Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods

Abstract

:1. Introduction

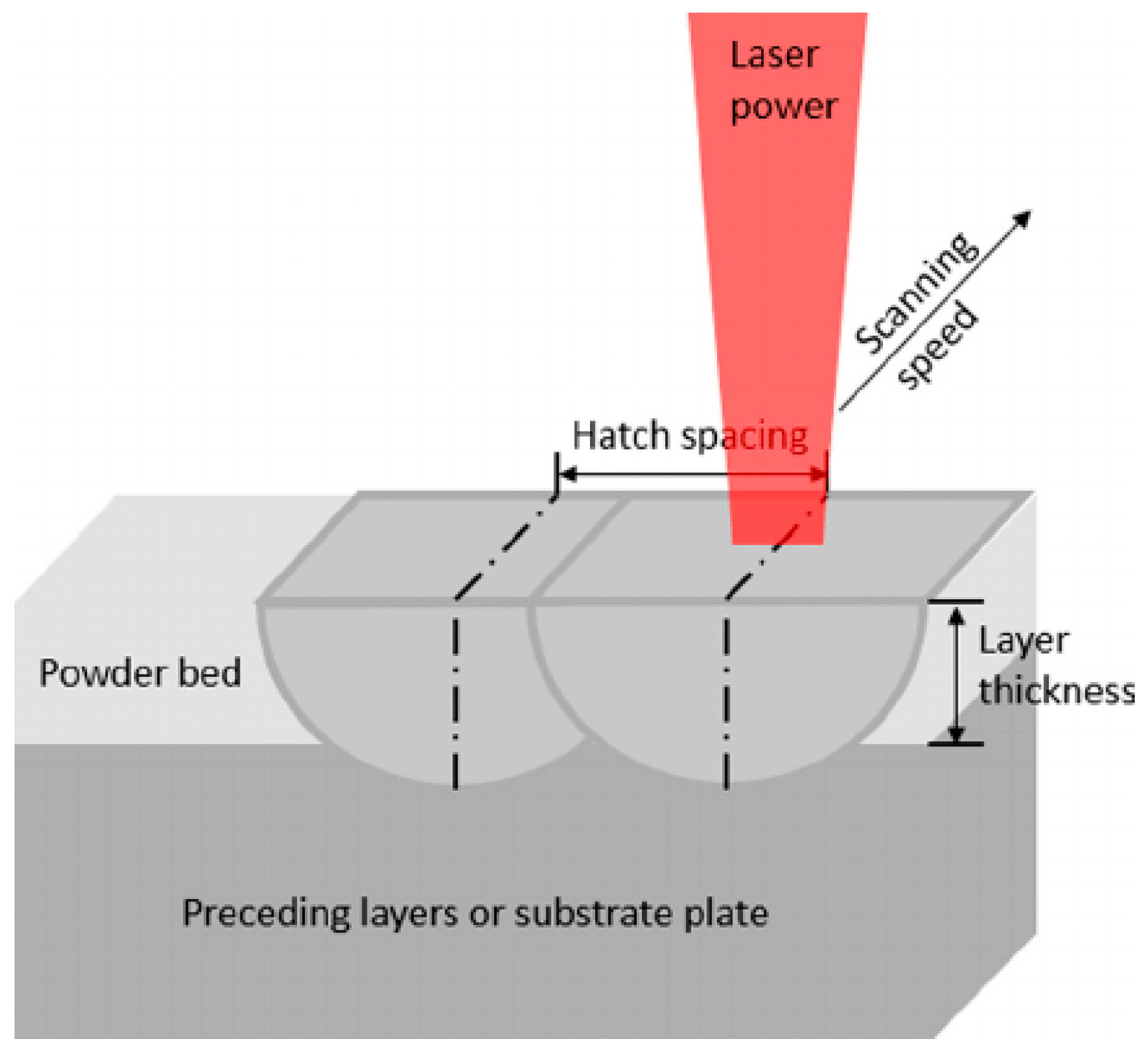

