Influence of Cooling Methods on the Residual Mechanical Behavior of Fire-Exposed Concrete: An Experimental Study

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Mix Proportion

2.2. Specimen Preparation and Curing

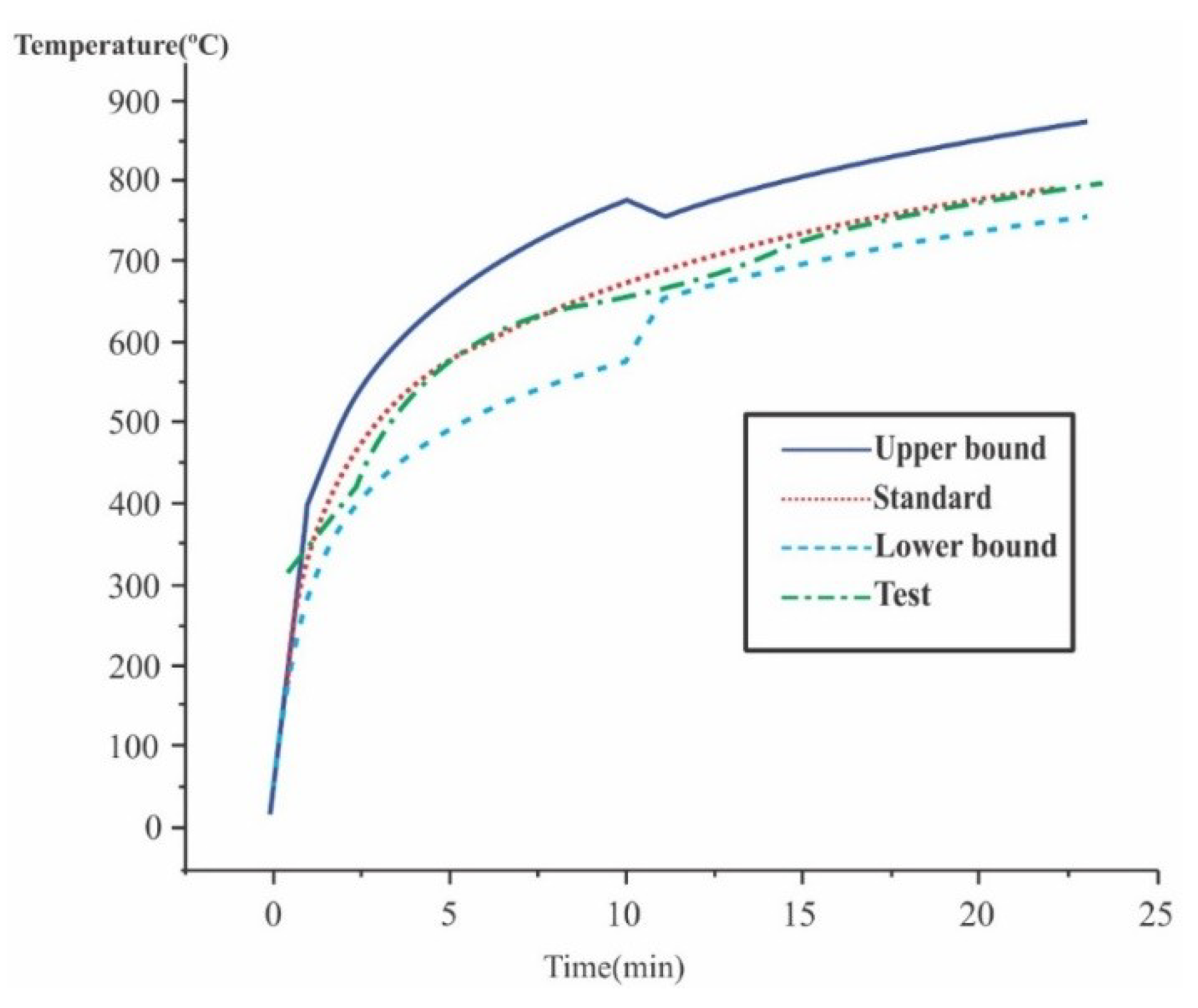

2.3. Heating and Cooling Methods

2.4. Test Set-Up

2.5. Statistical Approach

