Properties of Mortar with Recycled Aggregates, and Polyacrylonitrile Microfibers Synthesized by Electrospinning

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

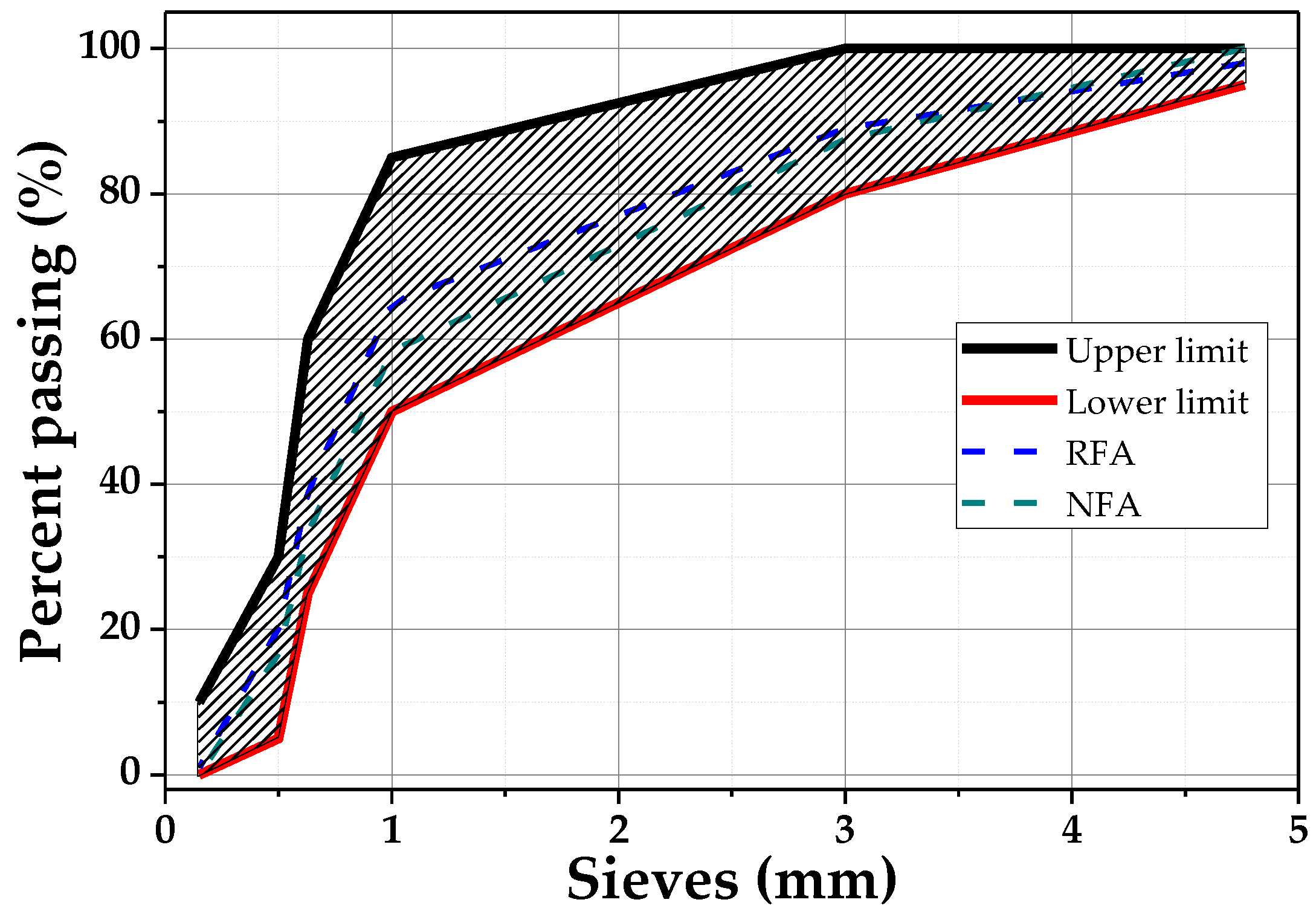

2.2. Production of Recycled Fine Aggregate

2.3. Production of PAN Microfiber by Electrospinning

Dispersion of Microfibers in Aqueous Medium

2.4. Design of Mortar Mix

2.5. Preparation of Specimens and Test Procedures

3. Results and Discussion

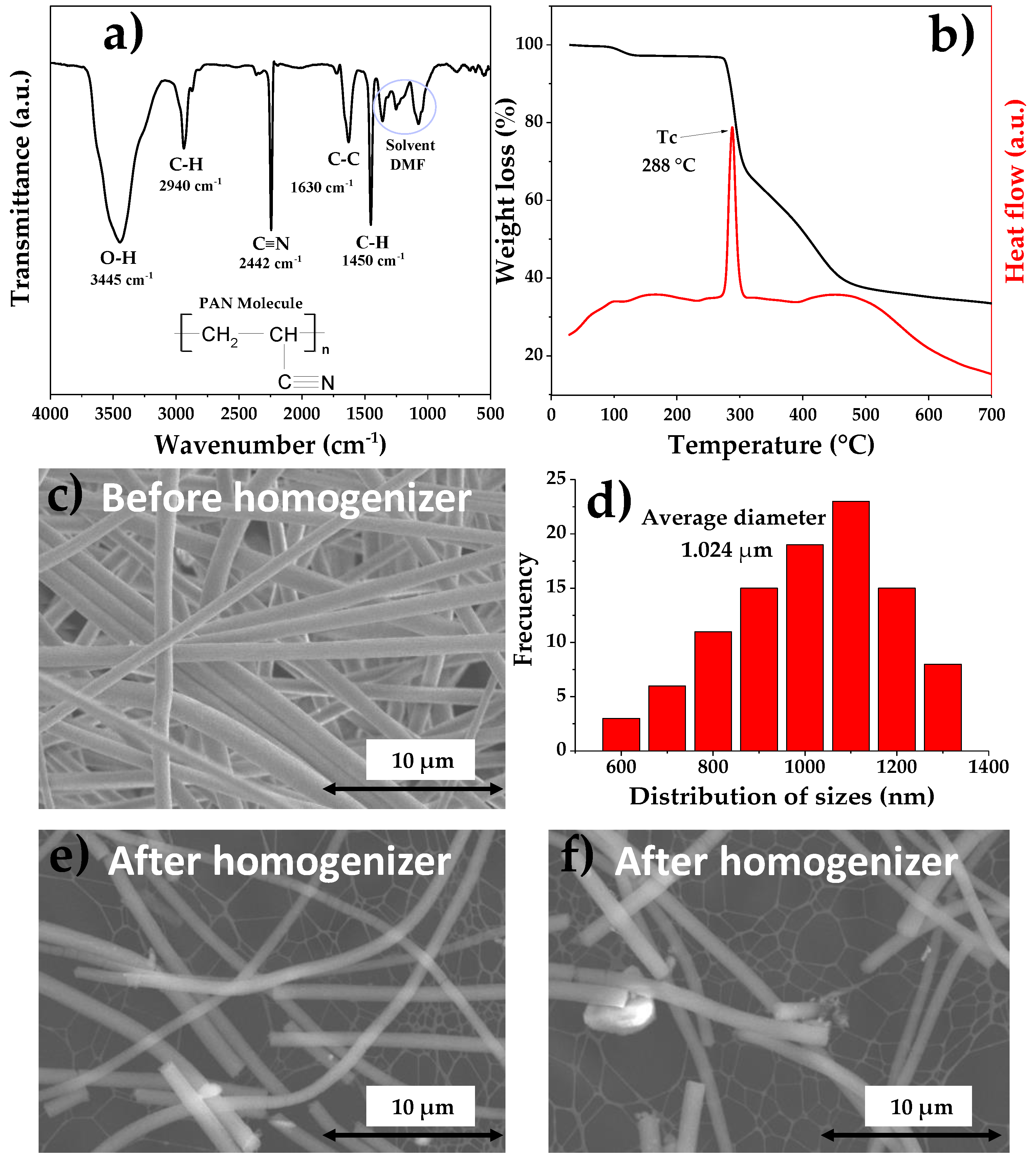

3.1. Microfibers of PAN by Electrospinning

3.2. Mortar

