Effect of Compound Fields of Ultrasonic Vibration and Applied Pressure on the 3D Microstructure and Tensile Properties of Recycled Al-Cu-Mn-Fe-Si Alloys

Abstract

:1. Introduction

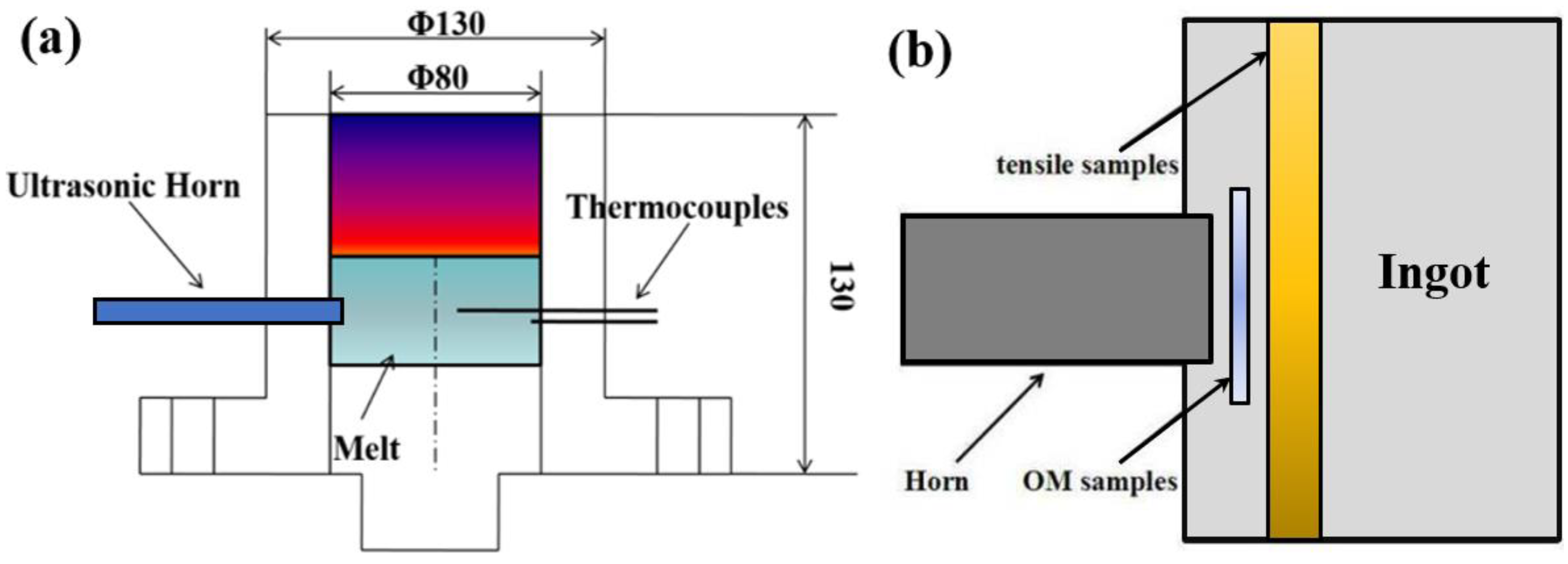

2. Materials, Methods and Experimental