3. Results and Discussion

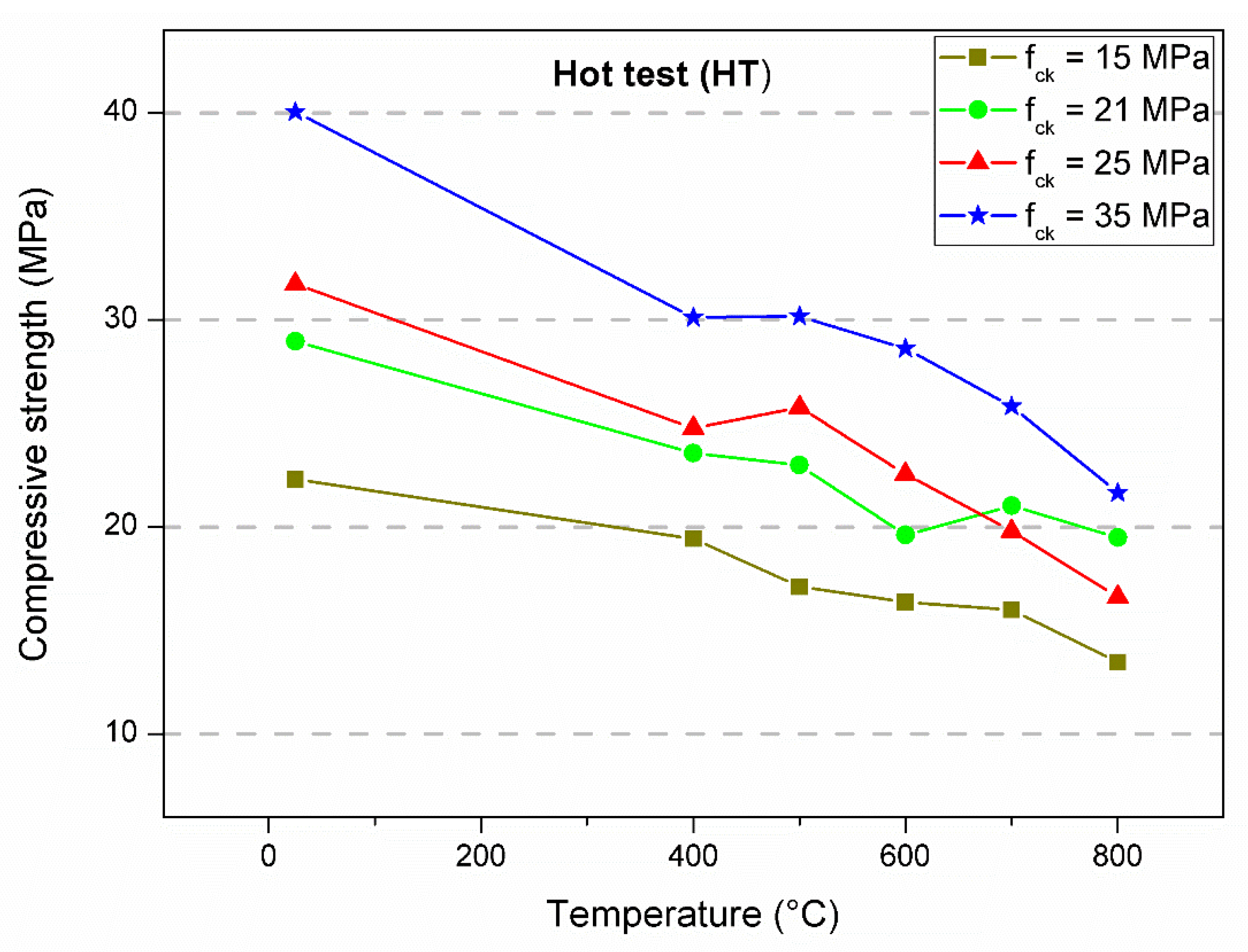

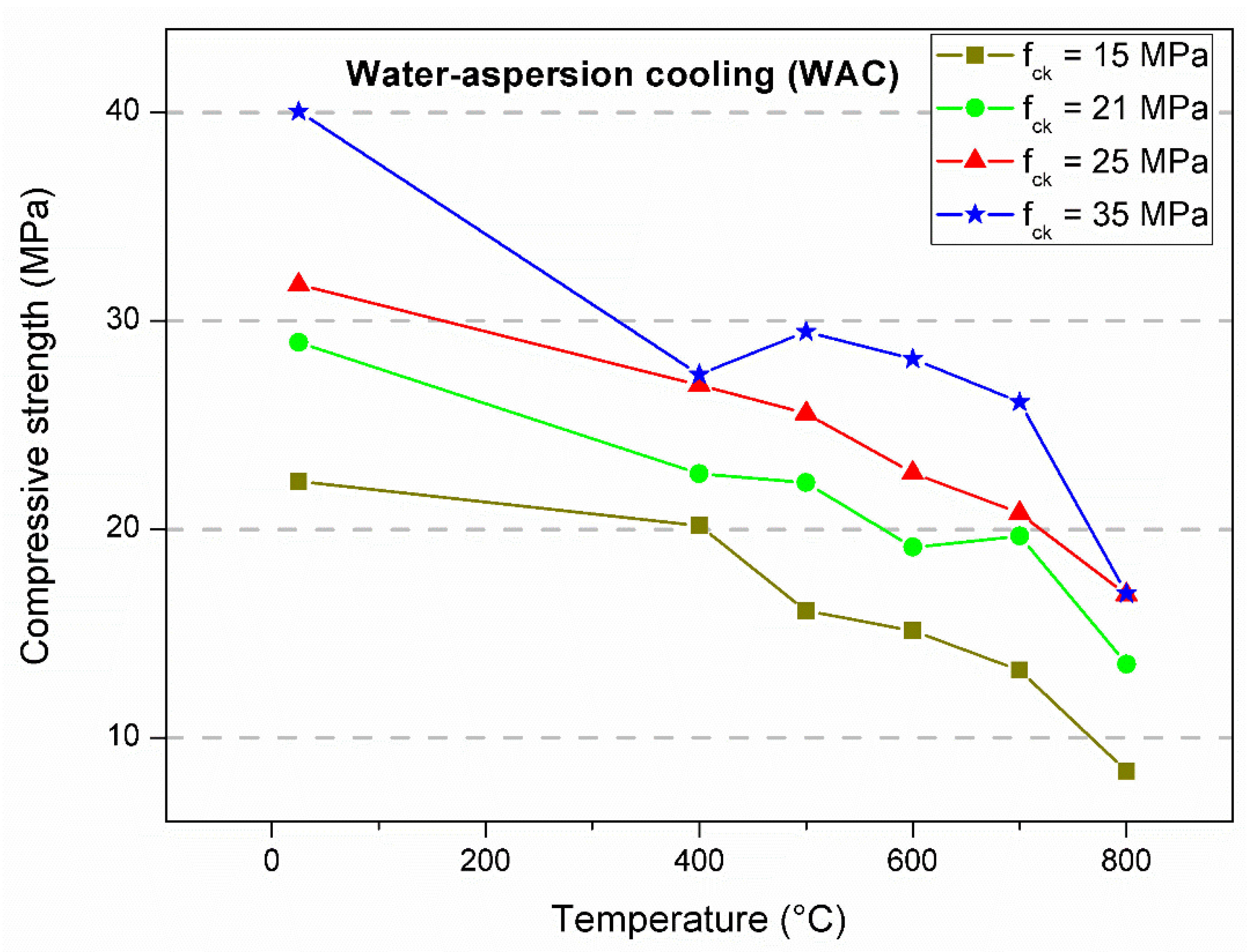

3.1. Mechanical Behavior

3.2. Statistical Analysis

3.3. Fire Degradation and Cooling Implications

4. Conclusions

- (1)

- The combined conditions (temperature, theoretical strength, and cooling method) had a significant influence on the residual strength. In general, the worst-case scenario was obtained considering high temperatures in the order of 800 °C, sudden cooling with water spray, and higher theoretical strengths. The best-case scenario was obtained with a 400 °C temperature, slow air cooling, and the lowest theoretical strengths;

- (2)

