After the shape and size of aggregate particles are determined, how to place them into a pre-defined empty container according to grading curves is not only to affect the density of concrete, but also to play a paramount role in the fracture processes. One of the essential tasks for virtual numerical concrete modeling is to tackle the placement of aggregates in concrete based upon the random distribution of grading particles. In the beginning, we created an empty container to represent a specimen, and then all the aggregates from the larger to the smaller were placed one after another into this container. In general, it started with the largest aggregates to be placed as it would be difficult to place them if they were processed at a later stage. There were three challenging tasks to be done as follows. (i) Check whether convex–concave profiles between placement particles are overlapping or not. This process usually requires knowledge of computational geometry. (ii) Commonly check one by one with all the aggregates that have been placed. However, to the best knowledge of the authors, there is no recognized most effective algorithm for detecting and identifying the overlapping of arbitrary-shape aggregates currently. (iii) As the amount of the already placed aggregates is increased, the try-placement aggregates may intersect with the placed ones, which are a high probability event. Further, the number of invalid try-placements leads to the subsequent inefficient overlap detection, which seriously influences the generation efficiency of mesostructure concrete material models.

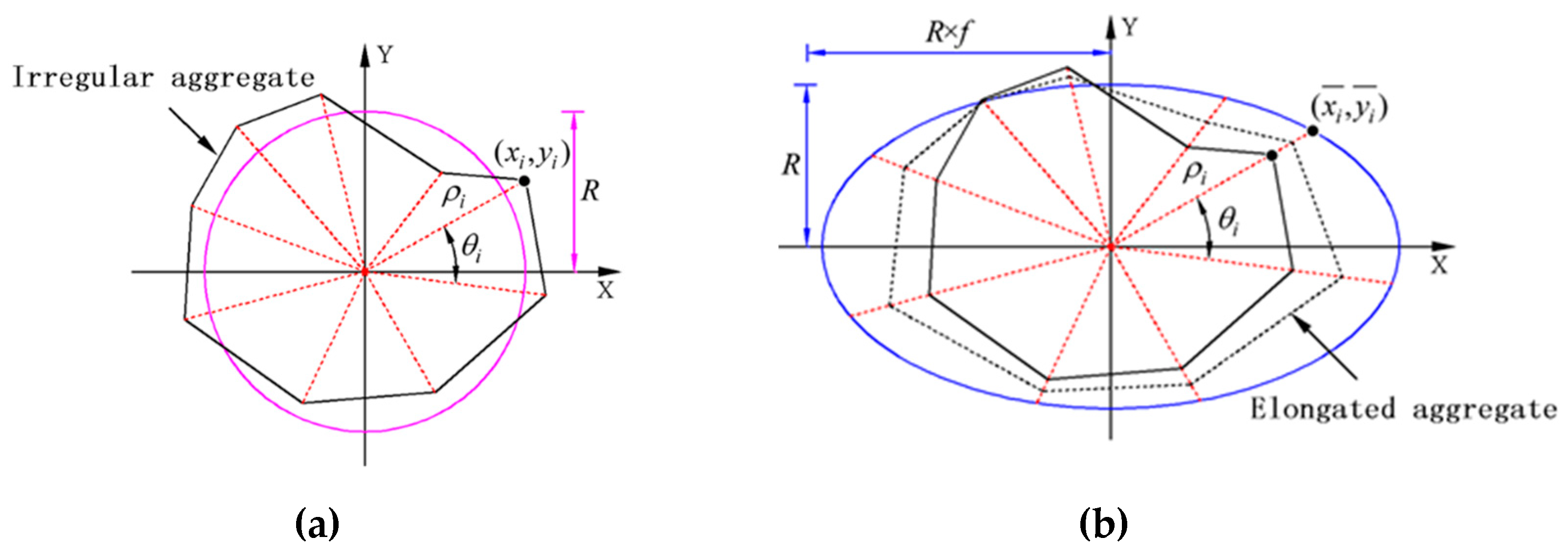

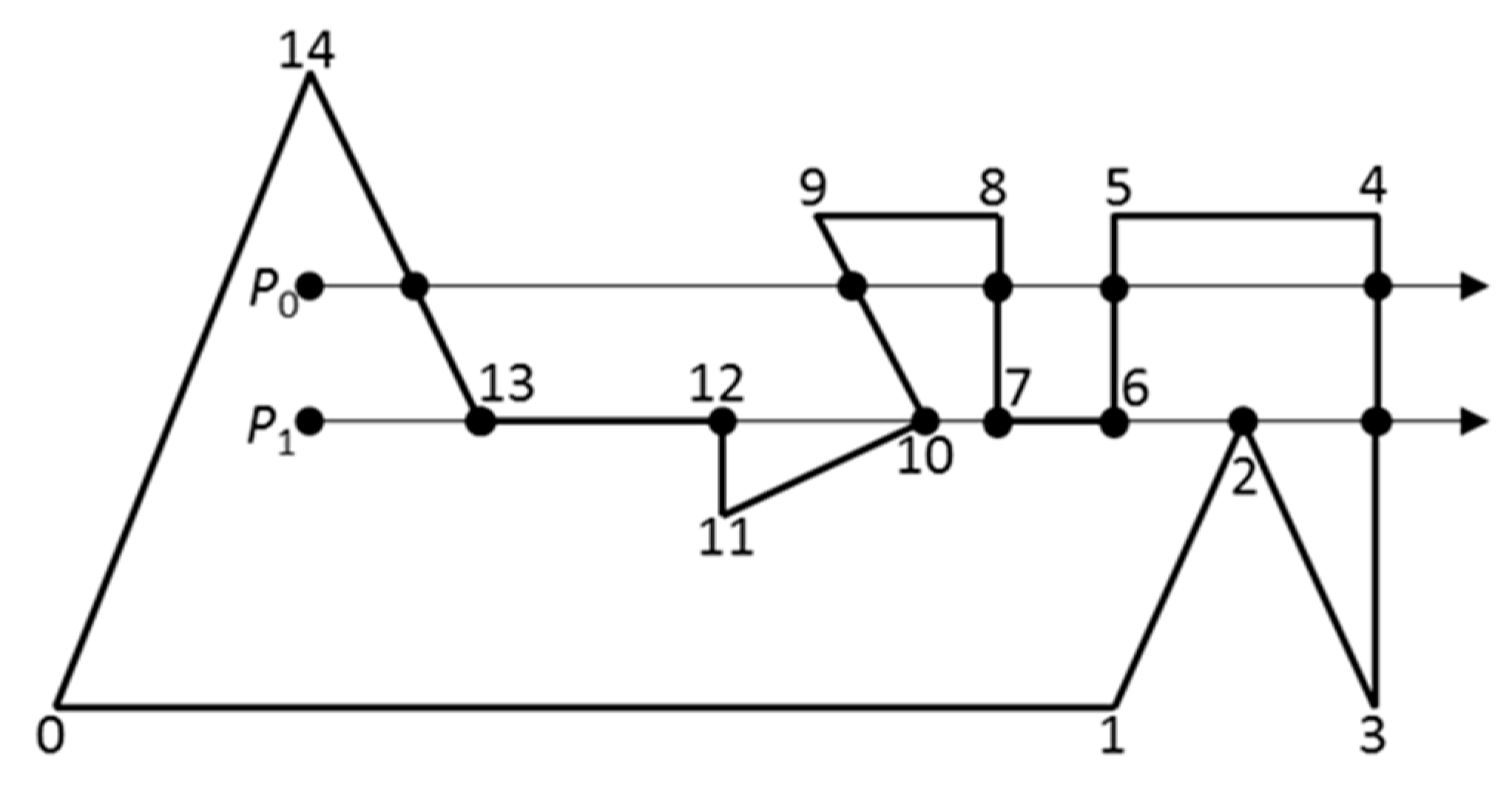

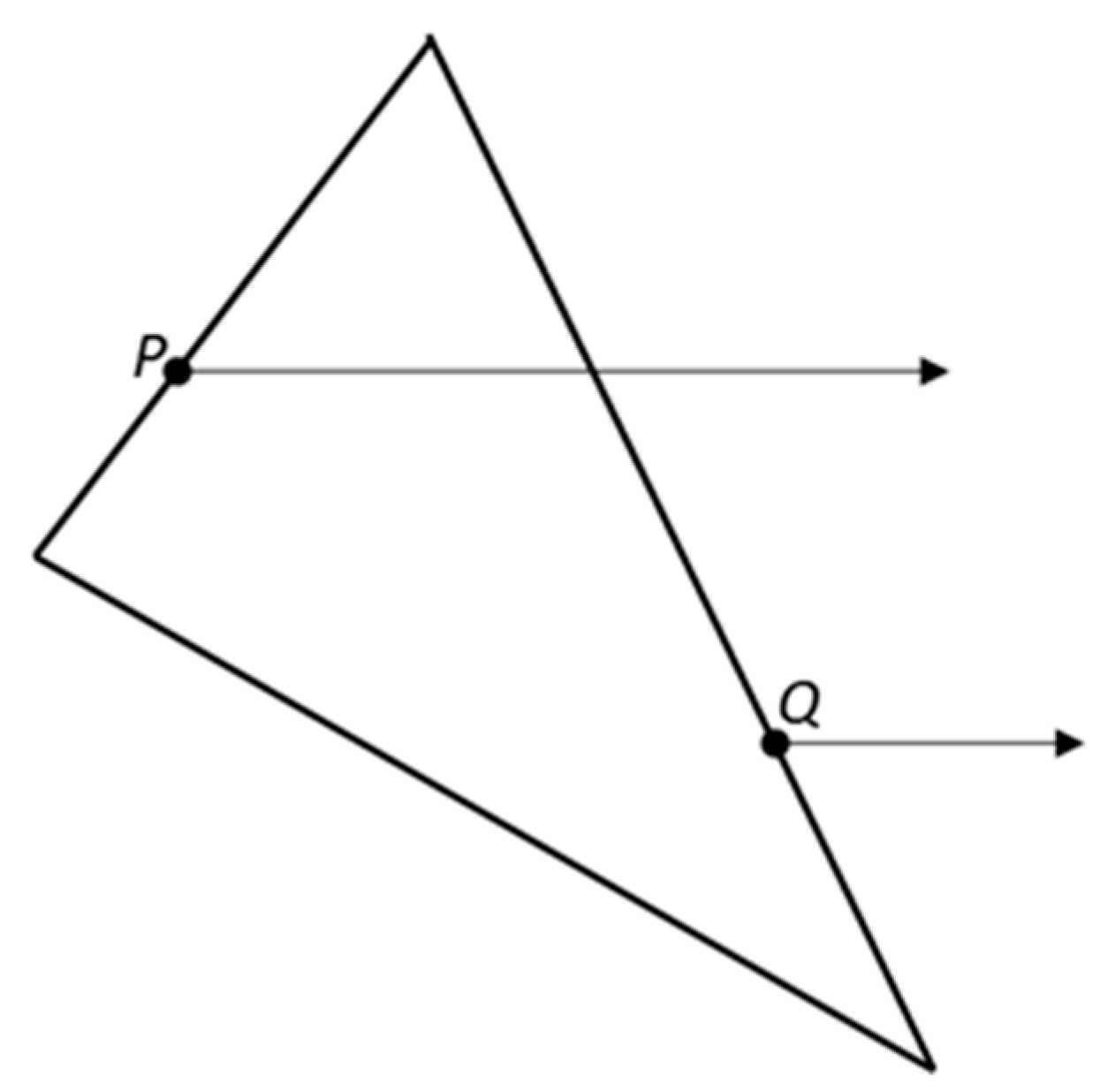

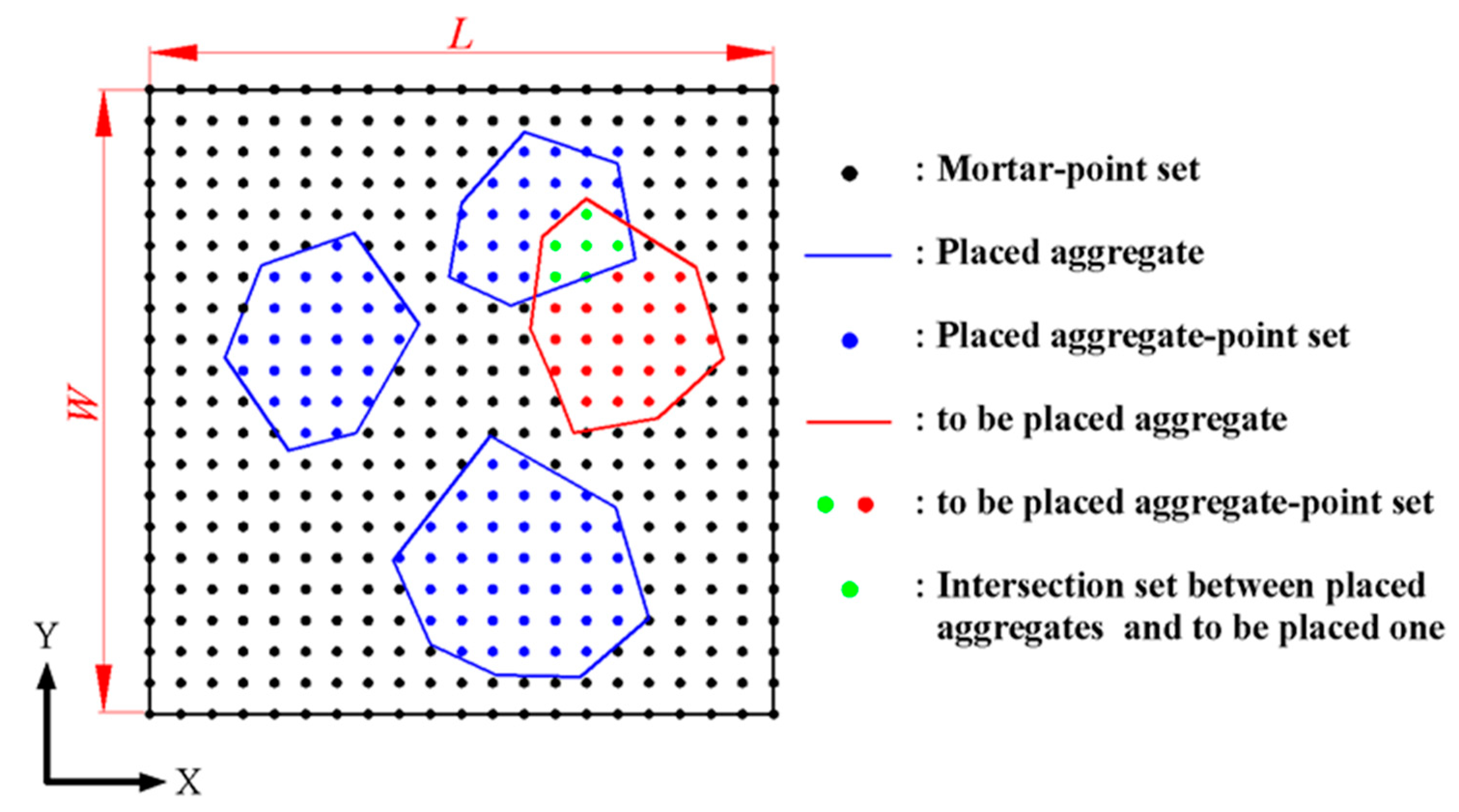

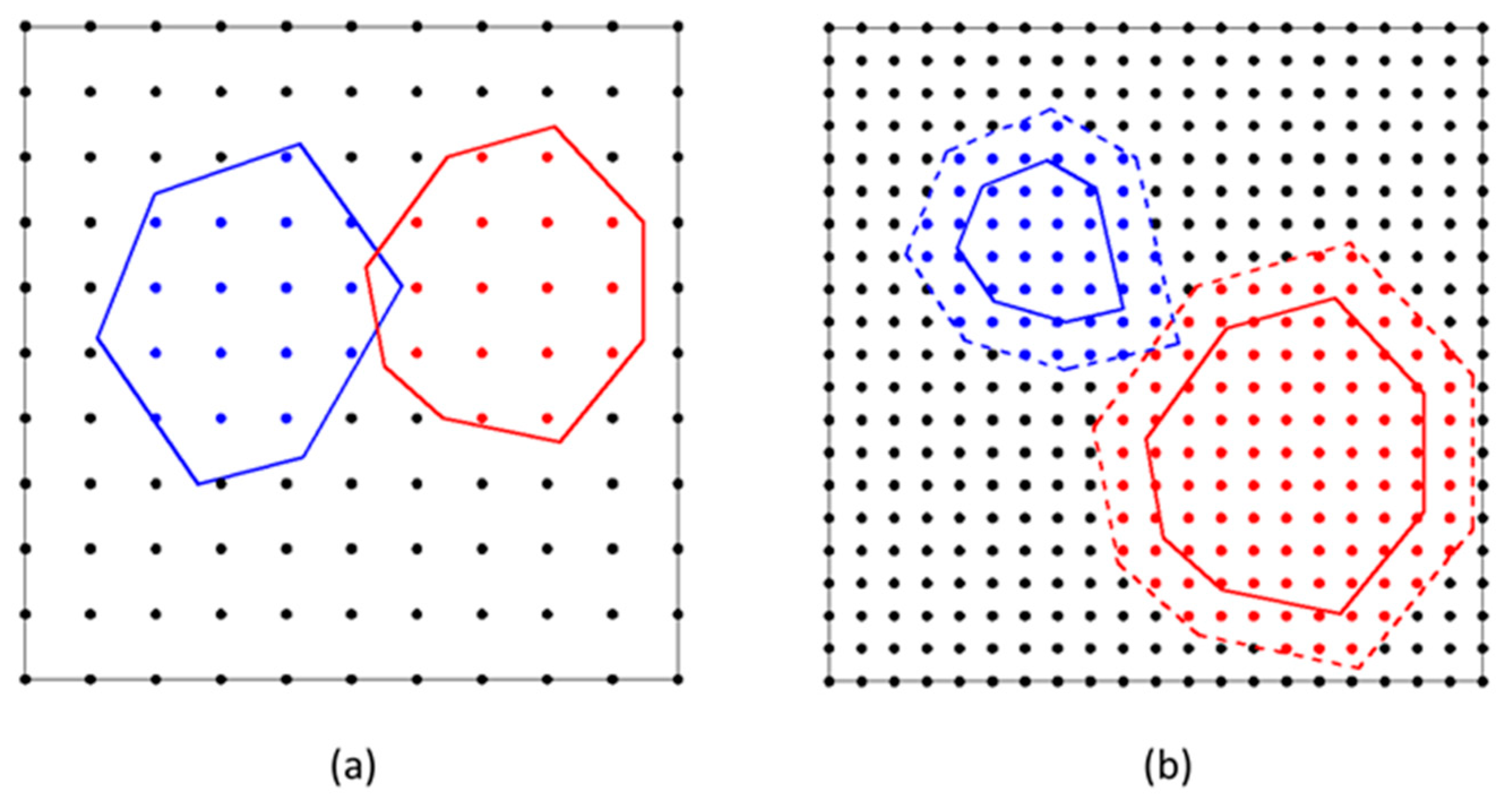

We developed a novel method for bypassing the disadvantage of the aggregate placement methods aforementioned. To give a framework of understanding, we took a two-dimensional polygon as an example to introduce some concepts that will be used later. The basic idea is to transform the overlap detection between polygons into the problem of whether there is any intersection between the point sets. Now let us take any rectangular concrete specimen (container), e.g., 100 mm × 100 mm, as an example to detail the placement procedure of aggregates, as shown in

Figure 9. To conveniently understand the placement procedure, we regarded any rectangular container as a dot matrix. The distance between any neighbor two points was determined by a minimum size of particle to be placed. Mortar-point set (

setMor), placed aggregates and their corresponding point set (

setAgg), trial placement aggregates and their corresponding point set (

setTry), and intersection set between placed aggregates and trial placement aggregates, are also defined in

Figure 9, respectively. We assumed that the successful placement aggregates in the container were not allowed to be intersected. In other words, the mutual intersection set between these successful placement aggregate sets should be empty.

4.1. A Representation of Dot Matrix for Model Geometry

Let the length, width, and height of a model geometry (rectangular box or container) be

L,

W, and

H, respectively. In the Cartesian coordinate system, the numbers of points in the geometry along with the directions of