3. Results

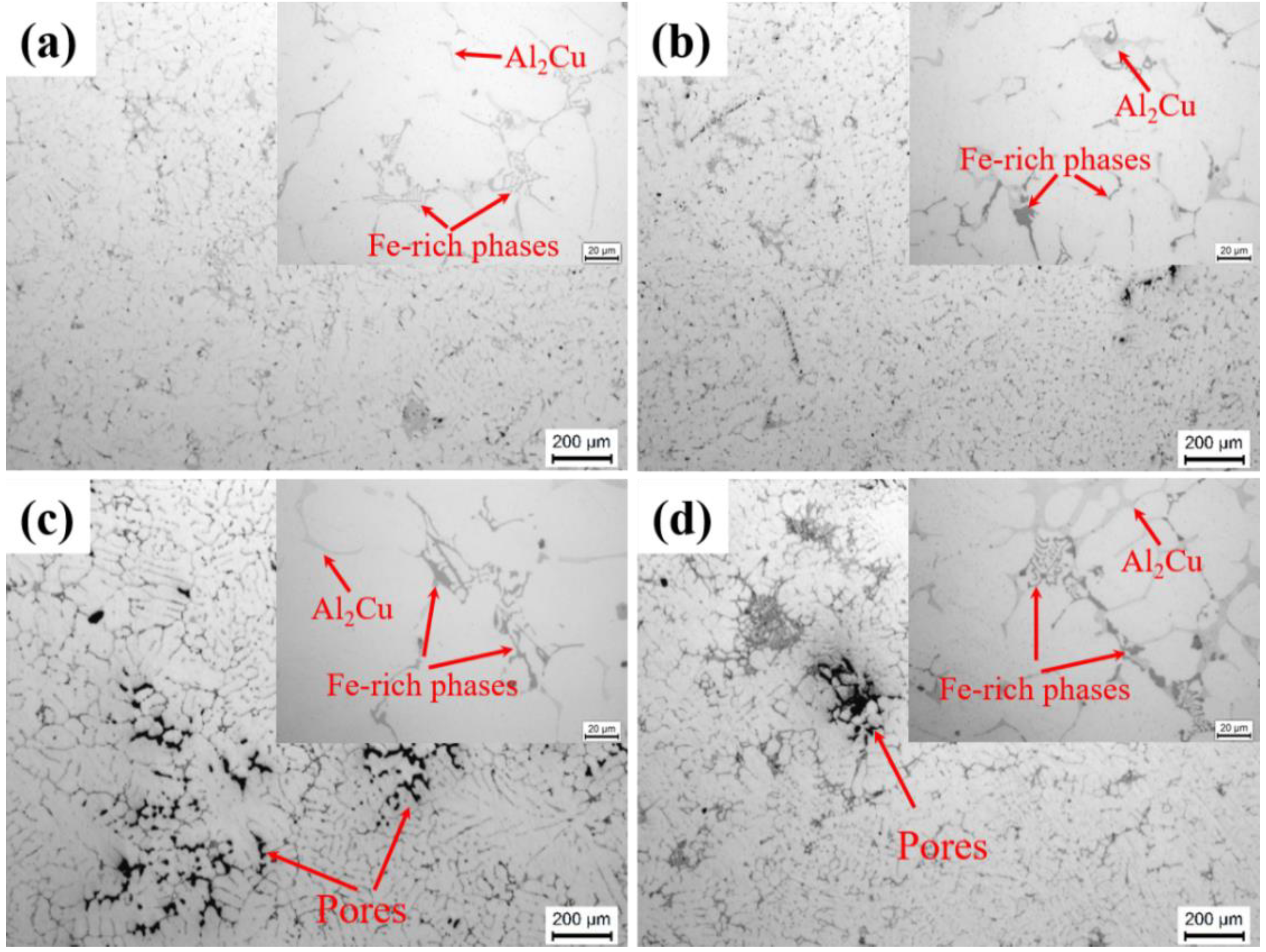

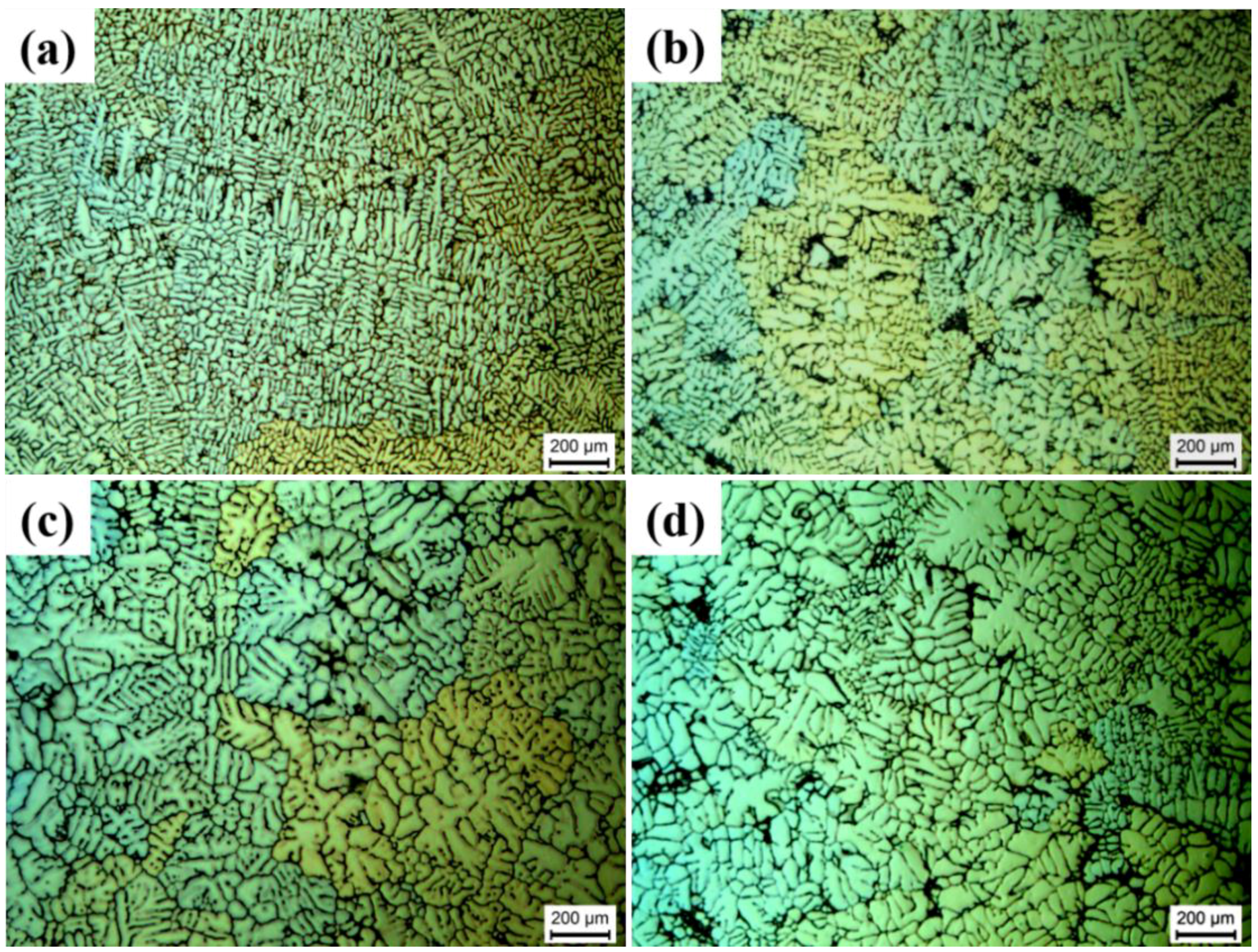

3.1. Optical Microstructure

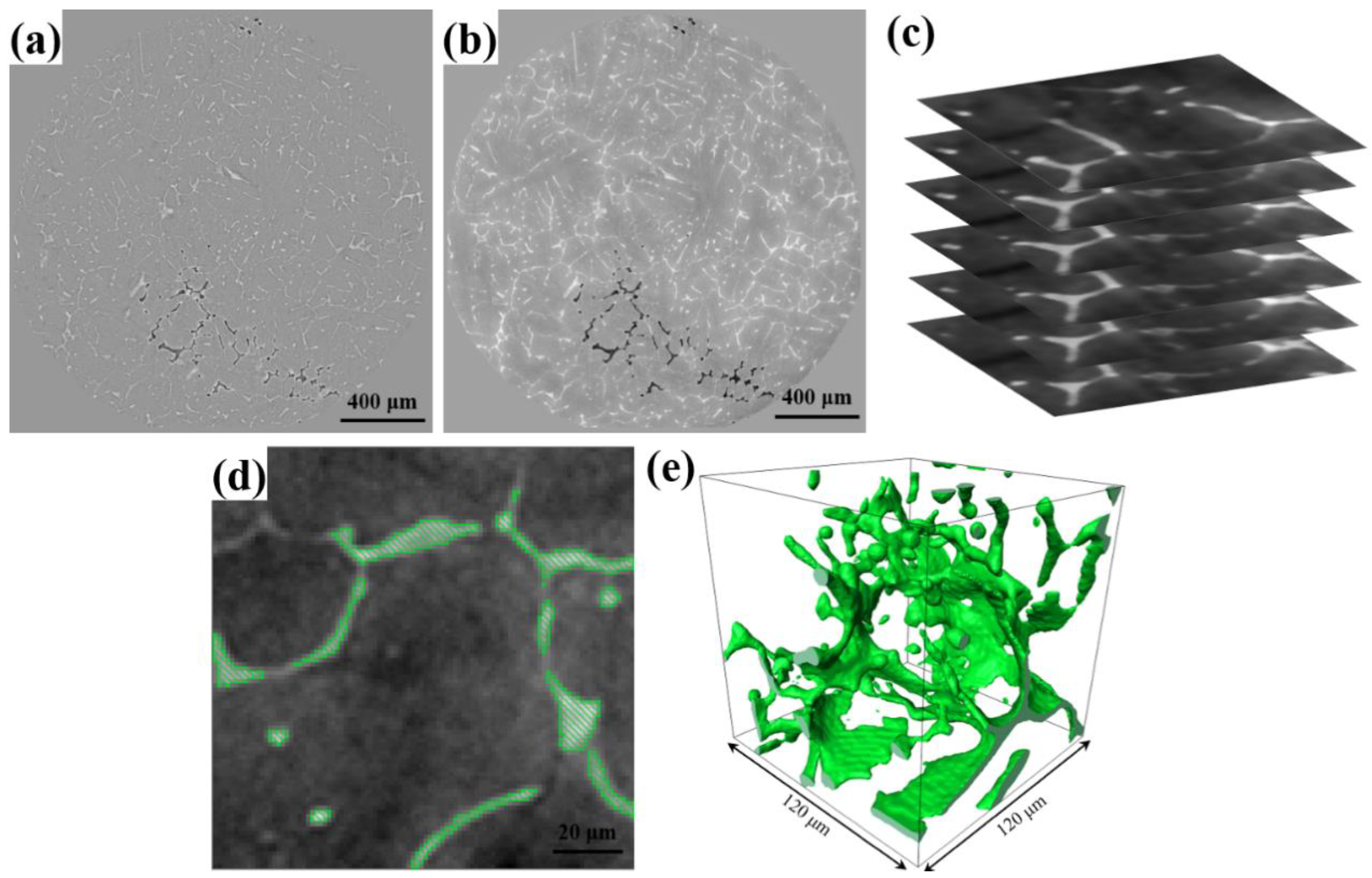

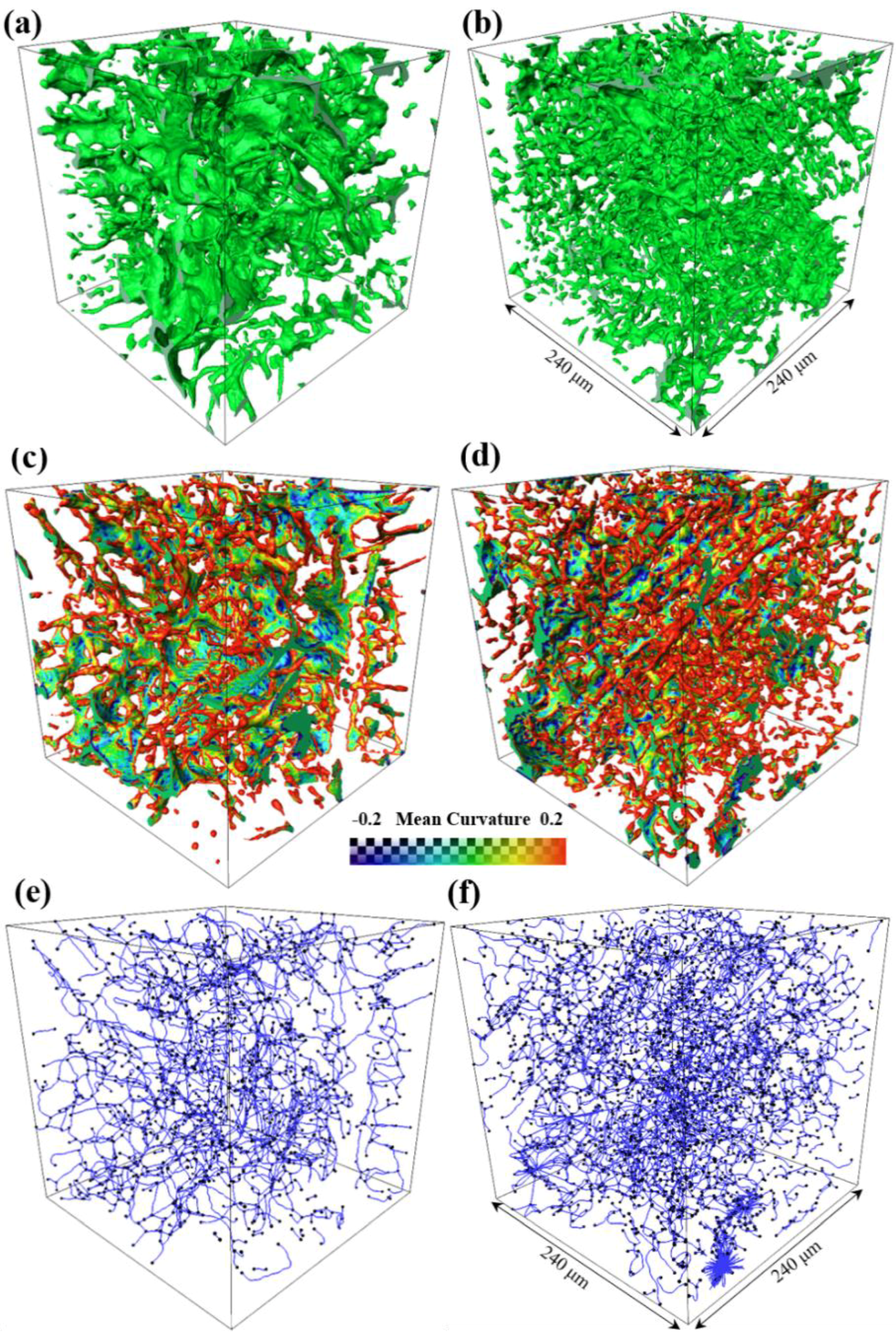

3.2. 3D Microstructure

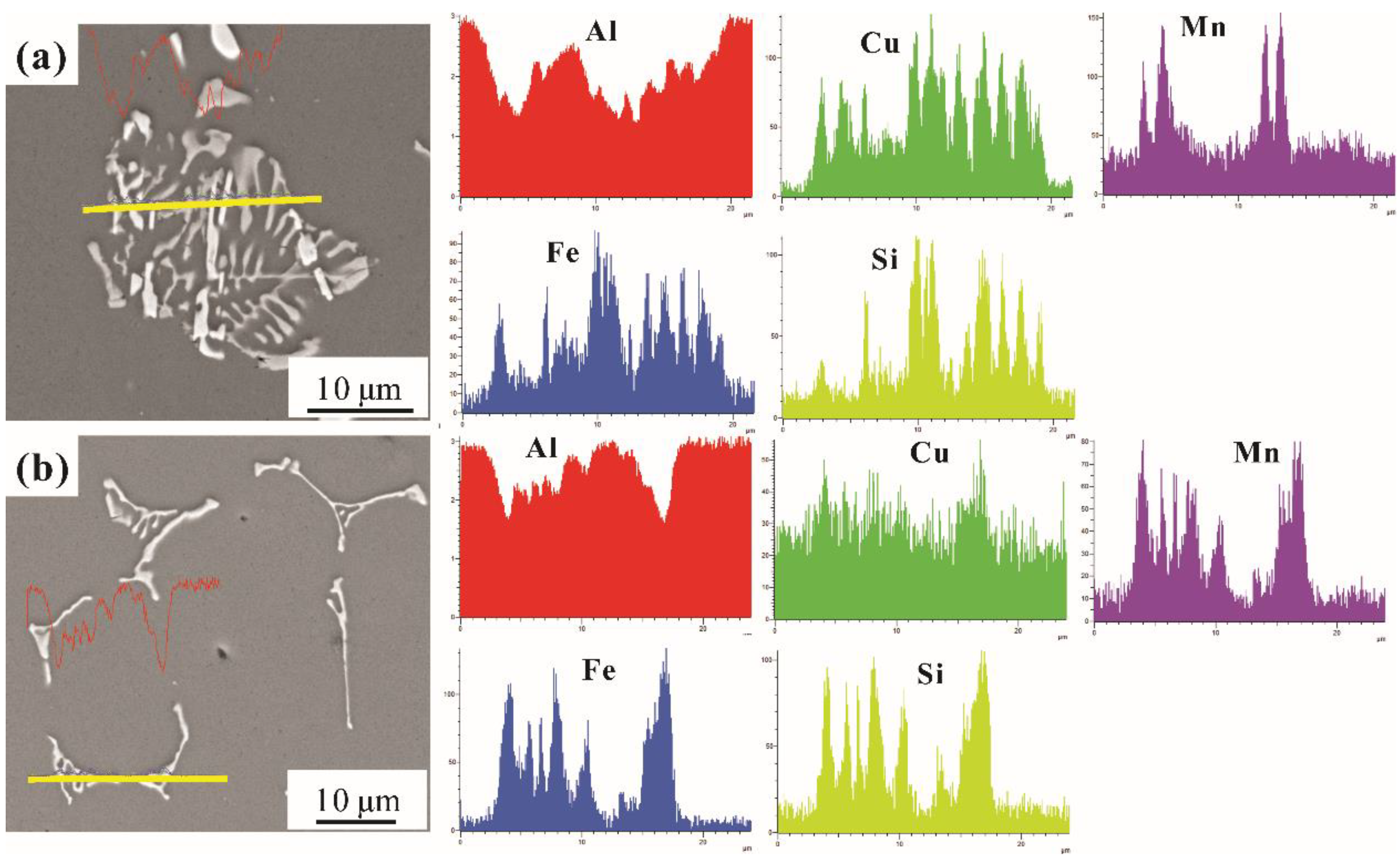

