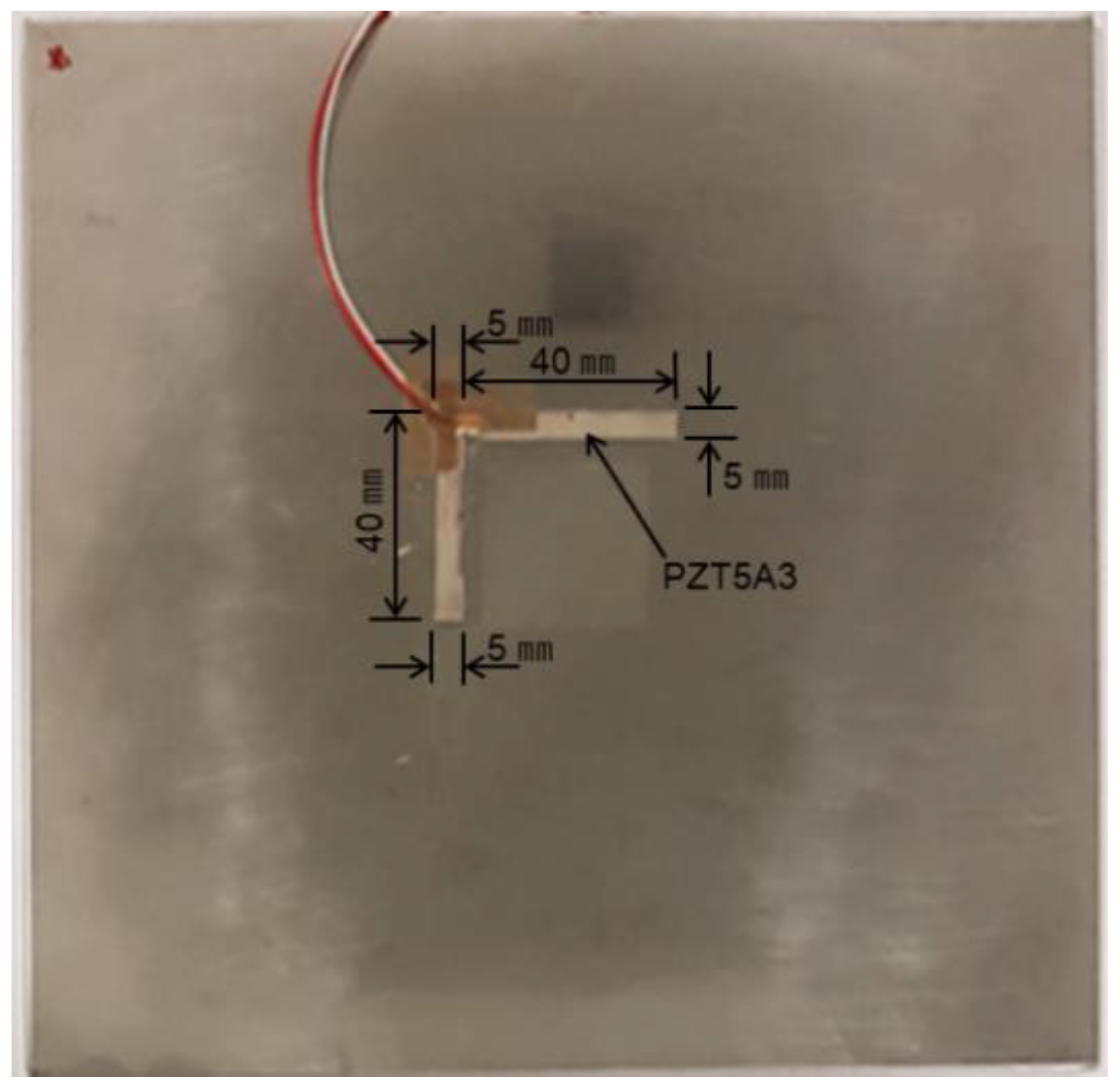

5. Defects Visualization Using the L-Shaped Sensor

5.1. Experimental Setup Using the L-Shaped Sensor

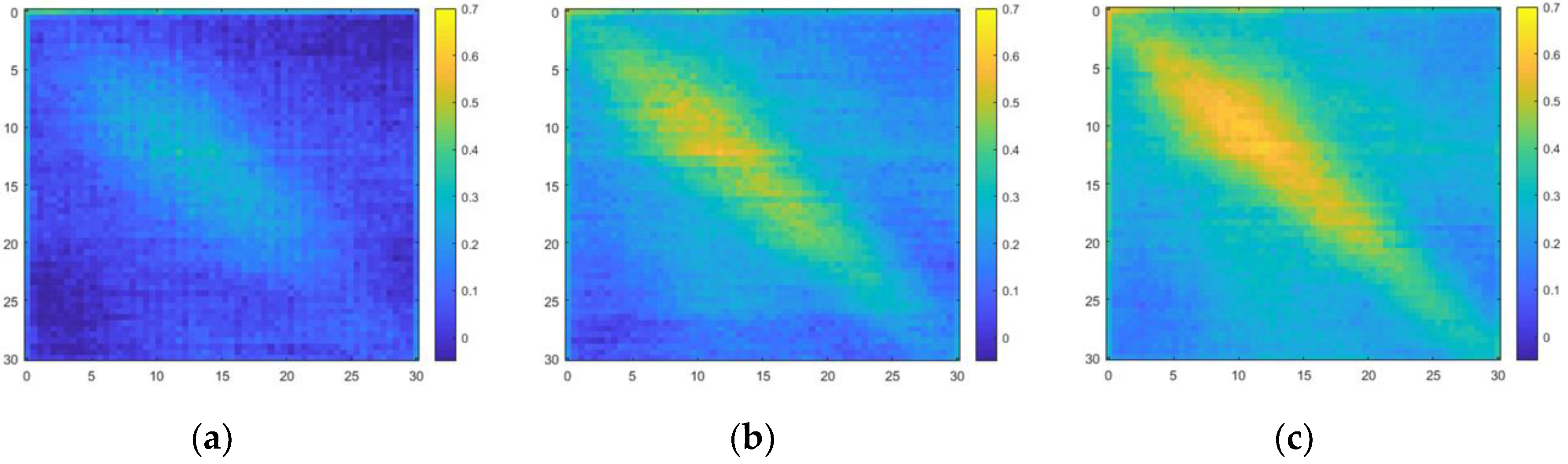

