Flame Spraying of Aluminum Coatings Reinforced with Particles of Carbonaceous Materials as an Alternative for Laser Cladding Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Aim of Study

- Preparation of material for spraying;

- Selection process parameters for each of the coating based on preliminary technological tests;

- Coating manufacturing;

- Examining the structure and tribological properties of aluminum coatings reinforced with carbon nanotubes and carburite;

- Comparison of obtained samples with coatings made of aluminum powder without the addition of carbonaceous materials.

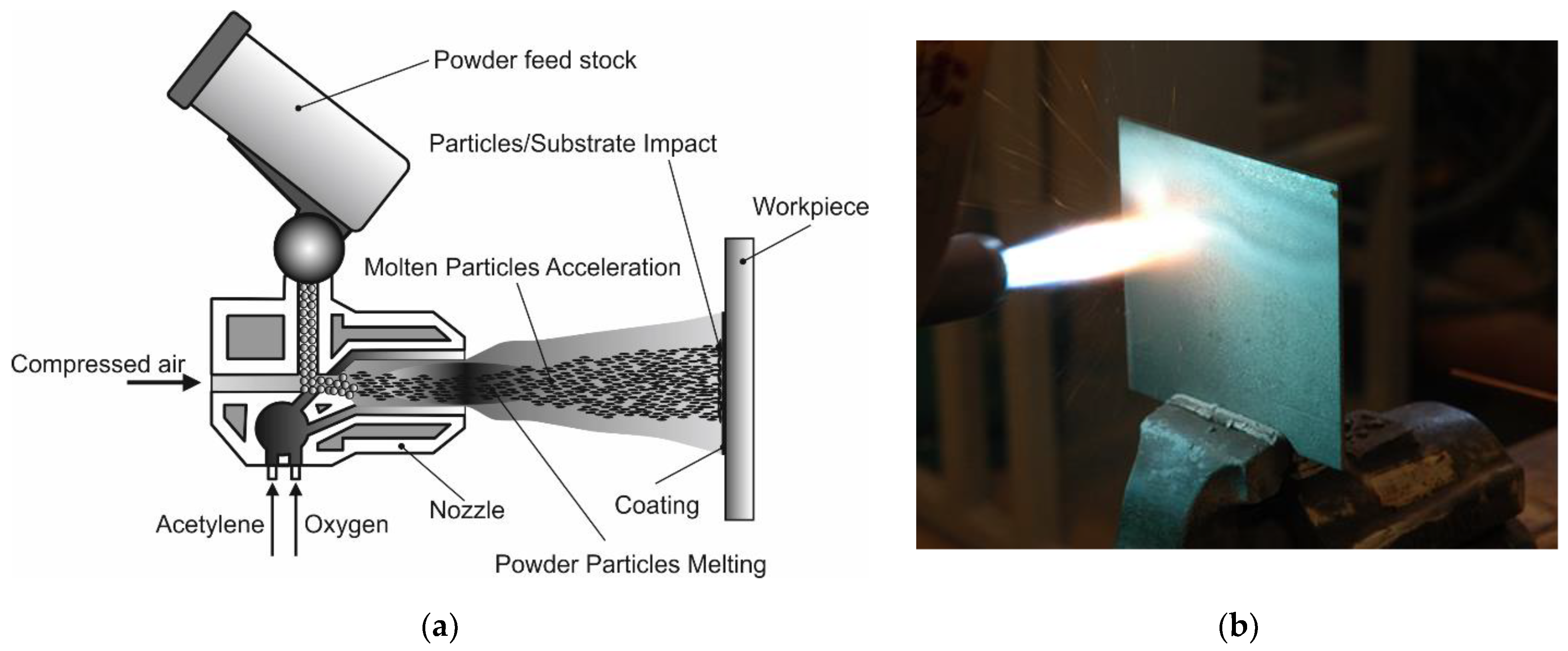

2.2. Materials, Devices and Spraying Parameters

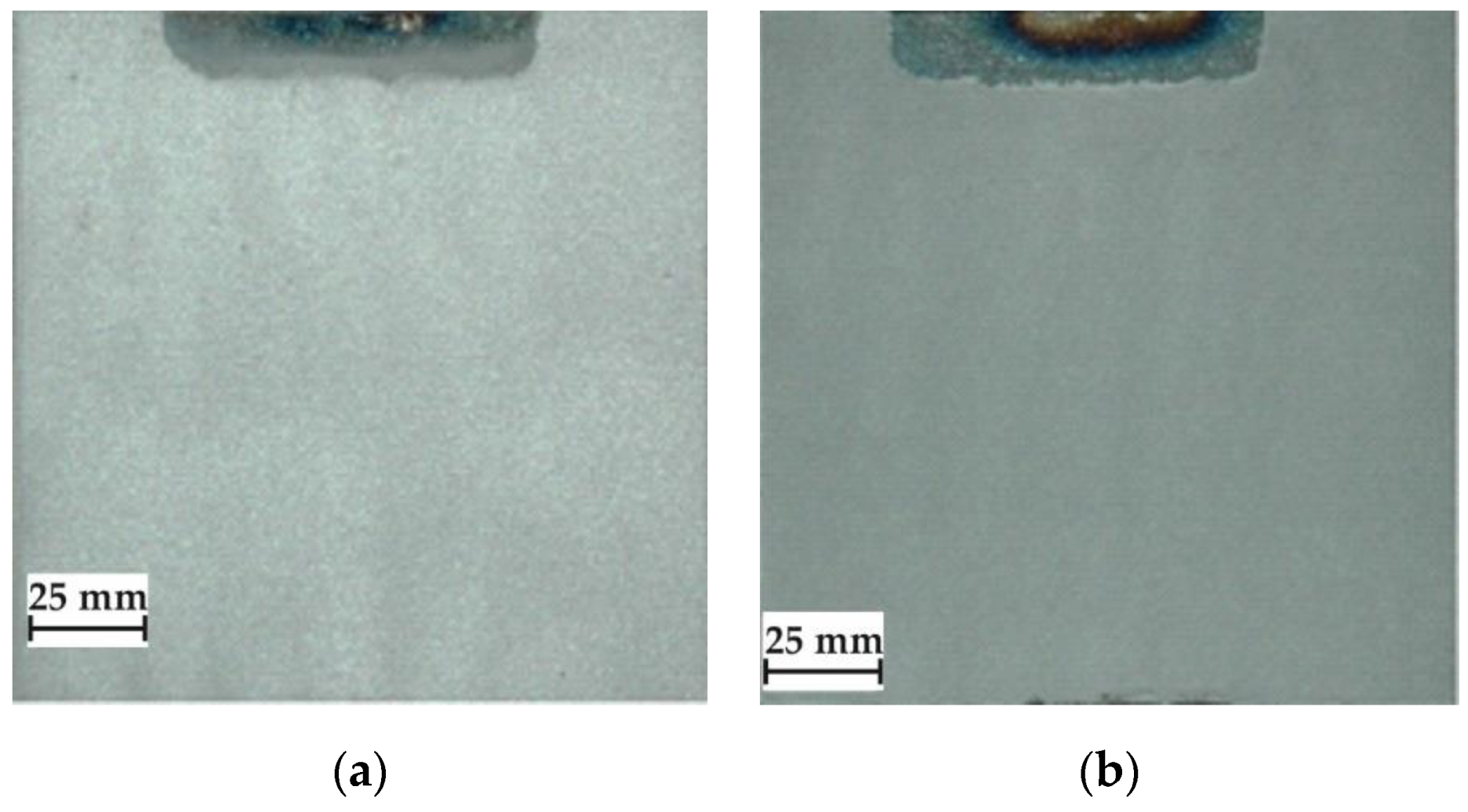

2.3. Visual and Metallographic Examination of Coatings

2.4. Hardness Measurements of Coatings

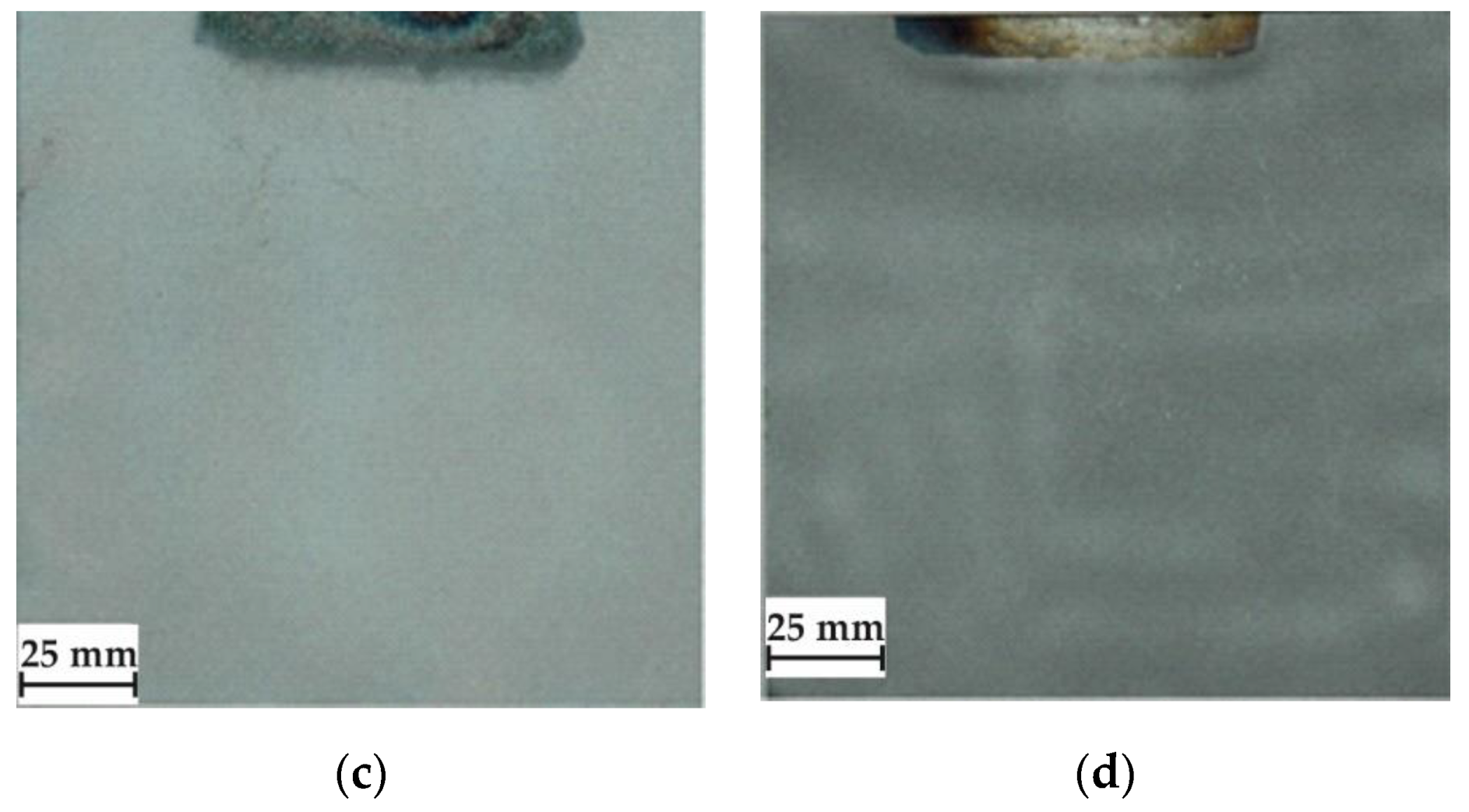

