Investigation of Sheet Metal Forming Using a Rapid Compression Machine

Abstract

:1. Introduction

2. Methods and Setup

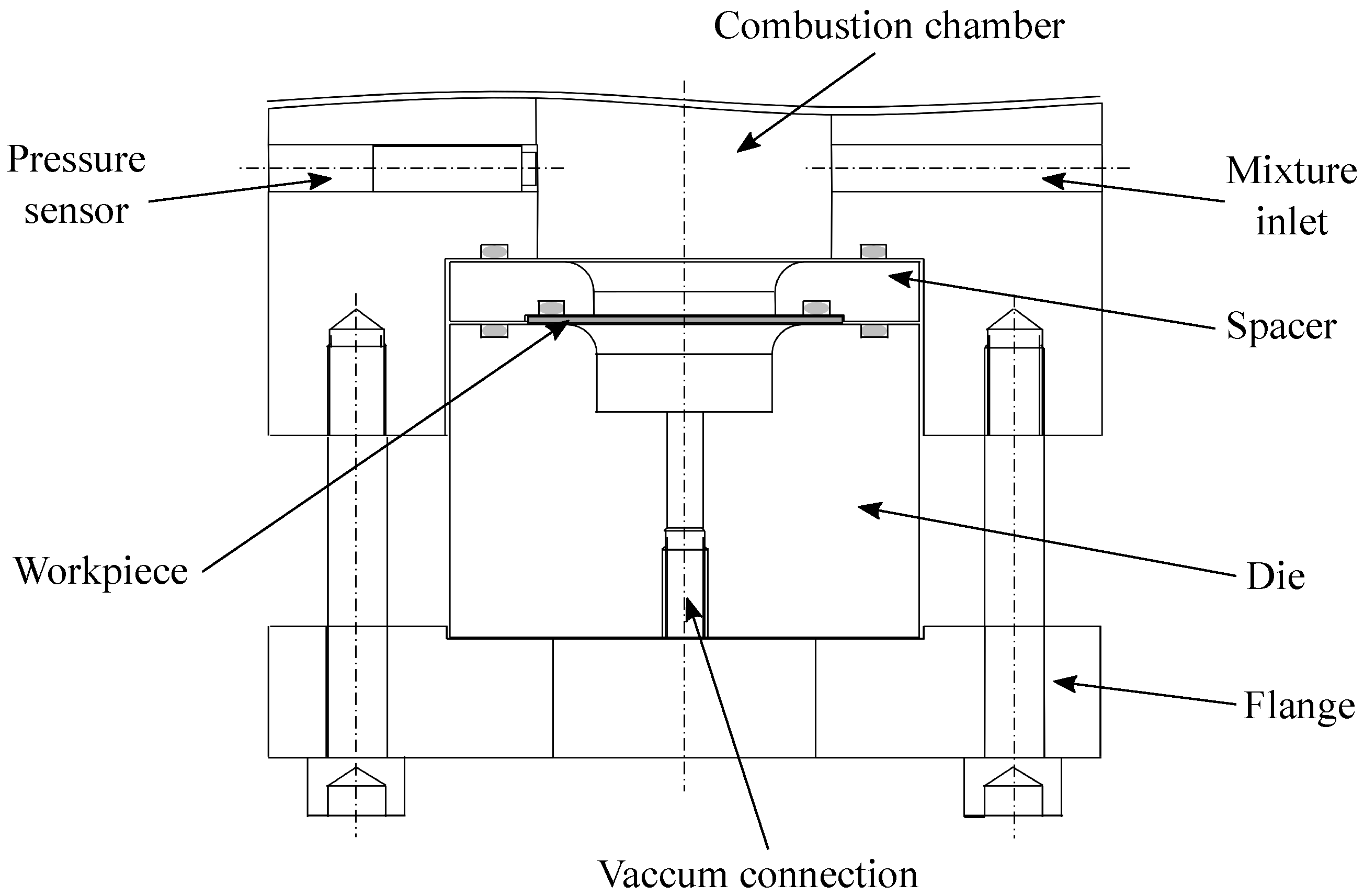

2.1. Experimental Setup

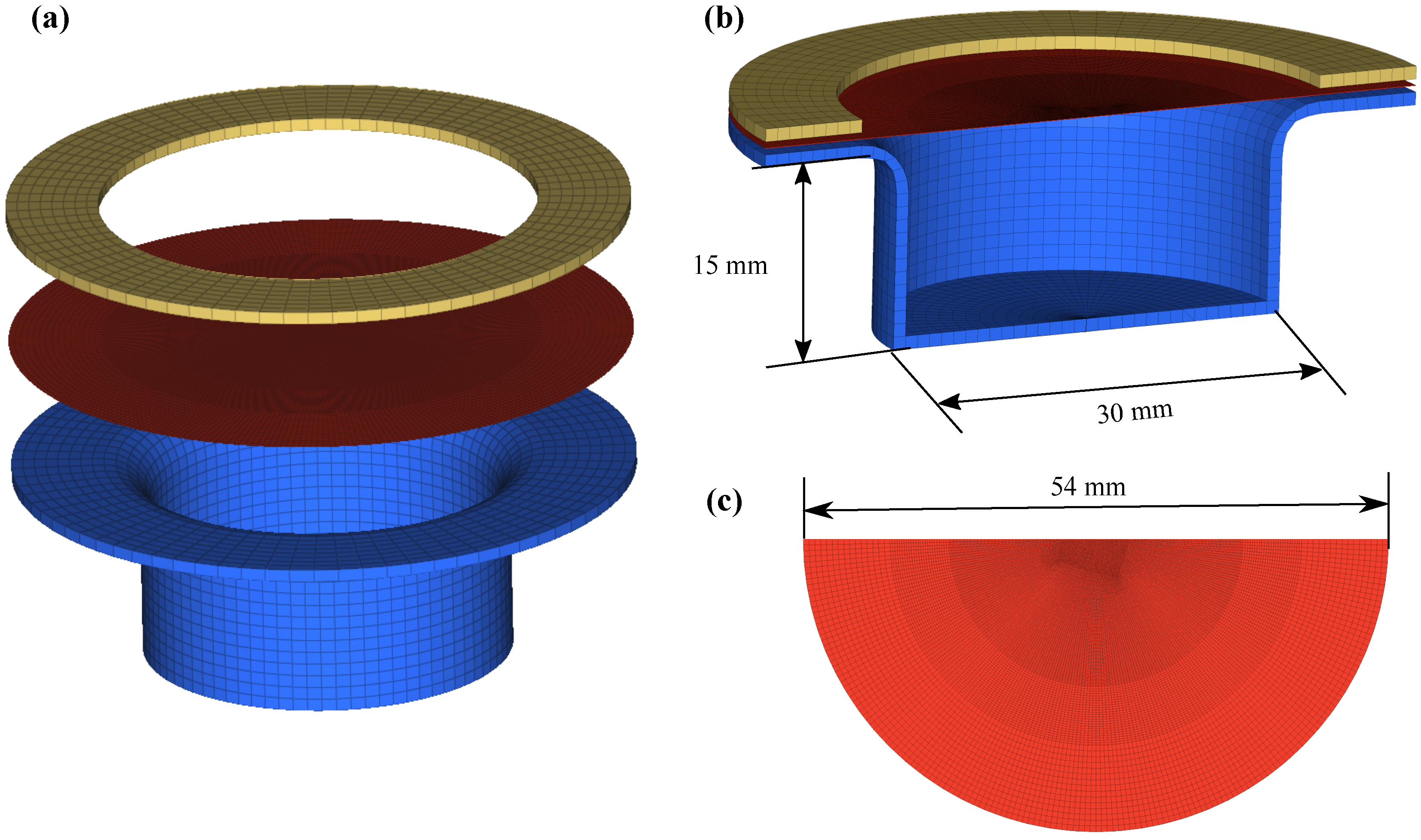

2.2. Numerical Modeling

3. Results and Discussion

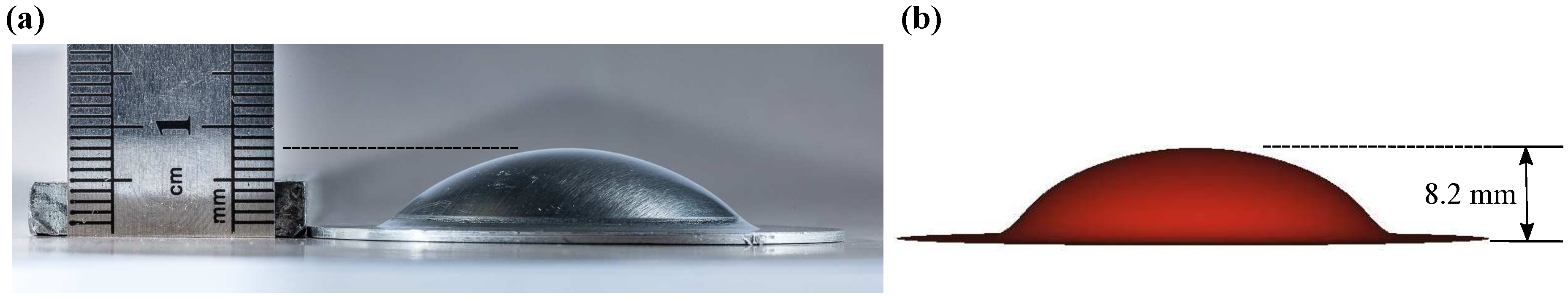

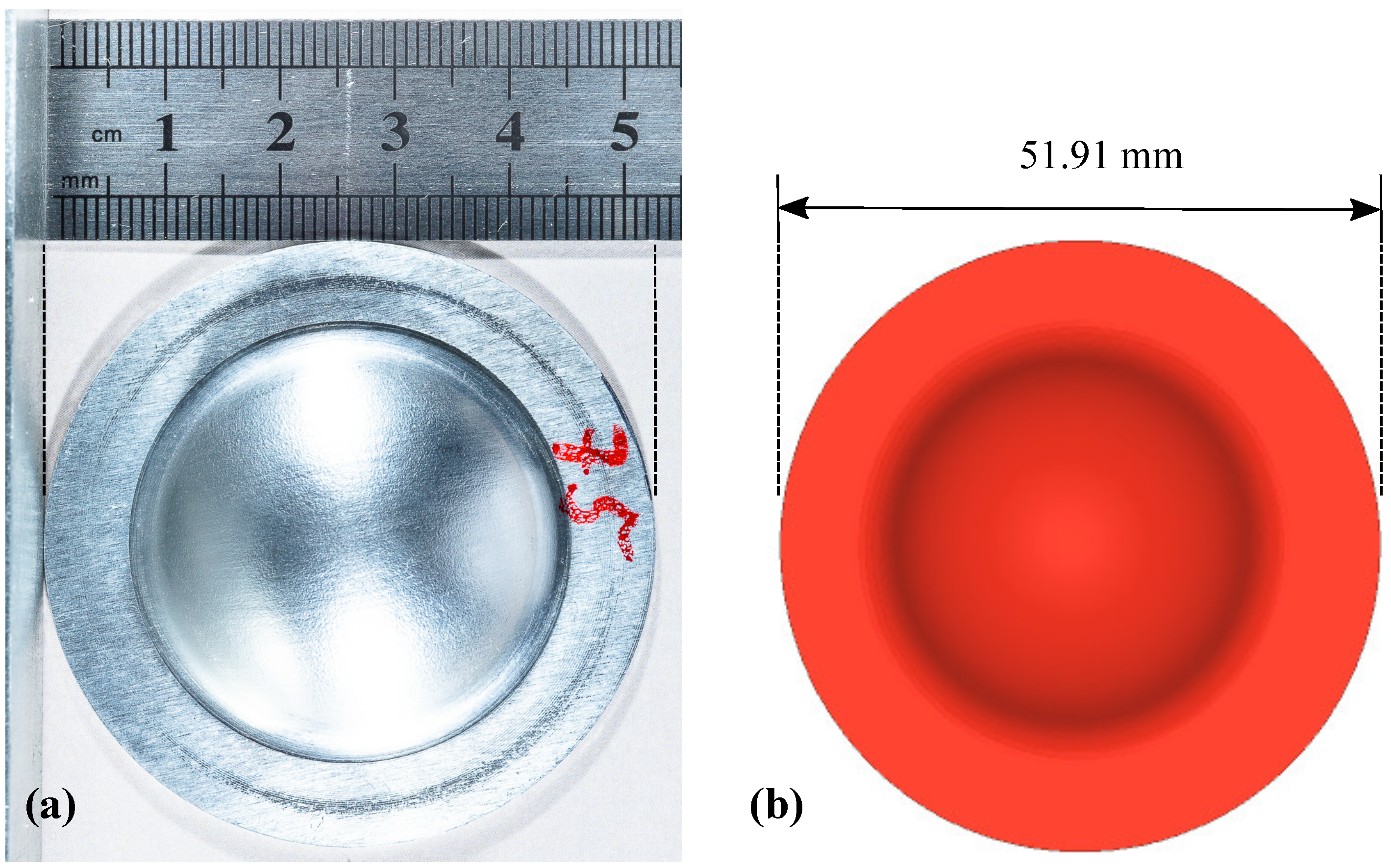

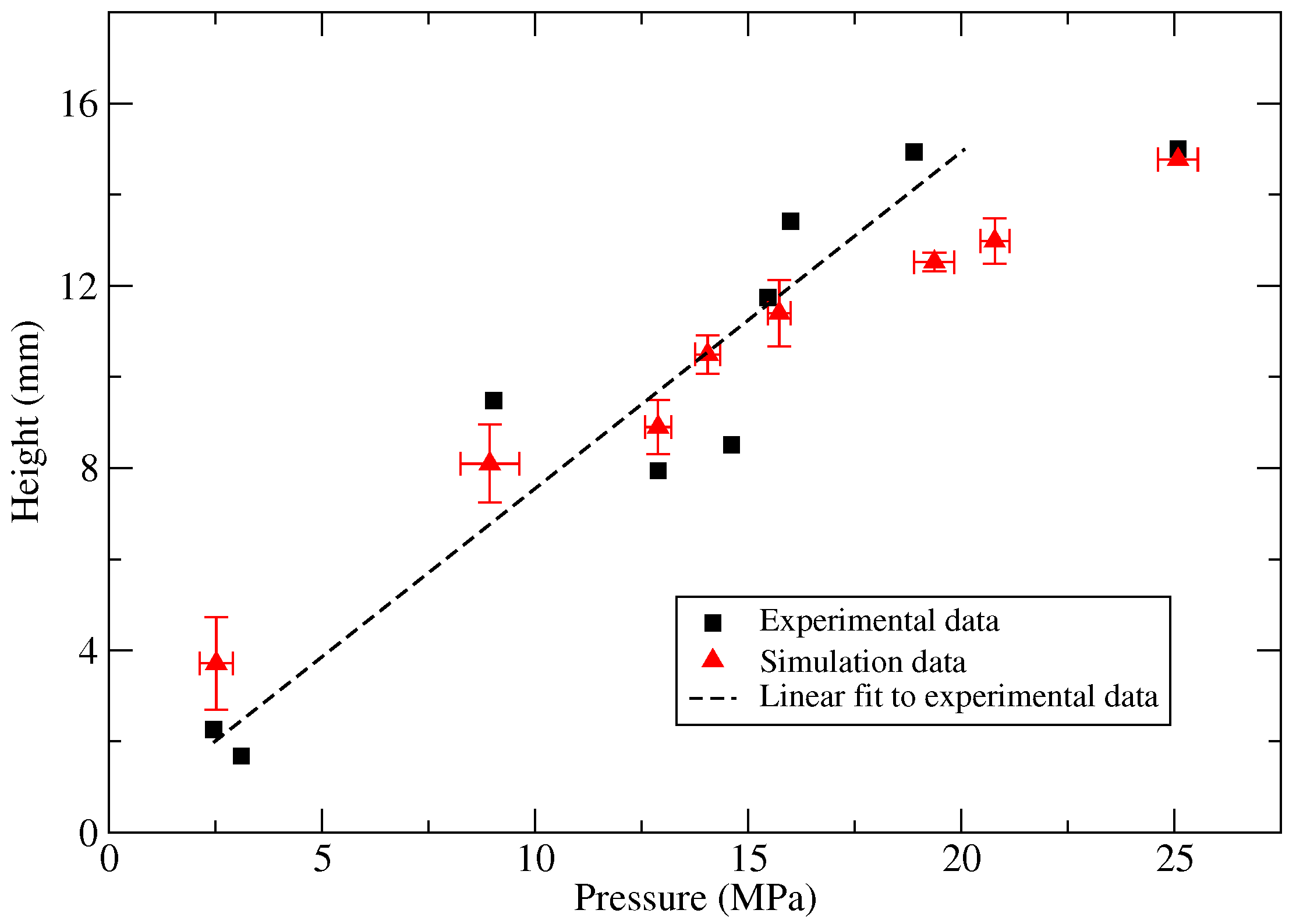

