1. Introduction

The construction sector has been trying to reduce its environmental impacts. Eco-friendly constituents have been an alternative to develop new cementitious materials. In order to enhance the cracking performance of mortars, the incorporation of natural fibers can contribute to better performance while ensuring a sustainable approach. According to previous studies, natural fibers such as sheep wool may improve the ductility of cementitious composites and also provide an adequate disposal of the waste [

1].

The incorporation of fibers enhances a better post-cracking behavior due to the higher fracture toughness, flexural strength, and impact resistance of the mortars [

2]. The benefits of fiber reinforcement in cementitious materials depend on the fiber type, their geometry, and their volume ratio and distribution [

3]. The use of natural fibers compared to man-made fibers has been achieving environmental, energy, and resource conservation benefits [

4]. There are three types of natural fibers: plant-based, mineral-derived, and animal-based. In this paper, the study focused on animal-based fibers, namely sheep’s wool fibers.

Natural sheep wool is considered as waste on a large-scale, taking into account that 270.000 tons of wool are produced by 90 million sheep in Europe [

3]. Indeed, 75% of the wool produced (around 150 million tons per year) is rejected by the textile industry [

4,

5]. Most of this material does not have a proper disposal method. Furthermore, the wool fibers have an elastic modulus of about 1–4 GPa, which can be comparable to the modulus of plastic fibers [

5].

Several studies have been carried out to investigate the incorporation of wool fibers in cementitious materials to improve the thermal insulation properties [

6,

7,

8,

9]. However, only a few studies, described next, have incorporated wool fibers with the purpose of improving the mechanical performance of cementitious composites.

Alyousef et al. [

10] analyzed the mechanical properties of reinforced concrete with wool fibers and found that the incorporation of fibers decreased the workability of concrete. Concerning the mechanical behavior, the fibers enhanced the ductility and flexural capacity of the composite. In terms of compressive strength, the incorporation of fibers implied a reduction of strength. This reduction was explained by the authors by the incorporation of wool up to 6% by weight of cement in the concrete, which led to a reduction of the total binder in the mix.

Fantilli et al. [

5] investigated the incorporation of 1% (in volume) of wool fibers in cementitious reinforced-mortars. The authors observed that the fibers reduced the brittle nature of the mortars due to the development of bridge mechanisms between the crack borders. In this research, an improvement in the fracture toughness in the reinforced mortars of 300% relative to the control mortar is reported. It could also be seen that the wool fibers promoted a reduction in the plastic shrinkage. The cementitious mortars reinforced with wool fibers presented the same mechanical performance (i.e., strengths and modulus of elasticity) as those in mortars with the most common vegetal fibers.

Giosué et al. [

11] investigated the replacement of 25% (in volume) of aggregates with wool fibers in lime-based lightweight mortars. The modified mortars were tested in the fresh and hardened state concerning workability, mechanical strength, and hygro-thermal properties. The results showed an increase of about 30% in the flexural strength of the modified mortars.

Kesikidou and Stefanidou [

12] investigated the incorporation of natural fibers in mortars. The authors analyzed mortars with two different binders, incorporating vegetal fibers such as jute, coconut, and kelp and showed that the natural fibers performed differently in relation to cement or lime-based binder. Lime-reinforced mortars presented a higher increase in flexural and compressive strength when compared to the cement-based reinforced mortars. Therefore, the compatibility of the fibers with the mortar’s composition should be evaluated.

As a conclusion of this review, it was found that, aside from all of the studies carried out on mortars with natural fibers, the incorporation of wool fibers in rendering cementitious mortars could not be found in the technical literature. This is relevant because rendering mortars mainly have the function of protecting the substrate. This means that a high compressive strength is not often necessary, but is important to minimize cracking. As a consequence, usually low strength mortars with a low binder/aggregate ratio are used, and from this aspect, leads to a different microstructure and a poorer adhesion between the binder, aggregates, and fibers.

Additionally, the compositions used result in a low modulus of elasticity, possibly nearer the modulus of elasticity of natural fibers than in the case of structural mortars. Finally, for rendering mortars, as a favorable cracking behavior is more important than a high mechanical strength, characteristics such as a low modulus of elasticity and ductility are mainly required. Therefore, the novelty of this work was in analyzing the feasibility of the incorporation of wool fibers in rendering mortars and their efficacy in improving those specific properties. Cement and cement-lime mortars with low binder/aggregate volumetric ratios of 1:4 and 1:3 were produced, respectively, with different fibers lengths of 1.5 and 3.0 cm, respectively. The ratios of incorporation were 10% and 20% of the total mortar volume.

