A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete

Abstract

:1. Introduction

2. Materials and Equipment

- Correction of antenna sizes and positions;

- Background removal with automatic foreground/background detection to mask uniform structures such as the surface and possible stratifications;

- Automatic gaining to compensate the damping of the radar waves in the base material;

- Time-zero estimation (automatic recognition of the surface position);

- Temperature compensation to allow immediate and accurate measurements directly after start-up.

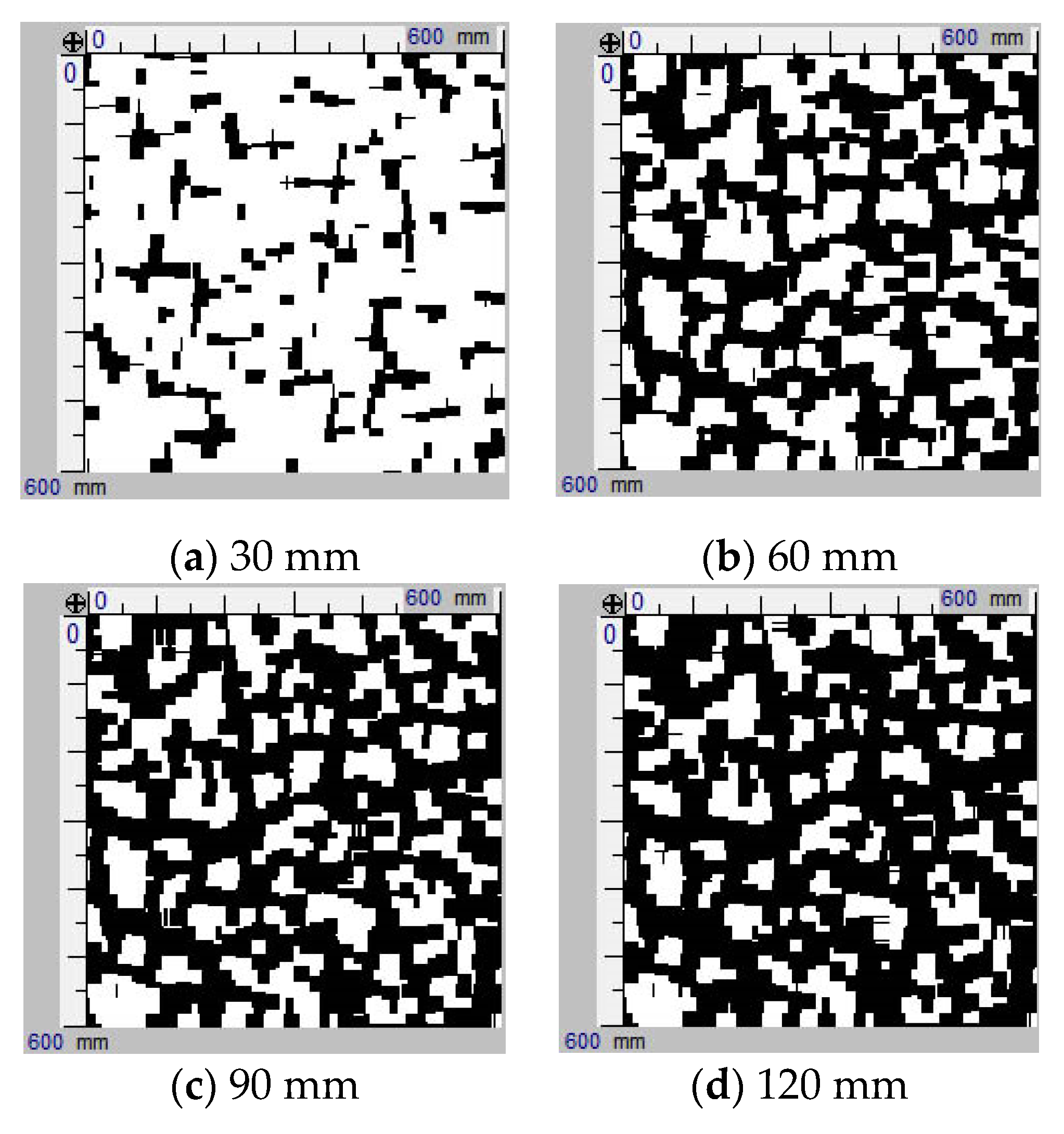

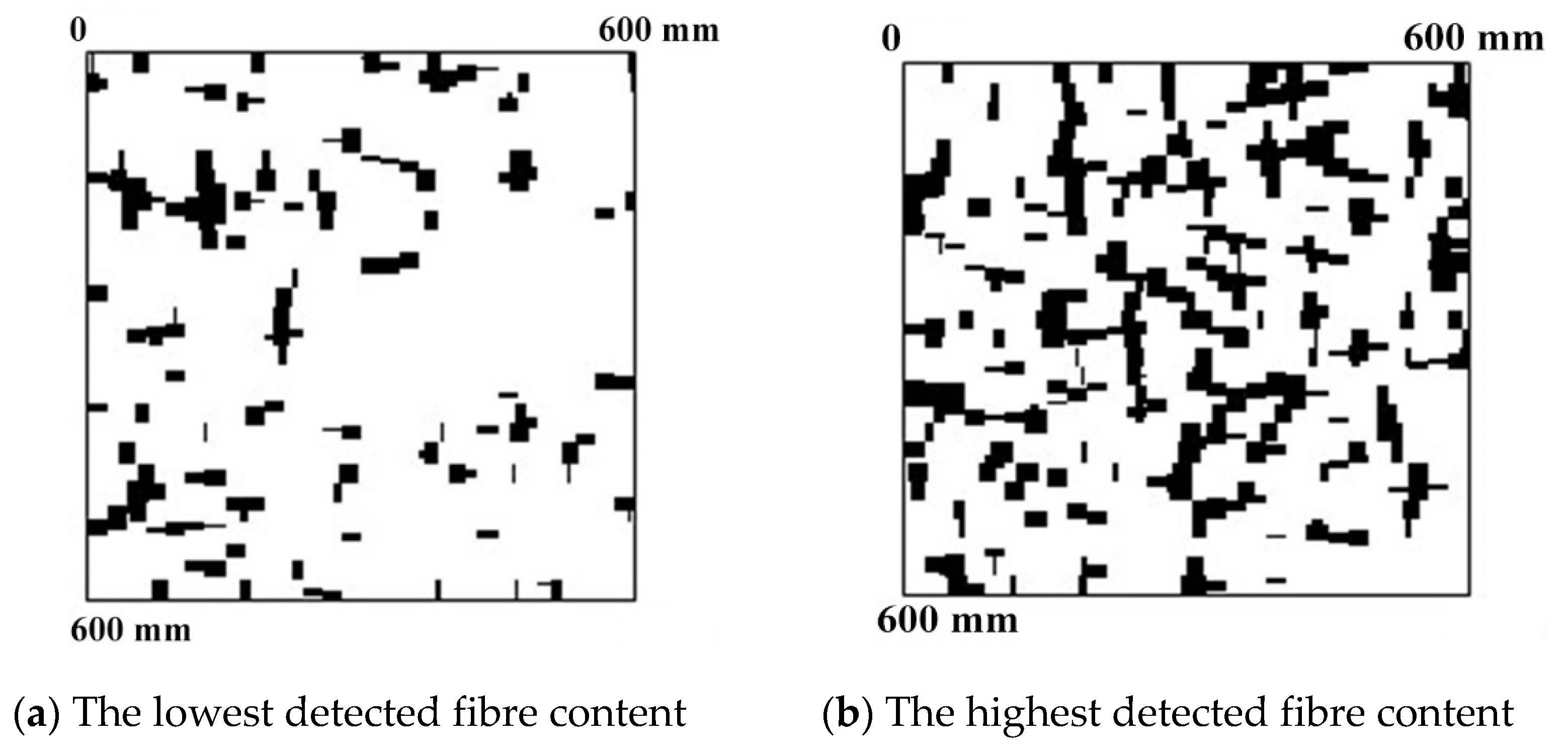

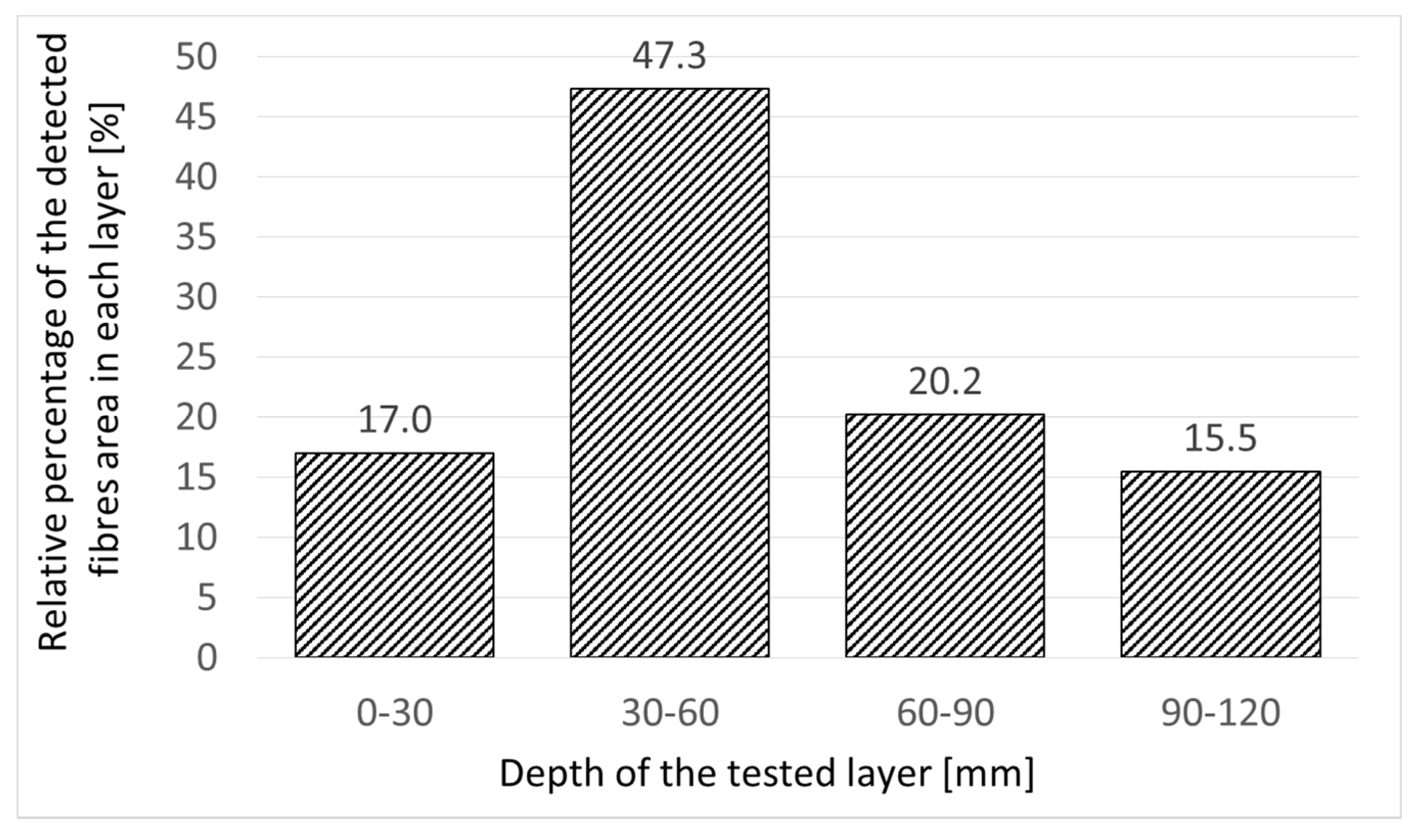

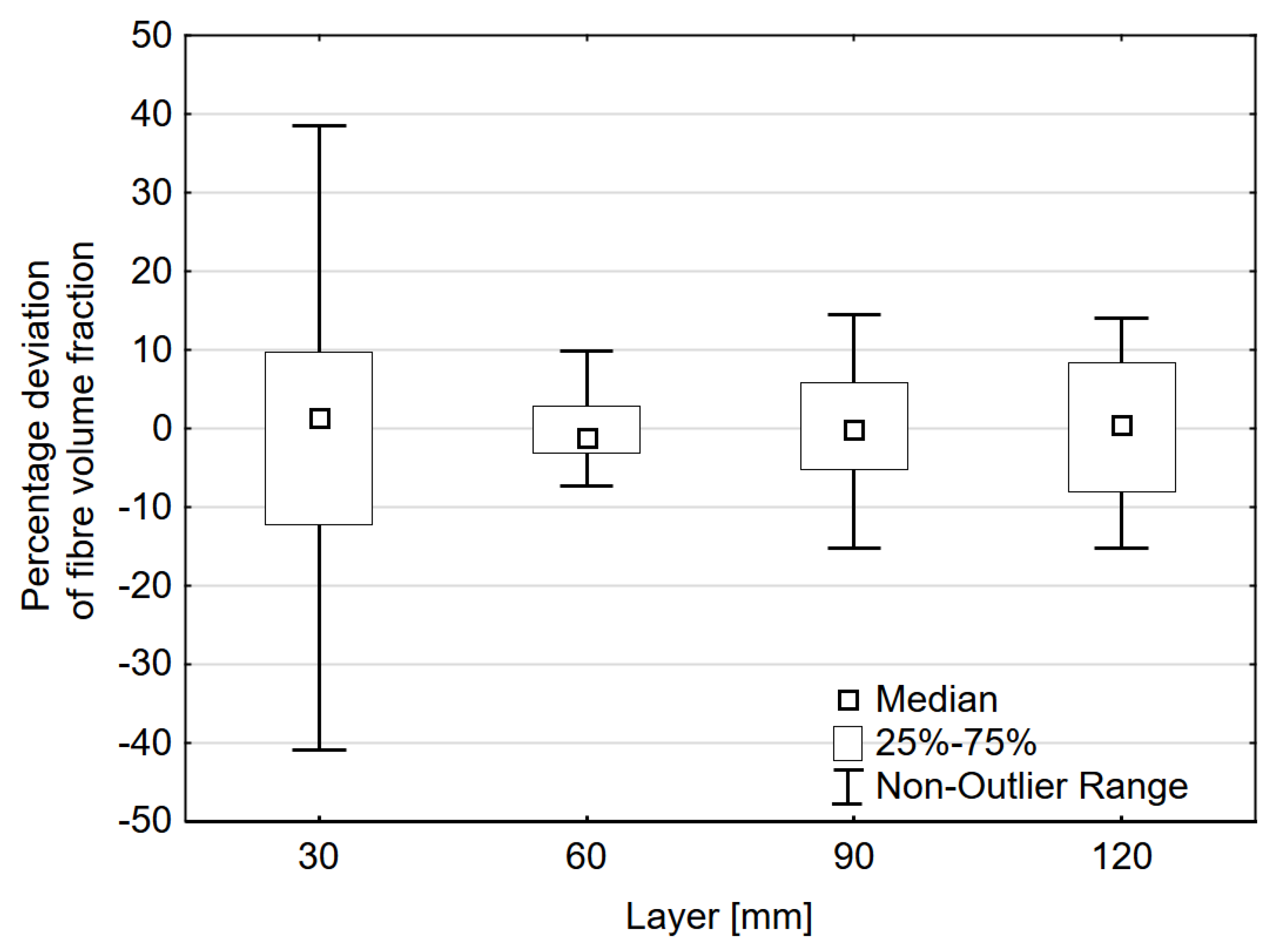

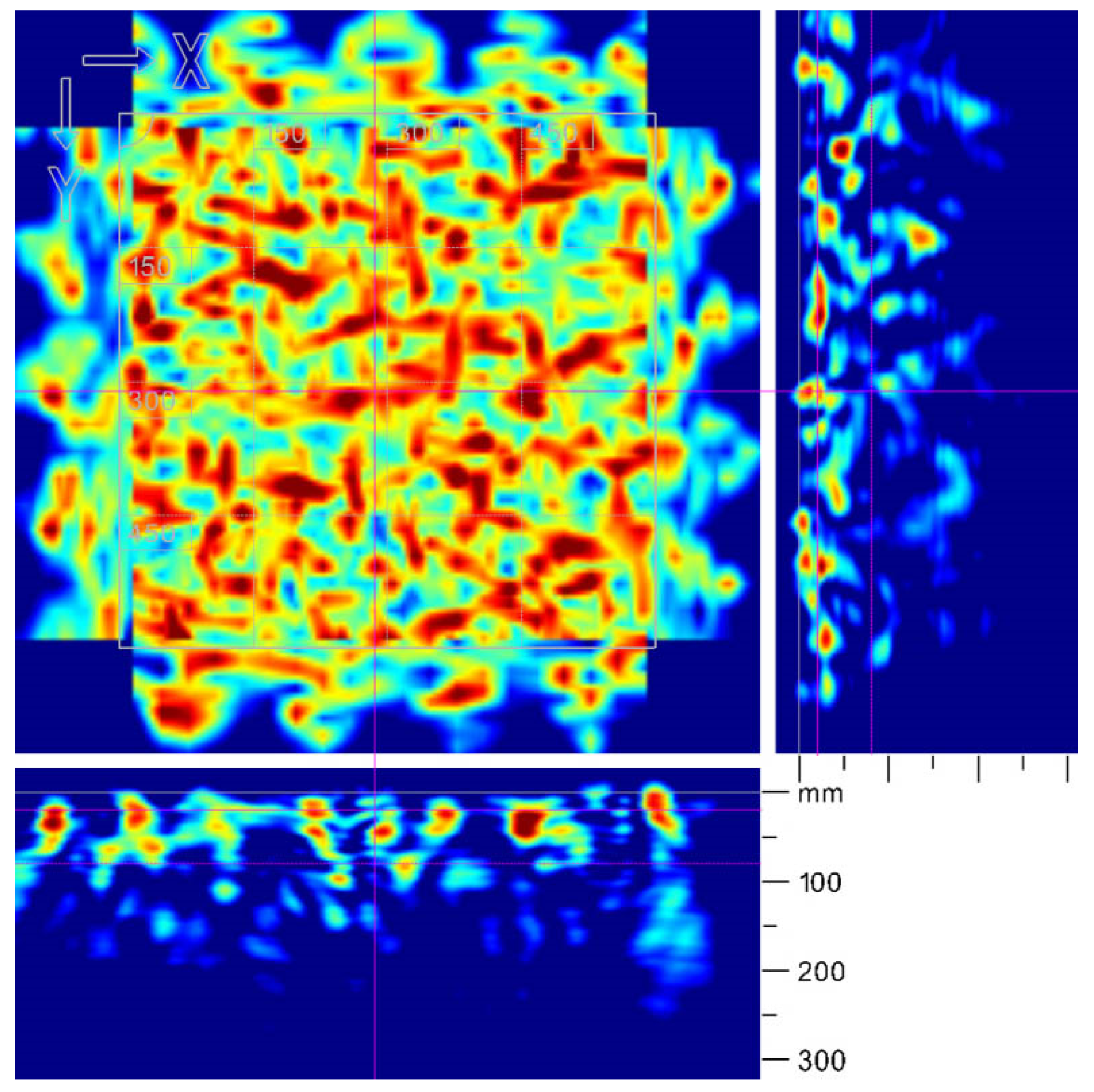

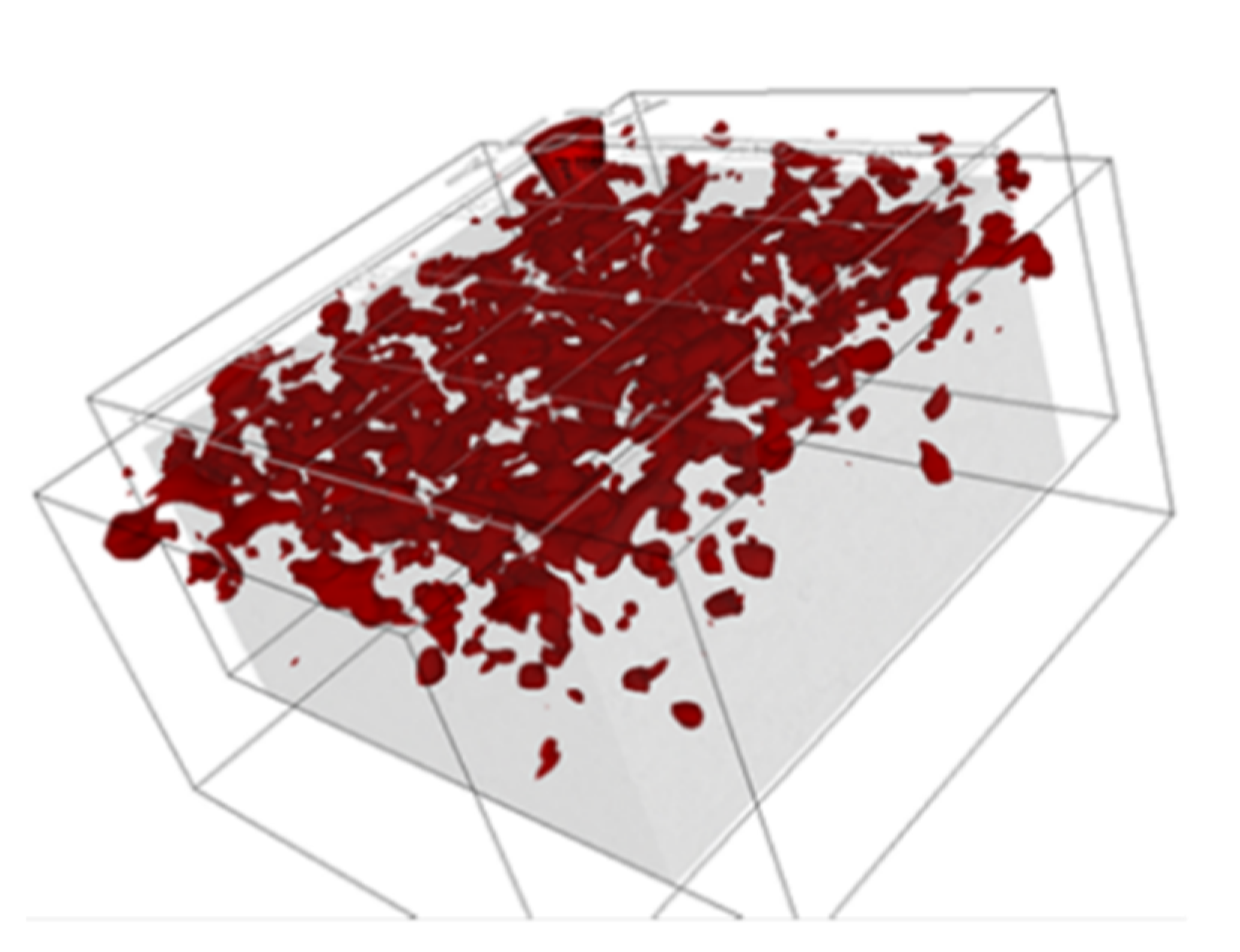

3. Test Results and Analysis

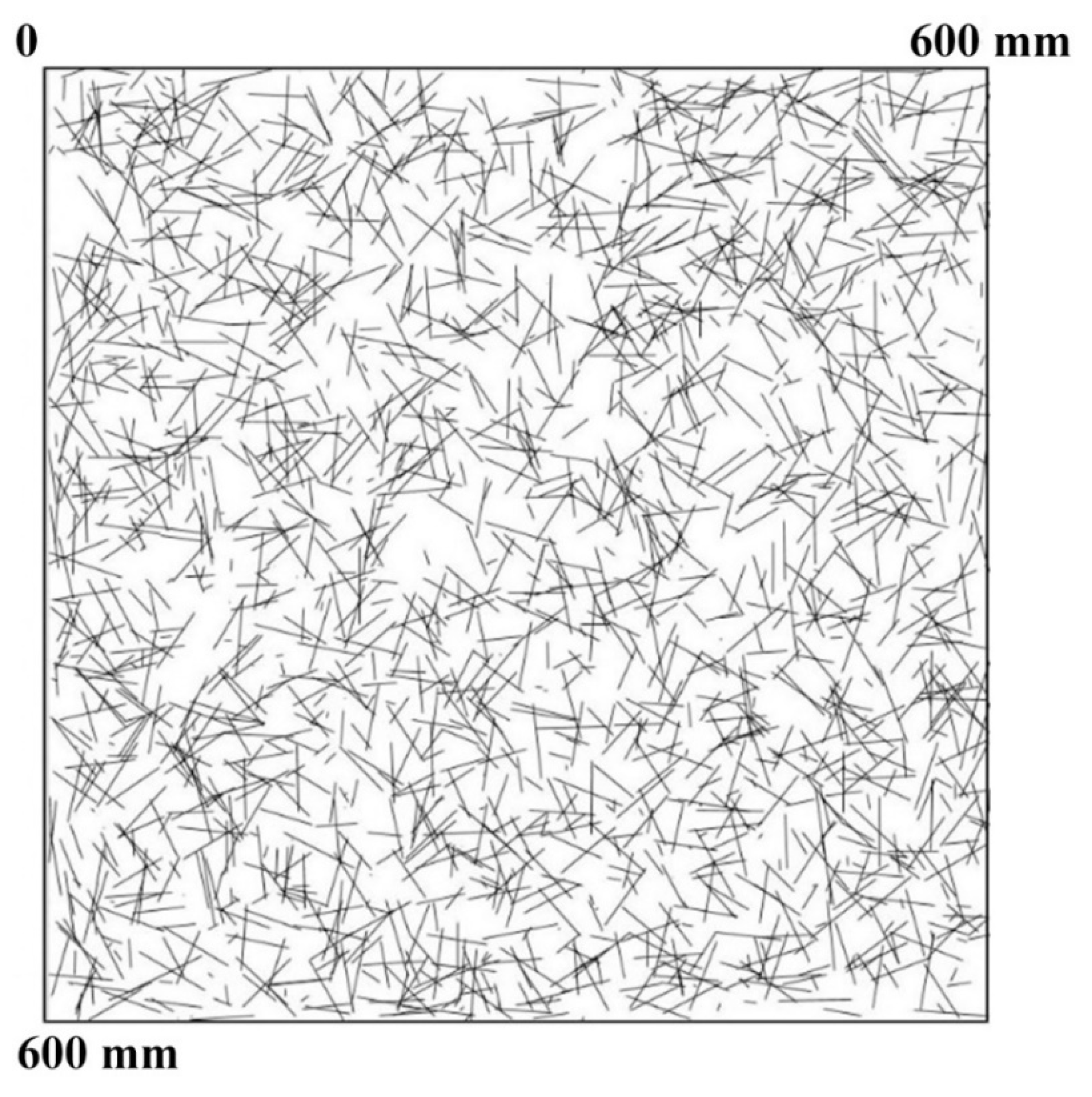

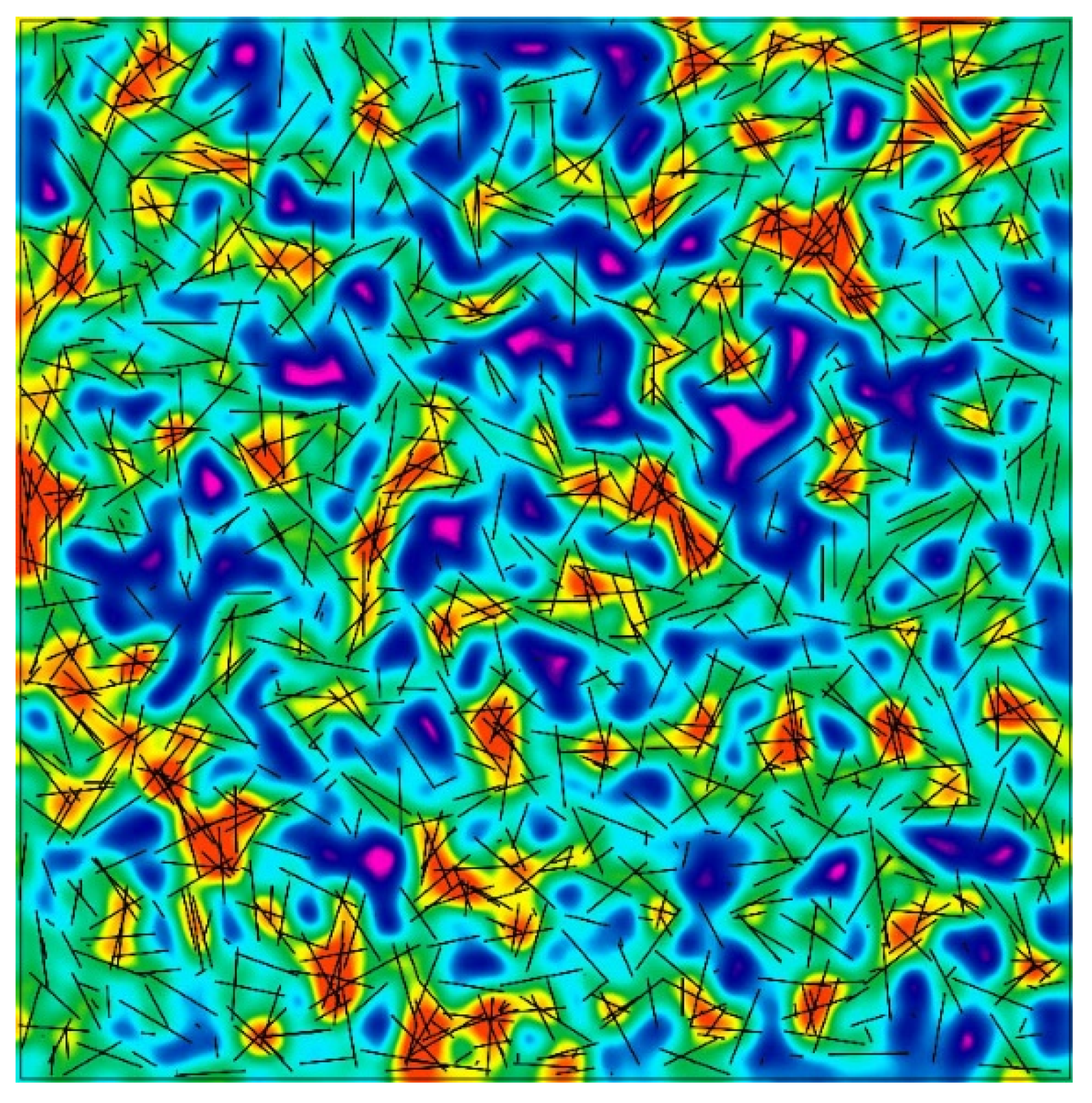

4. Fibre Spacing Determination and Discussion

