Optically Transparent Metamaterial Absorber Using Inkjet Printing Technology

Abstract

1. Introduction

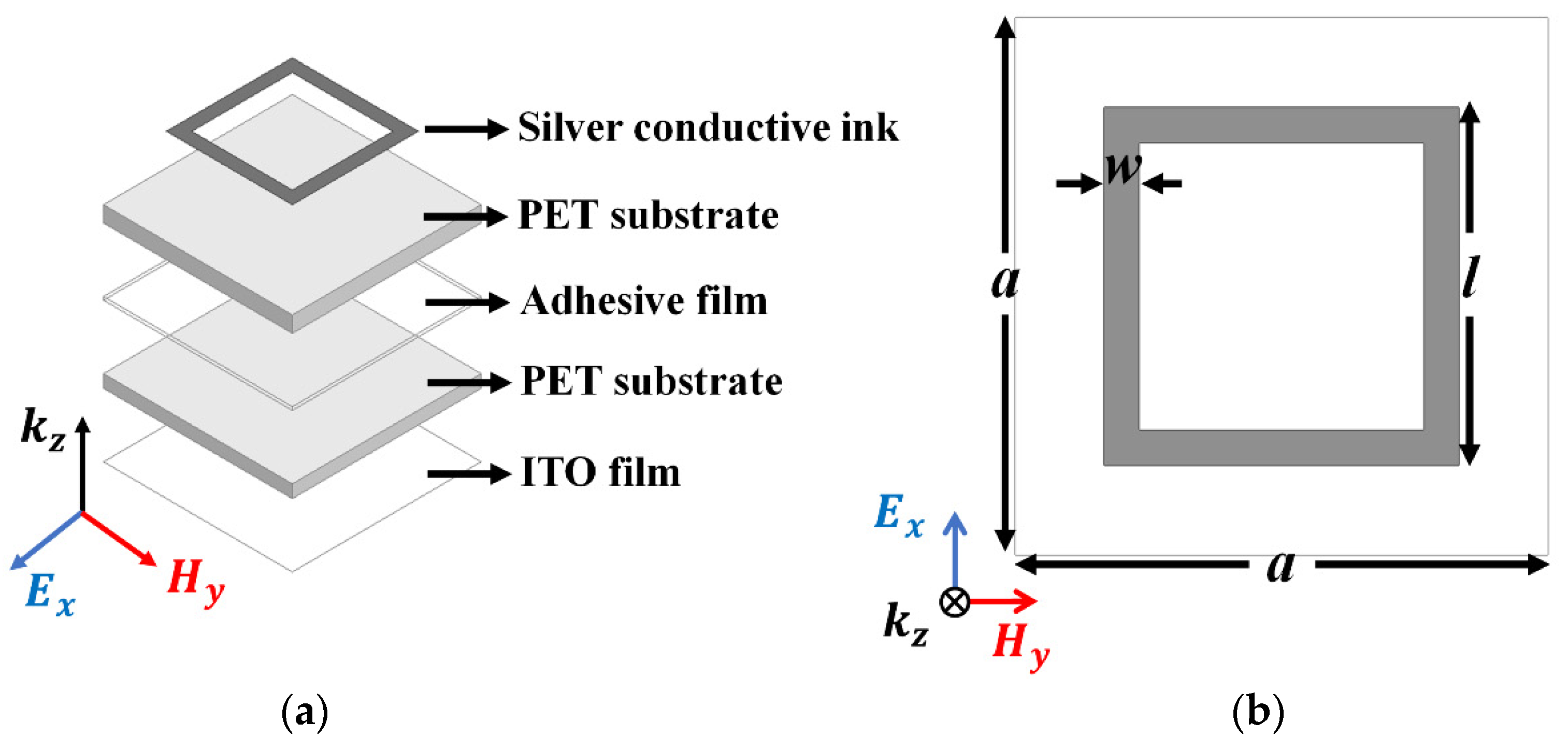

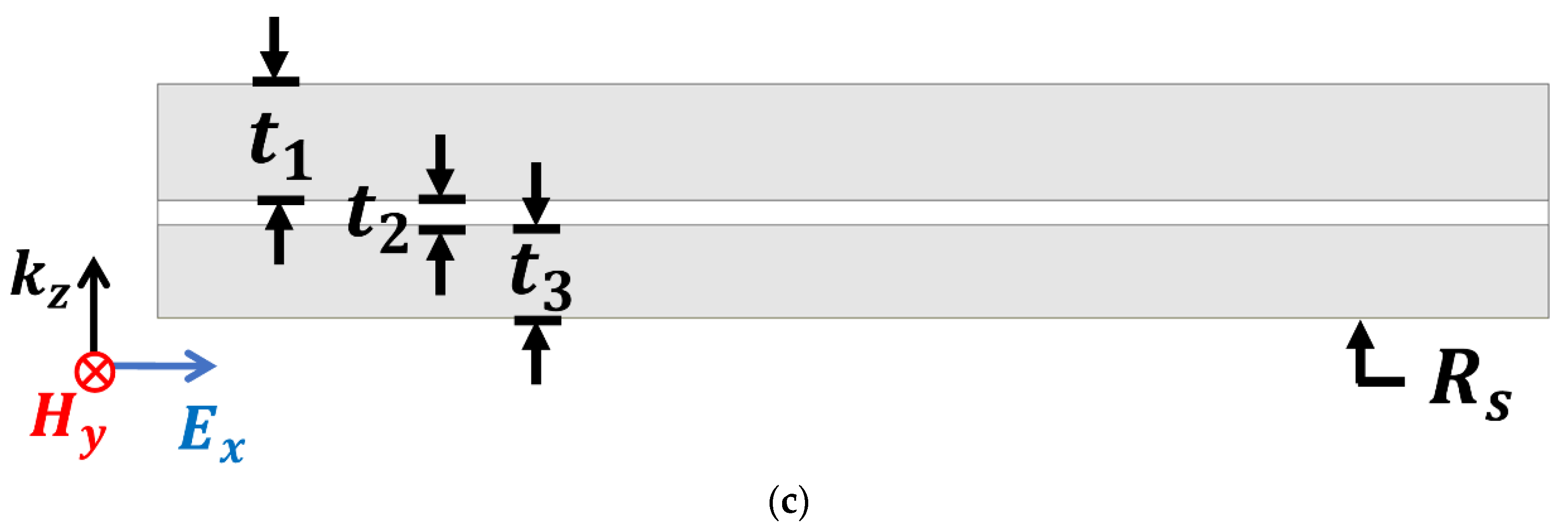