3.1. Dome Height and Outer Diameter

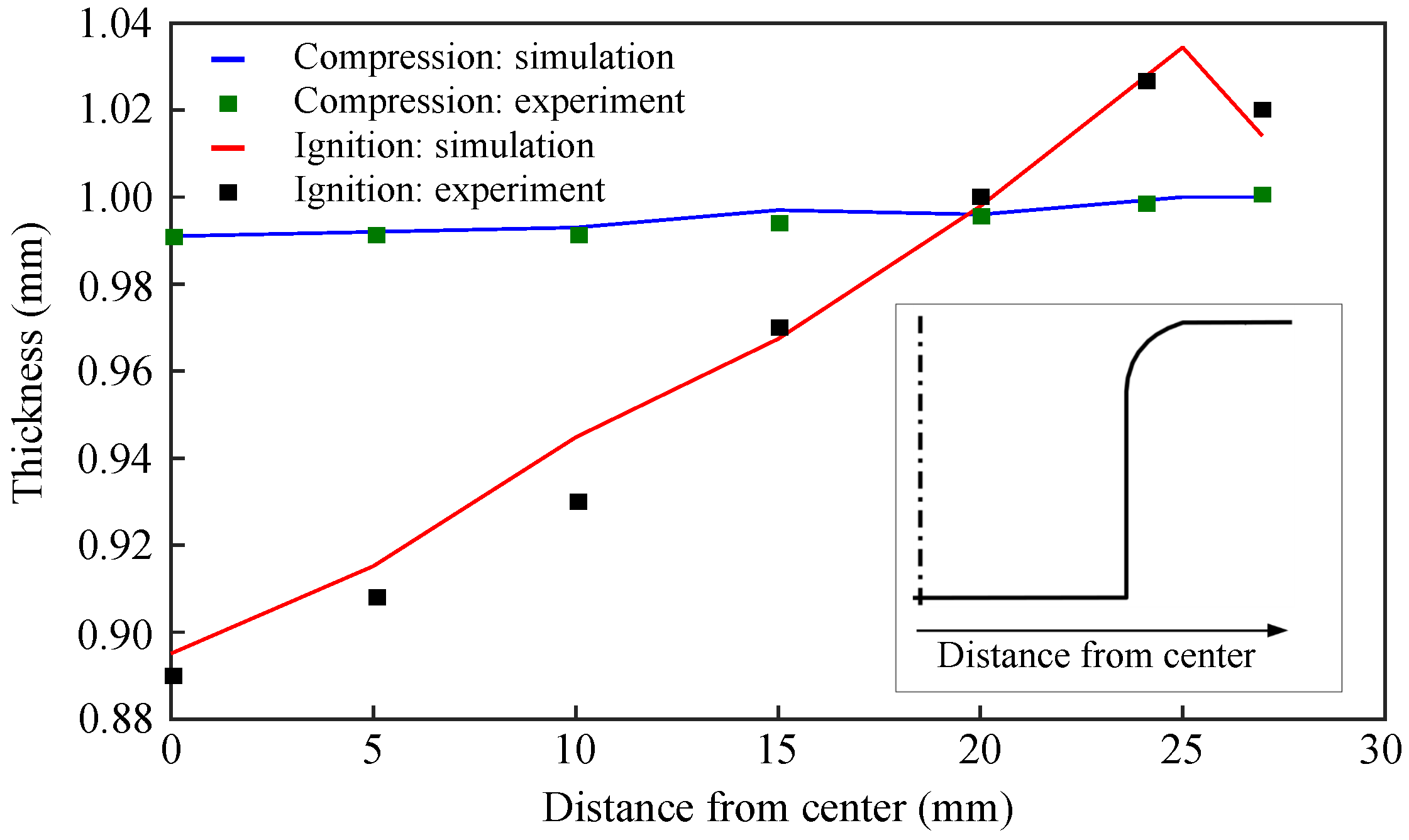

Thickness Variation

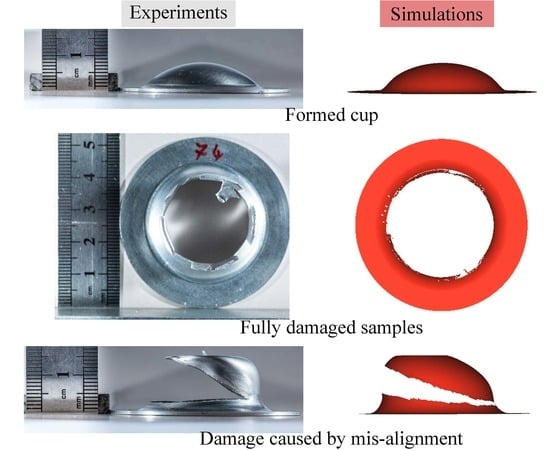

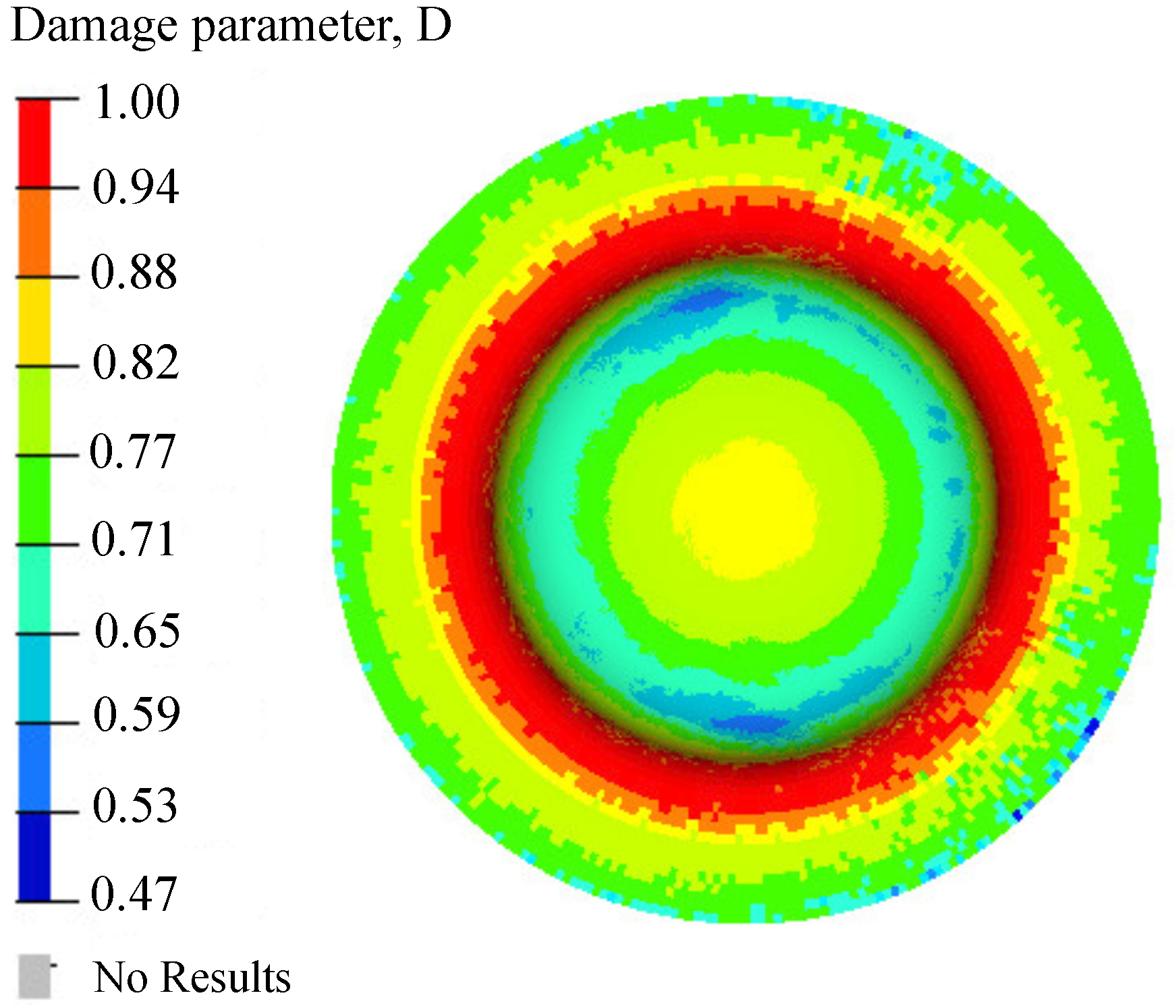

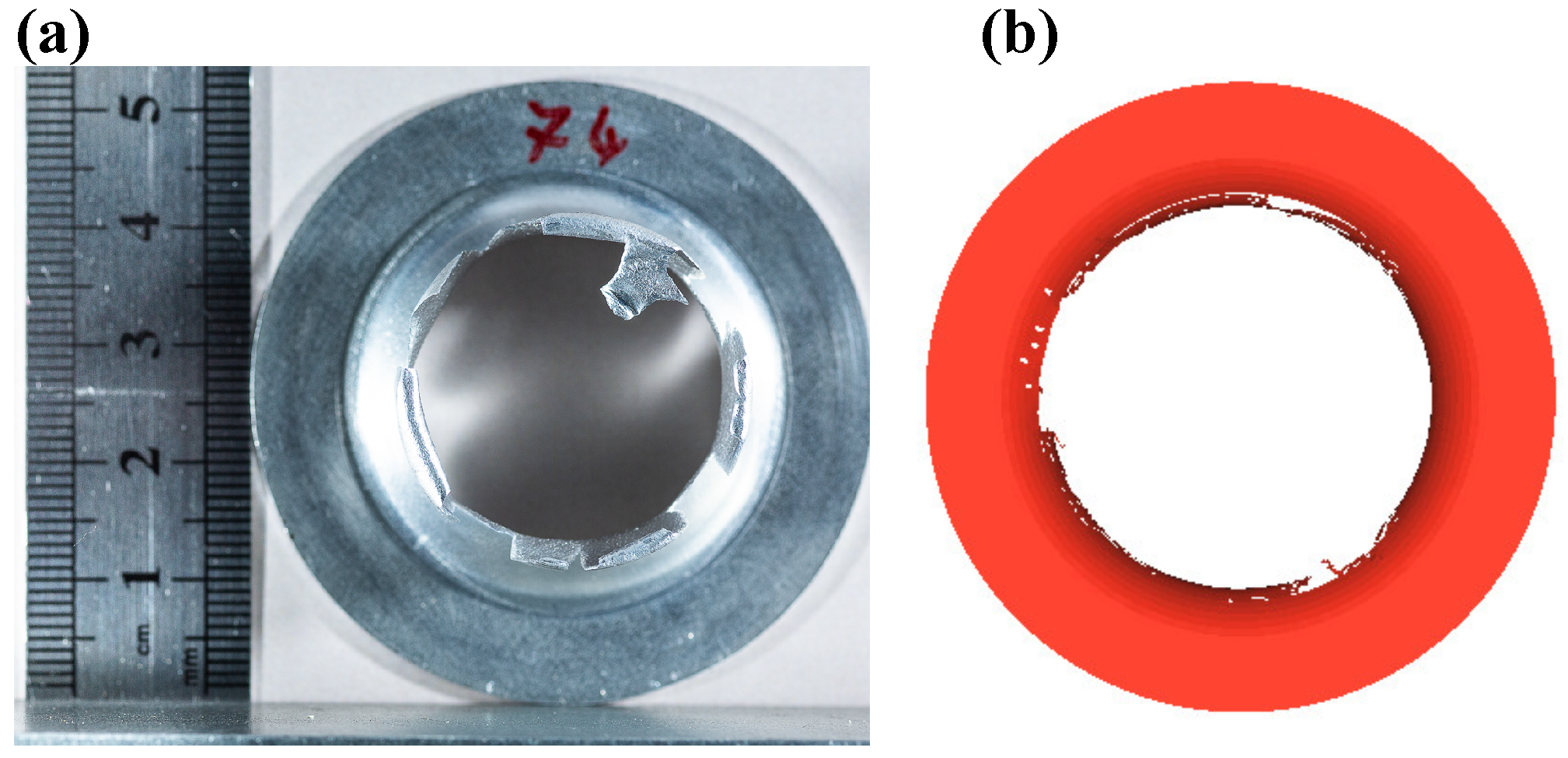

3.2. Damage in the Workpiece

3.3. Effect of Misalignment

4. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Assheton, R. History of