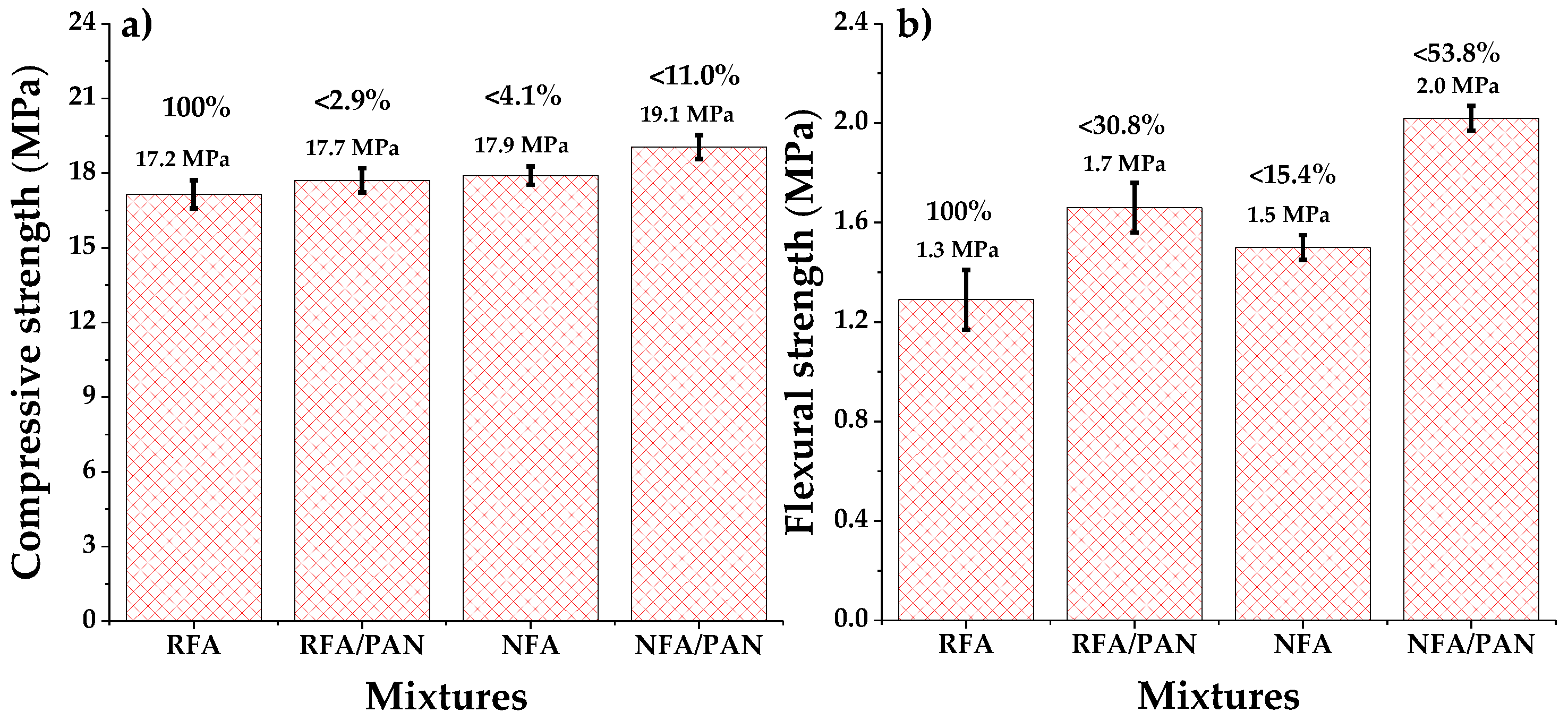

3.2.1. Compressive and Flexural Strength

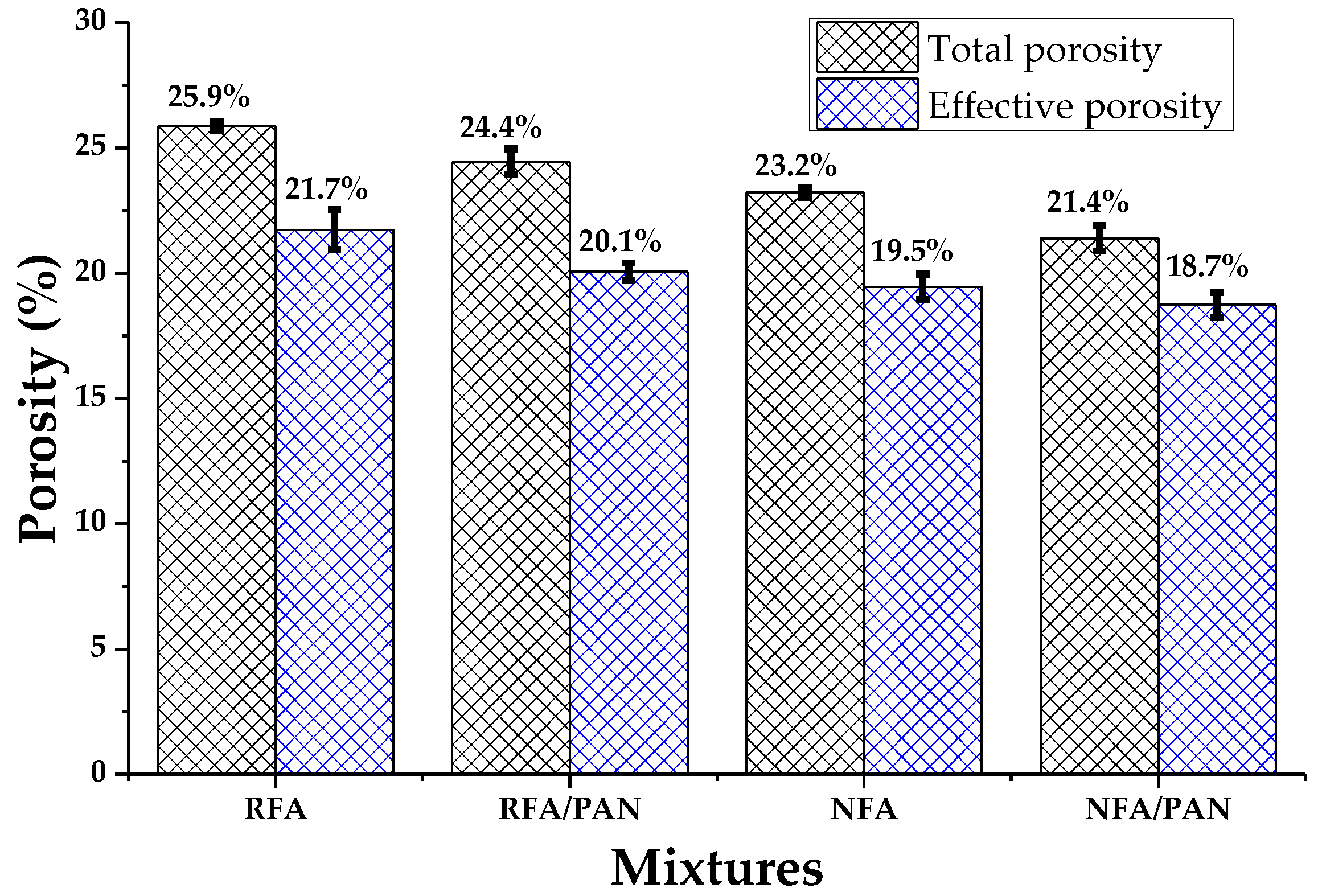

3.2.2. Total and Effective Porosity

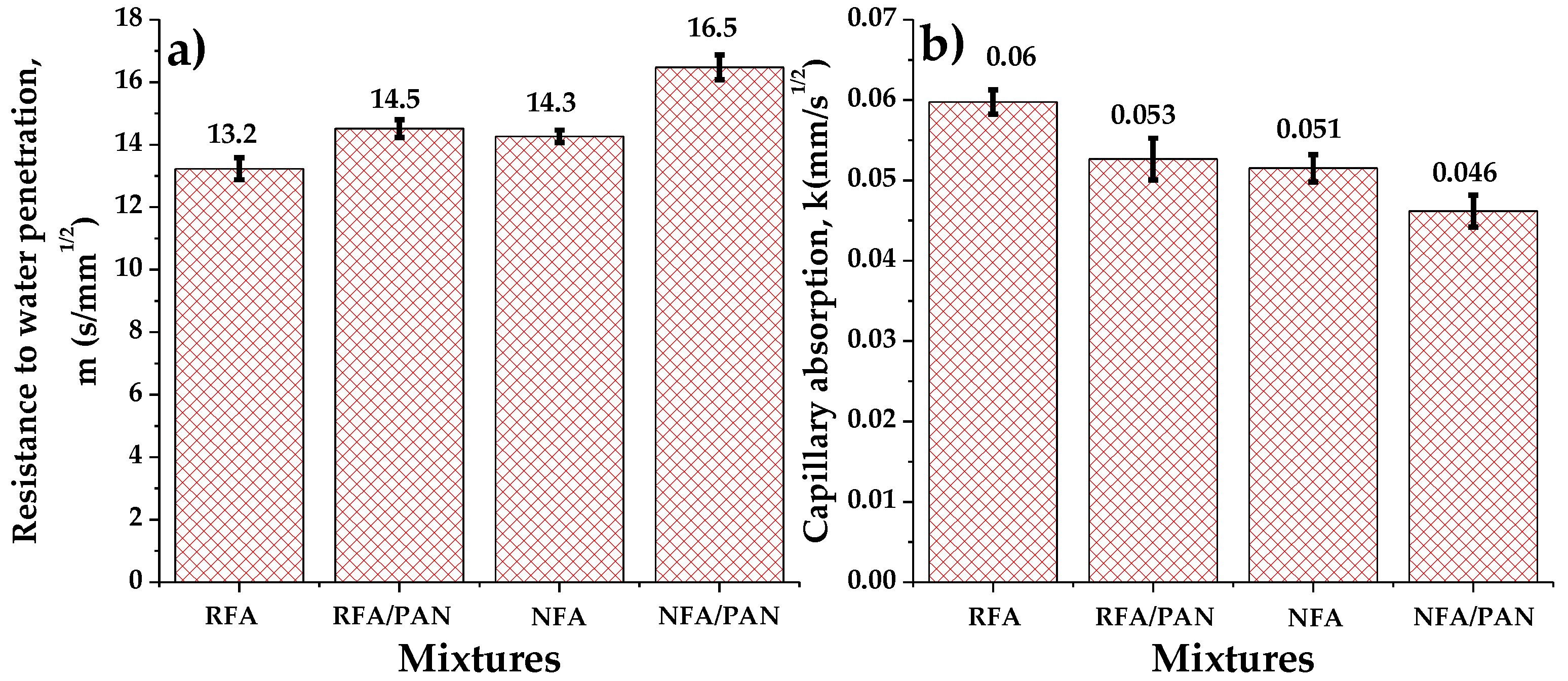

3.2.3. Capillary Absorption and Resistance to Water Penetration

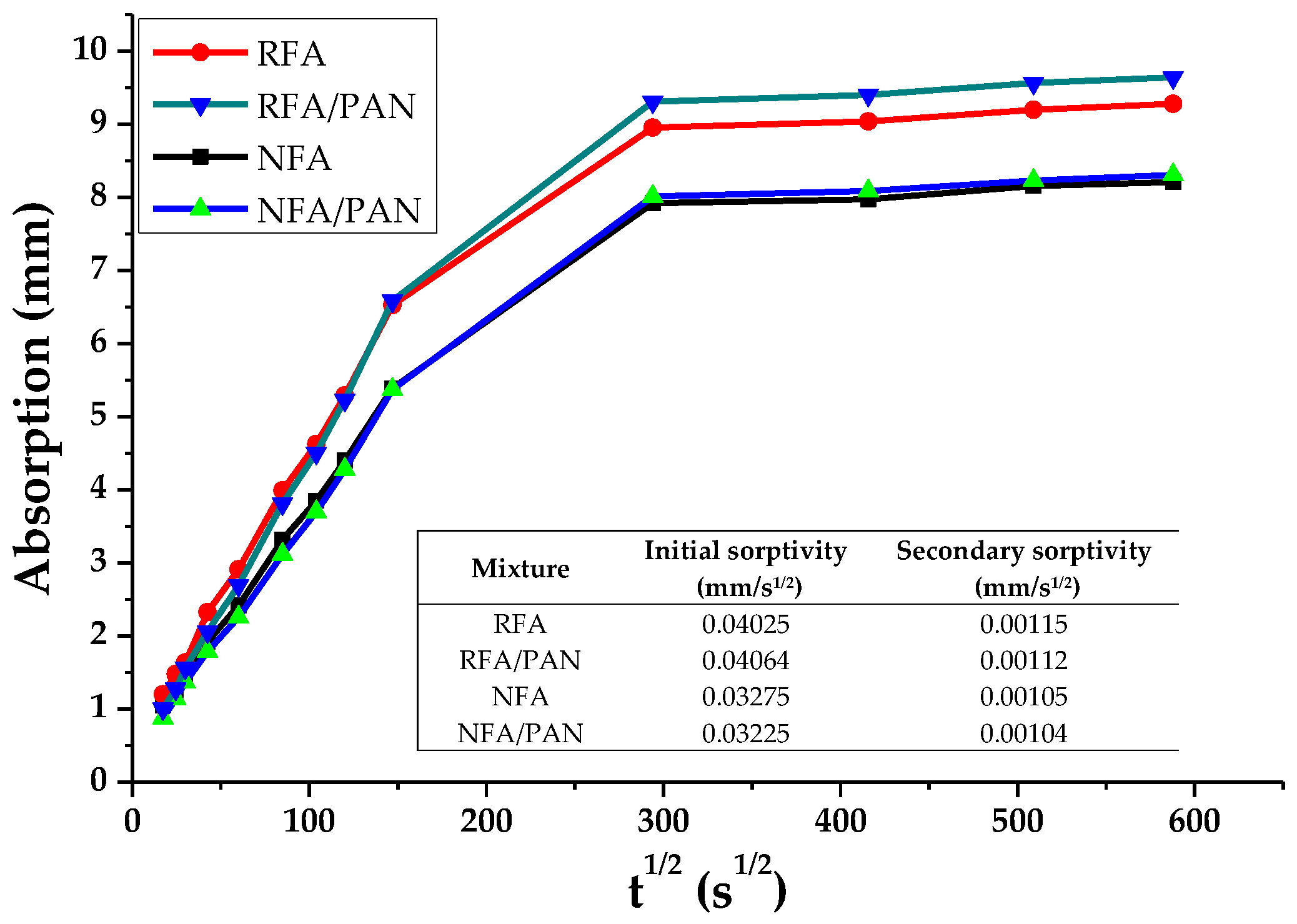

3.2.4. Sorptivity

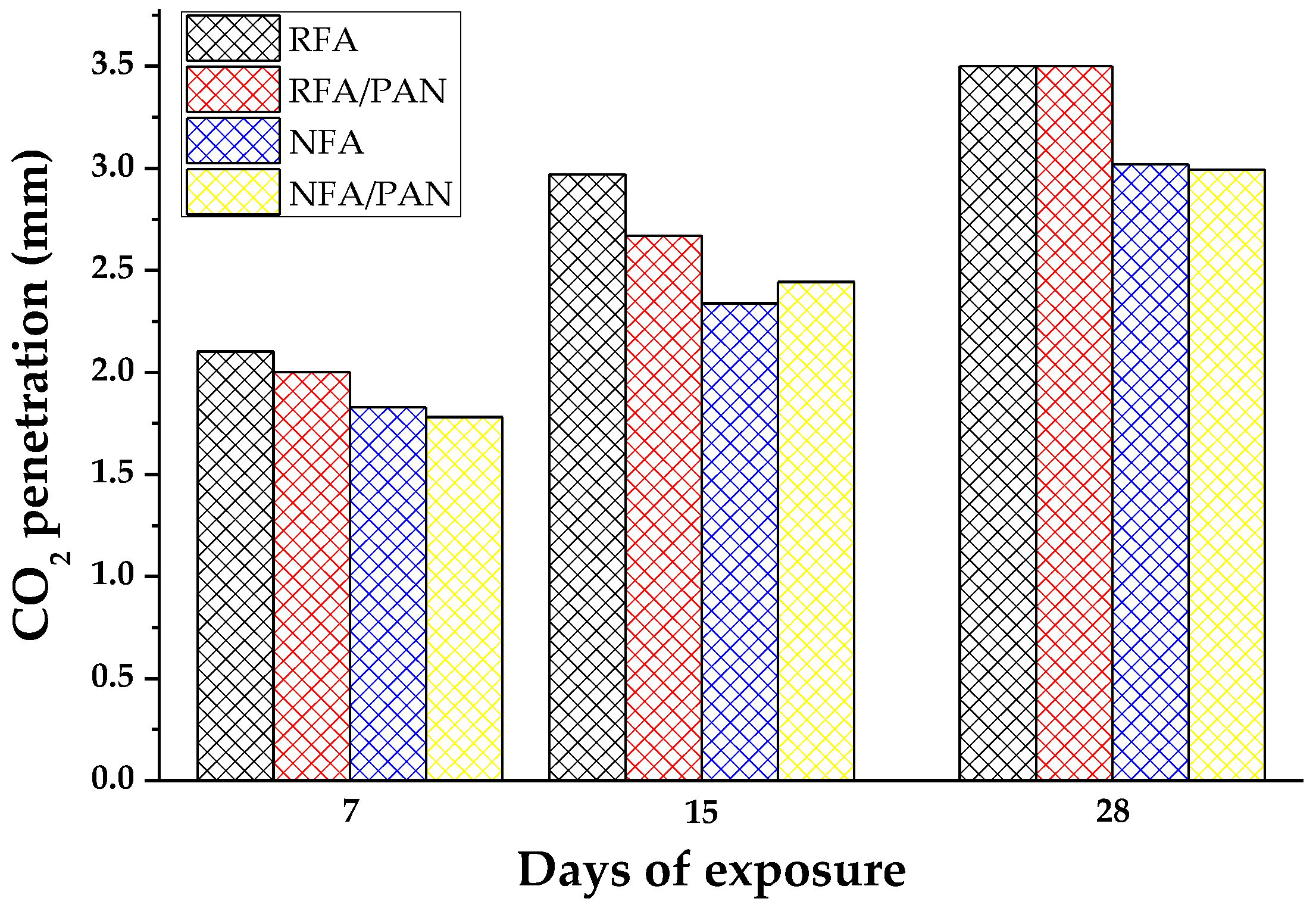

3.2.5. Carbonation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koenders, E.A.B.; Pepe, M.; Martinelli, E. Compressive Strength and Hydration Processes of Concrete with Recycled Aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Vázquez, E.; Barra, M.; Aponte, D.; Jiménez, C.; Valls, S. Improvement of the Durability of Concrete with Recycled Aggregates in Chloride Exposed Environment. Constr. Build. Mater. 2014, 67, 61–67. [Google Scholar] [CrossRef]

- Sas, W.; Dzięcioł, J.; Głuchowski, A. Estimation of Recycled Concrete Aggregate’s Water Permeability Coefficient as Earth Construction Material with the Application of an Analytical Method. Materials 2019, 12, 2920. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Sun, C.; Ding, X.; Kang, T.; Nie, X. Experimental Study on the Vegetation Growing Recycled Concrete and Synergistic Effect with Plant Roots. Materials 2019, 12, 1855. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Ruiperez, C.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V. Lightweight Masonry Mortars Made with Expanded Clay and Recycled Aggregates. Constr. Build. Mater. 2016, 118, 139–145. [Google Scholar] [CrossRef]

- Fang, S.-E.; Hong, H.-S.; Zhang, P.-H. Mechanical Property Tests and Strength Formulas of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Gómez-Soberón, J.M.; Corral-Higuera, R. SEM Image Analysis in Permeable Recycled Concretes with Silica Fume. A Quantitative Comparison of Porosity and the ITZ. Materials 2019, 12, 2201. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and Composition of Recycled Aggregates from Construction and Demolition Waste Suitable for Concrete Production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Zhao, Z. Re-Use of Fine Recycled Concrete Aggregates for the Manufacture of Mortars. Ph.D. Thesis, Université Lille 1, Lille, France, 14 February 2014. [Google Scholar]

