The Influence of WEDM Parameters Setup on the Occurrence of Defects When Machining Hardox 400 Steel

Abstract

1. Introduction

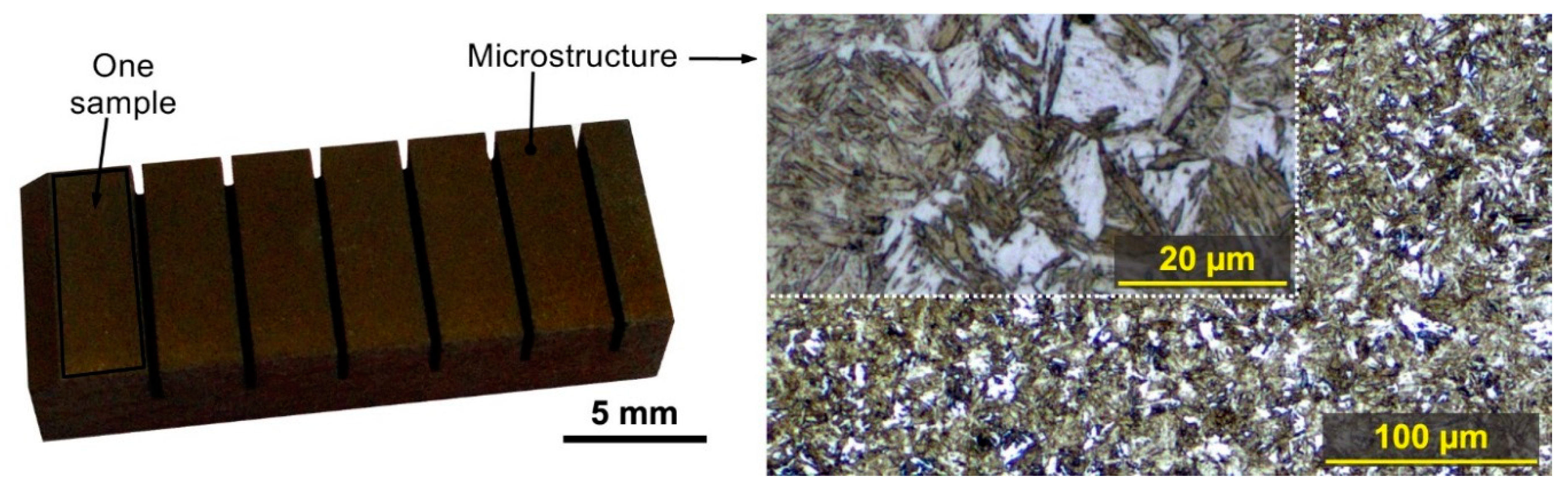

