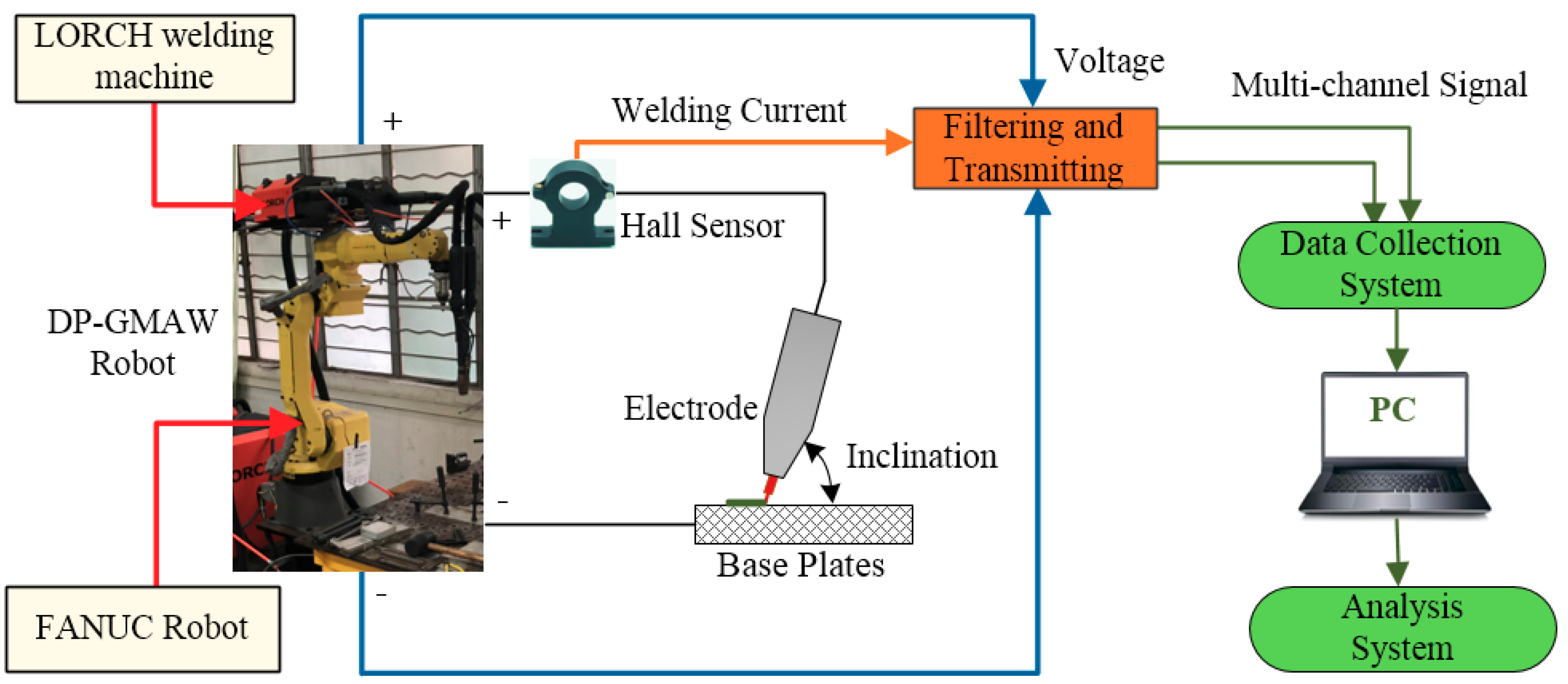

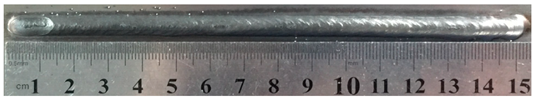

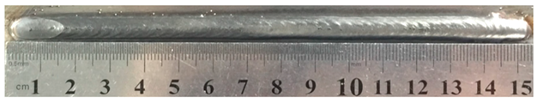

To explore the rule of the weld bead forming during the DP-GMAW process, actual experiments should be seriously designed and conducted. To achieve optimum control performance and obtain accurate and reliable experimental and measured data, this work employed an industrial robot to assist the welding operation and control. In general, the arc welding based on industrial robot operation can accurately control the welding speed, in order to assure during the same welding time, the welding torch goes through the base plate with the same length. In addition, the welding torch can maintain a constant inclination, and other auxiliary instruments can be effectively employed to collect and analyze the process data during the process. In a word, employing an industrial robot to assist the DP-GMAW process can not only increase the production efficiency, but also improve the accuracy of the control operation. These features can benefit the objective of the research in this work.