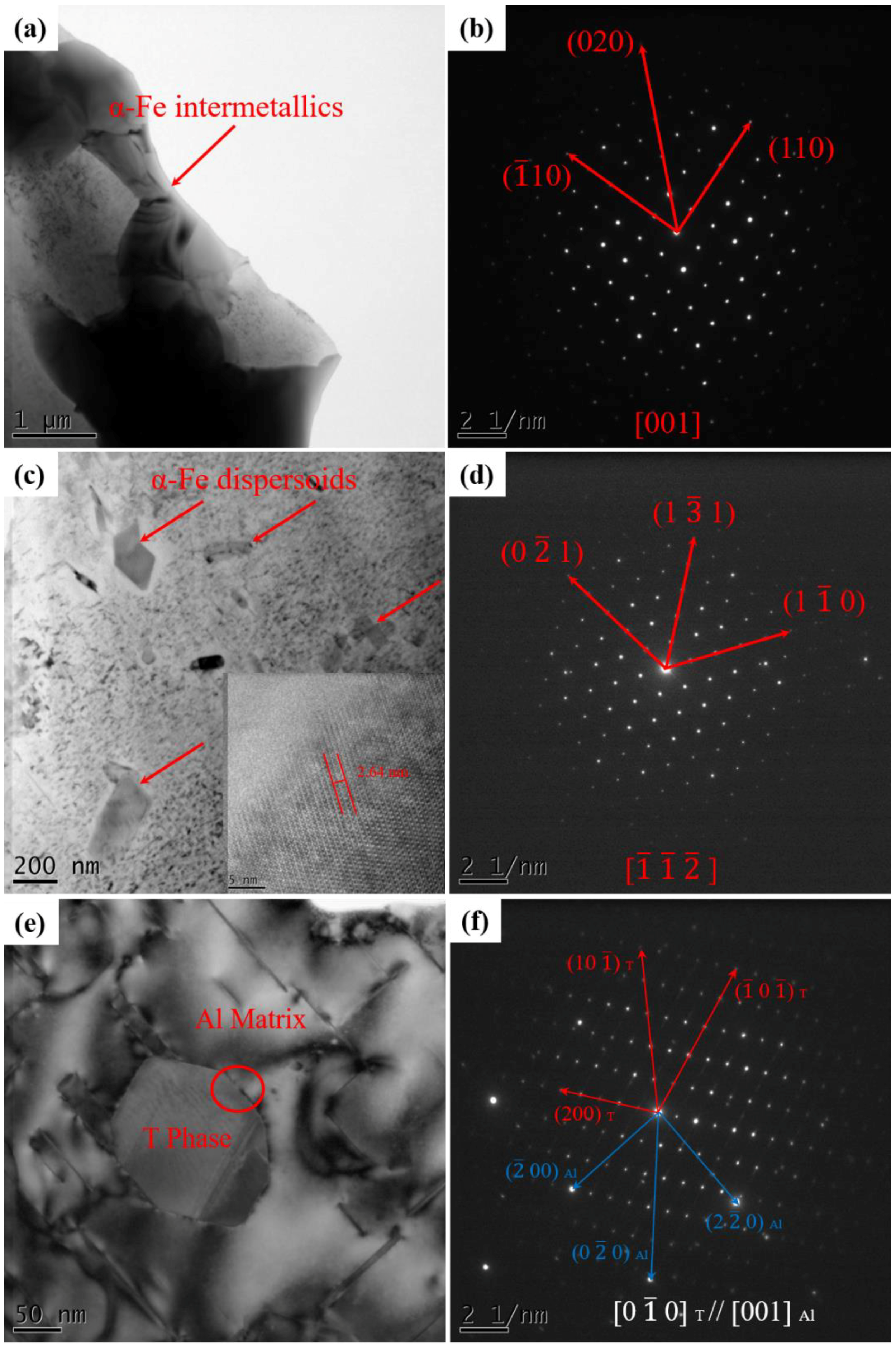

3.3. Heat Treatment Microstructural Analysis

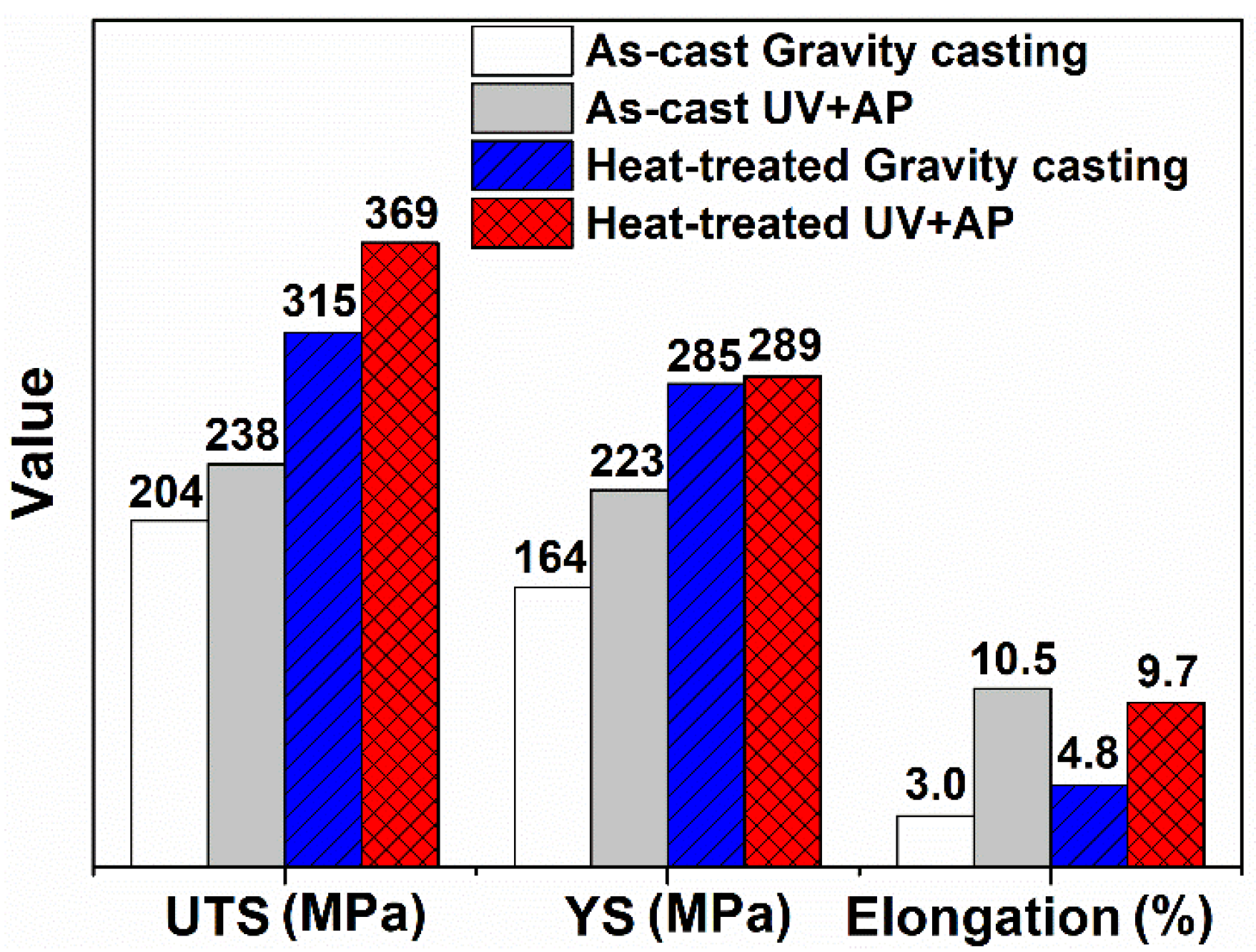

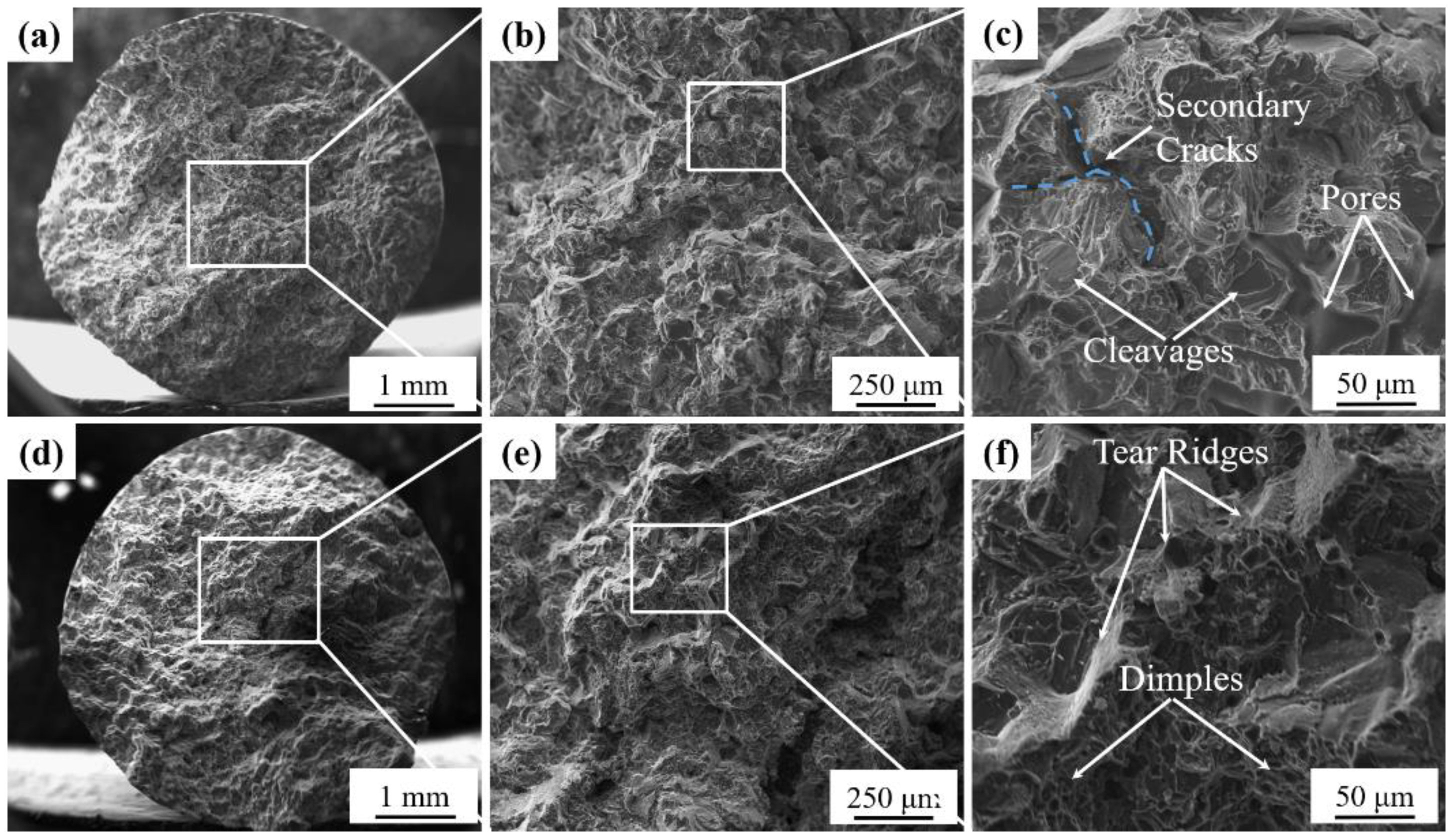

3.4. Tensile Test

4. Discussion

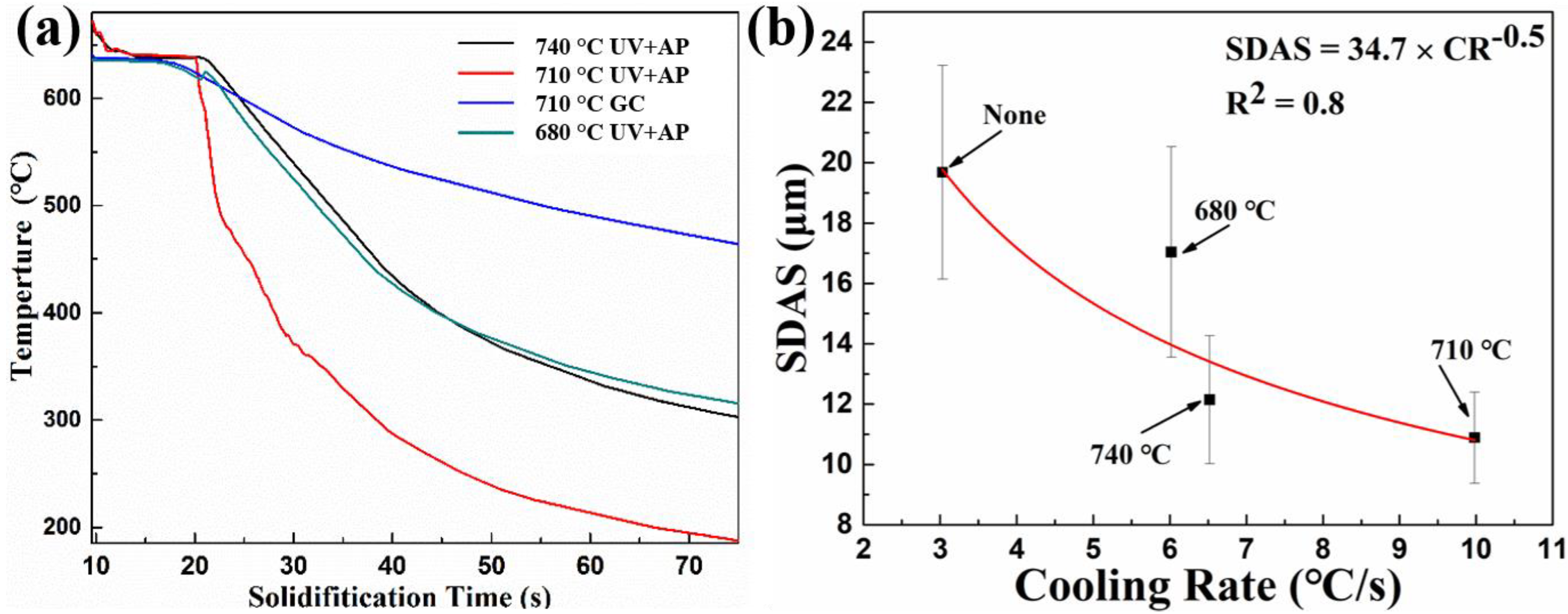

4.1. Effect of Pouring Temperature on the Microstructure

4.2. Effect of UV+AP on the 3D Microstructure

4.3. Strengthen Mechanism

4.3.1. Fine-Grained Strengthening

4.3.2. Orwan Strengthening

4.3.3. Solution Strengthening

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, W.W.; Zhu, Y.M.; Marceau, R.; Wang, L.Y.; Zhang, Q.; Gao, X.; Hutchinson, C. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity. Science 2019, 363, 972–975. [Google Scholar] [CrossRef] [PubMed]

- Kaufman, J.G.; Rooy, E.L. Aluminum Alloy Castings: Properties, Processes, and Applications; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Belov, N.A.; Aksenov, A.A.; Eskin, D.G. Iron in Aluminum Alloys: Impurity and Alloying Element; CRC Press: London, UK, 2002. [Google Scholar]