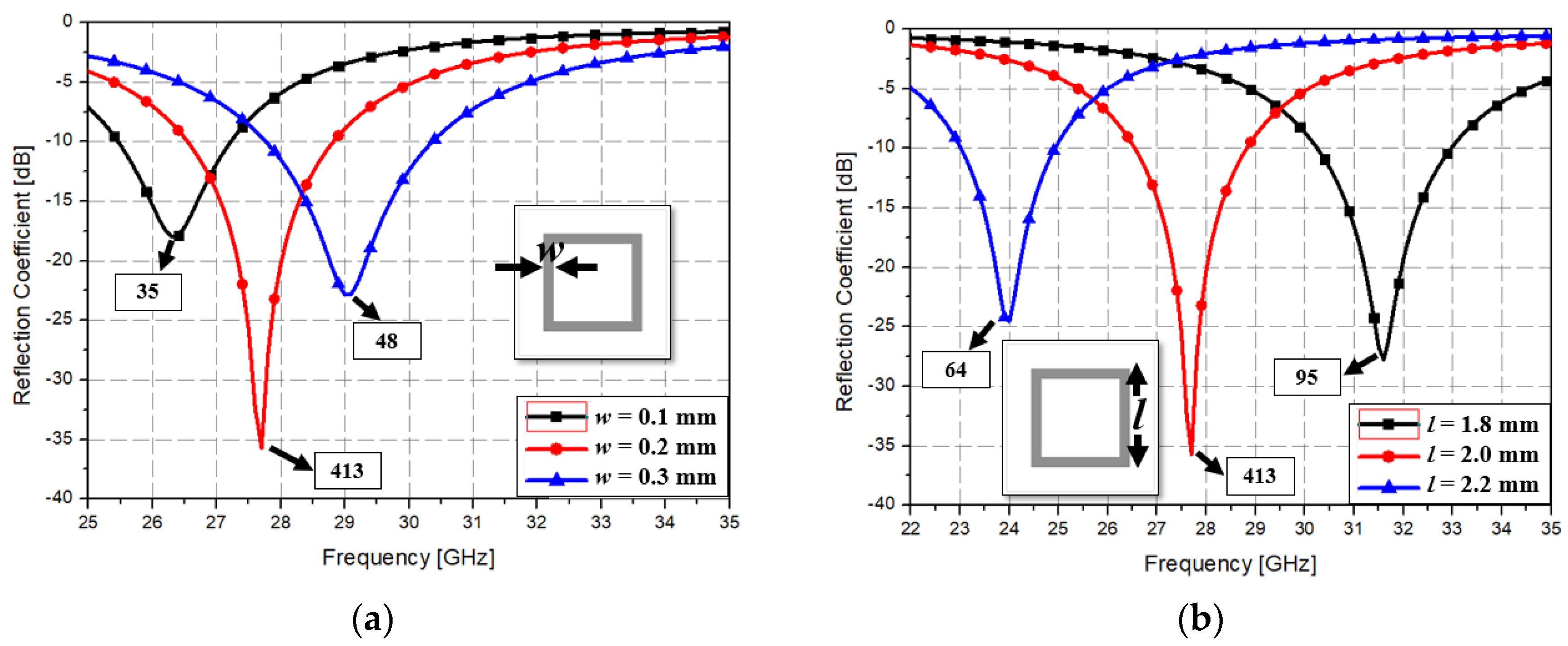

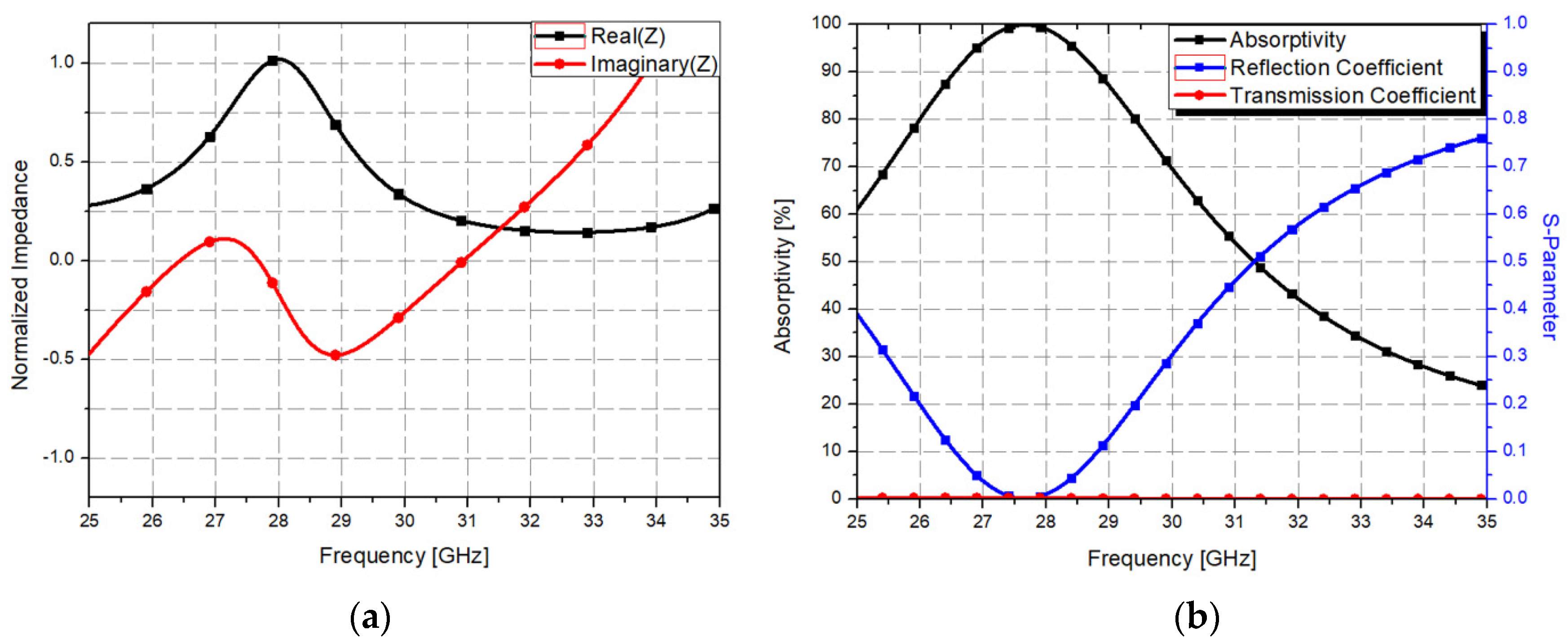

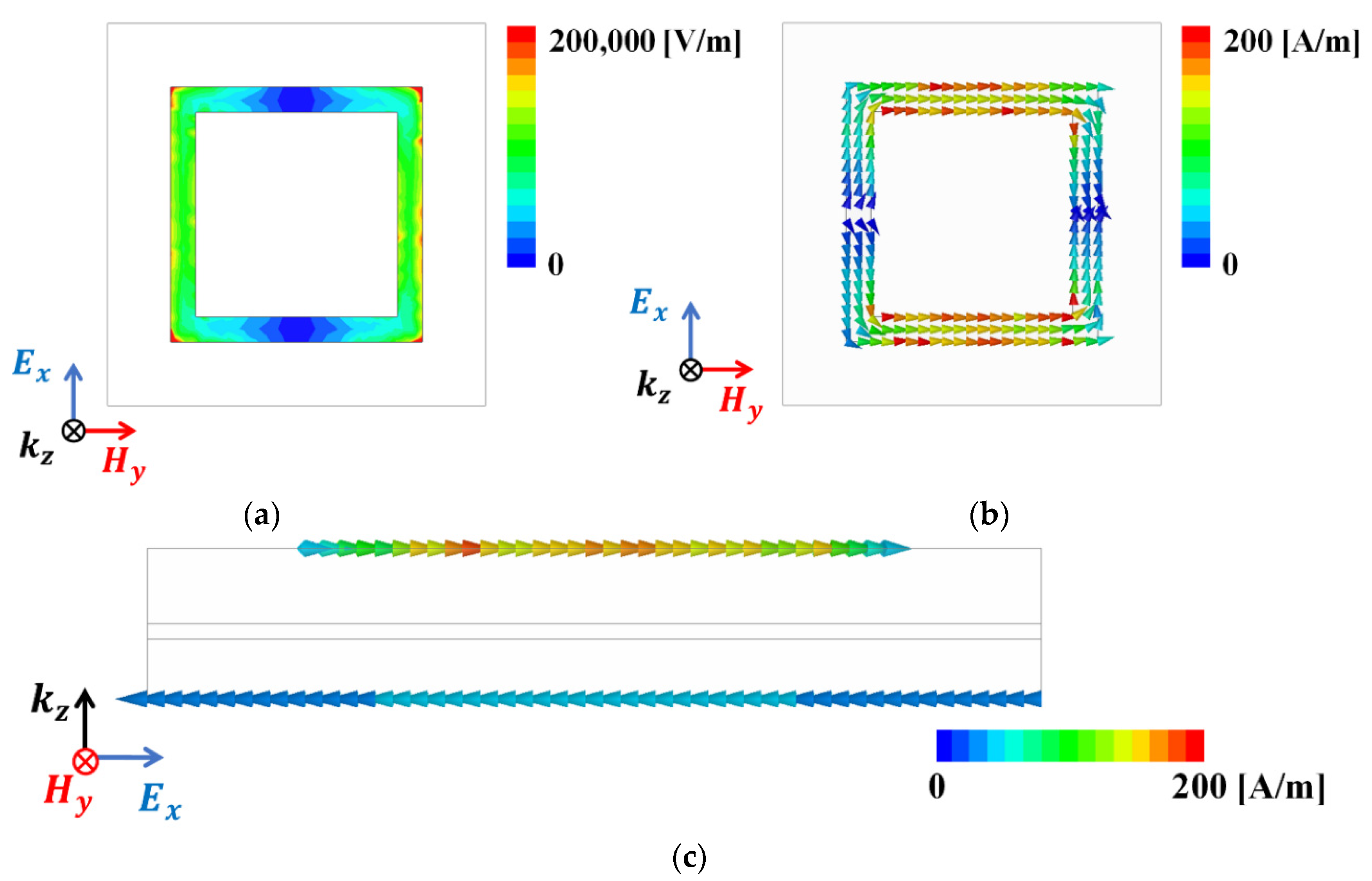

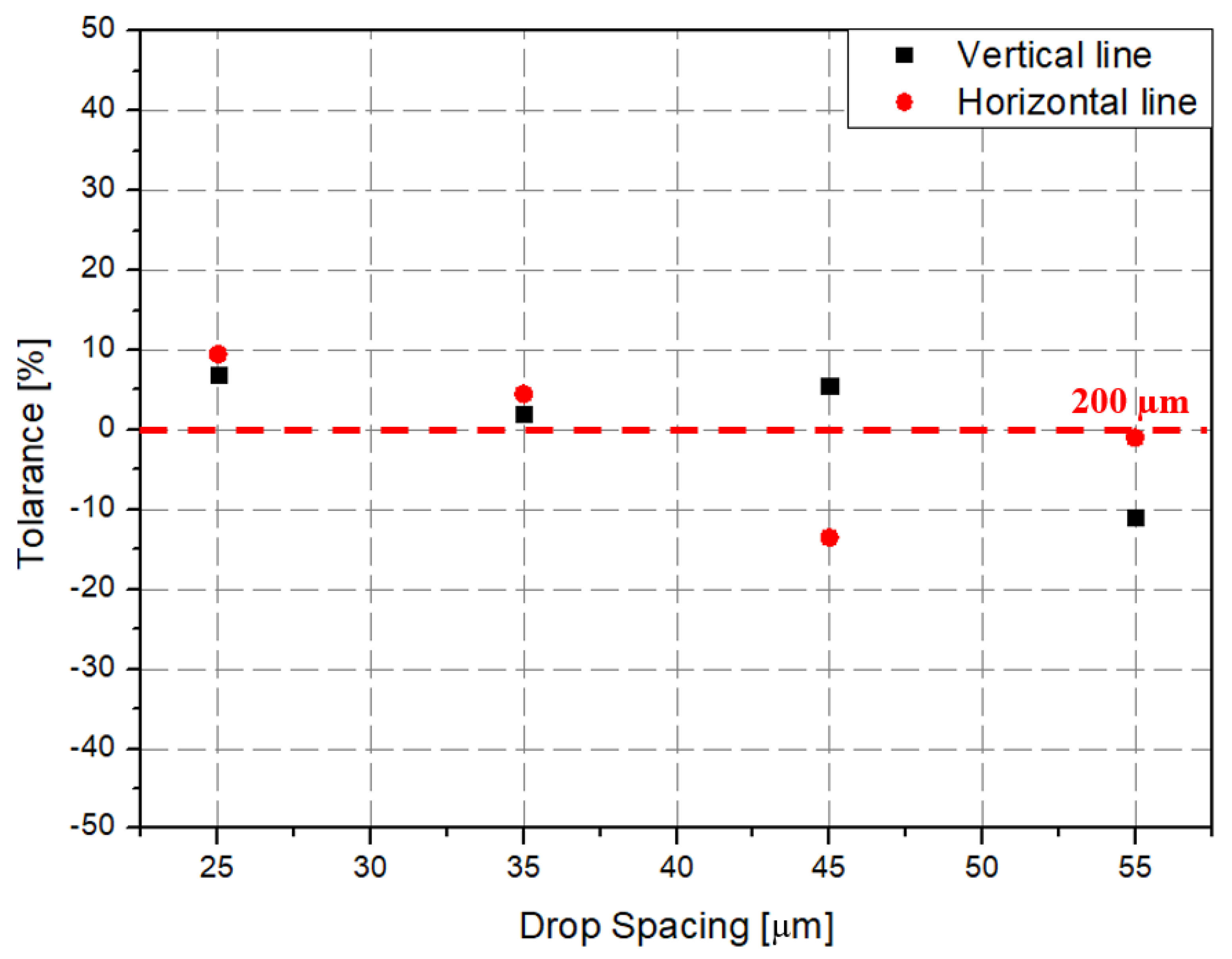