- Akça, K.R.; Çakır, Ö.; İpek, M. Properties of Polypropylene Fiber Reinforced Concrete Using Recycled Aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Zhao, Z.; Courard, L.; Michel, F.; Remond, S.; Damidot, D. Influence of Granular Fraction and Origin of Recycled Concrete Aggregates on Their Properties. Eur. J. Environ. Civ. Eng. 2018, 22, 1457–1467. [Google Scholar] [CrossRef]

- Zaharieva, R.; Buyle-Bodin, F.; Skoczylas, F.; Wirquin, E. Assessment of the Surface Permeation Properties of Recycled Aggregate Concrete. Cem. Concr. Compos. 2003, 25, 223–232. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez De Juan, M. Durability of Recycled Aggregate Concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An Overview of Study on Recycled Aggregate Concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoǧlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined Effect of Steel Fiber and Metakaolin Incorporation on Mechanical Properties of Concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Mechanical Properties of Concrete Produced with Recycled Coarse Aggregates—Influence of the Use of Superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Chen, S.Y.; Yang, C.J.; Chen, H.T. Effects of Insulation Materials on Mass Concrete with Pozzolans. Constr. Build. Mater. 2017, 137, 261–271. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive Strength and Durability of High-Volume Fly Ash Concrete Reinforced with Calcium Carbonate Nanoparticles; Elsevier Ltd: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Park, S.J.; Chase, G.G.; Jeong, K.U.; Kim, H.Y. Mechanical Properties of Titania Nanofiber Mats Fabricated by Electrospinning of Sol-Gel Precursor. J. Sol-Gel Sci. Technol. 2010, 54, 188–194. [Google Scholar] [CrossRef]

- Youssf, O.; Elgawady, M.A.; Mills, J.E.; Ma, X. An Experimental Investigation of Crumb Rubber Concrete Confined by Fibre Reinforced Polymer Tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Fraternali, F.; Farina, I.; Polzone, C.; Pagliuca, E.; Feo, L. On the Use of R-PET Strips for the Reinforcement of Cement Mortars. Compos. Part B Eng. 2013, 46, 207–210. [Google Scholar] [CrossRef]

- Avdeeva, A. Reinforcement of Concrete Structures by Fiberglass Rods 1 Introduction 2 Materials and Methods. MATEC Web Conf. 2016, 6, 1–5. [Google Scholar]

- Hawileh, R.A.; Rasheed, H.A.; Abdalla, J.A.; Al-Tamimi, A.K. Behavior of Reinforced Concrete Beams Strengthened with Externally Bonded Hybrid Fiber Reinforced Polymer Systems. Mater. Des. 2014, 53, 972–982. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M.; Zhao, J. Mixture Proportion Design Method of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete. Materials 2019, 12, 375. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano Reinforced Cement and Concrete Composites and New Perspective from Graphene Oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive Stress-Strain Behavior of Steel Fiber Reinforced-Recycled Aggregate Concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of High Performance Polypropylene Fibers in Concrete Lining of Water Tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of Glass and Nylon Fibers in Concrete for Controlling Early Age Micro Cracking in Bridge Decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and Durability Properties of High-Strength Concrete Containing Steel and Polypropylene Fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental Characterization of the Post-Cracking Response in Hybrid Steel/polypropylene Fiber-Reinforced Concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Foti, D. Use of Recycled Waste Pet Bottles Fibers for the Reinforcement of Concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of Polyvinyl Alcohol (PVA) Fibre on Dynamic and Material Properties of Fibre Reinforced Concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Orozco-Carmona, V.M.; Gaxiola, A.; Alvarado-Beltrán, C.G.; Pellegrini-Cervantes, M.J.; Baldenebro-López, F.J.; Castro-Beltrán, A. Evaluation of the Mechanical Properties, Durability and Drying Shrinkage of the Mortar Reinforced with Polyacrylonitrile Microfibers. Constr. Build. Mater. 2019, 210, 32–39. [Google Scholar] [CrossRef]

- Jayawickramage, R.A.P.; Balkus, K.J., Jr.; Ferraris, J.P. Binder Free Carbon Nanofiber Electrodes Derived from Polyacrylonitrile-Lignin Blends for High Performance Supercapacitors. Nanotechnology 2019, 30, 355402. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun Nanofiber Reinforced Composites: A Review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Li, W.; Kang, D. Synthesis of One-Dimensional Mesoporous Ag Nanoparticles-Modified TiO2 Nanofibers by Electrospinning for Lithium Ion Batteries. Materials 2019, 12, 2630. [Google Scholar] [CrossRef]

- Norm NMX-C-061-ONNCCE-2001: Construction Industry, Cement, Determination of the Compressive Strength of Hydraulic Cements; National Organization for Norms and Certification for Construction: Mexico City, Mexico, 2001.

- ASTM C33. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2003; Volume 4, pp. 1–11. [Google Scholar]

- ASTM C1437-99. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- De Guzman, D.S. Tecnologia Del Concreto Y Del Mortero; Biblioteca de la construcción; Bhandar Ed.: Santafé de Bogotá, Colombia, 2001. [Google Scholar]

- ASTM C109/C109M. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Mendivil-Escalante, J.M.; Gómez-Soberón, J.M.; Almaral-Sánchez, J.L.; Cabrera-Covarrubias, F.G. Metamorphosis in the Porosity of Recycled Concretes through the Use of a Recycled Polyethylene Terephthalate (PET) Additive. Correlations between the Porous Network and Concrete Properties. Materials 2017, 10, 176. [Google Scholar] [CrossRef]

- Test, C.C.; Content, A.; Rooms, M.; Concrete, P. Standard Practice for Making and Curing Concrete Test Specimens in the Field; ASTM International: West Conshohocken, PA, USA, 2002; Volume 4, pp. 1–8. [Google Scholar]