2. Experimental Setup and Material

2.1. Experimental Material

2.2. WEDM Machine Setup

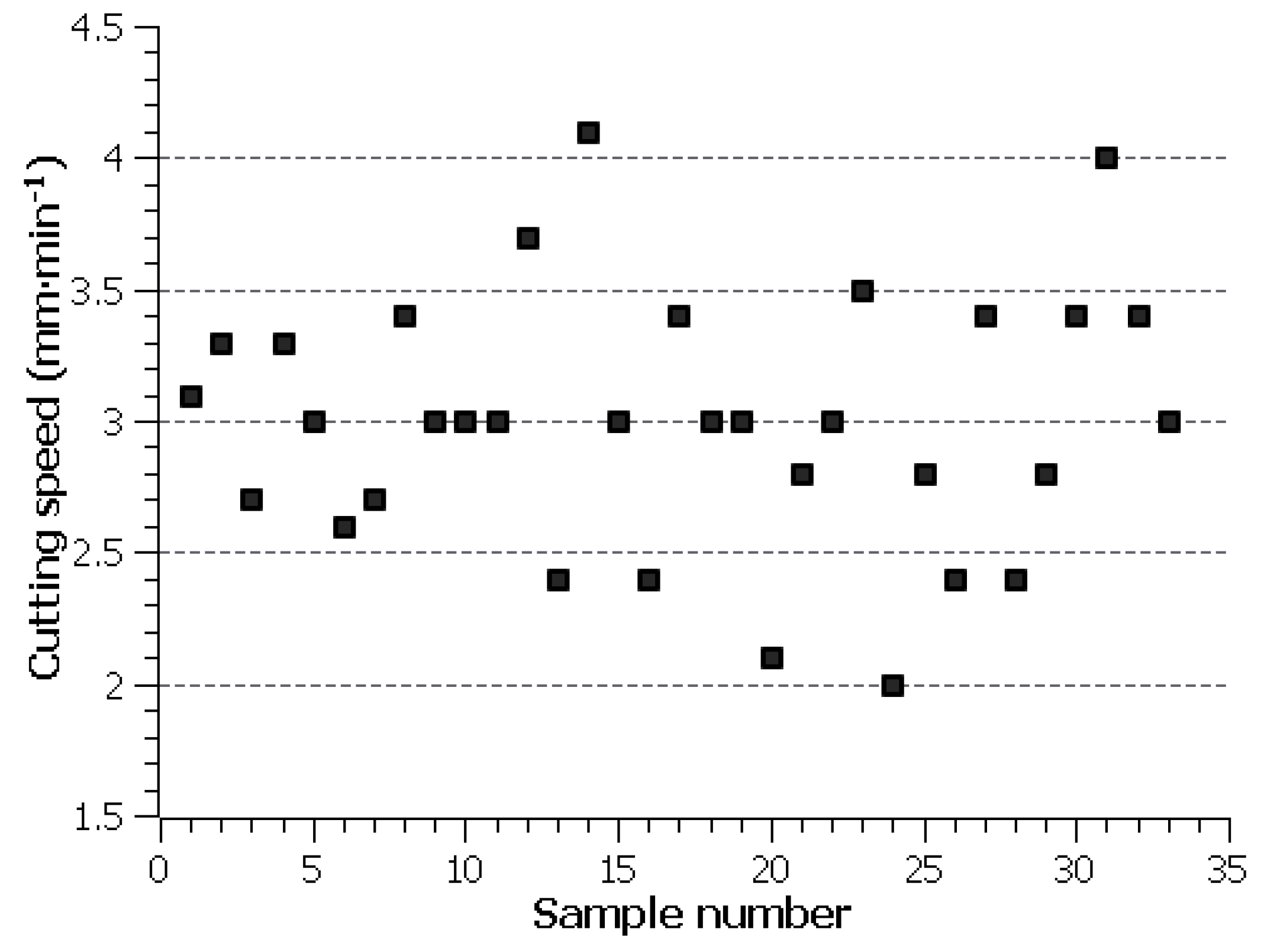

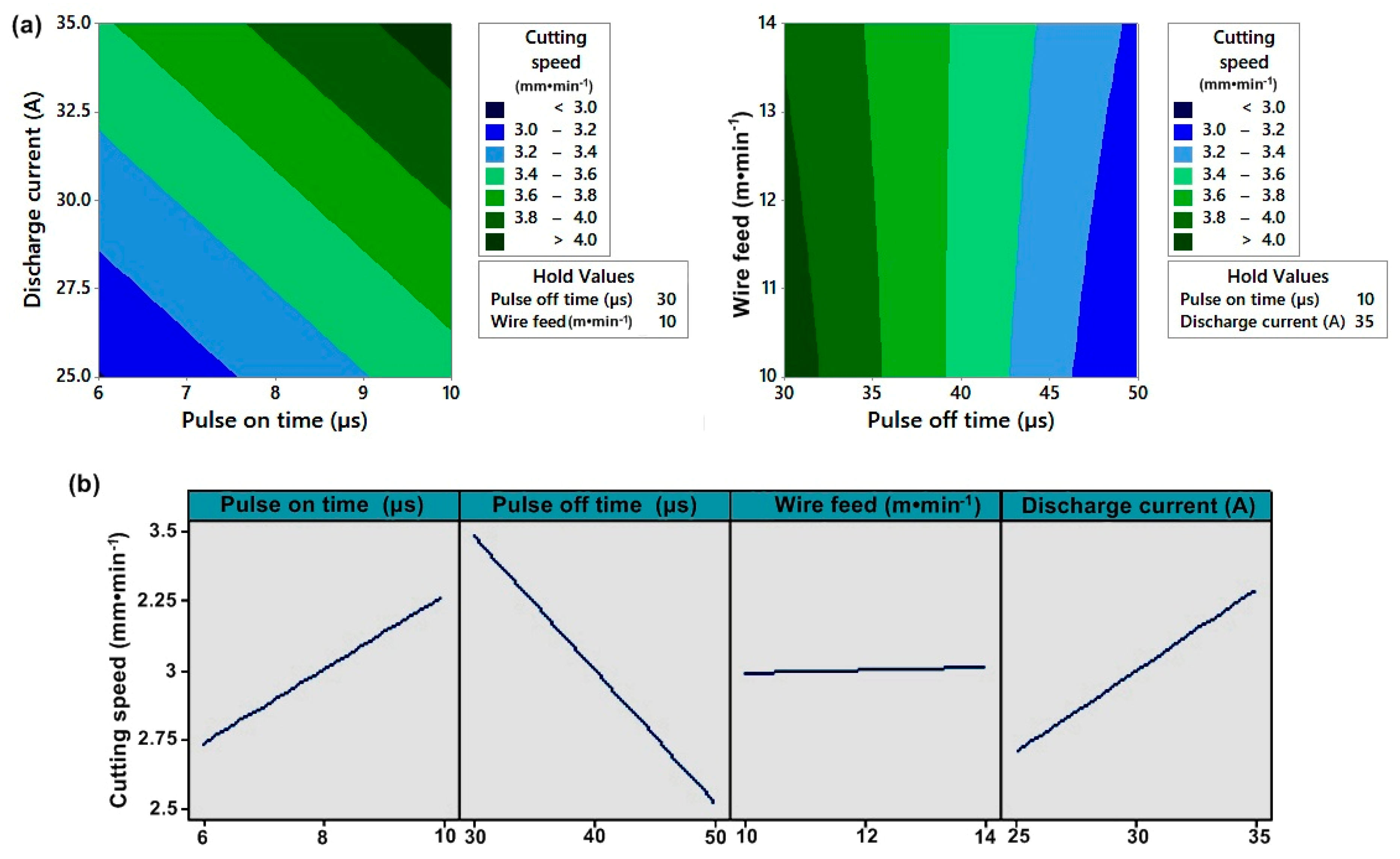

3. Statistical Evaluation of the Cutting Speed