2. Numerical Simulations

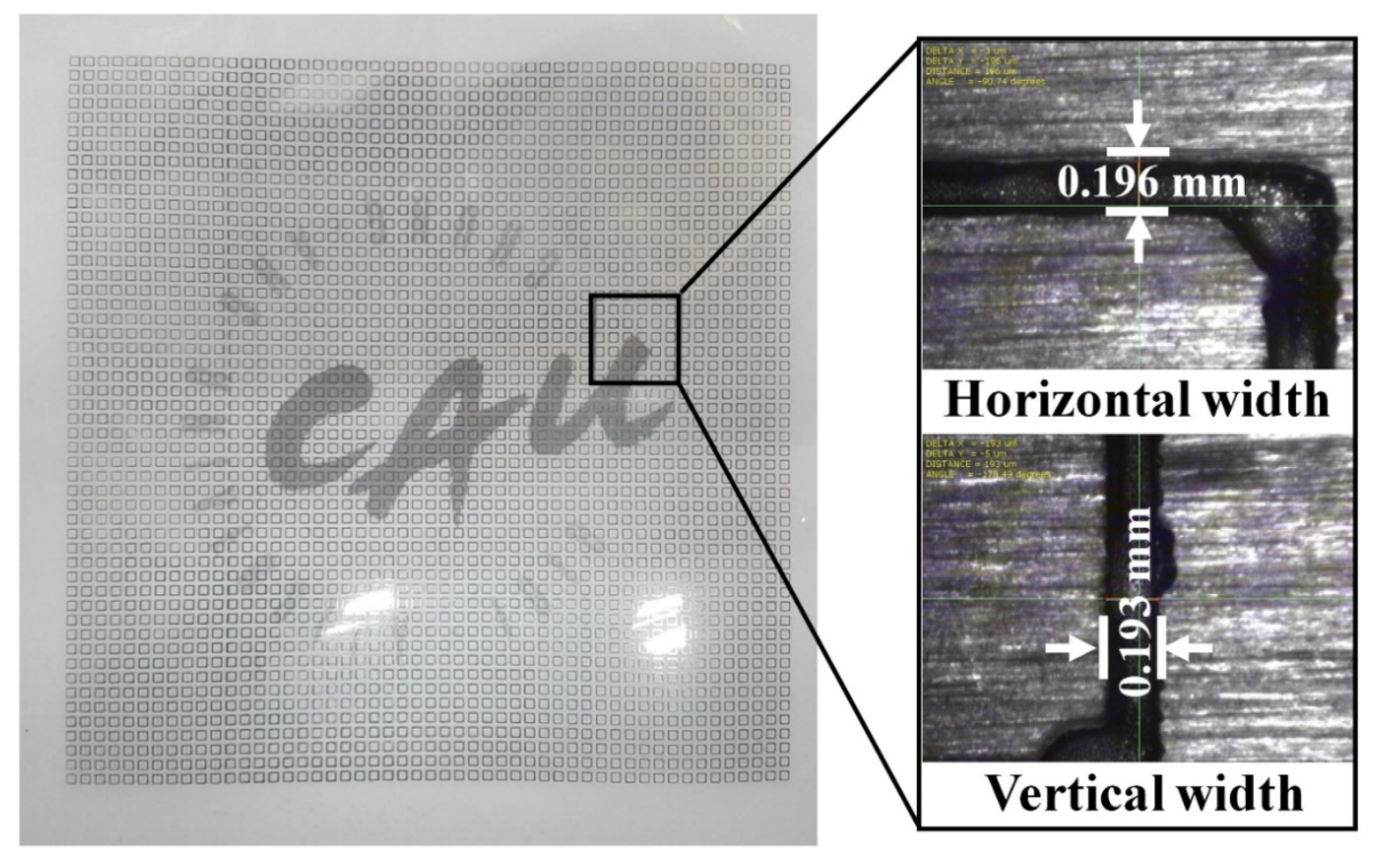

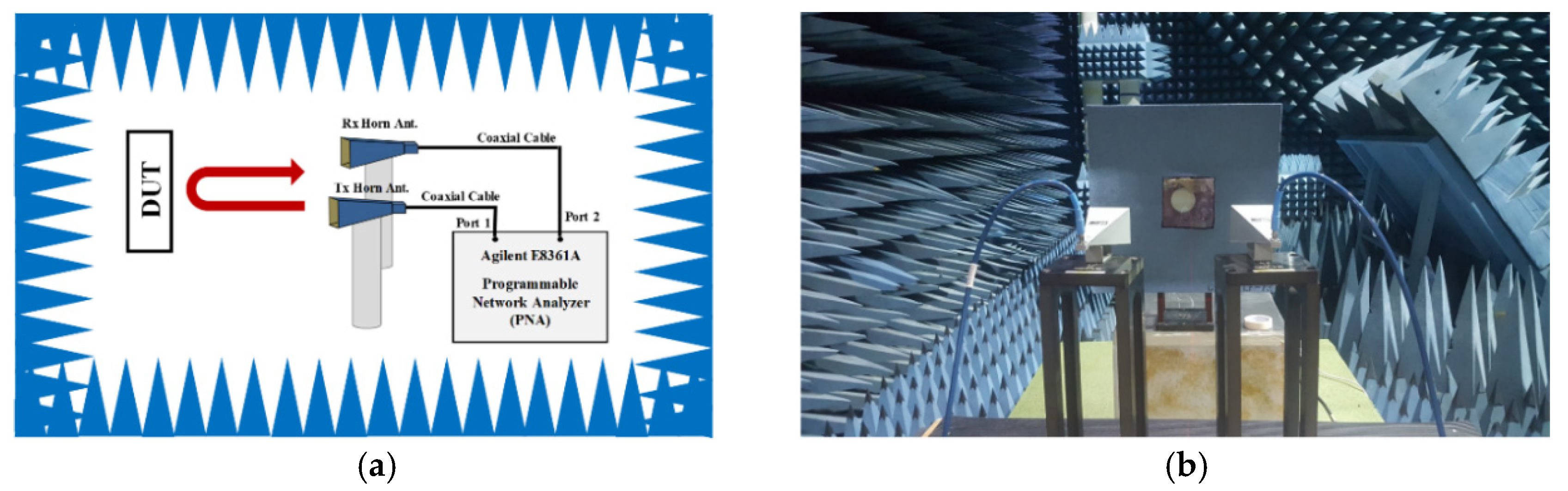

3. Experimental Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Watts, C.M.; Liu, X.; Padilla, W.J. Metamaterial electromagnetic wave absorbers. Adv. Mater. 2012, 24, 98–120. [Google Scholar] [CrossRef] [PubMed]

- Phon, R.; Ghosh, S.; Lim, S. Novel Multifunctional Reconfigurable Active Frequency Selective Surface. IEEE Trans. Antennas Propag. 2019, 67, 1709–1718. [Google Scholar] [CrossRef]

