Pressure-Driven Micro-Casting for Electrode Fabrication and Its Applications in Wear Grain Detections

Abstract

1. Introduction

2. Material and Methods

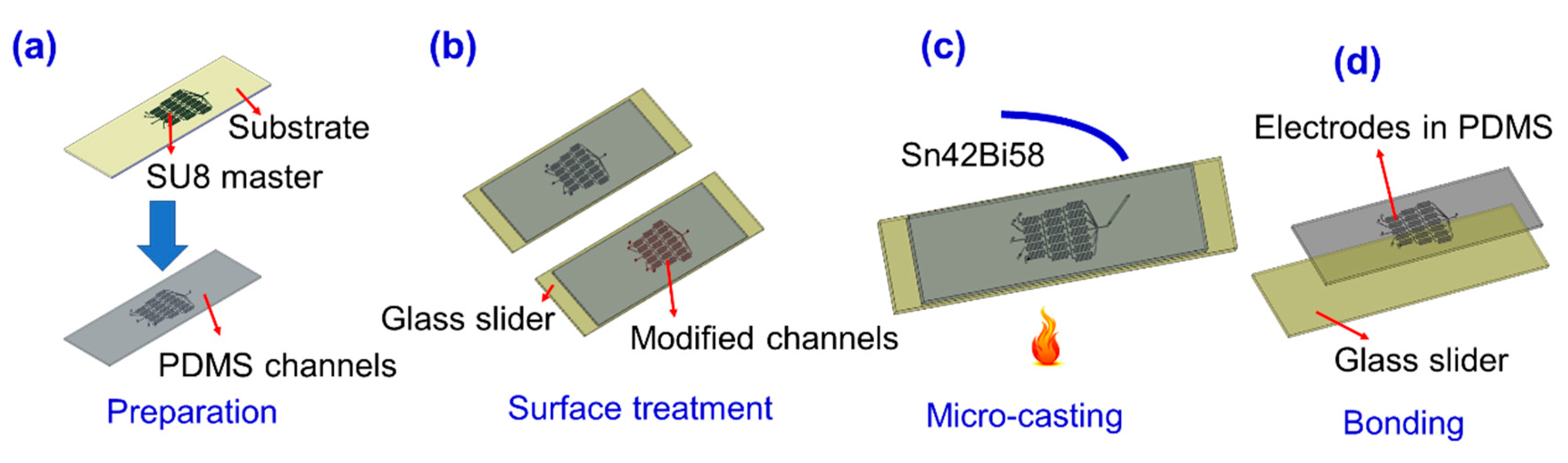

2.1. Electrode Fabrication by Pressure-Driven Micro-Casting Techniques

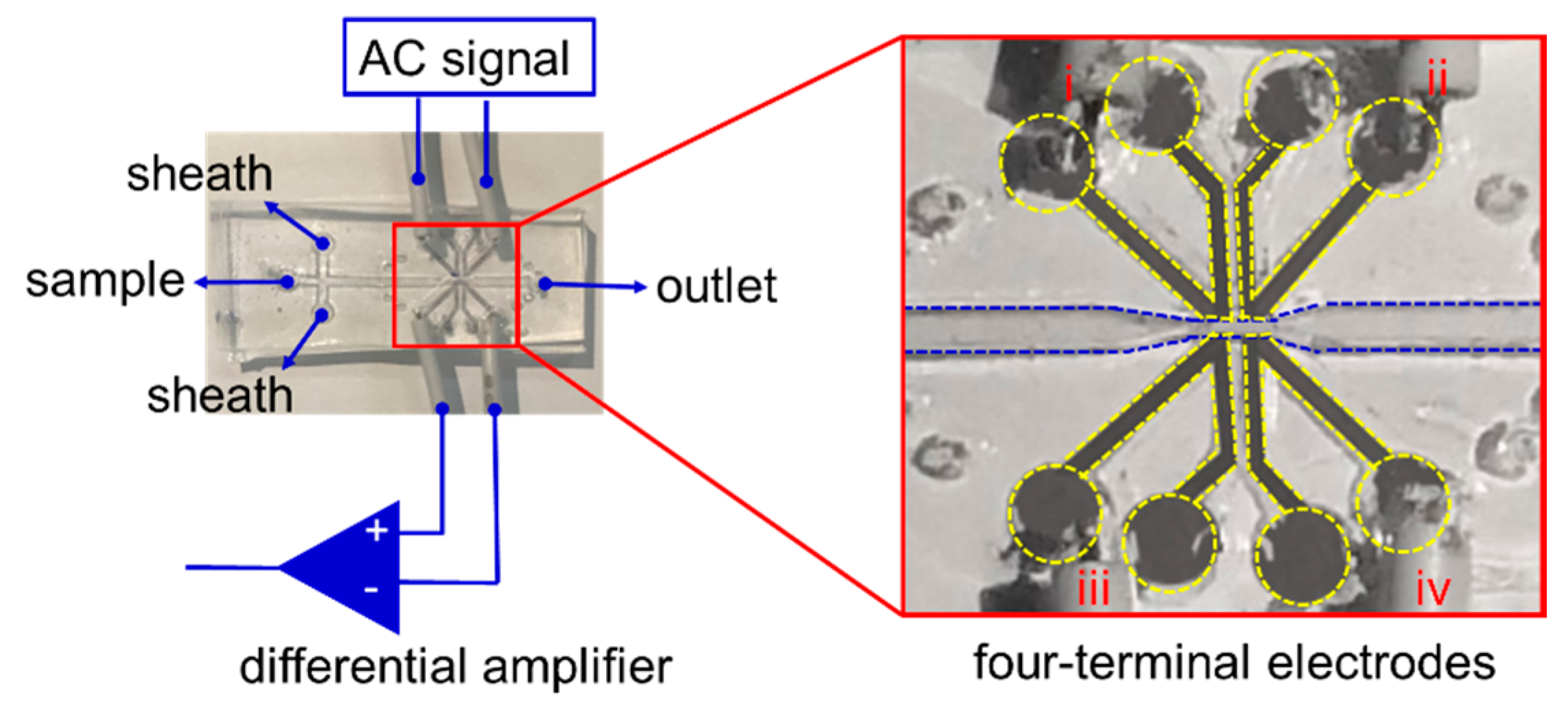

2.2. Procedures for Particle Classification/Counting Applications

3. Results and Discussions

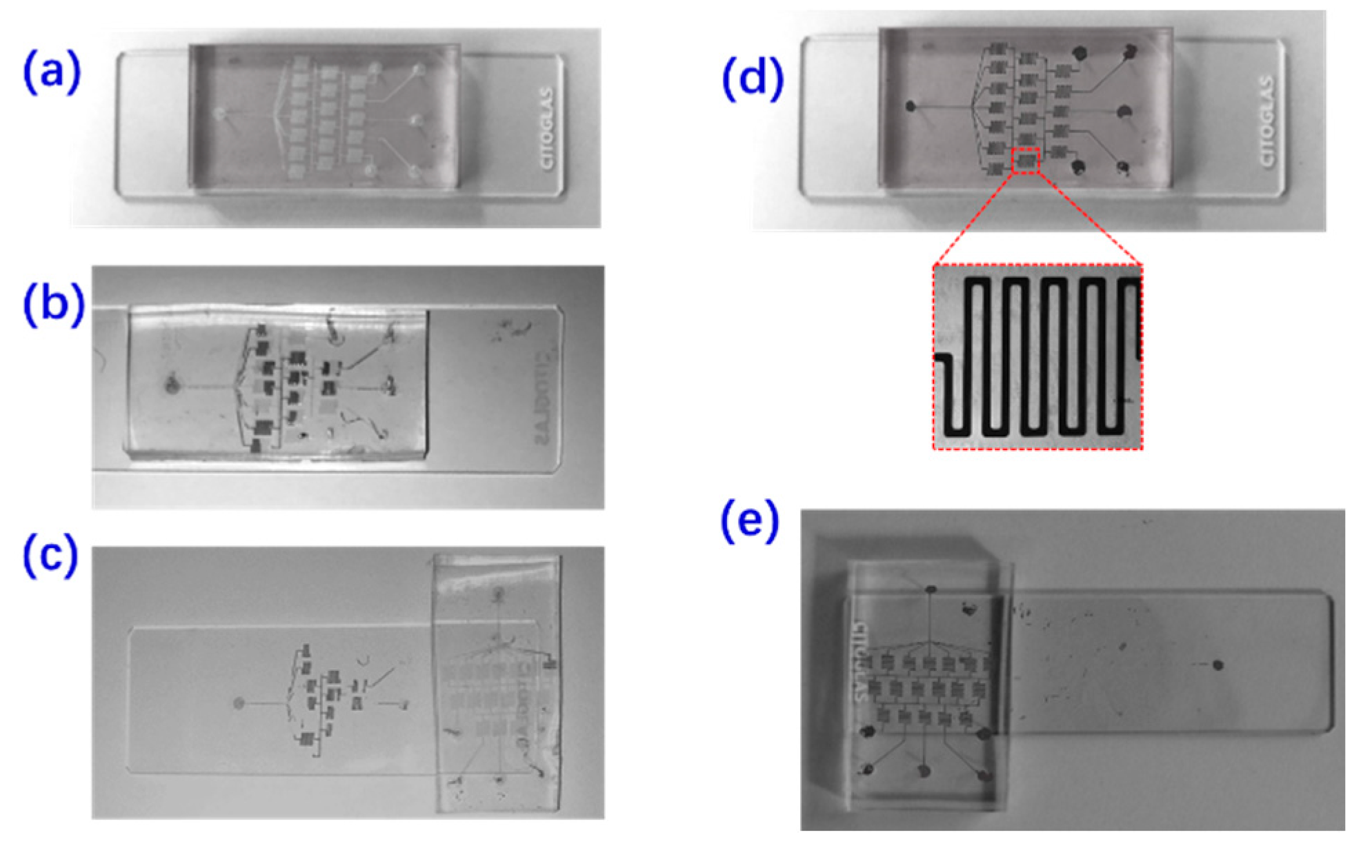

3.1. Effect of the Suface Treatment on the Micro-Casting Performance

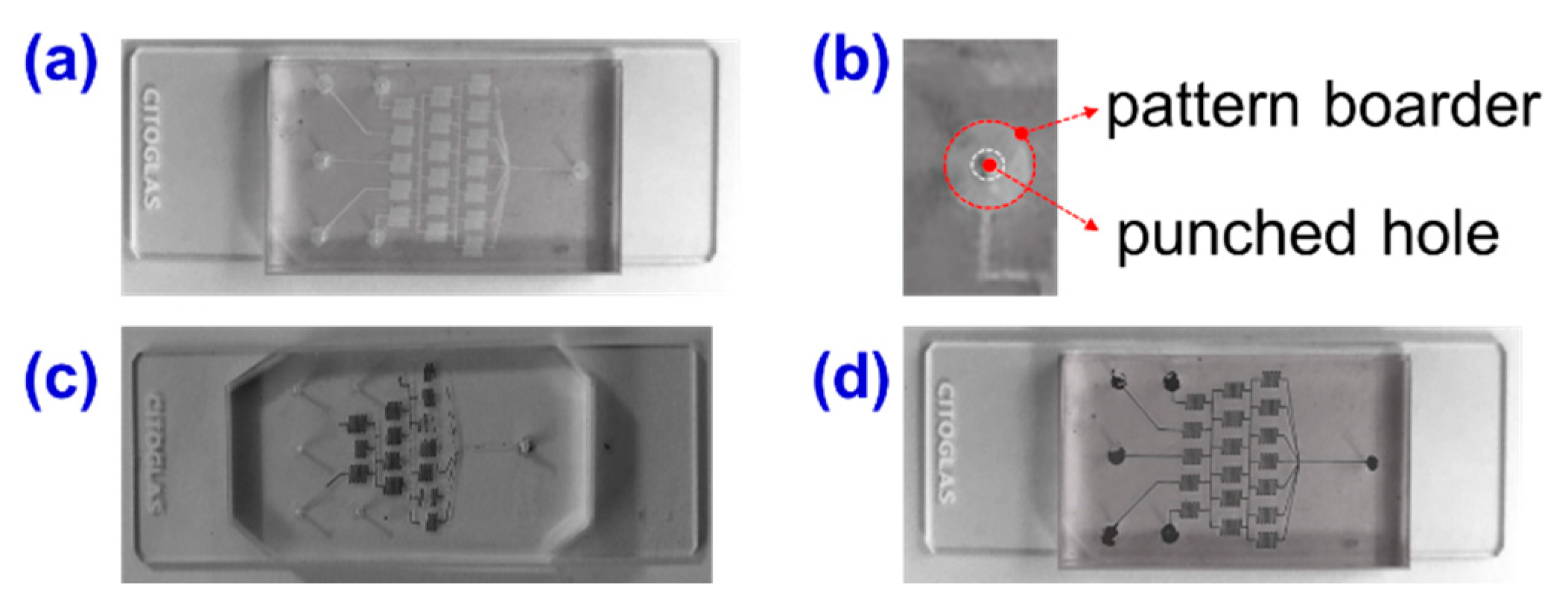