Explosions; Institute of Makers of Explosives: New York, NY, USA, 1930. [Google Scholar]

- Jagadeesh, G.; Takayama, K. Novel applications of micro-shock waves in biological sciences. J. Indian Inst. Sci. 2002, 82, 1–10. [Google Scholar]

- Mynors, D.J.; Zhang, B. Applications and capabilities of explosive forming. J. Mater. Process. Technol. 2002, 125, 1–25. [Google Scholar] [CrossRef]

- Bruschi, S.; Altan, T.; Banabic, D.; Bariani, P.; Brosius, A.; Cao, J.; Ghiotti, A.; Khraisheh, M.; Merklein, M.; Tekkaya, A. Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann. Manuf. Technol. 2014, 63, 727–749. [Google Scholar] [CrossRef]

- Tripathi, R.; Ramalingam, A.K.; Minwegen, H.; Alquaity, A.B.; Heufer, K.A.; Pitsch, H. Unraveling the high reactivity of 3-methyltetrahydrofuran over 2-methyltetrahydrofuran through kinetic modeling and experiments. Proc. Combust. Inst. 2019, 37, 221–230. [Google Scholar] [CrossRef]

- Cai, L.; Ramalingam, A.; Minwegen, H.; Heufer, K.A.; Pitsch, H. Impact of exhaust gas recirculation on ignition delay times of gasoline fuel: An experimental and modeling study. Proc. Combust. Inst. 2019, 37, 639–647. [Google Scholar] [CrossRef]

- Hemken, C.; Burke, U.; Lam, K.Y.; Davidson, D.F.; Hanson, R.K.; Heufer, K.A.; Kohse-Höinghaus, K. Toward a better understanding of 2-butanone oxidation: Detailed species measurements and kinetic modeling. Combust. Flame 2017, 184, 195–207. [Google Scholar] [CrossRef]

- Yasar, M. Gas detonation forming process and modeling for efficient spring-back prediction. J. Mater. Process. Technol. 2004, 150, 270–279. [Google Scholar] [CrossRef]

- Patil, S.P.; Popli, M.; Jenkouk, V.; Markert, B. Numerical modelling of the gas detonation process of sheet metal forming. J. Phys. Conf. Ser. 2016, 734, 032099. [Google Scholar] [CrossRef]

- Jenkouk, V.; Patil, S.; Markert, B. Joining of tubes by gas detonation forming. J. Physics Conf. Ser. 2016, 734, 032101. [Google Scholar] [CrossRef]