2.5. Erosive Wear Resistance of Coatings

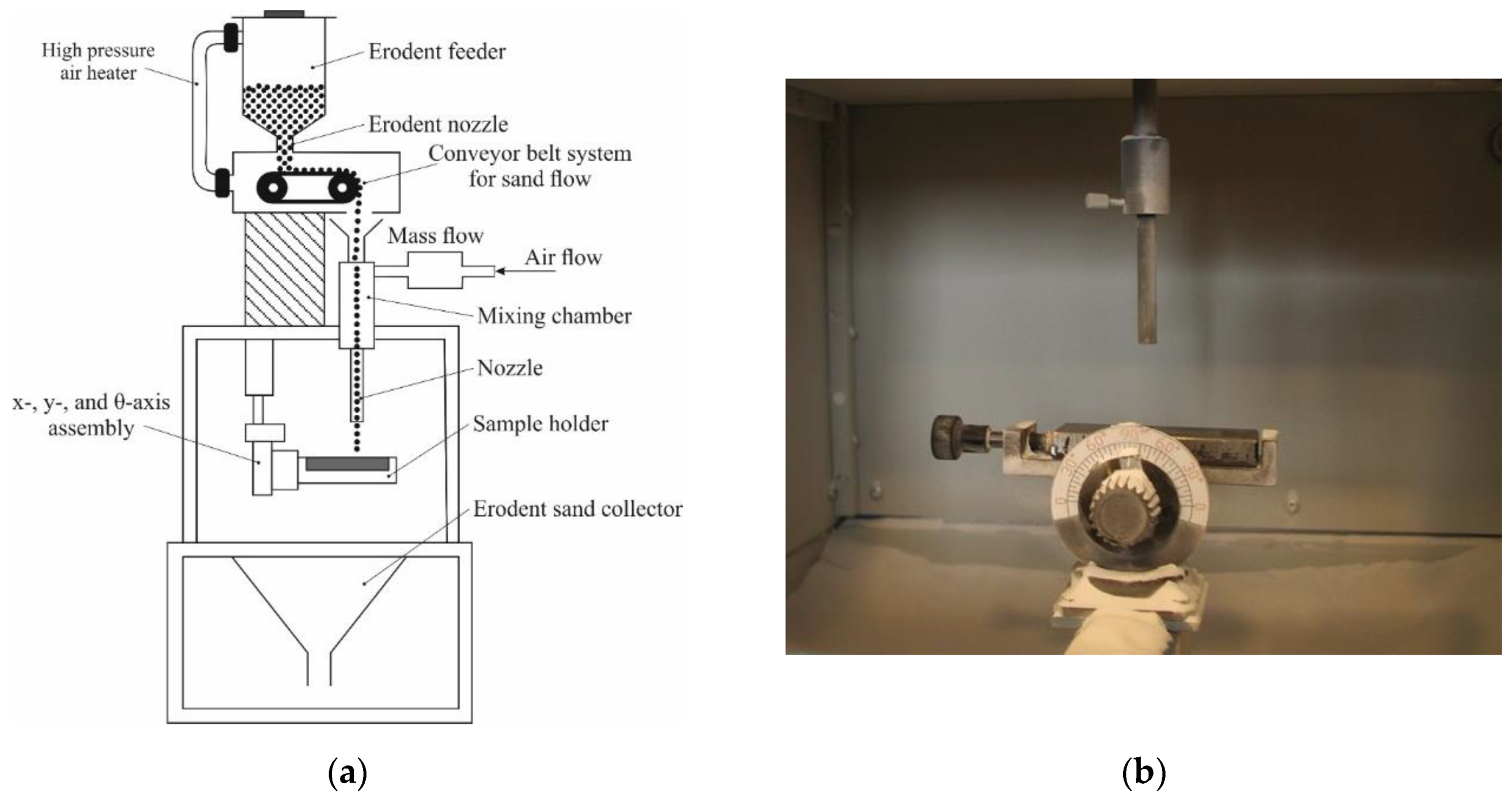

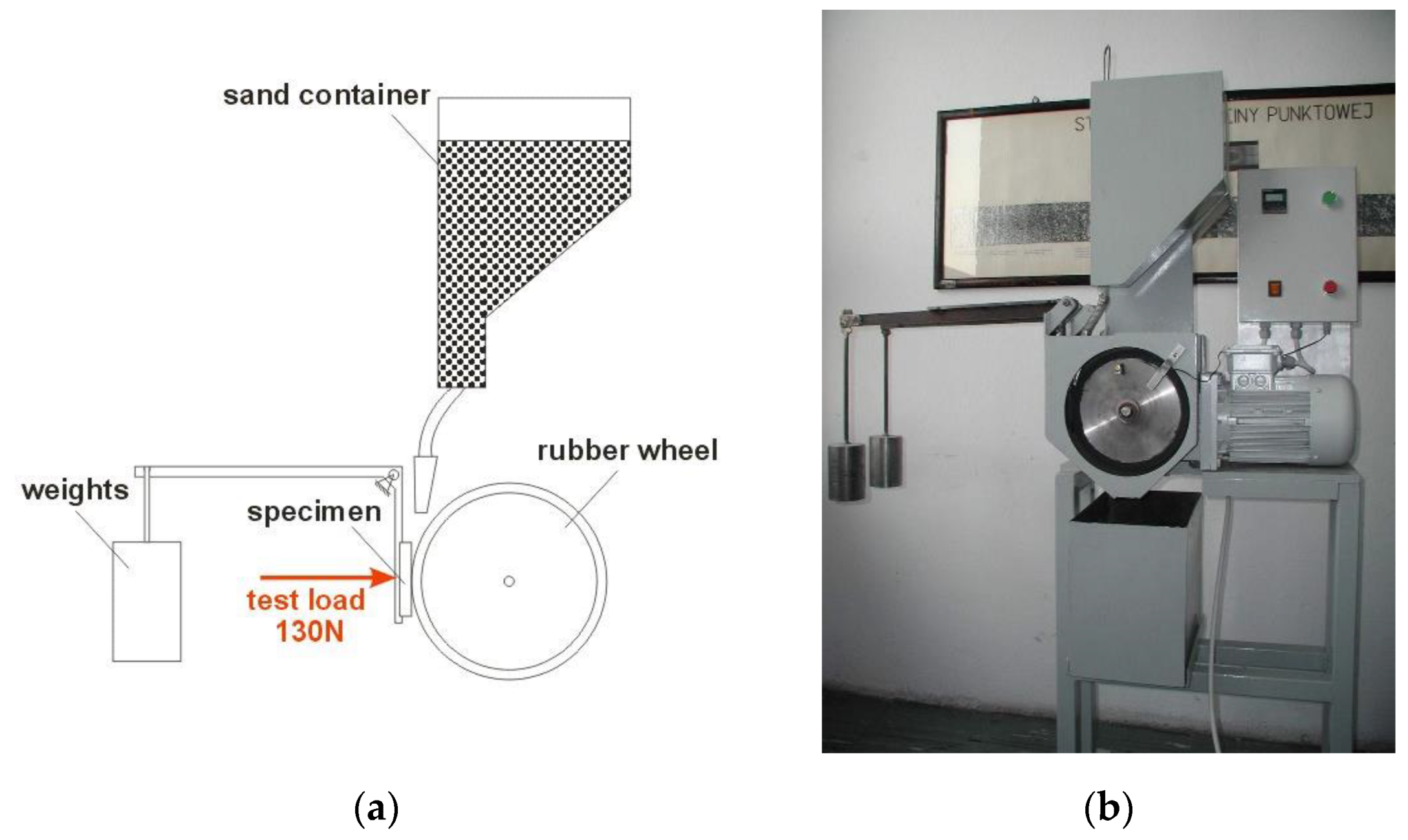

2.6. Abrasive Wear Resistance of Coatings

3. Results

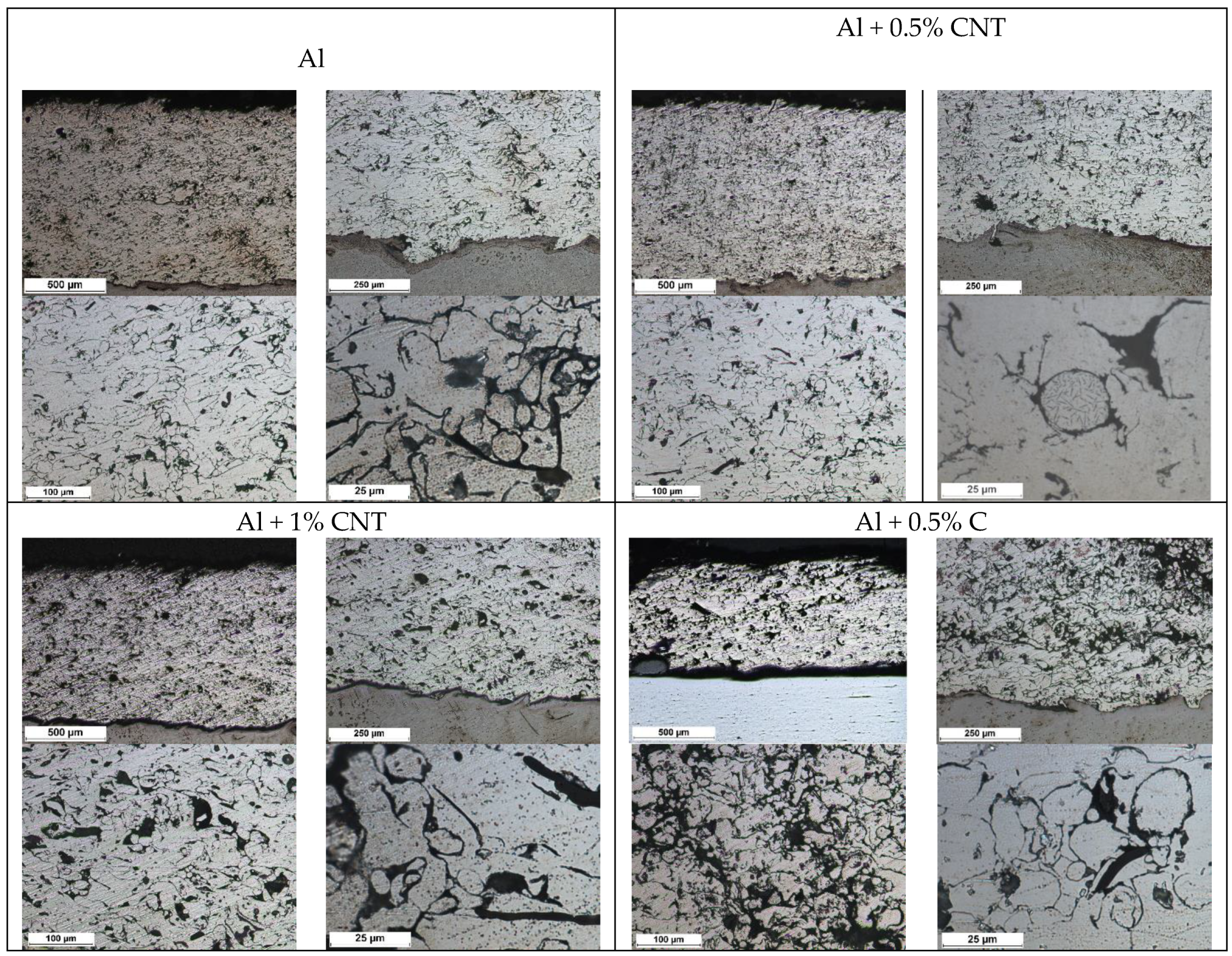

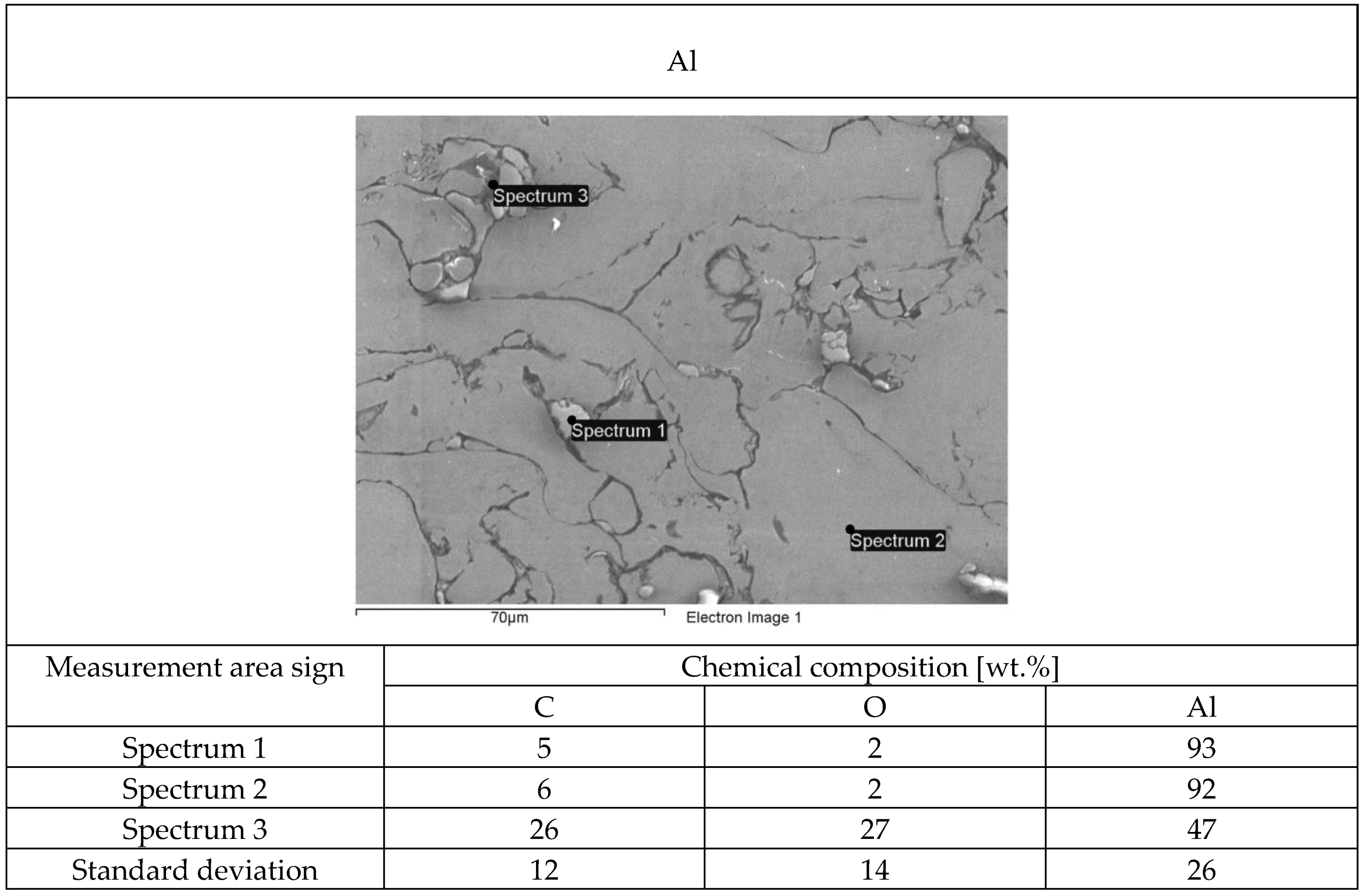

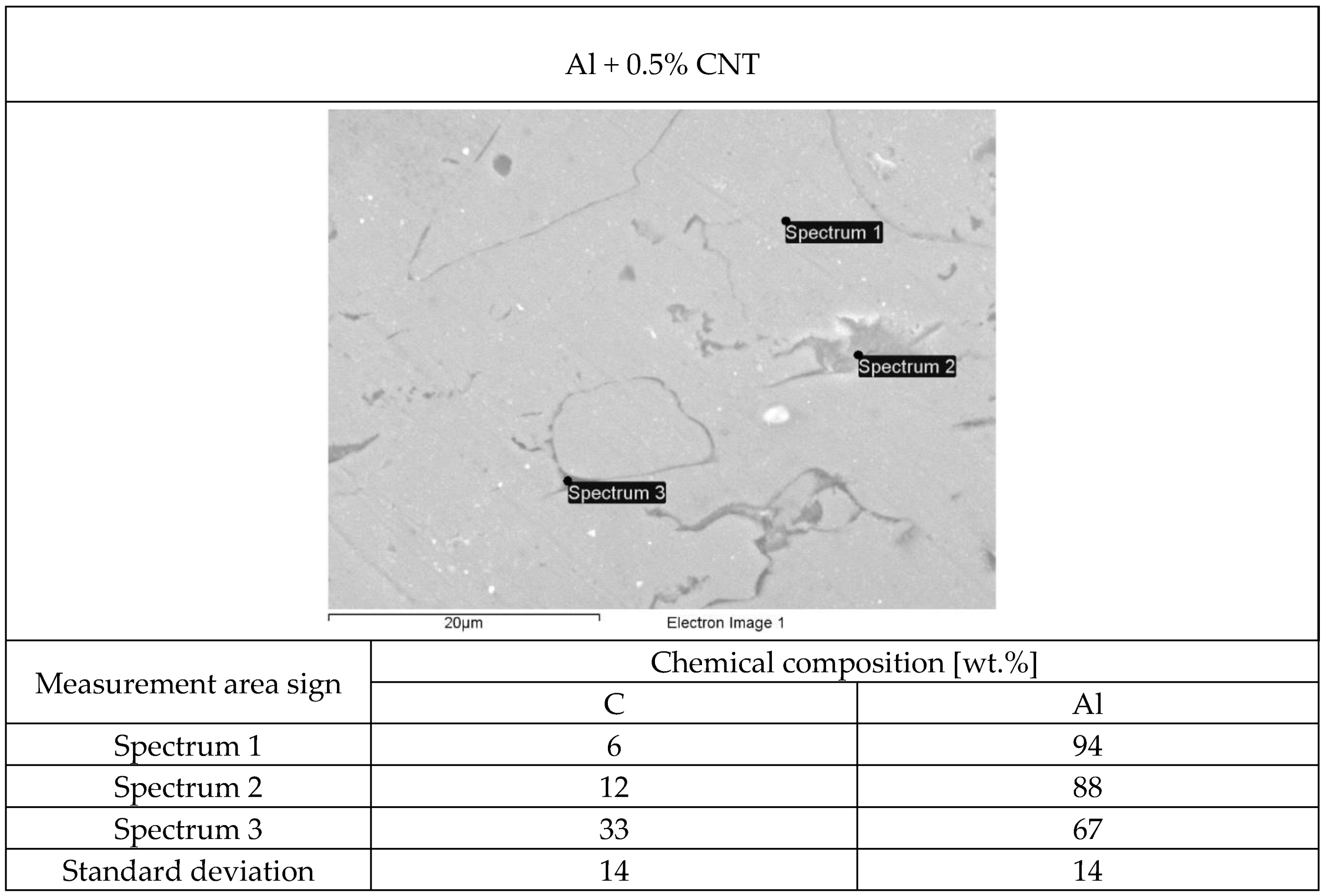