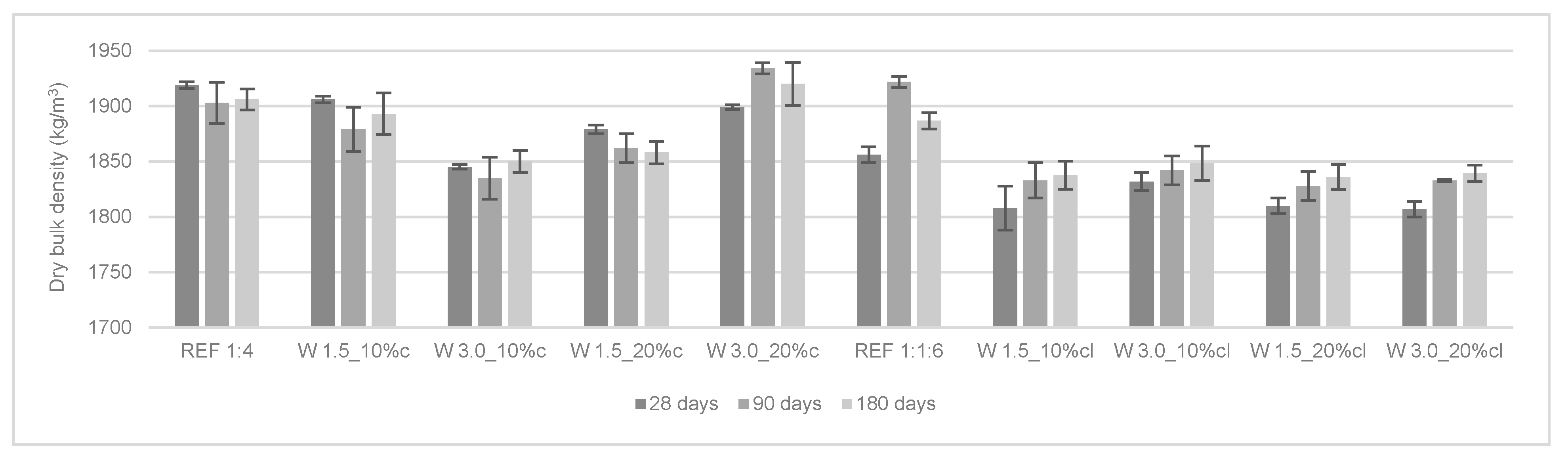

The mortars’ properties considered relevant for rendering mortars, namely workability, bulk density, dynamic modulus of elasticity, ultra-sound pulse velocity, flexural and compressive strengths, and protection to water action, were evaluated in the fresh and hardened states.

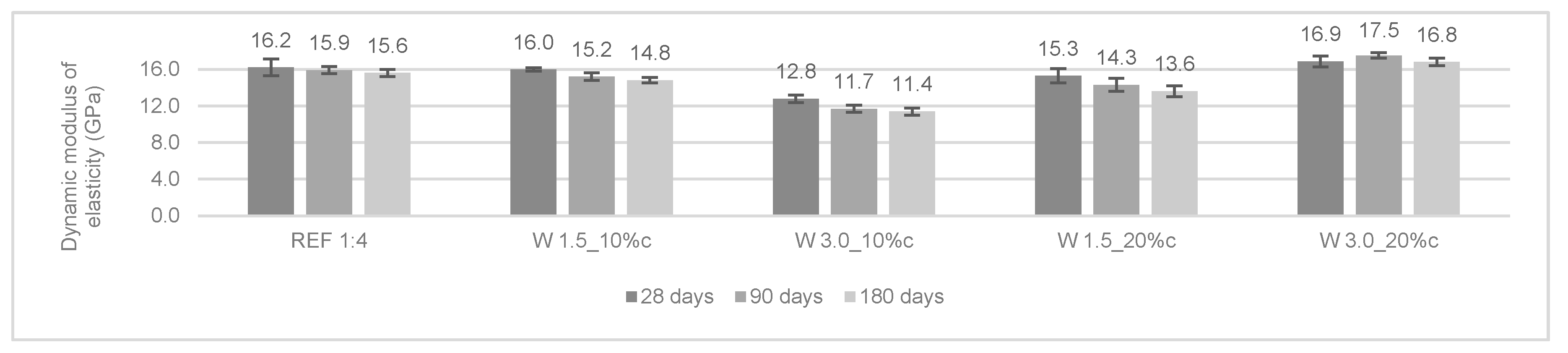

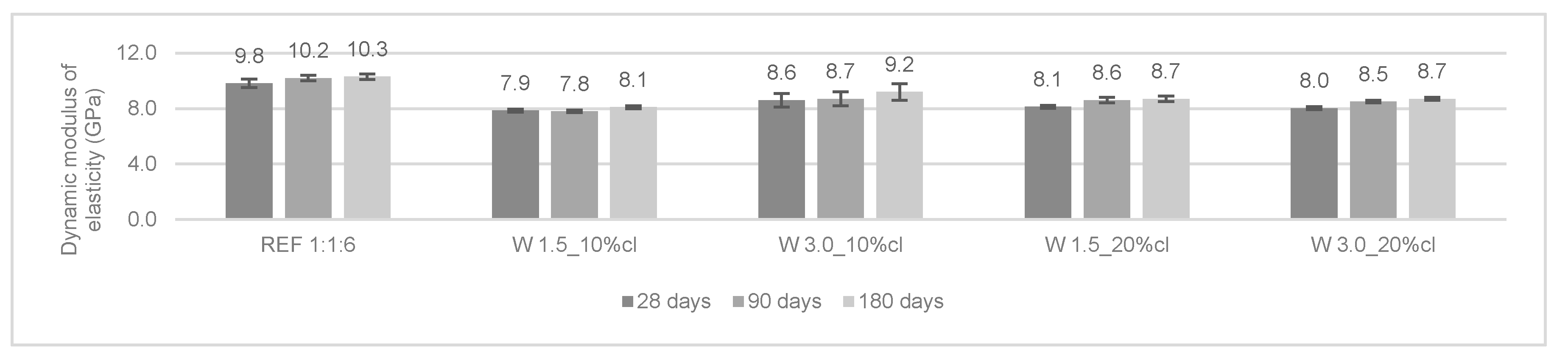

From the results, it could be seen that the incorporation of wool fibers in rendering mortars with a volumetric ratio of 1:4 (cement: aggregates) and 1:1:6 (cement:air-lime:aggregates) improved the cracking behavior of the materials as the modified mortars, in general, presented a higher flexural strength and a lower modulus of elasticity when compared to the plain mortars.

2. Experimental Program

The aim of this research was to evaluate the influence of natural fiber waste, namely sheep wool, incorporated in rendering mortars.

