1. Introduction

At present, the effective methods of modifying polymer insulation materials have been presented as by polymer dielectric nanocomposites (filling nanoparticles), ultra-clean process, blending, and chemical modification [

1,

2,

3]. The underlying modification mechanism and realizing their applications in the industrial production of insulated cables have always been advanced topics. It was especially noted that the dielectric performance of insulated polymers can be evidently modified by filling nanoparticles. However, the space-charge accumulation and electrical conductance of nanocomposites depends greatly on the contact area between nanofillers and polymeric matrix, which is required to control the nanofillers in minimal size and high dispersivity [

4]. Furthermore, high concentration of inorganic nanofillers to obtain nonlinear composites generally used in insulation systems will inevitably deteriorate mechanical properties and break down strength. These drawbacks and difficulties in developing cable accessories by nanodielectrics technology make it almost impossible to be fulfilled in practical industrial productions. Employing the first-principles calculations, Meunier studied the energetic feature of intrinsic traps introduced by physical and chemical defects and reasonably suggested that the polar group can present deep traps in polymer materials [

5,

6]. Recent reports indicated that excellent dielectric properties of modified polymers by chemically grafting are attributed to the trapping mechanism of space-charge suppression and break down strength improvement [

7]. However, due to low gasification temperature, the polar molecules are liable to vaporize in chemical grafting reactions so as to form gas bubbles in the pipeline of crosslinked polyethylene fabrication, which will cause severe degradation on insulation performance. Moreover, it is inevitable to produce by-product impurity in chemical grafting reactions, which need to be carried out at high temperature and pressure for a long time, leading to mechanical deterioration and conductivity augmentation of polymer materials. Therefore, the traditional chemical method of grafting micro-molecules cannot be feasible for industrial cable manufactures.

With the development of the marine development strategy, the submarine cable manufacture of high-grade and super-long crosslinked polyethylene (XLPE) has become a focus in electrical insulation research. However, the peroxide chemical crosslinking technology commonly used in the production of high-voltage cables represents some unavoidable shortcomings, such as high production energy consumption, low heat-transfer rate, long reaction time, and so on. In addition, scorching is liable to occur at the dead angle of mold in chemical crosslinking processes, thus forming defects in the insulation layer of high-voltage cable, which will worsen electrical characteristics [

8,

9]. Ultraviolet (UV) crosslinking technology is a characteristic non-thermosensitive grafting method with high production efficiency. A series of unique advantages, such as fast and continuous long time processing, small capital investment, and low consumptions of raw materials and energy in cable manufactures, make the UV-initiation technique stand out in crosslinking technology, and are promised to realize high voltage grade and super-length crosslinked cable in practical industrial productions [

10,

11,

12,

13]. The crosslinking configurations of polyamides and rubbers can be modified by employing triallyl cyanurate (TAC), Triallyl isocyanurate (TAIC), and trimethylolpropane trimethacrylate (TMPTMA) compounds with functional groups as auxiliary crosslinking agents in the polymer crosslinking process, resulting in considerable improvements of mechanical properties and thermal stability [

14,

15]. This strategy can also be exploited to improve the crosslinking degree of polyethylene, which, however, is rarely reported. The crosslinking configuration of UV-initiated XLPE is related to the double-bond conversion and polymerization degree of auxiliary crosslinker monomers, leading to bridged crosslinking networks between polyethylene molecules [

16]. Our research team has studied the crosslinking mechanisms of photon-auxiliary crosslinking agents such as TAIC, N.N-m-phenylene dimaleimide, and TMPTMA in UV-initiated polyethylene crosslinking process, and investigated their effects on DC dielectric properties of XLPE, as it has been previously reported that TAIC can remarkably quicken the crosslinking rate from minutes to seconds [

17]. We also found that TMPTMA represents the highest efficiency to improve DC dielectric performance of XLPE, while there have so far been no reports on exploiting TMPTMA in UV-initiated crosslinking process for ameliorating dielectric properties of XLPE.