3.2. Effect of the Inlet Dimensions on the Micro-Casting Performance

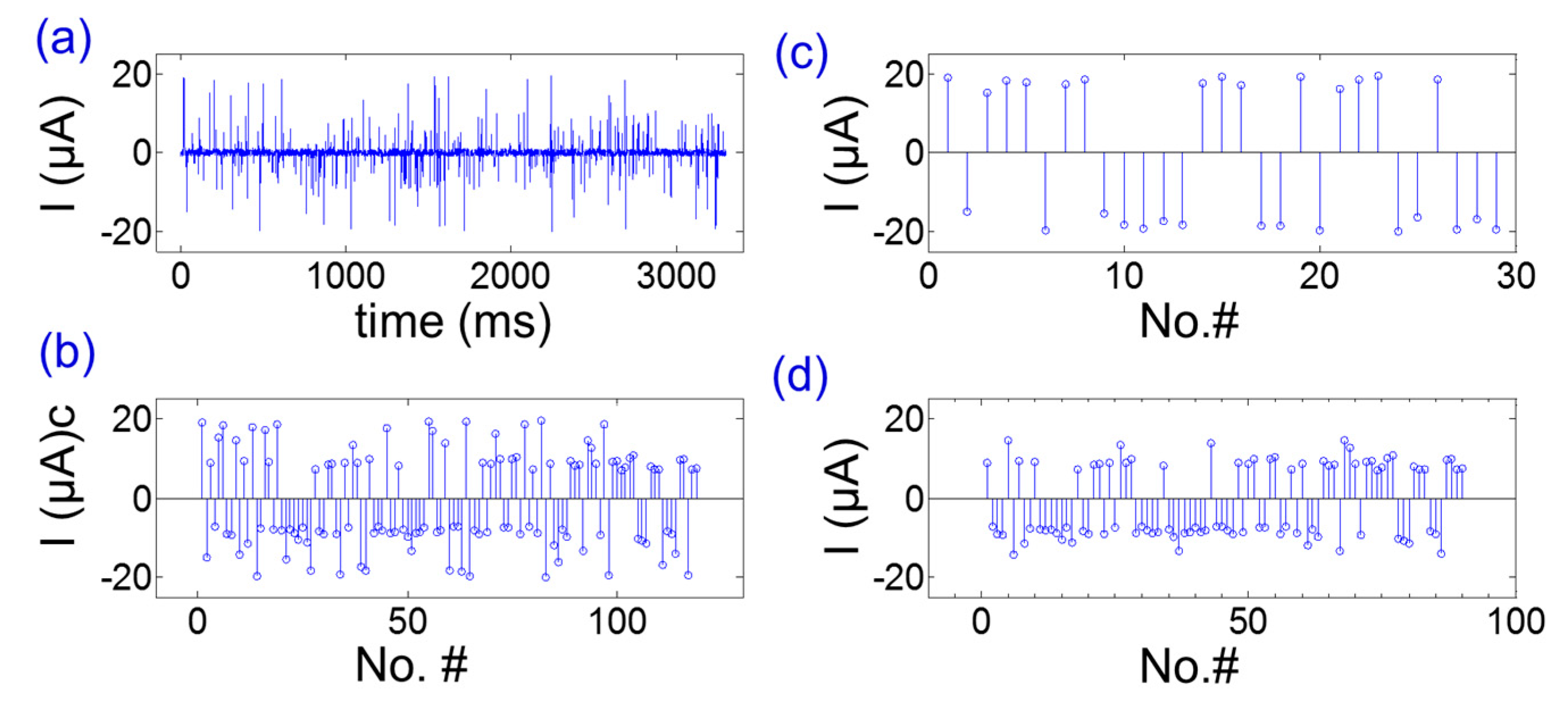

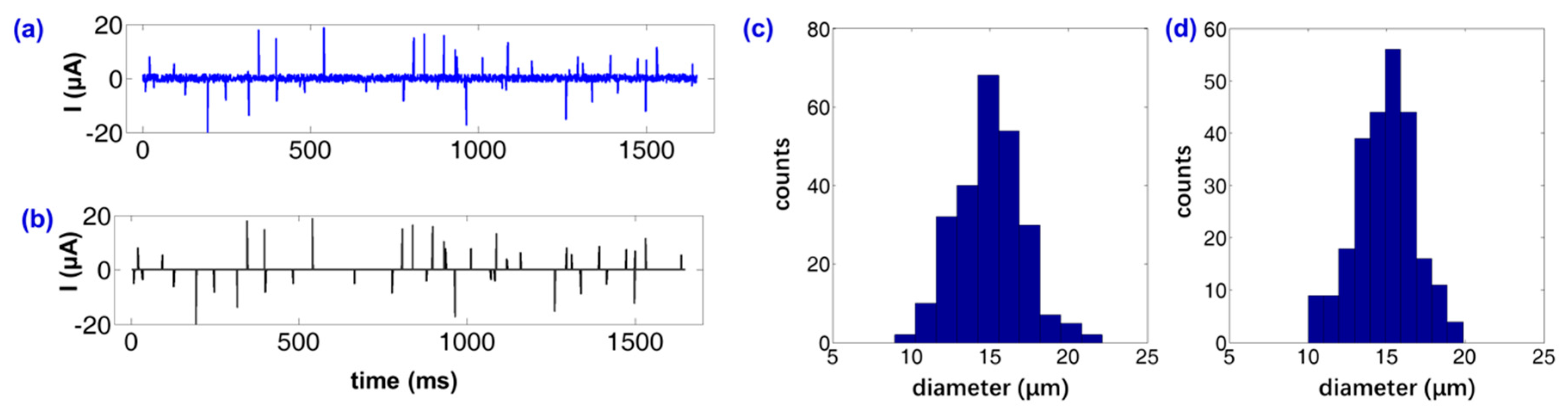

3.3. Proof of Concept: Application in Latex Particle Counting

3.4. Application in Abrasive Grains Detections

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, L.; Cheung, R. A review of silicon carbide development in mems applications. Int. J. Nanomanuf. 2009, 2, 225–240. [Google Scholar] [CrossRef]

- Ejeian, F.; Azadi, S.; Razmjou, A.; Orooji, Y.; Kottapalli, A.; Warkiani, M.E.; Asadnia, M. Design