Fractal Dimension Characterization of Joint Surface Morphology on Dissimilar Friction Stir Lap Welding of Al/Mg

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Analysis

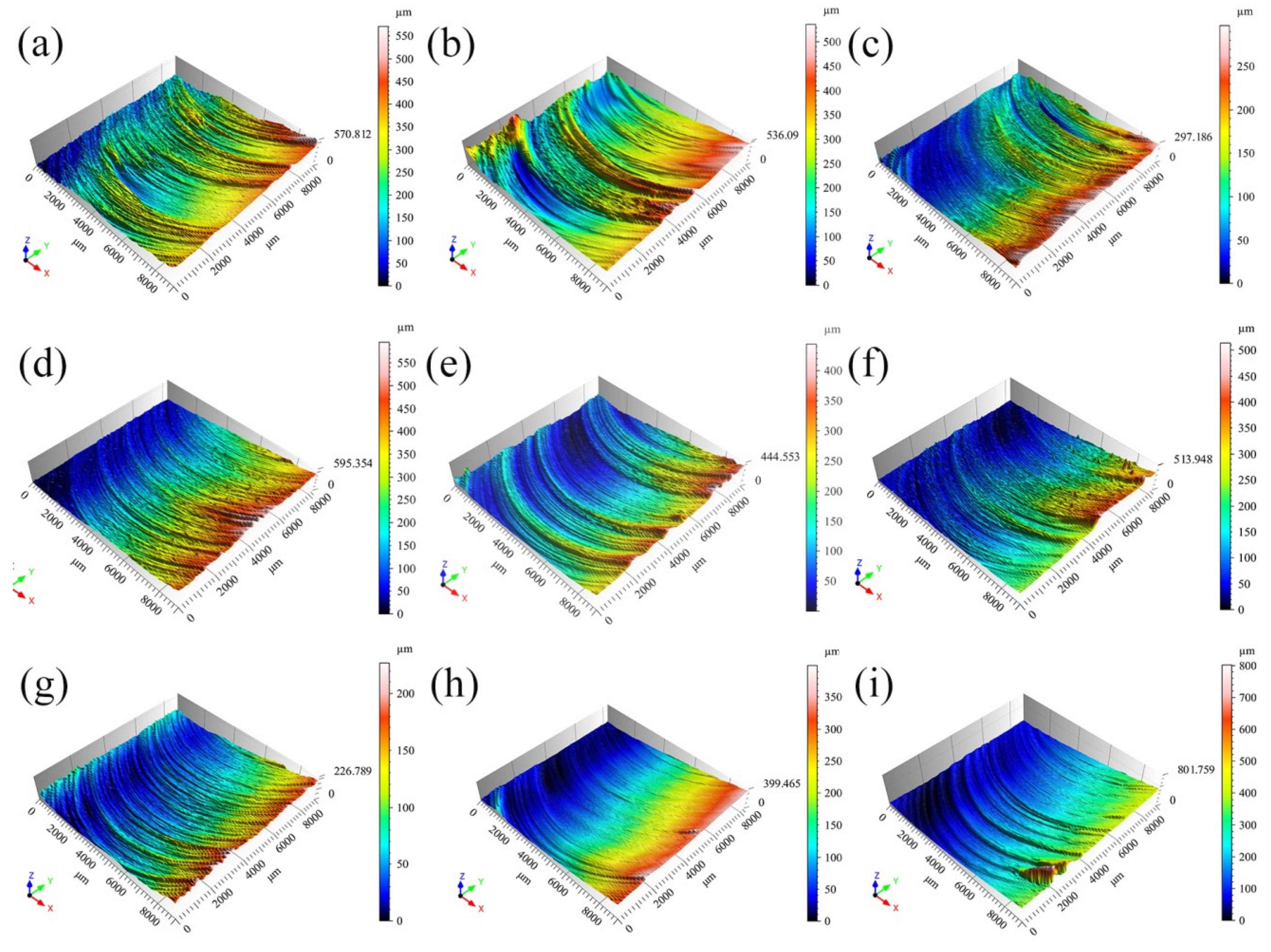

3.1. 3D Joint Surface Morphology

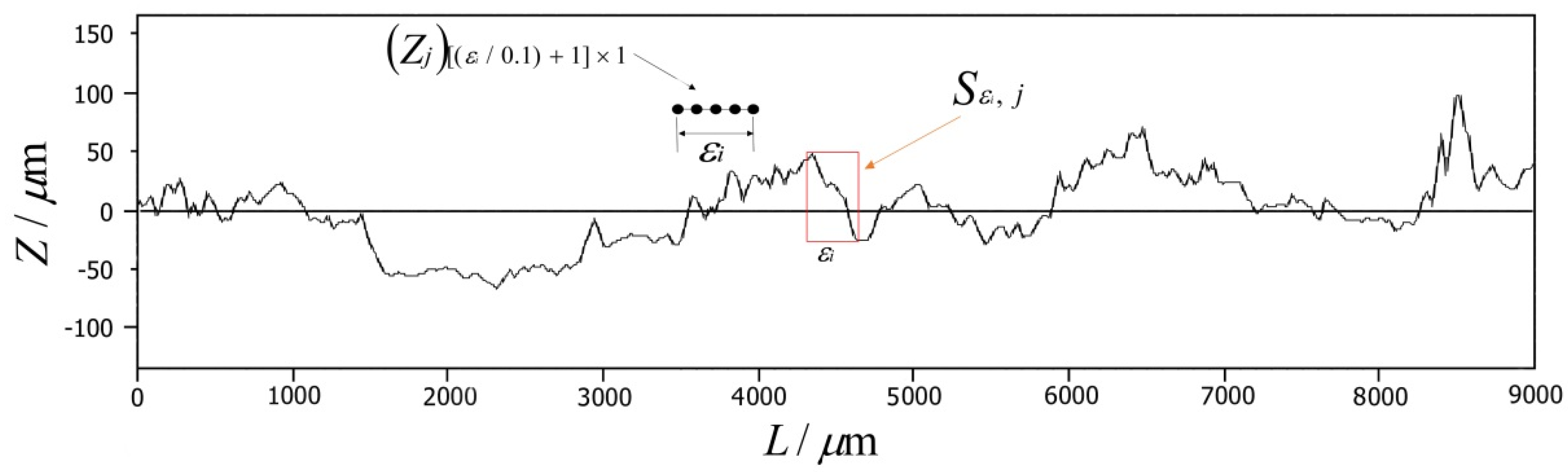