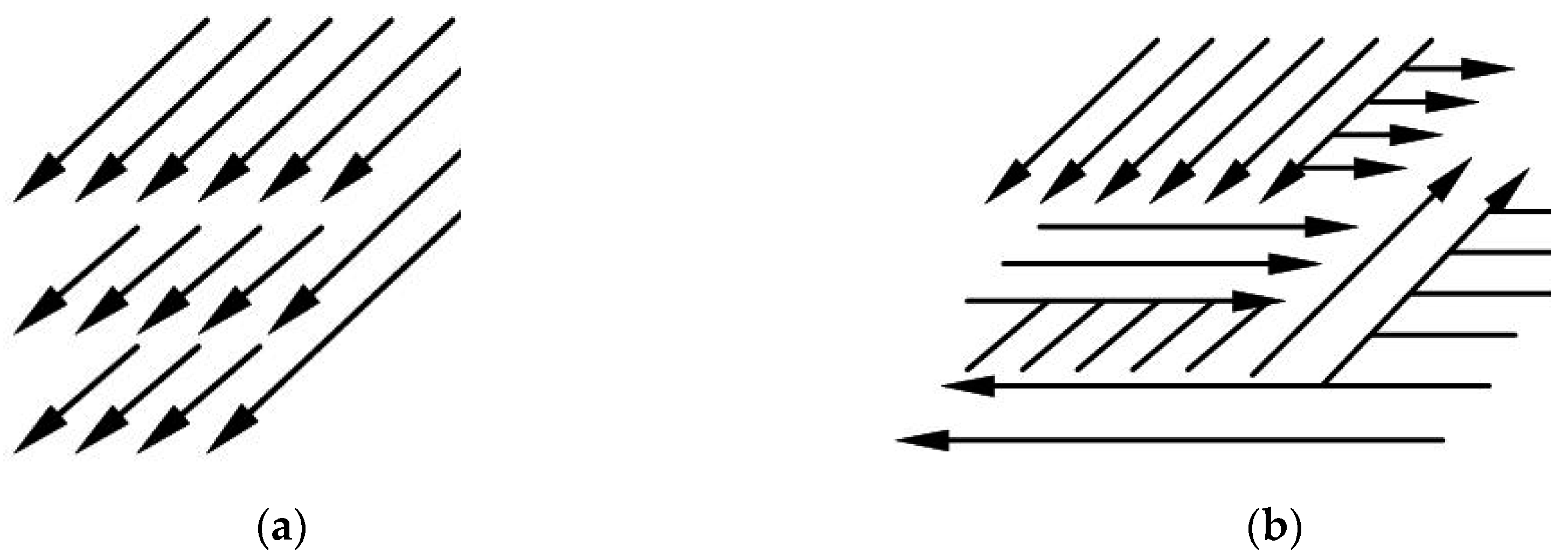

2. Materials and Methods

3. Results

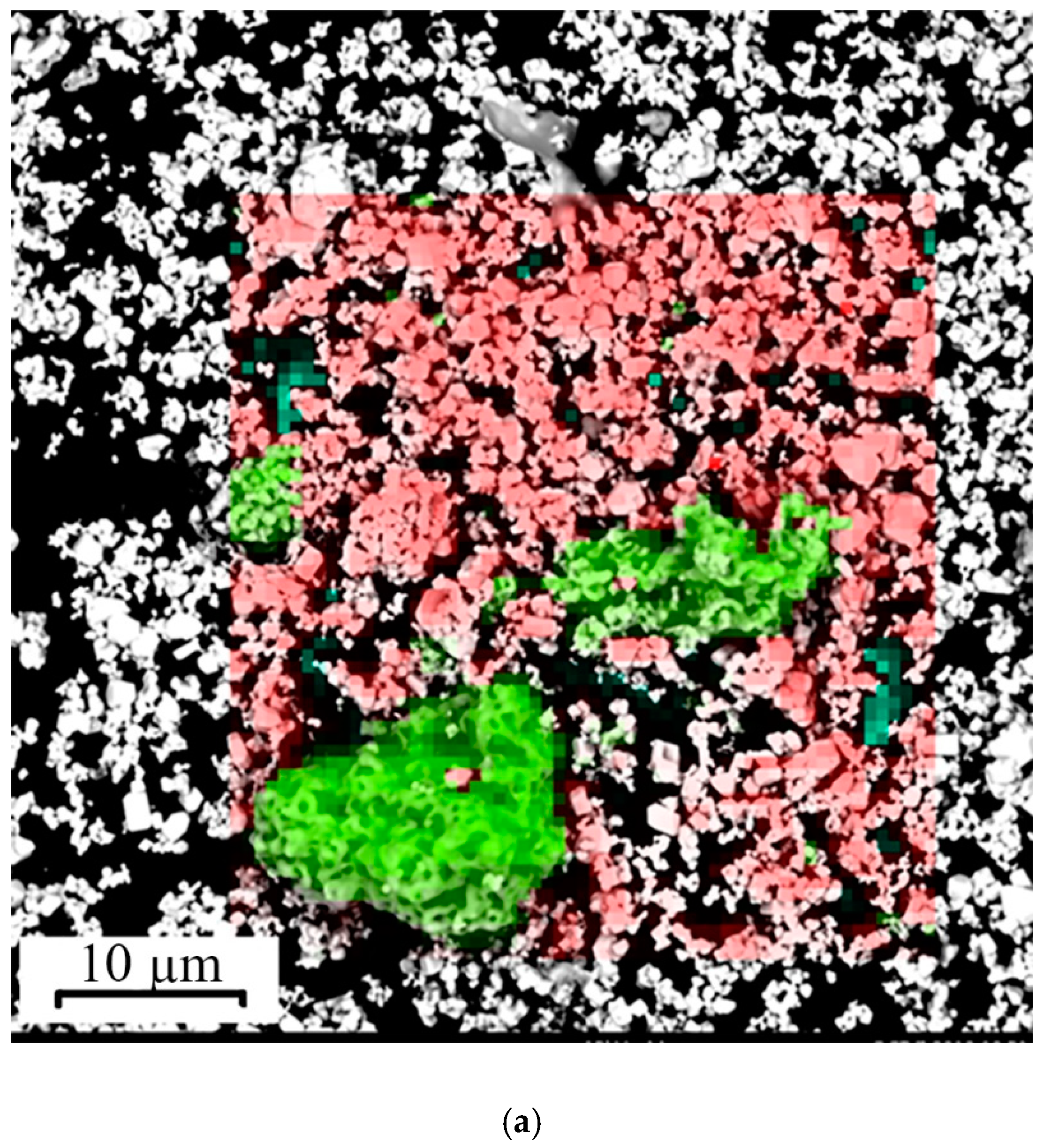

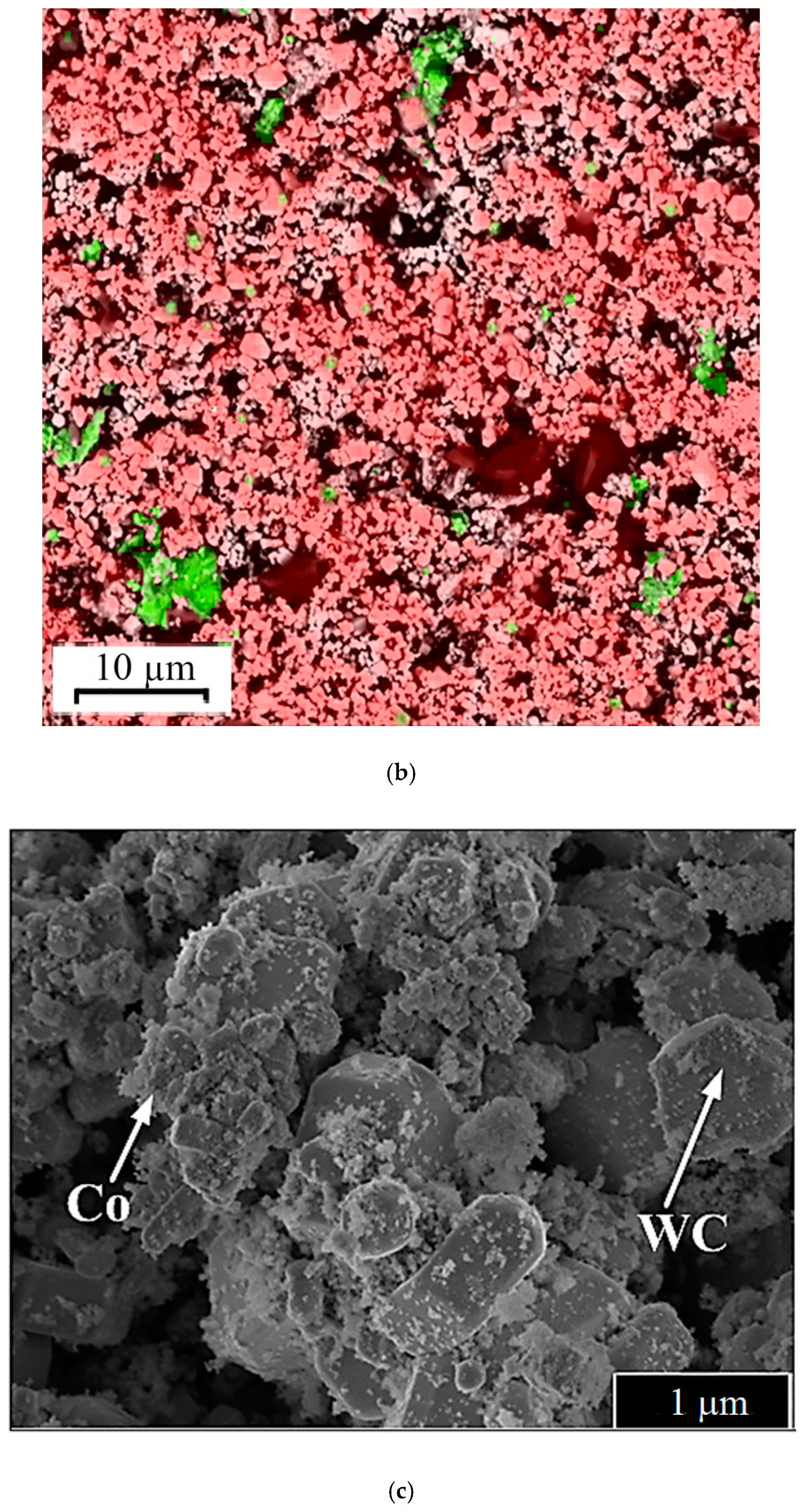