and applications of mems flow sensors: A review. Sens. Actuators A Phys. 2019, 295, 483–502. [Google Scholar] [CrossRef]

- Mijatovic, D.; Eijkel, J.C.; van den Berg, A. Technologies for nanofluidic systems: Top-down vs. Bottom-up—A review. Lab Chip 2005, 5, 492–500. [Google Scholar] [CrossRef] [PubMed]

- Iliescu, C.; Tan, K.L.; Tay, F.E.; Miao, J. Deep wet and dry etching of pyrex glass: A review. In Proceedings of the ICMAT (Symposium F), Singapore, 4–5 July 2005; pp. 75–78. [Google Scholar]

- MacDonald, E.; Wicker, R. Multiprocess 3d printing for increasing component functionality. Science 2016, 353, aaf2093. [Google Scholar] [CrossRef] [PubMed]

- Gates, B.D. Flexible electronics. Science 2009, 323, 1566–1567. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Fu, T.M.; Cheng, Z.; Hong, G.; Zhou, T.; Jin, L.; Duvvuri, M.; Jiang, Z.; Kruskal, P.; Xie, C. Syringe-injectable electronics. Nat. Nanotechnol. 2018, 10, 629. [Google Scholar] [CrossRef] [PubMed]

- Ladd, C.; So, J.H.; Muth, J.; Dickey, M.D. 3d printing of free standing liquid metal microstructures. Adv. Mater. 2013, 25, 5081–5085. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kumar, R.; Bandodkar, A.J.; Wang, J. Advanced materials for printed wearable electrochemical devices: A review. Adv. Electron. Mater. 2017, 3, 1600260. [Google Scholar] [CrossRef]

- Wang, J.; Sama, S.R.; Manogharan, G. Re-thinking design methodology for castings: 3d sand-printing and topology optimization. Int. J. Met. 2019, 13, 2–17. [Google Scholar] [CrossRef]

- Brown, J.F.; Silver, J.E. Method of Loading Sample into a Microfluidic Device. U.S. Patent 8,551,698 B2, 8 October 2013. [Google Scholar]