3.2. Experimental Program

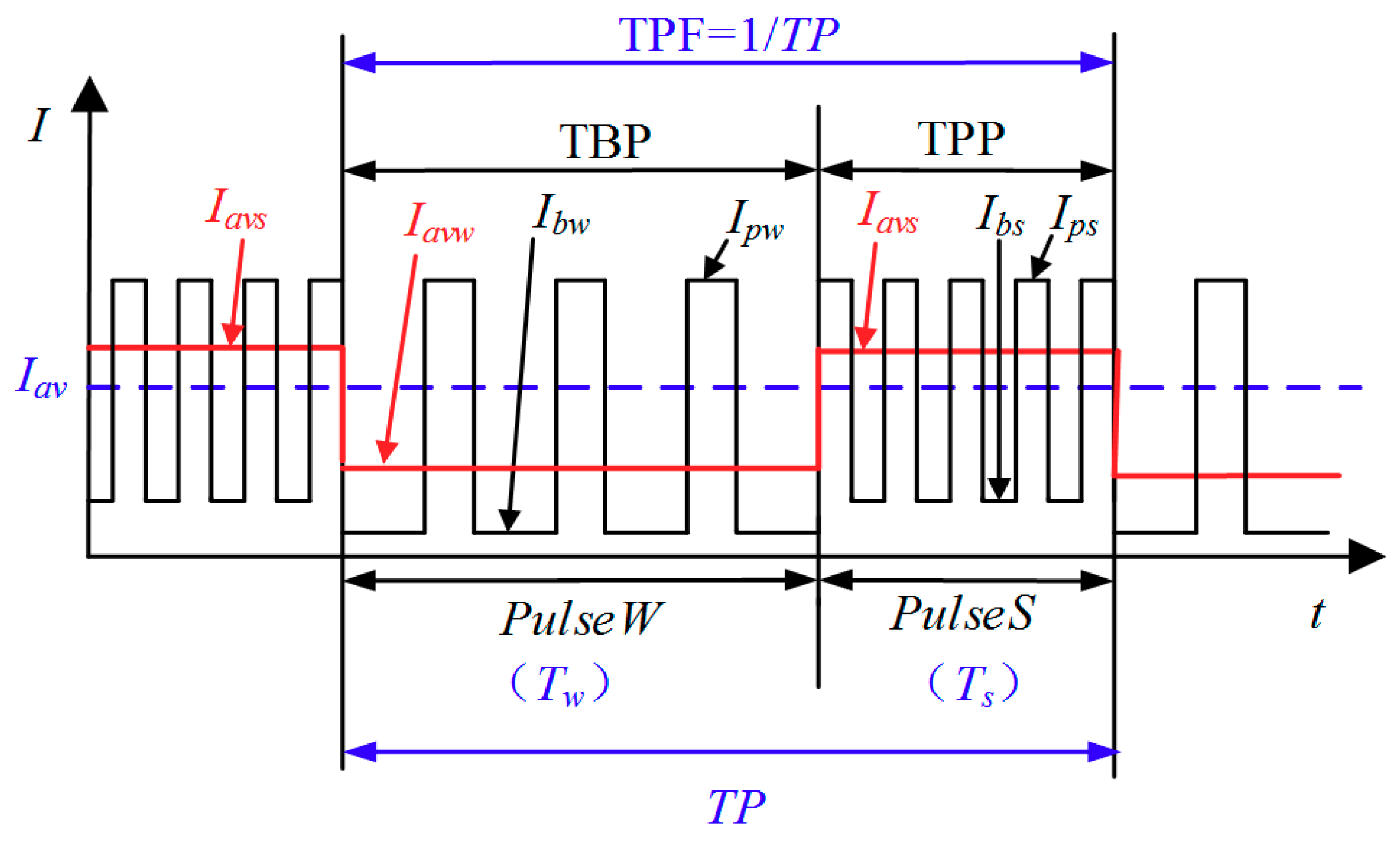

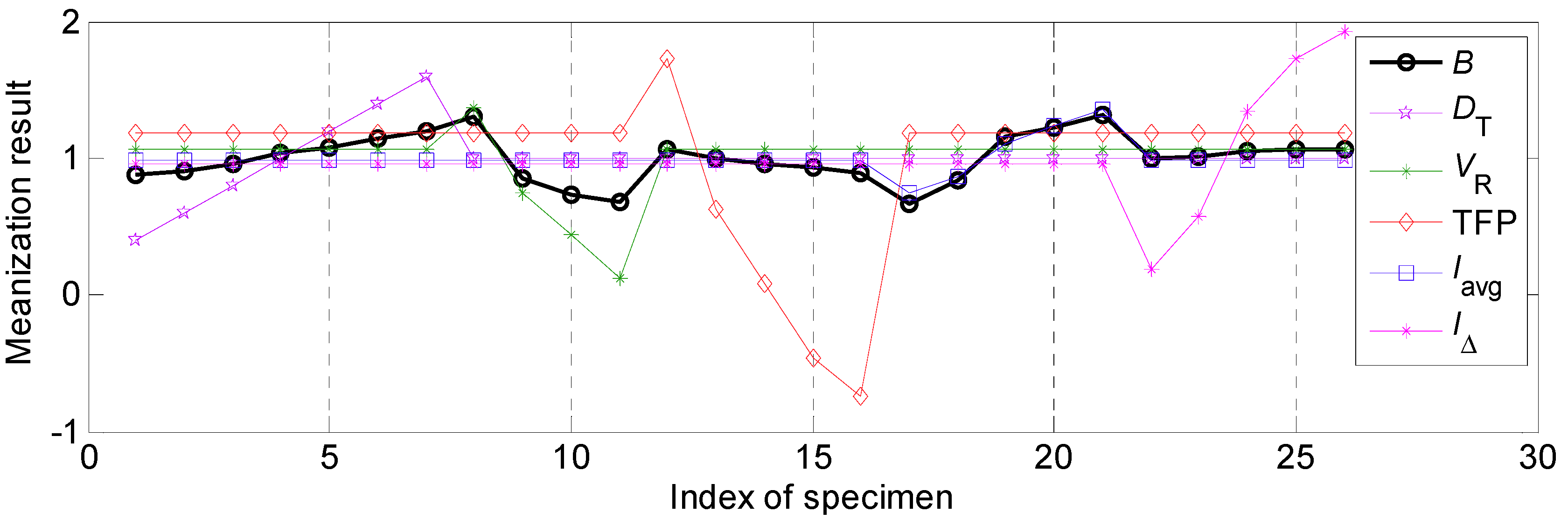

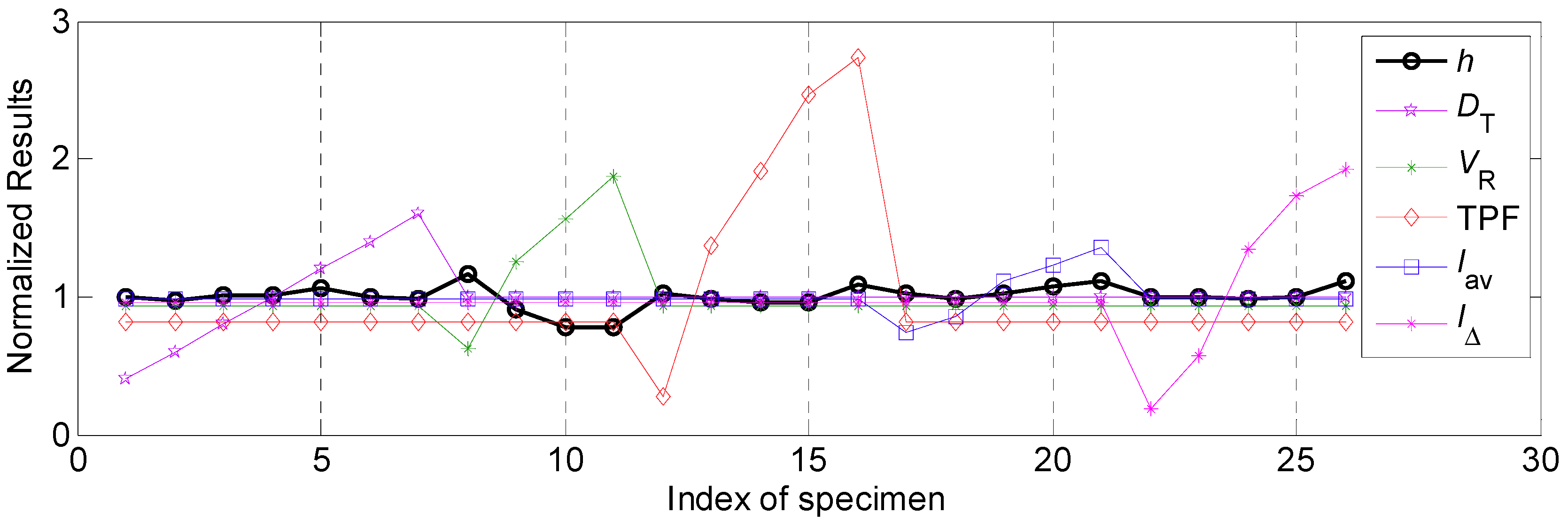

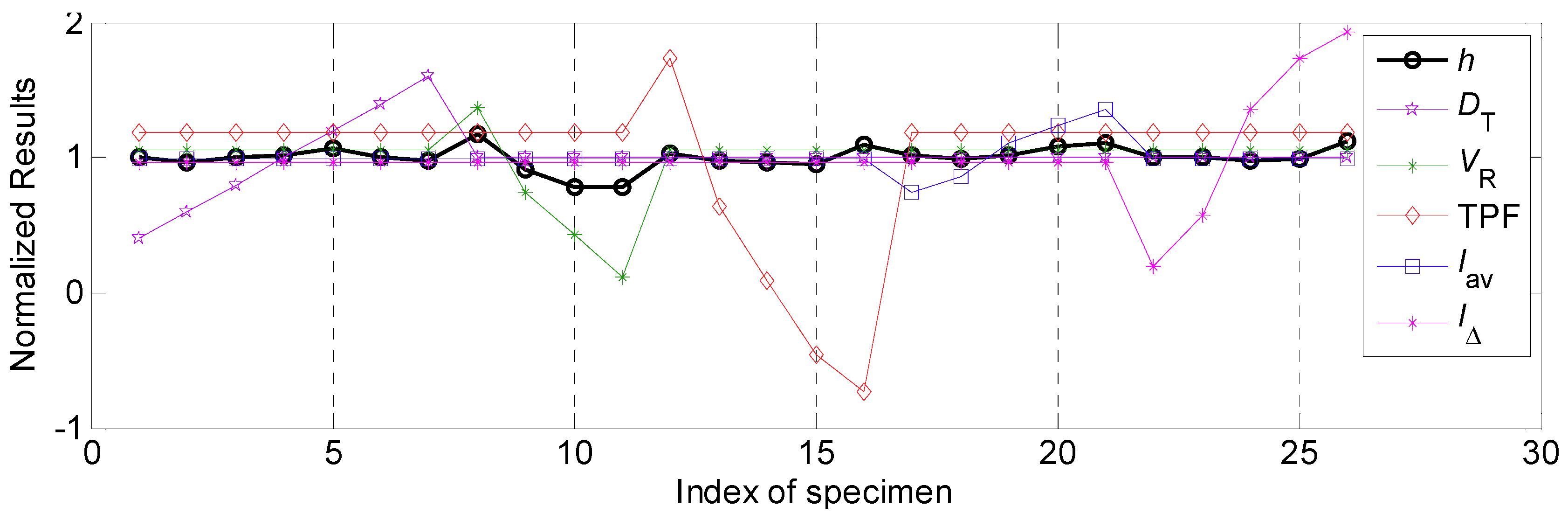

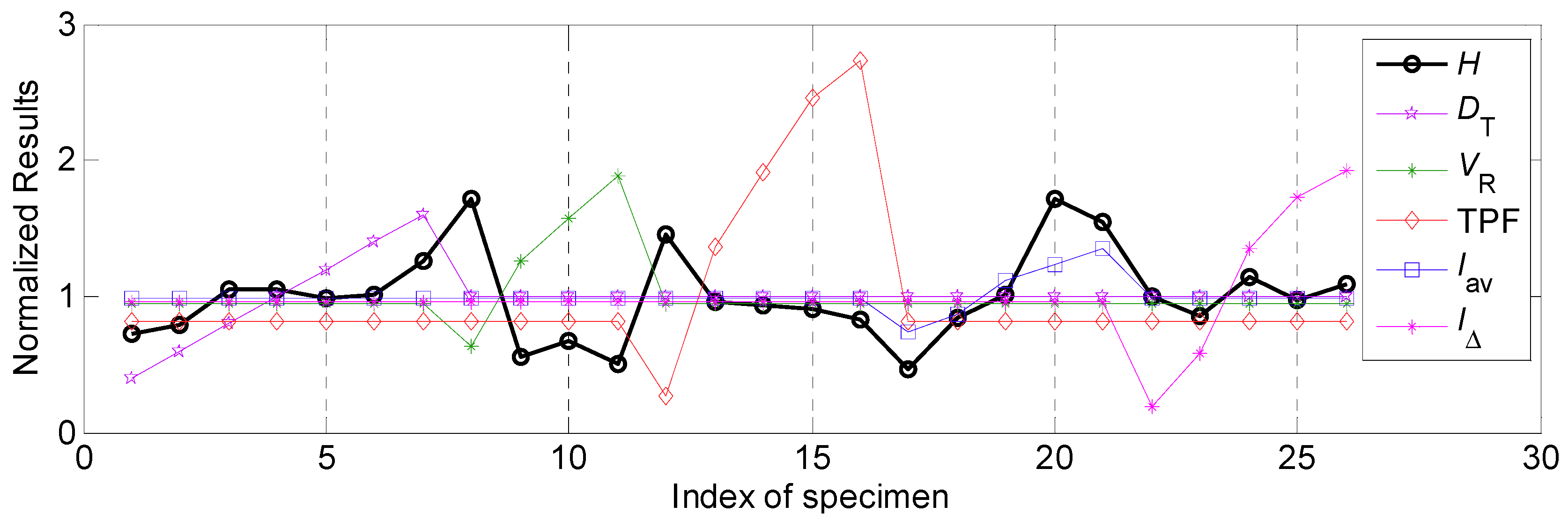

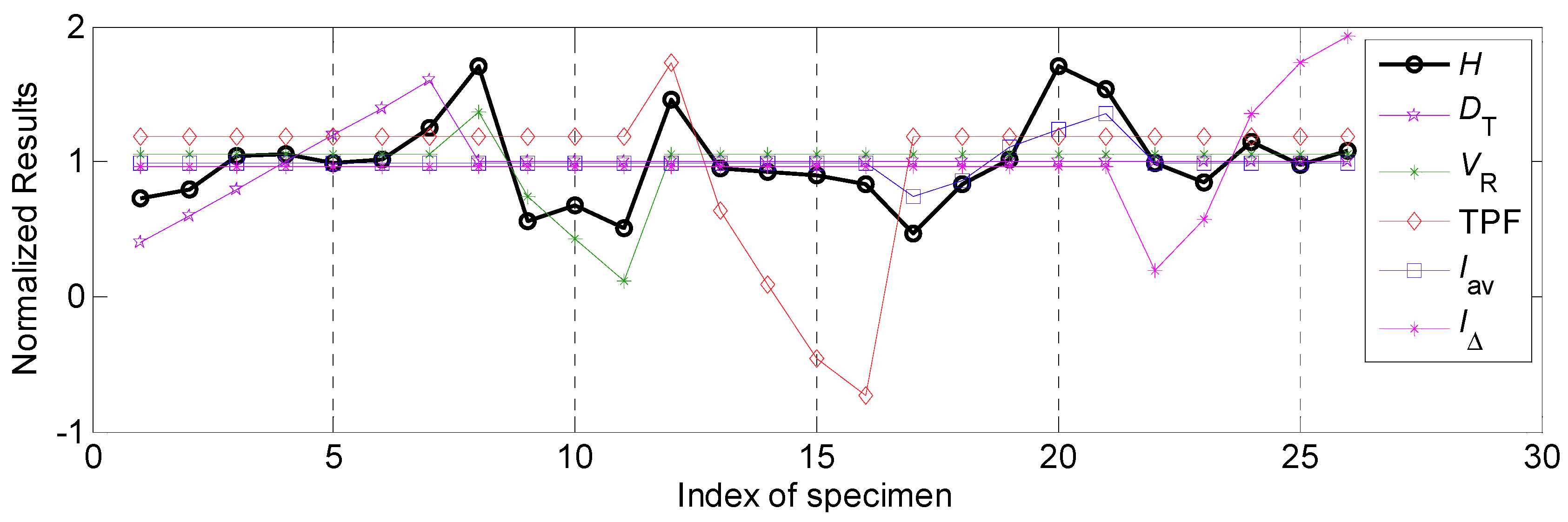

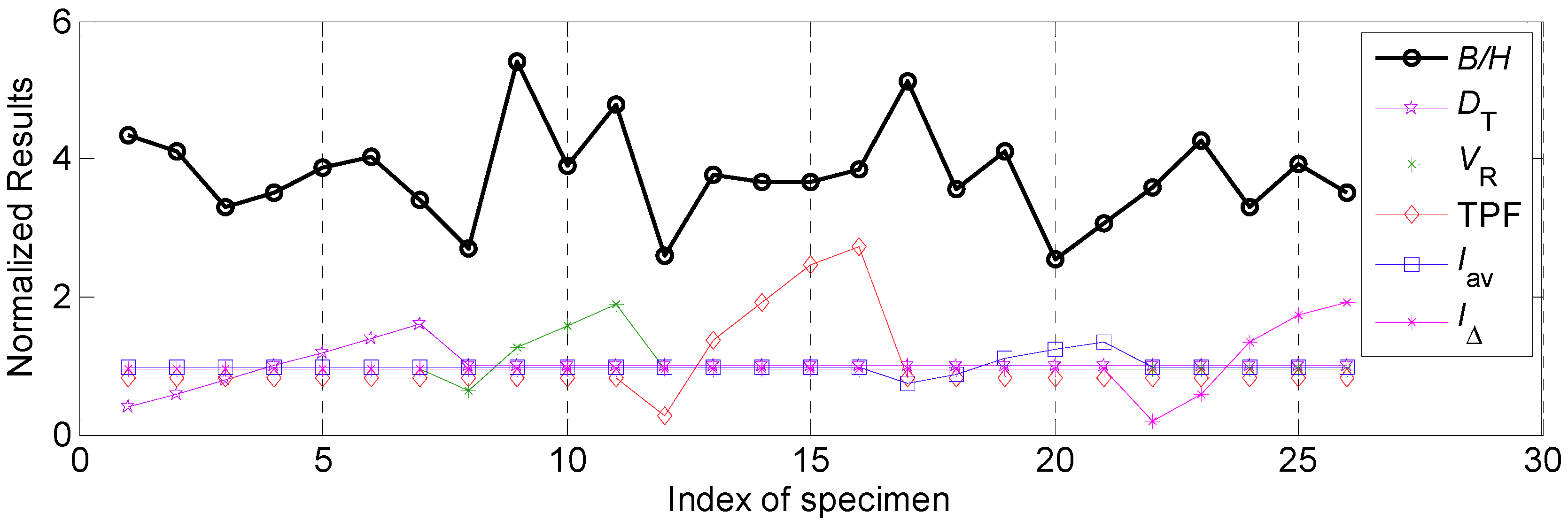

In this work,

twinpulse XT DP control process was employed. Under the circumstance, the number of adjustable parameters was so less. To