Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy

Abstract

1. Introduction

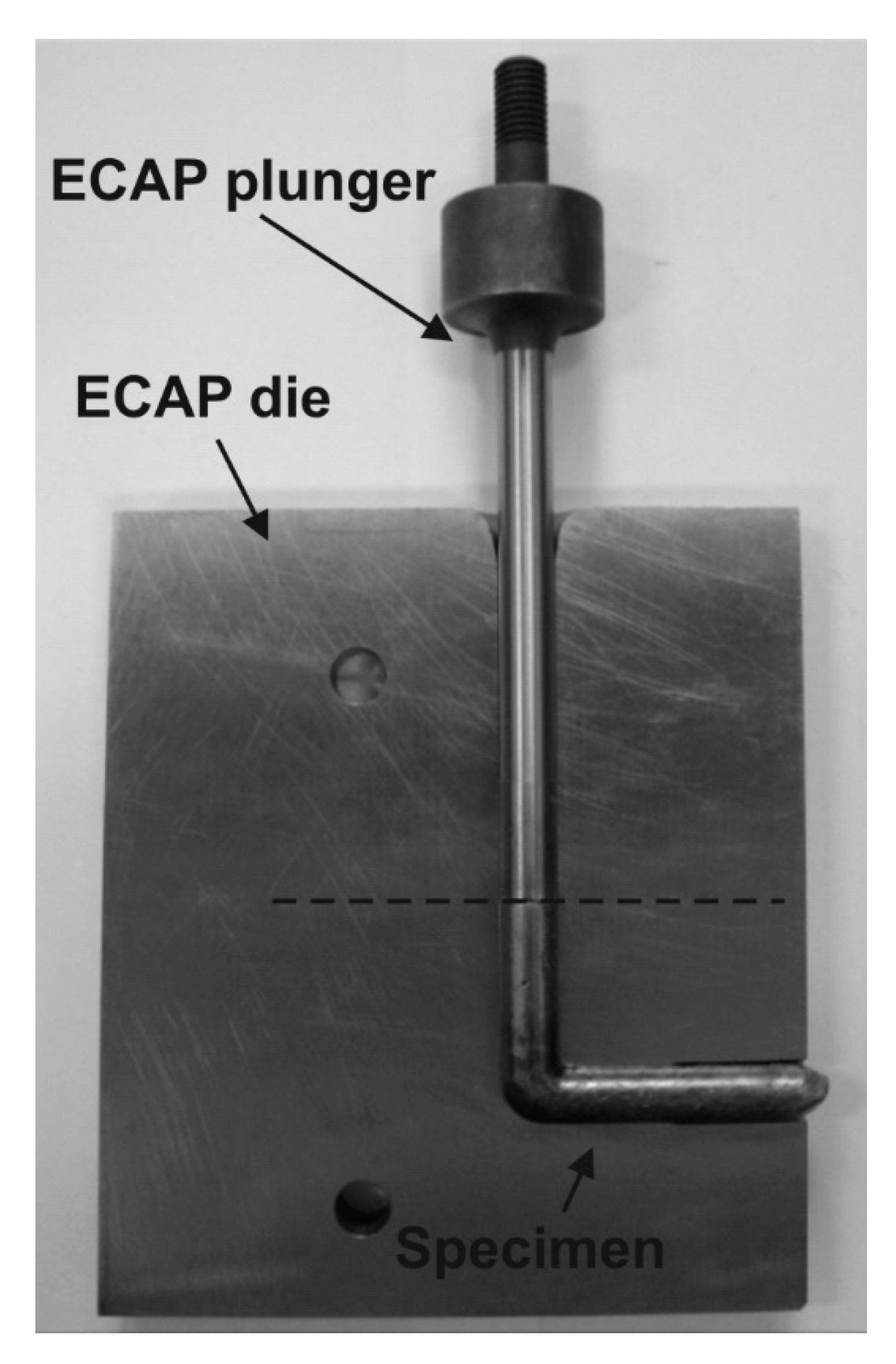

2. Materials and Methods

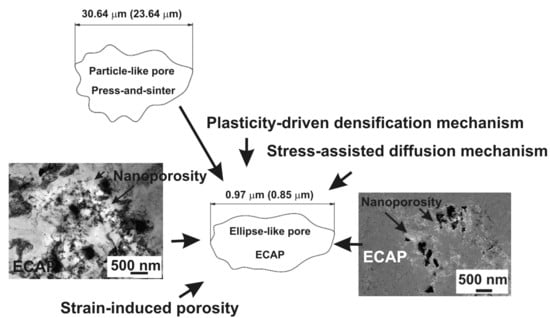

3. Results and Discussion

