Abstract

Nuclear energy is clean, reliable, and competitive with many useful applications, among which power generation is the most important as it can gradually replace fossil fuels and avoid massive pollution of environment. A by-product resulting from utilization of nuclear energy in both power generation and other applications, such as in medicine, industry, agriculture, and research, is nuclear waste. Safe and effective management of nuclear waste is crucial to ensure sustainable utilization of nuclear energy. Nuclear waste must be processed to make it safe for storage, transportation, and final disposal, which includes its conditioning, so it is immobilized and packaged before storage and disposal. Immobilization of waste radionuclides in durable wasteform materials provides the most important barrier to contribute to the overall performance of any storage and/or disposal system. Materials for nuclear waste immobilization are thus at the core of multibarrier systems of isolation of radioactive waste from environment aimed to ensure long term safety of storage and disposal. This Special Issue analyzes the materials currently used as well as novel materials for nuclear waste immobilization, including technological approaches utilized in nuclear waste conditioning pursuing to ensure efficiency and long-term safety of storage and disposal systems. It focuses on advanced cementitious materials, geopolymers, glasses, glass composite materials, and ceramics developed and used in nuclear waste immobilization, with the performance of such materials of utmost importance. The book outlines recent advances in nuclear wasteform materials including glasses, ceramics, cements, and spent nuclear fuel. It focuses on durability aspects and contains data on performance of nuclear wasteforms as well as expected behavior in a disposal environment.

Materials are at the core of multibarrier systems of isolation of radioactive (nuclear) waste from the environment. Relevant materials are used to ensure long-term safety of handling, storage, transportation, and disposal of nuclear waste. Nuclear waste immobilization is the conversion of waste into a wasteform by solidification, embedding, or encapsulation that reduces the potential for migration or dispersion of radionuclides during operational and disposal stages of waste lifecycle. Immobilization of waste is achieved by its chemical incorporation into the structure of a suitable matrix (typically cement, glass, or ceramic) so it is captured and unable to escape. Chemical immobilization is typically applied to high level waste (HLW). Encapsulation of waste is achieved by physically surrounding it in materials (typically bitumen or cement) so it is isolated, and radionuclides are retained. Physical encapsulation is often applied to intermediate level waste (ILW) but can also be used for HLW, especially where chemical incorporation of radionuclides in the surrounding matrix is also possible.

Within the repository, the wasteform is one part of a multiple engineered barrier system. During storage and transportation, the wasteform is the primary barrier preventing the release of radionuclides into the environment, while during post closure disposal, the wasteform will reduce the release of radionuclides from breached and compromised containers that could result due to corrosion, earthquake, human intrusion, igneous intrusion (volcano), or other disruptive phenomena.

Choosing a suitable wasteform (matrix) to use for nuclear waste immobilization is not easy and its durability is not the sole acceptance criterion. Priority is given to reliable, simple, rugged technologies and equipment, which may have advantages over complex or sensitive equipment and processes. A variety of matrix materials and techniques are available for immobilisation [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16]. The choice of the immobilization technology depends on the physical and chemical nature of the waste and the acceptance criteria for the storage and disposal facility to which the waste will be consigned.

Factors that are considered primarily when selecting a wasteform material are as follows [3,4]:

- Waste loading—able to accommodate a significant amount of waste (typically 25–45 weight %) to minimize volume;

- Ease of production—accomplished under reasonable conditions;

- Durability—low rate of dissolution to minimize the release of radioactive and chemical constituents;

- Radiation stability—high tolerance to radiation effects from the decay of radioactive constituents;

- Chemical flexibility—able to accommodate a mixture of radioactive and chemical constituents with minimum formation of secondary phases;

- Availability of natural analogues—availability of natural mineral or glass analogues may provide important clues about the long-term performance;

- Compatibility with the intended disposal environment—compatible with the near-field environment of the disposal facility.