- Sudden cooling with water spraying was the most severe condition, resulting in the greatest decreases in strength. This result can be explained by the sudden dimensional variation of the particulate constituents and the cementitious matrix, which generates cracks and weakens the ITZ;

- (3)

- Concretes with a higher theoretical strength showed a lower residual strength. A higher strength implied a denser cementitious matrix, a lower porosity, and more consistent ITZ. However, the accommodation of stresses and strains was impaired, resulting in more extensive cracking and more severe degradation of the material;

- (4)

- The higher the temperature, the greater the losses of strength due to the degradation of concrete by physical and chemical phenomena. During heating, there was evaporation of free water, the release of chemically bound water, phase changes, and chemical changes;

- (5)

- Statistical analysis showed that the values obtained by the mechanical tests were significant and that the conditions evaluated (temperature, theoretical strength, and cooling method) significantly influenced the residual strength;

- (6)

- In future studies, it is suggested that changes in the structure of the concrete cement matrix are studied using a scanning electron microscope (SEM) to aggregate information about changes in the matrix as a function of heating and cooling processes.

Author Contributions

Funding

Conflicts of Interest

References

- Botte, W.; Caspeele, R. Post-cooling properties of concrete exposed to fire. Fire Saf. J. 2017, 92, 142–150. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Hager, I. Behaviour of cement concrete at high temperature. Bull. Pol. Acad. Sci. 2013, 61, 145–154. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Z.; Xie, Q.; Shen, L. Effect of strain rate on compressive behaviour of high-strength concrete after exposure to elevated temperatures. Fire Saf. J. 2016, 83, 25–37. [Google Scholar] [CrossRef]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 °C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Felicetti, R.; Gambarova, P.G. The effects of high temperature on the residual compressive strength of high-strength siliceous concretes. ACI Mater. J. 1998, 95, 395–406. [Google Scholar] [CrossRef]

- Malhotra, H.L. Design of Fire-Resisting Structures; Surrey University Press: Glasgow, UK, 1982. [Google Scholar]

- Hertz, K.D. Danish investigations on silica fume concrete at elevated temperatures. ACI Mater. J. 1992, 89, 345–347. [Google Scholar] [CrossRef]

- Riley, M.A. Possible new method for the assessment of fire—Damaged concrete. Mag. Concr. Res. 1991, 43, 87–92. [Google Scholar] [CrossRef]

- Saad, M.; Abo-El-Enein, S.A.; Hanna, G.B.; Kotkata, M.F. Effect of silica fume on the phase composition and microstructure of thermally treated concrete. Cem. Concr. Res. 1996, 26, 1479–1484. [Google Scholar] [CrossRef]

- Morsy, M.S.; Galal, A.F.; Abo-El-Enein, S.A. Effect of temperature on phase composition and microstructure of artificial pozzolana-cement pastes containing burnt kaolinite clay. Cem. Concr. Res. 1998, 28, 1157–1163. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education: London, UK, 1995. [Google Scholar]

- Scheinherrová, L.; Vejmelková, E.; Keppert, M.; Bezdička, P.; Doleželová, M.; Krejsová, J.; Grzeszczyk, S.; Matuszek-Chmurowska, A.; Černý, R. Effect of Cu-Zn coated steel fibers on high temperature resistance of reactive powder concrete. Cem. Concr. Res. 2019, 117, 45–57. [Google Scholar] [CrossRef]

- Eidan, J.; Rasoolan, I.; Rezaeian, A.; Poorveis, D. Residual mechanical properties of polypropylene fiber-reinforced concrete after heating. Constr. Build. Mater. 2019, 198, 195–206. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkova, A. Mechanical properties of concrete composites subject to elevated temperature. Fire Saf. J. 2018, 95, 66–76. [Google Scholar] [CrossRef]

- Abid, M.; Hou, X.; Zheng, W.; Hussian, R.R. Effect of Fibers on High-Temperature Mechanical Behavior and Microstructure of Reactive Powder Concrete. Materials 2019, 12, 329. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, A.; Kodur, V. Residual response of fire-damaged high-strength concrete beams. Fire Mater. 2019, 43, 310–322. [Google Scholar] [CrossRef]