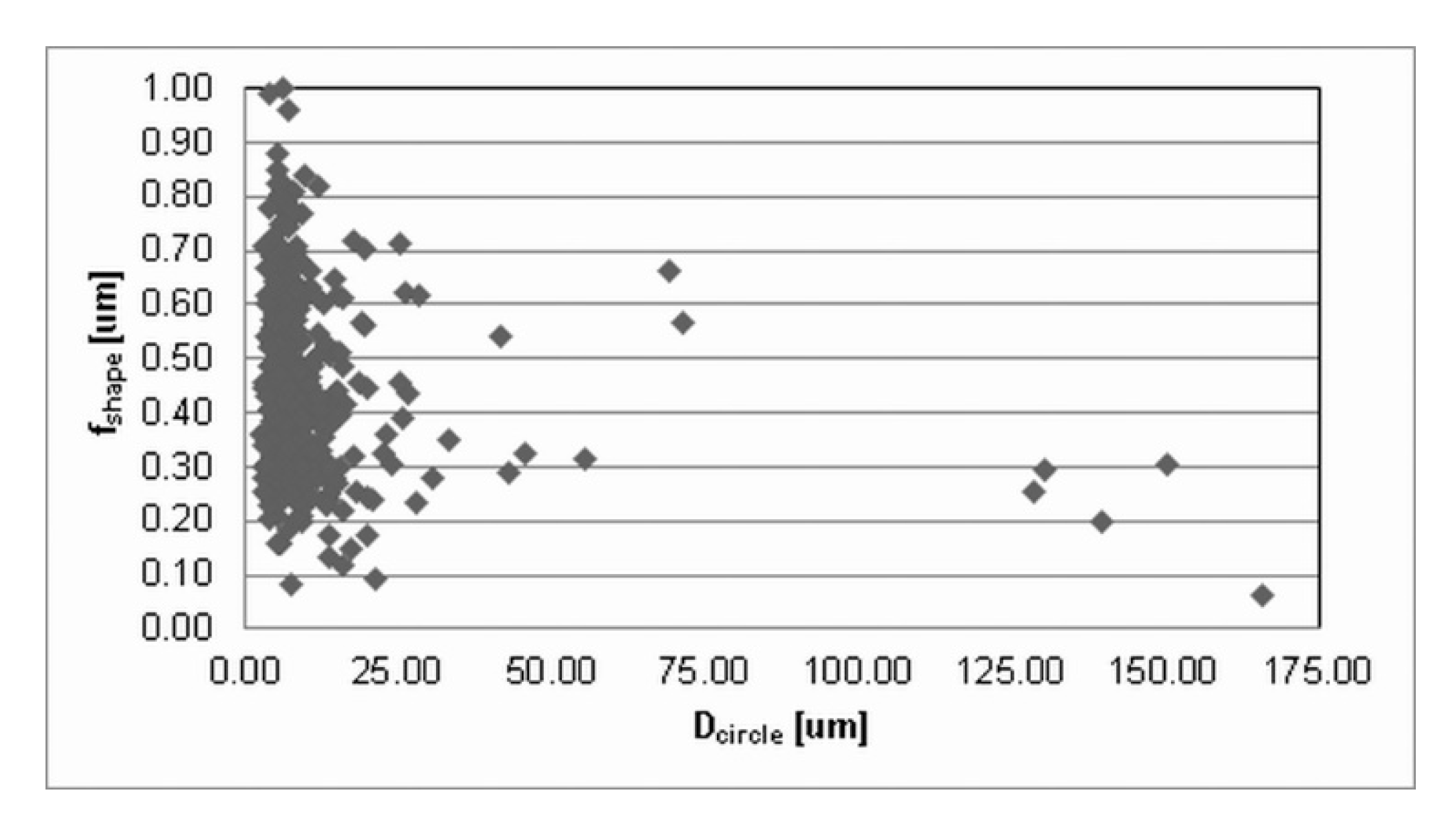

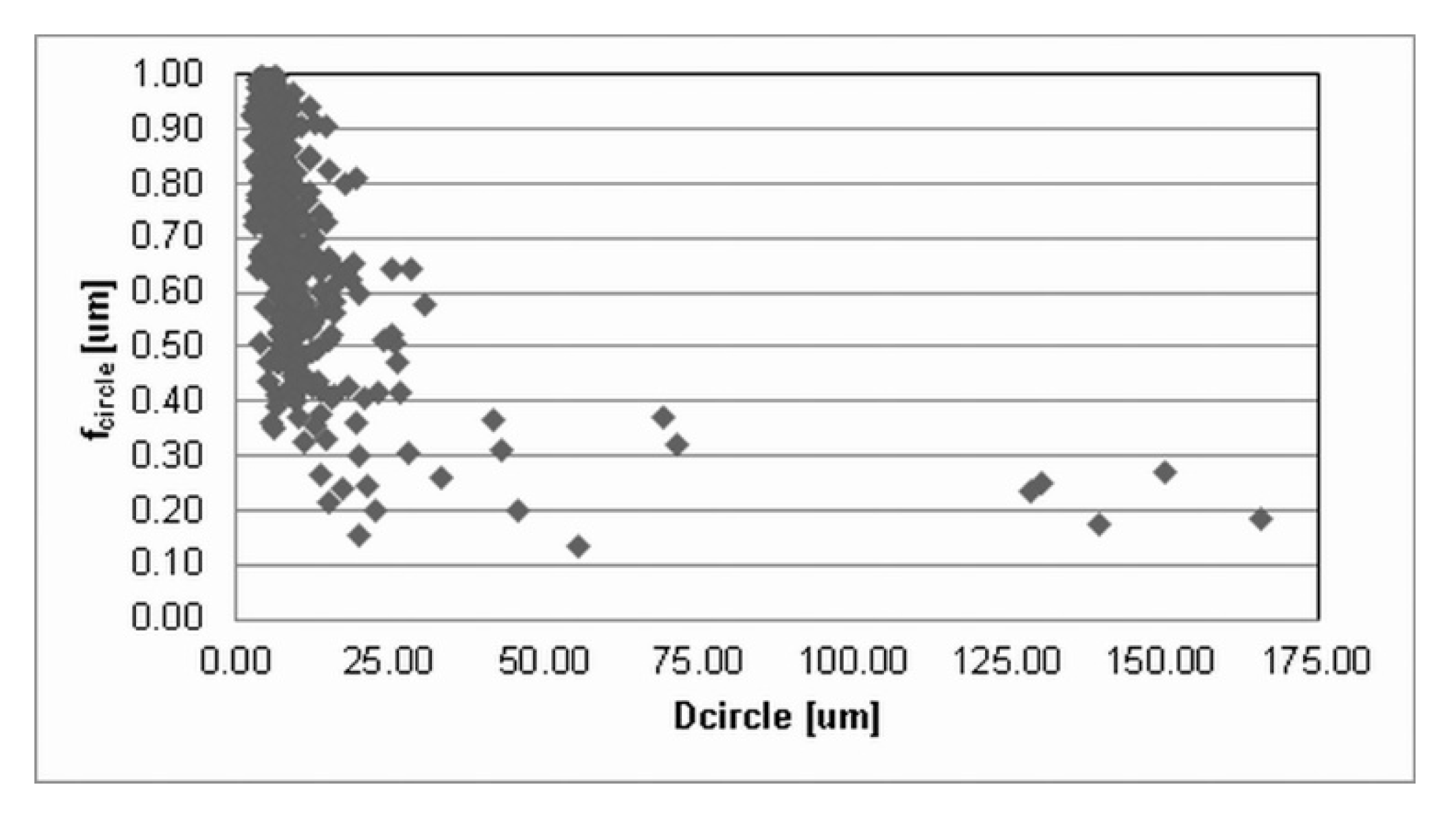

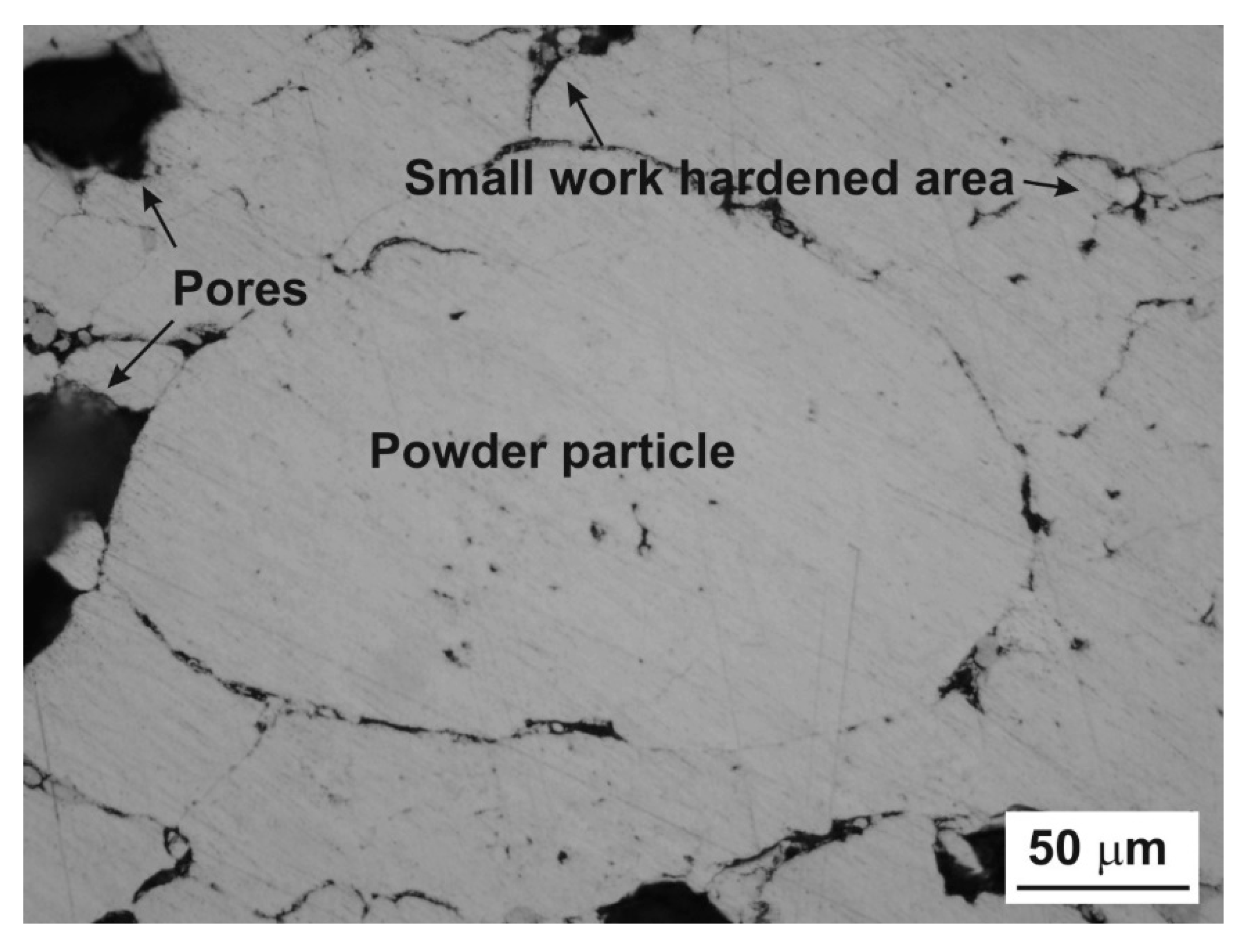

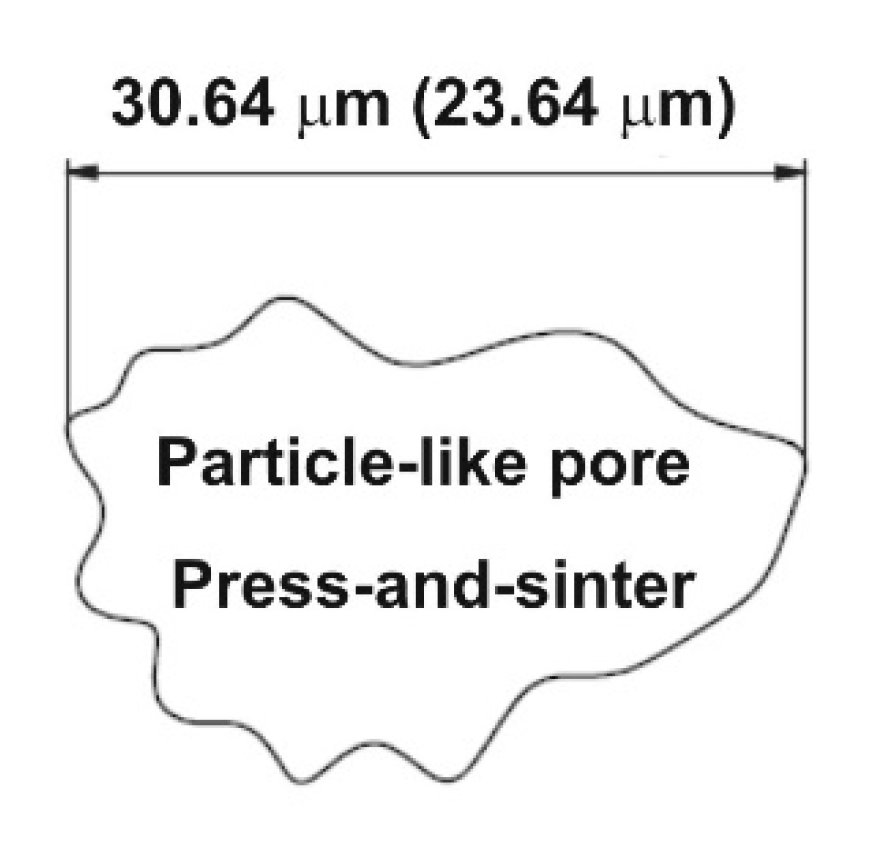

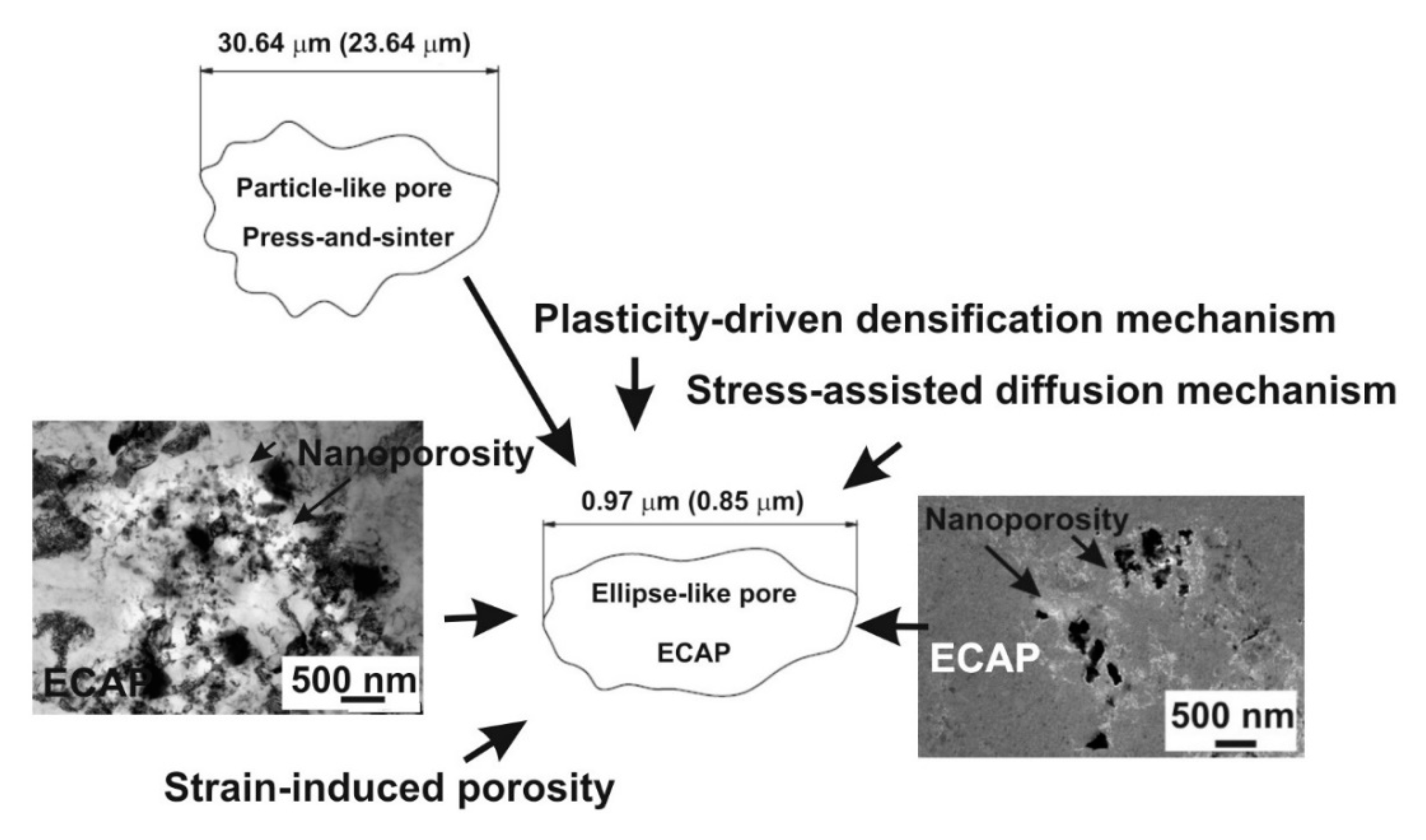