- Patil, S.; Prajapati, K.; Jenkouk, V.; Olivier, H.; Markert, B. Experimental and Numerical Studies of Sheet Metal Forming with Damage Using Gas Detonation Process. Metals 2017, 7, 556. [Google Scholar] [CrossRef]

- Patil, S.; Murkute, R.; Shirafkan, N.; Markert, B. Deformation of Stacked Metallic Sheets by Shock Wave Loading. Metals 2018, 8, 679. [Google Scholar] [CrossRef]

- Tekkaya, A.E. State-of-the-art of simulation of sheet metal forming. J. Mater. Process. Technol. 2000, 103, 14–22. [Google Scholar] [CrossRef]

- Goldsborough, S.S.; Hochgreb, S.; Vanhove, G.; Wooldridge, M.S.; Curran, H.J.; Sung, C.J. Advances in rapid compression machine studies of low-and intermediate-temperature autoignition phenomena. Prog. Energy Combust. Sci. 2017, 63, 1–78. [Google Scholar] [CrossRef]

- Ramalingam, A.; Zhang, K.; Dhongde, A.; Virnich, L.; Sankhla, H.; Curran, H.; Heufer, A. An RCM experimental and modeling study on CH4 and CH4/C2H6 oxidation at pressures up to 160 bar. Fuel 2017, 206, 325–333. [Google Scholar] [CrossRef]

- Nikiforakis, N.; Clarke, J. Numerical studies of the evolution of detonations. Math. Comput. Model. 1996, 24, 149–164. [Google Scholar] [CrossRef]

- LS-DYNA Theory Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2006.

- Lampman, S. ASM Handbook; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; Volume 21, pp. 541–547. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Smerd, R.; Winkler, S.; Salisbury, C.; Worswick, M.; Lloyd, D.; Finn, M. High strain rate tensile testing of automotive aluminum alloy sheet. Int. J. Impact Eng. 2005, 32, 541–560. [Google Scholar] [CrossRef]

- Ding, H.; Shen, N.; Shin, Y.C. Modeling of grain refinement in aluminum and copper subjected to cutting. Comput. Mater. Sci. 2011, 50, 3016–3025. [Google Scholar] [CrossRef]

- Schmitt, J.; Jalinier, J. Damage in sheet metal forming—I. Physical behavior. Acta Mater. 1982, 30, 1789–1798. [Google Scholar] [CrossRef]

- Jalinier, J.; Schmitt, J. Damage in sheet metal forming—II. Plastic instability. Acta Mater. 1982, 30, 1799–1809. [Google Scholar] [CrossRef]

- Zhao, C.R.; Kong, D.R.; Wang, S.Q.; Li, L.P.; Li, Y.Z. Analysis on the Effect Factors and Rules for Dynamic Ultra-high Pressure of Projectile Impacting Target Plate. In Proceedings of the International Conference on Mechanics and Materials Engineering (ICMME), Xi’an, China, 12–13 April 2014. [Google Scholar]

- Mamalis, A.; Manolakos, D.; Baldoukas, A. Simulation of sheet metal forming using explicit finite-element techniques: Effect of material and forming characteristics: Part 1. Deep-drawing of cylindrical cups. J. Mater. Process. Technol. 1997, 72, 48–60. [Google Scholar] [CrossRef]

| Young’s modulus (GPa) | 68.9 |

| Poisson’s ratio | 0.3 |

| Density (kg/m3) | 2770 |

| Tensile strength (MPa) | 353 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patil, S.P.; Fenard, Y.; Bailkeri, S.; Heufer, K.A.; Markert, B. Investigation of Sheet Metal Forming Using a Rapid Compression Machine. Materials 2019, 12, 3957. https://doi.org/10.3390/ma12233957

Patil SP, Fenard Y, Bailkeri S, Heufer KA, Markert B. Investigation of Sheet Metal Forming Using a Rapid Compression Machine. Materials. 2019; 12(23):3957. https://doi.org/10.3390/ma12233957

Chicago/Turabian StylePatil, Sandeep P., Yann Fenard, Shridhar Bailkeri, Karl Alexander Heufer, and Bernd Markert. 2019. "Investigation of Sheet Metal Forming Using a Rapid Compression Machine" Materials 12, no. 23: 3957. https://doi.org/10.3390/ma12233957

APA StylePatil, S. P., Fenard, Y., Bailkeri, S., Heufer, K. A., & Markert, B. (2019). Investigation of Sheet Metal Forming Using a Rapid Compression Machine. Materials, 12(23), 3957. https://doi.org/10.3390/ma12233957