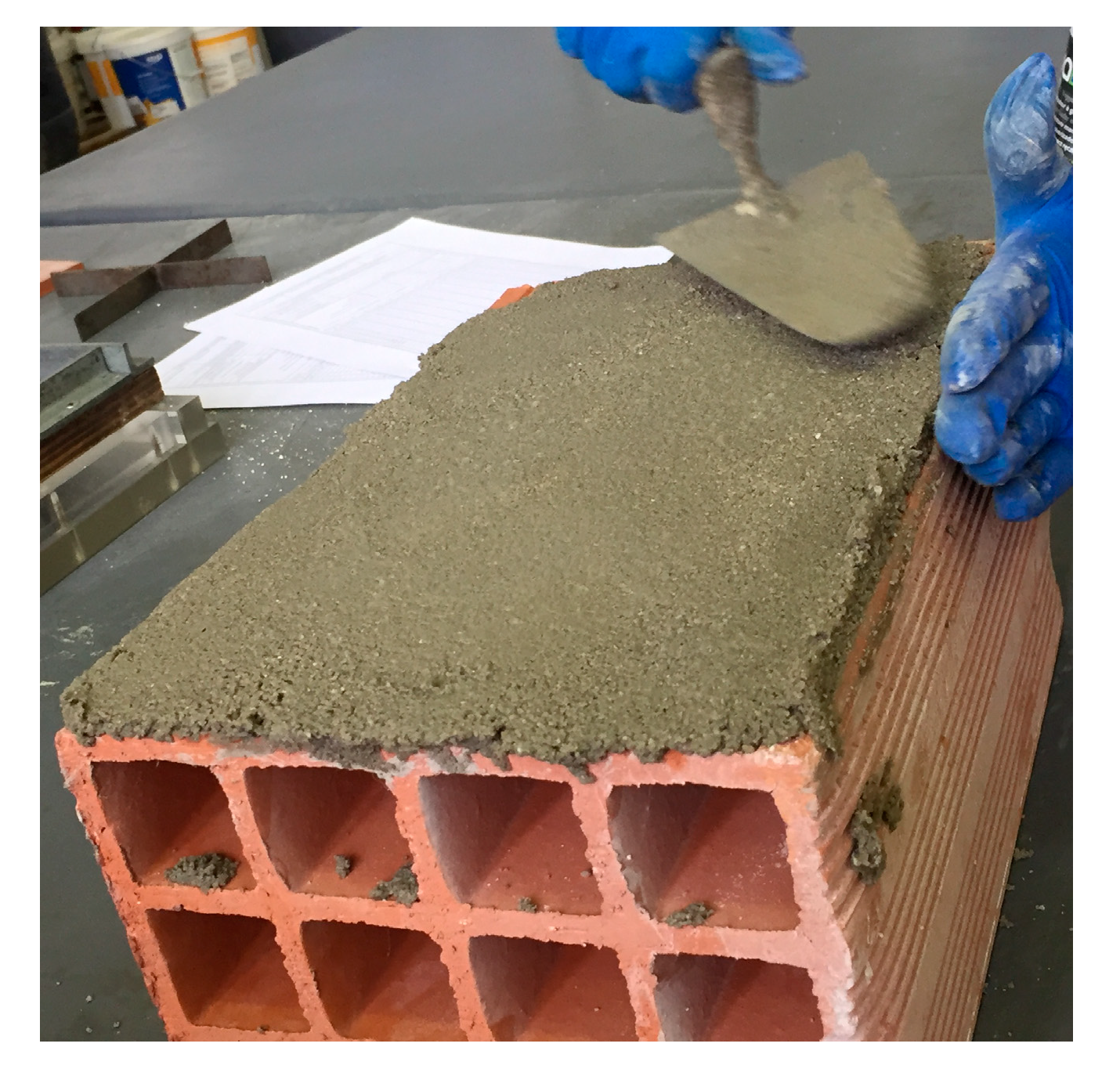

Cement mortars and cement-air lime-based mortars were produced. The volumetric proportions were 1:4 (cement: aggregates) and 1:1:6 (cement:air-lime:aggregates). Aside from the binder, the length and volume ratio were parameters used to formulate the analyzed mortars.

Mortars were identified as follows:

REF 1:4 (0% of incorporation—reference cement mortar)

W 1.5_10%c (10% of incorporation of 1.5 cm long wool fibers—cement mortar)

W 3.0_10%c (10% of incorporation of 3.0 cm long wool fibers—cement mortar)

W 1.5_20%c (20% of incorporation of 1.5 cm long wool fibers—cement mortar)

W 3.0_20%c (20% of incorporation of 3.0 cm long wool fibers—cement mortar)

REF 1:1:6 (0% of incorporation—reference cement-lime mortar)

W 1.5_10%cl (10% of incorporation of 1.5 cm long wool fibers—cement-lime mortar)

W 3.0_10%cl (10% of incorporation of 3.0 cm long wool fibers—cement-lime mortar)

W 1.5_20%cl (20% of incorporation of 1.5 cm long wool fibers—cement-lime mortar)

W 3.0_20%cl (20% of incorporation of 3.0 cm long wool fibers—cement-lime mortar)

2.1. Materials

The materials used were cement, air-lime, sand, and wool fibers. The binder used on the cement mortars was CEM II/B-L 32.5 N, according to EN 197-1 [

13]. The calcium hydrated lime powder—air lime—used was class CL80-S, according to EN 459-1 [