In the present paper, to develop the prospective molecular modification of polymer insulation materials, a strategic scheme of UV-initiated crosslinking reactions between the polyethylene molecules and the auxiliary crosslinking agent is employed to achieve XLPE materials with preferable dielectric performance, which can be practically used in industrial cable manufacture. We adopt TMPTMA with triple-carbonyl polar groups as an auxiliary crosslinking agent and benzophenone (BP) as the photon-initiator to accomplish crosslinking reactions of polyethylene molecules under UV irradiation, which will simultaneously introduce deep traps for charge carriers to ameliorate direct current (DC) dielectric properties. Linear low-density polyethylene (LLDPE) represents higher resistances to penetration, impact, and tear than ordinary low-density polyethylene, which makes it suitable to be processed into thin films. In particular, LLDPE is adapted to advanced plastic processes, such as film extrusion process, due to its excellent melting rheological property with a melt rheological index of 1.0 g/10 min. Furthermore, LLDPE shows remarkable endurance to environmental stress cracking, low temperature impact, and mechanical warping, which can be effectively applied in the extrusion and molding of pipe and sheet substances. Without long-chain branches on the molecular backbone, LLDPE molecules can easily form crosslinking and be grafted by functional molecular groups in crosslinking reactions, which facilitates the developments of a new crosslinking process and graft-modified polyethylene materials. Therefore, LLDPE is used as the pristine matrix material for preparing the modified XLPE materials in the present study. The first-principles electronic structure calculations are performed to consistently elucidate the electronic bound states with the energy level located in band-gap arising after polyethylene molecules are chemically connected by the auxiliary crosslinker of TMPTMA, which accounts for the underlying mechanism of inhibiting space-charge accumulation and reducing electrical conductivity.

2. Experiments and Theoretical Schemes

2.1. Material Preparation

The melting blend and hot-pressing approaches are employed in synthesis of TMPTMA-crosslinked polyethylene with the original materials being adopted as follows: linear low-density polyethylene (LLDPE, DFDA-7042, Sinopec Company Ltd., Beijing, China) as parent material, benzophenone (BP, Jinleiyuan Chemical Co., Ltd., Lianyungang, China) for initiating grafting reaction under photon irradiation, auxiliary crosslinking agent (TMPTMA, Sinopharm Chemical Reagent Co., Ltd., Shanghai, China), all of which have purity higher than 95%. In the melting blend process of preparing the initial mixtures, the pristine LLDPE are melted uniformly in Torque Rheometer (RM200C, Hapro Company Ltd., Harbin, China) at 160 °C for 3 min with stirring speed of 60 rpm, and then 2 wt. % BP photon-initiator and 1 wt. % auxiliary crosslinking agent are added and blended for 3 min then cooled to room temperature to obtain the uniform mixture materials.