- Ghosh, S.; Lim, S. Fluidically Switchable Metasurface for Wide Spectrum Absorption. Sci. Rep. 2018, 8, 10169. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Grzegorczyk, T.M.; Wu, B.I.; Pacheco, J.; Kong, J.A. Robust method to retrieve the constitutive effective parameters of metamaterials. Phys. Rev. E 2004, 70, 016608. [Google Scholar] [CrossRef] [PubMed]

- Aydin, K.; Bulu, I.; Ozbay, E. Subwavelength resolution with a negative-index metamaterial superlens. Appl. Phys. Lett. 2007, 90, 254102. [Google Scholar] [CrossRef]

- Ju, L.; Geng, B.; Horng, J.; Girit, C.; Martin, M.; Hao, Z.; Bechtel, H.A.; Liang, X.; Zettl, A.; Shen, Y.R.; et al. Graphene plasmonics for tunable terahertz metamaterials. Nat. Nanotechnol. 2011, 6, 630–634. [Google Scholar] [CrossRef]

- Grady, N.K.; Heyes, J.E.; Chowdhury, D.R.; Zeng, Y.; Reiten, M.T.; Azad, A.K.; Taylor, A.J.; Dalvit, D.A.; Chen, H.T. Terahertz metamaterials for linear polarization conversion and anomalous refraction. Science 2013, 340, 1304–1307. [Google Scholar] [CrossRef]

- Ta, S.X.; Park, I. Dual-band low-profile crossed asymmetric dipole antenna on dual-band AMC surface. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 587–590. [Google Scholar]

- Kim, D.; Yeo, J. Low-profile RFID tag antenna using compact AMC substrate for metallic objects. IEEE Antennas Wirel. Propag. Lett. 2008, 7, 718–720. [Google Scholar]

- Vallecchi, A.; De Luis, J.R.; Capolino, F.; De Flaviis, F. Low profile fully planar folded dipole antenna on a high impedance surface. IEEE Trans. Antennas Propag. 2012, 60, 51–62. [Google Scholar] [CrossRef]

- Cure, D.; Weller, T.M.; Miranda, F.A. Study of a low-profile 2.4-ghz planar dipole antenna using a high-impedance surface with 1-D varactor tuning. IEEE Trans. Antennas Propag. 2013, 61, 506–515. [Google Scholar] [CrossRef]

- Melik, R.; Unal, E.; Kosku Perkgoz, N.; Puttlitz, C.; Demir, H.V. Flexible metamaterials for wireless strain sensing. Appl. Phys. Lett. 2009, 95, 181105. [Google Scholar] [CrossRef]

- Melik, R.; Unal, E.; Perkgoz, N.K.; Puttlitz, C.; Demir, H.V.; Melik, R.; Unal, E.; Perkgoz, N.K.; Puttlitz, C. Metamaterial-based wireless strain sensors Metamaterial-based wireless strain sensors. Appl. Phys. Express 2009, 95, 011106. [Google Scholar]

- Salim, A.; Lim, S. Complementary split-ring resonator-loaded microfluidic ethanol chemical sensor. Sensors 2016, 16, 1802. [Google Scholar] [CrossRef] [PubMed]

- Sadeqi, A.; Sonkusale, S. Low-cost metamaterial-on-paper chemical sensor. Opt. Express 2017, 25, 1437–1440. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Lee, J.H.; Jung, H.I. A symmetric metamaterial element-based RF biosensor for rapid and label-free detection. Appl. Phys. Lett. 2011, 99, 163703. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, X.; Fan, Z.; Lv, X.; Chen, H. A Route to Terahertz Metamaterial Biosensor Integrated with Microfluidics for Liver Cancer Biomarker Testing in Early Stage. Sci. Rep. 2017, 7, 16378. [Google Scholar] [CrossRef]

- Cai, W.; Chettiar, U.K.; Kildishev, A.V.; Shalaev, V.M. Optical cloaking with metamaterials. Nat. Photonics 2007, 1, 224–227. [Google Scholar] [CrossRef]

- Islam, S.S.; Faruque, M.R.I.; Islam, M.T. A near zero refractive index metamaterial for electromagnetic invisibility cloaking operation. Materials 2015, 8, 4790–4804. [Google Scholar] [CrossRef]

- Watts, C.M.; Shrekenhamer, D.; Montoya, J.; Lipworth, G.; Hunt, J.; Sleasman, T.; Krishna, S.; Smith, D.R.; Padilla, W.J. Terahertz compressive imaging with metamaterial spatial light modulators. Nat. Photonics 2014, 8, 605–609. [Google Scholar] [CrossRef]

- Hunt, J.; Driscoll, T.; Mrozack, A.; Lipworth, G.; Reynolds, M.; Brady, D.; Smith, D.R. Metamaterial apertures for computational imaging. Science 2013, 339, 310–313. [Google Scholar] [CrossRef] [PubMed]

- Ziolkowski, R.W.; Erentok, A. Metamaterial-based efficient electrically small antennas. IEEE Trans. Antennas Propag. 2006, 54, 2113–2130. [Google Scholar] [CrossRef]

- Nelaturi, S.; Sarma, N.V.S.N. A compact microstrip patch antenna based on metamaterials for Wi-Fi and WiMAX applications. J. Electromagn. Eng. Sci. 2018, 18, 182–187. [Google Scholar] [CrossRef]

- Dong, Y.; Toyao, H.; Itoh, T. Compact circularly-polarized patch antenna loaded with metamaterial structures. IEEE Trans. Antennas Propag. 2011, 59, 4329–4333. [Google Scholar] [CrossRef]

