Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials

Abstract

:1. Introduction

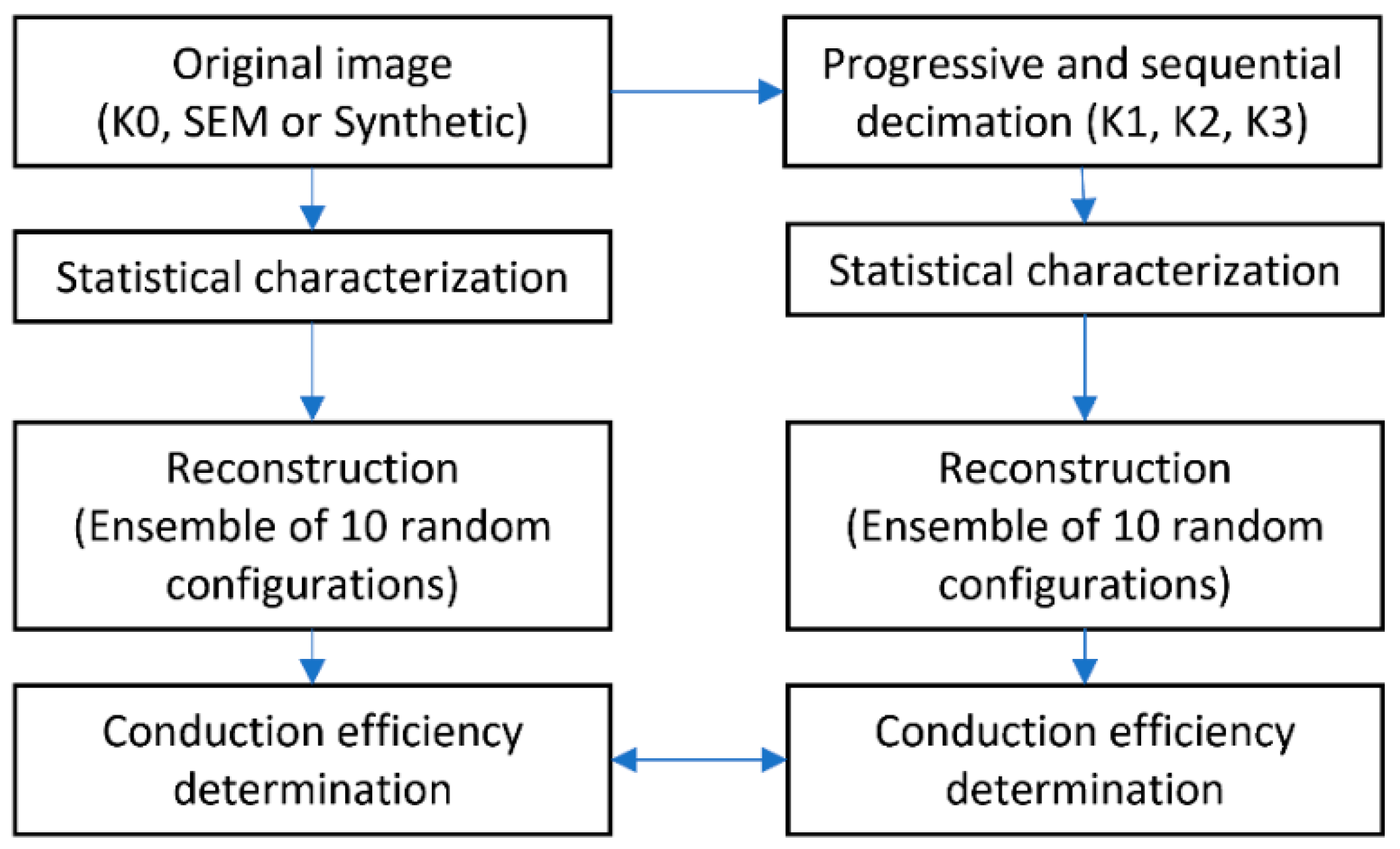

2. Methods and Materials

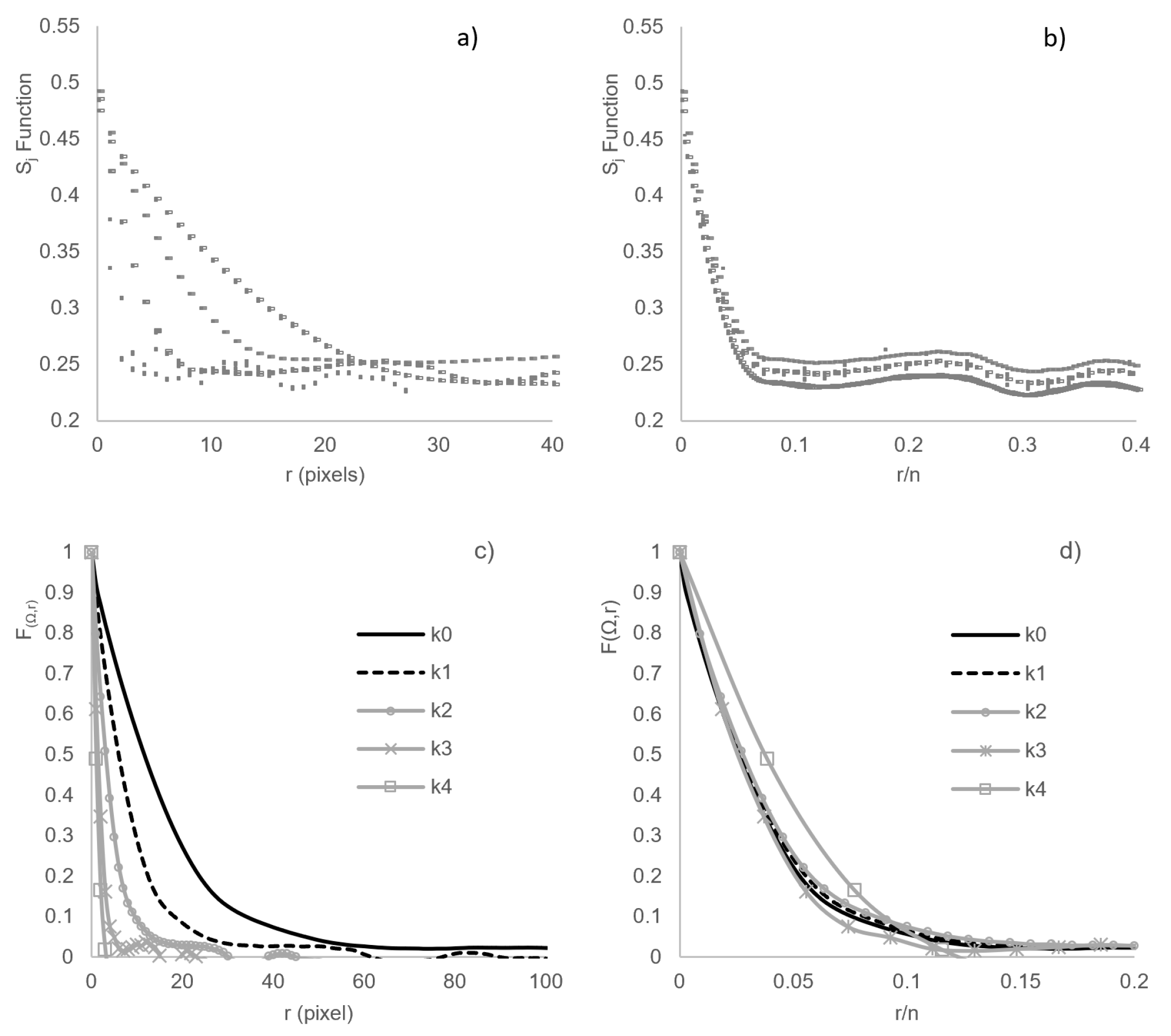

2.1. Statistical Descriptors and Reconstruction