- for positive integer numbers n:

- for other positive numbers z:

5. Conclusions

- The method based on the electromagnetic induction technique can be applied to estimate the approximate volume of steel fibre in a hardened SFRC element and the uniformity of fibre spacing. However, the method requires calibration to obtain good quality of results in deeper layers due to the “shadow” cast by the fibre present in the top layers. The method can be applied to detect steel fibre up to the 120 mm thickness of the tested element.

- The method based on the radar technique is suitable for instant detection of the areas with a clearly spaced fibre volume (too low or too high local fibre concentration). Theoretically, the method can be applied to detect steel fibre presence up to the 200 mm thickness of the tested element, yet only fibre present in upper layers is correctly detected. The testing equipment based on the radar technique used for fibre detection is able to recognize fibre concentration fields but not a single fibre.

- Both methods together can detect fibre concentration in SFRC volume but cannot detect a single fibre.

Author Contributions

Funding

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Cavalaro, S.H.P.; López, R.; Torrents, J.M.; Aguado, A. Improved assessment of fibre content and orientation with inductive method in SFRC. Mater. Struct. 2015, 48, 1859–1873. [Google Scholar] [CrossRef]

- Kovács, I.; Balázs, G.L. Structural Performance of Steel Fibre Reinforced Concrete; Publishing Company of Budapest University of Technology and Economics: Budapest, Hungary, 2004. [Google Scholar]

- Katzer, J.; Domski, J. Quality and mechanical properties of engineered steel fibres used as reinforcement for concrete. Constr. Build. Mater. 2012, 34. [Google Scholar] [CrossRef]

- Patil, S.P.; Sangle, K.K. Shear and flexural behaviour of prestressed and non-prestressed plain and SFRC concrete beams. J. King Saud Univ.-Eng. Sci. 2017. [Google Scholar] [CrossRef]

- Soetens, T.; Matthys, S.; Hertelé, S.; De Waele, W. Shear behaviour of prestressed precast SFRC girders. Eng. Struct. 2017, 142, 20–35. [Google Scholar] [CrossRef]

- Jang, S.-J.; Yun, H.-D. Combined effects of steel fiber and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Shi, Y.; Chi, Y.; Liu, Q.; Li, C. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Constr. Build. Mater. 2018, 181, 474–486. [Google Scholar] [CrossRef]