- Gil, M.; Bonache, J.; Selga, J.; García-García, J.; Martín, F. Broadband resonant-type metamaterial transmission lines. IEEE Microw. Wirel. Compon. Lett. 2007, 17, 97–99. [Google Scholar] [CrossRef]

- Liu, R.; Yang, X.M.; Gollub, J.G.; Mock, J.J.; Cui, T.J.; Smith, D.R. Gradient index circuit by waveguided metamaterials. Appl. Phys. Lett. 2009, 94, 92–95. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, J.H. Resonance frequency and bandwidth of the negative/positive nth mode of a composite right-/left-handed transmission line. J. Electromagn. Eng. Sci. 2018, 18, 1–6. [Google Scholar] [CrossRef]

- Holloway, C.L.; Kuester, E.F. A Low-Frequency Model for Wedge or Pyramid Absorber Arrays-11: Computed and Measured Results. IEEE Trans. Electromagn. Compat. 1994, 36, 307–313. [Google Scholar] [CrossRef]

- Head, J.W. The design of gradual transition (wedge) absorbers for a free-field room. Br. J. Appl. Phys. 1965, 16, 1009–1014. [Google Scholar] [CrossRef]

- Ha, J.; Shin, W.; Lee, J.H.; Kim, Y.; Kim, D.; Lee, Y.; Yook, J.-G. Effect of Plasma Area on Frequency of Monostatic Radar Cross Section Reduction. J. Electromagn. Eng. Sci. 2017, 17, 153–158. [Google Scholar] [CrossRef]

- Du Toit, L.J. The design of Jauman absorbers. IEEE Antennas Propag. Mag. 1994, 36, 17–25. [Google Scholar] [CrossRef]

- Jeong, H.; Lim, S. Broadband frequency-reconfigurable metamaterial absorber using switchable ground plane. Sci. Rep. 2018, 8, 9226. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Guler, U.; Kinsey, N.; Naik, G.V.; Boltasseva, A.; Guan, J.; Shalaev, V.M.; Kildishev, A.V. Refractory plasmonics with titanium nitride: Broadband. Adv. Mater. 2014, 26, 7959–7965. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.; Nguyen, T.T.; Lim, S. Subwavelength Metamaterial Unit Cell for Low-Frequency Electromagnetic Absorber Applications. Sci. Rep. 2018, 8, 16774. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.; Nguyen, T.T.; Lim, S. Meta-Dome for Broadband Radar Absorbing Structure. Sci. Rep. 2018, 8, 17893. [Google Scholar] [CrossRef] [PubMed]

- Schurig, D.; Mock, J.J.; Justice, B.J.; Cummer, S.A.; Pendry, J.B.; Starr, A.F.; Smith, D.R. Metamaterial Electromagnetic Cloak at Microwave Frequencies. Science 2006, 314, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Shahparnia, S.; Member, S.; Ramahi, O.M.; Member, S. Electromagnetic Interference (EMI) Reduction From Printed Circuit Boards (PCB) Using Electromagnetic Bandgap Structures. IEEE Trans. Electromagn. Compat. 2004, 46, 580–587. [Google Scholar] [CrossRef]

- Munaga, P.; Ghosh, S.; Bhattacharyya, S.; Chaurasiya, D.; Srivastava, K.V. An Ultra-thin Dual-Band Polarization-Independent Metamaterial Absorber for EMI/EMC Applications. In Proceedings of the 2015 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; Volume 11, pp. 5–8. [Google Scholar]

- Kim, H.K.; Lee, D.; Lim, S. A fluidically tunable metasurface absorber for flexible large-scale wireless ethanol sensor applications. Sensors 2016, 16, 1246. [Google Scholar] [CrossRef]

- Jeong, H.; Lim, S. A Stretchable Electromagnetic Absorber Fabricated Using Screen Printing Technology. Sensors 2017, 17, 1175. [Google Scholar] [CrossRef]

- Hu, M.; Gao, J.; Dong, Y.; Li, K.; Shan, G.; Yang, S.; Li, R.K.Y. Flexible transparent PES/silver nanowires/PET sandwich-structured film for high-efficiency electromagnetic interference shielding. Langmuir 2012, 28, 7101–7106. [Google Scholar] [CrossRef]

- Hautcoeur, J.; Talbi, L.; Hettak, K. Feasibility study of optically transparent CPW-fed monopole antenna at 60-GHz ISM bands. IEEE Trans. Antennas Propag. 2013, 61, 1651–1657. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Y.; Han, L.; Lin, J.; Jin, P. High-performance hierarchical graphene/metal-mesh film for optically transparent electromagnetic interference shielding. Carbon N. Y. 2017, 115, 34–42. [Google Scholar] [CrossRef]

- Singh, G.; Sheokand, H.; Ghosh, S.; Srivastava, K.V.; Ramkumar, J.; Ramakrishna, S.A. Excimer laser micromachining of indium tin oxide for fabrication of optically transparent metamaterial absorbers. Appl. Phys. A Mater. Sci. Process. 2019, 125, 23. [Google Scholar] [CrossRef]

- Sheokand, H.; Singh, G.; Ghosh, S.; Ramkumar, J.; Ramakrishna, S.A.; Srivastava, K.V. An Optically Transparent Broadband Microwave Absorber Using Interdigital Capacitance. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 113–117. [Google Scholar] [CrossRef]

- Sheokand, H.; Ghosh, S.; Singh, G.; Saikia, M.; Srivastava, K.V.; Ramkumar, J.; Ramakrishna, S.A. Transparent broadband metamaterial absorber based on resistive films. J. Appl. Phys. 2017, 122, 105105. [Google Scholar] [CrossRef]