- ASTM C348. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM C349. Standard Test Method for Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Pellegrini, M.J.; Barrios, C.P.; Nuñez, R.E.; Arredondo, S.P.; Baldenebro, F.J.; Rodríguez, M.; Ceballos, L.G.; Castro, A.; Fajardo, G.; Almeraya, F.; et al. Performance of Chlorides Penetration and Corrosion Resistance of Mortars with Replacements of Rice Husk Ash and Nano-SiO2. Int. J. Electrochem. Sci. 2015, 10, 332–346. [Google Scholar]

- ASTM C1585-04. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM, C.G. Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Shi, M.; Tang, C.; Yang, X.; Zhou, J.; Jia, F.; Han, Y.; Li, Z. Superhydrophobic Silica Aerogels Reinforced with Polyacrylonitrile Fibers for Adsorbing Oil from Water and Oil Mixtures. RSC Adv. 2017, 7, 4039–4045. [Google Scholar] [CrossRef]

- Zhao, W.; Lu, Y.; Wang, J.; Chen, Q.; Zhou, L.; Jiang, J.; Chen, L. Improving Crosslinking of Stabilized Polyacrylonitrile Fibers and Mechanical Properties of Carbon Fibers by Irradiating with γ-Ray. Polym. Degrad. Stab. 2016, 133, 16–26. [Google Scholar] [CrossRef]

- Huang, F.; Xu, Y.; Liao, S.; Yang, D.; Hsieh, Y.-L.; Wei, Q. Preparation of Amidoxime Polyacrylonitrile Chelating Nanofibers and Their Application for Adsorption of Metal Ions. Materials 2013, 6, 969–980. [Google Scholar] [CrossRef] [PubMed]

- Pang, T.; Zhou, Z.; Li, D.; Liu, H.; Zhang, Z.; Qi, L.; Song, C.; Gao, G.; Lv, Y. Crystal Structure and Reversible Photochromism of Pb (II)-N, N-Dimethylformamide Modified Keggin-Type Polyoxometalates. Cryst. Res. Technol. 2019, 54. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, Z.; Yin, Z.; Jiang, L.; Fang, S. Experimental FTIR and Simulation Studies on H-Bonds of Model Polyurethane in Solutions. I: In Dimethylformamide (DMF). Spectrochim. Acta Part. A Mol. Biomol. Spectrosc. 2011, 81, 598–603. [Google Scholar] [CrossRef] [PubMed]

- Hameed, N.; Sharp, J.; Nunna, S.; Creighton, C.; Magniez, K.; Jyotishkumar, P.; Salim, N.V.; Fox, B. Structural Transformation of Polyacrylonitrile Fibers during Stabilization and Low Temperature Carbonization. Polym. Degrad. Stab. 2016, 128, 39–45. [Google Scholar] [CrossRef]

- Qiao, M.; Kong, H.; Ding, X.; Zhang, L.; Yu, M. Effect of Graphene Oxide Coatings on the Structure of Polyacrylonitrile Fibers during Pre-Oxidation Process. RSC Adv. 2019, 9, 28146–28152. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Orozco-Carmona, V.M.; Alvarado-Beltrán, C.G.; Almaral-Sánchez, J.L.; Sepulveda-Guzman, S.; Jasso-Ramos, L.E.; Castro-Beltrán, A. Synthesis of Recycled Poly(ethylene terephthalate)/Polyacrylonitrile/Styrene Composite Nanofibers by Electrospinning and Their Mechanical Properties Evaluation. J. Polym. Environ. 2019, 27, 659–669. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Taylor, P.C.; Nahvi, A. Polyurethane-Carbon Microfiber Composite Coating for Electrical Heating of Concrete Pavement Surfaces. Heliyon 2019, 5, e02359. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of Recycled Aggregate Concrete Made with Recycled Aggregates with Different Amounts of Old Adhered Mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Ranjbar, M.M.; Madandoust, R. Combined Effects of Steel Fibers and Water to Cementitious Materials Ratio on the Fracture Behavior and Brittleness of High Strength Concrete. Eng. Fract. Mech. 2019, 216. [Google Scholar] [CrossRef]

- Singh, S.B.; Munjal, P.; Thammishetti, N. Role of Water/cement Ratio on Strength Development of Cement Mortar. J. Build. Eng. 2015, 4, 94–100. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Dong, C.X.; Ho, J.C.M. Axial and Lateral Stress-Strain Model for FRP Confined Concrete. Eng. Struct. 2015, 99, 285–295. [Google Scholar] [CrossRef]

- Hou, D.; Li, D.; Hua, P.; Jiang, J.; Zhang, G. Statistical Modelling of Compressive Strength Controlled by Porosity and Pore Size Distribution for Cementitious Materials. Cem. Concr. Compos. 2019, 96, 11–20. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Material Design and Characterization of High Performance Pervious Concrete. Constr. Build. Mater. 2015, 98, 51–60. [Google Scholar] [CrossRef]

- Katz, A.; Kulisch, D. Performance of Mortars Containing Recycled Fine Aggregate from Construction and Demolition Waste. Mater. Struct. Constr. 2017, 50, 199. [Google Scholar] [CrossRef]

- Pellegrini Cervantes, M.J.; Barrios Durstewitz, C.P.; Núñez Jaquez, R.E.; Almeraya Calderón, F.; Rodríguez Rodríguez, M.; Fajardo-San-Miguel, G.; Martinez-Villafañe, A. Accelerated Corrosion Test in Mortars of Plastic Consistency with Replacement of Rice Husk Ash and Nano-SiO2. Int. J. Electrochem. Sci. 2015, 10, 8630–8643. [Google Scholar]

- Sanawung, W.; Cheewaket, T.; Tangchirapat, W.; Jaturapitakkul, C. Influence of Palm Oil Fuel Ash and W/B Ratios on Compressive Strength, Water Permeability, and Chloride Resistance of Concrete. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Jiménez, L.F.; Moreno, E.I. Durability Indicators in High Absorption Recycled Aggregate Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Sobczak, L.; Brüggemann, O.; Putz, R.F. Polyolefin Composites with Natural Fibers and Wood-modification of the Fiber/filler–matrix Interaction. J. Appl. Polym. Sci. 2013, 127, 1–17. [Google Scholar] [CrossRef]