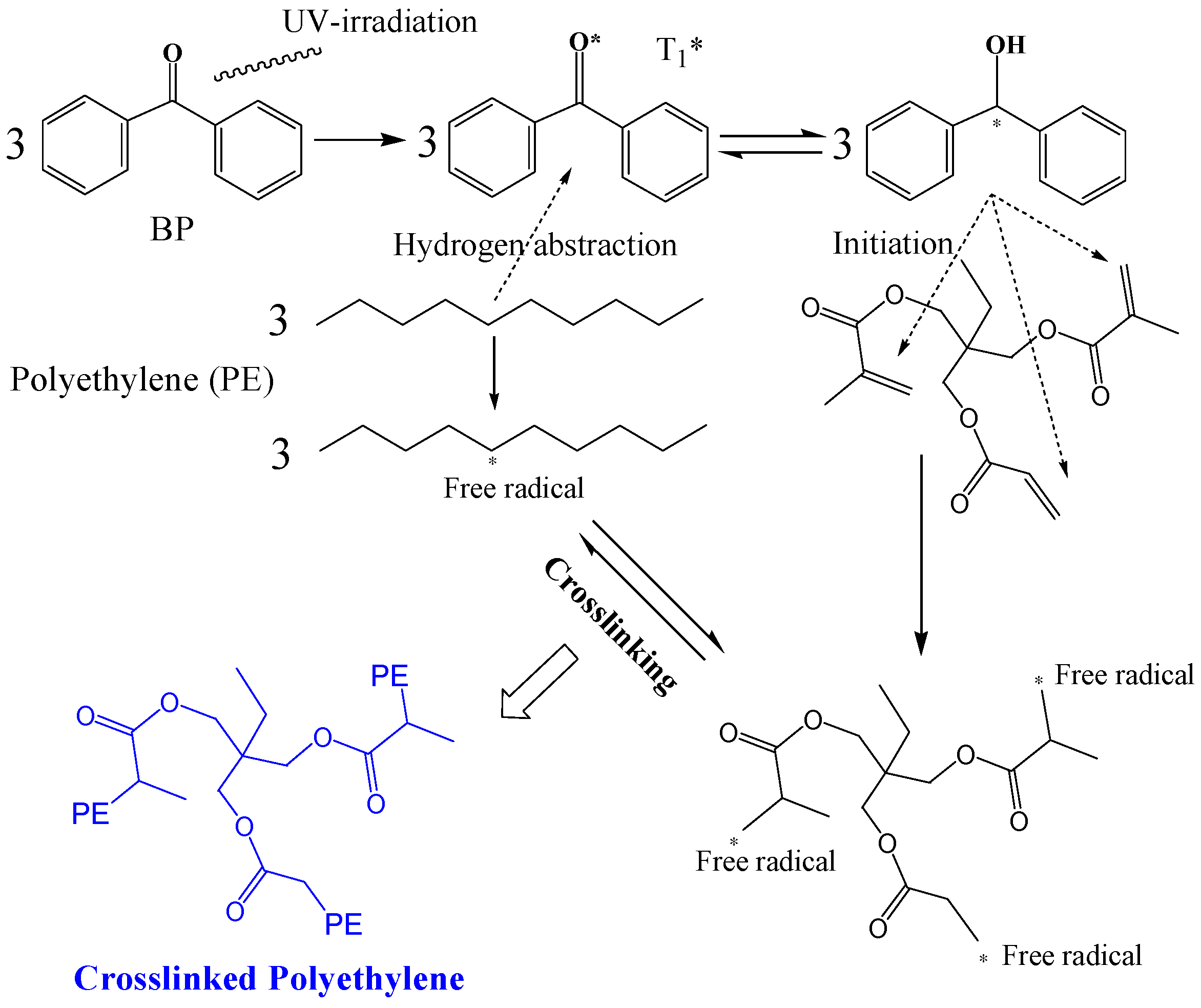

For photon-initiated crosslinking reactions, the prepared hot-pressed blend is first treated in a plate vulcanizer at 160 °C with the pressure being increased by 5 MPa per 5 min from 0 to 15 MPa so as to make the material melt, and then the melt material is irradiated by a light source array of UV LED units (NVSU233A-U365, Riya Electronics Chemistry Co., Ltd., Shanghai, China) for 2 s on an irradiation platform at normal pressure and room temperature in an air atmosphere. In this pivotal process, exploiting UV-transparency of the LLDPE fluid at the temperature higher than fusion point after being squeezed out from extruder, the UV lights are incident through the melting mixture of LLDPE, BP, and TMPTMA. Hydrogen abstractions from polyethylene molecules to UV-excited first-triplet (T

1) BP and the partial fractures of carbon double bonds on TMPTMA molecules are simultaneously initiated by instantaneous UV irradiation, leading to considerable amounts of transient free radicals on both polyethylene and TMPTMA molecules which will eventually form chemical bonds to accomplish crosslinking reactions, as schematically illustrated in

Figure 1. Since they are assisted by TMPTMA, the free radicals on polyethylene molecules connect to each other though TMPTMA and thus form a reticulated crosslinking system which is nominated here as XLPE-TMPTMA. The UV-initiated XLPE with TMPTMA crosslinker (UV-XLPE-TMPTMA) materials are finally achieved after short-circuit degassing at 80 °C for 48 h in a vacuum oven to eliminate the residual impurities of small molecules. In photon-initiated crosslinking process under UV irradiation, the power and wavelength of light-emitting are controlled on 1.0 W and 365 nm respectively, and light incident direction is 60° angle with the plane of thin film sample. Moreover, to ensure homogeneous crosslinking reaction across laterally film materials, the samples are mounted on the conveyor belt at a constant speed of 1.5 mm/s with a distance of 15 mm between the film plane and UV source.