5.2. Experimental Results of Defects Visualization in the Time-Domain

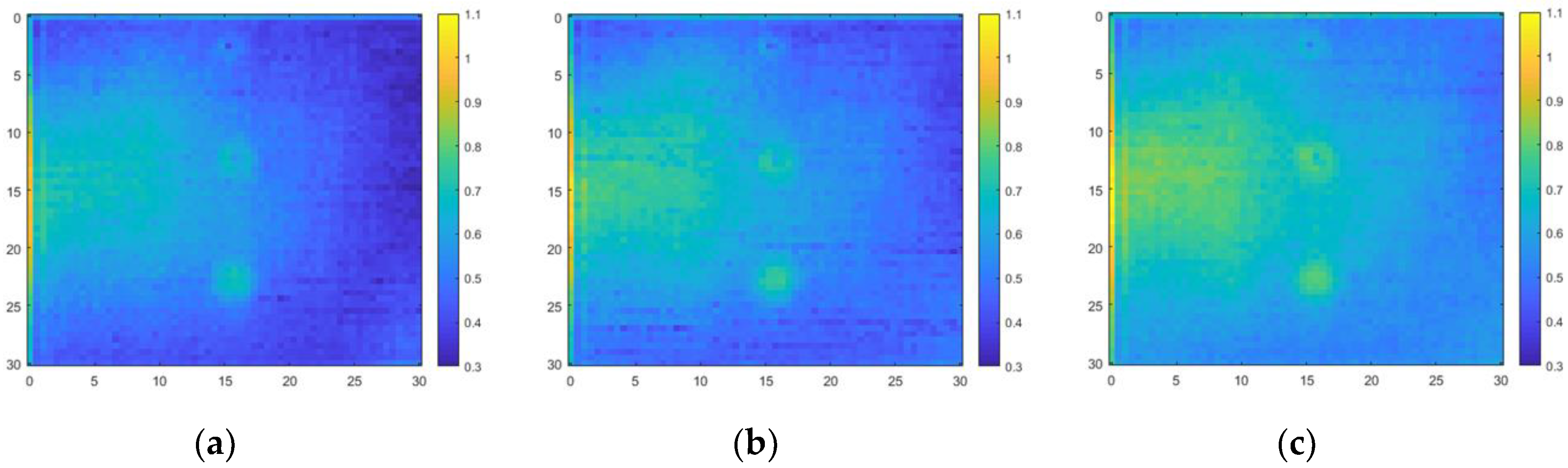

5.3. Algorithm for Detecting the Defects

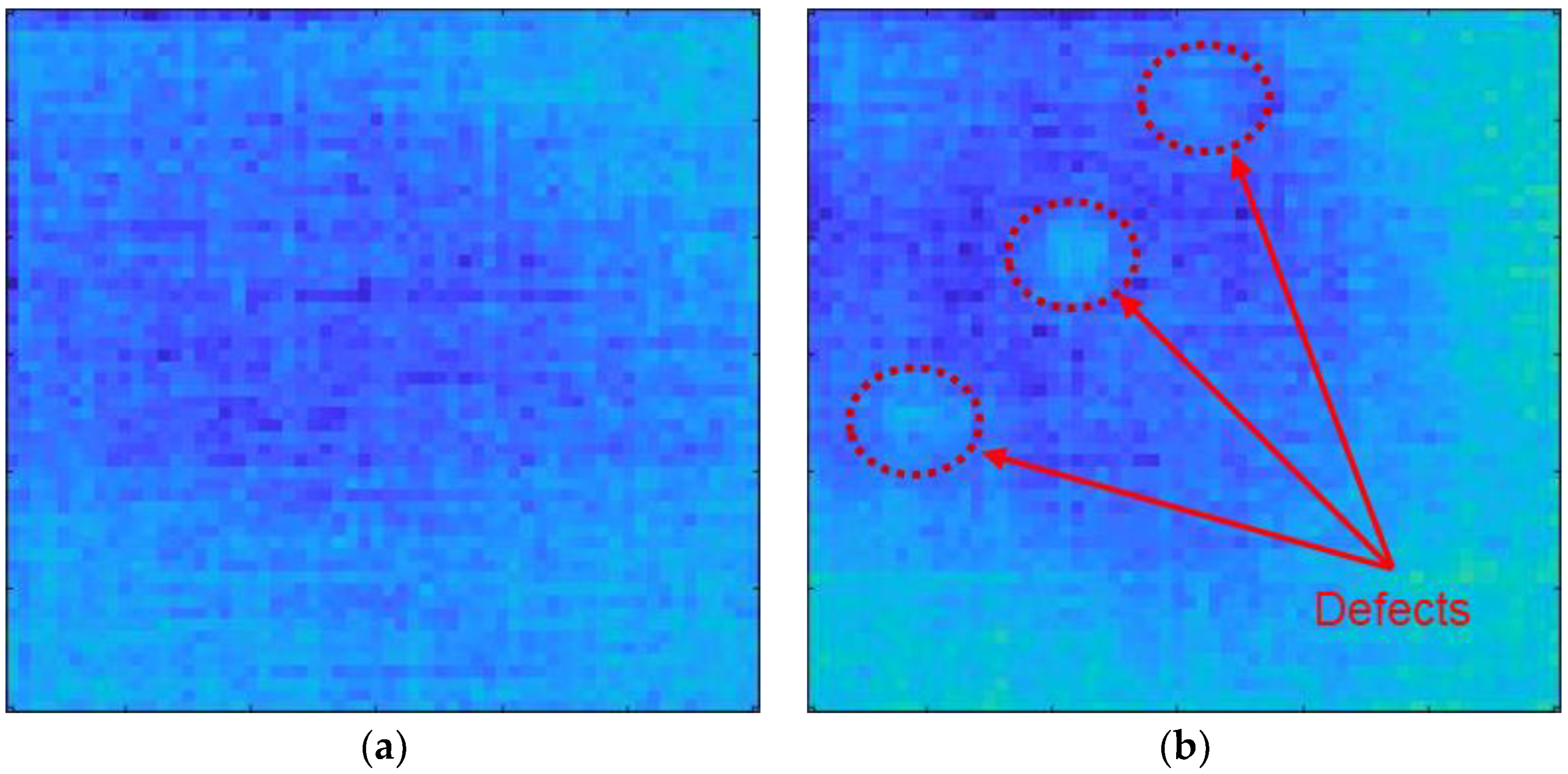

5.4. Results of Applying the Algorithm

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- NDT.net. Available online: https://www.ndt.net/search/docs.php3?id=24191 (accessed on 20 November 2019).