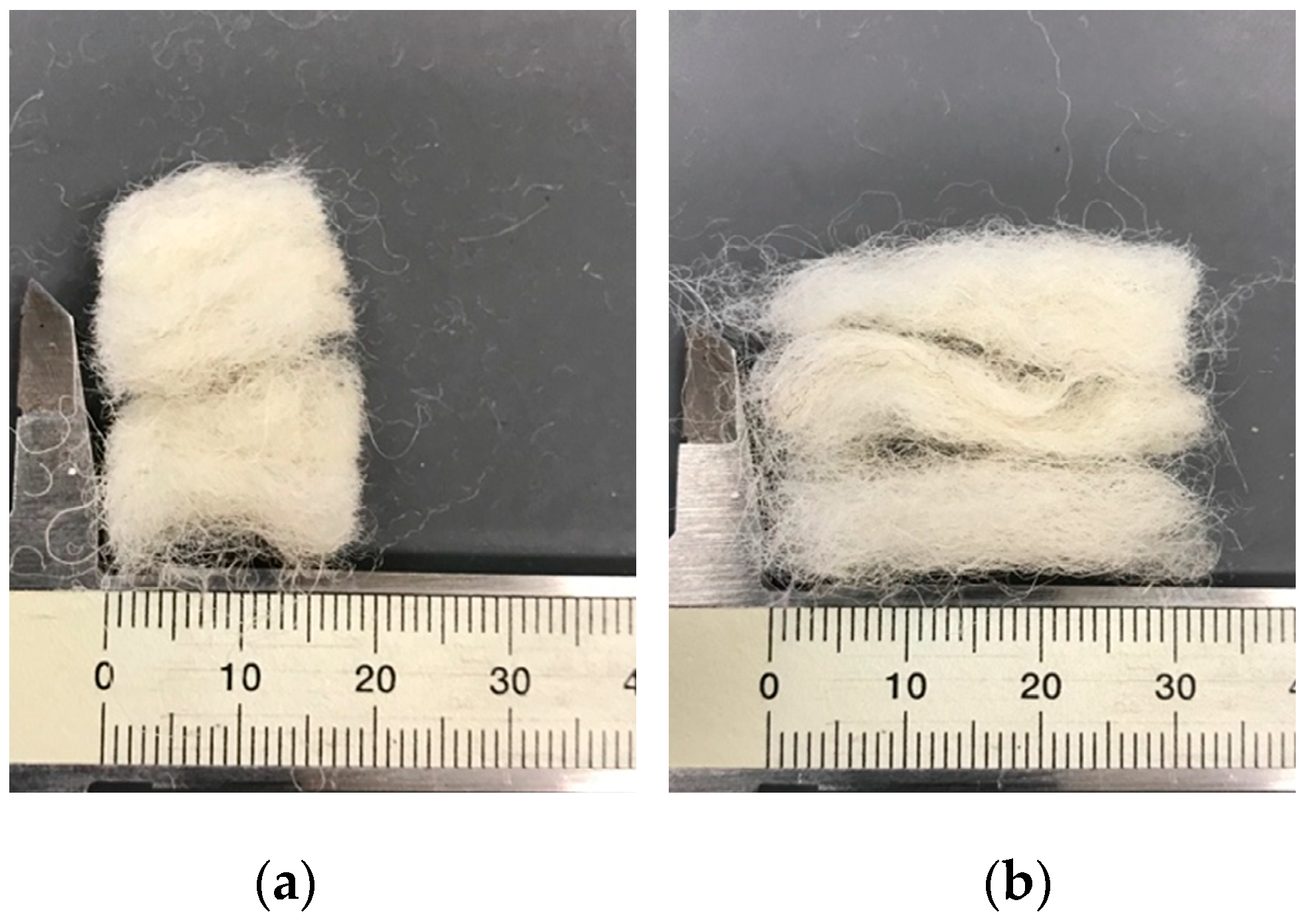

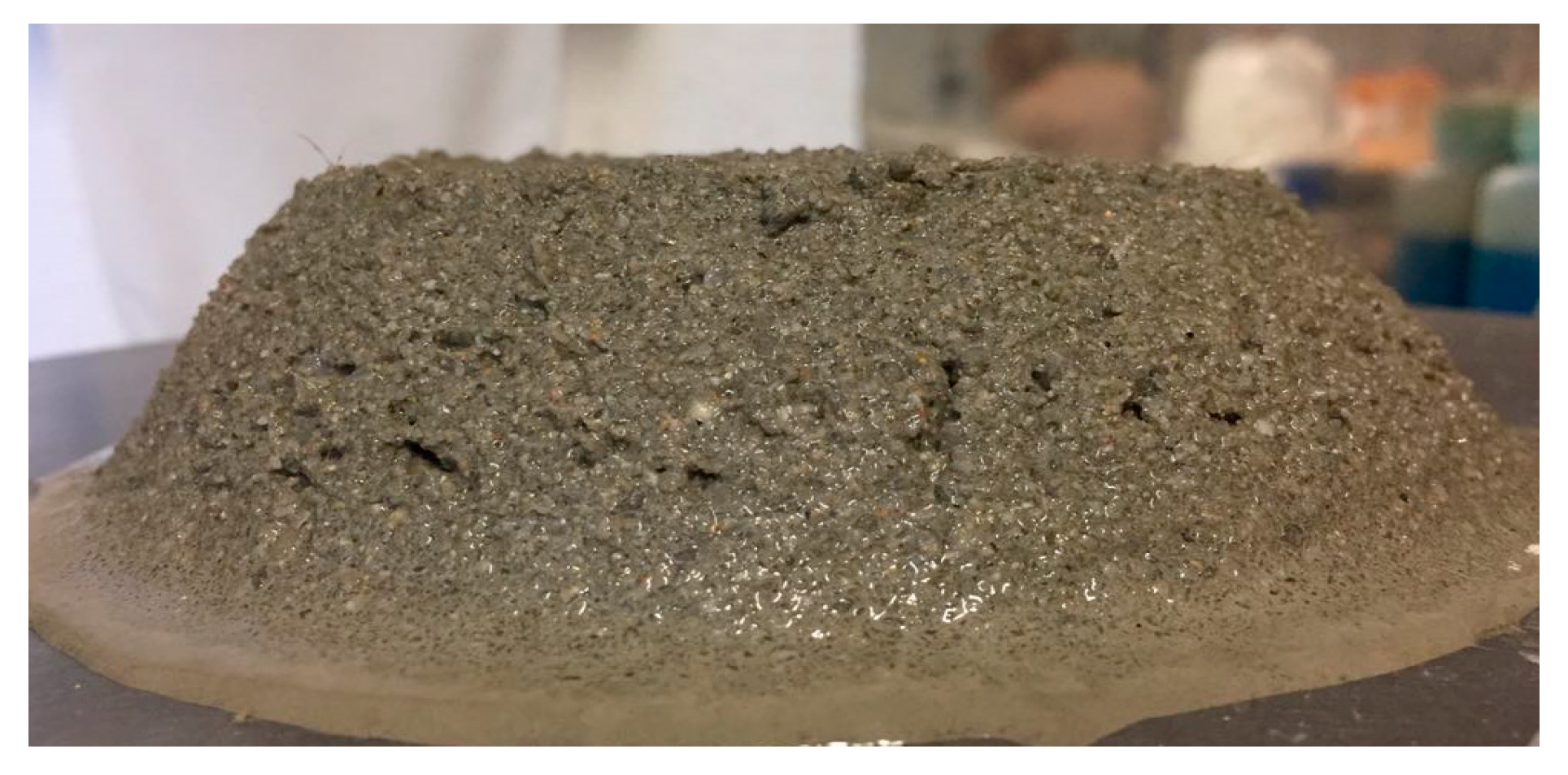

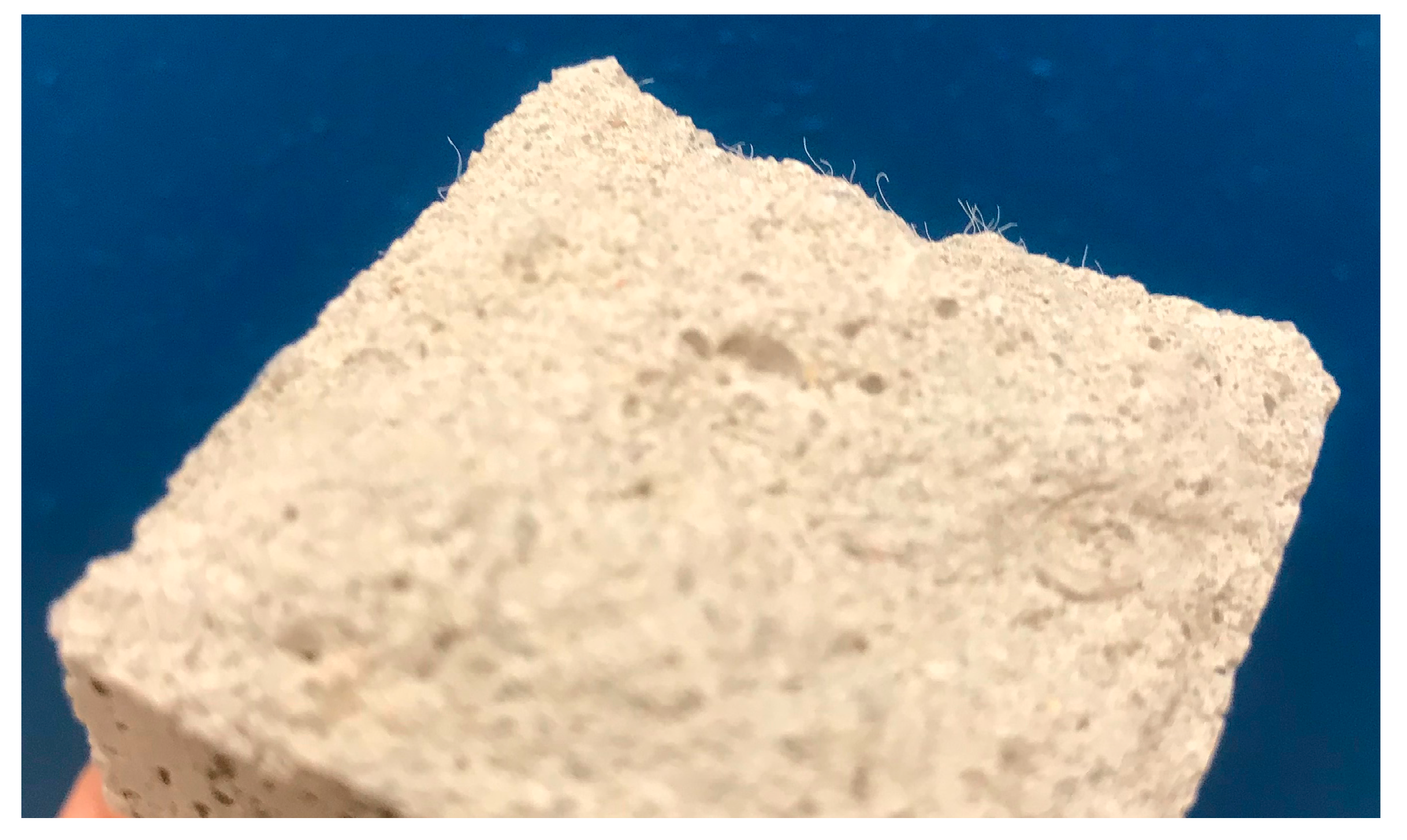

14]. The natural silica sand was previously washed, calibrated, and sieved for a required size distribution. The wool fibers were washed with neutral detergent, and dried at 40 °C. This procedure was applied to remove the impurities. The fiber length was obtained by manually cutting the waste material. The fibers were added in order to ensure a homogeneous dispersion in each mix composition. The homogeneity of the fibers in the mix was implemented by distributing them in a properly closed receptacle and blowing compressed air over them in order to achieve an adequate dispersion before adding to the mix.

Figure 1 presents the wool fibers used in the experimental campaign. The apparent bulk density of the constituents of the mortars produced is presented in

Table 1.

Table 2 presents the composition of the mortars produced in this work.

2.2. Methods

All tests carried out in the experimental program are described in

Table 3.

