Hydration Kinetics of Portland Cement–Silica Fume Binary System at Low Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods

2.3. Hydration Kinetics Model Based on Krstulovic–Dabic Equation

3. Results and Discussion

3.1. Hydration Heat Analysis of Portland Cement–Silica Fume Binary System

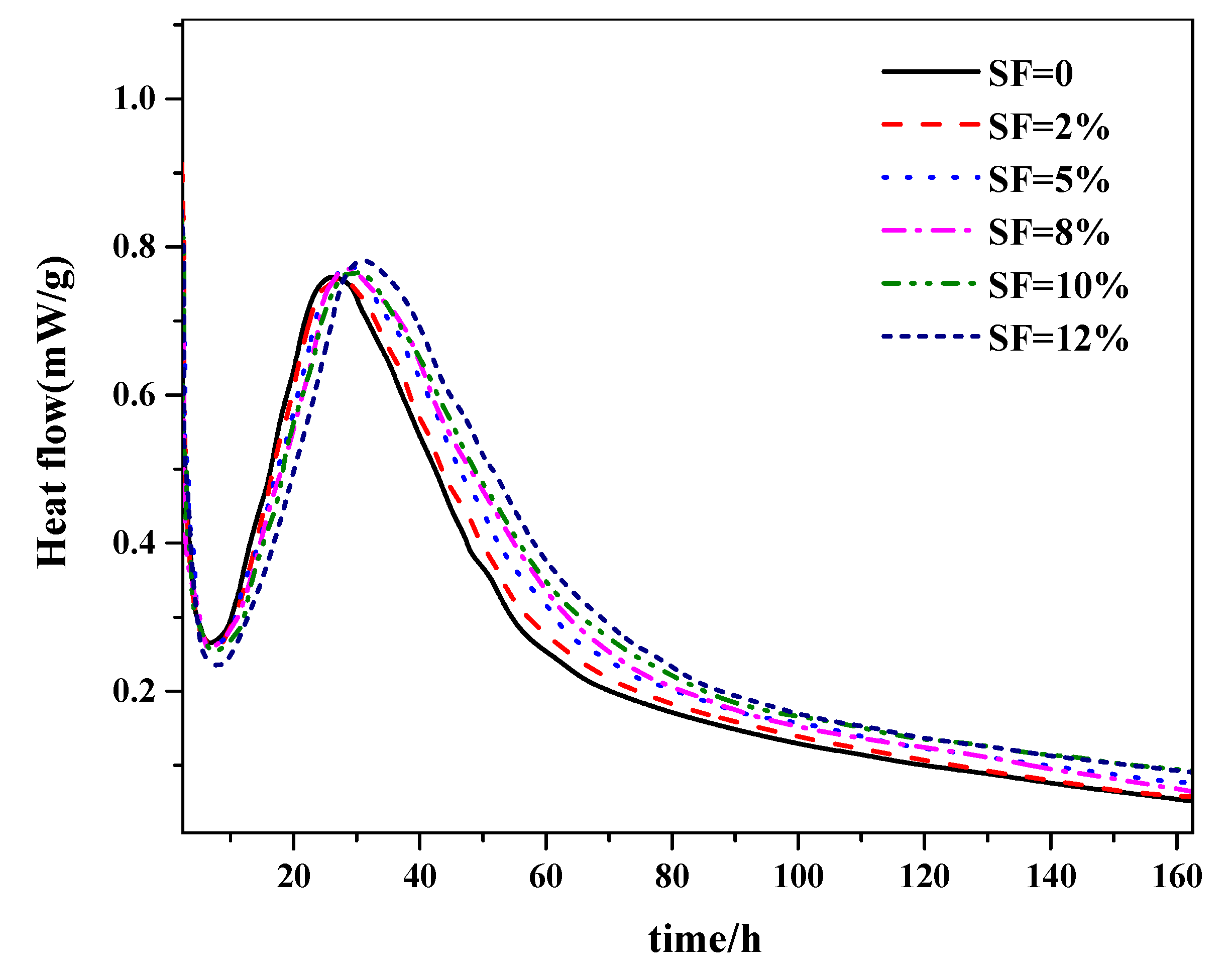

3.1.1. Effect of Silica Fume on the Hydration Heat and Hydration Rate

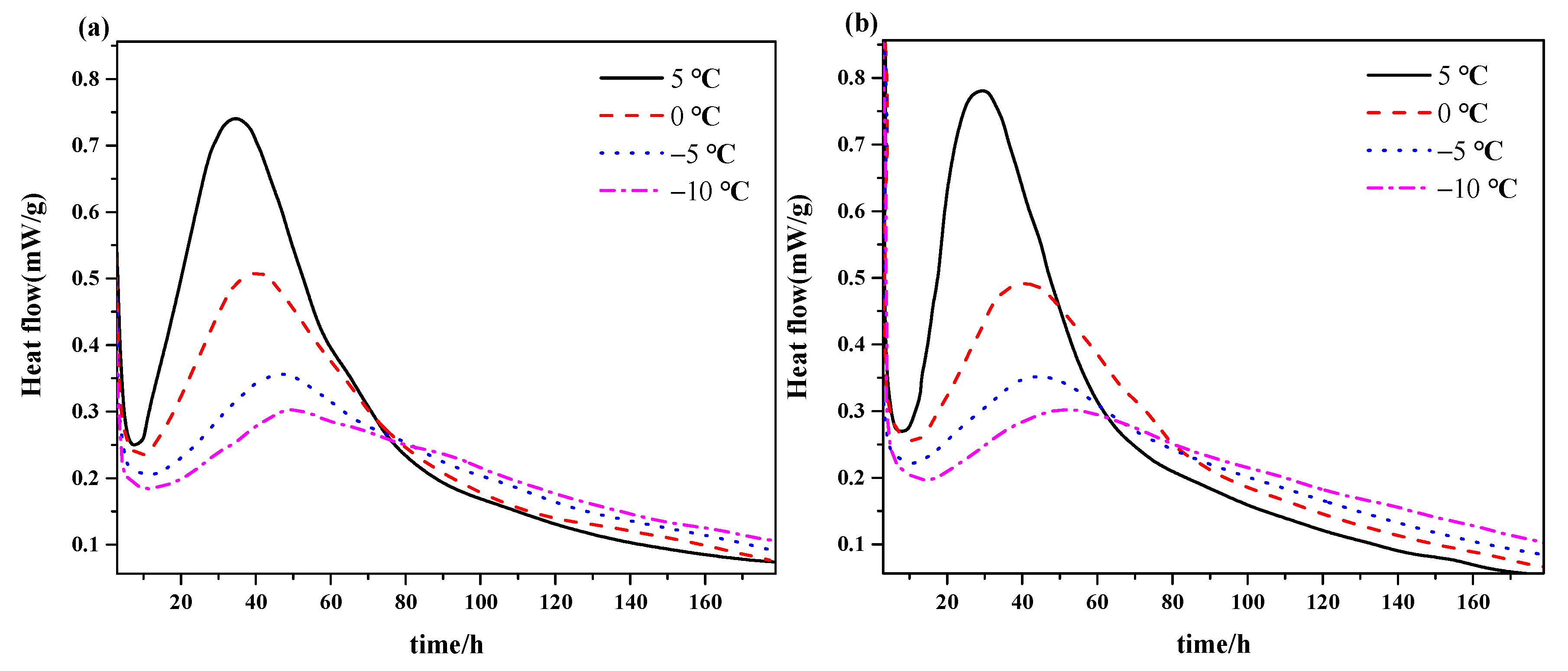

3.1.2. Effect of Temperature on the Hydration Heat and Rate