- Srinivasa Rao, K.; Rakesh Kumar, S.; Laxmi Narayana, A. Comparison of Performance of Standard Concrete and Fibre Reinforced Standard Concrete Exposed to Elevated Temperatures. Am. J. Eng. Res. 2013, 3, 20–26. [Google Scholar]

- Yousefieh, N.; Joshaghani, A.; Hajibandeh, E.; Shekarchi, M. Influence of fibers on drying shrinkage in restrained concrete. Constr. Build. Mater. 2017, 148, 833–845. [Google Scholar] [CrossRef]

- Ferrara, L.; Meda, A. Relationships between fibre distribution, workability and the mechanical properties of SFRC applied to precast roof elements. Mater. Struct. 2007. [Google Scholar] [CrossRef]

- Suuronen, J.P.; Kallonen, A.; Eik, M.; Puttonen, J.; Serimaa, R.; Herrmann, H. Analysis of short fibres orientation in steel fibre-reinforced concrete (SFRC) by X-ray tomography. J. Mater. Sci. 2013. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Katzer, J.; Bugdol, M.; Rudzki, M. X-ray computed tomography harnessed to determine 3D spacing of steel fibres in self compacting concrete (SCC) slabs. Constr. Build. Mater. 2015, 74. [Google Scholar] [CrossRef]

- Dupont, D.; Vandewalle, L. Distribution of steel fibres in rectangular sections. Cem. Concr. Compos. 2005. [Google Scholar] [CrossRef]

- Korl, S.; Wuersch, C.; Zanona, J. Innovative Sensor Technologies for Nondestructive Imaging of Concrete Structures: Novel Tools Utilising Radar and Induction Technologies. In Nondestructive Testing of Materials and Structures; Springer: Dordrecht, The Netherlands, 2013; pp. 131–136. [Google Scholar] [CrossRef]

- Agred, K.; Klysz, G.; Balayssac, J.P. Location of reinforcement and moisture assessment in reinforced concrete with a double receiver GPR antenna. Constr. Build. Mater. 2018. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. Combined non-destructive testing approach to waste fine aggregate cement composites. Sci. Eng. Compos. Mater. 2009, 16, 277–284. [Google Scholar] [CrossRef]

- Raj, B.; Jayakumar, T.; Rao, B.P.C. Non-destructive testing and evaluation for structural integrity. Sadhana 1995, 20, 5–38. [Google Scholar] [CrossRef]

- Operating Instruction PS200 (2016). Available online: https://www.hilti.com/medias/sys_master/documents/h99/9197518094366/Operating-Instruction-PS-200-01-EN-US-Operating-Instruction-PUB-5313205-000.pdf (accessed on 25 October 2019).

- Dérobert, X.; Aubagnac, C.; Abraham, O. Comparison of NDT techniques on a post-tensioned beam before its autopsy. NDT E Int. 2002, 35, 541–548. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kawano, H. Covermeter development in Japan and study on improving electromagnetic induction method. In Testing during Concrete Construction. Proceedings International RILEM Workshop; CRC Press: Boca Raton, FL, USA, 1991; pp. 396–403. [Google Scholar] [CrossRef]

- Operating Instruction PS1000 (2017). Available online: https://www.hilti.com/medias/sys_master/documents/h0c/9113409290270/PS_1000_EN-US_PUB_5070360_000.pdf (accessed on 25 October 2019).

- Gettu, R.; Gardner, D.R.; Saldivar, H.; Barragán, B.E. Study of the distribution and orientation of fibers in SFRC specimens. Mater. Struct. 2005. [Google Scholar] [CrossRef]

- Torrents, J.M.; Blanco, A.; Pujadas, P.; Aguado, A.; Juan-García, P.; Sánchez-Moragues, M.Á. Inductive method for assessing the amount and orientation of steel fibers in concrete. Mater. Struct. 2012. [Google Scholar] [CrossRef]

- Singh, H. Steel Fiber Reinforced Concrete Behavior, Modelling and Design—Chapter 2: Material Models, JSCE-VIFCEA Joint Seminar on Concrete Engineering; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kobaka, J.; Katzer, J.; Ponikiewski, T. A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete. Materials 2019, 12, 3507. https://doi.org/10.3390/ma12213507

Kobaka J, Katzer J, Ponikiewski T. A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete. Materials. 2019; 12(21):3507. https://doi.org/10.3390/ma12213507

Chicago/Turabian StyleKobaka, Janusz, Jacek Katzer, and Tomasz Ponikiewski. 2019. "A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete" Materials 12, no. 21: 3507. https://doi.org/10.3390/ma12213507

APA StyleKobaka, J., Katzer, J., & Ponikiewski, T. (2019). A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete. Materials, 12(21), 3507. https://doi.org/10.3390/ma12213507