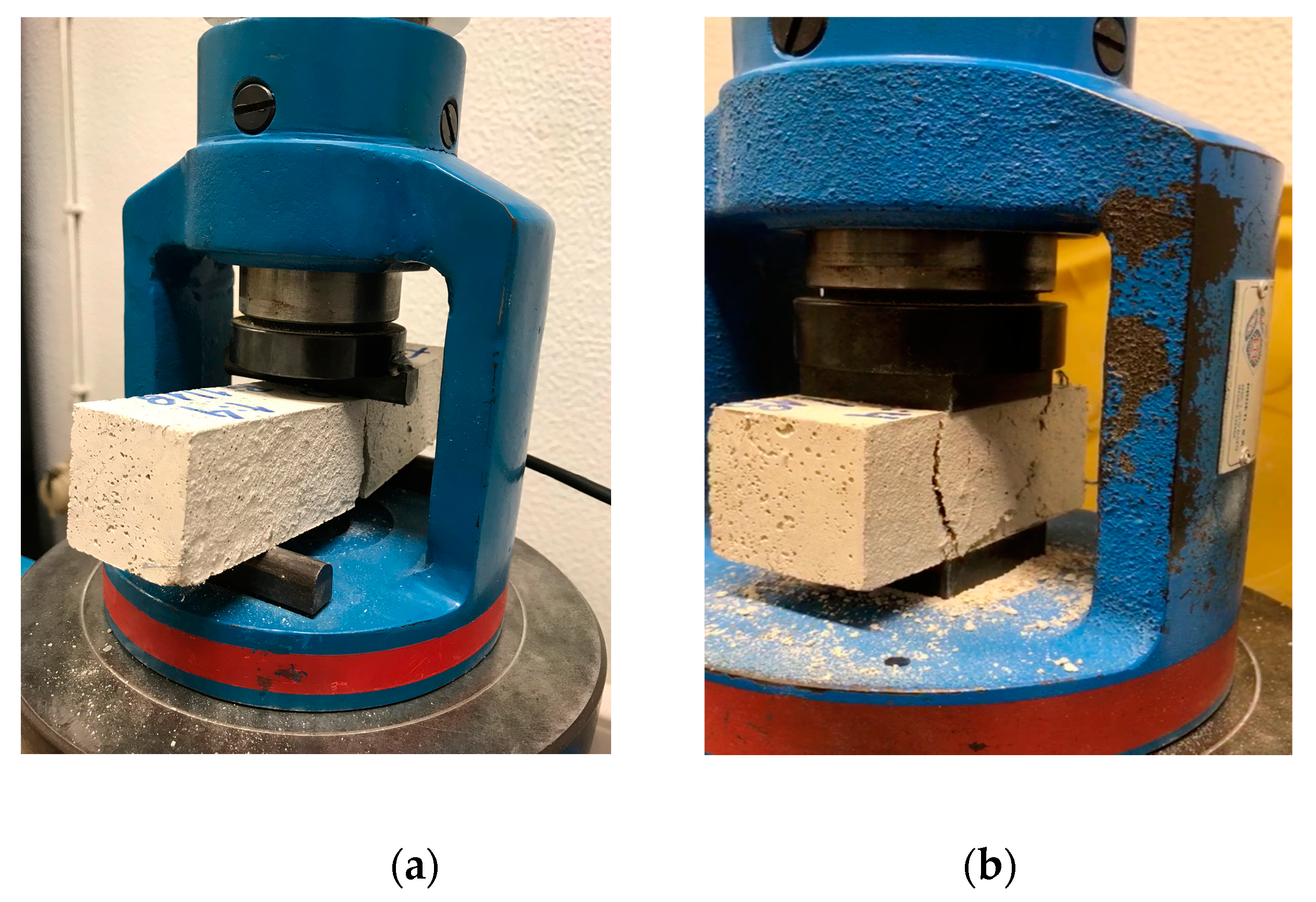

For the hardened mortar tests, prismatic samples (40 mm × 40 mm × 160 mm) were used, in accordance with European Standards.