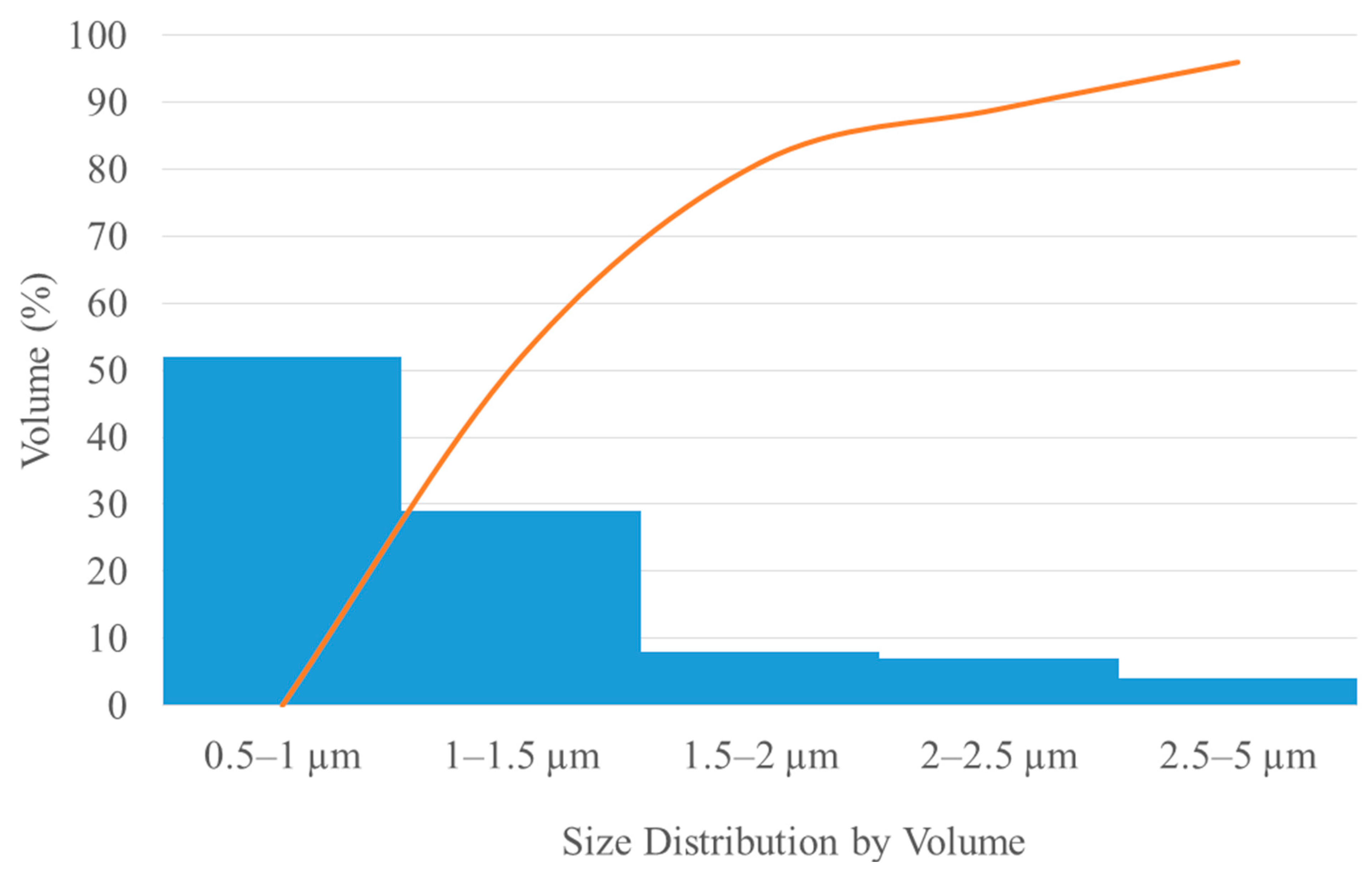

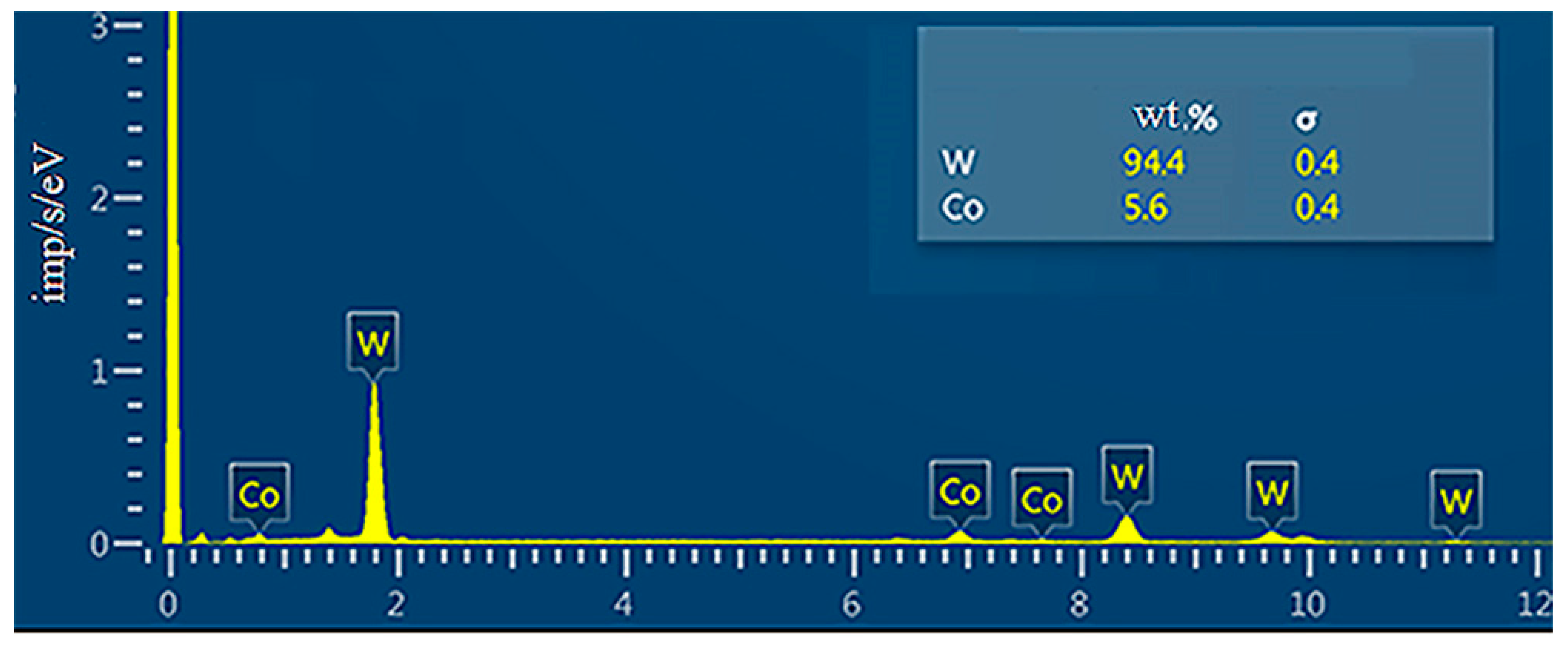

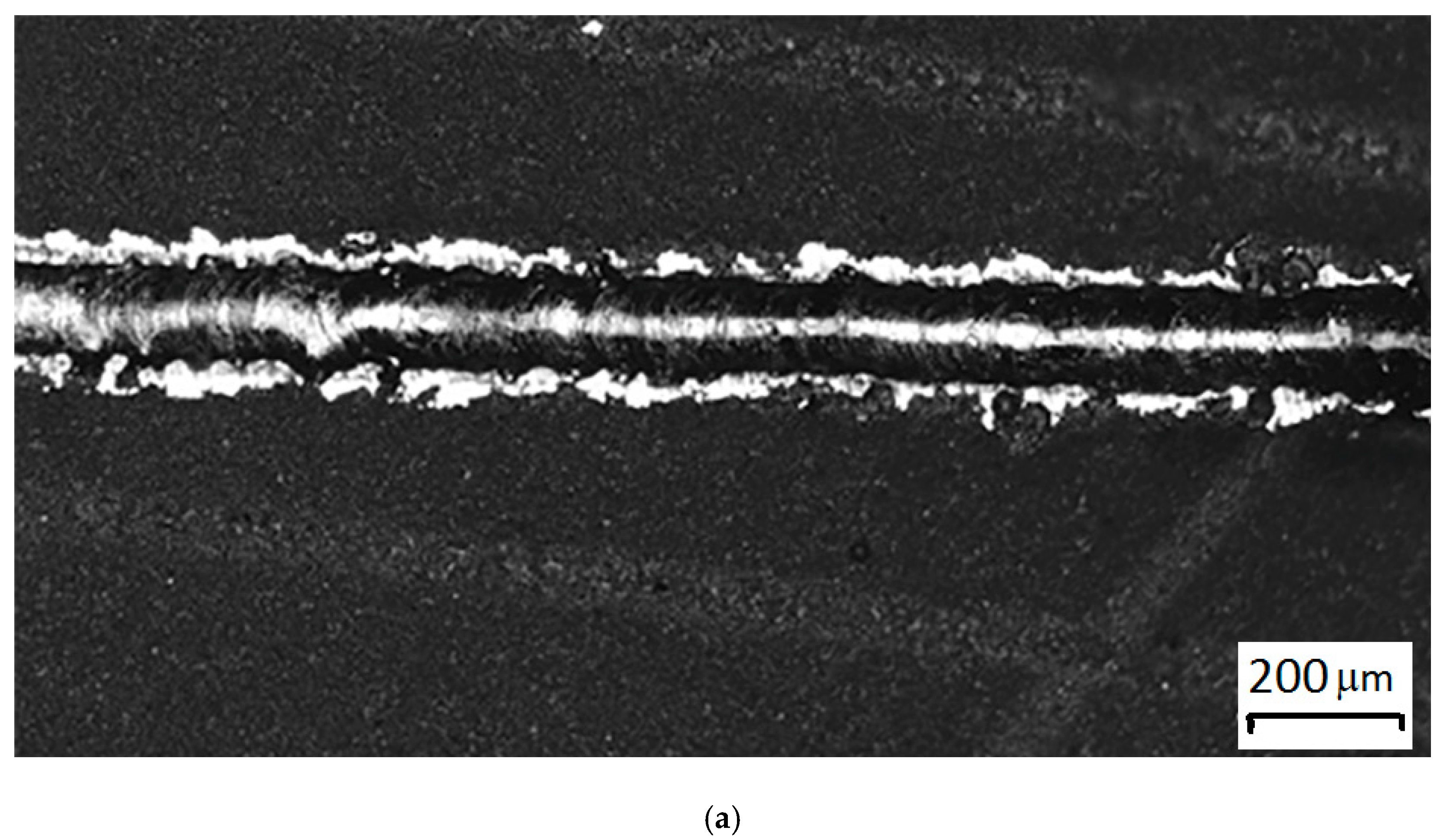