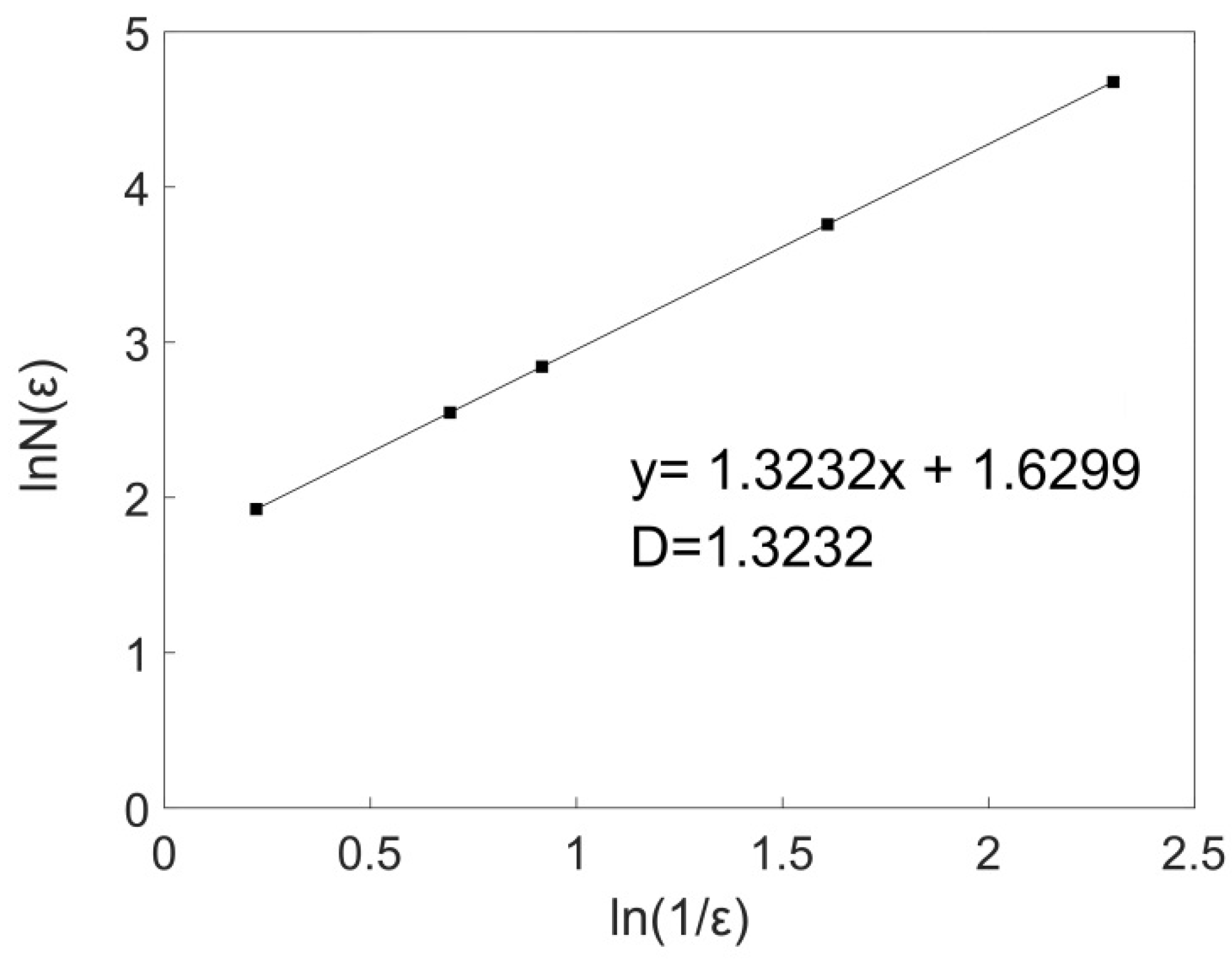

3.2. Calculation of Fractal Dimension of Cross-Sectional Curve of Joint Surface

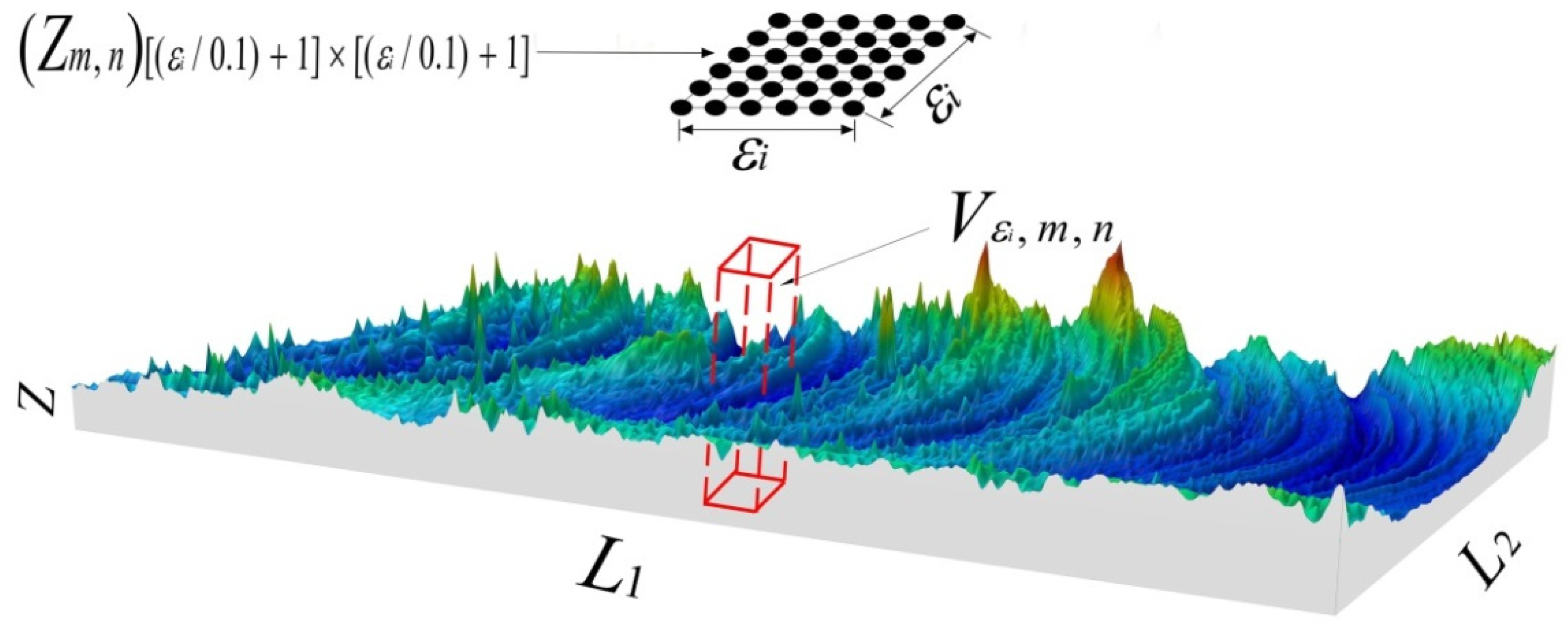

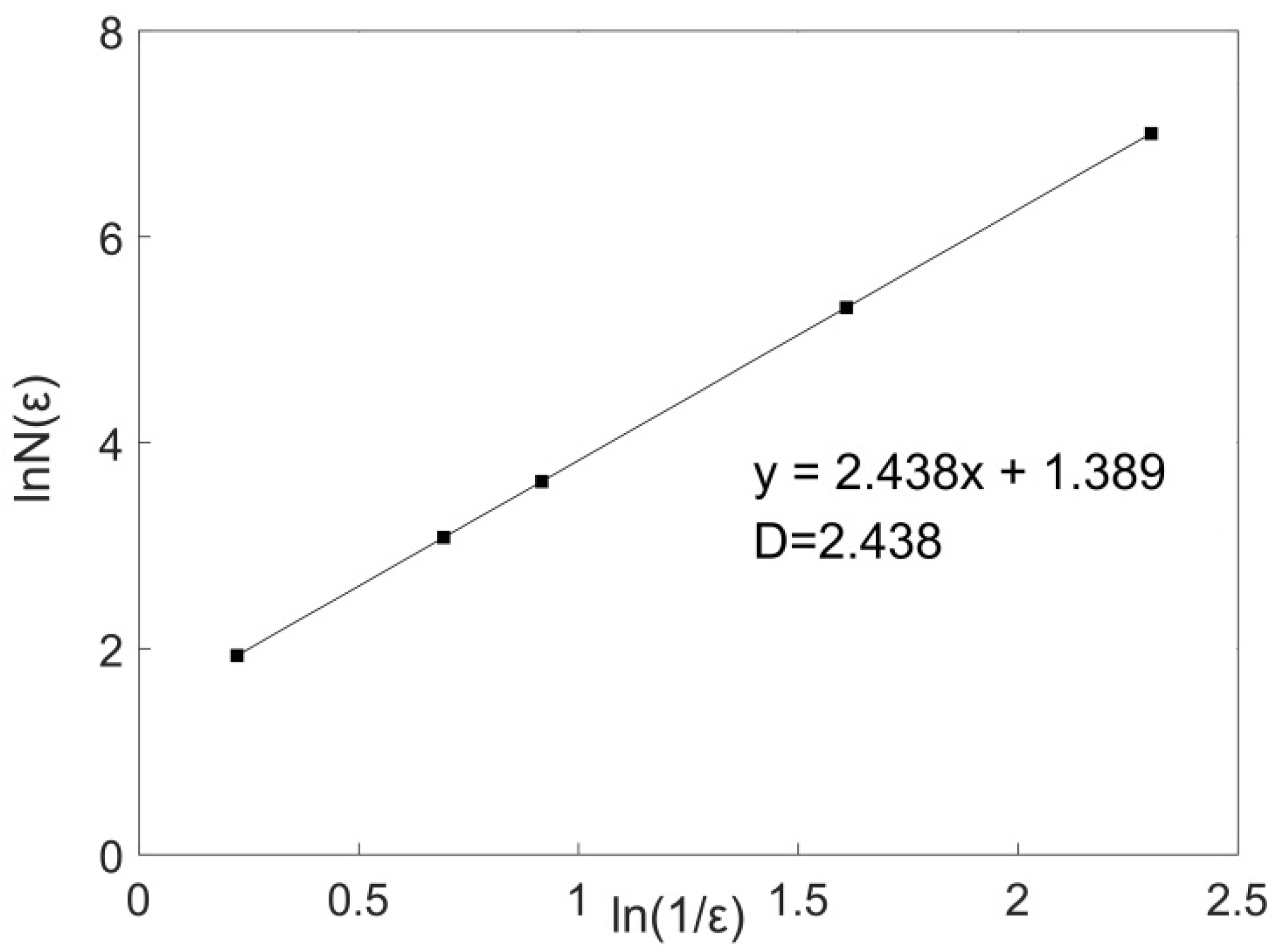

3.3. Calculation of Fractal Dimension of Curved Surface of Joint Surface