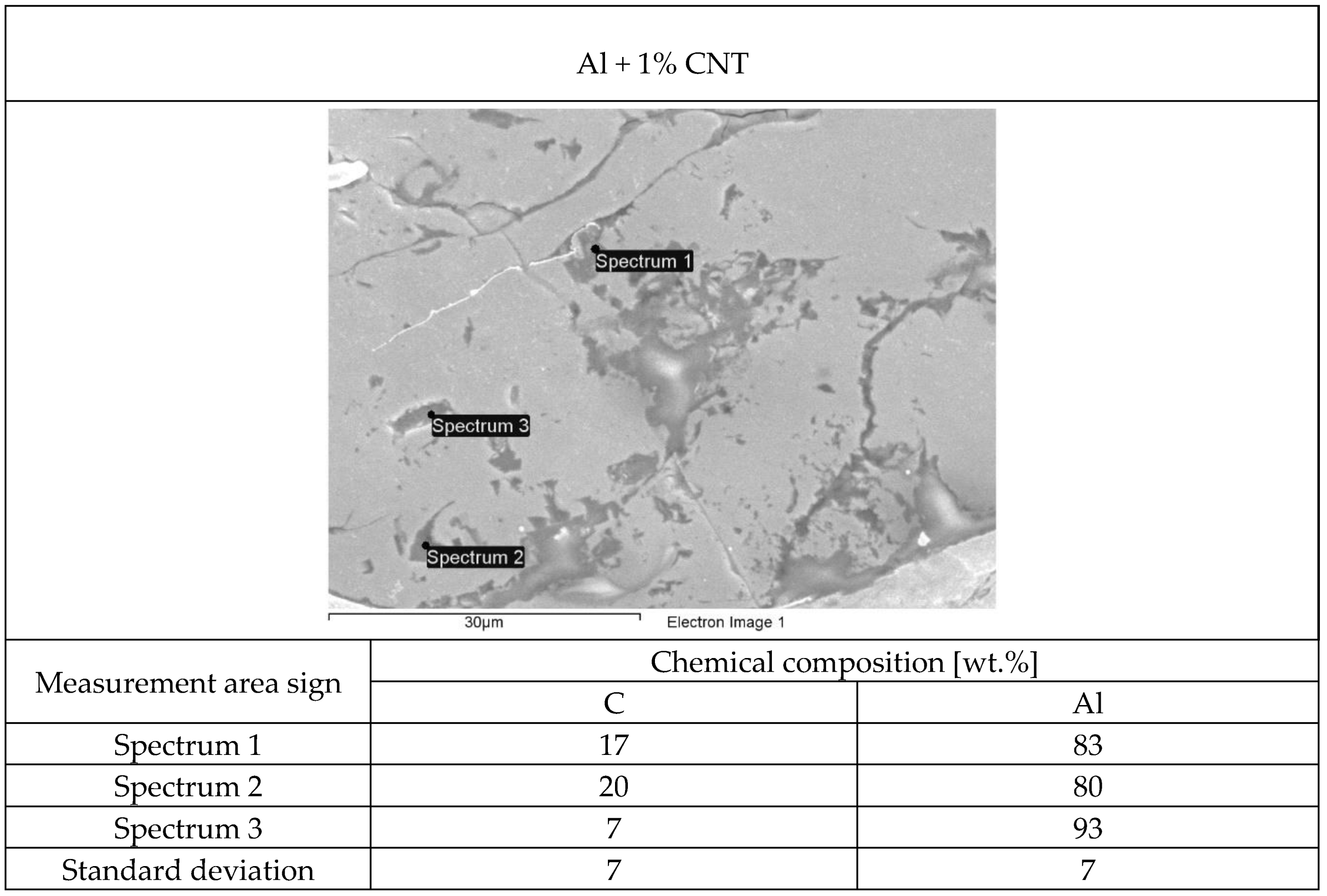

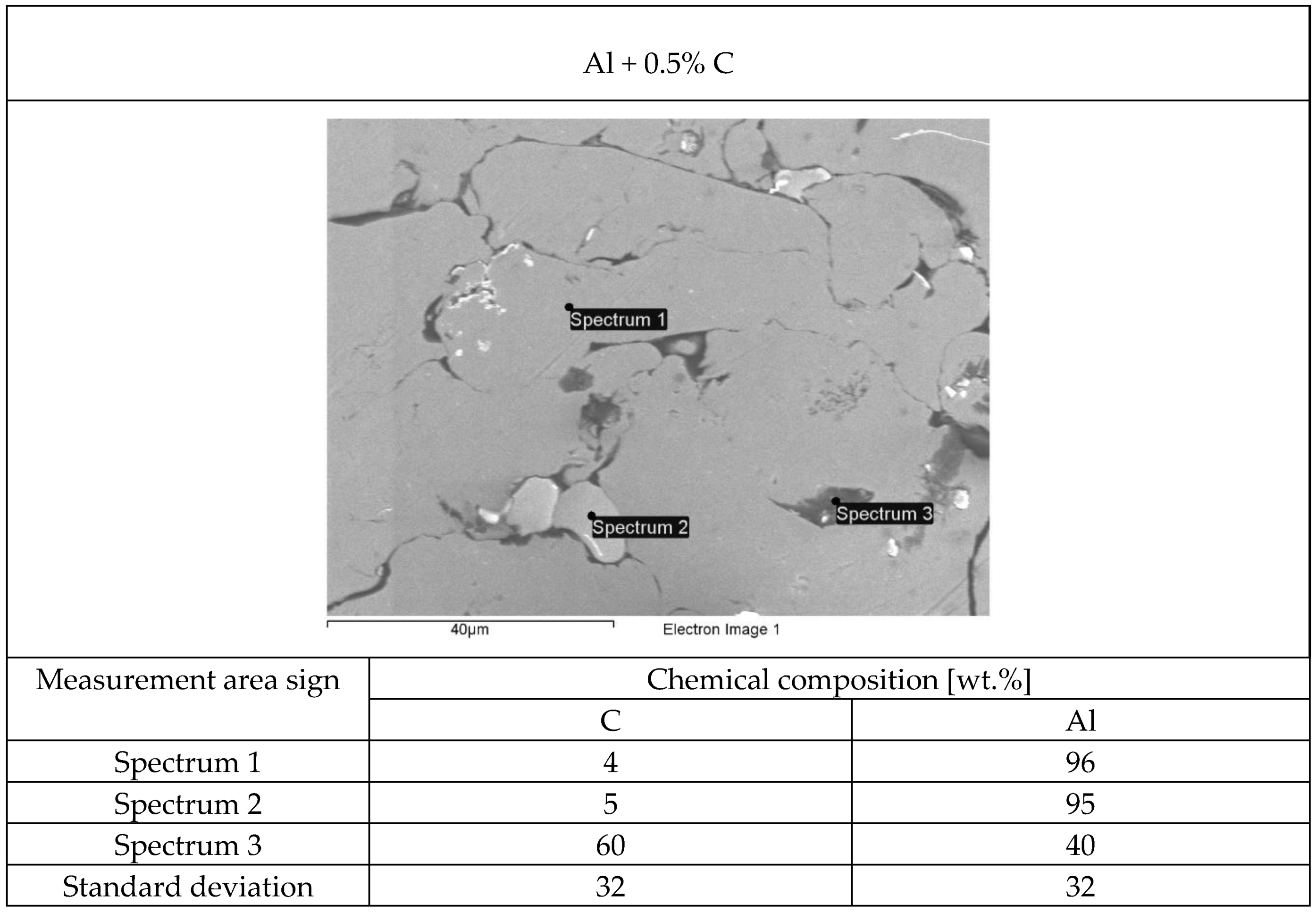

3.1. Metallographic Test Results

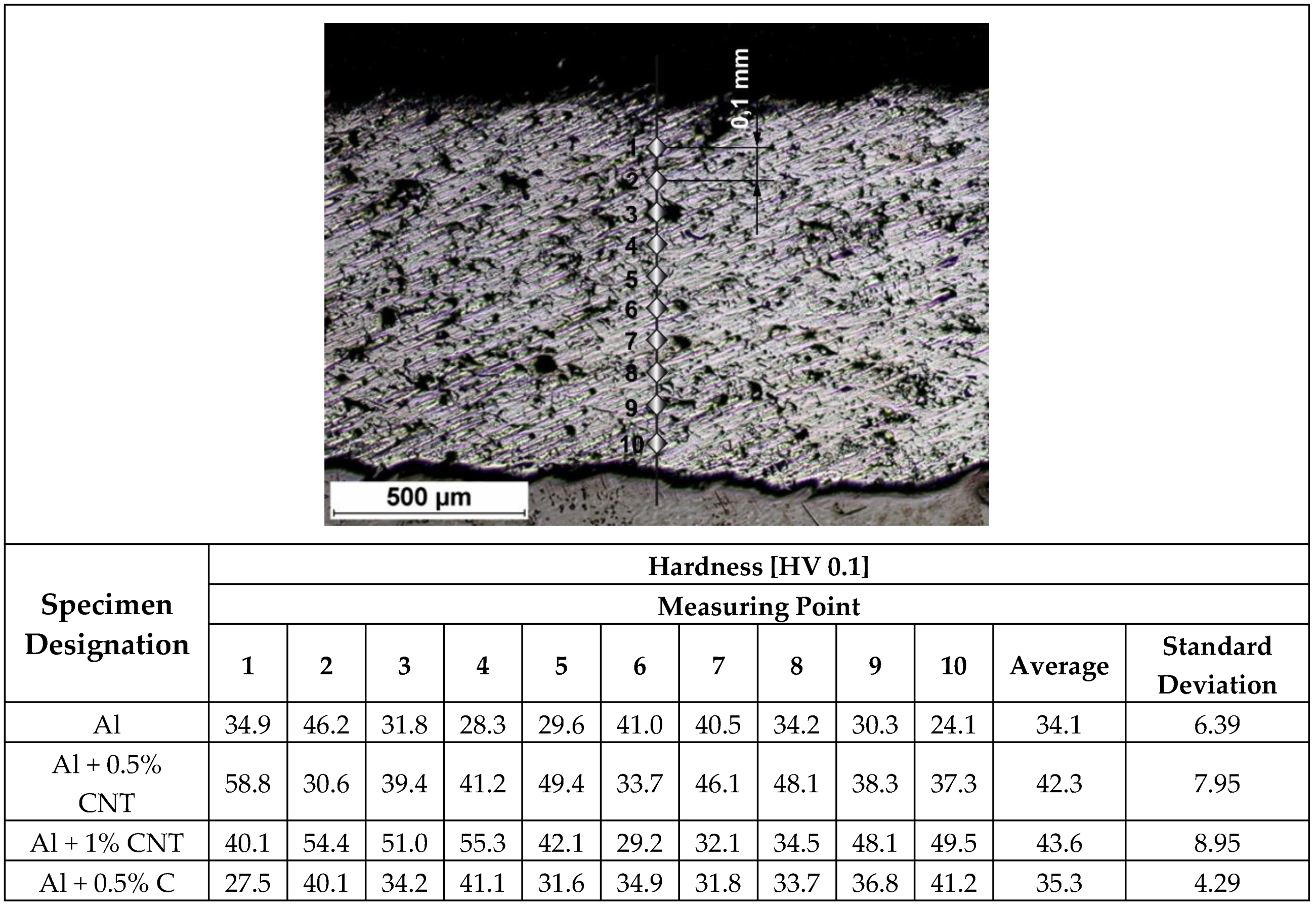

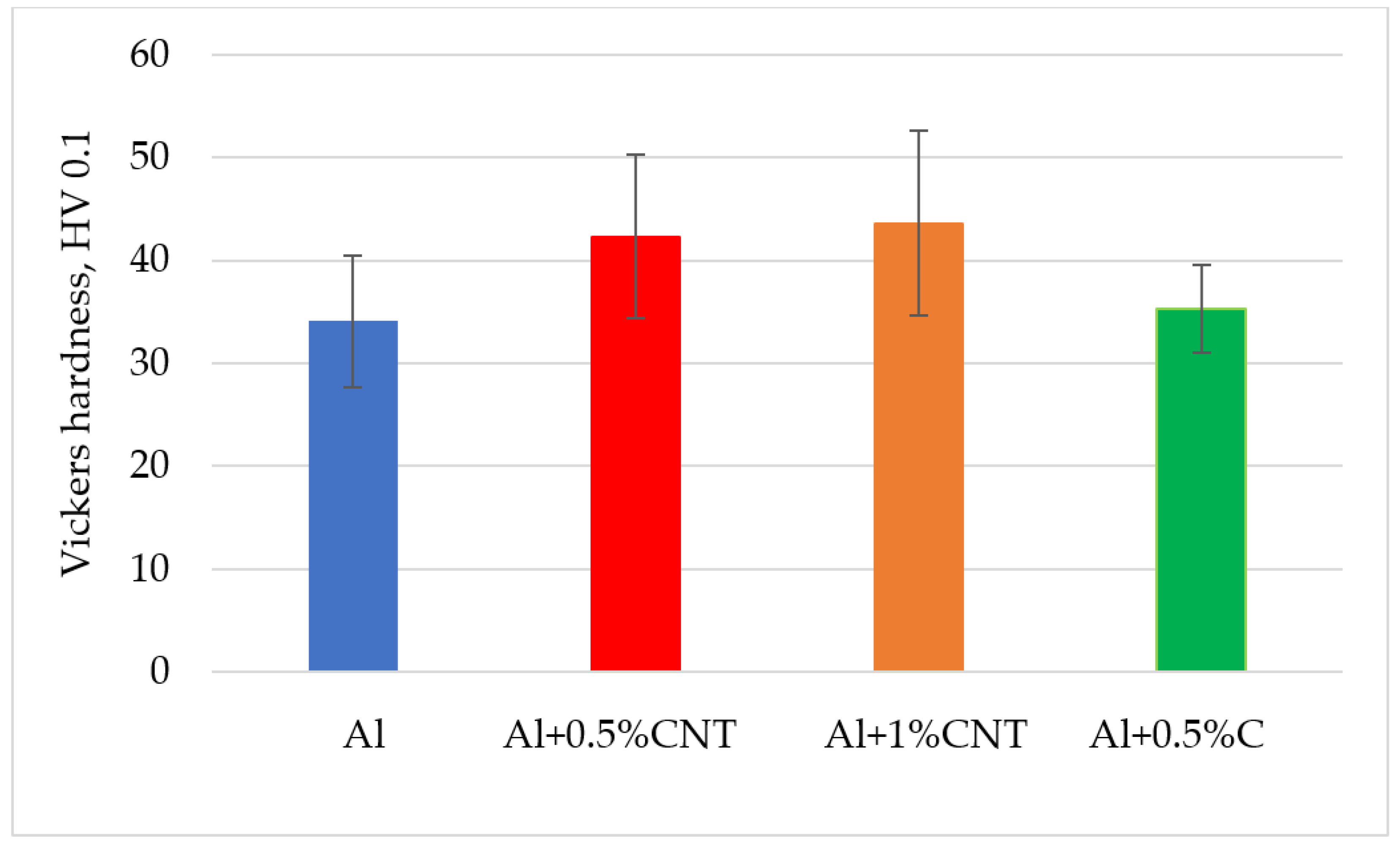

3.2. Hardness Measurements

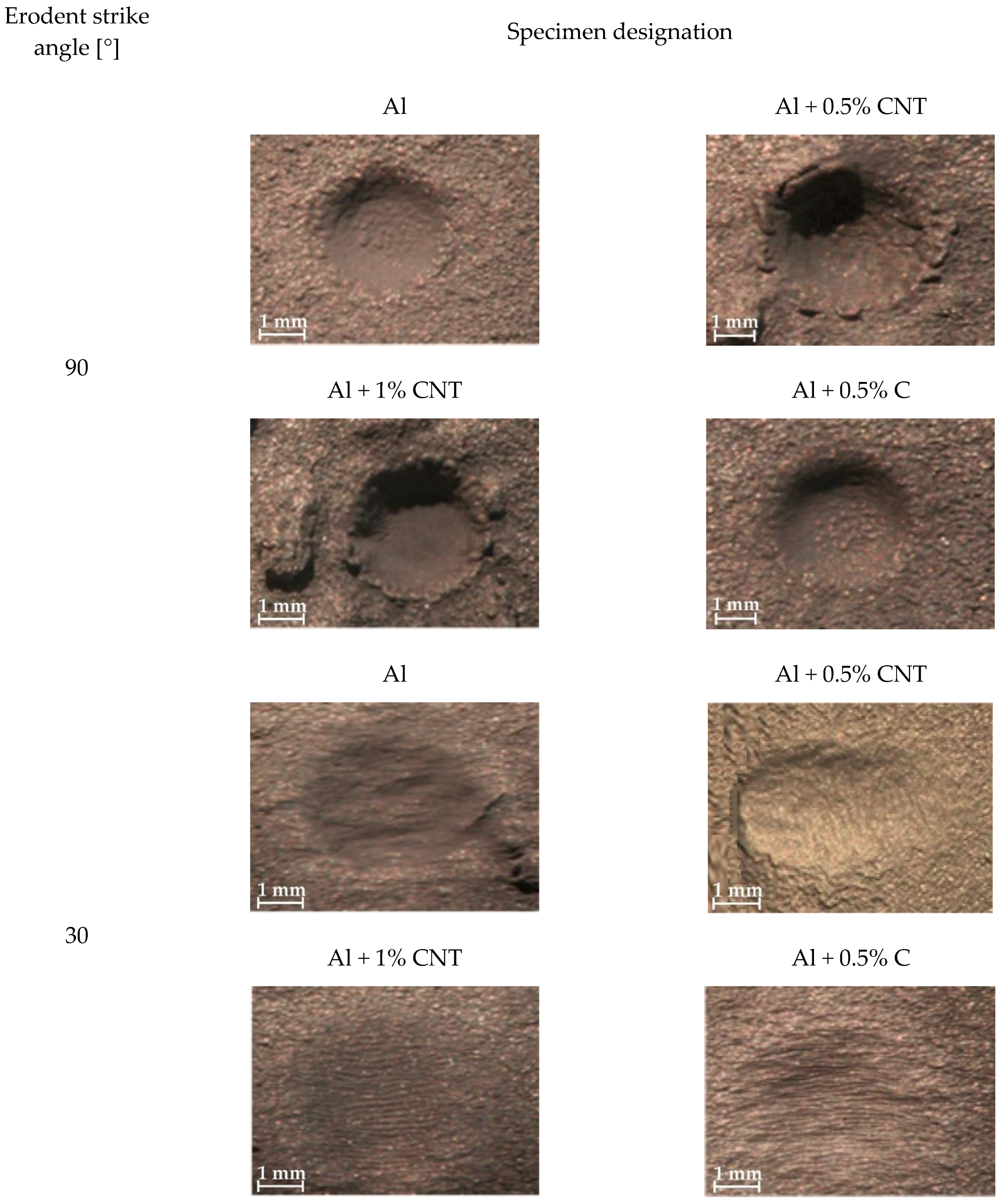