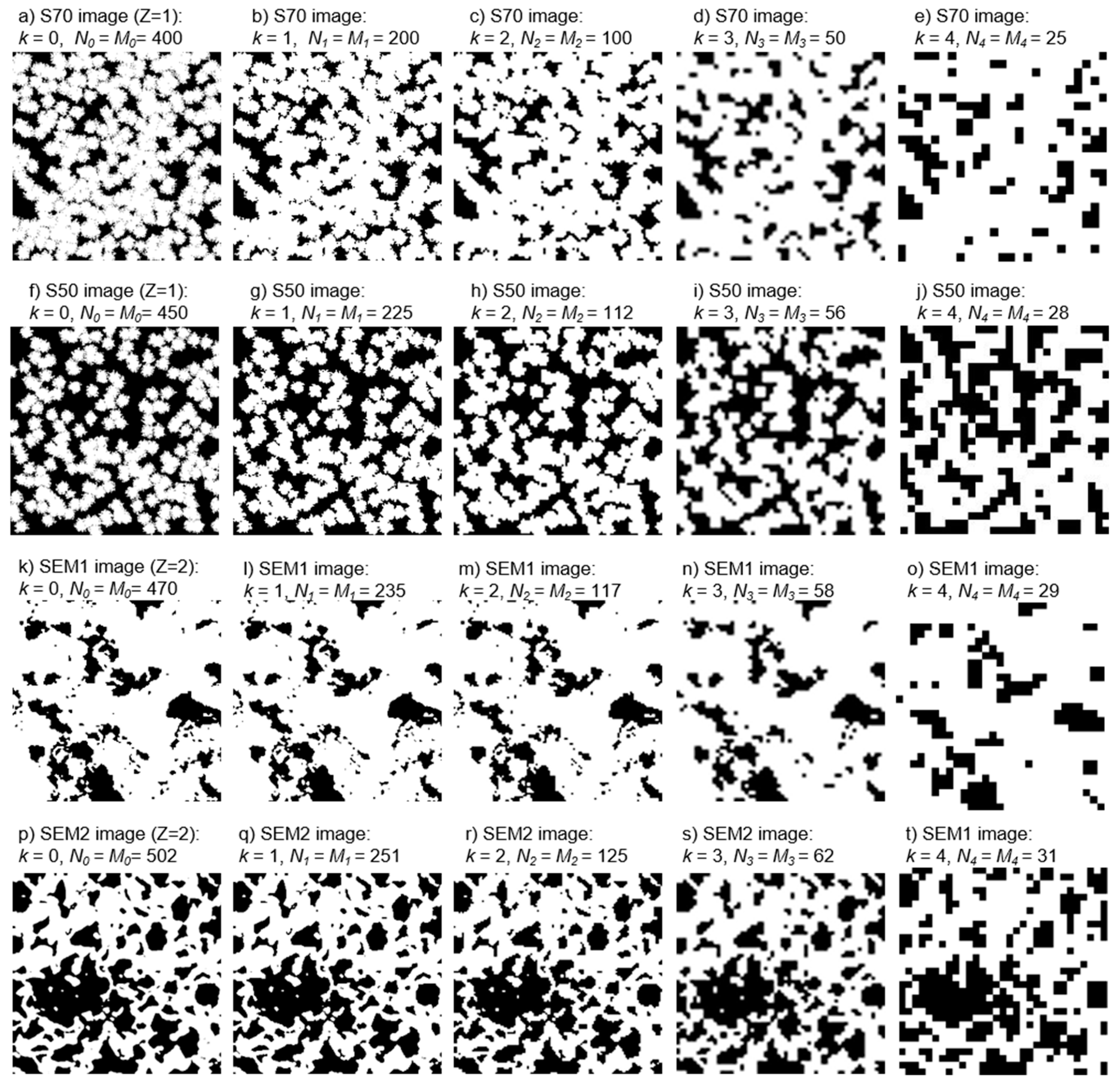

2.2. Decimation Process

2.3. Effective Transport Coefficient

3. Results and Discussion

3.1. Image Processing

3.2. Reconstruction and Statistical Analysis of Microstructures

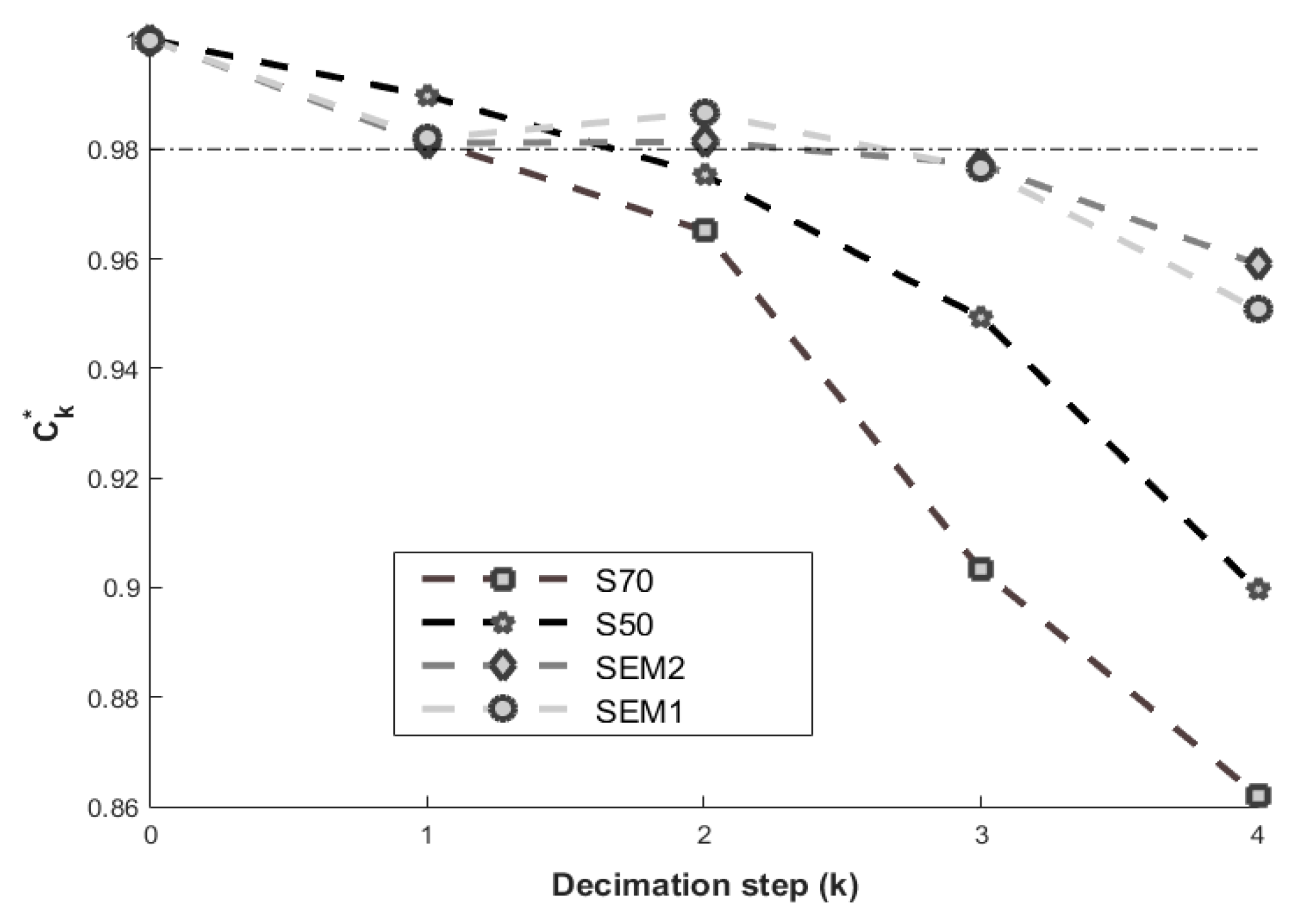

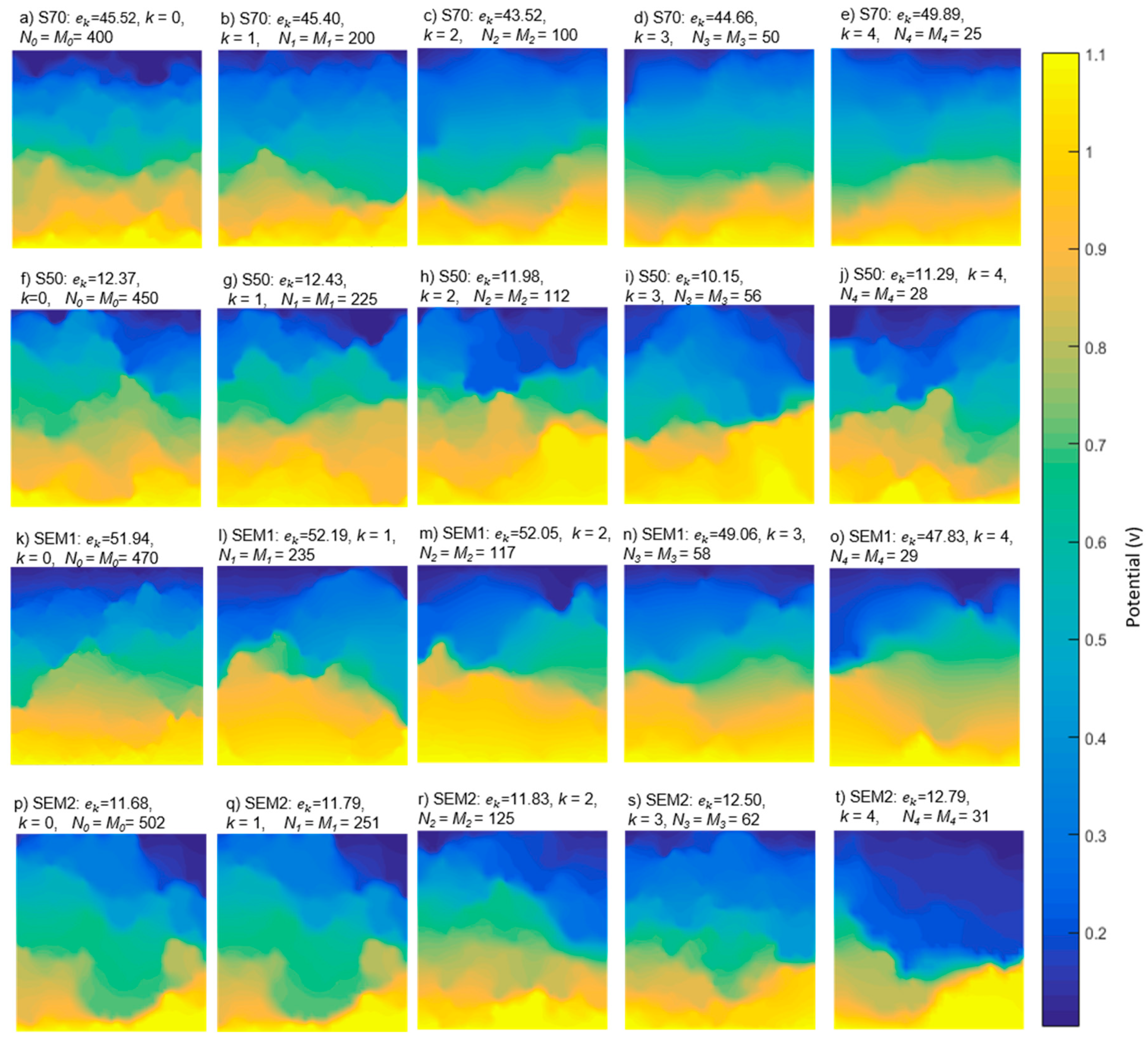