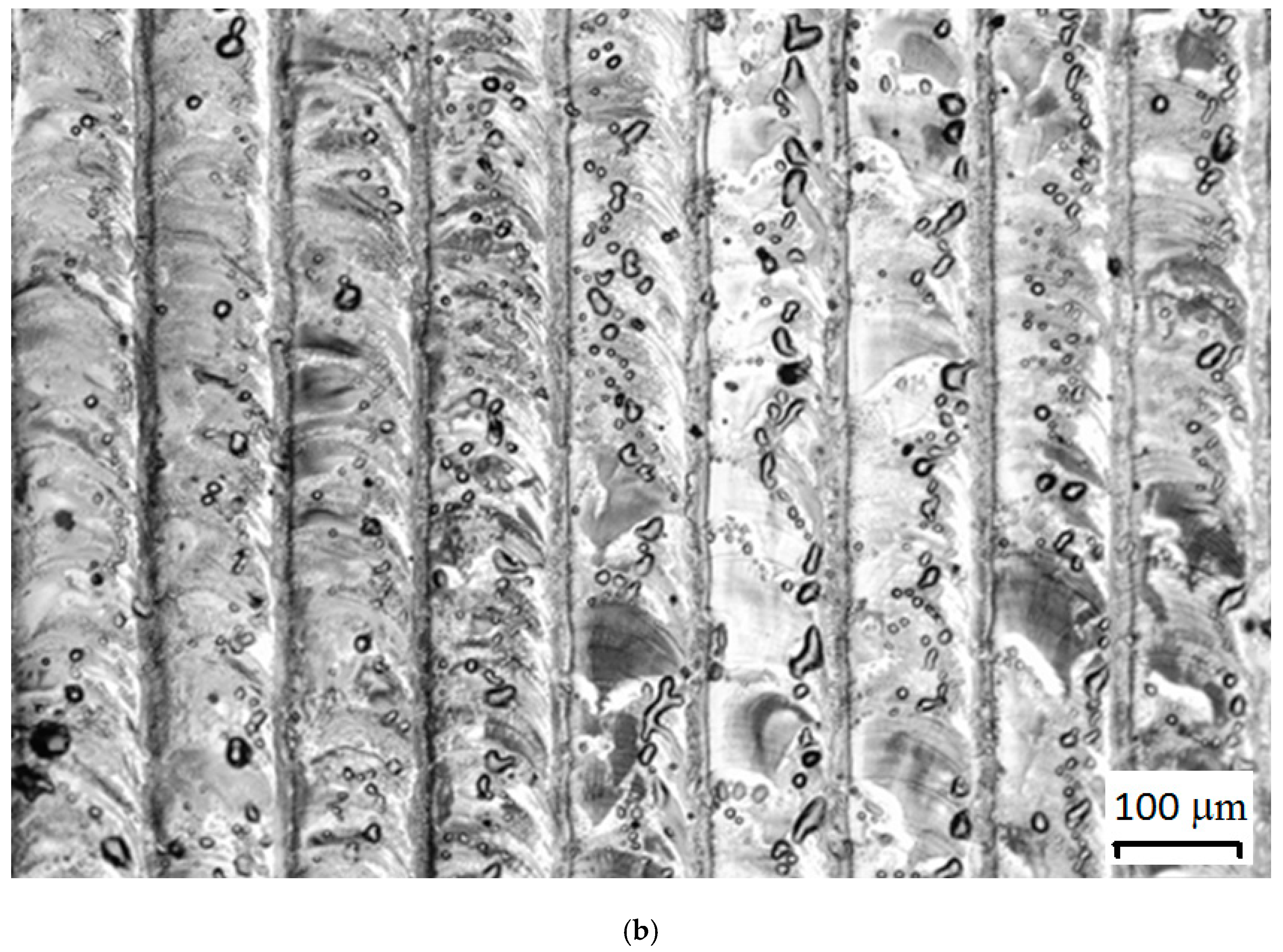

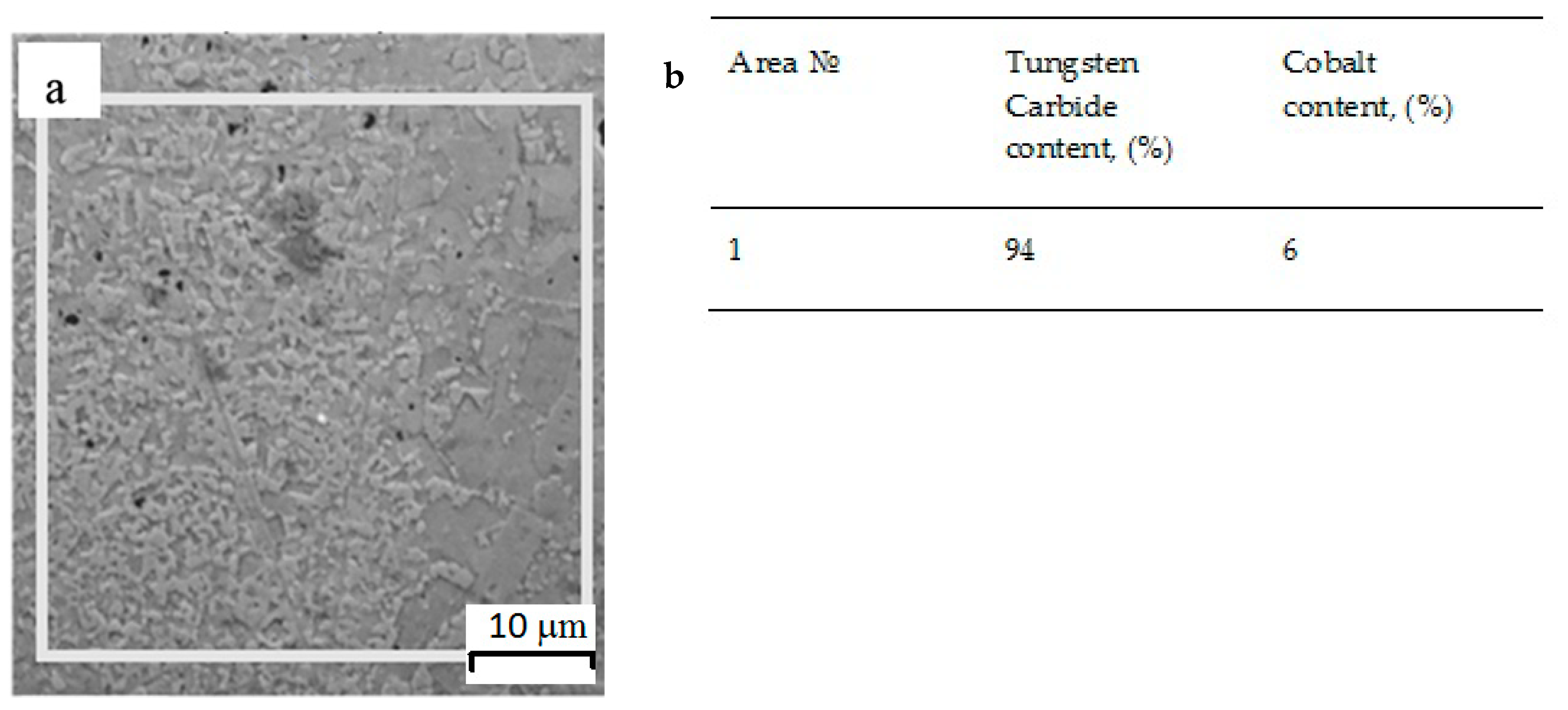

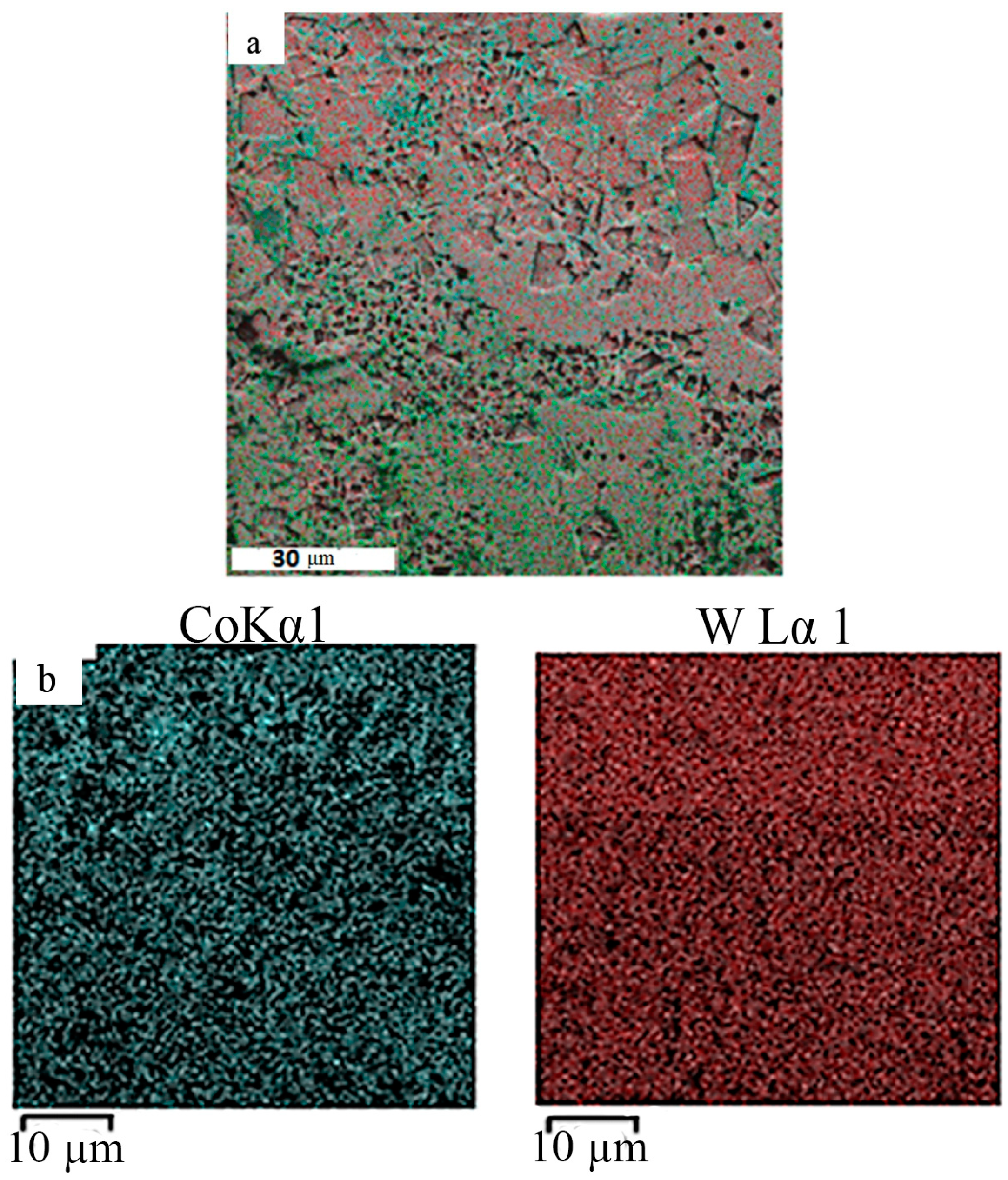

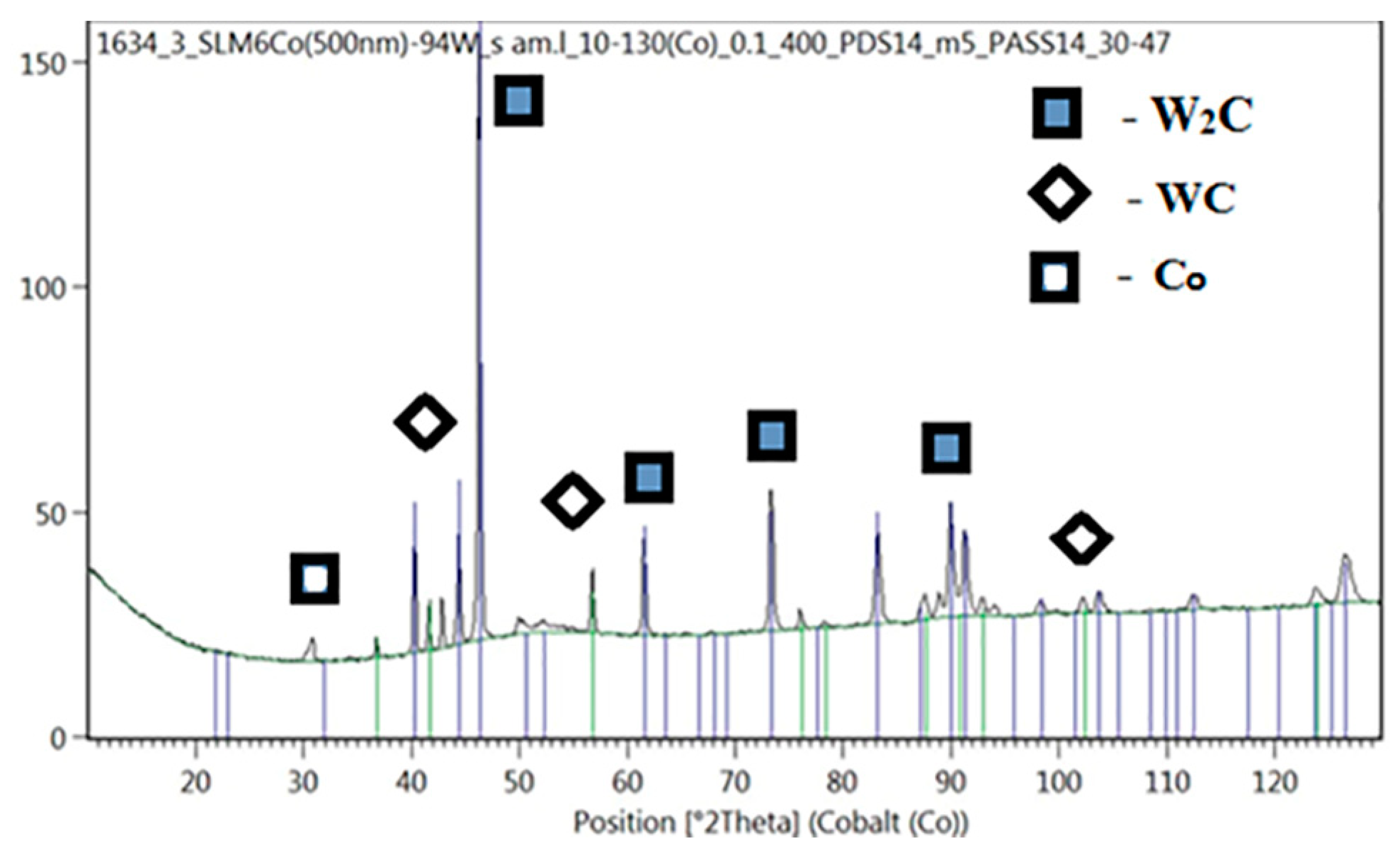