- Zhang, C.; Cheng, Q.; Yang, J.; Zhao, J.; Cui, T.J. Broadband metamaterial for optical transparency and microwave absorption. Appl. Phys. Lett. 2017, 110, 143511. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, J.; Pang, Y.; Wang, J.; Ma, H.; Qu, S. Transparent broadband metamaterial absorber enhanced by water-substrate incorporation. Opt. Express 2018, 26, 15665–15674. [Google Scholar] [CrossRef]

- Pradhan, J.K.; Ramakrishna, S.A.; Rajeswaran, B.; Umarji, A.M.; Achanta, V.G.; Agarwal, A.K.; Ghosh, A. High contrast switchability of VO_2 based metamaterial absorbers with ITO ground plane. Opt. Express 2017, 25, 9116–9121. [Google Scholar] [CrossRef]

- Lai, S.; Wu, Y.; Wang, J.; Wu, W.; Gu, W. Optical-transparent flexible broadband absorbers based on the ITO-PET-ITO structure. Opt. Mater. Express 2018, 8, 1585–1592. [Google Scholar] [CrossRef]

- Yun, T.; Eom, S.; Lim, S. Paper-Based Capacitive Touchpad Using Home Inkjet Printer. J. Disp. Technol. 2016, 12, 1411–1416. [Google Scholar] [CrossRef]

- Salim, A.; Lim, S. Review of recent inkjet-printed capacitive tactile sensors. Sensors 2017, 17, 2593. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Ling, K.; Kim, K.; Lim, S. Flexible inkjet-printed metamaterial absorber for coating a cylindrical object. Opt. Express 2015, 23, 5898–5906. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.K.; Zhou, D.; Luttgen, A.; Sarris, C.D. A Micro Copper Mesh-Based Optically Transparent Triple-Band Frequency Selective Surface. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 202–206. [Google Scholar] [CrossRef]

- Mantash, M.; Kesavan, A.; Denidni, T.A. Highly transparent frequency selective surface based on electrotextiles for millimeter-wave. Electron. Lett. 2019, 0718, 1–3. [Google Scholar]

- Dewani, A.A.; O’Keefe, S.G.; Thiel, D.V.; Galehdar, A. Window RF Shielding Film Using Printed FSS. IEEE Trans. Antennas Propag. 2018, 66, 790–796. [Google Scholar] [CrossRef]

- Ryan, C.G.M.; Eleftheriades, G.V. Single-and dual-band transparent circularly polarized patch antennas with metamaterial loading. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 470–473. [Google Scholar] [CrossRef]

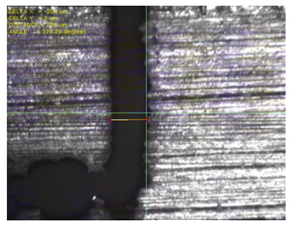

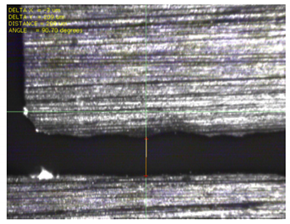

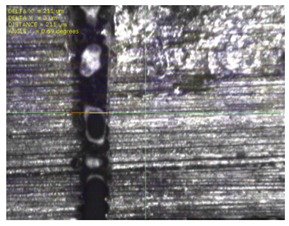

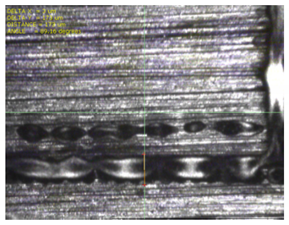

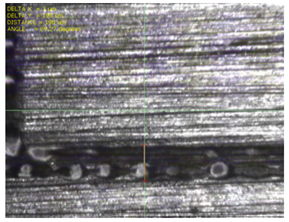

| Drop Spacing | Vertical Line | Horizontal Line |

|---|---|---|

| 15 μm |  (unstable) | |

| 25 μm |  |  |

| 35 μm |  |  |

| 45 μm |  |  |

| 55 μm |  |  |

| Reference | Transparency Method | Frequency Range [GHz] | Cost | Transparency 1 (>90%) |

|---|---|---|---|---|

| [55] | Electro-textile on acryl substrate | 27–35 | Low | No |

| [56] | Metal mesh fabrics using screen printing | 1.5–2.5 | Low | No |

| [57] | Metal mesh fabrics on ceramic substrate | 2.35–2.75 | High | No |

| [54] | Metal mesh fabrics on glass sheet substrate | 2.4, 3.7, 5.7 | Low | No |

| [46] | ITO sheet | 6.06–14.66 | High | Yes |

| Present study | Metal mesh introduced using inkjet printing | 26.8–28.2 | Low | Yes |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.; Tentzeris, M.M.; Lim, S. Optically Transparent Metamaterial Absorber Using Inkjet Printing Technology. Materials 2019, 12, 3406. https://doi.org/10.3390/ma12203406

Jeong H, Tentzeris MM, Lim S. Optically Transparent Metamaterial Absorber Using Inkjet Printing Technology. Materials. 2019; 12(20):3406. https://doi.org/10.3390/ma12203406

Chicago/Turabian StyleJeong, Heijun, Manos M. Tentzeris, and Sungjoon Lim. 2019. "Optically Transparent Metamaterial Absorber Using Inkjet Printing Technology" Materials 12, no. 20: 3406. https://doi.org/10.3390/ma12203406

APA StyleJeong, H., Tentzeris, M. M., & Lim, S. (2019). Optically Transparent Metamaterial Absorber Using Inkjet Printing Technology. Materials, 12(20), 3406. https://doi.org/10.3390/ma12203406