4. Analysis of the Machined Surface and Discussion

4.1. Experimental Methods

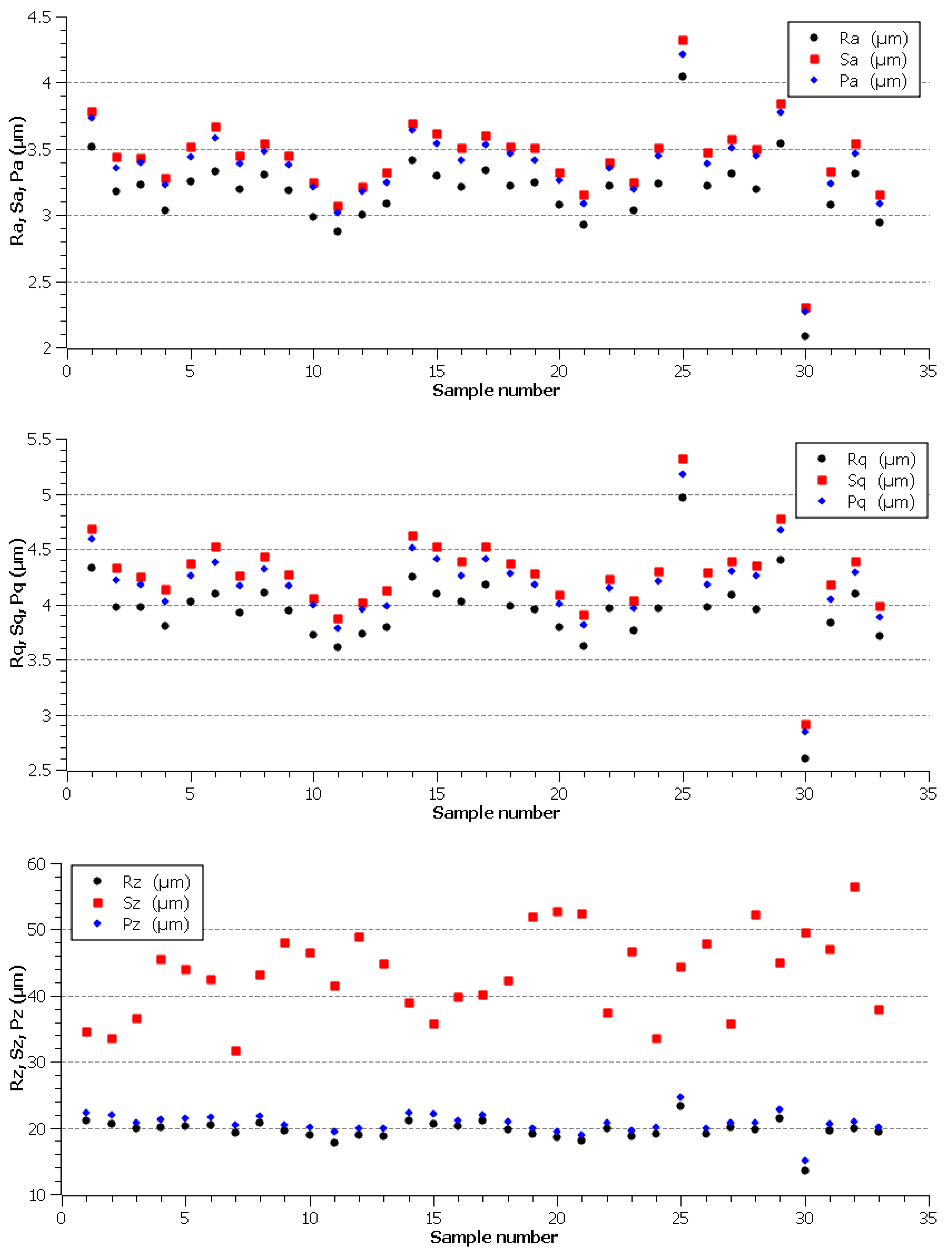

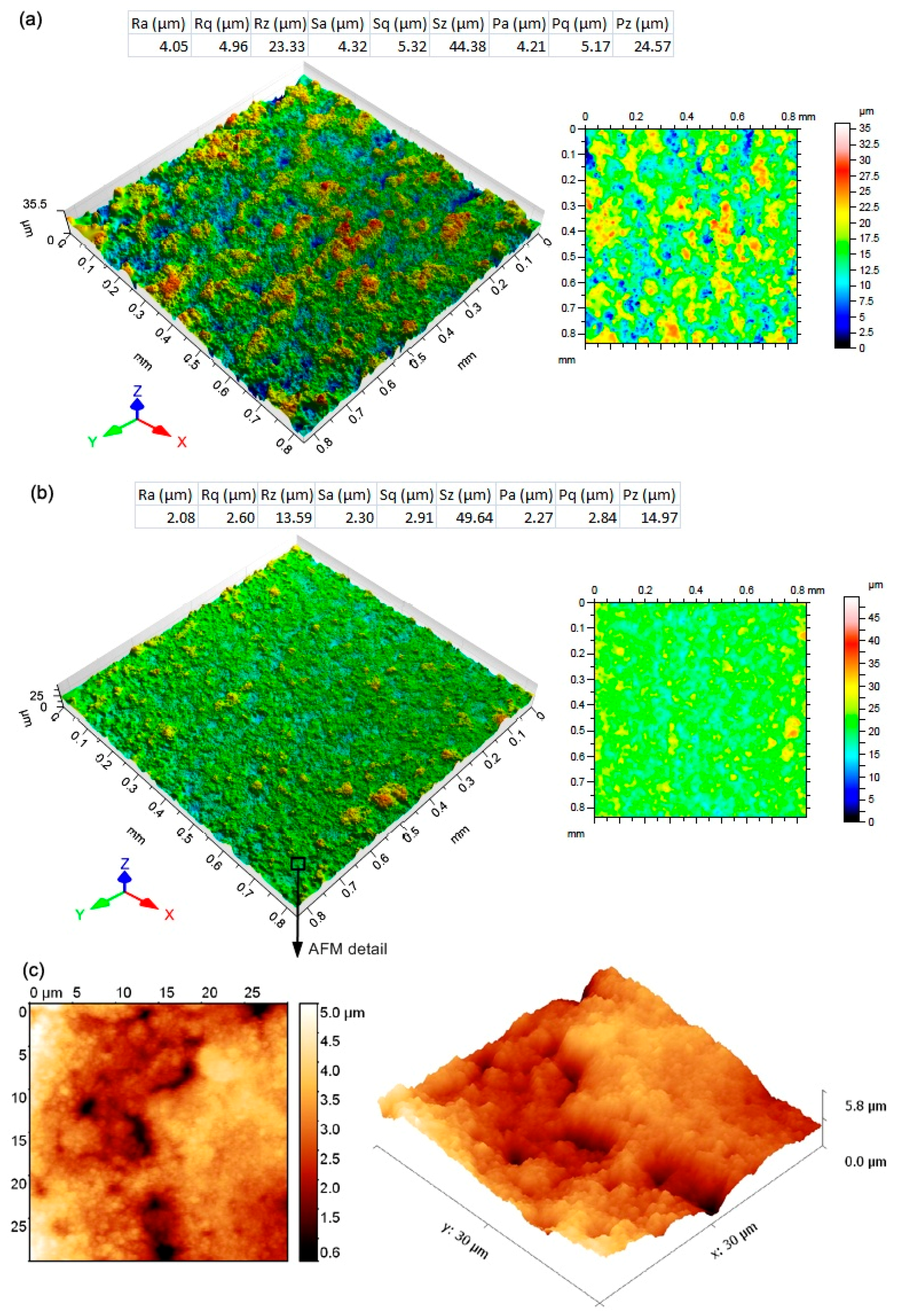