x,

y, and

z are

NumX,

NumY, and

NumZ, respectively, as indicated in

Figure 9 (to 2D case). The serial number of point is

N ∈ (1,

NumX ×

NumY) (to 3D case,

N ∈ (1,

NumX ×

NumY ×

NumZ), their order is in turn from the left-to-right to the bottom-to-top. These serial numbers are firstly stored in the mortar point set (

setMor). After the dot matrix is created, three attributes are held for any point among the model. These are the serial number

N, the row and column (

i,

j; to 3D case, (

i,

j,

k)), and the coordinates (

x,

y; to 3D case, (

x,

y,

z)). It is noted that if anyone among three attributes is known, the two others can be derived from it. For instance, from Equation (11), we could obtain the serial number

N of point P from its row and column (

i,

j; to 3D case, (

i,

j,

k)).

where

i = 1, 2, …,

NumX,

j = 1, 2, …,

NumY,

k = 1,2, …,

NumZ.

From Equations (12a) and (12b), the row and column (

i,

j; to 3D case, (

i, j, k)) can also be represented in terms of the serial number

N of point

P,

where

ceil() is the ceiling function, being the round up value.

Certainly, from Equation (13), the coordinates of point

P(

x,

y) (or to 3D case,

P(

x, y, z)), can be obtained from its row and column (

i, j; or to 3D case (

i, j, k)).

After the coordinates of point P(x, y, z) are determined, we could check if it is in the interior of a polygon or polyhedron (to be placed aggregate).

4.2. Aggregate Placement

Let point sets setAgg and setTry store the serial numbers of points within placed aggregates and the serial number of points within a trial placement aggregate, respectively. After the trial placement aggregates ordering from the larger one to the smaller one, we could place these aggregates into the dot matrix one after another from the larger one to the smaller one. Therefore, the times of try-placement are reduced, and the probability of try-placement successfulness is enhanced. Since all the trial placement aggregates are created from the same origin, the coordinates of the try-placement aggregates need to be translated into the dot matrix coordinate system during aggregate parking.

Firstly, we randomly took a serial number N from mortar set, setMor, so that its coordinates, (x, y, z), can be obtained from Equations (12a), (12b) and (13). Further, we translated the origin coordinate of a trial placement aggregate to the coordinate position to the serial number N. Next we checked if this placement was successful to meet two conditions: (a) the trial placement aggregate is inside the computational domain and (b) if the condition (a) is satisfied, the point set of setTry needs to be determined but not allowing intersection between setTry and setAgg.

If the two conditions above-mentioned are satisfied, this aggregate placement can be considered to be successful. Next, this setTry was copied into setAgg. Then the difference operation of the point set, (setMor − setTry), must be done to eliminate the successful placement aggregate previously from the mortar point set. Finally, the trial placement point set of setTry was emptied. However, if one of the two conditions above-mentioned is not satisfied, another point N needs to be taken from the mortar point set of setMor. The coordinates of point N also need to be determined. The point N was taken as the center of the to-be-placed aggregate and we again checked if the two conditions aforementioned were satisfied. Others need to be repeatedly done as did like the previous discussion until completing aggregate placement. A more detailed procedure of aggregate placement is given as follows.