obtain the effects of main process parameters on the weld bead forming rule during the DP-GMAW process, five process parameters in this new control process, which were twin pulse relation

DT, welding speed

VR, twin pulse frequency TPF, twin pulse current change in percent

I∆ and average welding current

Iav, were selected to explore the effects. According to our previous works about this process [

26], the reasonable varying ranges of these five parameters had been confirmed. Then for each process parameter, different values were employed. To achieve comprehensive and further exploration, total 26 experiments which corresponded different process parameters combinations were designed and conducted in this work, which can be shown in

Table 2. To clearly present the variation of each process parameter in the table, different color backgrounds were employed to highlight the corresponding variations of the five process parameters. It can be noticed that apart from the data which was highlighted using different color background, other data for one process parameter was the same for different experiments.

During the experimental process, to assure obtaining reliable and accurate experimental and observation results, each array of the experiments was conducted three times, and then the results of the most stable experiments were chosen to do further analyses.

3.3. Experimental Data Processing

To accurately obtain key experimental data and then explore the rule of the weld bead forming, each base plate used in the experiment should be carefully preprocessed. In this work, the surface of the base plate had been processed by angle grinder to eliminate the oxides, and then seriously washed by special alcohol. Then, after the surface of base plate clear and dry enough, welding actions can be taken.