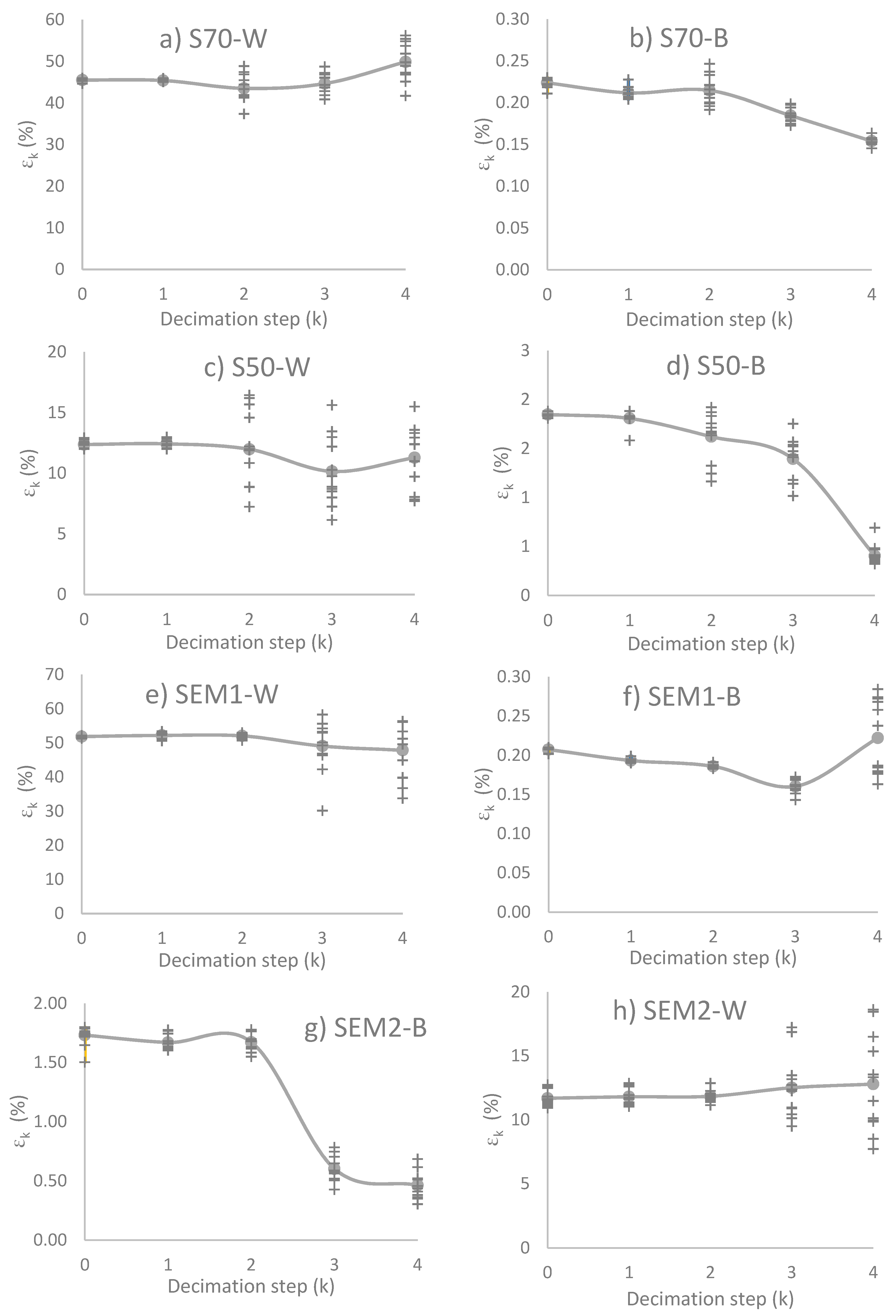

3.3. Effective Transport Coefficient

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barbosa, R.; Andaverde, J.; Escobar, B.; Cano, U. Stochastic reconstruction and a scaling method to determine effective transport coefficients of a proton exchange membrane fuel cell catalyst layer. J. Power Sources 2011, 196, 1248–1257. [Google Scholar] [CrossRef]

- Cano, U.; Barbosa, R. Reconstruction of PEM fuel cell electrodes with micro- and nano-structures. In Micro & Nano-Engineering of Fuel Cells; Leung, D.Y.C., Xuan, J., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Escobar, B.; Barbosa, R.; Yoshida, M.M.; Gomez, Y.V. Carbon nanotubes as support of well dispersed platinum nanoparticles via colloidal synthesis. J. Power Sources 2013, 243, 88–94. [Google Scholar] [CrossRef]

- Ortegon, J.; Ledesma-Alonso, R.; Barbosa, R.; Castillo, J.V.; Atoche, A.C. Material phase classification by means of Support Vector Machines. Comput. Mater. Sci. 2018, 148, 336–342. [Google Scholar] [CrossRef]