Step 1. Read the container size, i.e., L, W, H, NumX, NumY, NumZ, and the aggregate volume fraction, AggRatio.

Step 2. (i) Generate a database of grading trial placement aggregates, and sort the aggregates in the database from the larger one to the smaller one; (ii) empty three point sets: setMor, setAgg, and setTry; and (iii) matrix the container domain, and store all the corresponding point serial numbers to setMor.

Step 3. Initialize AggTotal = 0.0 (i.e., assign an initial value of null to the area of all aggregates in the container), and update the total areas of the current aggregates when successfully placing.

Step 4. Take individual aggregate from the database as a trial placement one.

Step 5. Choose a point randomly from setMor and translate the origin of the trial placement aggregate in Step 4 to the position of this point.

Step 6. Check if the trial placement aggregate is properly in the computational domain. If the answer is yes, then go to Step 7, else if the answer is no, then go to Step 5.

Step 7. Determine for the point set of a trial placement aggregate, setTry.

Step 8. Check if there exists any intersection set between setTry and setAgg. If the answer is yes, then empty point set setTry and go to Step 5, else if the answer is no, then go to Step 9.

Step 9. (i) Store the data information of successfully placed aggregates, e.g., their vertex coordinates; (ii) add setTry into setAgg, next subtract setTry from setMor, and then empty setTry; and (iii) add the area (or volume) of aggregate into AggTotal.

Step 10. Check if AggTotal < (AggRatio × (L × W × H)) is satisfied, if the answer is yes, then go to Step 4, else if the answer is no, then the process of aggregate placements terminates.

From the process of a typical try-placement, we readily find that the position of the aggregate placement is in the mortar point set of setMor, in our DMM. In other words, the successful placement aggregates in setAgg have been moved into some regions. These regions were ever occupied by some mortar points in setMor so that at this moment the new mortar point set of setMor should be updated by setMor subtracting setAgg. Therefore, it is impossible to occupy the positions of the placed aggregates by the new consequent placement aggregates. Indeed, DMM dramatically enhances the probability of successful aggregate placement and reduces the number of placement attempts. Another merit of our DMM is that the complicated geometry evaluation is not involved in justifying the overlap between trial placement aggregate and placed ones in the container and instead arbitrary shape of aggregates including concave or convex shapes and uneven profiles can be processed. A most salient issue in the present method is how to determine the trial placement aggregate set of setTry, which will be treated in the later section. The overlapping judgment between aggregates is transformed into the issue of whether there is an intersection between the point sets, which makes the problem easier to understand and more convenient in the implementation of programming algorithms.