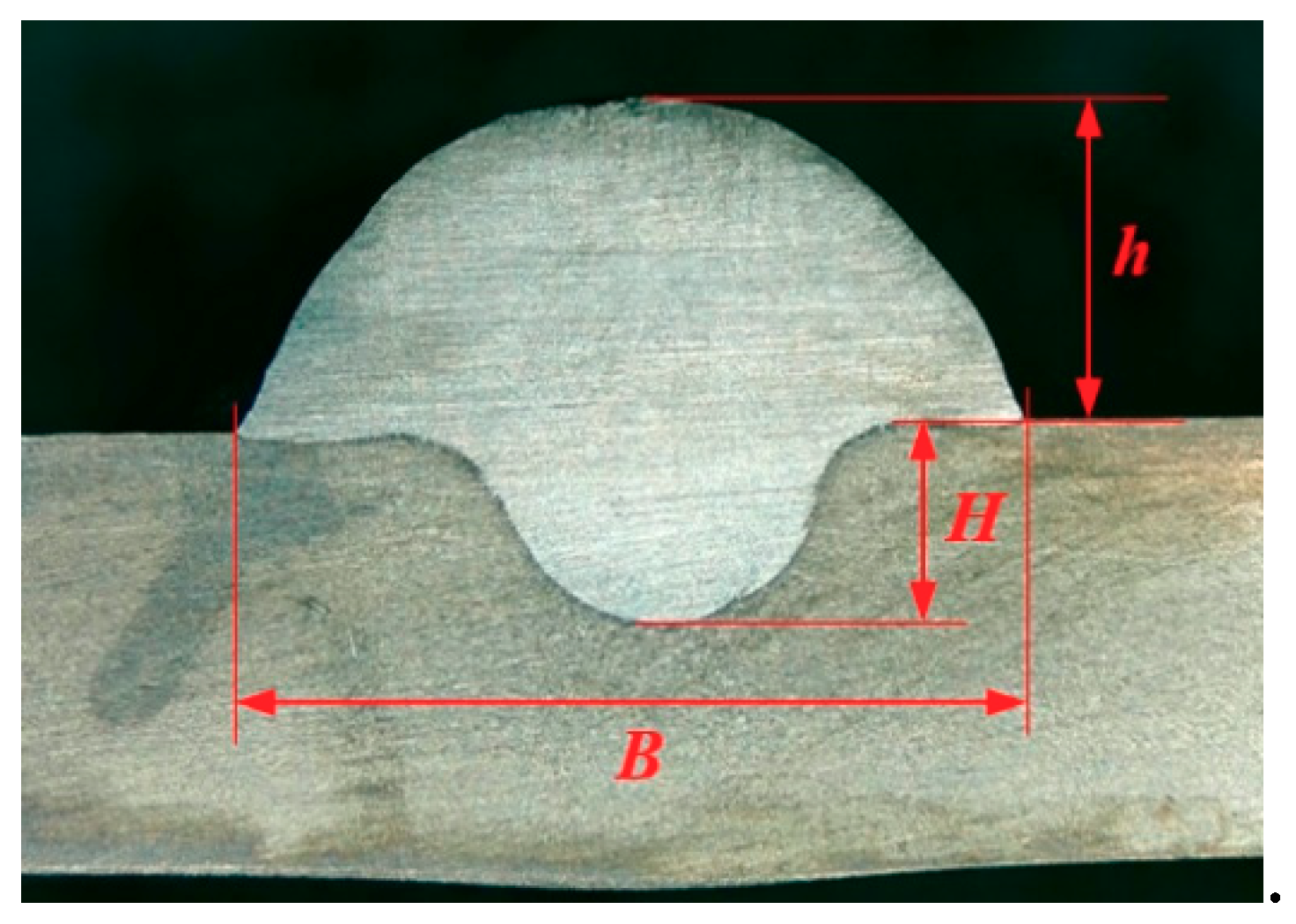

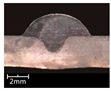

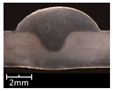

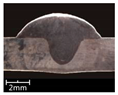

To explore the rule of weld bead forming, some key characteristic parameters should be collected for each experiment. The parameters can be chosen according to the appearance of the weld bead.

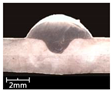

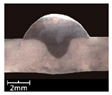

Figure 3 showed an actual photo and detailed characteristic parameters definitions of a weld bead. In the

Figure 3, three characteristic parameters were marked, they were respectively bead width

B, bead height

h, and penetration

H. To obtain accurate data of these parameters, these three values were independently measured by two staffs. Firstly, for

B and

h, five positions were selected in the middle of the weld bead, then using Vernier caliper and electron microscope to independently measure. For total four collected values for each parameter, the maximum and minimum values were rejected, and then a mean value could be considered as a final measurement value. This method can avoid random errors appearing during the measurement. As for the penetration

H, serious sampling measurement should also be conducted. Two weld bead specimens with 1.5 cm of length in the middle of the weld bead were incised, and then the specimens were polished, cleaned by anhydrous alcohol and metallographic corroded. After the specimens was dried, clear appearance of the cross section of the weld bead can be obtained. Similarly, two methods, which respectively employed Vernier caliper and electron microscope, were used and then more data had been collected. Then the mean value of each measurement was considered as a final value of the penetration

H. Hence, the accuracy of the measurement in this work can be guaranteed and convinced.

In this work, grey system theory and corresponding grey relational analysis method was used to process the experimental data. Grey system theory was established by Professor Deng in 1982 [

27], who proposed a new method to focus on the problems with less data and limited information. The grey relational analysis was a multi-factor statistical analysis method in the grey system theory. Its analysis was conducted for the grey control system using relational method. This method did not require a large number of data, so it can avoid data loss resulted from asymmetrical information. It can confirm the effects of process parameters on the operation results when the number of specimens were not enough and the relations between the elements and the results were not clear. In this work, the weld bead forming during the DP-GMAW process was affected by twin pulse relation, welding speed, twin pulse frequency and other process parameters. However, which process parameters had higher or lower effects, and what corresponding rules were, were required to be further focused on or researched. Hence, this work employed the grey relational analysis method to analyze the effects of different process parameters on the weld bead forming. The work can serve the further rule research about the welding process, instruct the parameter selection and predict key information of weld bead forming.

The analysis can be executed by following procedures.

Step 1: Confirm the data of the analysis element sequence based on analysis objective, which was the three key characteristic parameters of the weld bead forming in this work, and then collected the analysis data.