- Rane, T.D.; Zec, H.; Wang, T.H. A serial sample loading system: Interfacing multi-well plates with microfluidic devices. J. Lab. Autom. 2012, 17, 370. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Tan, W.K.; Fuh, J.Y.H.; Loh, H.T.; Wong, Y.S.; Thian, S.C.H.; Lu, L. Micro-mould fabrication for a micro-gear via vacuum casting. J. Mater. Process. Technol. 2007, 192, 334–339. [Google Scholar] [CrossRef]

- Höving, S.; Janasek, D.; Novo, P. Flow rate independent gradient generator and application in microfluidic free-flow electrophoresis. Anal. Chim. Acta 2018, 1044, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Klapperich, C.M. Mechanical and chemical analysis of plasma and ultraviolet–ozone surface treatments for thermal bonding of polymeric microfluidic devices. Lab Chip 2007, 7, 876–882. [Google Scholar] [CrossRef] [PubMed]

- Fritz, J.L.; Owen, M.J. Hydrophobic recovery of plasma-treated polydimethylsiloxane. J. Adhes. 1995, 54, 33–45. [Google Scholar] [CrossRef]

- Hossain, M.M.; Trinh, Q.H.; Sudhakaran, M.; Sultana, L.; Mok, Y.S. Improvement of mechanical strength of hydrophobic coating on glass surfaces by an atmospheric pressure plasma jet. Surf. Coat. Technol. 2019, 357, 12–22. [Google Scholar] [CrossRef]

- Sun, T.; Morgan, H. Single-cell microfluidic impedance cytometry: A review. Microfluid. Nanofluidics 2010, 8, 423–443. [Google Scholar] [CrossRef]

- Xu, R. Light scattering: A review of particle characterization applications. Particuology 2015, 18, 11–21. [Google Scholar] [CrossRef]

- Müller, D.; Glöckler, F.; Kienle, A. Application of mie theory for enhanced size determination of microparticles using optical particle counters. Appl. Opt. 2019, 58, 4575–4584. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Jin, K.; Li, J.; Liu, J.; Li, J.; Li, T.; Li, S. A low cost and portable smartphone microscopic device for cell counting. Sens. Actuators A Phys. 2018, 274, 57–63. [Google Scholar] [CrossRef]

- Vaclavek, T.; Prikryl, J.; Foret, F. Resistive pulse sensing as particle counting and sizing method in microfluidic systems: Designs and applications review. J. Sep. Sci. 2019, 42, 445–457. [Google Scholar] [CrossRef] [PubMed]

- Salari, A.; Navi, M.; Dalton, C. A novel alternating current multiple array electrothermal micropump for lab-on-a-chip applications. Biomicrofluidics 2015, 9, 014113. [Google Scholar] [CrossRef] [PubMed]

- Salari, A. Ac Electrothermal Fluid Transport for Biofluid Applications; University of Calgary: Calgary, AB, Canada, 2015. [Google Scholar]

- Li, S.; Ren, Y.; Cui, H.; Yuan, Q.; Wu, J.; Eda, S.; Jiang, H. Alternating current electrokinetics enhanced in-situ capacitive immunoassay. Electrophoresis 2015, 36, 471–474. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, E.; Xing, B.; Li, S.; Yu, C.; Li, J.; Wei, C.; Cheng, C. Pressure-Driven Micro-Casting for Electrode Fabrication and Its Applications in Wear Grain Detections. Materials 2019, 12, 3710. https://doi.org/10.3390/ma12223710

Cheng E, Xing B, Li S, Yu C, Li J, Wei C, Cheng C. Pressure-Driven Micro-Casting for Electrode Fabrication and Its Applications in Wear Grain Detections. Materials. 2019; 12(22):3710. https://doi.org/10.3390/ma12223710

Chicago/Turabian StyleCheng, E, Ben Xing, Shanshan Li, Chengzhuang Yu, Junwei Li, Chunyang Wei, and Cheng Cheng. 2019. "Pressure-Driven Micro-Casting for Electrode Fabrication and Its Applications in Wear Grain Detections" Materials 12, no. 22: 3710. https://doi.org/10.3390/ma12223710

APA StyleCheng, E., Xing, B., Li, S., Yu, C., Li, J., Wei, C., & Cheng, C. (2019). Pressure-Driven Micro-Casting for Electrode Fabrication and Its Applications in Wear Grain Detections. Materials, 12(22), 3710. https://doi.org/10.3390/ma12223710