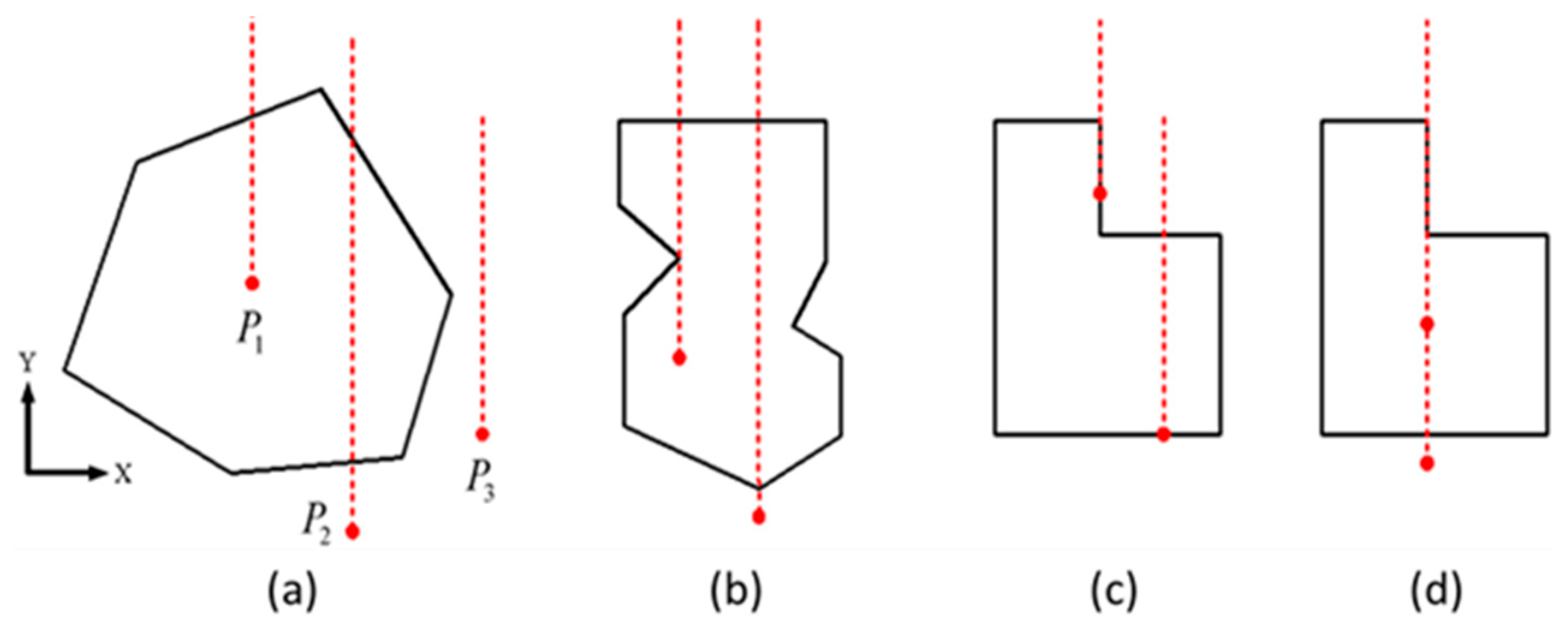

4.3. Determination of a Trial Placement Aggregate Set of setTry

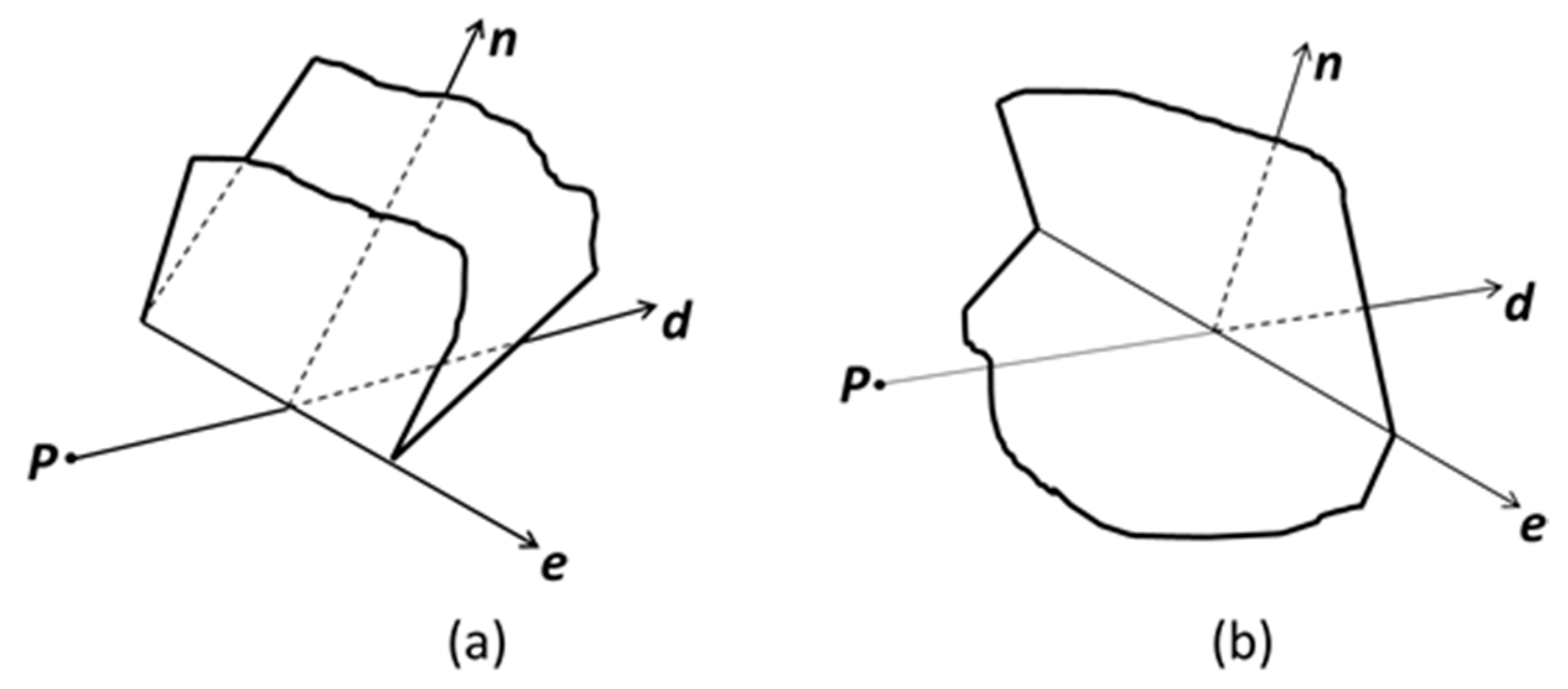

How to quickly locate the points inside the trial placement aggregate in a container largely determines the efficiency of aggregate parking. The easiest way is to traverse all the points in the mortar point set,

setMor, and determine if each of the points is inside the trial placement aggregate. However, this method is extremely inefficient. One of the ideal methods should consider the points solely around a trial placement aggregate. Thus the approximately occupied region of the trial placement aggregate in the container can be determined. At the same time, the number of judgments for the point positions can be greatly reduced, and the calculation efficiency can be improved. The procedure we proposed was that a minimum rectangular box, which could at least contain all the points in a trial placement aggregate, was first determined, as indicated in

Figure 10 (to 2D case). This box is determined by Equations (14a) and (14b),

where

Left and

Right are the columns on the left and right boundaries of the box, respectively;

Bottom and

Top indicate the rows on the bottom and top boundaries of the box;

Back and

Front indicate the layers on the back and front boundaries of the box;

ceil() and

floor() give the corresponding round up value and round down value; min_

X, max_

X, min_

Y, max_

Y, min_

Z, and max_

Z are the corresponding minimum and maximum coordinates of the polygon vertices in the trial placement aggregate. From Equations (14a) and (14b), the range of the rows, columns, and layers of the points surrounded by the box in the dot matrix can be inferred, and the coordinates of each point are evaluated by Equation (13), and the positional relationship between the points and the polygon will be used to determine

setTry, in which the points are all inside the polygon.

During the aggregate placement, the geometrical overlap between a try-placement aggregate and the already placed ones may occur potentially within the one unit of dot matrix (see in

Figure 11a), even though there is not any intersection set between their point sets at all. To overcome the overlap, we appropriately zoomed in the profile of a trial placement aggregate as a virtual boundary. The point set surrounded by the virtual boundary was used to examine if it overlaps with the point set (

setAgg) of the already placed aggregates. In detail, the length at the direction of the polar axis was increased by a segment,

T/2, where

T is the minimum value of allowance distance between aggregates in concrete. From our experience, this allowance distance

T can be evaluated by Equation (15). Moreover, such parameter

T introduced also benefits to avoid the singularity of the mesh shape when meshing later. After detecting the status of intersection set between the points surrounded by the virtual boundary of a try-placement and the points by the already placed ones, the determination of the locations and vertices in the trial placement aggregate was stored or not, as indicated in

Figure 11b.