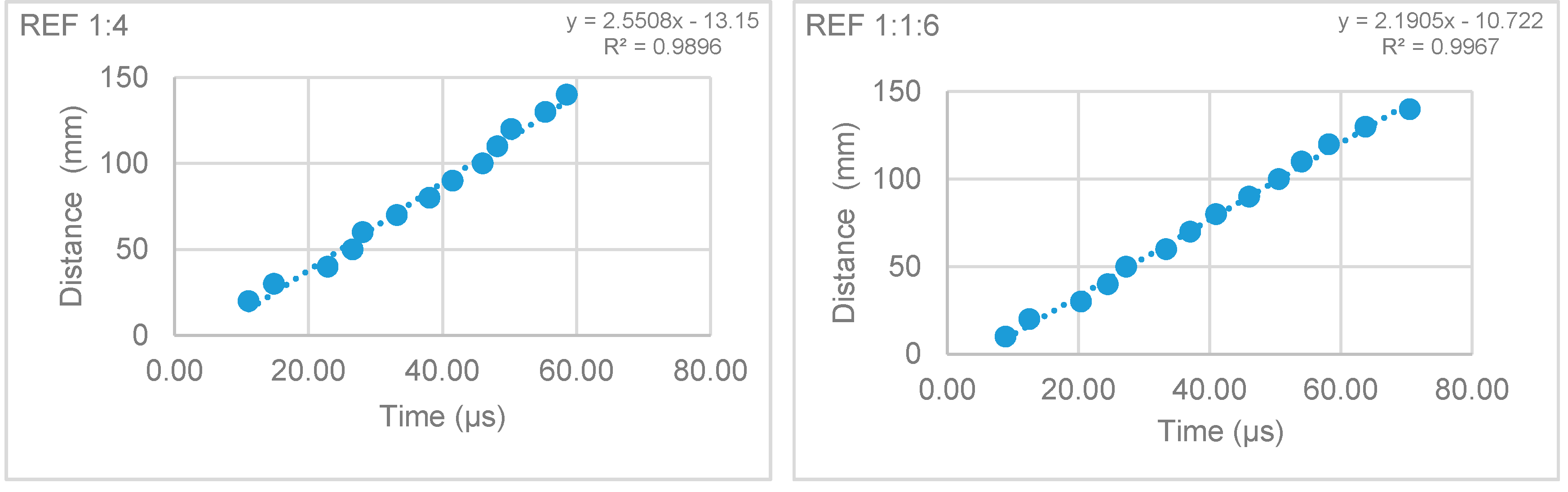

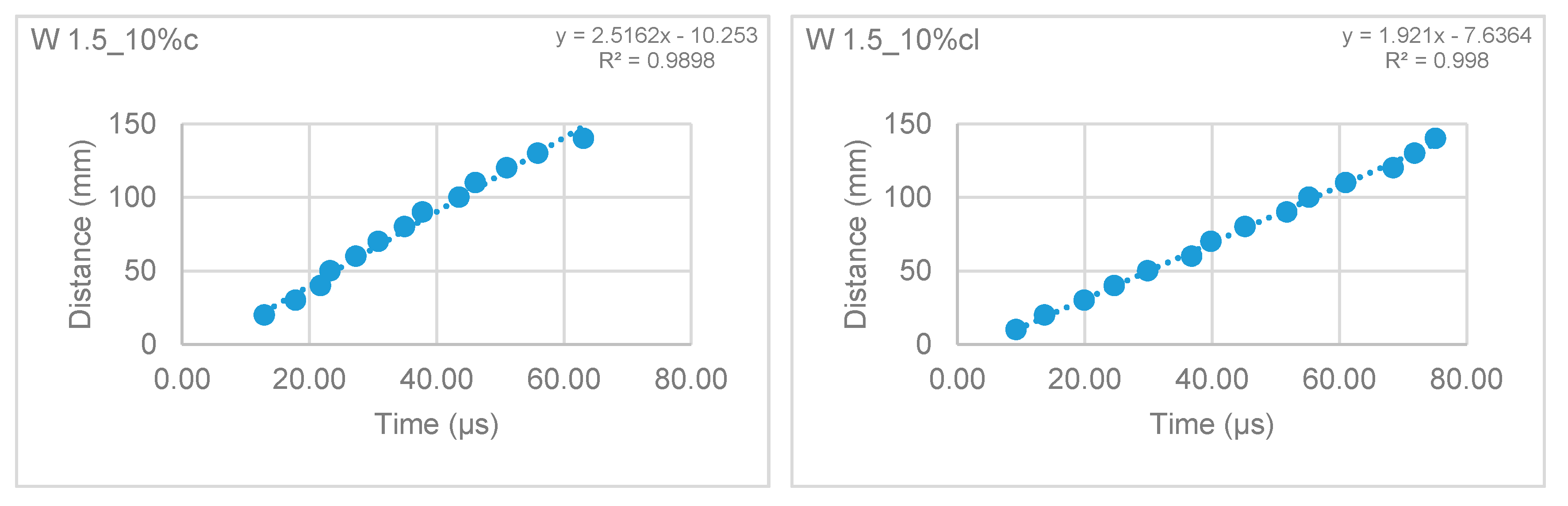

For ultra-sound pulse velocity, the direct and indirect methods were used for the measurements. In the direct transmission method, the electrodes are placed on the opposite surfaces of the specimen. In the indirect method, the electrodes are positioned on the same surface of the prism: the transmitter electrode is fixed at a specific point and the receptor moves over the specimen, and at different distances, the transmission time is measured allowing for the velocity to be calculated.

In order to analyze the susceptibility to cracking of the mortars produced in this work, some parameters were calculated. The Center Scientifique et Technique du Bâtiment (CSTB) [

15] refers to the dynamic modulus of elasticity and flexural strength ratio (E/σ

f) as indicators of the mortar’s ability to resist cracking. This criterion is based on the fact that a lower dynamic modulus of elasticity provides a higher deformation capacity of the material, and a greater flexural strength induces the material to withstand tensions without cracking. Therefore, the tendency to crack due to restrained shrinkage is greater when the ratio between the modulus of elasticity and tensile strength is high.

Another parameter to evaluate the susceptibility to crack is based on the flexural and compressive strengths. The ductility of the material can be associated to this ratio (σ

f/σ

c) (i.e., the mortar is considered more ductile when this value is closer to 1). Ductility is a measure of the deformability of the material before fracture. Cracking resistance is correlated with the deformation capacity of the mortar and its ability to absorb stress without cracking [

23].

The ability to absorb energy before fracture is correlated with the toughness of the mortar. The fracture toughness was calculated by the total area under the strain–stress curve of the results of flexural strength at 28 days.

Regardless of the binder used, all hardened mortars were cured as specified by EN 1015-11 [

21]. The specimens were kept in molds for two days at a temperature of 20 ± 2 °C and a relative humidity of 95 ± 5%. After demolding, all specimens were maintained in the same conditions for a total of seven days. After that, the specimens were kept at 20 ± 2 °C and the relative humidity was reduced to 65 ± 5%, until testing.

4. Conclusions

From the results of the experimental campaign, it was concluded that the incorporation of wool fibers in rendering mortars presented a satisfactory performance concerning the mechanical and cracking behavior. All of the modified mortars presented less susceptibility to cracking when compared with the mortars without fibers, based on the parameters evaluated.

In general, the reinforced mortars presented a decrease in the dynamic modulus of elasticity, which can be considered an advantage of the incorporation of wool fibers. W 3.0_10%c and W 1.5_10%cl obtained a similar decrease of 20% of modulus of elasticity when compared to the control mortar.