4.2. Surface Topography Analysis

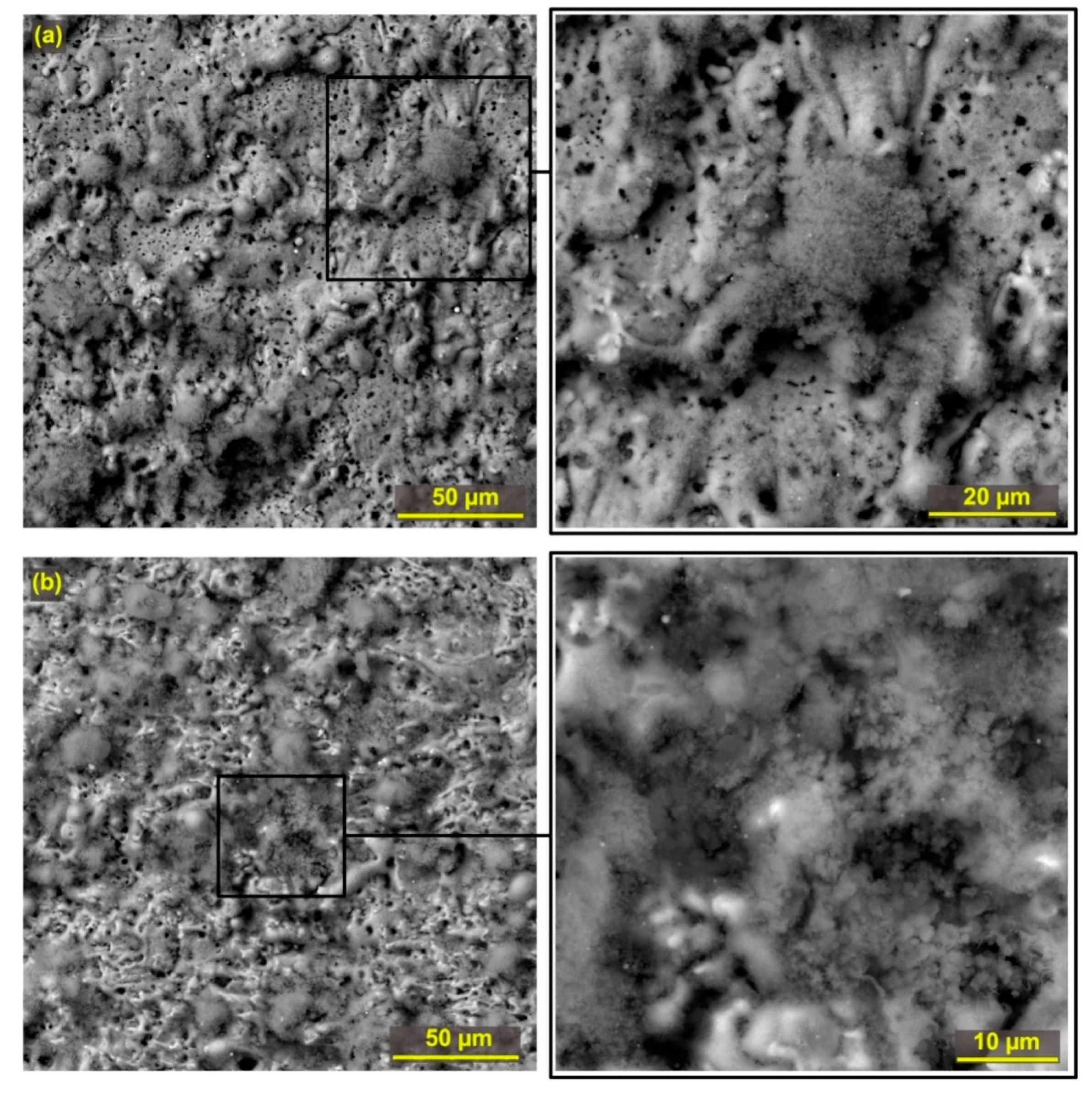

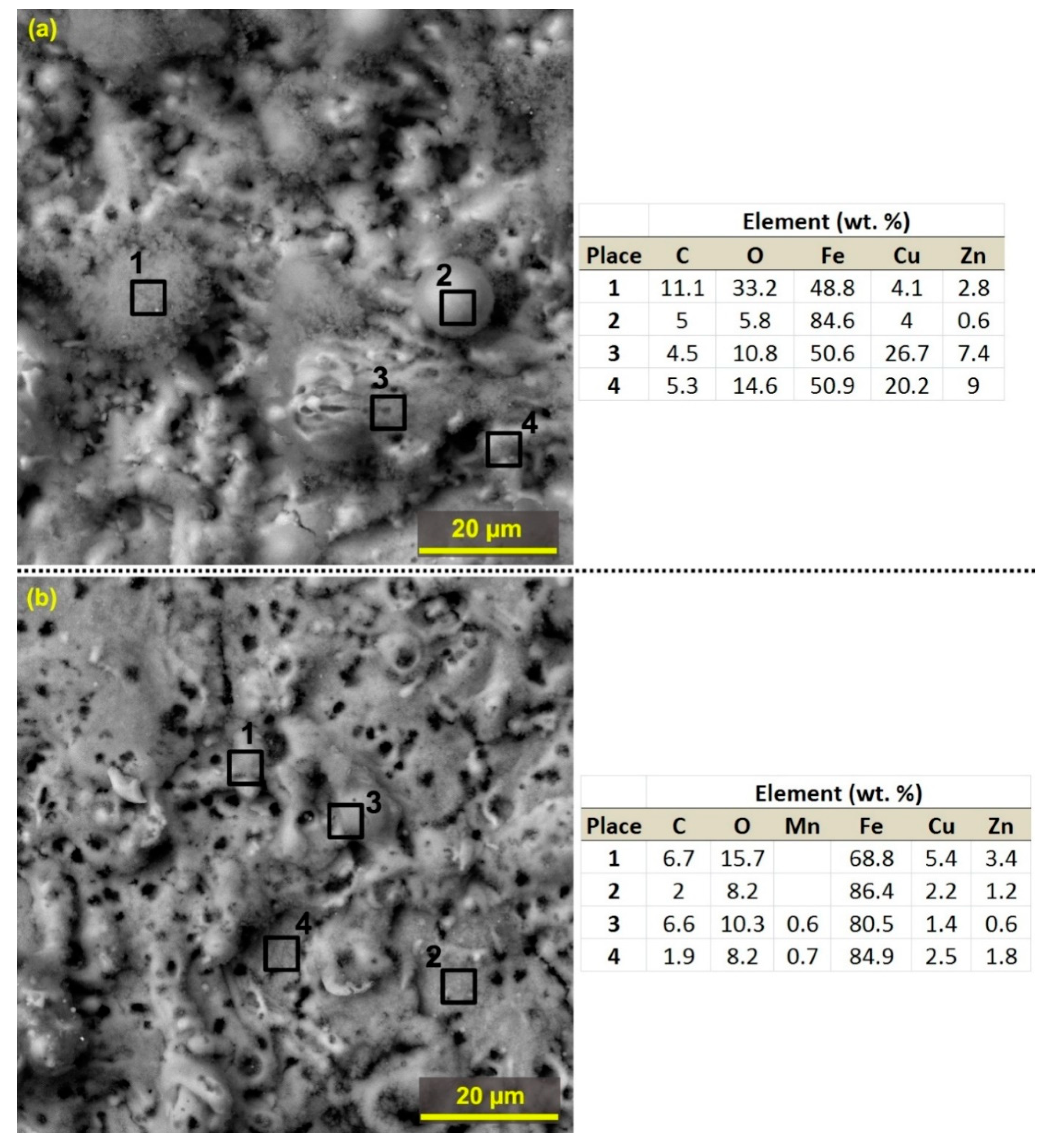

4.3. Surface Area Analysis

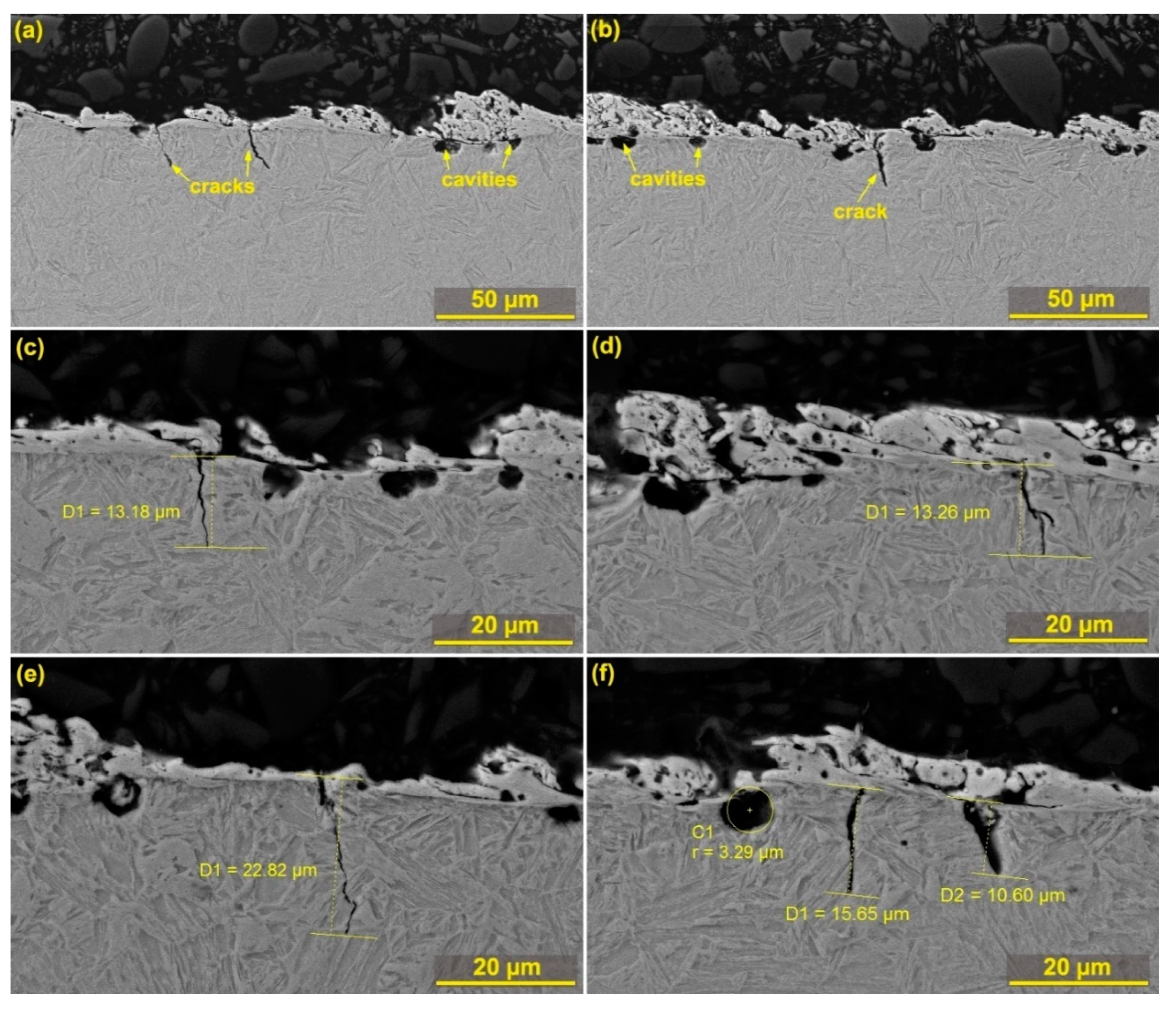