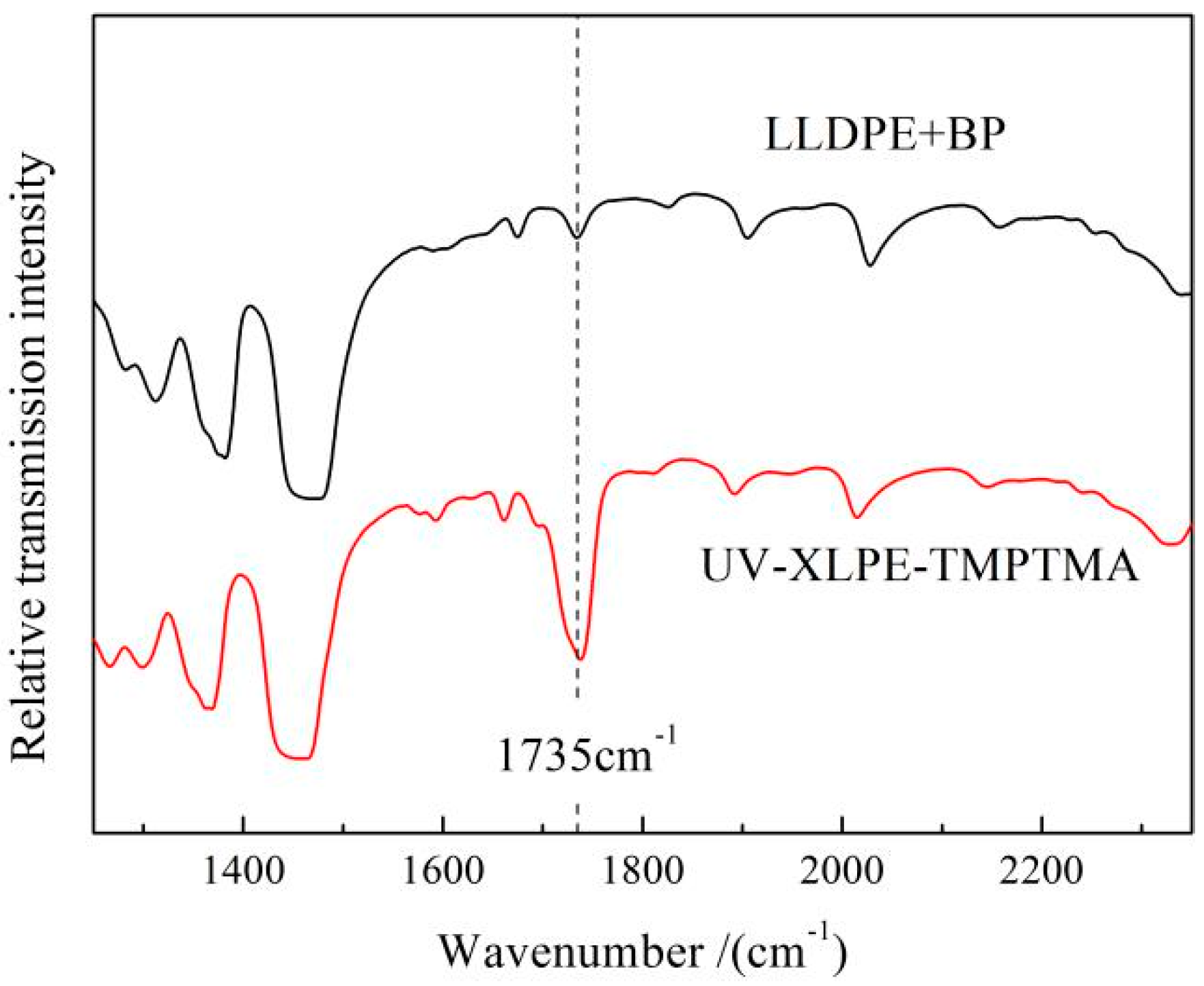

2.2. Characterization and Measurement

To detect the molecules of auxiliary crosslinking agent being grafted onto polyethylene molecular chains through UV-initiated crosslinking reactions, the molecular structures of prepared samples are characterized by Fourier Transform Infrared (FT-IR) Spectroscopy (FT/IR-6100, Jiasco Trading Co., Ltd., Shenyang, China) in spectral range of 500 ~ 4000 cm−1 with a scanning resolution of 2 cm−1. Complying to the standards of GB/T 2951.21-2008 and ASTM D 2765-2011 respectively, the crosslinking degree of XLPE is tested by thermal elongation and gel extraction experiments in which the prepared materials are pressed into dumbbell-shaped samples under 0.2 MPa and then degassed for 30 min at 200 °C in vacuum oven.