- Missemer, L.; Ouedraogo, E.; Malecot, Y.; Clergue, C.; Rogat, D. Fire spalling of ultra-high performance concrete: From a global analysis to microstructure investigations. Cem. Concr. Res. 2019, 115, 207–219. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Zhao, X.Y. Residual mechanical properties of compound concrete containing demolished concrete lumps after exposure to high temperatures. Fire Saf. J. 2019, 105, 62–78. [Google Scholar] [CrossRef]

- Fernandes, B.; Gil, A.M.; Bolina, F.L.; Tutikian, B.F. Microstructure of concrete subjected to elevated temperatures: Physico-chemical changes and analysis techniques. Rev. IBRACON Estrut. Mater. 2017, 10, 838–863. [Google Scholar] [CrossRef]

- Rajawat, D.; Siddique, S.; Shrivastava, S.; Chaudhary, S.; Gupta, T. Influence of fine ceramic aggregates on the residual properties of concrete subjected to elevated temperature. Fire Mater. 2018, 42, 834–842. [Google Scholar] [CrossRef]

- Dauti, D.; Tengattini, A.; Dal Pont, S.; Toropovs, N.; Briffaut, M.; Weber, B. Analysis of moisture migration in concrete at high temperature through in-situ neutron tomography. Cem. Concr. Res. 2018, 111, 41–55. [Google Scholar] [CrossRef]

- Xotta, G.; Mazzucco, G.; Salomoni, V.A.; Majorana, C.E.; Willam, K.J. Composite behavior of concrete materials under high temperatures. Int. J. Solids Struct. 2015, 64, 86–99. [Google Scholar] [CrossRef]

- Sinaie, S.; Heidarpour, A.; Zhao, X.L. A micro-mechanical parametric study on the strength degradation of concrete due to temperature exposure using the discrete element method. Int. J. Solids Struct. 2016, 88, 165–177. [Google Scholar] [CrossRef]

- Hertz, K.D. Concrete strength for fire safety design. Mag. Concr. Res. 2005, 57, 445–453. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Gül, R. Effect of elevated temperatures and cooling regimes on normal strength concrete. Fire Mater. 2009, 33, 79–88. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Y.; Li, Y.; Wang, S.; Liu, Y.; Song, K.I. Impact of high-temperature-water cooling damage on the mechanical properties of concrete. Constr. Build. Mater. 2019, 215, 233–243. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Yuan, G.L.; Dong, Y.N. Influence of Cooling Methods and Standing Time on Different Aggregate Concrete Strengths after Elevated Temperature. Adv. Mater. Res. 2011, 250, 155–159. [Google Scholar] [CrossRef]

- Chan, S.Y.N.; Luo, X.; Sun, W. Effect of high temperature and cooling regimes on the compressive strength and pore properties of high performance concrete. Constr. Build. Mater. 2000, 14, 261–266. [Google Scholar] [CrossRef]

- Tanaçan, L.; Ersoy, H.Y.; Arpacıoğlu, Ü. Effect of high temperature and cooling conditions on aerated concrete properties. Constr. Build. Mater. 2009, 23, 1240–1248. [Google Scholar] [CrossRef]

- Lee, J.; Xi, Y.; Willam, K. Properties of Concrete after High-Temperature Heating and Cooling. Mater. J. 2008, 105, 334–341. [Google Scholar] [CrossRef]

- Karakoç, M.B. Effect of cooling regimes on compressive strength of concrete with lightweight aggregate exposed to high temperature. Constr. Build. Mater. 2013, 41, 21–25. [Google Scholar] [CrossRef]

- Kim, G.Y.; Choe, G.C.; Kang, Y.W.; Lee, T.G. Mechanical Properties of Concrete depending on Cooling Conditions After High Temperature Heating. J. Adv. Concr. Technol. 2014, 12, 82–90. [Google Scholar] [CrossRef][Green Version]

- Xiang, S.; Zeng, L.; Zhang, J.; Chen, J.; Liu, Y.; Cheng, G.; Mo, J. A DIC-Based Study on Compressive Responses of Concrete after Exposure to Elevated Temperatures. Materials 2019, 12, 2044. [Google Scholar] [CrossRef] [PubMed]