We now needed to address how to realize the point set operations such as their intersection and difference. In general, there are two ways, such as self-developing algorithm and the functions in the standard template library (STL) to accomplish these tasks. The latter is used to efficiently implement such set operations in our dot matrix method because the functions

set_

intersection() and

set_

difference() in STL of the computer language C++ provide us with a solution to these problems. Fortunately, the two set functions in STL only have the linear time complexity

O(

n). Thus the executed efficiency of our procedure is only dependent on the point amount of dot matrix. Indeed, the larger the point number of dot matrix, the slower the running of placement aggregate procedure. As a guideline,

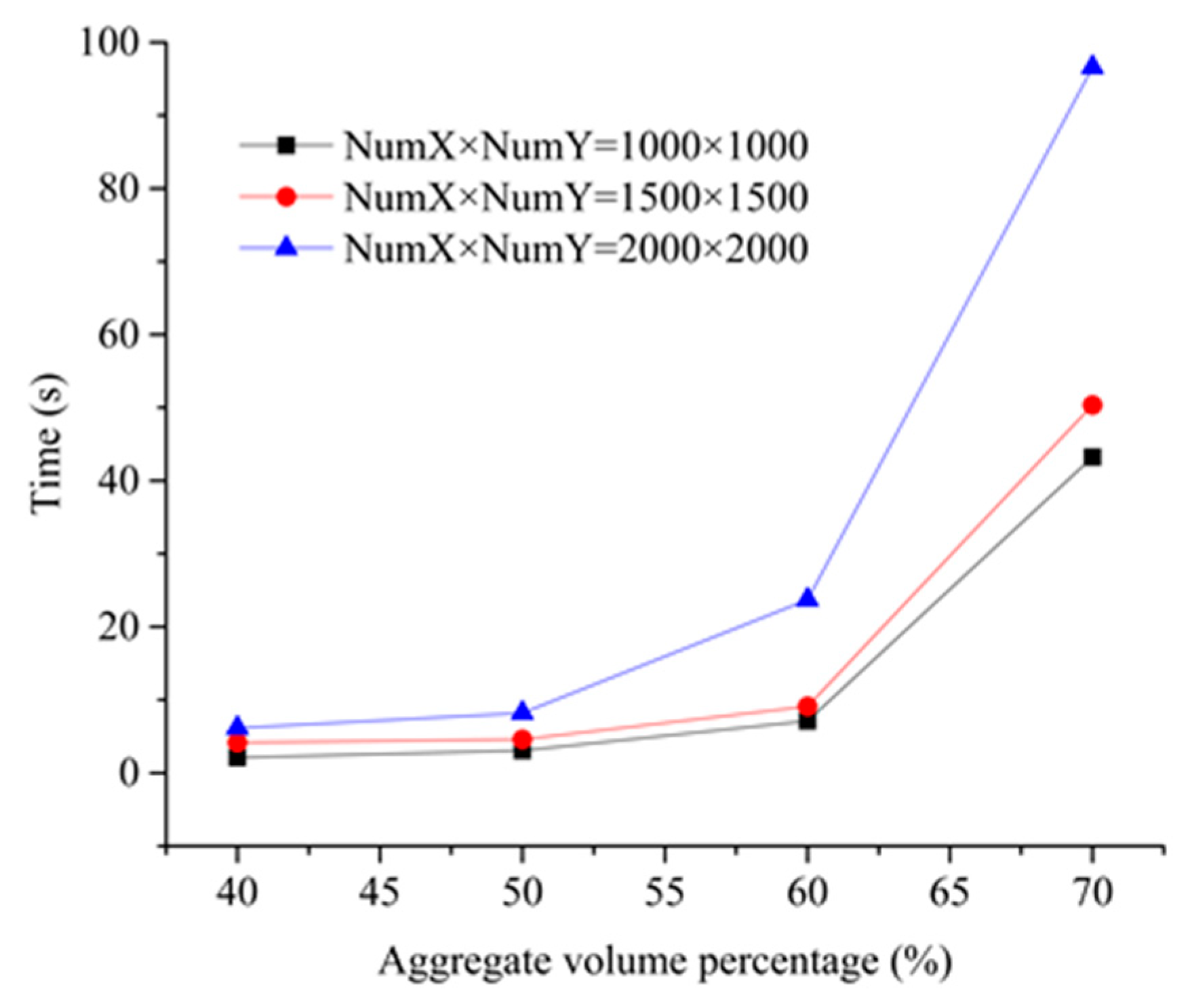

NumX and

NumY can be determined as follows:

where

Dmin represents the smallest size of aggregates in the study.