3.2. Hydration Kinetics Model of Composition Cementing Material at Low Temperature

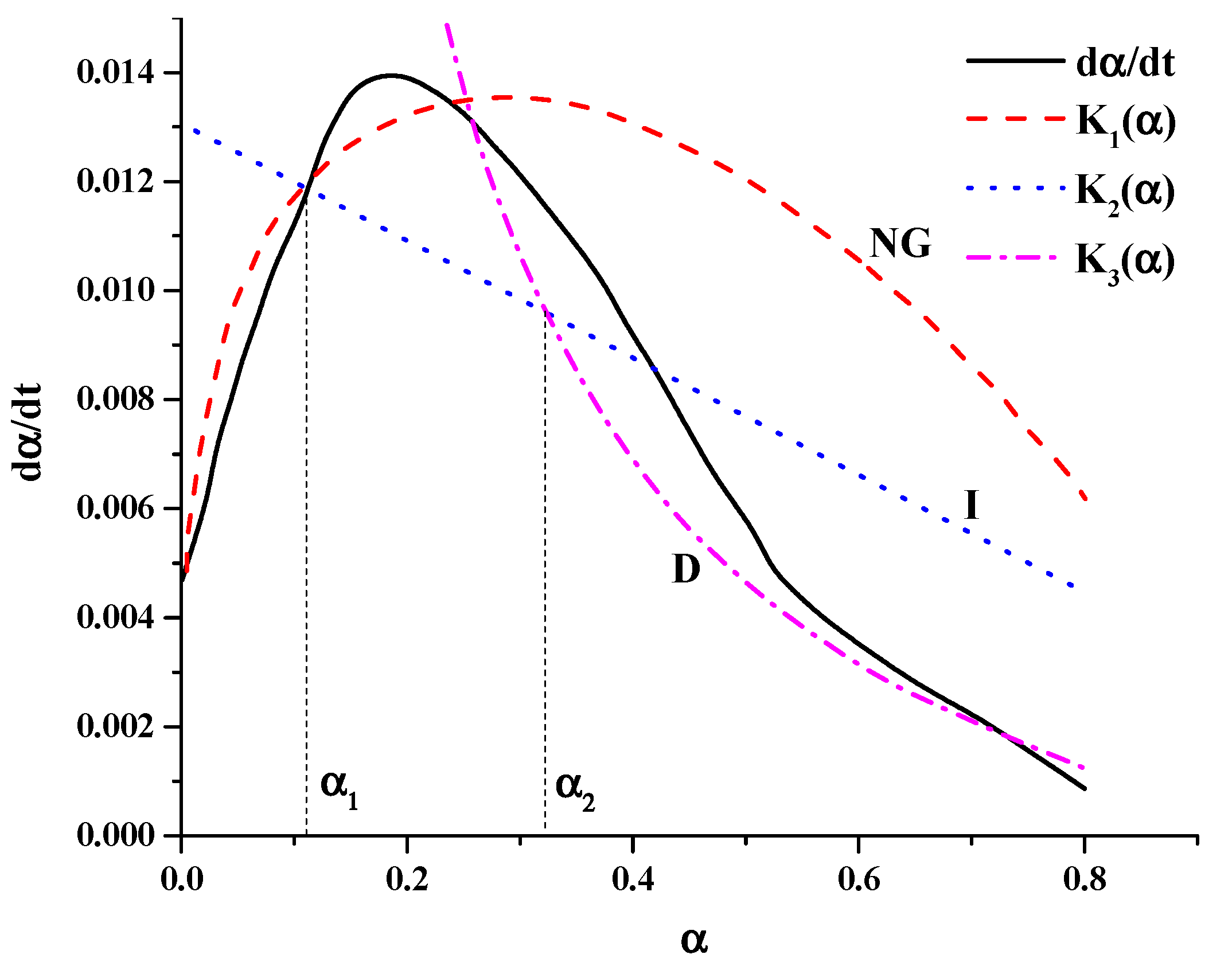

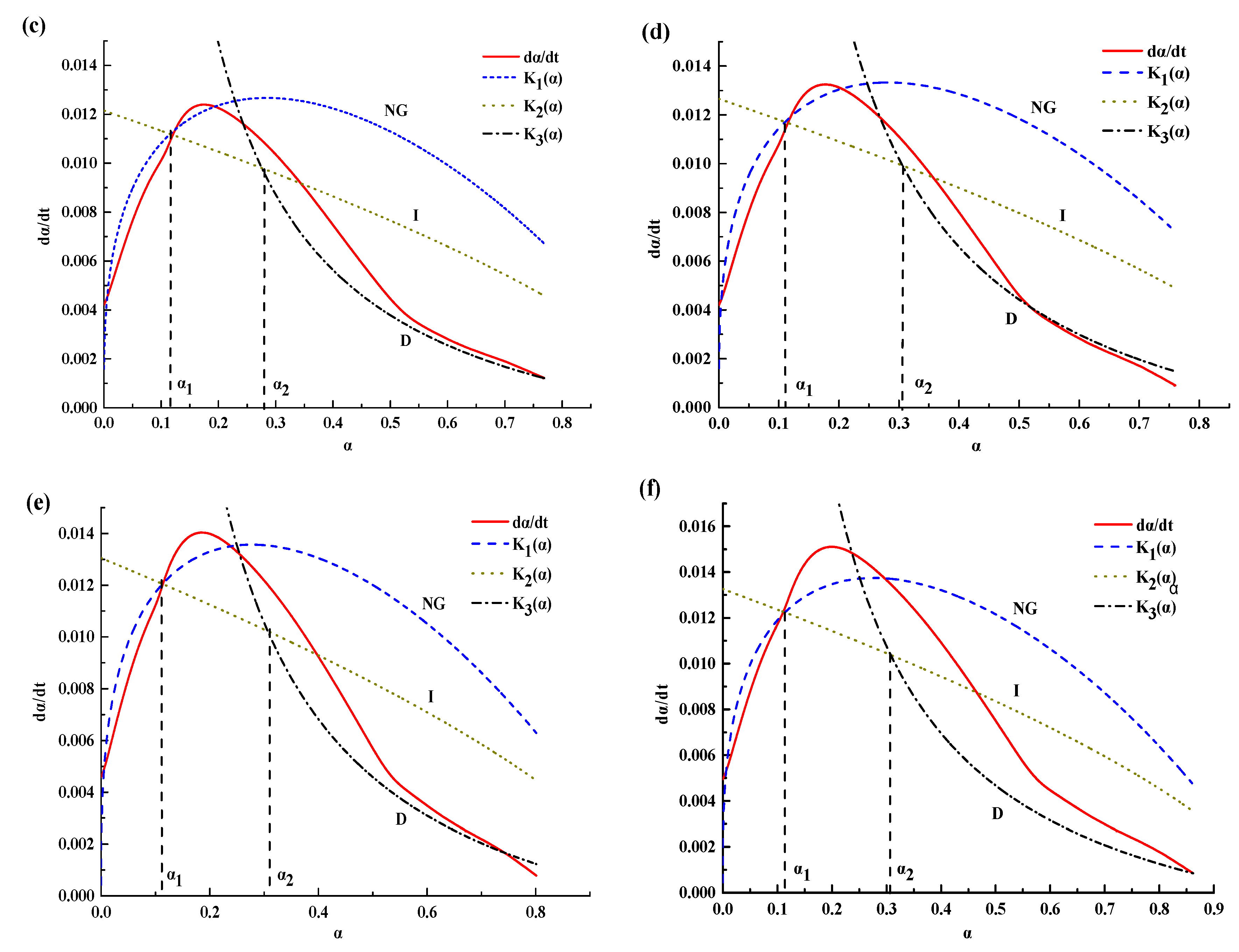

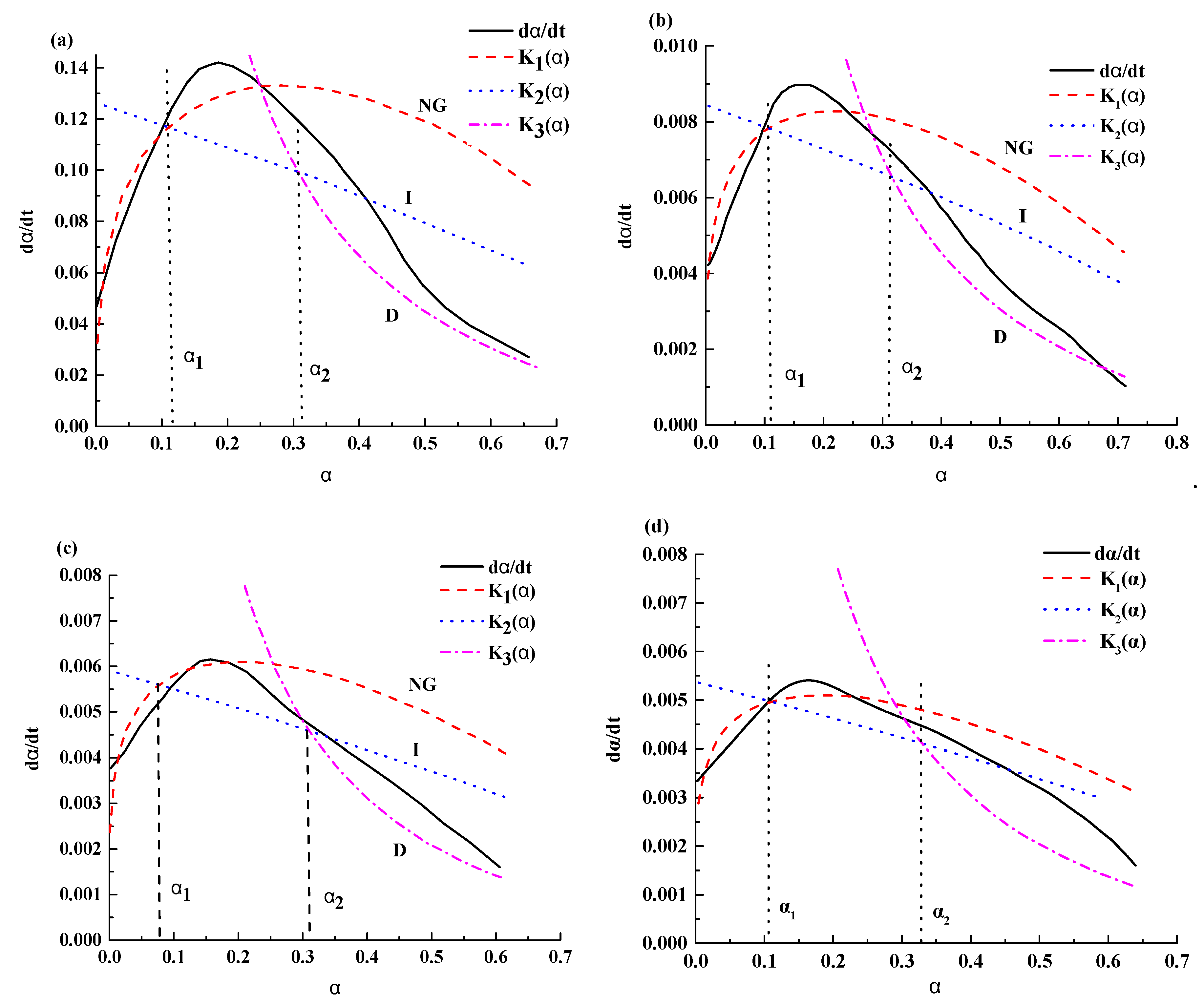

3.2.1. Analyze the Model Calculation’s Result Based on Krstulovic–Dabic Equation

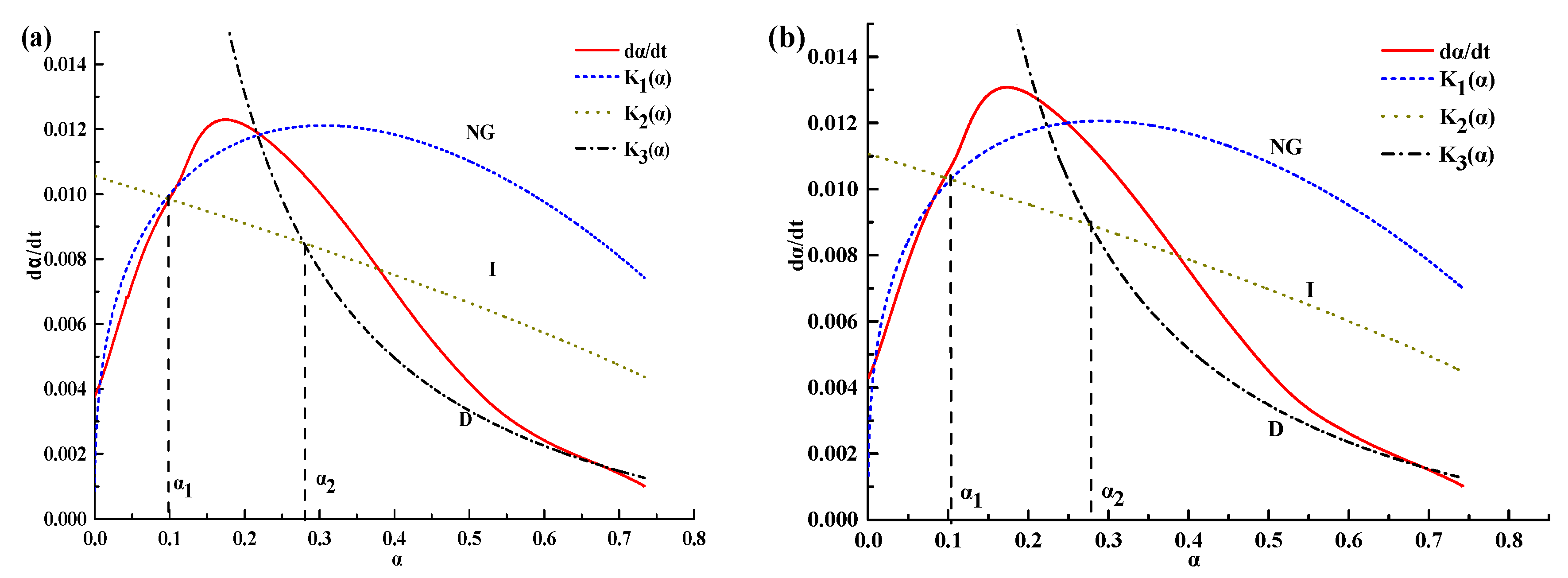

3.2.2. Effect of Silica Fume on the Hydration Kinetics Evolution

3.2.3. Effect of Temperature on the Hydration Kinetics Evolution

4. Conclusions

- (1)