- ASTM. ASTM C150/C150M-19a: Standard specification for Portland cement. ASTM Int. 2019. [Google Scholar] [CrossRef]

- Reilly, V.A.O. Concrete Dosage Method; Editora Centro de Informacion de la Construcion: Havana, Cuba, 1998; p. 77. (In Spanish) [Google Scholar]

- Carvalho, E.F.T. Study of Residual Strength of Concrete Submitted to Fire; MSc Dissertation; Department of Civil Engineering: OuroPreto, Brazil, 2000; p. 96. (In Portuguese) [Google Scholar]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Turatsinze, A.; Bonnet, S.; Granju, J.L. Cement-based materials incorporating rubber aggregates: Shrinkage length changes. In Brittle Matrix Composites 7; Woodhead Publishing: Sawston, UK, 2003; pp. 359–368. [Google Scholar]

- Bentur, A. Cementitious materials—Nine millennia and a new century: Past, present, and future. J. Mater. Civ. Eng. 2002, 14, 2–22. [Google Scholar] [CrossRef]

- Bonen, D.; Tasdemir, M.A.; Sarkar, S. The evolution of cementitious materials through history. MRS Online Proc. Libr. Arch. 1994, 370. [Google Scholar] [CrossRef]

- Kovler, K.; Roussel, N. Properties of fresh and hardened concrete. Cem. Concr. Res. 2011, 41, 775–792. [Google Scholar] [CrossRef]

- Ollivier, J.P.; Maso, J.C.; Bourdette, B. Interfacial transition zone in concrete. Adv. Cem. Based Mater. 1995, 2, 30–38. [Google Scholar] [CrossRef]

- Diamond, S.; Huang, J. The ITZ in concrete—A different view based on image analysis and SEM observations. Cem. Concr. Compos. 2001, 23, 179–188. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Sun, Z.; Shah, S. Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Mater. J. 2012, 109, 451–461. [Google Scholar] [CrossRef]

- Jenq, Y.S.; Shah, S.P. Features of mechanics of quasi-brittle crack propagation in concrete. Int. J. Fract. 1991, 51, 103–120. [Google Scholar] [CrossRef]

- Wu, B.; Tang, K. Modelling on crack propagation behaviours at concrete matrix-aggregate interface. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1803–1814. [Google Scholar] [CrossRef]

- Georgali, B.; Tsakiridis, P.E. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. 2005, 27, 255–259. [Google Scholar] [CrossRef]

| Theoretical Strength 1 (fck) | Reference 20 °C | Cooled Naturally (NC) | ||||

|---|---|---|---|---|---|---|

| 400 °C | 500 °C | 600 °C | 700 °C | 800 °C | ||

| 15 | 22.29 1 [100] 2 | 23.02 [103] | 22.54 [101] | 21.04 [94] | 15.55 [70] | 10.55 [47] |

| (0.43) 3 | (2.54) | (2.25) | (3.35) | (1.52) | (1.66) | |

| 21 | 28.94 [100] | 25.91 [89] | 25.53 [88] | 22.98 [79] | 20.64 [71] | 17.54 [61] |

| (0.93) | (3.35) | (2.03) | (2.03) | (2.87) | (2.82) | |

| 25 | 31.71 [100] | 30.99 [98] | 27.97 [88] | 26.07 [82] | 25.35 [80] | 15.69 [50] |

| (1.28) | (2.91) | (1.18) | (2.32) | (3.25) | (1.75) | |

| 35 | 40.02 [100] | 35.59 [89] | 35.52 [89] | 34.40 [86] | 27.59 [69] | 19.29 [48] |

| (2.23) | (5.08) | (5.71) | (2.39) | (4.47) | (2.97) | |

| Theoretical Strength 1 (fck) | Reference 20 °C | Hot Test (HT) | ||||

|---|---|---|---|---|---|---|

| 400 °C | 500 °C | 600 °C | 700 °C | 800 °C | ||

| 15 | 22.29 1 [100] 2 | 19.42 [87] | 17.11 [77] | 16.35 [73] | 15.98 [72] | 13.46 [60] |

| (0.43) 3 | (2.55) | (1.49) | (1.96) | (2.17) | (1.55) | |

| 21 | 28.94 [100] | 23.54 [81] | 22.98 [79] | 19.61 [68] | 21.01 [73] | 19.48 [67] |