3.1. Preparation and Study of Powder Compositions for SLM

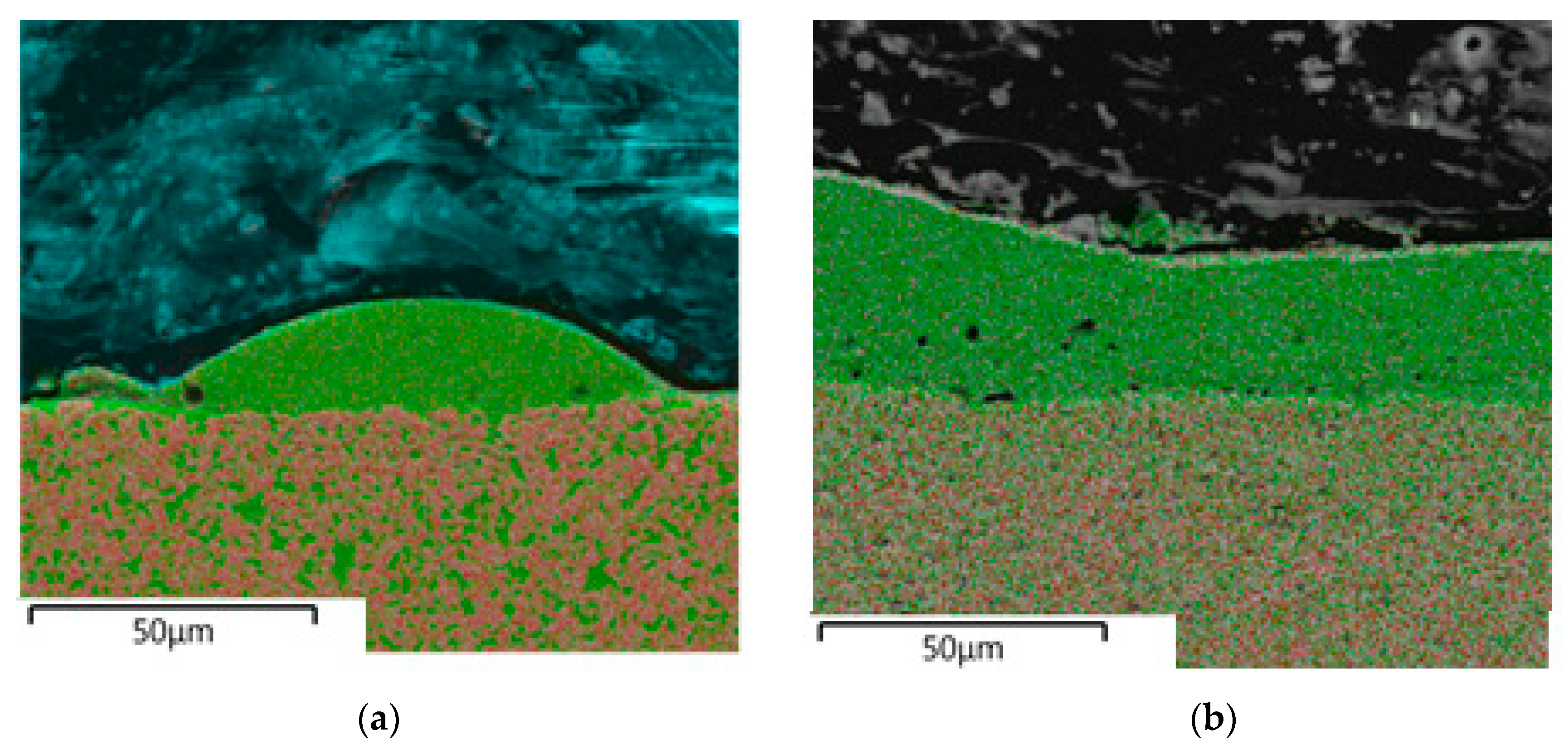

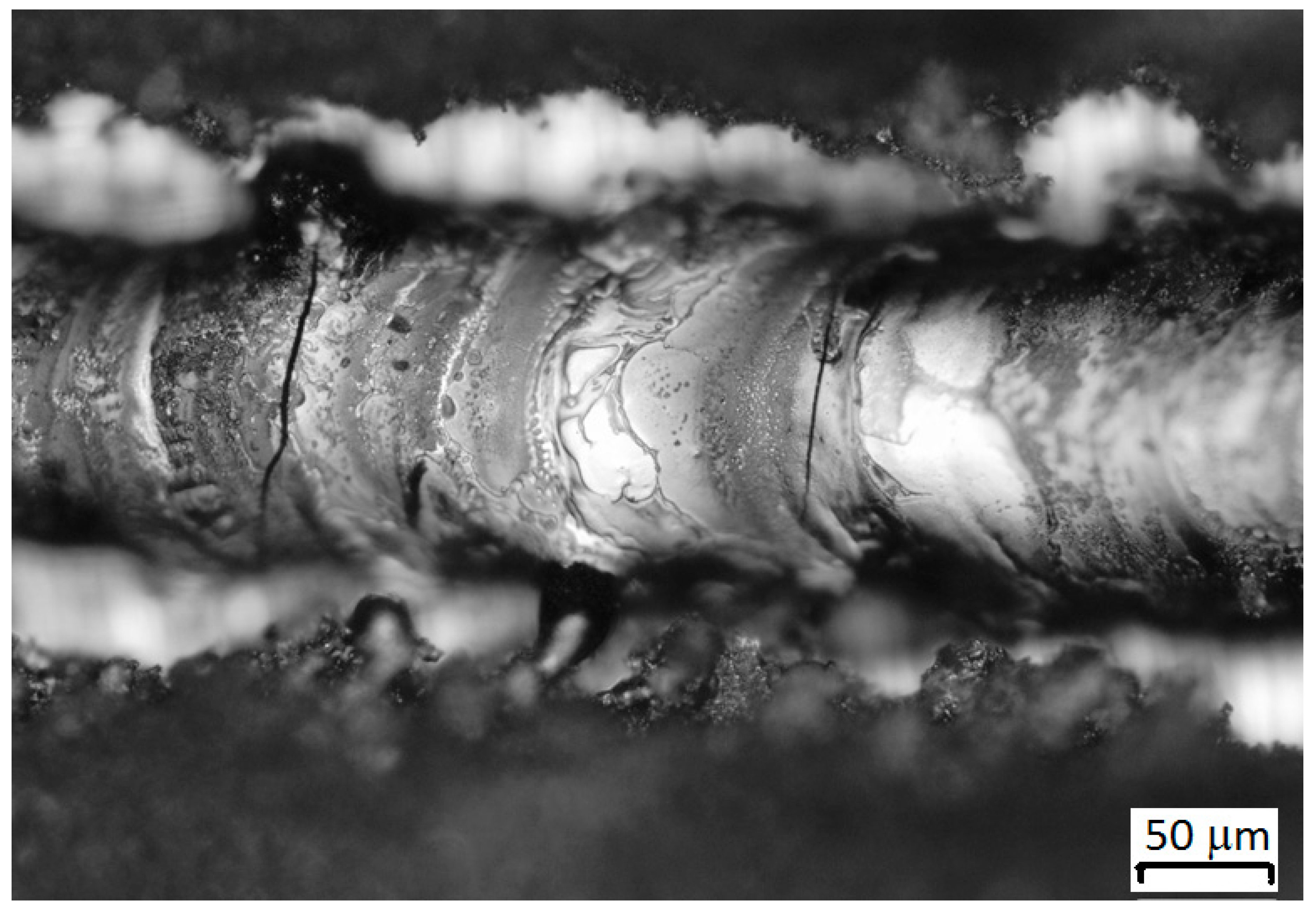