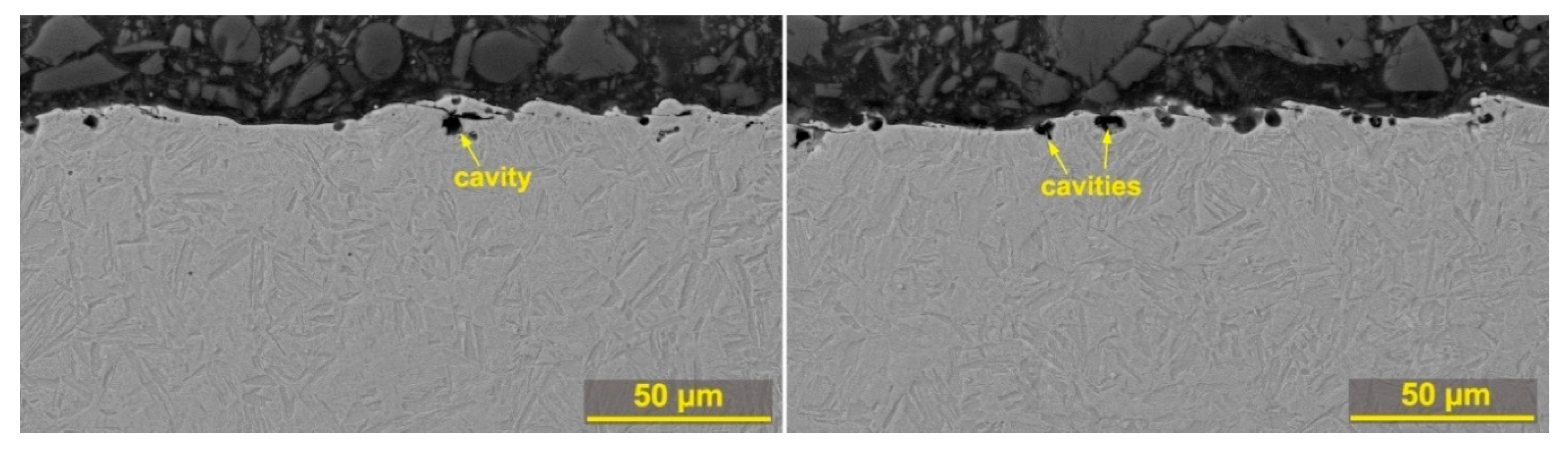

4.4. The Subsurface Analysis

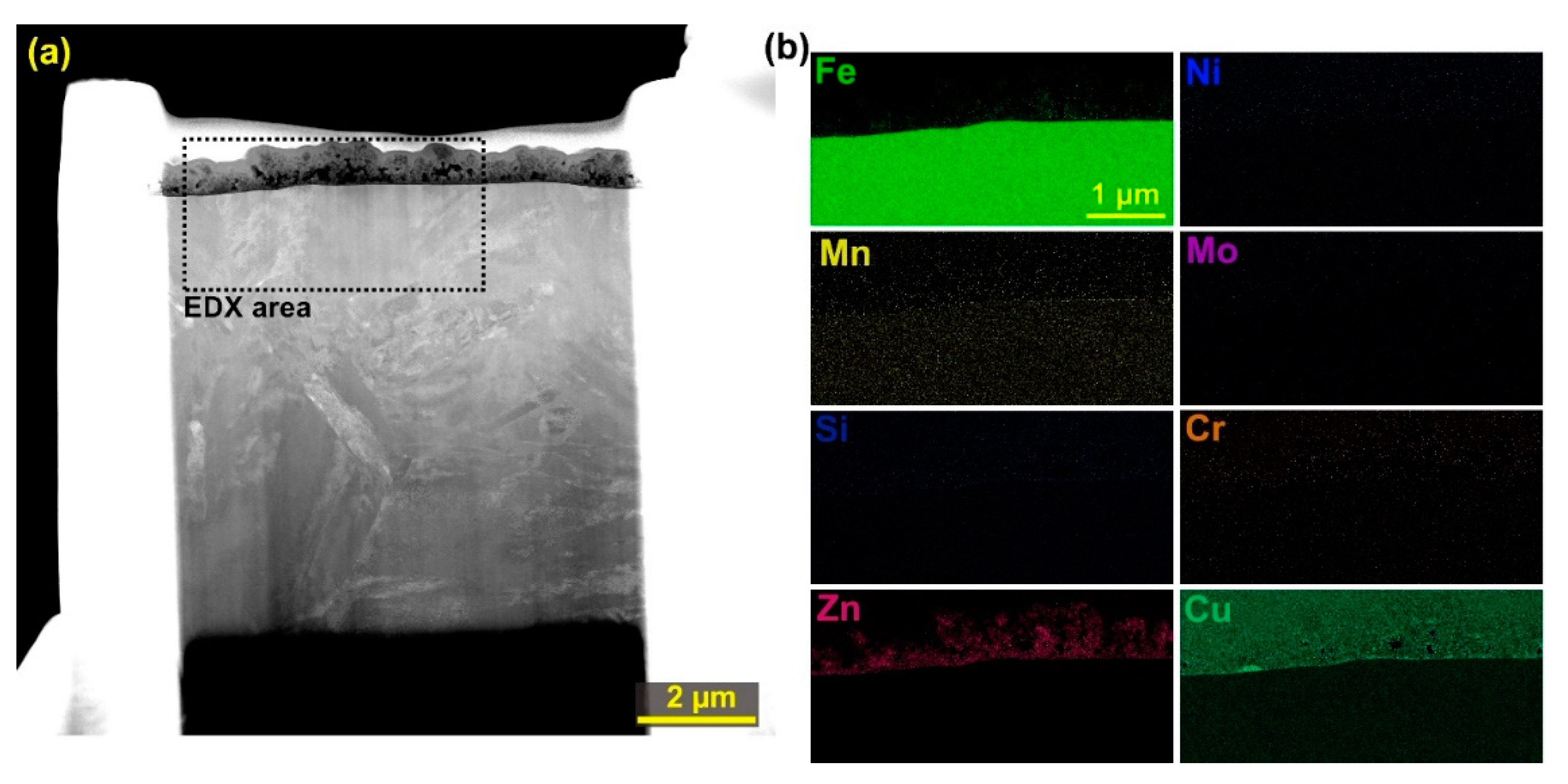

4.5. The Analysis of TEM Lamella

5. Conclusions

- Sample 31 was machined at the highest speed of 4 mm·min−1 without breaking of the wire electrode with machine setting parameters: U = 50 V, Ton = 10 µs, Toff = 30 µs, v = 14 m·min−1 and I = 35 A,