- Scruby, C.B.; Drain, L.E. Laser Ultrasonics: Techniques and Applications; CRC Press: New York, NY, USA, 1990; pp. 223–321. [Google Scholar]

- Gholizadeh, S.A. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Han, D.-H.; Kang, L.-H. Nondestructive evaluation of GFRP composite including multi-delamination using THz spectroscopy and imaging. Compos. Struct. 2018, 185, 161–175. [Google Scholar] [CrossRef]

- Han, D.-H.; Kang, L.-H. GUI Development for Defect Visualization of Composite Structures Based on Terahertz Wave. Trans. Korean Soc. Mech. Eng. 2018, 42, 287–292. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.; Fan, M. Pulsed eddy current non-destructive testing and evaluation: A review. Chin. J. Mech. Eng. 2017, 30, 500–514. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.; Fung, S.; Wang, Q.; Tsai, J.M.; Daneman, M.; Boser, B.E.; Horsley, D.A. Ultrasonic fingerprint sensor using a piezoelectric micromachined ultrasonic transducer array integrated with complementary metal oxide semiconductor electronics. Appl. Phys. Lett. 2015, 106, 263503. [Google Scholar] [CrossRef]

- Huggett, D.J.; Dewan, M.W.; Wahab, M.A.; Okeil, A.; Liao, T.W. Phased array ultrasonic testing for post-weld and online detection of friction stir welding defects. Res. Nondestruct. Eval. 2017, 28, 187–210. [Google Scholar] [CrossRef]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- ISO. Available online: https://www.iso.org/standard/61881.html (accessed on 20 November 2019).

- Matsuda, O.; Larciprete, M.C.; Voti, R.L.; Wright, O.B. Fundamentals of picosecond laser ultrasonics. Ultrasonics 2015, 56, 3–20. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Qiu, J.; Ji, H. Laser Ultrasonic Imaging for Impact Damage Visualization in Composite Structure. In Proceedings of the 7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014. [Google Scholar]

- Gao, S.; Dai, X.; Liu, Z.; Tian, G. High-performance wireless piezoelectric sensor network for distributed structural health monitoring. Int. J. Distrib. Sens. Netw. 2016, 12, 1–16. [Google Scholar] [CrossRef]

- Kang, S.-H.; Han, D.-H.; Kang, L.-H. Development of Defect Visualization System Based on Laser Ultrasonic Propagation Imaging. In Proceedings of the 2018 the Society for Aerospace System Engineering Spring Conference, Jeju, Korea, 25–28 April 2018. [Google Scholar]

- Hong, K.M. Development of Laser Ultrasonic Technique for Measurement of Internal Defects Using Pulse Laser with Laser Interferometer. Ph.D. Thesis, Chonbuk National University, Jeonju, Korea, 2017. [Google Scholar]

- Song, K.S. Evaluation of Metal Material Welding Flaw by Non-Contact NDT Method Using Laser Guide Ultrasonic Wave and Ultrasonic Signal Visualization. Ph.D. Thesis, Chosun University, Gwangju, Korea, 2006. [Google Scholar]

- Kim, J.G.; Choi, S.; Jhang, K.Y. Simulations for Internal Defect Inspection Using Laser Generated Ultrasonic Wave in Ablation Regime. J. Korean Soc. Nondestruct. Test. 2014, 34, 226–232. [Google Scholar] [CrossRef]

- Lee, S.S.; Jang, T.S. Understanding of Laser-based Ultrasonics. J. Korean Soc. Nondestruct. Test. 2002, 22, 74–87. [Google Scholar]

- Pan, S.; Li, Q.; Xian, Z.; Su, N.; Zeng, F. The Effects of Laser Parameters and the Ablation Mechanism in Laser Ablation of C/SiC Composite. Materials 2019, 12, 3076. [Google Scholar] [CrossRef] [PubMed] [Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-H.; Han, D.-H.; Kang, L.-H. Defect Visualization of a Steel Structure Using a Piezoelectric Line Sensor Based on Laser Ultrasonic Guided Wave. Materials 2019, 12, 3992. https://doi.org/10.3390/ma12233992

Kang S-H, Han D-H, Kang L-H. Defect Visualization of a Steel Structure Using a Piezoelectric Line Sensor Based on Laser Ultrasonic Guided Wave. Materials. 2019; 12(23):3992. https://doi.org/10.3390/ma12233992

Chicago/Turabian StyleKang, Sang-Hyeon, Dae-Hyun Han, and Lae-Hyong Kang. 2019. "Defect Visualization of a Steel Structure Using a Piezoelectric Line Sensor Based on Laser Ultrasonic Guided Wave" Materials 12, no. 23: 3992. https://doi.org/10.3390/ma12233992