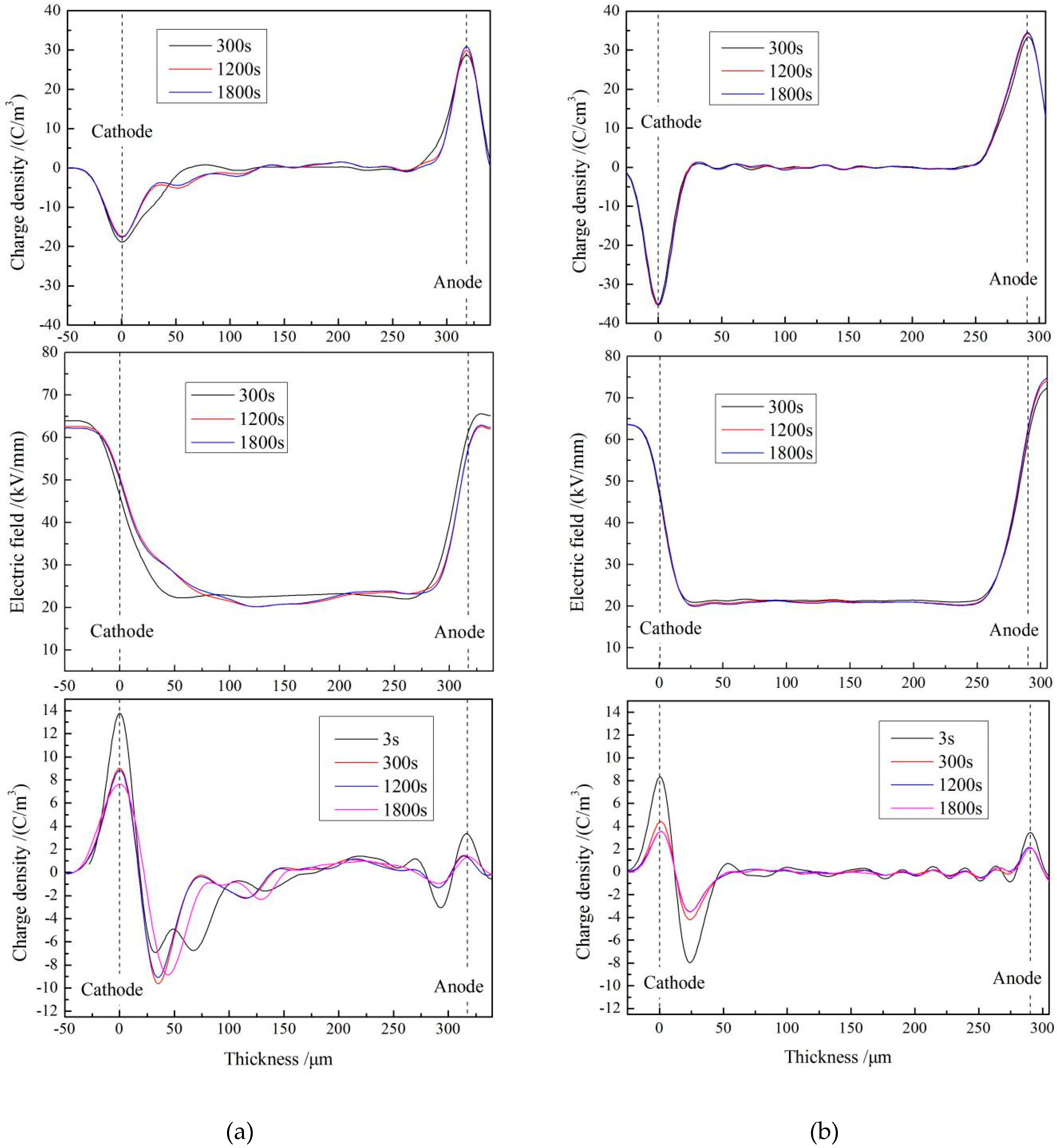

Using a pulsed electro-acoustic system (HY-PEA-DPT01, HeYi Electric Co., Ltd., Shanghai, China), the space-charge distributions are measured at ambient temperature of 25 °C by applying an electric field of 40 kV/mm in polarization for 30 min and then short-circuiting for 30 min, in which the tested materials are fabricated into 50 × 50 × 0.3 mm3 film samples with both sides being evaporated by aluminum electrode films in 25 mm diameter. Thermally stimulated depolarization currents (TSDC, Harbin University of Science and Technology, Harbin, China) are tested to analyze the energy level distribution of charge traps, for which the samples in 0.1 mm thickness are first polarized under an electric field of 40 kV/mm for 30 min and then rapidly cooled by liquid nitrogen down to −50 °C being stabilized for 3 min. The depolarization currents are measured in short circuit when temperature is raised from −50 to 150 °C with a heating rate of 3 °C/min.