- The hydration process of the binary system at low temperature could be divided into three stages, namely, nucleation and growth (NG), interactions at phase boundaries (I), and diffusion (D);

- (2)

- The n values for the binary system varied in the range of 1.2 to 1.6, indicating that the hydration of the binary system at low temperature was a complex elementary reaction;

- (3)

- Silica fume can reduce the total heat at the later stage of the hydration and the reaction order n, but increase the heat flow at the accelerating stage and the hydration rate constant K. Low temperature prolonged the hydration induction period, decreased and delayed the secondary exothermic peak, as well as reduced the n and K value.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, T.; Chen, H.; Li, X.; Zhu, Z. Hydration behavior of magnesium potassium phosphate cement and stability analysis of its hydration products through thermodynamic modeling. Cem. Concr. Res. 2017, 98, 101–110. [Google Scholar] [CrossRef]

- Cabrera-Luna, K.; Maldonado-Bandala, E.E.; Nieves-Mendoza, D.; Garcia, J.I.E. Supersulfated binders based on volcanic raw material: Optimization, microstructure and reaction products. Constr. Build. Mater. 2018, 176, 145–155. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, P.; Liu, S.; Gao, Z. Hydration and microstructure of cement-based materials under microwave curing. Constr. Build. Mater. 2016, 114, 831–838. [Google Scholar] [CrossRef]

- Rogers, A.K.; Stevenson, C.M. Protocols for laboratory hydration of obsidian, and their effect on hydration rate accuracy: A Monte Carlo simulation study. J. Archaeol. Sci. Rep. 2017, 16, 117–126. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Y.X. Coupling of chemical kinetics and thermodynamics for simulations of leaching of cement paste in ammonium nitrate solution. Cem. Concr. Res. 2017, 95, 95–107. [Google Scholar] [CrossRef]

- Damidot, D.; Lothenbach, B.; Herfort, D.; Glasser, F.P. Thermodynamics and cement science. Cem. Concr. Res. 2011, 41, 679–695. [Google Scholar] [CrossRef]