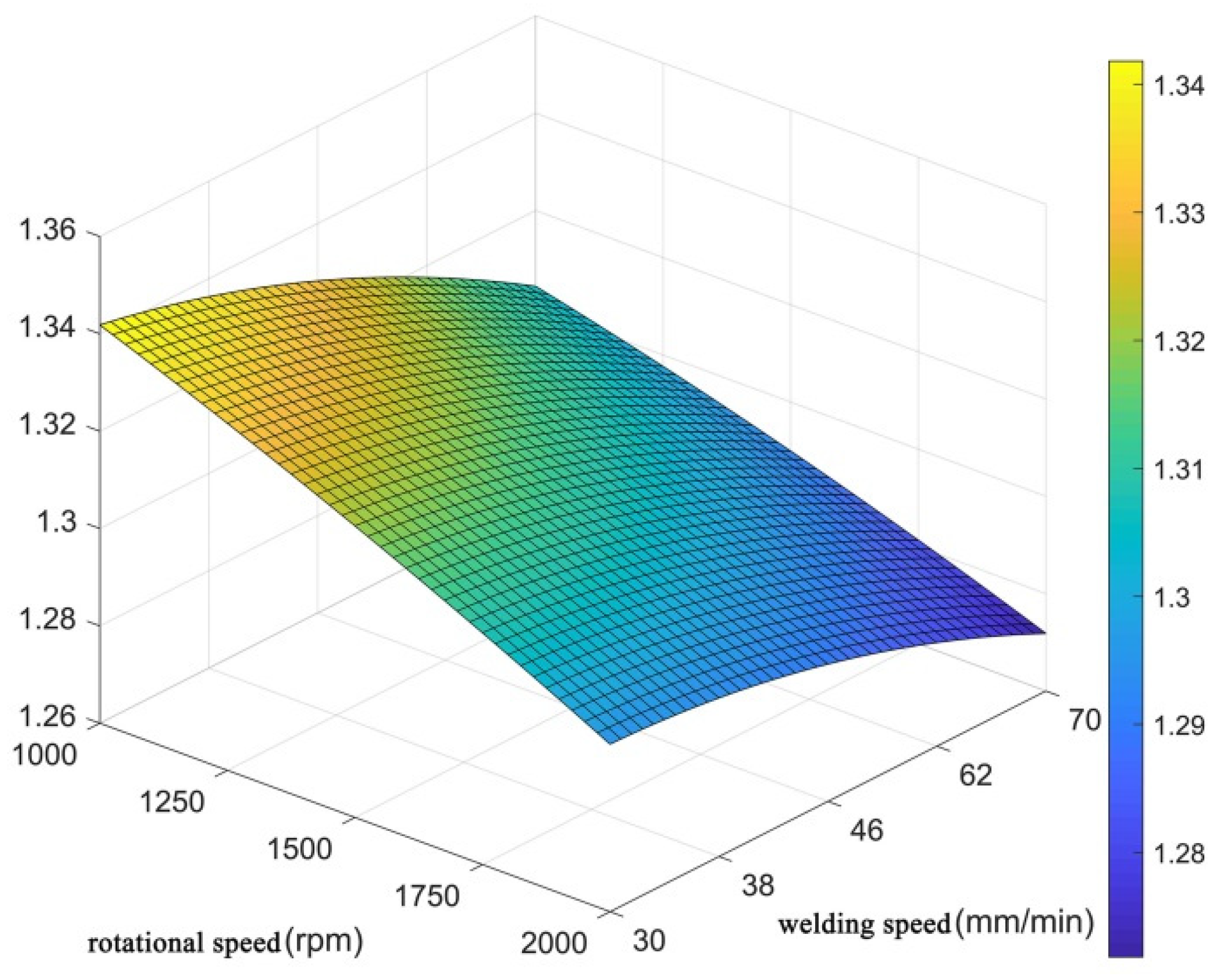

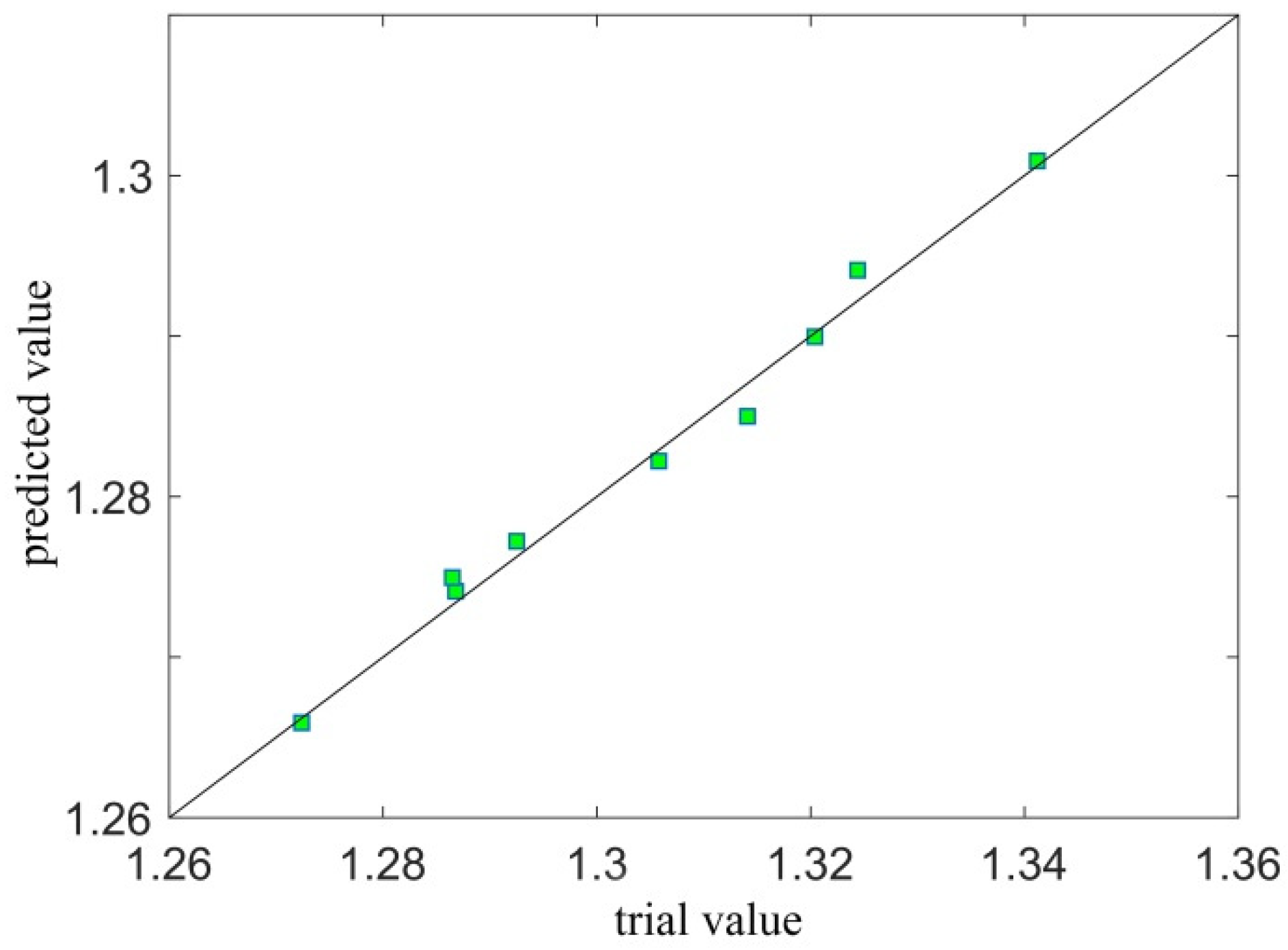

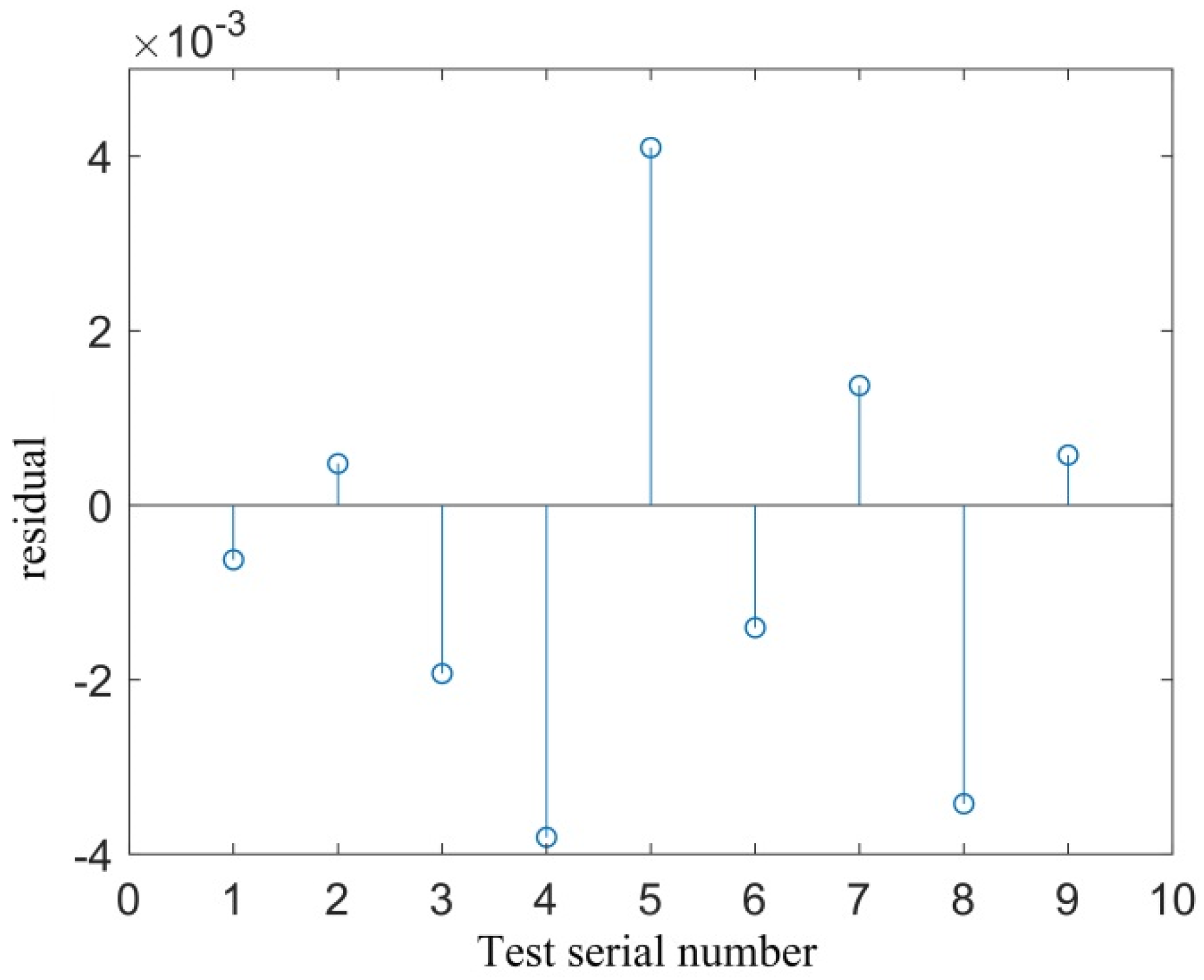

3.4. Influence of Welding Process Parameters on Fractal Dimension

4. Conclusions

- The box-width transformation method was used to calculate the fractal dimensions of the cross-sectional curve and the curved surface of the joint surface, and it was found that there was a very high linear correlation between and . This showed that its morphology had fractal characteristics, and the fractal dimension D could be used as an indicator of the quality of the joint surface.

- A high-accuracy response surface model that related the welding process parameters and fractal dimension was obtained using the CCD method, which directly reflected the influence of the process parameters on the fractal dimension. When the rotational speed was fixed, the fractal dimension D of the joint surface decreased with the increase in the welding speed. When the welding speed was fixed, the fractal dimension D decreased with the increase in the rotational speed. The effect of the rotational speed was more significant.