4.4. Generation of Irregular Stone and Rounded Stone Concrete Models

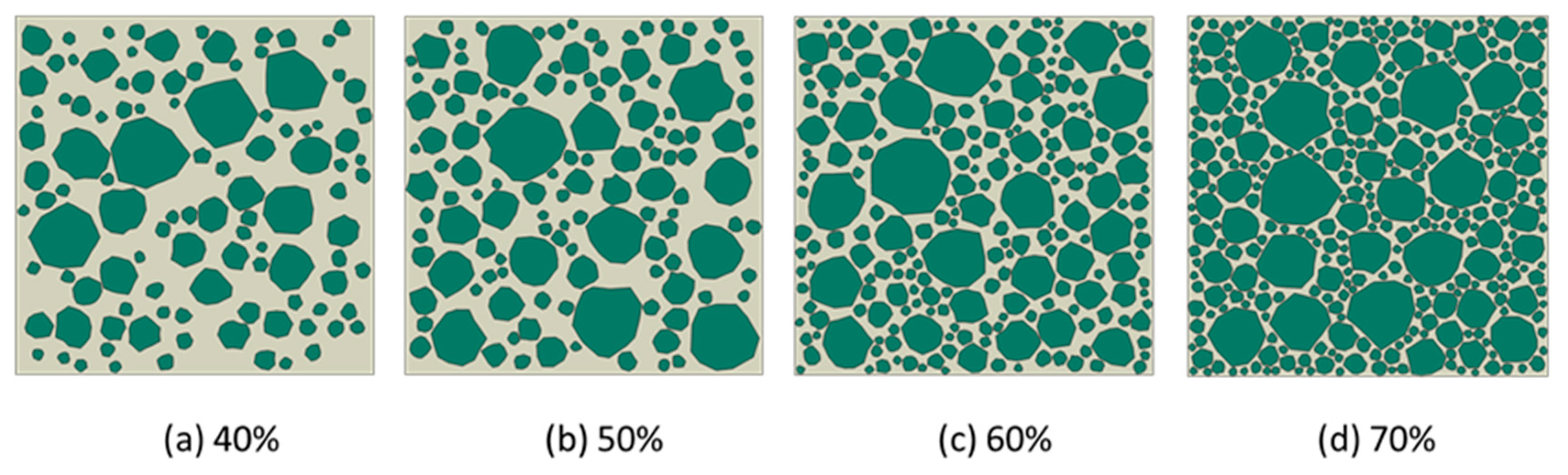

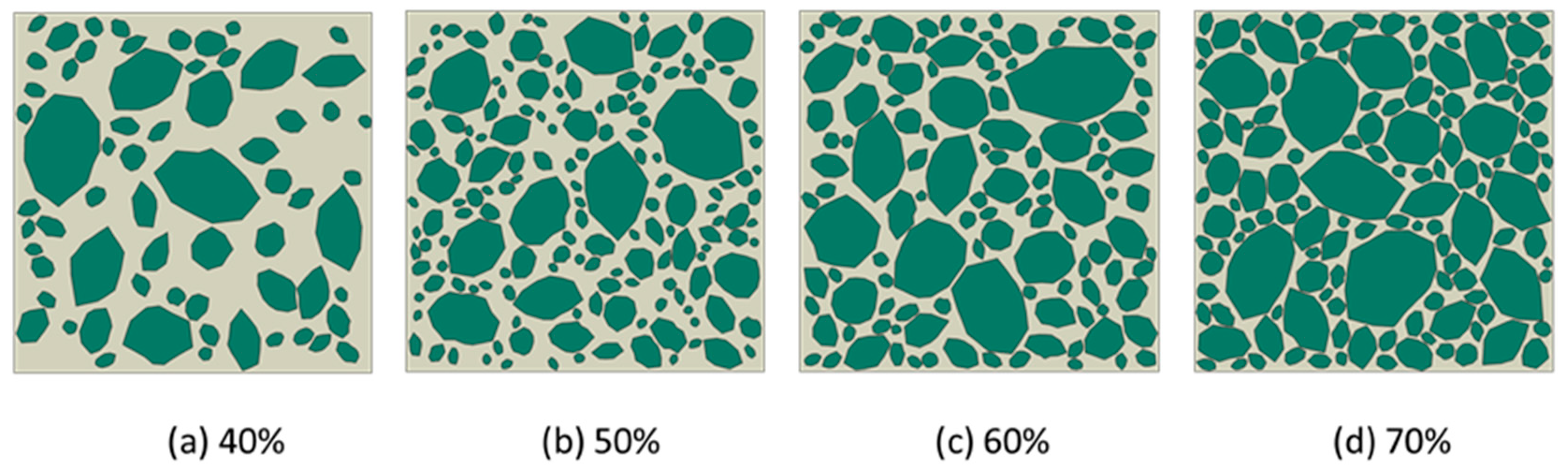

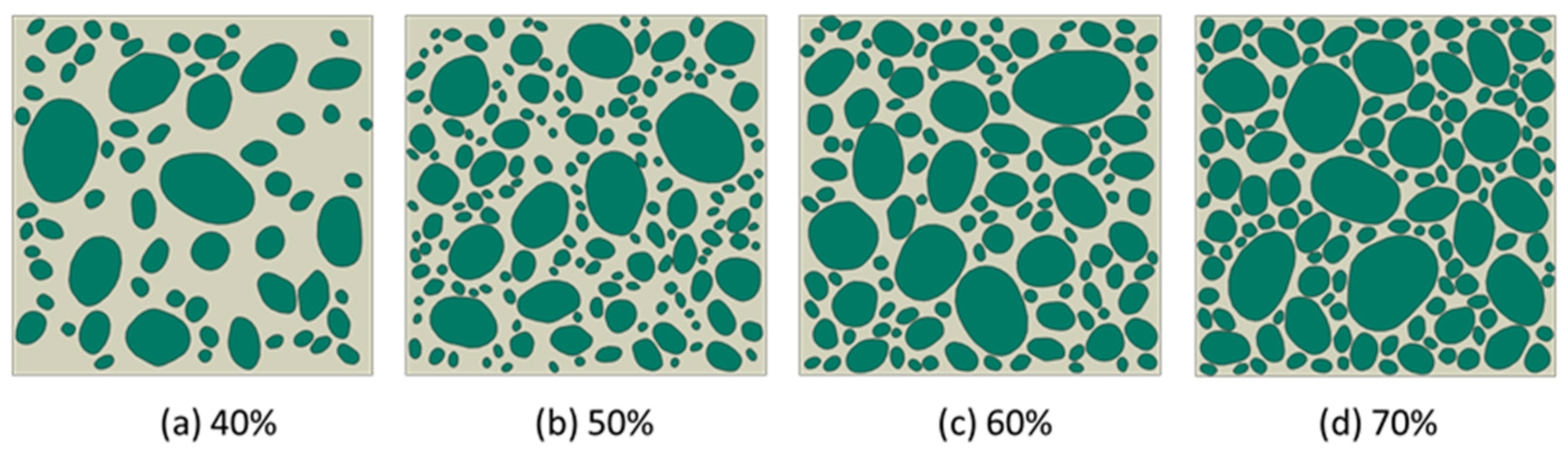

From the placement principle of numerical concrete constituents aforementioned, the concrete material models are given as in

Figure 12, based on the irregular aggregate grading in concrete, while in

Figure 13, the created concrete models were based on the elongated aggregate grading. Noted that in the present work, the sieve diameters were as follows, 2.36 mm, 4.75 mm, 9.5 mm, 16.0 mm, and 19.0 mm. Further, the minimum aggregate size was limited to 0.6 times the minimum sieve diameter, and the maximum aggregate size was 1.2 times the maximum sieve diameter.

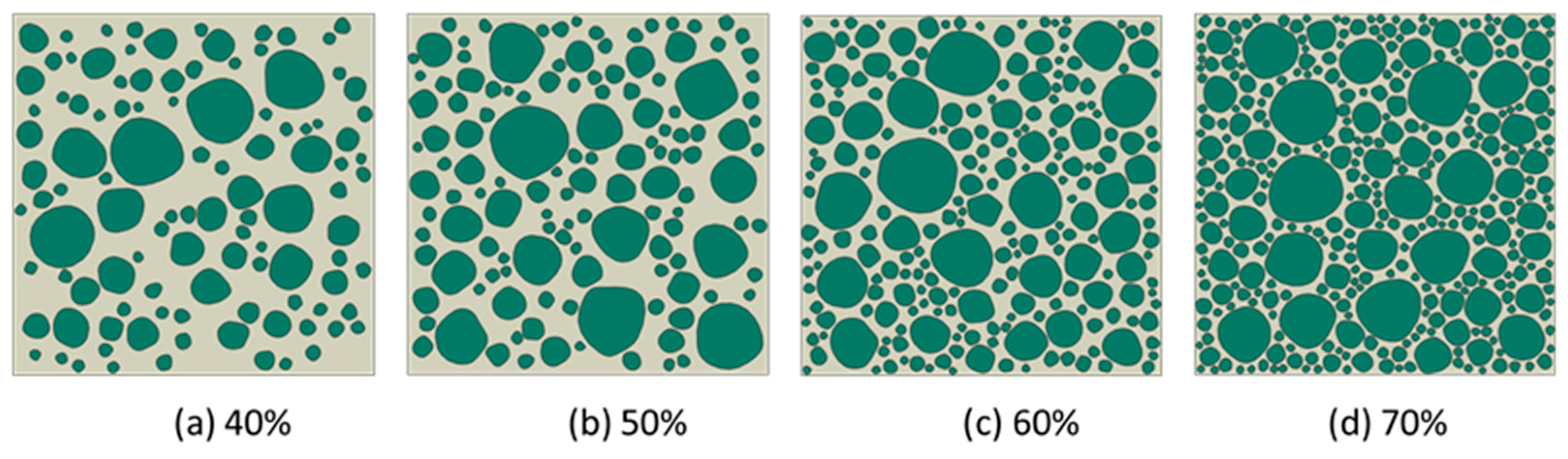

The generation of rounded aggregates was based on the shape of crushed ones in the present work. The difference between the two fashions used to generate aggregates only was how to utilize the vertex data of polygon. For example, in

Figure 14a, the construction of crushed aggregates was to connect the vertices of the polygons with straight lines. However, the construction of rounded aggregates uses the midpoint of each side of the polygon as a control point and connects the control points through the spline curves. In many meshing software systems such as Gmsh [

38] and Abaqus [

39], the script can provide a plotting function for the spline, as long as the coordinates of the control points given in turn. The rounded aggregate volume produced by this method will be slightly lower than the predetermined aggregate volume. This small difference is a side effect caused by the midpoint of each side of the polygon as a spline control point. However, if the vertex of the polygon is used as the spline control point, the final aggregate volume may not only be higher than the predetermined aggregate volume, but also cause mutual overlap between the aggregates, as shown in

Figure 14b. Therefore, the former method was used to construct the shape of gravel aggregate in the present work. According to the construction principle of gravel aggregate, the numerical concrete models under different aggregate volume fractions are depicted as shown in

Figure 15 and

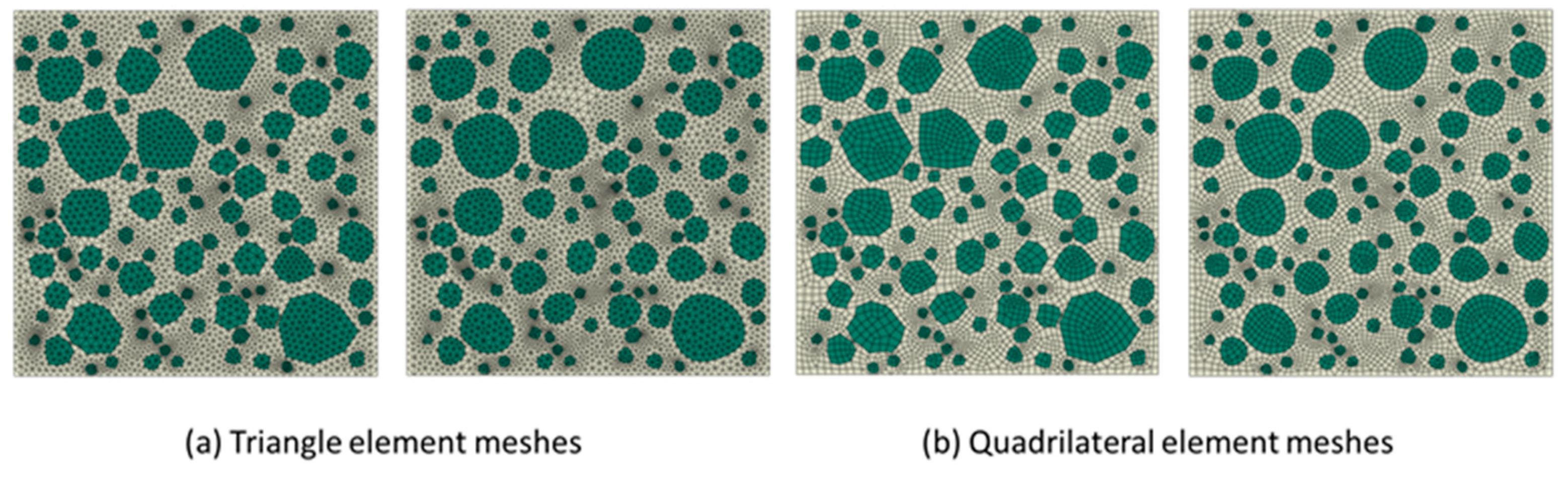

Figure 16. We could readily obtain the finite element meshes of such mesostructure concrete models by anyone of free or commercial FE meshing software systems such as Gmsh [

38] and Abaqus [

39], as given in

Figure 17. It is noted that our proposed method could also be employed to provide the essential database for the discrete element methods when regarding placed aggregates as material particles.