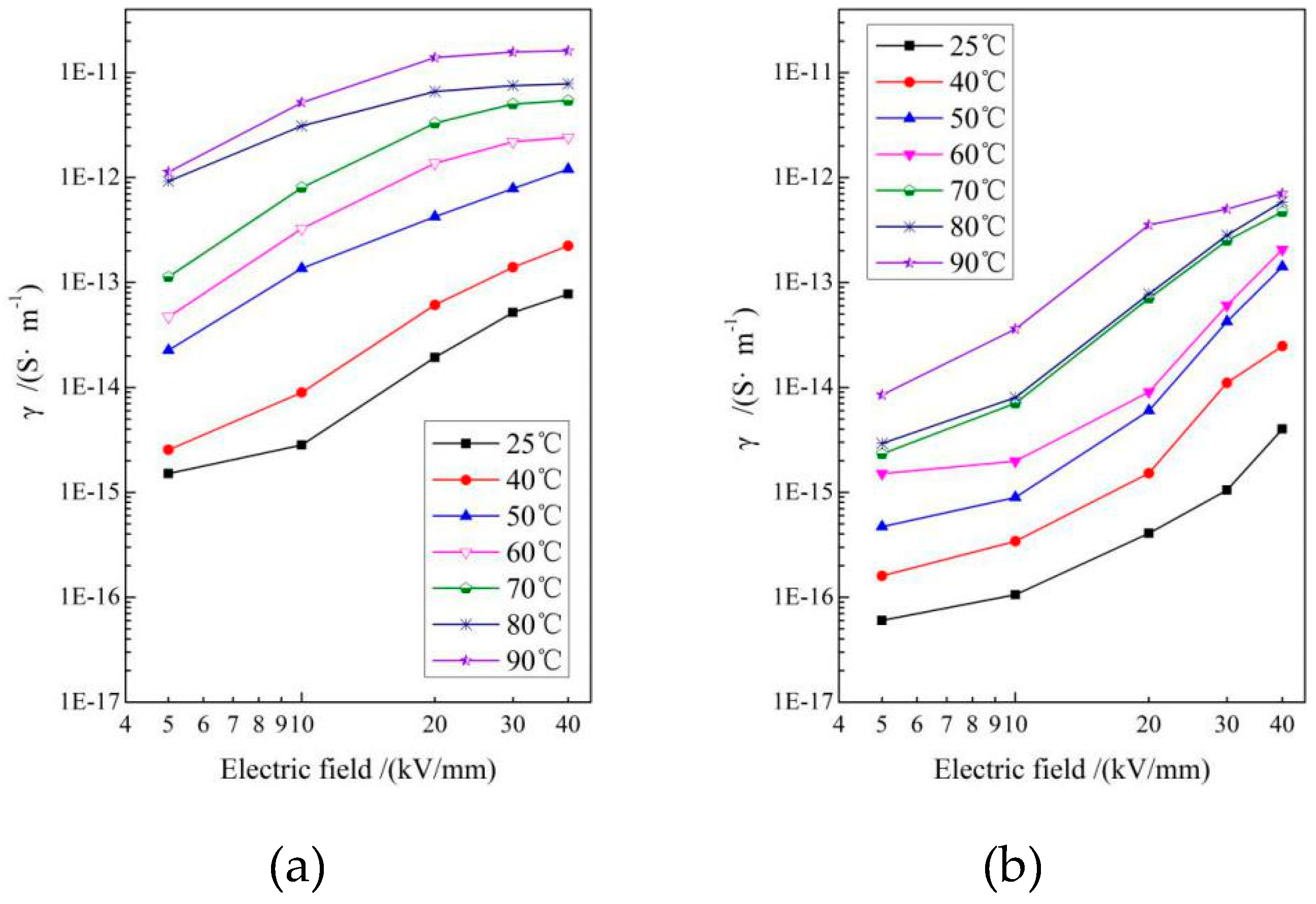

Electrical conductivity is measured by a three-electrode system at variable temperatures from 25 to 90 °C for the circular film samples of 50 mm diameter and 300 µm thickness with the evaporated aluminum electrodes on both sides. The protective electrode in annular shape (inner and outer diameters of 54 mm and 76 mm, respectively) encircles the disc of the measuring electrode (50 mm in diameter) on one side of the film samples, and the circular electrode with a larger diameter of 78 mm on the other side is used for applying high voltage. After the samples are heated and stabilized at the testing temperature for 60 min, the electric field at each point covering the range of 3–40 kV/mm is applied for 60 min to measure the stable conductance current.