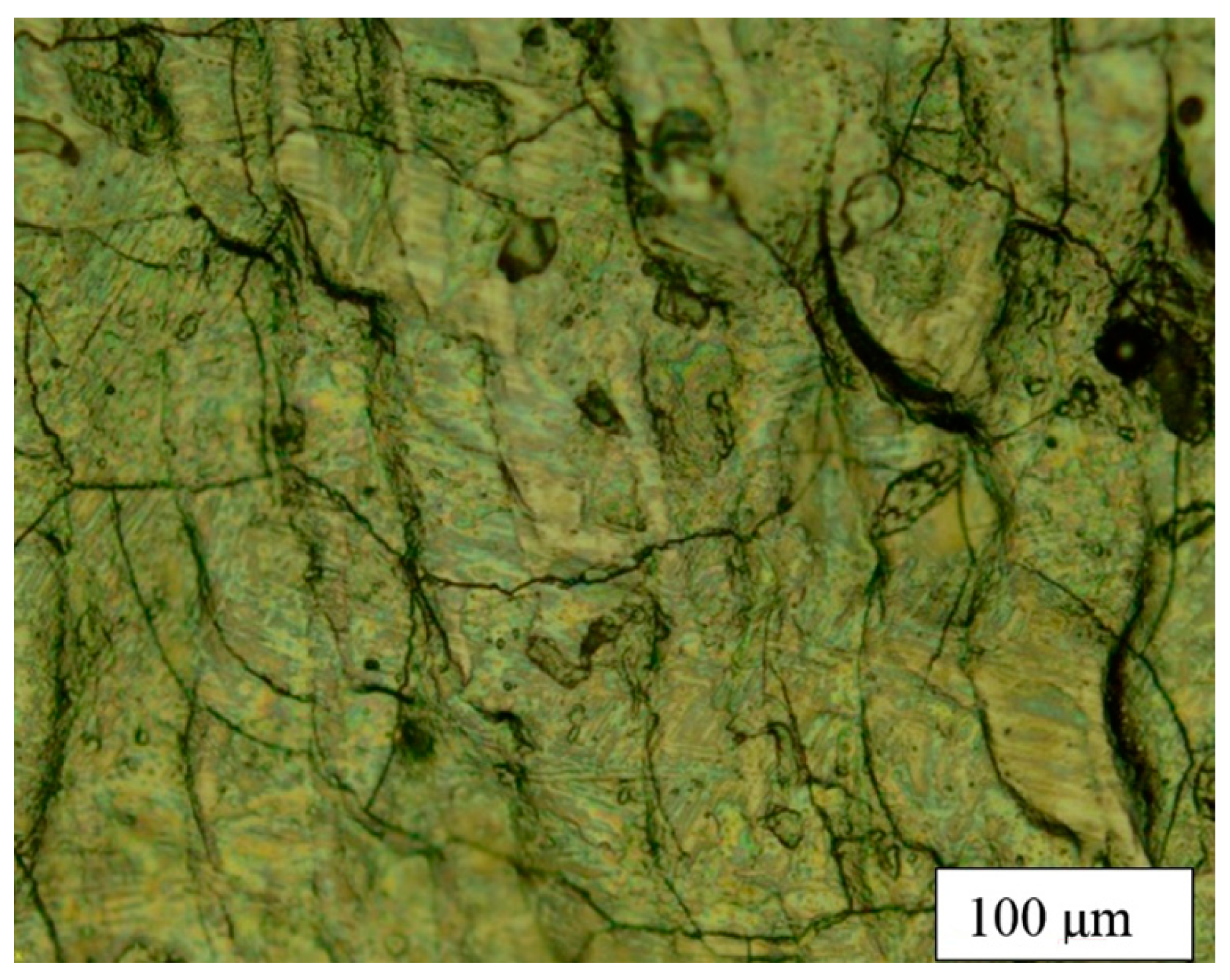

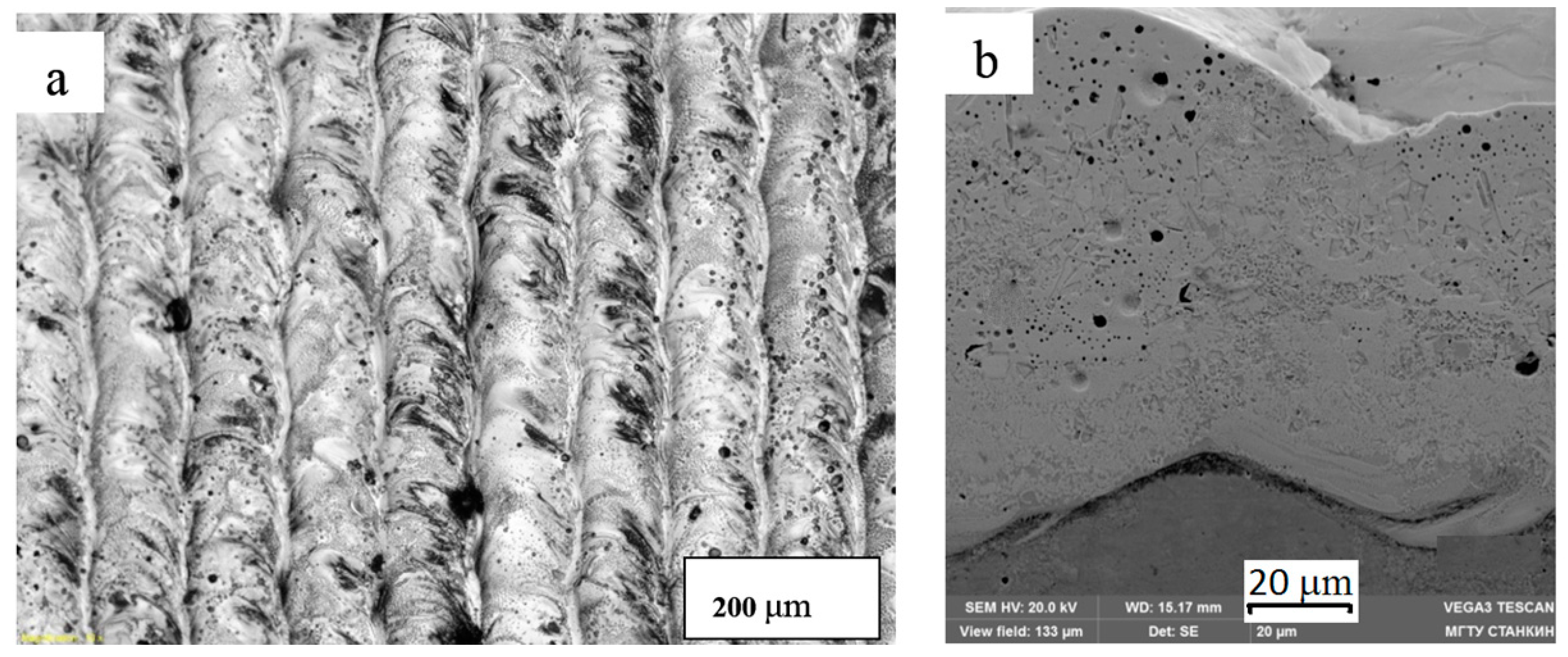

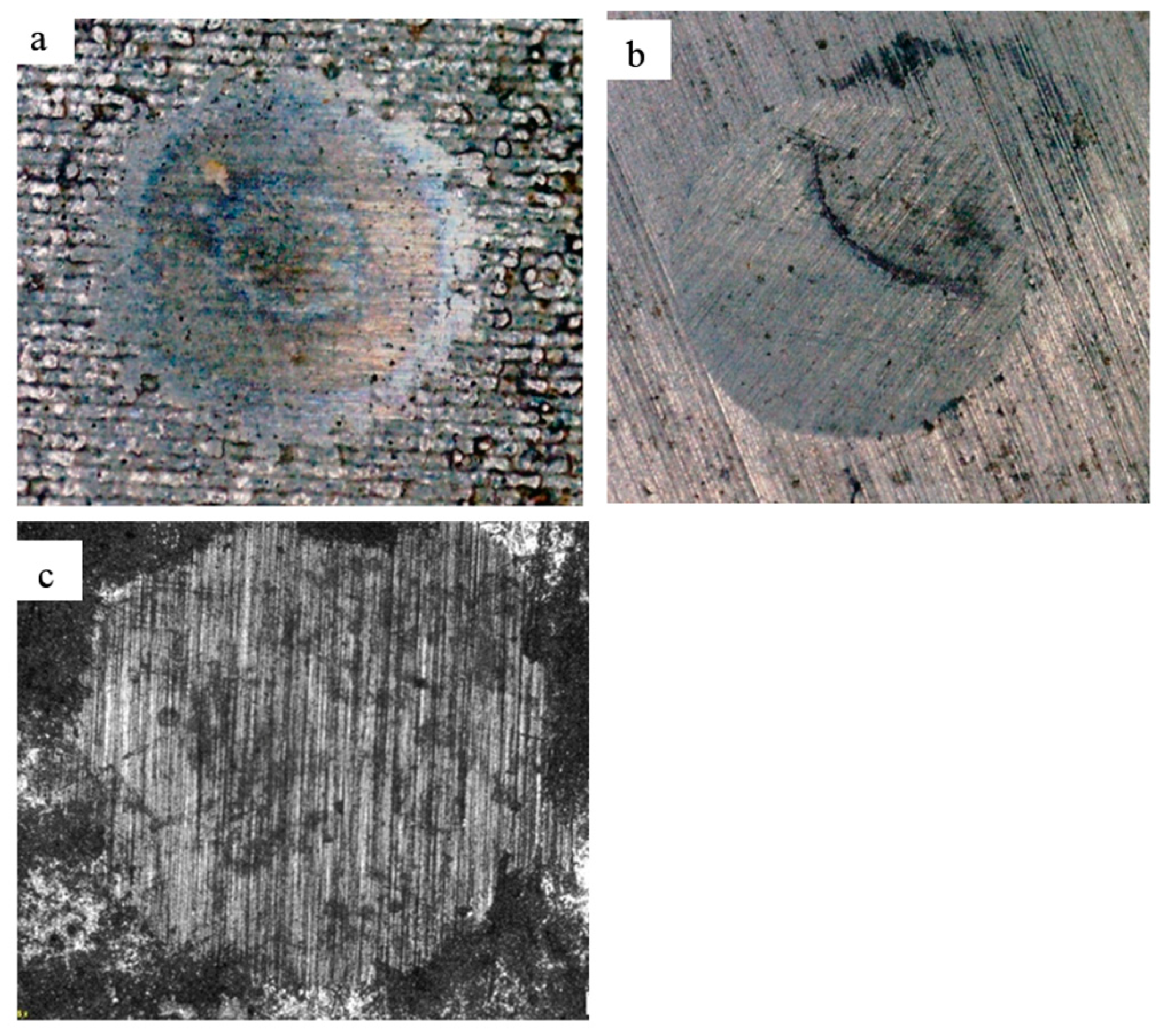

3.2. Structure and Properties of Samples Obtained by SLM

4. Conclusions

5. Patents

- RU2669034C1. The method of obtaining products from powder material 94WC6Co.