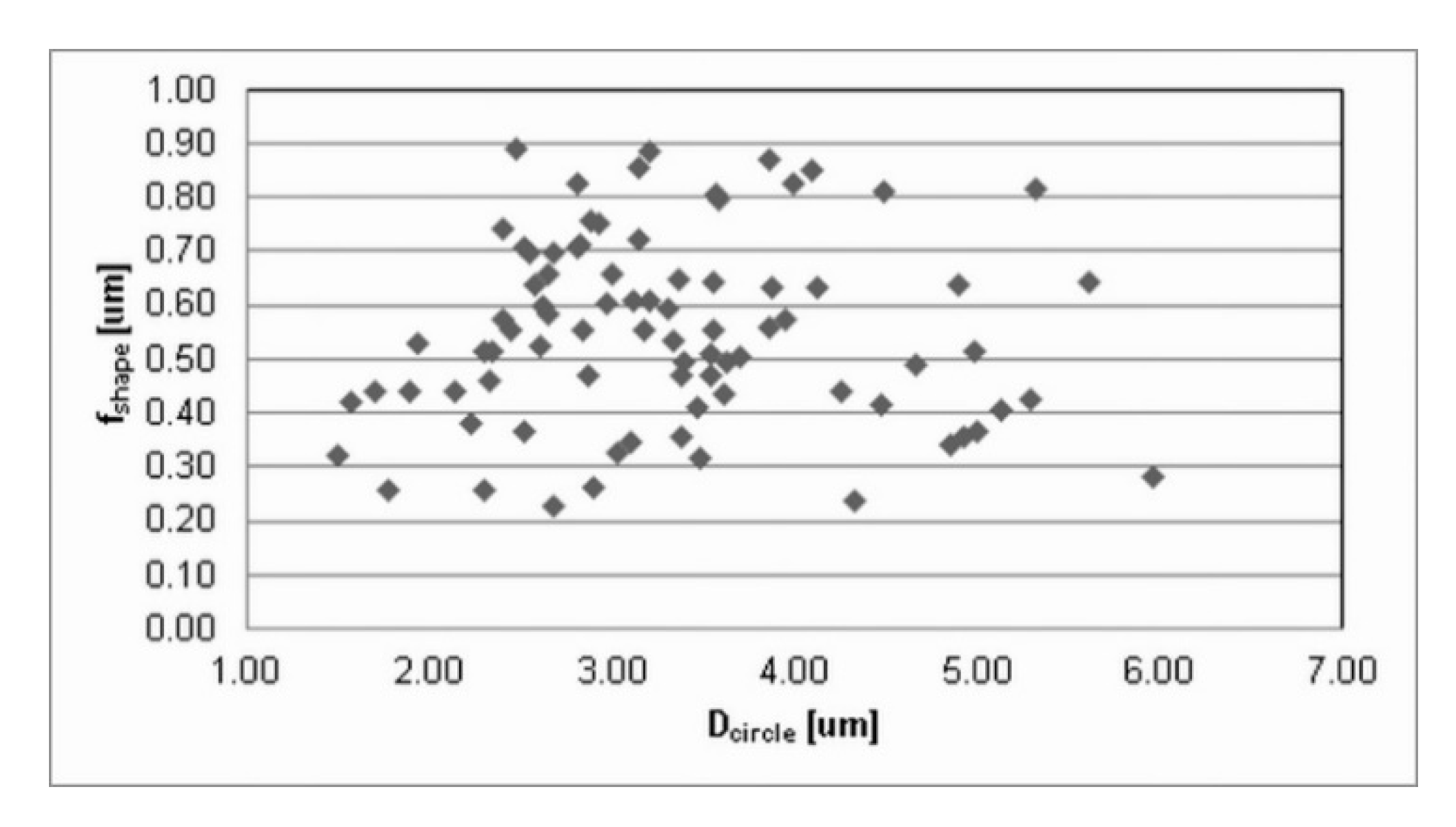

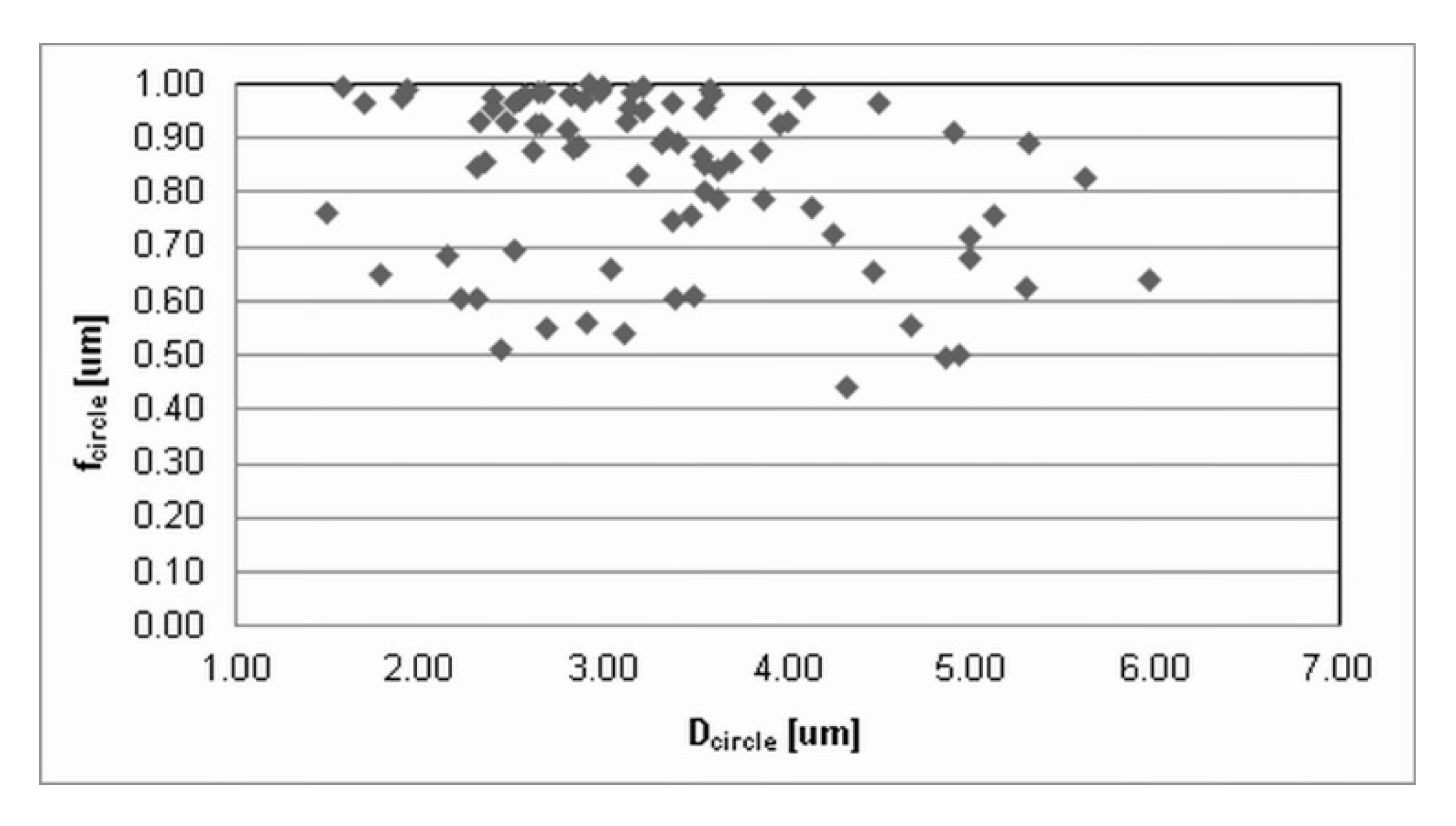

3.1. Image Analysis

3.2. Processing of Aluminium PM Alloy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Šalak, A. Ferrous Powder Metallurgy, 1st ed.; Cambridge International Science Publishing: Cambridge, UK, 1997. [Google Scholar]

- Bidulská, J.; Kvackaj, T.; Kocisko, R.; Bidulský, R.; Actis Grande, M. Influence of ECAP-Back pressure on the porosity distribution. Acta Phys. Pol. A 2010, 117, 864–868. [Google Scholar] [CrossRef]

- Bidulská, J.; Kvačkaj, T.; Bidulský, R.; Actis Grande, M. The porosity evaluation during ECAP in aluminium PM alloy. Acta Phys. Pol. A 2012, 122, 553–556. [Google Scholar] [CrossRef]

- Lapovok, R. The role of back-pressure in equal channel angular extrusion. J. Mater. Sci. 2005, 40, 341–346. [Google Scholar] [CrossRef]