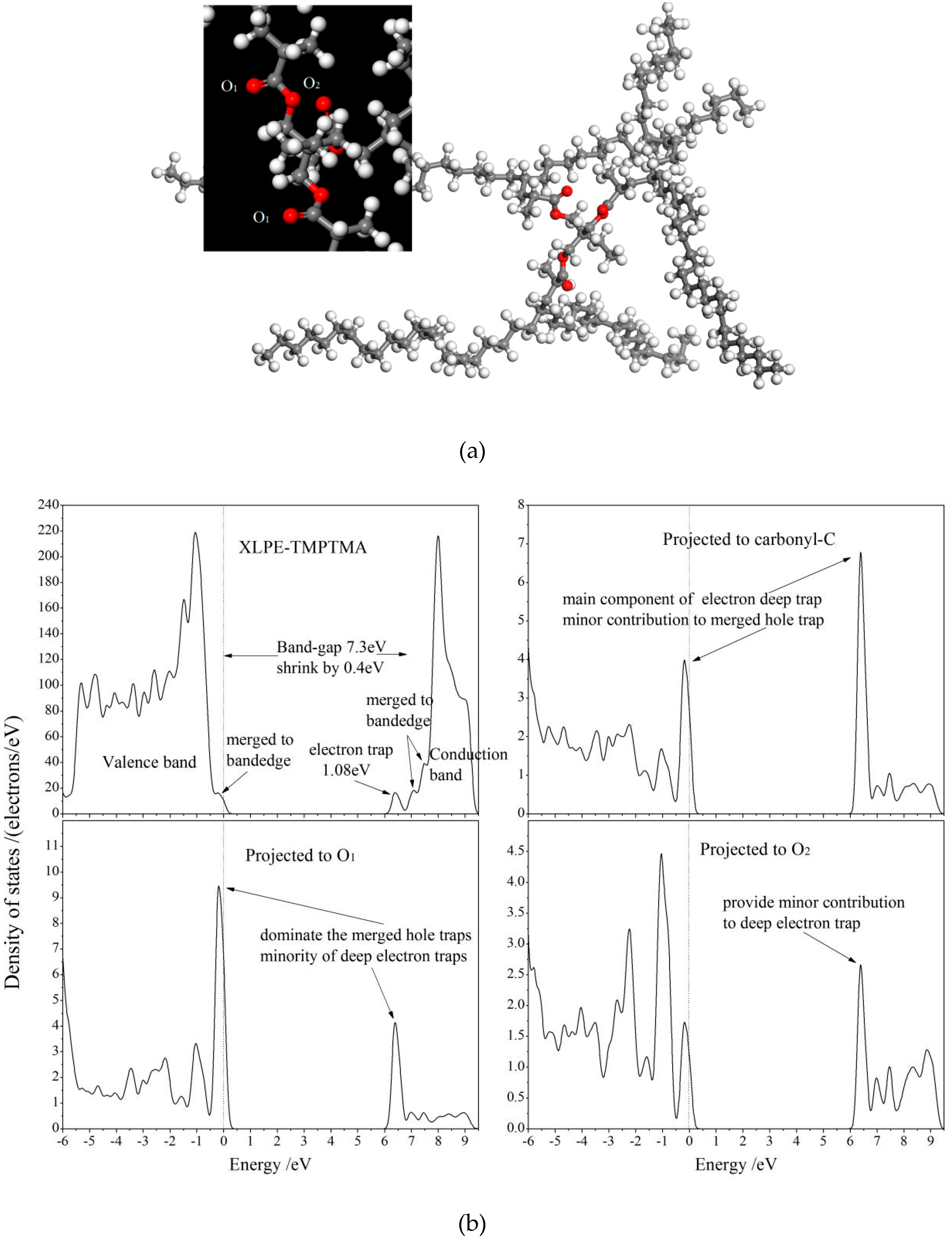

2.3. Molecular Model and Theoretical Methodology

The model of polyethylene molecules in 20 polymerization degrees, being connected by an auxiliary crosslinker molecule near the middle position of polyethylene backbone chain, is initially constructed with random distributed torsion based on rotational isomeric state (RIS) model [

18]. The constructed initial polymer configurations are geometrically optimized to structural relaxation by total energy functional minimization with conjugated gradient algorithm in first-principles calculations [

19], so that the energy change, atomic force, and displacement are theoretically evaluated to be lower than 1.0 × 10

−5 eV/atom, 0.03 eV/Å and 0.001 Å, respectively. The electronic structures are calculated for molecular orbitals and electronic density of states to investigate band-edge features and grafting-introduced trap states. The first-principles calculations are performed by employing the scheme of all-electron numerical atom-orbitals as implemented in DMol3 program of Materials studio 8.0 software package (Accelrys Inc., Materials Stutio v8.0.0.843, San Diego, CA, USA). The detailed schemes and parameters adopted in DMol3 calculations are listed in

Table 1.

4. Conclusions

Exploiting auxiliary crosslinking agents in the photon-initiated crosslinking process, the DC dielectric performance of XLPE has been evidently improved with UV irradiation technology. The underlying mechanism of suppressing charge injection and restraining electrical conductance is elucidated by TSDC analysis and quantum mechanics calculations in combination with the conductivity field variation at various temperatures of cable operation. The auxiliary crosslinking efficiency of UV-XLPE-TMPTMA has been verified by thermal elongation test and IR transmission