- RU2669135C1. The method of manufacturing products by selective laser melting of a powder composition WC–Co.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ISO/ASTM. 52900:2015 Additive Manufacturing—General Principles—Terminology; ISO/ASTM International: Geneva, Switzerland, 2015; p. 19. Available online: https://www.sis.se/api/document/preview/919975/ (accessed on 15 August 2015).

- Grigor’ev, S.N.; Tarasova, T.V. Possibilities of the Technology of Additive Production for Making Complex-Shape Parts and Depositing Functional Coatings from Metallic Powders. Met. Sci. Heat Treat. 2016, 57, 579–584. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Tarasova, T.V.; Nazarov, A.P. Influence of heat treatment on the structural phase composition and properties of heat-resistant cobalt alloys obtained by selective laser melting. Prospect. Mater. 2014, 7, 73–80. [Google Scholar]

- Gladush, G.G.; Smurov, I. Physics of Laser Materials Processing: Theory and Experiment; Springer Science & Business Media: Berlin, Germany, 2011; 534p. [Google Scholar]

- Yadroitsev, I. Selective Laser Melting: Direct Manufacturing of 3D-Objects by Selective Laser Melting of Metal Powders; Lap Lambert Academic Publishing: Saarbüken, Germany, 2009; 266p. [Google Scholar]

- Shishkovsky, I.V. Laser Synthesis of Functional Mesostructures and Tridimensional Products; FIZMATLIT: Moscow, Russia, 2009; 424p. [Google Scholar]

- Tarasova, T.V. Additive Manufacturing: Teaching Guide; Higher Education; INFRA-M: Moscow, Russia, 2019; 196p, Available online: http://znanium.com/catalog/product/1046704 (accessed on 19 October 2019). [CrossRef]

- Tarasova, T.V.; Gusarov, A.V.; Protasov, K.E.; Filatova, A.A. The influence of thermal fields on the structure of corrosion-resistant steels in various laser processing schemes. Metall. Heat Treat. Met. 2017, 7, 37–44. [Google Scholar]

- Grigoryev, S.N.; Tarasova, T.V.; Gvozdeva, G.O. Optimization of parameters of laser surfacing of Al-Si system alloys. Metall. Heat Treat. Met. 2015, 10, 15–20. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, P.; Jia, Y.; Yu, Z.; Sokkalingam, R.; Shi, X.; Ji, P.; Eckert, J.; Prashanth, K.G. Microstructure and Mechanical Properties of Al–(12–20) Si Bi-Material Fabricated by Selective Laser Melting. Materials 2019, 12, 2126. [Google Scholar] [CrossRef]

- Chekotu, J.C.; Groarke, R.; O’Toole, K.; Brabazon, D. Advances in Selective Laser Melting of Nitinol Shape Memory Alloy Part Production. Materials 2019, 12, 809. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Huang, S.; Zhu, S.; Wang, F.; Li, D. Manufacturing and Analysis of High-Performance Refractory High-Entropy Alloy via Selective Laser Melting (SLM). Materials 2019, 12, 720. [Google Scholar] [CrossRef]

- Tian, X.; Li, D.; Heinrich, J.G. Rapid prototyping of porcelain products by layer-wise slurry deposition (LSD) and direct laser sintering. Rapid Prototyp. J. 2012, 18, 362–373. [Google Scholar] [CrossRef]

- Yves-Christian, H.; Jan, W.; Wilhelm, M.; Konrad, W.; Reinhart, P. Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- Zhou, P.; Qi, H.; Zhu, Z.; Qin, H.; Li, H.; Chu, C.; Yan, M. Development of SiC/PVB composite powders for selective laser sintering additive manufacturing of SiC. Materials 2018, 11, 2012. [Google Scholar] [CrossRef]

- Evans, A.G.; Charles, E.A. Fracture toughness determinations by indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Lisovsky, F.A. Formation of nonequilibrium dihedral angles in composite materials. Int. J. Powder Metall. 1990, 26, 45–49. [Google Scholar]

- Khmyrov, R.S.; Safronov, V.A.; Gusarov, A.V. Obtaining crack-free WC-Co alloys by selective laser melting. Phys. Procedia 2016, 83, 874–881. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Safronov, V.A.; Gusarov, A.V. Synthesis of nanostructured WC-Co hardmetal by selective laser melting. Procedia IUTAM 2017, 23, 114–119. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Shevchukov, A.P.; Gusarov, A.V.; Tarasova, T.V. Phase composition and microstructure of WC–Co alloys obtained by selective laser melting. Mech. Ind. 2017, 18, 714. [Google Scholar] [CrossRef]

- Laoui, T.; Froyen, L.; Kruth, J.-P. Effect of Mechanical Alloying on Selective Laser Sintering of WC-9Co powder. Powder Metall. 1999, 42, 203–205. [Google Scholar]

- Xiao, C.L.; Stampfl, J.; Prinz, F.B. Mechanical and Thermal Expansion Behavior of Laser Deposited Metal Matrix Composites of Invar and TiC. Mater. Sci. Eng. 2000, 282, 86–90. [Google Scholar]

- Amado, J.M.; Tobar, M.J.; Yáñez, A.; Amigó, V.; Candel, J.J. Crack free tungsten carbide reinforced Ni(Cr) layers obtained by laser cladding. Phys. Procedia 2011, 12, 338–344. [Google Scholar] [CrossRef]

- Candel, J.J.; Amigó, V.; Ramos, J.A.; Busquets, D. Sliding wear resistance of TiCp reinforced titanium composite coating produced by laser cladding. Surf. Coat. Technol. 2010, 204, 3161–3166. [Google Scholar] [CrossRef]

- Leunda, J.; Soriano, C.; Sanz, C.; Navas, V.G. Laser cladding of canadium-carbide tool steels for die repair. Phys. Procedia 2011, 12, 345–352. [Google Scholar] [CrossRef]

- Al-Aqeeli, N.; Saheb, N.; Laoui, T.; Mohammad, K. The synthesis of nanostructured wc-based hardmetals using mechanical alloying and their direct consolidation. J. Nanomater. 2014, 2014, 1–16. [Google Scholar] [CrossRef]

- Enayati, M.H.; Aryanpour, G.R.; Ebnonnasir, A. Production of nanostructured WC–Co powder by ball milling. Int. J. Refract. Met. Hard Mater. 2009, 27, 159–163. [Google Scholar] [CrossRef]

- Oskolkova, T.N.; Budovskikh, E.A. Hardening of the surface of carbide-tungsten carbide by electric explosive treatment. Metallurgy 2011, 1, 88–92. [Google Scholar]

- Goncharov, V.L. Physical and Chemical Foundations of Low-Temperature Deposition of Tungsten Carbides and Their Compositions from Volatile Fluorides at Reduced Pressures: The Dissertation: 02.00.04; 11 FORMAT: Moscow, Russia, 2010; 147p. [Google Scholar]

| Parameter | Value |

|---|---|

| Total particles investigated | 216,452 pc |

| Granulometry | 0.5–5 μm |

| Average particle size | 0.8 μm |

| Form | irregular |

| Chemical composition | 94% WC, 6% Co (trace Si, Cu, Ni, Fe, C, O) |

| Structure | cast material |

| Product Material | 94 wt% WC + 6 wt% Co | BK6 | BK20 |

|---|---|---|---|

| Wear rate × 10−13 (m3/m∙N) | 8.4 | 11 | 43 |

| Hardness (HV) | 2500 | 1550 | 1050 |

| Fracture toughness coefficient (MPa∙m1/2) | 6.9 | 8.9 | 10.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.; Tarasova, T.; Gusarov, A.; Khmyrov, R.; Egorov, S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials 2019, 12, 3425. https://doi.org/10.3390/ma12203425

Grigoriev S, Tarasova T, Gusarov A, Khmyrov R, Egorov S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials. 2019; 12(20):3425. https://doi.org/10.3390/ma12203425

Chicago/Turabian StyleGrigoriev, Sergei, Tatiana Tarasova, Andrey Gusarov, Roman Khmyrov, and Sergei Egorov. 2019. "Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods" Materials 12, no. 20: 3425. https://doi.org/10.3390/ma12203425

APA StyleGrigoriev, S., Tarasova, T., Gusarov, A., Khmyrov, R., & Egorov, S. (2019). Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials, 12(20), 3425. https://doi.org/10.3390/ma12203425