- Balog, M.; Simancik, F.; Bajana, O.; Requena, G. ECAP vs. direct extrusion-techniques for consolidation of ultra-fine Al particles. Mater. Sci. Eng. A 2009, 504, 1–7. [Google Scholar] [CrossRef]

- Wu, X.; Xu, W.; Xia, K. Pure aluminum with different grain size distributions by consolidation of particles using equal-channel angular pressing with back pressure. Mater. Sci. Eng. A 2008, 493, 241–245. [Google Scholar] [CrossRef]

- Šimčák, D.; Kvačkaj, T.; Kočiško, R.; Bidulský, R.; Kepič, J.; Puchý, V. Evaluation of hight purity aluminium after asymmetric rolling at ambient and cryogenic temperatures. Acta Metall. Slovaca 2017, 23, 99–104. [Google Scholar] [CrossRef]

- Xia, K.N. Consolidation of particles by severe plastic deformation: Mechanism and applications in processing bulk ultrafine and nanostructured alloys and composites. Adv. Eng. Mater. 2010, 12, 724–729. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Segal, V.M.; Krasilnikov, N.A.; Drobyshevskiy, A.E.; Kopylov, V.I. Plastic working of metals by simple shear. Russ. Metall. 1981, 1, 99–105. [Google Scholar]

- Furuno, K.; Akamatsu, H.; Oh-ishi, K.; Furukawa, M.; Horita, Z.; Langdon, T.G. Microstructure development in equal channel angular pressing using a 60° die. Acta Mater. 2004, 52, 2497–2507. [Google Scholar] [CrossRef]

- Perig, A.V.; Golodenko, N.N. Alternative study of a bevel punch-assisted ECAE scheme. Acta Metall. Slovaca 2018, 24, 306–324. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Segal, V.M.; Goforth, R.E.; Frey, N.D.; DeLo, D.P. Workability of commercial-purity titanium and 4340 steel during equal channel angular extrusion at cold-working temperatures. Metall. Mater. Trans. A 1999, 30, 1425–1435. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Gubicza, J.; Czeppe, T.; Lendvai, J.; Xu, C.; Valiev, R.Z.; Langdon, T.G. Developing a strategy for the processing of age-hardenable alloys by ECAP at room temperature. Mater. Sci. Eng. A 2009, 516, 248–252. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Mukai, M.; Yamanoi, M.; Watanabe, H.; Higashi, K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure. Scr. Mater. 2001, 45, 89–94. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Ghosh, M.; Ray, A.K.; Xu, C.; Langdon, T.G. On the feasibility of using a continuous processing technique incorporating a limited strain imposed by ECAP. Mater. Sci. Eng. A 2008, 485A, 476–480. [Google Scholar] [CrossRef]

- Test Methods for Metal Powders and Powder Metallurgy Products; Standard 40: Determination of Impact Energy of Unnotched Powder Metallurgy (PM) Test Specimens; Metal Powder Industries Federation: Princeton, NJ, USA, 2019.

- Bidulská, J.; Kvačkaj, T.; Bidulský, R.; Actis Grande, M.; Lityńska-Dobrzyńska, L.; Dutkiewicz, J. The densification phenomena in powder metallurgy aluminium alloy Al-Zn-Mg-Cu. Chem. Listy 2011, 105, S471–S473. [Google Scholar]

- Bidulská, J.; Kvačkaj, T.; Pokorny, I.; Bidulský, R.; Actis Grande, M. Identification of the critical pore sizes in sintered and ECAPed aluminium 6xxx alloy. Arch. Metall. Mater. 2013, 58, 371–375. [Google Scholar] [CrossRef][Green Version]

- Test Methods for Metal Powders and Powder Metallurgy Products; Standard 10: Determination of the Tensile Properties of Powder Metallurgy (PM) Materials; Metal Powder Industries Federation: Princeton, NJ, USA, 2019.

- Xu, Y.-H.; Pitot, H.C. An improved stereologic method for three-dimensional estimation of particle size distribution from observations in two dimensions and its application. Comput. Methods Programs Biomed. 2003, 72, 1–20. [Google Scholar] [CrossRef]

- Cappia, F.; Pizzocri, D.; Schubert, A.; Van Uffelen, P.; Paperini, G.; Pellottiero, D.; Macián-Juan, R.; Rondinella, V.V. Critical assessment of the pore size distribution in the rim region of high burnup UO2 fuels. J. Nucl. Mater. 2016, 480, 138–149. [Google Scholar] [CrossRef]

- Vander Voort, G.F. Metallography: Principles and Practice; ASM International: Cleveland, OH, USA, 1999. [Google Scholar]

- Vander Voort, G.F. Etching Techniques for Image Analysis. Microstructural Science; Elsevier: London, UK, 1981; pp. 135–154. [Google Scholar]

- Vander Voort, G.F. Phase Identification by Selective Etching; Vander Voort, G.F., Ed.; Applied Metallography. Van Nostrand Reinhold: Amsterdam, The Netherlands, 1986; pp. 1–19. [Google Scholar]

- Gilmas, M.; Chottin, J.; Dougan, M.J.; Hug, E. Evolution of damage and fracture in two families of Ni–Cu–Mo sinter-hardened steels with various initial porosities. Mater. Sci. Eng. A 2016, 654, 85–93. [Google Scholar] [CrossRef]