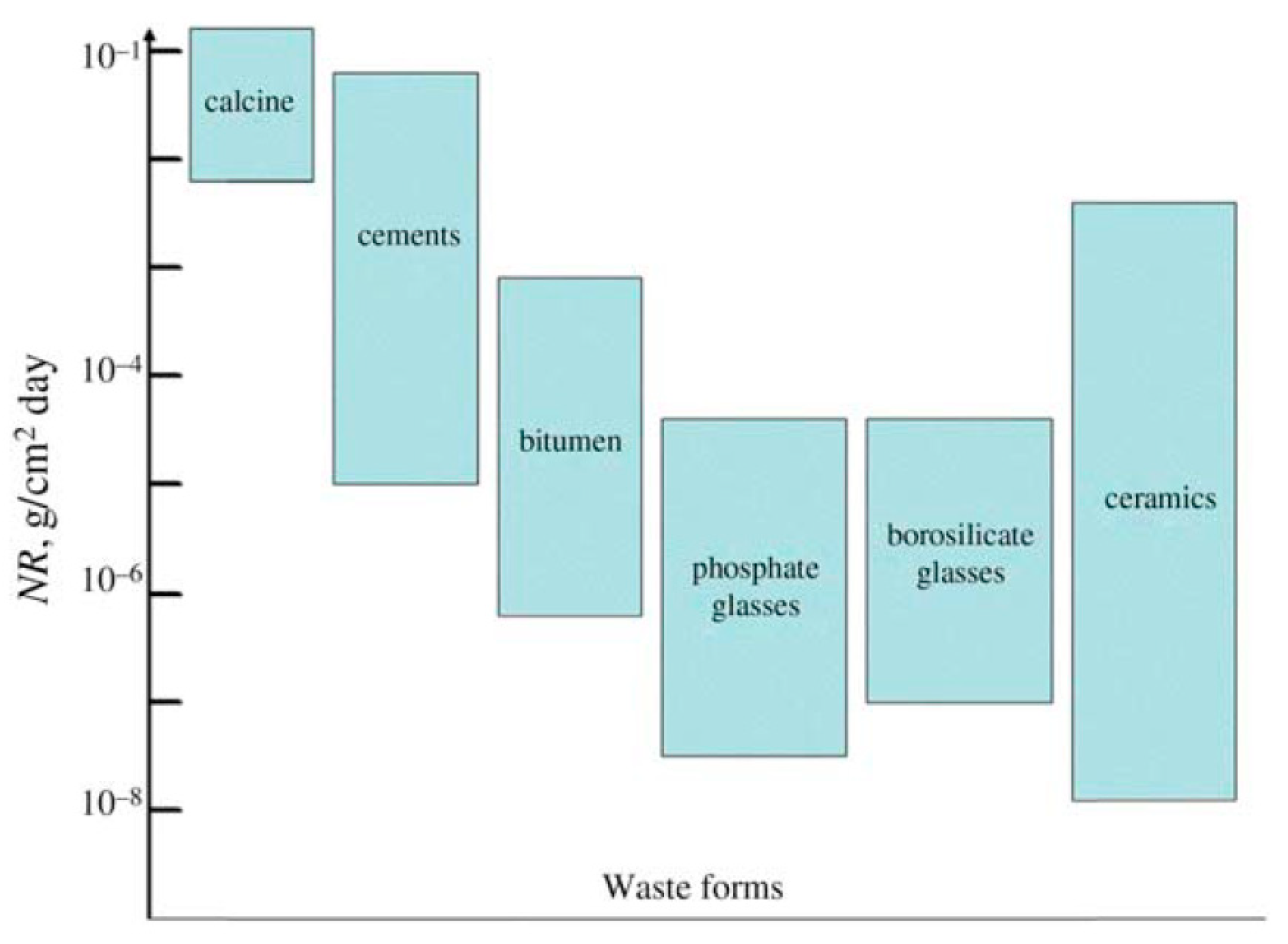

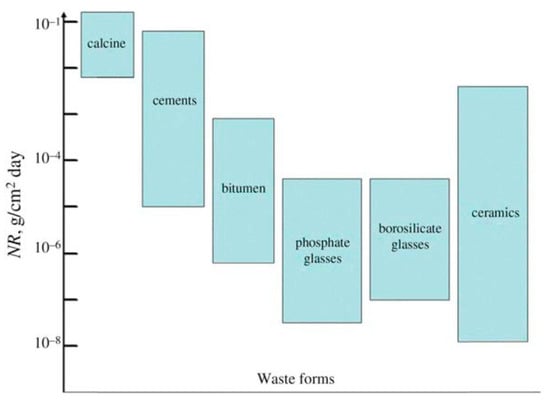

A host of regulatory, process, and product requirements has led to the investigation and adoption of a variety of matrices and technologies for waste immobilization. The resistance of the wasteform to aqueous corrosion and release of radionuclides in the disposal environment—chemical durability—is a critical parameter. Figure 1 shows schematically the water durability of main nuclear wasteforms used.

Figure 1.

Normalized leaching rates of various wasteforms (after Reference [1]).

The main immobilization technologies that are available commercially and have been demonstrated to be viable are cementation [1,2,3,4,5] and vitrification [1,3,4,8,9,10,11,12,13,14,15,16], whereas bitumen and polymeric materaisl are used to a smaller extent (see data in [1]) and ceramification is a perspective technology [1,3,6,7,8,12,14,15,16]. Table 1 shows generic features and limitations of main wasteforms currently used on industrial scale.

Table 1.

Features and limitations of main wasteforms currently used.