- using a regression analysis, a mathematical model was created to calculate the cutting speed, with a positive effect of the factor Ton, I and the negative effect of Toff on the cutting speed, based on the Main effect plot,

- the lowest roughness parameter values were obtained for Sample 30, i.e., only Ra 2.08 µm, (by machine parameters setup: U = 70 V, Ton = 6 µs, Toff = 30 µs, v = 14 m·min−1, and I = 35 A), and this pattern also had a visibly smoother 3D relief surface,

- the surface morphology of Sample 30 with the lowest roughness was covered by a noticeably smaller amount of recast layer than all other samples, and there was also significantly less diffusion of elements from the wire electrode,

- the subsurface analysis revealed a large number of cracks up to 22 µm in length and burned cavities in all samples produced, except for Sample 30, whose surface was covered with only a small amount of small cavities,

- the recast layer thickness for all samples examined was below 20 µm and covered the entire surface of each sample except for Sample 30, which was only covered by the recast layer by 20%, and the thickness did not exceed 5 µm,

- the analysis of TEM lamellae showed a homogeneous distribution of elements in the base material, with the recast layer as the only area with different concentration of elements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McGeough, J.A. Advanced Methods of Machining; Springer Science & Business Media: New York, NY, USA, 1988. [Google Scholar]

- Knight, A.W.; Geoffrey, B. Fundamentals of Metal Machining and Machine Tools, 3rd ed.; CRC Press: New York, NY, USA, 2005; ISBN 1574446592. [Google Scholar]

- Jain, V.K. Advanced Machining Processes; Allied Publishers: New Delhi, India, 2009. [Google Scholar]

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tool. Manu 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Frydman, S.; Pękalski, G. Structure and hardness changes in welded joints of Hardox steels. Arch. Civ. Mech. Eng. 2008, 8, 15–27. [Google Scholar] [CrossRef]

- Manjaiah, M.; Laubscher, R.F.; Kumar, A.; Basavarajappa, S. Parametric optimization of MRR and surface roughness in wire electro discharge machining (WEDM) of D2 steel using Taguchi−based utility approach. Int. J. Mech. Mater. Eng. 2016, 11, 7. [Google Scholar] [CrossRef]

- Lusi, N.; Muzaka, K.; Soepangkat, B.O.P. Parametric optimization of wire electrical discharge machining process on AISI H13 tool steel using weigthed principal component analysis (WPCA) and taguchi method. ARPN J. Eng. Appl. Sci. 2016, 11, 945–951. [Google Scholar]

- Klocke, F.; Hensgen, L.; Klink, A.; Ehle, L.; Schwedt, A. Structure and composition of the white layer in the wire−EDM process. Procedia CIRP 2016, 42, 673–678. [Google Scholar] [CrossRef]

- Abdullah, B.; Nordin, M.F.N.; Basir, M.H.M. Investigation on CR, MRR and SR of wire electrical discharge machining (WEDM) on high carbon steel S50C. J. Teknol. 2015, 76, 109–113. [Google Scholar] [CrossRef][Green Version]

- Reddy, C.B.; Reddy, C.E.; Reddy, D.R. Experimental investigation of surface finish and material removal rate of P20 die−tool steel in wire−EDM using multiple regression analysis. GSTF J. Eng. Technol. (JET) 2012, 1, 735–744. [Google Scholar]

- Sinha, P.; Kumar, R.; Singh, G.K.; Thomas, D. Multi−objective optimization of wire EDM of AISI D3 tool steel using orthogonal array with principal component analysis. Mater. Today Proc. 2015, 2, 3778–3787. [Google Scholar] [CrossRef]

- Nayak, B.B.; Mahapatra, S.S.; Chatterjee, S.; Abhishek, K. Parametric appraisal of WEDM using harmony search algorithm. Mater. Today Proc. 2015, 2, 2562–2568. [Google Scholar] [CrossRef]

- Mouralova, K.; Klakurkova, L.; Matousek, R.; Prokes, T.; Hrdy, R.; Kana, V. Influence of the cut direction through the semi−finished product on the occurrence of cracks for X210Cr12 steel using WEDM. Arch. Civ. Mech. Eng. 2018, 18, 1318–1331. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Prokes, T. Effect of width of kerf on machining accuracy and subsurface layer after WEDM. J. Mater. Eng. Perform. 2018, 27, 1–9. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Zahradnicek, R.; Bednar, J.; Hrabec, P.; Prokes, T.; Matouse, R.; Fiala, Z. Quality of surface and subsurface layers after WEDM aluminum alloy 7475−T7351 including analysis of TEM lamella. Int. J. Adv. Manuf. Tech. 2018, 99, 2309–2326. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Bednar, J.; Benes, L.; Zahradnicek, R. Analysis of surface morphology and topography of pure aluminium machined using WEDM. Measurement 2018, 114, 169–176. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2013; ISBN 978−1118146927−X. [Google Scholar]

- Harcarik, M.; Jankovych, R. Relationship between values of profile and areal surface texture parameters. MM Sci. J. 2016, 5, 1659–1662. [Google Scholar] [CrossRef]

- ISO; BSEN. “25178–2: Geometric Product Specification, Surface Texture (Areal). Part 2: Terms, Definitions and Surface Texture Parameters”; British Standards Institute: London, UK, 2012. [Google Scholar]