| (0.93) | (2.71) | (1.06) | (2.78) | (2.65) | (1.37) | |

| 25 | 31.71 [100] | 24.75 [78] | 25.75 [81] | 22.54 [71] | 19.79 [62] | 16.61 [52] |

| (1.28) | (3.52) | (0.63) | (2.16) | (0.97) | (2.49) | |

| 35 | 40.02 [100] | 30.09 [75] | 30.16 [75] | 28.59 [71] | 25.82 [65] | 21.63 [54] |

| (2.23) | (3.63) | (2.46) | (4.03) | (2.64) | (3.18) | |

| Theoretical Strength 1 (fck) | Reference 20 °C | Cooled after Water Aspersion (WAC) | ||||

|---|---|---|---|---|---|---|

| 400 °C | 500 °C | 600 °C | 700 °C | 800 °C | ||

| 15 | 22.29 1 [100] 2 | 20.17 [90] | 16.08 [72] | 15.14 [68] | 13.24 [59] | 8.41 [38] |

| (0.43) 3 | (1.74) | (2.35) | (1.24) | (1.66) | (1.07) | |

| 21 | 28.94 [100] | 22.67 [78] | 22.23 [77] | 19.14 [66] | 19.67 [68] | 13.52 [47] |

| (0.93) | (2.89) | (3.52) | (2.08) | (2.47) | (1.35) | |

| 25 | 31.71 [100] | 27.06 [85] | 25.54 [81] | 22.69 [72] | 20.76 [65] | 16.85 [53] |

| (1.28) | (3.28) | (2.30) | (2.85) | (1.66) | (0.94) | |

| 35 | 40.02 [100] | 27.41 [68] | 29.47 [74] | 28.15 [70] | 26.09 [65] | 16.92 [42] |

| (2.23) | (2.86) | (2.96) | (3.46) | (3.64) | (3.61) | |

| Effect | p-Value | Effect Size | Observed Power |

|---|---|---|---|

| Corrected Model | 0.000 | 0.880 | 1.000 |

| Intercept | 0.000 | 0.989 | 1.000 |

| Test method (M) | 0.000 | 0.285 | 1.000 |

| Temperature (T) | 0.000 | 0.689 | 1.000 |

| Strength (fck) | 0.000 | 0.760 | 1.000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, E.F.T.d.; Silva Neto, J.T.d.; Soares Junior, P.R.R.; Maciel, P.d.S.; Fransozo, H.L.; Bezerra, A.C.d.S.; Gouveia, A.M.C.d. Influence of Cooling Methods on the Residual Mechanical Behavior of Fire-Exposed Concrete: An Experimental Study. Materials 2019, 12, 3512. https://doi.org/10.3390/ma12213512

Carvalho EFTd, Silva Neto JTd, Soares Junior PRR, Maciel PdS, Fransozo HL, Bezerra ACdS, Gouveia AMCd. Influence of Cooling Methods on the Residual Mechanical Behavior of Fire-Exposed Concrete: An Experimental Study. Materials. 2019; 12(21):3512. https://doi.org/10.3390/ma12213512

Chicago/Turabian StyleCarvalho, Espedito Felipe Teixeira de, João Trajano da Silva Neto, Paulo Roberto Ribeiro Soares Junior, Priscila de Souza Maciel, Helder Luis Fransozo, Augusto Cesar da Silva Bezerra, and Antônio Maria Claret de Gouveia. 2019. "Influence of Cooling Methods on the Residual Mechanical Behavior of Fire-Exposed Concrete: An Experimental Study" Materials 12, no. 21: 3512. https://doi.org/10.3390/ma12213512

APA StyleCarvalho, E. F. T. d., Silva Neto, J. T. d., Soares Junior, P. R. R., Maciel, P. d. S., Fransozo, H. L., Bezerra, A. C. d. S., & Gouveia, A. M. C. d. (2019). Influence of Cooling Methods on the Residual Mechanical Behavior of Fire-Exposed Concrete: An Experimental Study. Materials, 12(21), 3512. https://doi.org/10.3390/ma12213512