Author Contributions

Funding

Conflicts of Interest

References

- Gao, Y.; Morisada, Y.; Fujii, H.; Liao, J. Dissimilar friction stir lap welding of magnesium to aluminum using plasma electroytic oxidation. Mater. Sci. Eng. A 2018, 711, 109–118. [Google Scholar] [CrossRef]

- Liu, Z.L.; Meng, X.C.; Ji, S.D.; Li, Z.W.; Wang, L. Improving tensile properties of Al/Mg joint by smashing intermetallic compounds via ultrasonic-assisted staionary shoulder friction stir welding. J. Manuf. Process. 2018, 31, 552–559. [Google Scholar] [CrossRef]

- Sato, Y.S.; Park, S.H.C.; Michiuchi, M.; Kokawa, H. Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys. Scr. Mater. 2004, 50, 1233–1236. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Friction stir lap joining aluminum and magnesium alloys. Scr. Mater. 2008, 58, 433–436. [Google Scholar] [CrossRef]

- Li, P.; You, G.; Wen, H.; Guo, W.; Tong, X.; Li, S. Friction stir welding between the high-pressure die casting of AZ91 magnesium alloy and A383 aluminum alloy. J. Mater. Process. Technol. 2019, 264, 55–63. [Google Scholar] [CrossRef]

- Mehta, K.P.; Carlone, P.; Astarita, A.; Scherillo, F.; Rubino, F.; Vora, P. Conventional and cooling assisted friction stir welding of AA6061 and AZ31B alloys. Mater. Sci. Eng. A 2019, 759, 252–261. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, G.; Liu, S.; Xie, Y.L.; Wang, G.G.; Jang, B.; Tang, A.; Pan, F.S. Microstructure evolution and mechanical properties of friction stir welded dissimilar joints of as-extruded AM60 and AZ31 alloys. Mater. Sci. Eng. A 2019, 759, 479–489. [Google Scholar] [CrossRef]

- Abdollahzadeh, A.; Shokuhfar, A.; Cabrera, J.M.; Zhilyaev, A.P.; Omidvar, H. In-situ nanocomposite in friction stir welding of 6061-T6 aluminum alloy to AZ31 magnesium alloy. J. Mater. Process. Technol. 2019, 263, 296–307. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, X.; Ma, Y.; Liu, S.; Zang, L.; Chen, Y. Microstructure and corrosion behavior of friction stir-welded 6061 Al/AZ31 Mg joints with a Zr interlayer. Materials 2019, 12, 1115. [Google Scholar] [CrossRef]

- Kumar, S.; Wu, C.S.; Zhen, S.; Ding, W. Effect of ultrasonic vibration on welding load, macrostructure, and mechanical properties of Al/Mg alloy joints fabricated by friction stir lap welding. Int. J. Adv. Manuf. Technol. 2019, 100, 1787–1799. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Lv, Z.; Huang, T.; Zhang, Y.; Cao, J.; Zhou, L.; Feng, J. Microstructures and mechanical properties of micro friction stir welding (μFSW) of 6061-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 1084–1091. [Google Scholar] [CrossRef]

- Wang, T.; Ao, S.S.; Manladan, S.M.; Cai, Y.C.; Luo, Z. Microstructure and Properties of Surface-Modified Plates and Their Welded Joints. Materials 2019, 12, 2883. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, D.; Zhao, G.; Li, G.; Tang, H. The effect of welded joint properties on the surface characteristics of laser-welded 2205 duplex stainless steel. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Praveen, A.S.; Arjunan, A. Parametric optimisation of high-velocity oxy-fuel nickel-chromium-silicon-boron and aluminium-oxide coating to improve erosion wear resistance. Mater. Res. Express 2019, 6, 096560. [Google Scholar] [CrossRef]

- Boccarusso, L.; Astarita, A.; Carlone, P.; Scherillo, F.; Rubino, F.; Squillace, A. Dissimilar friction stir lap welding of AA 6082-Mg AZ31, Force analysis and microstructure evolution. J. Manuf. Process. 2019, 44, 376–388. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Wen, Q. Surface analysis of stationary shoulder friction stir processed AZ31B magnesium alloy. Mater. Sci. Technol. 2019, 35, 628–631. [Google Scholar] [CrossRef]

- Colmenero, A.N.; Orozco, M.S.; Macías, E.J.; Fernández, J.B.; Muro, J.C.S.; Fals, H.C.; Roca, A.S. Optimization of friction stir spot welding process parameters for Al-Cu dissimilar joints using the energy of the vibration signals. Int. J. Adv. Manuf. Technol. 2019, 100, 2795–2802. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.; Pan, K.; Wang, J. Multi-Objective Optimization of Friction Stir Spot-Welded Parameters on Aluminum Alloy Sheets Based on Automotive Joint Loads. Metals 2019, 9, 520. [Google Scholar] [CrossRef]

- Dubuc, B.; Zucker, S.W.; Tricot, C.; Quiniou, J.F.; Wehbi, D. Evaluating the fractal dimension of surfaces. Proc. R. Soc. Lond. A Math. Phys. Sci. 1989, 425, 113–127. [Google Scholar] [CrossRef]