- ISO; EN. “4287–Geometrical Product Specifications (GPS)–Surface Texture: Profile Method–Terms, Definitions and Surface Texture Parameters”; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- Altuğ, M. Investigation of Hardox 400 Steel exposed to heat treatment processes in WEDM. Politek. Derg. 2019, 22, 237–244. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Prokes, T.; Horynova, M. Comparison of morphology and topography of surfaces of WEDM machined structural materials. Measurement 2017, 104, 12–20. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Zahradnicek, R.; Bednar, J.; Hrabec, P.; Prokes, T.; Hrdy, R. Analysis of cut orientation through half−finished product using WEDM. Mater. Manuf. Process. 2019, 34, 70–82. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Bednar, J.; Zahradnicek, R.; Prokes, T.; Matousek, R.; Fiserova, Z.; Otoupalik, J. Using a DoE for a comprehensive analysis of the surface quality and cutting speed in WED−machined hadfield steel. J. Mech. Sci. Technol. 2019, 33, 1–16. [Google Scholar] [CrossRef]

- Huang, C.A.; Hsu, F.Y.; Yao, S.J. Microstructure analysis of the martensitic stainless steel surface fine−cut by the wire electrode discharge machining (WEDM). Mater. Sci. Eng. A 2004, 371, 119–126. [Google Scholar] [CrossRef]

- Huang, C.A.; Hsu, C.C.; Kuo, H.H. The surface characteristics of P/M high−speed steel (ASP 23) multi−cut with wire electrical discharge machine (WEDM). J. Mater. Process Tech. 2003, 140, 298–302. [Google Scholar] [CrossRef]

- Kovar, K.J.; Zahradnicek, R. Machining of highly oriented pyrolitic graphite using WEDM and the resulting quality of the surface. MM Sci. J. 2016, 6, 1621–1624. [Google Scholar]

- Mouralova, K.; Prokes, T.; Benes, L. Surface and subsurface layers defects analysis after WEDM affecting the subsequent lifetime of produced components. Arab. J. Sci. Eng. 2019, 44, 1–13. [Google Scholar] [CrossRef]

| Parameter | Discharge Current (A) | Pulse off Time (µs) | Pulse on Time (µs) | Gap Voltage (V) | Wire Feed (m·min−1) |

|---|---|---|---|---|---|

| Level 1 | 25 | 50 | 6 | 50 | 10 |

| Level 2 | 30 | 40 | 8 | 60 | 12 |

| Level 3 | 35 | 30 | 10 | 70 | 14 |

| Number of Sample | Discharge Current (A) | Gap voltage (V) | Pulse off Time (µs) | Pulse on Time (µs) | Wire Feed (m·min−1) | Number of Sample | Discharge Current (A) | Gap Voltage (V) | Pulse off Time (µs) | Pulse on Time (µs) | Wire Feed (m·min−1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 30 | 70 | 40 | 8 | 12 | 18 | 30 | 60 | 40 | 8 | 12 |

| 2 | 30 | 60 | 30 | 8 | 12 | 19 | 30 | 60 | 40 | 8 | 12 |

| 3 | 25 | 60 | 40 | 8 | 12 | 20 | 25 | 70 | 50 | 6 | 14 |

| 4 | 30 | 60 | 40 | 10 | 12 | 21 | 25 | 50 | 30 | 6 | 14 |

| 5 | 30 | 50 | 40 | 8 | 12 | 22 | 30 | 60 | 40 | 8 | 12 |

| 6 | 30 | 60 | 50 | 8 | 12 | 23 | 25 | 70 | 30 | 10 | 14 |

| 7 | 30 | 60 | 40 | 6 | 12 | 24 | 25 | 50 | 50 | 6 | 10 |

| 8 | 35 | 60 | 40 | 8 | 12 | 25 | 30 | 60 | 40 | 8 | 12 |

| 9 | 30 | 60 | 40 | 8 | 10 | 26 | 25 | 50 | 50 | 10 | 14 |

| 10 | 30 | 60 | 40 | 8 | 14 | 27 | 25 | 50 | 30 | 10 | 10 |

| 11 | 30 | 60 | 40 | 8 | 12 | 28 | 35 | 50 | 50 | 6 | 14 |

| 12 | 35 | 50 | 30 | 6 | 10 | 29 | 35 | 50 | 50 | 10 | 10 |

| 13 | 25 | 70 | 50 | 10 | 10 | 30 | 35 | 70 | 30 | 6 | 14 |

| 14 | 35 | 70 | 30 | 10 | 10 | 31 | 35 | 50 | 30 | 10 | 14 |

| 15 | 30 | 60 | 40 | 8 | 12 | 32 | 30 | 60 | 40 | 8 | 12 |

| 16 | 35 | 70 | 50 | 6 | 10 | 33 | 25 | 70 | 30 | 6 | 10 |

| 17 | 35 | 70 | 50 | 10 | 14 | – | – | – | – | – | – |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouralova, K.; Prokes, T.; Benes, L.; Bednar, J. The Influence of WEDM Parameters Setup on the Occurrence of Defects When Machining Hardox 400 Steel. Materials 2019, 12, 3758. https://doi.org/10.3390/ma12223758

Mouralova K, Prokes T, Benes L, Bednar J. The Influence of WEDM Parameters Setup on the Occurrence of Defects When Machining Hardox 400 Steel. Materials. 2019; 12(22):3758. https://doi.org/10.3390/ma12223758

Chicago/Turabian StyleMouralova, Katerina, Tomas Prokes, Libor Benes, and Josef Bednar. 2019. "The Influence of WEDM Parameters Setup on the Occurrence of Defects When Machining Hardox 400 Steel" Materials 12, no. 22: 3758. https://doi.org/10.3390/ma12223758

APA StyleMouralova, K., Prokes, T., Benes, L., & Bednar, J. (2019). The Influence of WEDM Parameters Setup on the Occurrence of Defects When Machining Hardox 400 Steel. Materials, 12(22), 3758. https://doi.org/10.3390/ma12223758