- Green, J.A.S. Aluminum Recycling and Processing for Energy Conservation and Sustainability; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Zhang, L.F.; Gao, J.W.; Damoah, L.N.W.; Robertson, D.G. Removal of iron from aluminum: A review. Miner. Process. Extr. Metall. Rev. 2012, 33, 99–157. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, W.W.; Yang, C.; Zhang, D.T.; Wang, Z. Effect of Si on Fe-rich intermetallic formation and mechanical properties of heat-treated Al-Cu-Mn-Fe alloys. J. Mater. Res. 2018, 33, 898–911. [Google Scholar] [CrossRef]

- Zhang, W.W.; Lin, B.; Cheng, P.; Zhang, D.T.; Li, Y.Y. Effects of Mn content on microstructures and mechanical properties of Al−5.0Cu−0.5Fe alloys prepared by squeeze casting. Trans. Nonferr. Met. Soc. China 2013, 23, 1525–1531. [Google Scholar] [CrossRef]

- Easton, M.A.; Qian, M.; Prasad, A.; StJohn, D.H. Recent advances in grain refinement of light metals and alloys. Curr. Opin. Solid State Mater. Sci. 2016, 20, 13–24. [Google Scholar] [CrossRef]

- Eskin, D.G.; Mi, J.W. Solidification Processing of Metallic Alloys Under External Fields; Springer: Materials Park, OH, USA, 2018. [Google Scholar]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloys Melts; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Jung, J.G.; Ahn, T.Y.; Cho, Y.H.; Kim, S.H.; Lee, J.M. Synergistic effect of ultrasonic melt treatment and fast cooling on the refinement of primary Si in a hypereutectic Al-Si alloy. Acta Mater. 2018, 144, 31–40. [Google Scholar] [CrossRef]

- Liu, Z.L.; Li, R.Q.; Jiang, R.P.; Zhang, L.H.; Li, X.Q. Scalable ultrasound-assisted casting of ultra-large 2219 Al alloy ingots. Metall. Mater. Trans. A 2019, 50, 1146–1152. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.Q.; Li, R.Q.; Jiang, R.P.; Zhang, L.H. Effects of high-intensity ultrasound on the microstructures and mechanical properties of ultra-large 2219 Al alloy ingot. Mater. Sci. Eng. A 2019, 763, 138–154. [Google Scholar] [CrossRef]

- Xuan, Y.; Liu, T.; Nastac, L.; Brewer, L.; Levin, I.; Arvikar, V. The influence of ultrasonic cavitation on the formation of Fe-rich intermetallics in A383 alloy. Metall. Mater. Trans. A 2018, 49, 3346–3357. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Wang, G.; Stjohn, D.H.; Qian, M. The effect of ultrasonic melt treatment on macro-segregation and peritectic transformation in an Al-19Si-4Fe alloy. Metall. Mater. Trans. A 2018, 48, 5579–5590. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhang, W.W.; Zhao, H.D.; You, D.D.; Zhang, D.T.; Shao, M.; Zhang, W. Research progress on squeeze casting in China. China Foundry 2014, 11, 239–246. [Google Scholar]

- Zhang, W.W.; Lin, B.; Luo, Z.; Zhao, Y.L.; Li, Y.Y. Formation of Fe-rich intermetallic compounds and their effect on the tensile properties of squeeze-cast Al-Cu alloys. J. Mater. Res. 2015, 30, 2474–2484. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, W.X.; Zheng, X.P.; Zhao, Y.L.; Lou, Z.H.; Zhang, W.W. Developing high performance mechanical properties at elevated temperature in squeeze cast Al-Cu-Mn-Fe-Ni alloys. Mater. Charact. 2019, 150, 128–137. [Google Scholar] [CrossRef]

- Zhang, W.W.; Zhao, Y.L.; Zhang, D.T.; Luo, Z.Q.; Yang, C.; Li, Y.Y. Effect of Si addition and applied pressure on microstructure and tensile properties of as-cast Al-5.0Cu-0.6Mn-1.2Fe alloys. Trans. Nonferr. Met. Soc. China 2018, 28, 1061–1072. [Google Scholar] [CrossRef]

- Yue, H.Y.; Zhang, Z.T.; Yue, H.Y.; Zhang, J.; Yang, S.T.; Li, T.J. Effect of compound field on horizontal continuous casting of Al-1wt.%Si alloy. China Foundry 2015, 12, 123–128. [Google Scholar]

- Chen, G.; Yang, M.; Jin, Y.; Zhang, H.M.; Han, F.; Chen, Q.; Zhao, Z.D. Ultrasonic assisted squeeze casting of a wrought aluminum alloy. J. Mater. Process. Technol. 2019, 266, 19–25. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Jie, J.C.; Wu, L.; Fu, Y.; Li, M.; Lu, Y.; Li, T.J. Microstructure and mechanical properties of Al-8 pct Si alloy prepared by direct chill casting under electromagnetic and ultrasonic fields. Metall. Mater. Trans. A 2014, A45, 2014–2022. [Google Scholar] [CrossRef]

- Tao, R.; Zhao, Y.T.; Kai, X.Z.; Zhao, Z.H.; Ding, R.F.; Liang, L.; Xu, W.T. Microstructures and properties of in situ ZrB2/AA6111 composites synthesized under a coupled magnetic and ultrasonic field. J. Alloys Compd. 2018, 754, 114–123. [Google Scholar] [CrossRef]

- Yuan, D.; Yang, X.; Wu, S.S.; Lü, S.L.; Hu, K. Development of high strength and toughness nano-SiCp/A356 composites with ultrasonic vibration and squeeze casting. J. Mater. Process. Technol. 2019, 269, 1–9. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, W.W.; Meng, F.S.; Wang, Z.; Zhang, D.T.; Yang, C. Microstructure and mechanical properties of as-cast Al-5.0Cu-0.6Mn-0.6Fe alloy produced by ultrasonic vibration and applied pressure. Rare Met. Mater. Eng. 2018, 47, 457–462. [Google Scholar]

- Zhao, Y.L.; Zhang, Y.; Luo, Z.; Wang, Z.; Zhang, W.W. Effect of ultrasonic vibration and applied pressure on the microstructure and mechanical property of Al-5.0Cu-0.6Mn-0.6Fe alloys. Mater. Sci. Forum 2016, 850, 559–565. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.L.; Luo, Z.; Zhao, Y.L.; Xia, W.; Zhang, W.W. Effect of applied pressure and ultrasonic vibration on microstructure and microhardness of Al-5.0Cu alloy. Trans. Nonferr. Met. Soc. China 2016, 26, 2296–2303. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed X-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef] [PubMed]