3.3. Tests Results of the Coatings Erosive Wear Resistance

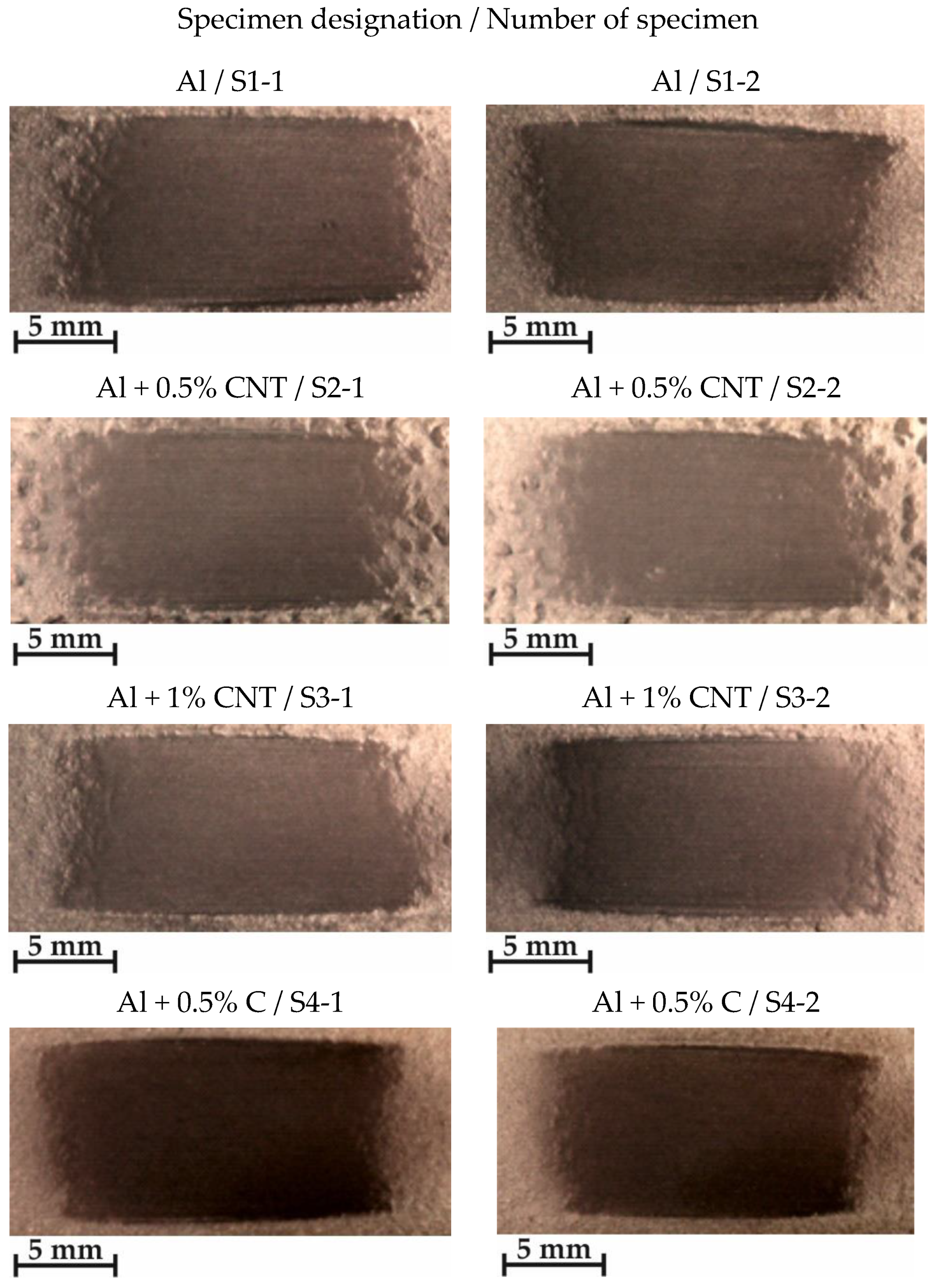

3.4. Tests Results of the Coatings’ Wear Resistance

4. Discussion

5. Conclusions

- Producing aluminum matrix coatings with carbon materials reinforcement with high quality is possible using flame spraying technology.