- Hall, C. Water Sorptivity of Mortars and Concretes: A Review. Mag. Concr. Res. 1989, 41, 51–61. [Google Scholar] [CrossRef]

- Awasthi, A.V.K.M.S.; Goyal, S.K.N.O.Y. Recycled Aggregate from C&D Waste Modified by Dry Processing and Used as A Partial Replacement of Coarse Aggregate in Concrete. J. Mater. Sci. Surf. Eng. 2017, 5, 671–678. [Google Scholar]

- Pan, G.; Zhan, M.; Fu, M.; Wang, Y.; Lu, X. Effect of CO2 Curing on Demolition Recycled Fine Aggregates Enhanced by Calcium Hydroxide Pre-Soaking. Constr. Build. Mater. 2017, 154, 810–818. [Google Scholar] [CrossRef]

- Paul, S.C.; Panda, B.; Huang, Y.; Garg, A.; Peng, X. An Empirical Model Design for Evaluation and Estimation of Carbonation Depth in Concrete. Measurement 2018, 124, 205–210. [Google Scholar] [CrossRef]

- Almeida, A.E.F.S.; Tonoli, G.H.D.; Santos, S.F.; Savastano, H. Improved Durability of Vegetable Fiber Reinforced Cement Composite Subject to Accelerated Carbonation at Early Age. Cem. Concr. Compos. 2013, 42, 49–58. [Google Scholar] [CrossRef]

| Properties | NFA | RFA | PAN Microfibers | Cement |

|---|---|---|---|---|

| Diameter range (µm) | - | - | 0.6–1.3 | - |

| Average microfiber diameter (µm) | - | - | 1.024 | |

| Modulus of elasticity (GPa) | - | - | 2.5 | - |

| Hardness (GPa) | - | - | 0.48 | - |

| PAN Molecular weight (g/mol) | - | - | 150,000 | - |

| PAN concentration (% by weight of DMF) | - | - | 12 | - |

| Specific gravity (kg/m3) | 2.56 | 2.15 | - | 3.150 |

| Moisture (%) | 6.15 | 3.04 | - | - |

| Water absorption (%) | 4.16 | 13.63 | - | - |

| Fineness modulus | 2.88 | 3.04 | - | - |

| Type | Natural | Recycled | Polymeric | 30R |

| Mixtures | % of RFA | % of NFA | % of Microfibers | Water (l) | Cement (kg) | NFA (kg) | RFA (kg) | PAN Microfibers (kg) | Mix Flow (%) |

|---|---|---|---|---|---|---|---|---|---|

| RFA | 25 | 75 | 0 | 2.847 | 4.908 | 10.124 | 3.374 | - | 116.6 |

| RFA/PAN | 25 | 75 | 0.05 | 2.847 | 4.908 | 10.124 | 3.374 | 0.00245 | 115.7 |

| NFA | - | 100 | 0 | 2.847 | 4.908 | 13.499 | - | - | 117.2 |

| NFA/PAN | - | 100 | 0.05 | 2.847 | 4.908 | 13.499 | - | 0.00245 | 115.5 |

| Test | Form of the Specimen (type) | Dimensions of the Specimen (cm) | Curing Time (days) | Standard/Reference |

|---|---|---|---|---|

| Flexural strength | Prisms | 4 × 4 × 16 | 28 | ASTM C 348 [46] |

| Compressive strength | Post-test pieces of mortar bending | 4 × 4 | 28 | ASTM C 349 [47] |

| Total porosity | Cubes | 5 × 5 | 28 | [48] |

| Effective porosity | Cylinders | 7.5 in diameter and 8 in height | 28 | ASTM C 1585 [49] |

| Resistance to water penetration and capillary absorption | Cubes | 4 × 4 | - | [35] |

| Accelerated carbonation | Cylinders | 7.5 in diameter and 2 in height | 7, 15 and 28 | [50] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chinchillas-Chinchillas, M.J.; Pellegrini-Cervantes, M.J.; Castro-Beltrán, A.; Rodríguez-Rodríguez, M.; Orozco-Carmona, V.M.; Peinado-Guevara, H.J. Properties of Mortar with Recycled Aggregates, and Polyacrylonitrile Microfibers Synthesized by Electrospinning. Materials 2019, 12, 3849. https://doi.org/10.3390/ma12233849

Chinchillas-Chinchillas MJ, Pellegrini-Cervantes MJ, Castro-Beltrán A, Rodríguez-Rodríguez M, Orozco-Carmona VM, Peinado-Guevara HJ. Properties of Mortar with Recycled Aggregates, and Polyacrylonitrile Microfibers Synthesized by Electrospinning. Materials. 2019; 12(23):3849. https://doi.org/10.3390/ma12233849

Chicago/Turabian StyleChinchillas-Chinchillas, Manuel J., Manuel J. Pellegrini-Cervantes, Andrés Castro-Beltrán, Margarita Rodríguez-Rodríguez, Víctor M. Orozco-Carmona, and Héctor J. Peinado-Guevara. 2019. "Properties of Mortar with Recycled Aggregates, and Polyacrylonitrile Microfibers Synthesized by Electrospinning" Materials 12, no. 23: 3849. https://doi.org/10.3390/ma12233849

APA StyleChinchillas-Chinchillas, M. J., Pellegrini-Cervantes, M. J., Castro-Beltrán, A., Rodríguez-Rodríguez, M., Orozco-Carmona, V. M., & Peinado-Guevara, H. J. (2019). Properties of Mortar with Recycled Aggregates, and Polyacrylonitrile Microfibers Synthesized by Electrospinning. Materials, 12(23), 3849. https://doi.org/10.3390/ma12233849