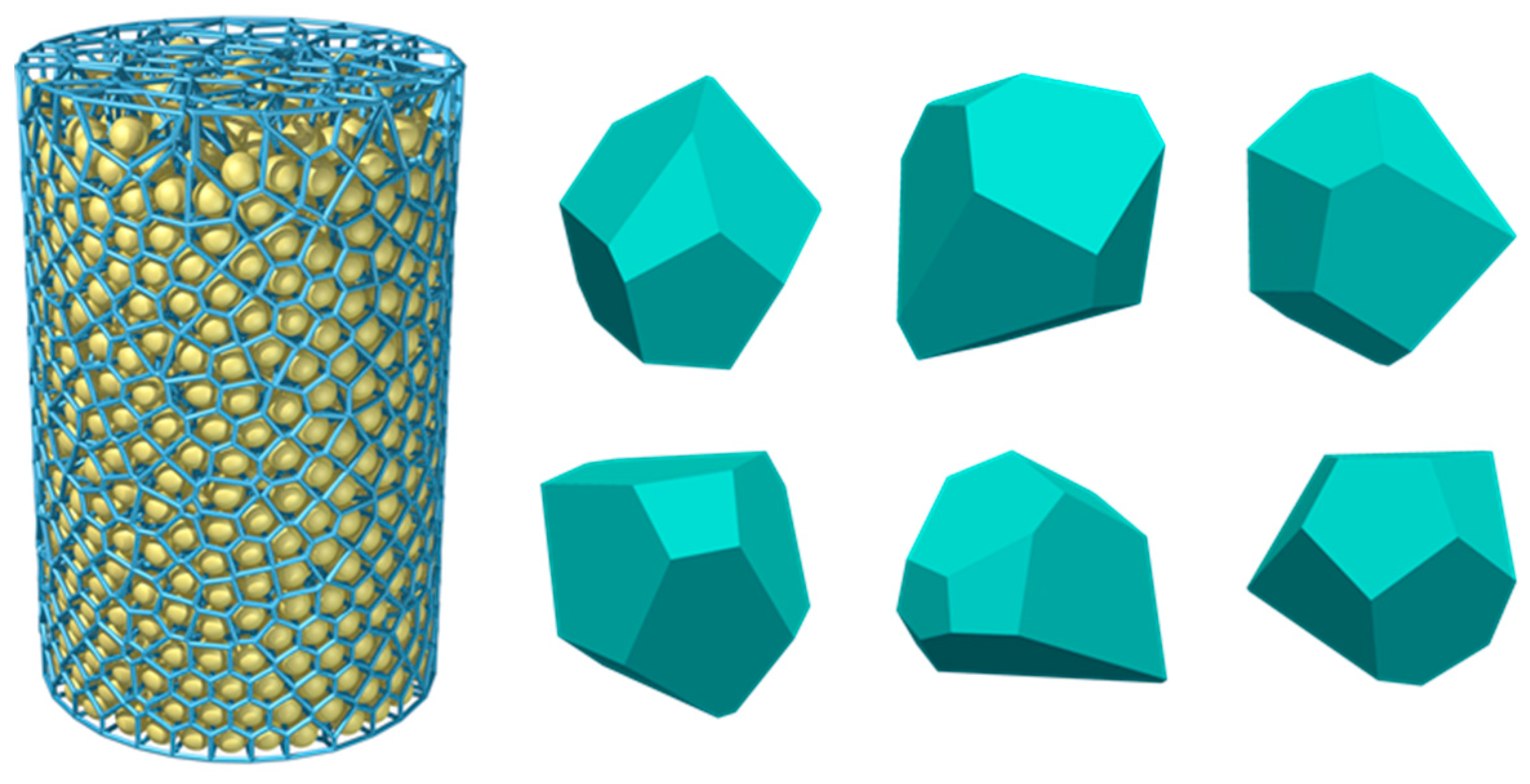

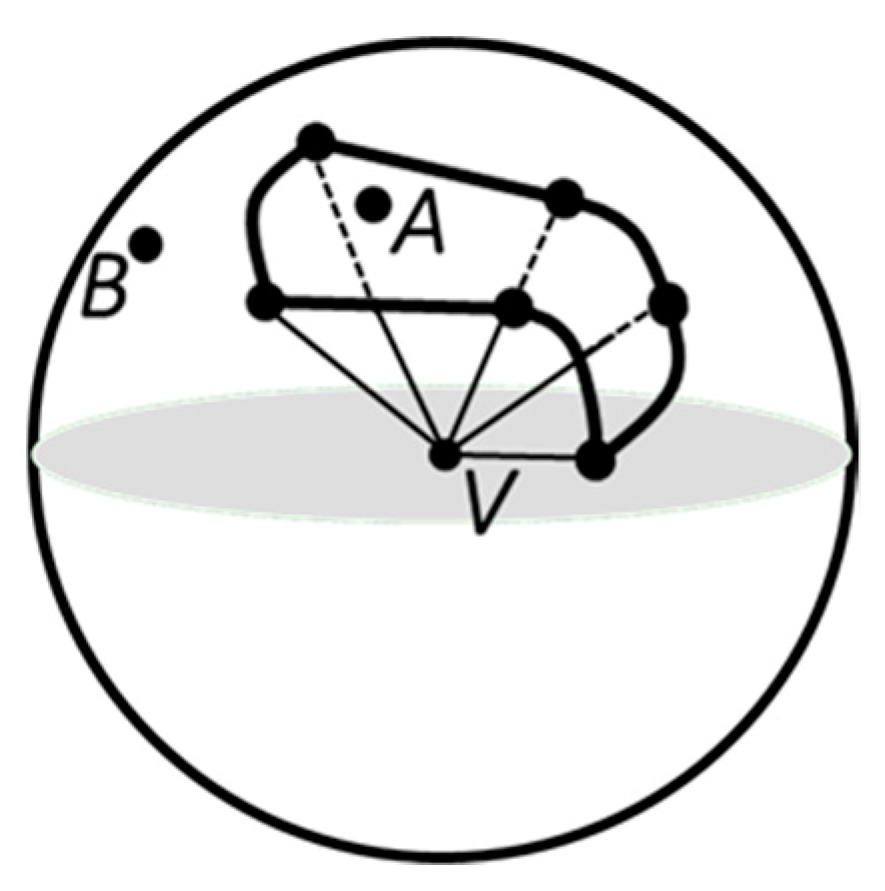

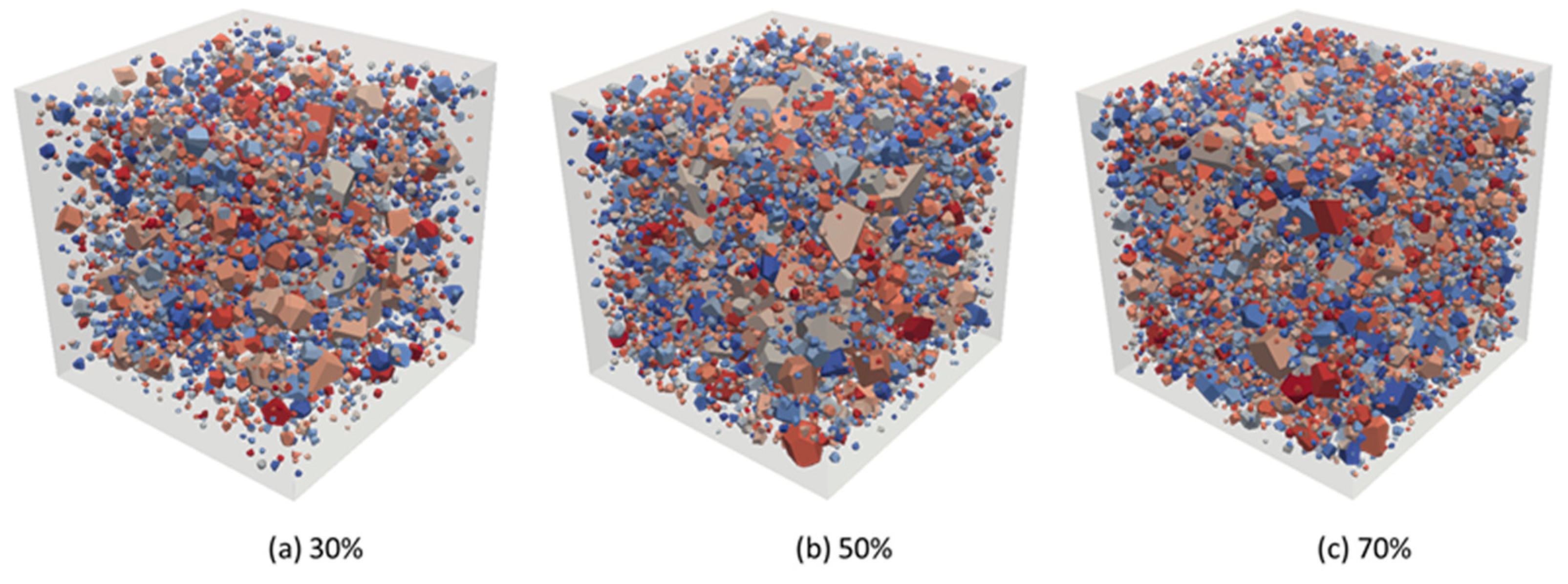

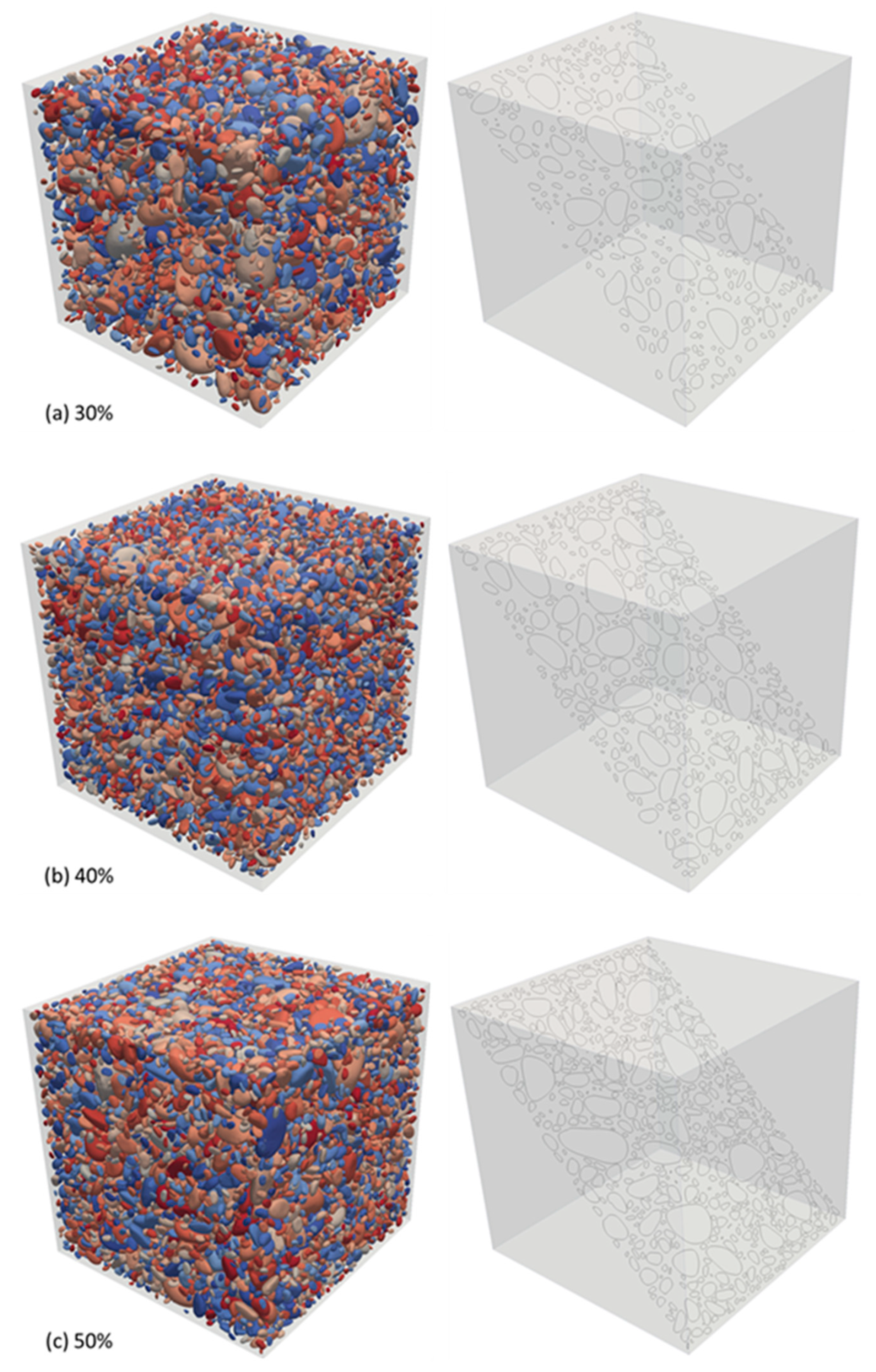

4.6. Generation of 3D Rounded and Crushed Stone Concrete Models

In the 3D case, the sieve diameters were as follows, 2.36 mm, 4.75 mm, 9.5 mm, 16.0 mm, 19.0 mm, 26.5 mm, and 31.5 mm. Similar to the 2D case, the minimum aggregate size was limited to 0.6 times the minimum sieve diameter, and the maximum aggregate size was 1.2 times the maximum sieve diameter. We used the 3D Voronoi cell library [

33] to create the database of generating concrete composite material models. The irregular convex-shaped aggregates taken from the database according to the grading curve in

Section 2.3 were placed into a pre-defined container using the present DMM, as shown in

Figure 19. It is noted that in our DMM, we could create a numerical concrete model relying on grading curve and aggregate volume fraction, both accurately and flexibly.

As the discussions in

Section 1 and

Section 2, the increasingly mature 3D laser scanning technology provides us with a tool to characterize the arbitrary surface morphology of aggregate particles. Thus we established the rounded aggregate database according to the grading curve above but the individual aggregate particles obtained by Artec 3D laser scanning equipment [

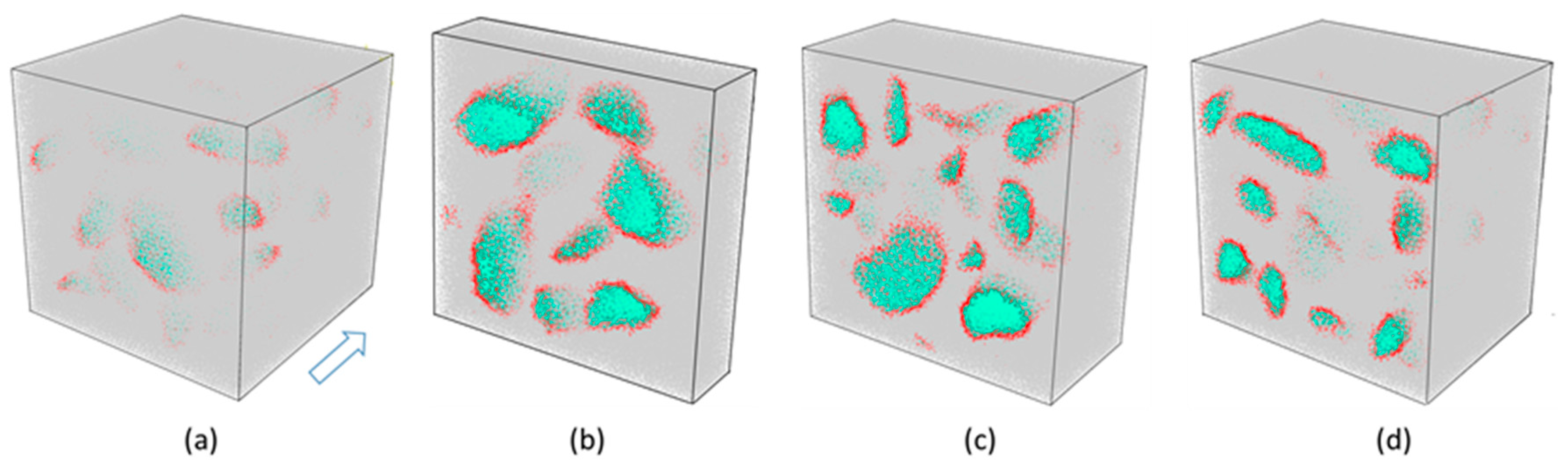

32]. Consequently, we again employed DMM to construct the rounded aggregate composite models, as indicated in

Figure 20. To conveniently observe the spatial distribution of the aggregate particles, we presented three typical slices that are also shown in

Figure 20. Certainly, these slice results were not only to help understanding the mesolevel constitutions of the concrete models but also to verify and validate the present DMM’s applicability and efficiency. At the same time, we could check if there was any overlapping aggregate with help of slice at any position in the models to judge whether the concrete models by DMM were successful or not. It was emphasized here that since the output accuracy of the 3D laser scanning device was generally adjustable, we could consider the topography geometric data of a given aggregate from the viewpoint of the compromise in both compatibility and usability in accordance with the purpose and requirements of numerical concrete models. It was pointed out that the present 3D results were visualized by ParaView software (visited on 7 August 2019) [