spectra. It has been demonstrated that UV irradiation technique can successfully initiate crosslinking reactions between polyethylene molecules and auxiliary crosslinking agents to achieve modified XLPE with sufficient crosslinking degree and excellent thermal elongation performance. The modified DC dielectric performance of UV-XLPE-TMPTMA is attributed to the deep traps engendered by the polar carbonyl of grafted TMPTMA which is testified by TSDC analysis and first-principles calculations. The charges, being captured by these deep traps in higher density, will form effective electrostatic shielding layers near electrodes to impede charge injections and thus remarkably inhibit space-charge accumulation inside XLPE materials. Compared with LLDPE, lower conductivity has been acquired by the XLPE with TMPTMA as an auxiliary crosslinker which represents prominent efficiency of ameliorating dielectric properties. The first-principles calculations also indicate that the multiple electronic bound states can be engendered by the grafted TMPTMA, which will decrease the density of state at the edges of both conduction and valance bands, consequently leading to decreased carrier mobility. The present study suggests a prospective strategic scheme of UV-initiated graft modification for realizing high-performance insulating materials in HVDC cable production. Nevertheless, this paper only presents the most important study on the DC dielectric performance of modified XLPE, concerning the improvement of space-charge accumulation and the suppression of electrical conductance. For practical applications in DC insulated cable, the other electrical properties, such as DC breakdown strength when the polarity reverses, and electric tree characteristics under impulse voltage or DC short circuit, should be further researched in future work.