- In the aluminum with carburite reinforcement flame-sprayed coating structure, areas were observed with a share of carbon above 61 wt.%. In the aluminum coating with 1 of carbon nanotubes, similar areas were observed with a share of carbon about 33 wt.%.

- The addition of carbon nanotubes to aluminum powder resulted in increasing the hardness of flame-sprayed coatings by about 10 HV 0.1.

- The carbon materials reinforced aluminum flame-sprayed coatings have lower erosive wear resistance than pure aluminum coatings with large and small angles of erodent incidence.

- The metal-mineral type wear resistance of flame-sprayed aluminum coatings reinforced with carbon nanotubes or carburite is 10% to 20% higher in comparison to pure aluminum coating.

Funding

Conflicts of Interest

References

- Kelly, A. Composite materials after seventy years. J. Mater. Sci. 2006, 41, 905–912. [Google Scholar] [CrossRef]

- Rawal, S. Metal-matrix composites for space applications. JOM 2001, 53, 14–17. [Google Scholar] [CrossRef]

- Shelly, J.S.; LeClaire, R.; Nichols, J. Metal-matrix composites for liquid rocket engines. JOM 2001, 53, 18–21. [Google Scholar] [CrossRef][Green Version]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forro, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Takashi, I. Overview of trends in advanced composite research and applications in Japan. Adv. Compos. Mater. 2006, 15, 3–37. [Google Scholar]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites. A review. Polymer 2007, 48, 4907–4920. [Google Scholar] [CrossRef]

- Curtin, W.A.; Sheldon, B.W. CNT-reinforced ceramics and metals. Mater. Today 2004, 7, 44–49. [Google Scholar] [CrossRef]

- Saffar, K.P.A.; Najafi, A.R.; Moeinzadeh, M.H.; Sudak, L.J. A Finite Element Study of Crack Behavior for Carbon Nanotube Reinforced Bone Cement. World J. Mech. 2013, 3, 13–21. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Singh, V.; Balani, K.; McCartney, D.G.; Seal, S.; Agarwal, A. Carbon nanotube reinforced aluminum composite coating via cold spraying. Surf. Coat. Technol. 2008, 202, 5162–5169. [Google Scholar] [CrossRef]

- Keshri, A.K.; Balani, K.; Bakshi, S.R.; Singh, V.; Laha, T.; Seal, S.; Agarwal, A. Structural transformations in carbon nanotubes during thermal spray processing. Surf. Coat. Technol. 2009, 203, 2193–2201. [Google Scholar] [CrossRef]

- Wu, Y.; Kim, G. Carbon nanotube reinforced aluminum composite fabricated by semi-solid powder processing. J. Mater. Process. Technol. 2011, 211, 1341–1347. [Google Scholar] [CrossRef]

- Liao, J.; Tan, M.; Ramanujan, R.V.; Shukla, S. Carbon nanotube evolution in aluminum matrix during composite fabrication process. Mater. Sci. Forum 2011, 690, 294–297. [Google Scholar] [CrossRef]

- Feng, Y.; Yuana, H.; Zhanga, M. Fabrication and properties of silver-matrix composites reinforced by carbon nanotubes. Mater. Charact. 2005, 55, 211–218. [Google Scholar] [CrossRef]

- Bakshia, S.R.; Singhb, V.; Seal, S.; Agarwal, A. Aluminum composite reinforced with multiwalled carbon nanotubes from plasma spraying of spray dried powders. Surf. Coat. Technol. 2009, 203, 1544–1554. [Google Scholar] [CrossRef]

- Zeng, X.; Zhou, G.; Xu, Q.; Xiong, Y.; Luo, C.H.; Wu, J. A new technique for dispersion of carbon nanotube in a metal melt. Mater. Sci. Eng. A 2010, 527, 5335–5340. [Google Scholar] [CrossRef]

- Kondoh, K.; Fukuda, H.; Umeda, J.; Imai, H.; Fugetsu, B.; Endo, M. Microstructural and mechanical analysis of carbon nanotube reinforced magnesium alloy powder composites. Mater. Sci. Eng. A 2010, 527, 4103–4108. [Google Scholar] [CrossRef]

- He, X.; Kitipornchai, S.; Liew, K.M. Buckling analysis of multi-walled carbon nanotubes: A continuum model accounting for van der Waals interaction. J. Mech. Phys. Solids 2005, 53, 303–326. [Google Scholar] [CrossRef]

- Tan, H.; Jiang, L.Y.; Huangc, Y.; Liu, B.; Hwang, K.C. The effect of van der Waals-based interface cohesive law on carbon nanotube-reinforced composite materials. Compos. Sci. Technol. 2007, 67, 2941–2946. [Google Scholar] [CrossRef]

- Silva, A.P.; Devezas, T.C.; Segadaes, A.M. Statistical Modelling of the Particle Size Composition of an Alumina Matrix for No-Cement Self-Flowing Refractory Castables. Mater. Sci. Forum 2006, 514–516, 604–608. [Google Scholar] [CrossRef]

- Silva, J.M.A.; Devezas, T.C.; Silva, A.P.; Ferreira, J.A.M. Mechanical Characterization of Composites with Embedded Optical Fibers. J. Compos. Mater. 2005, 39, 1261–1281. [Google Scholar] [CrossRef]

- Czuprynski, A. Properties of Al2O3/TiO2 and ZrO2/CaO flame-sprayed coatings. Mater. Tehnol./Mater. Technol. 2017, 51, 205–212. [Google Scholar] [CrossRef]

- Czuprynski, A.; Gorka, J.; Adamiak, M.; Tomiczek, B. Testing of flame sprayed Al2O3 matrix coatings containing TiO2. Arch. Metall. Mater. 2016, 61, 1363–1370. [Google Scholar] [CrossRef]

- Czuprynski, A.; Gorka, J.; Adamiak, M. Examining properties of arc sprayed nanostructured coatings. Metalurgija 2016, 55, 173–176. [Google Scholar]

- Adamiak, M.; Czuprynski, A.; Kopysc, A.; Monica, Z.; Olender, M.; Gwiazda, A. The Properties of Arc-Sprayed Aluminum Coatings on Armor-Grade Steel. Metals 2018, 8, 142. [Google Scholar] [CrossRef]

- Lisiecki, A. Mechanisms of hardness increase for composite surface layers during laser gas nitriding of the Ti6A14V alloy. Mater. Tehnol. Mater. Technol. 2017, 51, 577–583. [Google Scholar] [CrossRef]

- Lisiecki, A.; Kurc-Lisiecka, A. Erosion wear resistance of Titanium-Matrix Composite Ti/TiN produced by diode-laser gas nitriding. Mater. Tehnol. Mater. Technol. 2017, 51, 29–34. [Google Scholar] [CrossRef]

- Lisiecki, A.; Piwnik, J. Tribological characteristic of titanium alloy surface layers produced by diode laser gas nitriding. Arch. Metall. Mater. 2016, 61, 543–552. [Google Scholar] [CrossRef]

- Lisiecki, A. Comparison of Titanium Metal Matrix Composite surface layers produced during laser gas nitriding of Ti6Al4V alloy by different types of lasers. Arch. Metall. Mater. 2016, 61, 1777–1783. [Google Scholar] [CrossRef]

- Lisiecki, A. Titanium Matrix Composite Ti/TiN Produced by Diode Laser Gas Nitriding. Metals 2015, 5, 54–69. [Google Scholar] [CrossRef]

- Klimpel, A.; Dobrzanski, L.A.; Lisiecki, A.; Janicki, D. The study of properties of Ni-W2C and Co-W2C powders thermal sprayed deposits. J Mater Process Tech. 2005, 164, 1068–1073. [Google Scholar] [CrossRef]

- Dobrzanski, L.A.; Klimpel, A.; Bonek, M.; Lisiecki, A. Surface-layer’s structure of X40CrMoV5-1 steel remelted and/or WC alloyed with HPDL laser. Mater. Sci. Forum 2003, 437–438, 69–72. [Google Scholar] [CrossRef]

- Klimpel, A.; Dobrzanski, L.A.; Lisiecki, A.; Janicki, D. The study of the technology of laser and plasma surfacing of engine valves face made of X40CrSiMo10-2 steel using cobalt-based powders. J. Mater. Process. Tech. 2006, 175, 251–256. [Google Scholar] [CrossRef]

- Laha, T.; Agarwal, A.; McKechnie, T.; Seal, S. Synthesis and characterization of plasma spray formed carbon nanotube reinforced aluminum composite. Mater. Sci. Eng. A 2004, 381, 249–258. [Google Scholar] [CrossRef]

- Thermal spraying. Pre-Treatment of Surfaces of Metallic Parts and Components for Thermal Spraying; EN 13507; CEN: Brussels, Belgium, 2018. [Google Scholar]

- Thermal Spraying—Zinc, Aluminium and Their Alloys—Part 1: Design Considerations and Quality Requirements for Corrosion Protection Systems; ISO 2063-1; ISO: Geneva, Switzerland, 2017.