- Stiapis, C.S.; Skouras, E.D.; Burganos, V.N. Advanced Laguerre Tessellation for the Reconstruction of Ceramic Foams and Prediction of Transport Properties. Materials 2019, 12, 1137. [Google Scholar] [CrossRef] [PubMed]

- Čapek, P.; Hejtmánek, V.; Brabec, L.; Zikánová, A.; Kočiřík, M. Stochastic Reconstruction of Particulate Media Using Simulated Annealing: Improving Pore Connectivity. Transp. Porous. Med. 2009, 76, 179–198. [Google Scholar] [CrossRef]

- Jiao, Y.; Stillinger, F.H.; Torquato, S. Modeling Heterogeneous Materials via Two-Point Correlation Functions. II. Algorithmic Details and Applications. Phys. Rev. E 2008, 77, 031135. [Google Scholar] [CrossRef] [PubMed]

- Patelli, E.; Schuëller, G. On optimization techniques to reconstruct microstructures of random heterogeneous media. Comput. Mater. Sci. 2009, 45, 536–549. [Google Scholar] [CrossRef]

- Torquato, S. Random Heterogeneous Materials: Microstructure and Macroscopic Properties; Interdisciplinary Applied Mathematics Series 16; Springer: New York, NY, USA, 2002. [Google Scholar]

- Zhao, X.; Yao, J.; Yi, Y. A New Stochastic Method of Reconstructing Porous Media. Transp. Porous Med. 2007, 69, 1–11. [Google Scholar] [CrossRef]

- Xiao, G.; Xia, Q.; Cheng, X.; Chen, W. Research on Formation Conditions of the Ultrafine-Grained Structure of the Cylindrical Parts Manufactured by Power Spinning Based on Small Strains. Materials 2018, 11, 1891. [Google Scholar] [CrossRef]

- Butt, M.T.Z.; Preuss, K.; Titirici, M.-M.; Rehman, H.U.; Briscoe, J. Biomass-Derived Nitrogen-Doped Carbon Aerogel Counter Electrodes for Dye Sensitized Solar Cells. Materials 2018, 11, 1171. [Google Scholar] [CrossRef] [PubMed]

- Ledesma-Alonso, R.; Barbosa, R.; Ortegon, J. Effect of the image resolution on the statistical descriptors of heterogeneous media. Phys. Rev. E 2018, 97, 023304. [Google Scholar] [CrossRef] [PubMed]

- Müllner, T.; Zankel, A.; Svec, F.; Tallarek, U. Finite-size effects in the 3D reconstruction and morphological analysis of porous polymers. Mater. Today 2014, 17, 404–411. [Google Scholar] [CrossRef]

| Name | Size (Pixel) | |

|---|---|---|

| S70 | 400 × 400 | 70 |

| S50 | 450 × 450 | 50 |

| SEM1 | 470 × 470 | 78.20 |

| SEM2 | 502 × 502 | 80.48 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, A.; Barbosa, R.; Rios, A.; Ortegon, J.; Escobar, B.; Gayosso, B.; Couder, C. Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials. Materials 2019, 12, 3757. https://doi.org/10.3390/ma12223757

Rodriguez A, Barbosa R, Rios A, Ortegon J, Escobar B, Gayosso B, Couder C. Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials. Materials. 2019; 12(22):3757. https://doi.org/10.3390/ma12223757

Chicago/Turabian StyleRodriguez, Abimael, Romeli Barbosa, Abraham Rios, Jaime Ortegon, Beatriz Escobar, Beatriz Gayosso, and Carlos Couder. 2019. "Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials" Materials 12, no. 22: 3757. https://doi.org/10.3390/ma12223757

APA StyleRodriguez, A., Barbosa, R., Rios, A., Ortegon, J., Escobar, B., Gayosso, B., & Couder, C. (2019). Effect of An Image Resolution Change on the Effective Transport Coefficient of Heterogeneous Materials. Materials, 12(22), 3757. https://doi.org/10.3390/ma12223757