40].

As an example of mesostructure concrete model by DMM, we employed DMM to construct the concrete geometry model with mesostructure. The aggregate volume fraction in the model was small to simplify the problem as well as to conveniently visualize the components. After these works, one of the simplest ways is that we could apply any mesh generation software to a geometry zone identified with the concrete model with the aggregate distribution to yield a great number of tetrahedron with mesh. We further utilized the surface coordinates provided by the aggregates in the mesostructure model to delimit where these aggregates locate in the mesh so that we could assign to the corresponding material properties with respect to aggregates, interface transformation zones, and mortar. Here we presented a lattice model by our DMM combined with Gmsh software [

38], as shown in

Figure 21. Among this lattice model, it is noted that the beams or rods between aggregate zones (represented by beams or rods with the aggregate properties) and mortar (also represented by beams or rods but with different properties to distinguish from the aggregates) are regarded as the interface beams or rods, which are characterized by interface models. Indeed we could establish reinforced concrete models by DMM, as did in [

41,

42,

43], to investigate the behaviors of reinforced concrete beams. Furthermore, we could also construct beam-particle models to study cracking process in concrete by DMM combined with discrete element methods such as in [

44,

45]. These works will be done in the future.

The limit of the present DMM is that in the 3D case, a huge memory was sometimes required to deal with a large number of discrete integer and float variables in the study. For example, if a 3D dot matrix of concrete model is composed by the integer number of 1000 × 1000 × 1000, it at least needs approximately the memory of 7.45 GB for computers to process the primary data of interest. Therefore, further work is needed to develop a parallel computing method for DMM. Another future task that needs to be finished is how to deal with periodic material boundaries in the construction process of composite material models.