- Zhou, Z.-F.; Hu, M.-Y.; Xin, H.; Chen, B.; Wang, G.-X. Experimental and theoretical studies on the droplet temperature behavior of R407C two-phase flashing spray. Int. J. Heat Mass Transf. 2019, 136, 664–673. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, W.; Chen, B.; Wang, G.; Guo, L. An experimental study on the spray and thermal characteristics of R134a two-phase flashing spray. Int. J. Heat Mass Transf. 2012, 55, 4460–4468. [Google Scholar]

- Thermal Spraying—Characterization and Testing of Thermally Sprayed Coatings; ISO 14923; ISO: Geneva, Switzerland, 2005.

- Metallic Materials—Vickers Hardness Test—Part 1: Test Method; ISO 6507; ISO: Geneva, Switzerland, 2018.

- Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets; ASTM G76-95; ASTM: West Conshohocken, PA, USA, 2000.

- Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus; ASTM G65-00; ASTM: West Conshohocken, PA, USA, 2000.

- Wei, X.; Wang, M.S.; Bando, Y.; Golberg, D. Thermal stability of carbon nanotubes probed by anchored tungsten nanoparticles. J. Sci. Technol. Adv. Mater. 2011, 12, 1–6. [Google Scholar] [CrossRef]

- Burda, M.; Kik, T.; Koziol, K.; Gruszczyk, A. Development of methods of carbon nanotubes input to weld pool. Weld. Technol. Rev. 2011, 12, 43–50. [Google Scholar]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 85th ed.; CRC Press: Boca Raton, FL, USA, 2003; pp. 15–52. [Google Scholar]

- Gaskell, D.R. Introduction to the Thermodynamics of Materials, 4th ed.; Taylor & Francis: New York, NY, USA, 2017. [Google Scholar]

| Specification | Unit | Guaranteed Parameters | Obtained Results |

|---|---|---|---|

| Aluminum content (Al) | % | min 99.7 | 99.7 |

| Iron content (Fe) | % | max 0.2 | 0.2 |

| Silicon content (Si) | % | max 0.12 | 0.12 |

| Copper content (Cu) | % | max 0.004 | 0.004 |

| Moisture | % | max 0.1 | 0.1 |

| Bulk density | g/dm3 | min 1000 | 1050 |

| Granulation above 0.045 mm | % | 85.0−100.0 | 98.0 |

| Granulation above 0.1 mm | % | 5.0−30.0 | 15.3 |

| Granulation above 0.16 mm | % | max 5.0 | 0.0 |

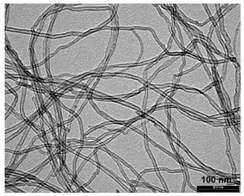

Structure of Nanocyl NC 7000 carbon nanotubes | |||

| Properties | Unit | Value | Measurement Method |

| Average diameter | Nanometer | 9.5 | TEM |

| Average length | Micrometer | 1.5 | TEM |

| Carbon purity | % | 90 | TGA |

| Metal oxide | % | 10 | TGA |

| Amorphous carbon | - | 1) | HRTEM |

| Surface area | m2/g | 250–300 | BET |

| Note: 1) pyrolytically deposited carbon on the surface of the NC 7000. | |||

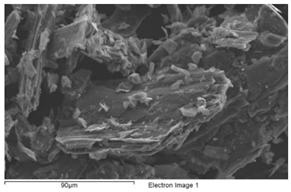

Structure of filter dust carburite | |||

| Properties | Unit | Value | |

| Fraction size | Millimeter | >0 up to 1 | |

| Dust content | % | 5 | |

| Moisture content | % | 1 | |

| Carburite content | % | 94 | |

| Granulation [mm] | % | >1 mm up to 10%; <0.06 mm up to 70% | |

| Sample Number | Type of Powder | Oxygen Pressure [bar] | Acetylene Pressure [bar] | Assist. Gas (Compressed Air) Pressure [bar] | Number of the Orifice for the Powder | Mass of Used Powder [g] | Powder Yield [%] |

|---|---|---|---|---|---|---|---|

| 1 | Al | 4 | 0.7 | 3 | 2 | 93.5 | 60.3 |

| 2 | Al + 0.5% CNT 1) | 4 | 0.7 | 3 | 2 | 97.0 | 56.2 |

| 3 | Al + 1% CNT | 4 | 0.7 | 3 | 2 | 100.8 | 57.0 |

| 4 | Al + 0.5% C 2) | 4 | 0.7 | 3 | 2 | 99.7 | 59.4 |

| Specimen Designation | Hardness [HV 0.1] | ||||||

|---|---|---|---|---|---|---|---|

| Measuring Point | |||||||

| 1 | 2 | 3 | 4 | 5 | Average | Standard Deviation | |

| Al | 35.2 | 32.5 | 34.8 | 37.2 | 35.1 | 34.96 | 1.67 |

| Al + 0.5% CNT | 59.2 | 62.8 | 56.5 | 54.2 | 55.5 | 57.64 | 3.42 |

| Al + 1% CNT | 41.2 | 43.2 | 37.5 | 39.2 | 38.7 | 39.96 | 2.25 |

| Al + 0.5% C | 30.2 | 27.3 | 28.2 | 27.0 | 28.0 | 28.14 | 1.25 |

| Erodent Strike Angle [°] | Specimen Designation | Mass Loss [g] | Volume Loss [mm3] | Erosion Rate [g/min] | Resistance to Erosion as per ASTM G76 [0.001mm3/g] |

|---|---|---|---|---|---|

| 90 | Al | 0.0054 | 1.985 | 0.00068 | 0.12255 |

| Al + 0.5% CNT | 0.0117 | 4.301 | 0.00146 | 0.26552 | |

| Al + 1% CNT | 0.0071 | 2.610 | 0.00089 | 0.16113 | |

| Al + 0.5% C | 0.0064 | 2.353 | 0.00080 | 0.14524 | |

| 30 | Al | 0.0036 | 1.324 | 0.00045 | 0.08170 |

| Al + 0.5% CNT | 0.0066 | 2.426 | 0.00083 | 0.14978 | |

| Al + 1% CNT | 0.0045 | 1.654 | 0.00056 | 0.10212 | |

| Al + 0.5% C | 0.0039 | 1.434 | 0.00049 | 0.08851 |

| Specimen Designation | Number of Specimen | Weight Before Test [g] | Weight after Test [g] | Mass Loss [g] | Average Mass Loss [g] | Average Volume Loss [mm3] | Relative 1) Abrasion Resistance |

|---|---|---|---|---|---|---|---|

| Al | S1-1 | 43.9675 | 43.8413 | 0.1262 | 0.1418 | 52.1324 | 1.00 |

| S1-2 | 42.3855 | 42.2281 | 0.1574 | ||||

| Al + 0.5% CNT | S2-1 | 56.5170 | 56.3924 | 0.1246 | 0.1286 | 47.26103 | 1.10 |

| S2-2 | 53.8604 | 53.7279 | 0.1325 | ||||

| Al + 1% CNT | S3-1 | 56.9638 | 56.8322 | 0.1316 | 0.1279 | 47.0221 | 1.11 |

| S3-2 | 57.4587 | 57.3345 | 0.1242 | ||||

| Al + 0.5% C | S4-1 | 59.4423 | 59.3199 | 0.1224 | 0.1190 | 43.7500 | 1.19 |

| S4-2 | 61.1152 | 60.9996 | 0.1156 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czupryński, A. Flame Spraying of Aluminum Coatings Reinforced with Particles of Carbonaceous Materials as an Alternative for Laser Cladding Technologies. Materials 2019, 12, 3467. https://doi.org/10.3390/ma12213467

Czupryński A. Flame Spraying of Aluminum Coatings Reinforced with Particles of Carbonaceous Materials as an Alternative for Laser Cladding Technologies. Materials. 2019; 12(21):3467. https://doi.org/10.3390/ma12213467

Chicago/Turabian StyleCzupryński, Artur. 2019. "Flame Spraying of Aluminum Coatings Reinforced with Particles of Carbonaceous Materials as an Alternative for Laser Cladding Technologies" Materials 12, no. 21: 3467. https://doi.org/10.3390/ma12213467

APA StyleCzupryński, A. (2019). Flame Spraying of Aluminum Coatings Reinforced with Particles of Carbonaceous Materials as an Alternative for Laser Cladding Technologies. Materials, 12(21), 3467. https://doi.org/10.3390/ma12213467