Set

n data in the analysis element sequence and constitute a matrix as follows:

where

m is the number of the element, and

In this work, the value of

n was 5. In other words, there were five data in the analysis element sequence:

X1′ denoted the twin pulse relation,

X2′ denoted the traveling speed of the industrial robot,

X3′ denoted the twin pulse frequency,

X4′ denoted the current change in percent and

X5′ denoted the average welding current. Since the number of parameters combinations was 26, the value of

m was 26. Hence, the total above data can compose of an

m ×

n matrix.

Step 2: Confirm the data in the reference sequence

The reference sequence should be an ideal comparing criterion, the data in the reference sequence can choose the optimum or the worst values, or choose other values based on special objectives.

In this work, the characteristic parameters, which were bead width B, bead height h and penetration H, were chosen as the data which constituted the reference sequence, and then the researches can focus on the relational degree between these three key characteristic parameters and above five process parameters in analysis element sequence.

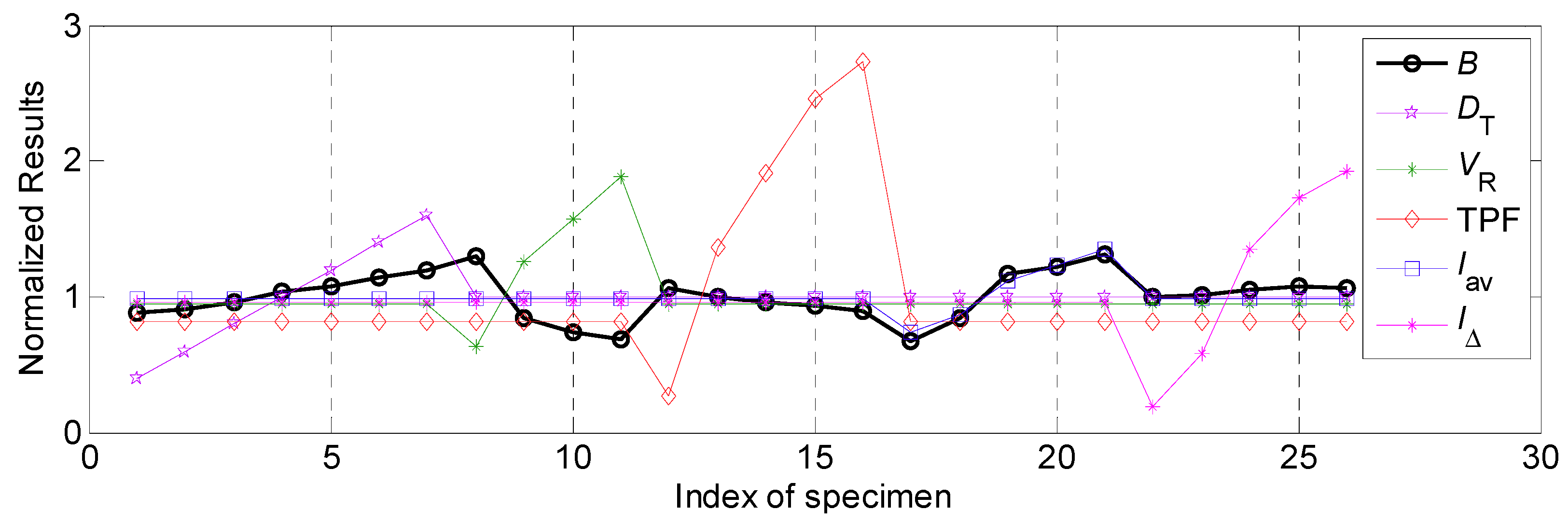

Step 3: Perform normalization operations on the data of each element

Because each data in the analysis element sequence had different physical meanings and had different units. To conveniently compare the data, the data can be normalized by mean value. The detailed algorithm was as follows:

Then the matrix of the data in the analysis element sequence (Equation (3)) can be transformed as follows:

Step 4: Calculate the absolute error between each value in the data included in the analysis element sequence and corresponding data in the reference sequence, the calculation was as follows:

Step 5: (1). Confirm the minimum value:

(2). Confirm the maximum value:

Step 6: Calculate the relational coefficient sequence, corresponding equation was as follows:

where

ρ was the distinguishing coefficient, and the value range was between 0 and 1. Smaller value of

ρ meant that the difference between relation coefficients was larger and the distinguishing ability was stronger. In general, the value of

ρ was 0.5, which also was adopted by this work.

Step 7: Calculate the grey relational degree

For each element, which should be evaluated the effect on the data in the reference, calculated the mean value of the corresponding relational coefficients in order to reflect the relational relation between data in the analysis element sequence and corresponding data in the reference sequences, this value was named as grey relational degree, the detailed calculation was as follows:

Step 8: Obtain the final grey relational rank for each analysis result according to the corresponding grey relational degrees.