- Lumley, R.N.; Sercombe, T.B.; Schaffer, G.M.; Hall, B.J. The influence of the atmosphere on the sintering of aluminum. Metall. Mater. Trans. A 1999, 30, 457–463. [Google Scholar] [CrossRef]

- Schaffer, G.M.; Hall, B.J. The influence of the atmosphere on the sintering of aluminum. Metall. Mater. Trans. A 2002, 33, 3279–3284. [Google Scholar] [CrossRef]

- Parilak, L.; Dudrova, E.; Bidulsky, R.; Kabatova, M. Derivation, testing and application of a practical compaction equation for cold die-compacted metal powders. Powder Technol. 2017, 322, 447–460. [Google Scholar] [CrossRef]

- Murphy, T.F. Evaluation of the shapes of pores and particles in Powder Metallurgy (PM) materials using automated image analysis techniques. Microsc. Microanal. 2010, 16, 718–719. [Google Scholar] [CrossRef]

- Poskovic, E.; Franchini, F.; Actis Grande, M.; Ferraris, L.; Bidulsky, R. Effect of granulometry and oxygen content on SMC magnetic properties. Acta Metall. Slovaca 2017, 23, 356–362. [Google Scholar] [CrossRef]

- Simchi, A.; Veltl, G. Investigation of warm compaction and sintering behaviour of aluminium alloys. Powder Metall. 2003, 46, 159–164. [Google Scholar] [CrossRef]

- Koch, C.C. Nanostructured Materials: Processing, Properties and Potential Applications, 2nd ed.; Noyes Publications: New York, NY, USA, 2002; ISBN 0-8155-1451-4. [Google Scholar]

- Ribbe, J.; Baither, D.; Schmitz, G.; Divinski, S.V. Network of porosity formed in ultrafine-grained Copper produced by equal channel angular pressing. Phys. Rev. Lett. 2009, 102, 165501–165504. [Google Scholar] [CrossRef] [PubMed]

- Lapovok, R.; Tomus, D.; Mang, J.; Estrin, Y.; Lowe, T.C. Evolution of nanoscale porosity during equal-channel angular pressing of titanium. Acta Mater. 2009, 57, 2909–2918. [Google Scholar] [CrossRef]

- Ovidko, I.A.; Sheinerman, A.G.; Skiba, N.V. Elongated nanoscale voids at deformed special grain boundary structures in nanocrystalline materials. Acta Mater. 2011, 59, 678–685. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rusz, S.; Kuc, D.; Hilser, O.; Palka, P.; Boczkal, G. Superplastic deformation of two phase MgLiAl alloy after TCAP pressing. Acta Metall. Slovaca 2017, 23, 215–221. [Google Scholar] [CrossRef]

- Hilser, O.; Rusz, S.; Maziarz, W.; Dutkiewicz, J.; Tanski, T.; Snopinski, P.; Dzugan, J. Structure and properties of AZ31 magnesium alloy after combination of hot extrusion and ECAP. Acta Metall. Slovaca 2017, 23, 222–228. [Google Scholar] [CrossRef]

- Kvackaj, T.; Kocisko, R.; Tiza, J.; Bidulska, J.; Kovacova, A.; Bidulsky, R.; Bacso, J.; Vlado, M. Application of workability test to SPD processing. Arch. Metall. Mater. 2013, 58, 407–412. [Google Scholar] [CrossRef]

| Applied Process | Pressing Pressure | fcircle | fshape | Dcircle | Aspect | P* | Rm |

|---|---|---|---|---|---|---|---|

| [MPa] | [-] | [-] | [µm] | [µm] | [%] | [MPa] | |

| press-and-sinter | 400 | 0.92 | 0.70 | 30.64 | 2.24 | 7.88 | 151 |

| ecap | 0.91 | 0.67 | 0.97 | 1.88 | 1.69 | 203 | |

| press-and-sinter | 500 | 0.93 | 0.72 | 30.20 | nd** | 7.60 | 162 |

| ecap | 0.91 | 0.65 | 0.90 | nd | 1.61 | 215 | |

| press-and-sinter | 600 | 0.92 | 0.69 | 23.64 | 2.21 | 7.18 | 162 |

| ecap | 0.91 | 0.67 | 0.85 | 1.82 | 1.42 | 221 | |

| press-and-sinter | 0.89 | 0.64 | 21.27 | nd | 6.91 | 164 | |

| ecap | 700 | 0.9 | 0.64 | 0.79 | nd | 1.36 | 234 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bidulská, J.; Bidulský, R.; Actis Grande, M.; Kvačkaj, T. Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy. Materials 2019, 12, 3724. https://doi.org/10.3390/ma12223724

Bidulská J, Bidulský R, Actis Grande M, Kvačkaj T. Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy. Materials. 2019; 12(22):3724. https://doi.org/10.3390/ma12223724

Chicago/Turabian StyleBidulská, Jana, Róbert Bidulský, Marco Actis Grande, and Tibor Kvačkaj. 2019. "Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy" Materials 12, no. 22: 3724. https://doi.org/10.3390/ma12223724

APA StyleBidulská, J., Bidulský, R., Actis Grande, M., & Kvačkaj, T. (2019). Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy. Materials, 12(22), 3724. https://doi.org/10.3390/ma12223724