- Ba, H.; Gong, C.; Lin, T.; Zhongmao, H.; Yao, L. Hydration kinetics of C3S in a NaNO2 solution at negative temperature. J. Chin. Ceram. Soc. 1996, 24, 466–469. [Google Scholar]

- Yan, P.; Xu, L.; Zhang, G. Hydration Properties of Portland Cement at 0°C~20°C. Mater. Rev. (China) 2012, 26, 114–117. [Google Scholar]

- He, M.; Ba, H.; Wang, Y. Research and Argument on the Thermodynamic Model of Cement Hydration at Minus Temperature. Mater. Sci. Technol. 2005, 13, 435–437. [Google Scholar]

- Wang, X.Y.; Lee, H.S. Modeling of hydration kinetics in cement based materials considering the effects of curing temperature and applied pressure. Constr. Build. Mater. 2012, 28, 1–13. [Google Scholar] [CrossRef]

- De Schutter, G. Hydration and temperature development of concrete made with blast-furnace slag cement. Cem. Concr. Res. 1999, 29, 143–149. [Google Scholar] [CrossRef]

- De Schutter, G.; Taerwe, L. General Hydration Model for Portland Cement and Blast Furnace Slag Cement. Cem. Concr. Res. 1995, 3, 593–604. [Google Scholar] [CrossRef]

- Wang, X.Y.; Cho, H.K.; Lee, H.S. Prediction of temperature distribution in concrete incorporating fly ash or slag using a hydration model. Compos. Part B Eng. 2011, 42, 27–40. [Google Scholar] [CrossRef]

- Papadakis, V.G. Experimental investigation and theoretical modeling of silica fume activity in concrete. Cem. Concr. Res. 1999, 29, 79–86. [Google Scholar] [CrossRef]

- Krstulović, R.; Dabić, P. A conceptual model of the cement hydration process. Cem. Concr. Res. 2000, 30, 693–698. [Google Scholar] [CrossRef]

- Yan, P.; Zheng, F. Kinetics model for the hydration mechanism of cementitious materials. J. Chin. Ceram. Soc. 2006, 35, 555–559. [Google Scholar]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Bentz, D.P.; Garboczi, E.J. Percolation of phases in a three-dimensional cement paste microstructural mode. Cem. Concr. Res. 1991, 21, 325–344. [Google Scholar] [CrossRef]

- Martinelli, E.; Eduardus, A.B. A numerical recipe for modelling hydration and heat flow in hardening concrete. Cem. Concr. Compos. 2013, 40, 48–58. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0958946513000516 (accessed on 14 November 2019). [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | NaO2 | Loss | Others |

|---|---|---|---|---|---|---|---|---|

| 63.66 | 21.26 | 4.50 | 2.80 | 1.66 | 2.58 | 0.18 | 2.66 | 0.7 |

| SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | MgO | K2O | Loss | Others |

|---|---|---|---|---|---|---|---|---|

| 86.62 | 0.51 | 1.52 | 1.02 | 0.58 | 2.77 | 2.03 | 3.88 | 1.07 |

| No. | Cement (g) | Silica Fume (g) | Water (g) | Sodium Nitrite (g) | Sand (g) |

|---|---|---|---|---|---|

| A | 450 | 0 | 189 | 0 | 1350 |

| B | 441 | 9 | 189 | 0 | 1350 |

| C | 427.5 | 22.5 | 189 | 0 | 1350 |

| D | 414 | 36 | 189 | 0 | 1350 |

| E | 405 | 45 | 189 | 0 | 1350 |

| F | 396 | 54 | 189 | 0 | 1350 |

| G | 450 | 0 | 189 | 38.25 | 1350 |

| H | 441 | 9 | 189 | 38.25 | 1350 |

| I | 427.5 | 22.5 | 189 | 38.25 | 1350 |

| J | 414 | 36 | 189 | 38.25 | 1350 |

| K | 405 | 45 | 189 | 38.25 | 1350 |

| L | 396 | 54 | 189 | 38.25 | 1350 |

| n | NG | I | D | α1 | α2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| KNG | sd | KI | sd | KD | sd | ||||