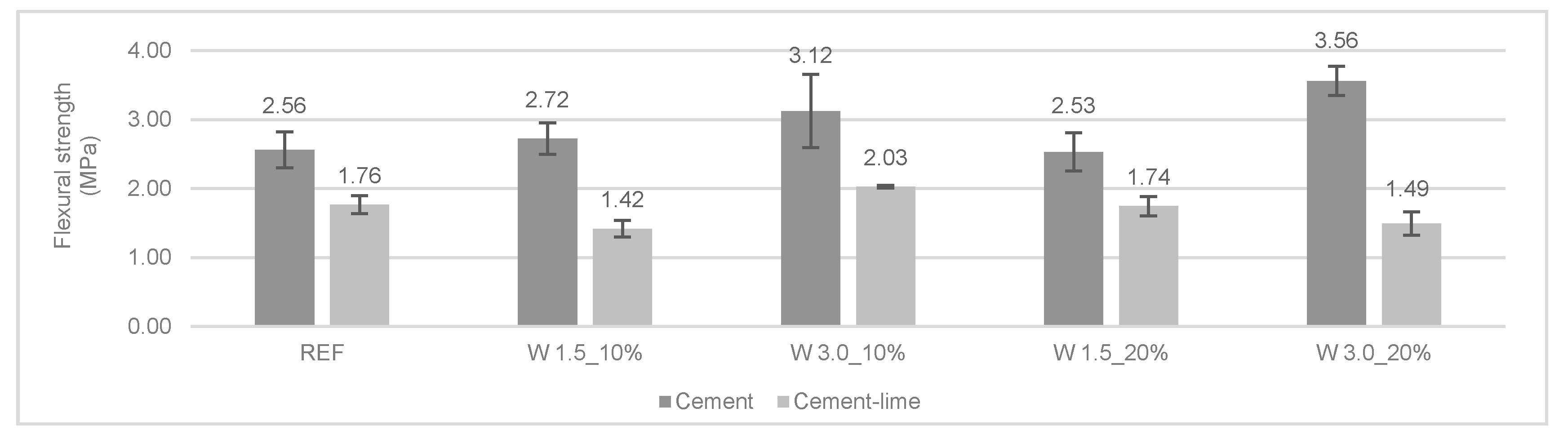

Regarding flexural strength, the modified cement mortars presented an increase when compared to the reference mortar. The addition of longer fibers enhanced the mechanical strength of the mortars. W 3.0_20%c obtained an increase of 40% in flexural strength when compared to REF 1:4. The cement-lime modified mortars obtained a slight reduction in flexural strength, with the exception of W 3.0_10%cl.

The dynamic modulus of elasticity and flexural strength ratio (E/σf) was analyzed as an indicator of the mortars’ ability to resist cracking. It could be seen that all of the modified mortars, regardless of the binder used, presented a lower (E/σf) ratio, which could lead to a lesser tendency to crack due to restrained shrinkage when compared to the reference mortars.

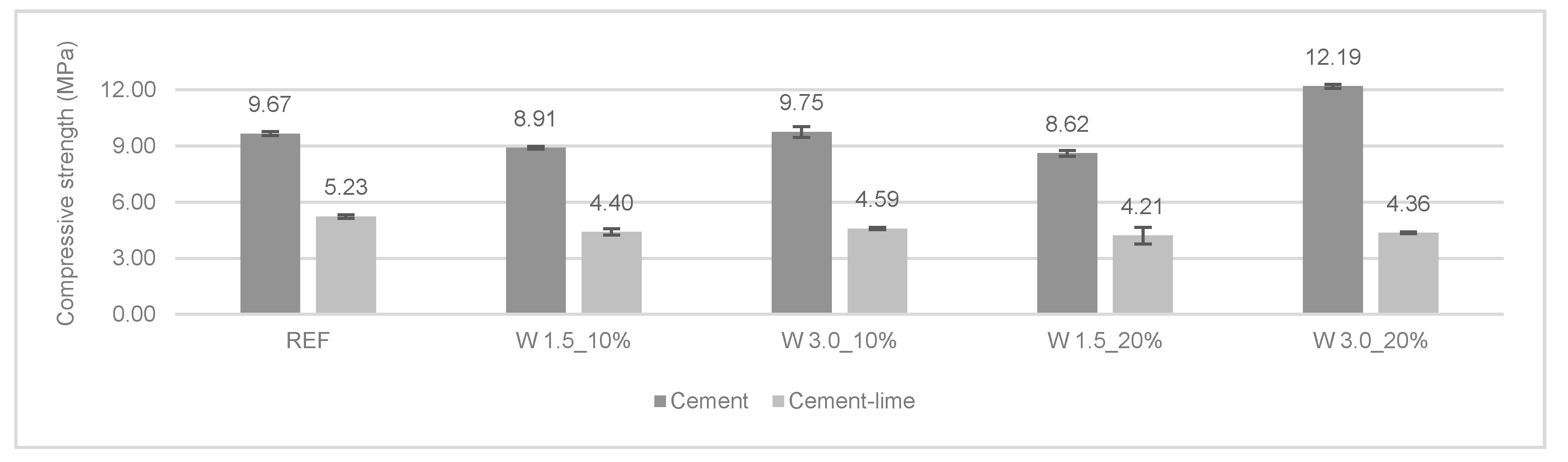

The ratio (σf/σc) is related to the mortar’s ductility. According to the results, all the modified mortars presented a higher ratio (σf/σc) compared to the reference mortars, which allows concluding that the incorporation of fibers increased the ductility of those mortars, based on this parameter.

Regarding fracture toughness, the modified cement mortars presented improvements. In fact, the toughness increment was higher when longer fibers were incorporated. However, for the cement-lime mortars, the toughness results did not present any significant contribution of the incorporation of the fibers.

Besides the analyzed parameters related with the cracking behavior, it was also found that, concerning compressive strength, the incorporation of longer fibers in cement mortars (W 3.0_10%c and W 3.0_20%c) resulted in an increase.

The results obtained in this work identify the advantages of the addition of the natural wool fibers in rendering mortars, namely concerning the improvement in the mechanical, and in particular of the cracking behavior.