- Spanos, L.; Liu, Q.; Irene, E.A.; Zettler, T.; Hornung, B.; Wortman, J.J. Investigation of roughened silicon surfaces using fractal analysis. II. Chemical etching, rapid thermal chemical vapor deposition, and thermal oxidation. J. Vac. Sci. Technol. A Vac. Surf. Film. 1994, 12, 2653–2661. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Hu, Y.; Chen, S.; Lin, Z. Microstructural characteristics and mechanical properties of friction stir lap welding joint of Alclad 7B04-T74 aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 78, 1415–1425. [Google Scholar] [CrossRef]

| Calculated Curve No. | Section Position (mm) | Box Count | Curvilinear Fractal Dimension D | ||||

|---|---|---|---|---|---|---|---|

| N(0.8) | N(0.5) | N(0.4) | N(0.2) | N(0.1) | |||

| 1 | x = 0 | 5.2 | 9.3 | 12.4 | 29.8 | 71.7 | 1.2658 |

| 2 | x = 1 | 6.5 | 12.1 | 16.3 | 41.1 | 103.4 | 1.3313 |

| 3 | x = 2 | 6.4 | 12 | 16.1 | 40.3 | 101.1 | 1.3256 |

| 4 | x = 3 | 6.9 | 12.9 | 17.4 | 43.9 | 110.9 | 1.3382 |

| 5 | x = 4 | 6.9 | 12.8 | 17.2 | 42.9 | 107.4 | 1.3232 |

| 6 | x = 5 | 6.4 | 11.9 | 16 | 40.2 | 100.9 | 1.3278 |

| 7 | x = 6 | 6.2 | 11 | 14.5 | 34 | 79.8 | 1.2992 |

| 8 | x = 7 | 6.4 | 11.9 | 15.9 | 39.7 | 98.9 | 1.3152 |

| 9 | x = 8 | 6.6 | 12.3 | 16.5 | 41.2 | 102.8 | 1.3183 |

| 10 | x = 9 | 6.3 | 11.6 | 15.5 | 38.1 | 93.7 | 1.2964 |

| Average value | 1.3141 | ||||||

| Section Position | Average Value μ | Standard Deviation σ |

|---|---|---|

| x = 1 mm | 0.0744 | 3.692 |

| x = 4 mm | 0.0882 | 3.808 |

| x = 7 mm | 0.0945 | 3.976 |

| εi | N(εi) | Surface Fractal Dimension D |

|---|---|---|

| 0.8 | 6.9 | |

| 0.5 | 21.7 | |

| 0.4 | 37.4 | 2.438 |

| 0.2 | 202.9 | |

| 0.1 | 1099.6 |

| Symbol | Factor | Level Coding | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| A | Rotational speed (rpm) | 1000 | 1500 | 2000 |

| B | Welding speed (mm/min) | 30 | 50 | 70 |

| Serial Number | Welding Speed (mm/min) | Rotational Speed (rpm) | Fractal Dimension |

|---|---|---|---|

| 1 | 30 | 1000 | 1.3412 |

| 2 | 50 | 1000 | 1.3204 |

| 3 | 70 | 1000 | 1.2925 |

| 4 | 30 | 1500 | 1.3244 |

| 5 | 50 | 1500 | 1.3141 |

| 6 | 70 | 1500 | 1.2868 |

| 7 | 30 | 2000 | 1.3058 |

| 8 | 50 | 2000 | 1.2865 |

| 9 | 70 | 2000 | 1.2724 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F | |

|---|---|---|---|---|---|---|

| Model | 0.005204 | 5 | 0.001041 | 116.07 | <0.0001 | significant |

| ω | 0.003271 | 1 | 0.003271 | 364.86 | <0.0001 | |

| ν | 0.001776 | 1 | 0.001776 | 198.09 | <0.0001 | |

| ων | 0.0000758 | 1 | 0.0000758 | 8.45 | 0.0227 | |

| ω2 | 0.000008844 | 1 | 0.000008844 | 0.99 | 0.3537 | |

| ν2 | 0.000067 | 1 | 0.000067 | 7.47 | 0.0292 | |

| Residual | 0.00006276 | 7 | 0.000008966 | |||

| Lack of Fit | 0.00006276 | 3 | 0.00002092 | |||

| Pure Error | 0 | 4 | 0 | |||

| Cor Total | 0.005266 | 12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Luo, Y.; Zhang, Z.; Zhang, H.; Guo, X.; Wang, S.; Cui, H.; Zhang, Y. Fractal Dimension Characterization of Joint Surface Morphology on Dissimilar Friction Stir Lap Welding of Al/Mg. Materials 2019, 12, 3941. https://doi.org/10.3390/ma12233941

Zhao Y, Luo Y, Zhang Z, Zhang H, Guo X, Wang S, Cui H, Zhang Y. Fractal Dimension Characterization of Joint Surface Morphology on Dissimilar Friction Stir Lap Welding of Al/Mg. Materials. 2019; 12(23):3941. https://doi.org/10.3390/ma12233941

Chicago/Turabian StyleZhao, Yadong, Yalong Luo, Zhipeng Zhang, Haixiao Zhang, Xuefeng Guo, Shuguang Wang, Hongbao Cui, and Yangming Zhang. 2019. "Fractal Dimension Characterization of Joint Surface Morphology on Dissimilar Friction Stir Lap Welding of Al/Mg" Materials 12, no. 23: 3941. https://doi.org/10.3390/ma12233941

APA StyleZhao, Y., Luo, Y., Zhang, Z., Zhang, H., Guo, X., Wang, S., Cui, H., & Zhang, Y. (2019). Fractal Dimension Characterization of Joint Surface Morphology on Dissimilar Friction Stir Lap Welding of Al/Mg. Materials, 12(23), 3941. https://doi.org/10.3390/ma12233941