- Patrick, P.; Vanessa, W. X-ray tomography for lithium ion battery research: A practical guide. Annu. Rev. Mater. Res. 2017, 47, 451–479. [Google Scholar]

- Yu, J.M.; Wanderka, N.; Rack, A.; Daudin, R.; Boller, E.; Markötter, H.; Manzoni, A.; Vogel, F.; Arlt, T.; Manke, I.; et al. Influence of impurities, strontium addition and cooling rate on microstructure evolution in Al-10Si-0.3 Fe casting alloys. J. Alloys Compd. 2018, 766, 818–827. [Google Scholar] [CrossRef]

- Gutiérrez, R.F.; Sket, F.; Maire, E.; Wilde, F.; Boller, E.; Requena, G. Effect of solution heat treatment on microstructure and damage accumulation in cast Al-Cu alloys. J. Alloys Compd. 2017, 697, 341–352. [Google Scholar] [CrossRef]

- Wang, B.; Tan, D.Y.; Lee, T.L.; Khong, J.C.; Wang, F.; Eskin, D.; Connolley, T.; Fezzaa, K.; Mi, J. Ultrafast synchrotron X-ray imaging studies of microstructure fragmentation in solidification under ultrasound. Acta Mater. 2018, 144, 505–515. [Google Scholar] [CrossRef]

- Daudin, R.; Terzi, S.; Lhuissier, P.; Tamayo, J.; Scheel, M.; Babu, N.H.; Eskin, D.G.; Salvo, L. Particle-induced morphological modification of Al alloy equiaxed dendrites revealed by sub-second in situ microtomography. Acta Mater. 2017, 125, 303–310. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Song, D.F.; Lin, B.; Zhang, C.; Zheng, D.H.; Inguva, S.; Li, T.; Sun, Z.Z.; Wang, Z.; Zhang, W.W. 3D characterization of ultrasonic melt processing on the microstructural refinement of Al-Cu alloys by synchrotron X-ray tomography. Mater. Charact. 2019, 153, 354–365. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, W.; Koe, B.; Connolley, T.; Irvine, S.; Allan, P.K.; Schlepütz, C.M.; Zhang, W.; Wang, F.; Eskin, D.G.; et al. 3D Characterisation of the Fe-rich intermetallic phases in recycled Al alloys by synchrotron X-ray microtomography and skeletonisation. Scr. Mater. 2018, 146, 321–326. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, Z.; Zhang, C.; Zhang, W.W. Synchrotron X-ray tomography investigation of 3D morphology of intermetallic phases and pores and their effect on the mechanical properties of cast Al-Cu alloys. J. Alloys Compd. 2019, 777, 1054–1065. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Thermo Scientific Avizo Software 9 User’s Guide; Thermo Fisher Scientific: Munich, Germany, 2018.

- Mendoza, R.; Alkemper, J.; Voorhees, P.W. The morphological evolution of dendritic microstructures during coarsening. Metall. Mater. Trans. A 2003, 34, 481–489. [Google Scholar] [CrossRef]

- Li, Y.J.; Muggerud, A.M.F.; Olsen, A.; Furu, T. Precipitation of partially coherent α-Al(Mn,Fe)Si dispersoids and their strengthening effect in AA 3003 alloy. Acta Mater. 2012, 60, 1004–1014. [Google Scholar] [CrossRef]

- Flemings, M.C. Solidification Process; Macgrraw-Hill: New York, NY, USA, 1974. [Google Scholar]

- Dixit, M.; Mishra, R.; Sankaran, K. Structure-property correlations in Al 7050 and Al 7055 high-strength aluminum alloys. Mater. Sci. Eng. A 2008, 478, 163–172. [Google Scholar] [CrossRef]

- Li, Y.J.; Arnberg, L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Mater. 2003, 51, 3415–3428. [Google Scholar] [CrossRef]

| Nominal Composition | Cu | Mn | Fe | Si | Al |

|---|---|---|---|---|---|

| Al-5.0Cu-0.6Mn-0.5Fe-0.6 Si | 5.67 | 0.65 | 0.51 | 0.66 | Bal. |

| Casting Conditions | Total Volume (μm3) | Number of Segment | Mean Length (μm) | Number of Node | Mean Radius |

|---|---|---|---|---|---|

| Gravity casting | 121,712 | 2043 | 17.38 | 1723 | 0.789 |

| UV+AP | 98,209 | 3624 | 17.21 | 2926 | 0.658 |

| Phases | Al | Cu | Mn | Fe | Si | Identified Phases |

|---|---|---|---|---|---|---|

| White | 78.7 | 13.1 | 1.1 | 6.0 | 1.1 | α(CuFe) (Al7Cu2Fe) |

| Grey | 73.6 | 4.3 | 4.7 | 9.7 | 7.7 | α-Fe (Al15(FeMn)3(SiCu)2) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Lin, B.; Song, D.; Zheng, D.; Sun, Z.; Xie, C.; Zhang, W. Effect of Compound Fields of Ultrasonic Vibration and Applied Pressure on the 3D Microstructure and Tensile Properties of Recycled Al-Cu-Mn-Fe-Si Alloys. Materials 2019, 12, 3904. https://doi.org/10.3390/ma12233904

Zhao Y, Lin B, Song D, Zheng D, Sun Z, Xie C, Zhang W. Effect of Compound Fields of Ultrasonic Vibration and Applied Pressure on the 3D Microstructure and Tensile Properties of Recycled Al-Cu-Mn-Fe-Si Alloys. Materials. 2019; 12(23):3904. https://doi.org/10.3390/ma12233904

Chicago/Turabian StyleZhao, Yuliang, Bo Lin, Dongfu Song, Donghai Zheng, Zhenzhong Sun, Chunxiao Xie, and Weiwen Zhang. 2019. "Effect of Compound Fields of Ultrasonic Vibration and Applied Pressure on the 3D Microstructure and Tensile Properties of Recycled Al-Cu-Mn-Fe-Si Alloys" Materials 12, no. 23: 3904. https://doi.org/10.3390/ma12233904

APA StyleZhao, Y., Lin, B., Song, D., Zheng, D., Sun, Z., Xie, C., & Zhang, W. (2019). Effect of Compound Fields of Ultrasonic Vibration and Applied Pressure on the 3D Microstructure and Tensile Properties of Recycled Al-Cu-Mn-Fe-Si Alloys. Materials, 12(23), 3904. https://doi.org/10.3390/ma12233904