The general requirements against one another need optimization for any technological approach considered. For example, ceramics are credited with having higher chemical durability than glasses, however, radionuclides will be released at similar or even higher rates compared with glassy wasteforms (see, e.g., Figure 1) if they are incorporated in the lower durability crystalline phases and intergranular glassy phases.

This book contains 10 dedicated papers prepared by lead researchers covering different aspects of nuclear wasteforms and their expected behavior. They purposely analyze the materials currently used as well as novel materials for nuclear waste immobilization including technological approaches utilized in nuclear waste conditioning pursuing to ensure efficiency and long-term safety of storage and disposal systems, including cementitious materials, glasses, and ceramics. The book outlines recent advances in nuclear wasteform materials including cements, glasses, ceramics, cements, and spent nuclear fuel with focus on durability aspects and presenting data on performance of nuclear wasteforms, as well as expected behavior in a disposal environment.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ojovan, M.I.; Lee, W.E.; Kalmykov, S.N. An Introduction to Nuclear Waste Immobilisation, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2019; p. 497. [Google Scholar]

- Abdel Rahman, R.O.; Rahimov, R.Z.; Rahimova, N.R.; Ojovan, M.I. Cementitious Materials for Nuclear Waste Immobilization; Wiley: Chichester, UK, 2015; p. 232. [Google Scholar]

- Lee, W.E.; Ojovan, M.I.; Jantzen, C.M. Radioactive Waste Management and Contaminated Site Clean-up: Processes, Technologies and International Experience; Woodhead: Cambridge, UK, 2013; p. 924. [Google Scholar]

- National Research Council. Waste Forms Technology and Performance: Final Report; National Academies Press: Washington, DC, USA, 2011; p. 308. [Google Scholar]

- Glasser, F. Application of inorganic cements to the conditioning and immobilisation of radioactive wastes. In Handbook of Advanced Radioactive Waste Conditioning Technologies; Ojovan, M.I., Ed.; Woodhead: Cambridge, UK, 2011; pp. 67–135, 512. [Google Scholar]

- Kinoshita, H. Development of ceramic matrices for high level radioactive waste. In Handbook of Advanced Radioactive Waste Conditioning Technologies; Ojovan, M.I., Ed.; Woodhead: Cambridge, UK, 2011; pp. 67–135, 512. [Google Scholar]

- Burakov, B.E.; Ojovan, M.I.; Lee, W.E. Crystalline Materials for Actinide Immobilisation; Imperial College Press: London, UK, 2010; p. 198. [Google Scholar]

- Donald, I.W. Waste Immobilisation in Glass and Ceramic Based Hosts; Wiley: Chichester, UK, 2010; p. 507. [Google Scholar]

- Jantzen, C.M.; Brown, K.G.; Pickett, J.B. Durable glass for thousands of years. Int. J. Appl. Glass Sci. 2010, 1, 38–62. [Google Scholar] [CrossRef]

- Caurant, D.; Loiseau, P.; Majerus, O.; Aubin-Chevalsdonnet, V.; Bardez, I. Quintas, A. Glasses, Glass-Ceramics and Ceramics for Immobilization of Highly Radioactive Nuclear Wastes; Nova Science Publishers: New York, NY, USA, 2009; p. 359. [Google Scholar]

- Ojovan, M.I.; Lee, W.E. New Developments in Glassy Nuclear Wasteforms; Nova Science Publishers: New York, NY, USA, 2007; p. 131. [Google Scholar]

- Lee, W.E.; Ojovan, M.I.; Stennett, M.C.; Hyatt, N.C. Immobilisation of radioactive waste in glasses, glass composite materials and ceramics. Adv. Appl. Ceram. 2006, 105, 3–12. [Google Scholar] [CrossRef]

- Vienna, J.D. Nuclear Waste Glasses. In Properties of Glass Forming Melts; Pye, L.D., Joseph, I., Montenaro, A., Eds.; CRC Press: Boca Raton, FL, USA, 2015; pp. 391–404, 512. [Google Scholar]

- Stefanovsky, S.V.; Yudintsev, S.V.; Giere, R.; Lumpkin, G.R. Nuclear waste forms. In Energy, Waste and the Environment: A Geochemical Perspective; Gieré, R., Stille, P., Eds.; Geological Society of London: London, UK, 2004; pp. 37–63, 688. [Google Scholar]

- Ewing, R.C. The Design and Evaluation of Nuclear-waste Forms Clues from Mineralogy. Canadian Mineralogist 2001, 39, 697–715. [Google Scholar] [CrossRef]

- Lutze, W.; Ewing, R.C. Radioactive Waste Forms for the Future; Elsevier: Amsterdam, The Netherlands, 1988; p. 778. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).