| 0 | 1.57 | 1.60×10−2 | 2.33×10−3 | 3.52×10−3 | 1.32×10−2 | 7.28×10−4 | 1.05×10−3 | 0.1 | 0.28 |

| 2% | 1.52 | 1.61×10−2 | 3.52×10−3 | 3.69×10−3 | 8.96×10−3 | 7.59×10−4 | 8.37×10−4 | 0.1 | 0.28 |

| 5% | 1.5 | 1.70×10−2 | 1.32×10−3 | 4.05×10−3 | 8.57×10−3 | 8.26×10−4 | 6.34×10−4 | 0.12 | 0.28 |

| 8% | 1.49 | 1.79×10−2 | 4.68×10−3 | 4.22×10−3 | 7.50×10−3 | 9.67×10−4 | 4.57×10−4 | 0.11 | 0.31 |

| 10% | 1.48 | 1.83×10−2 | 3.00×10−3 | 4.35×10−3 | 7.02×10−3 | 1.00×10−3 | 1.47×10−3 | 0.11 | 0.31 |

| 12% | 1.48 | 1.85×10−2 | 3.58×10−3 | 4.42×10−3 | 7.84×10−3 | 1.02×10−3 | 1.39×10−3 | 0.12 | 0.31 |

| n | NG | I | D | α1 | α2 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| KNG | sd | KI | sd | KD | sd | |||||

| Pure cement | 5℃ | 1.57 | 1.60×10−2 | 2.08×10−3 | 3.52×10−3 | 1.20×10−2 | 7.28×10−4 | 1.79×10−3 | 0.10 | 0.28 |

| 0℃ | 1.36 | 9.27×10−3 | 7.70×10−3 | 2.39×10−3 | 7.70×10−3 | 4.50×10−4 | 2.30×10−3 | 0.13 | 0.26 | |

| −5℃ | 1.32 | 7.02×10−3 | 6.92×10−4 | 1.66×10−3 | 3.75×10−3 | 3.14×10−4 | 5.29×10−3 | 0.08 | 0.26 | |

| −10℃ | 1.29 | 5.89×10−3 | 1.28×10−3 | 1.43×10−3 | 1.05×10−2 | 3.05×10−4 | 1.44×10−2 | 0.09 | 0.29 | |

| 8% silica fume | 5℃ | 1.49 | 1.79×10−2 | 2.48×10−3 | 4.22×10−3 | 3.98×10−3 | 9.67×10−4 | 2.26×10−3 | 0.11 | 0.31 |

| 0℃ | 1.32 | 1.13×10−2 | 3.15×10−3 | 2.81×10−3 | 4.79×10−3 | 6.66×10−4 | 4.09×10−4 | 0.11 | 0.32 | |

| −5℃ | 1.29 | 8.29×10−3 | 2.10×10−3 | 1.97×10−3 | 3.69×10−4 | 4.57×10−4 | 3.14×10−3 | 0.08 | 0.31 | |

| −10℃ | 1.25 | 6.87×10−3 | 2.64×10−3 | 1.79×10−3 | 7.49×10−3 | 4.41×10−4 | 1.05×10−2 | 0.11 | 0.33 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Deng, Y.; Liu, R. Hydration Kinetics of Portland Cement–Silica Fume Binary System at Low Temperature. Materials 2019, 12, 3896. https://doi.org/10.3390/ma12233896

Li Y, Deng Y, Liu R. Hydration Kinetics of Portland Cement–Silica Fume Binary System at Low Temperature. Materials. 2019; 12(23):3896. https://doi.org/10.3390/ma12233896

Chicago/Turabian StyleLi, Yao, Yonggang Deng, and Runqing Liu. 2019. "Hydration Kinetics of Portland Cement–Silica Fume Binary System at Low Temperature" Materials 12, no. 23: 3896. https://doi.org/10.3390/ma12233896

APA StyleLi, Y., Deng, Y., & Liu, R. (2019). Hydration Kinetics of Portland Cement–Silica Fume Binary System at Low Temperature. Materials, 12(23), 3896. https://doi.org/10.3390/ma12233896