The Effect of Coating Density on Functional Properties of SiNx Coated Implants

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Composition

2.2.2. Surface Roughness

2.2.3. Scratch Resistance over Time in Solution

2.2.4. Wear Resistance

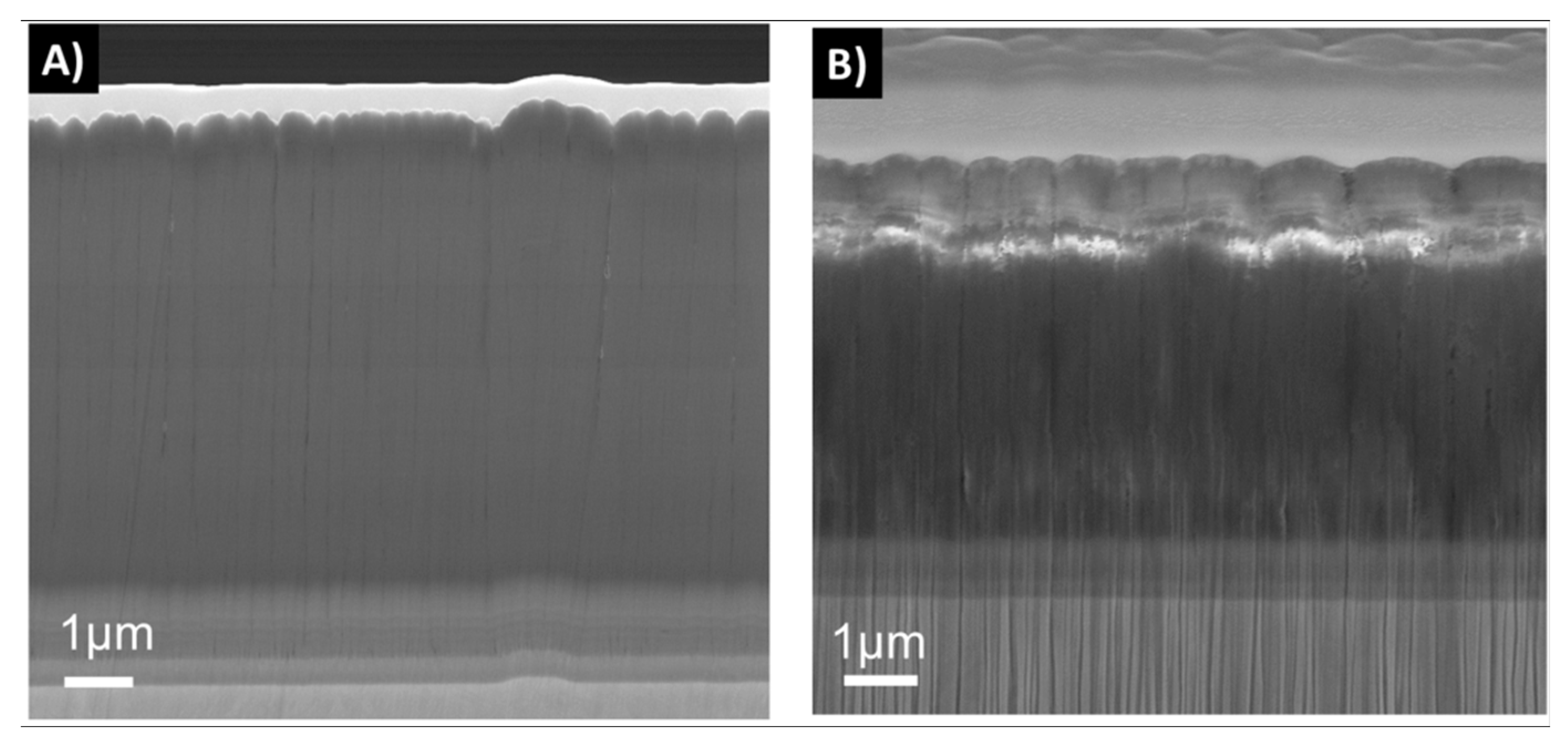

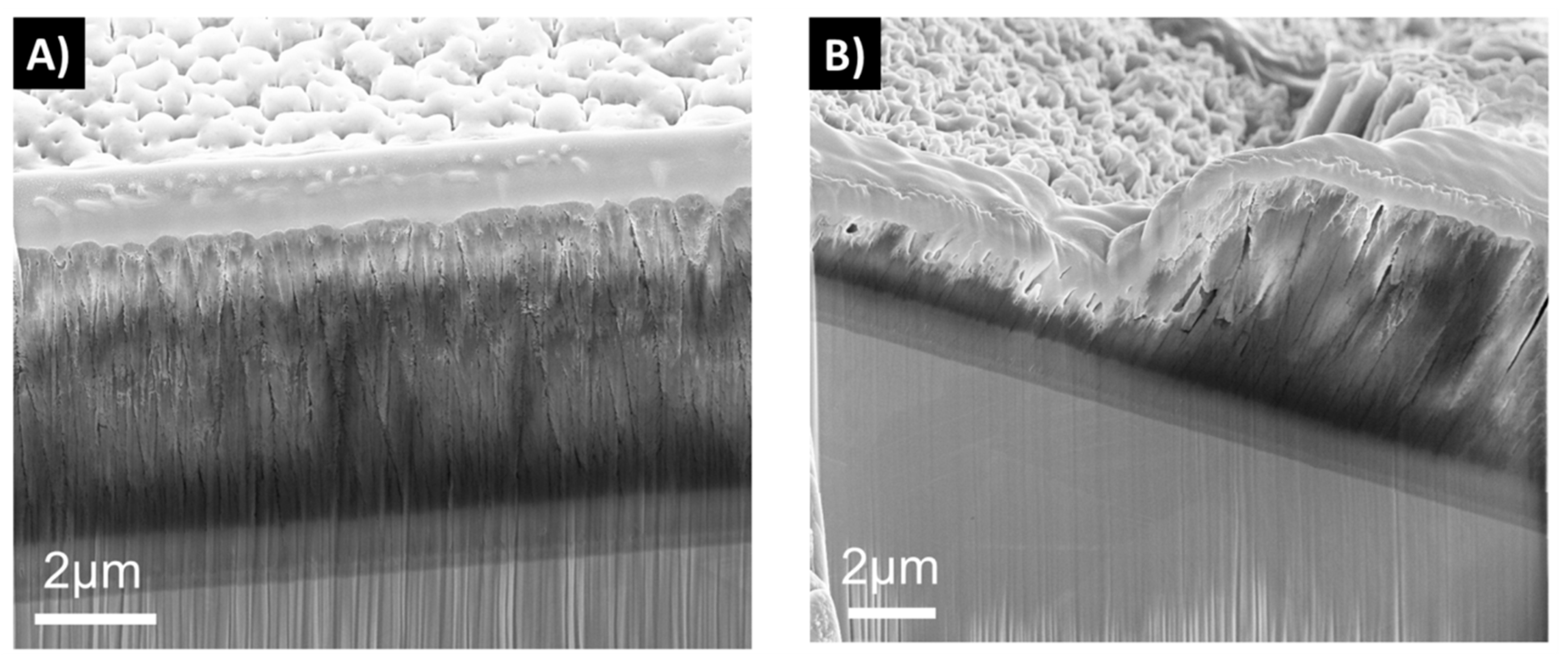

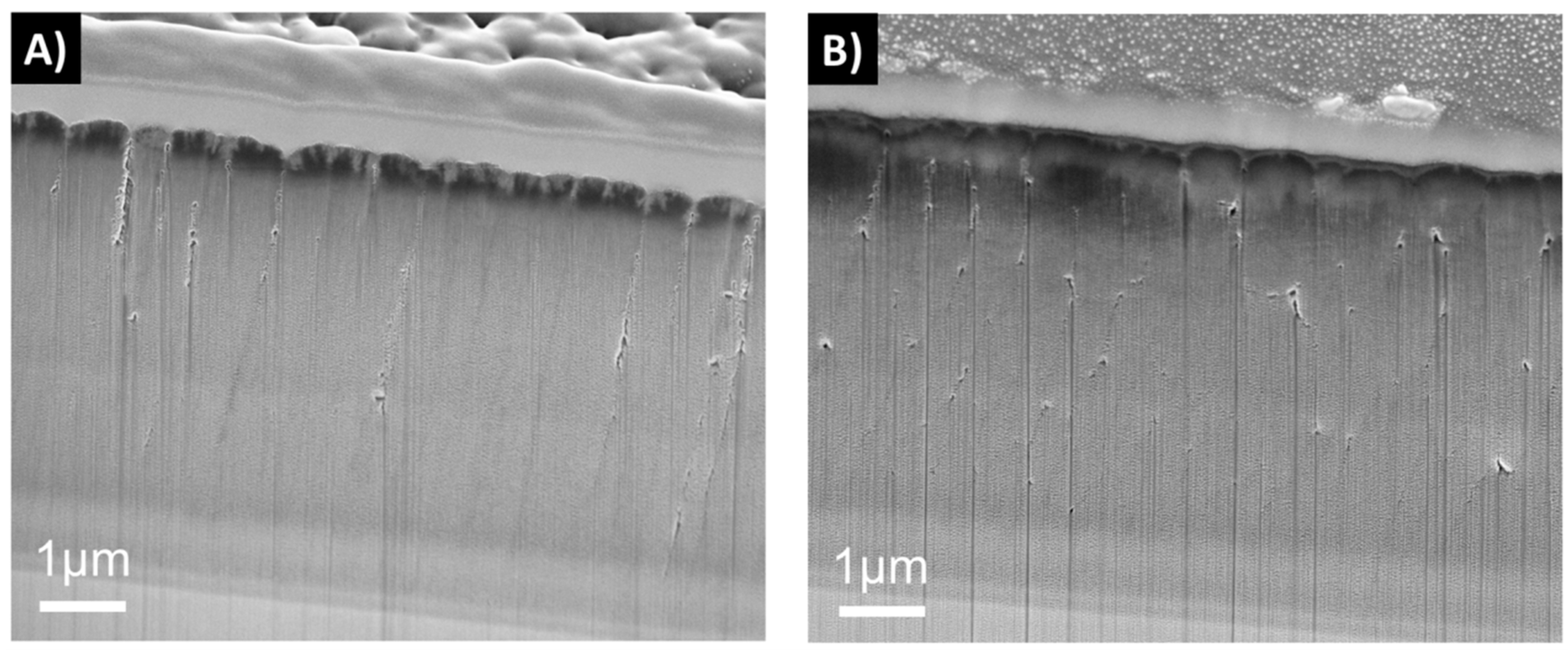

2.2.5. Cross Section Characterization

2.2.6. Statistical Analysis

3. Results

3.1. Composition

3.2. Surface Roughness

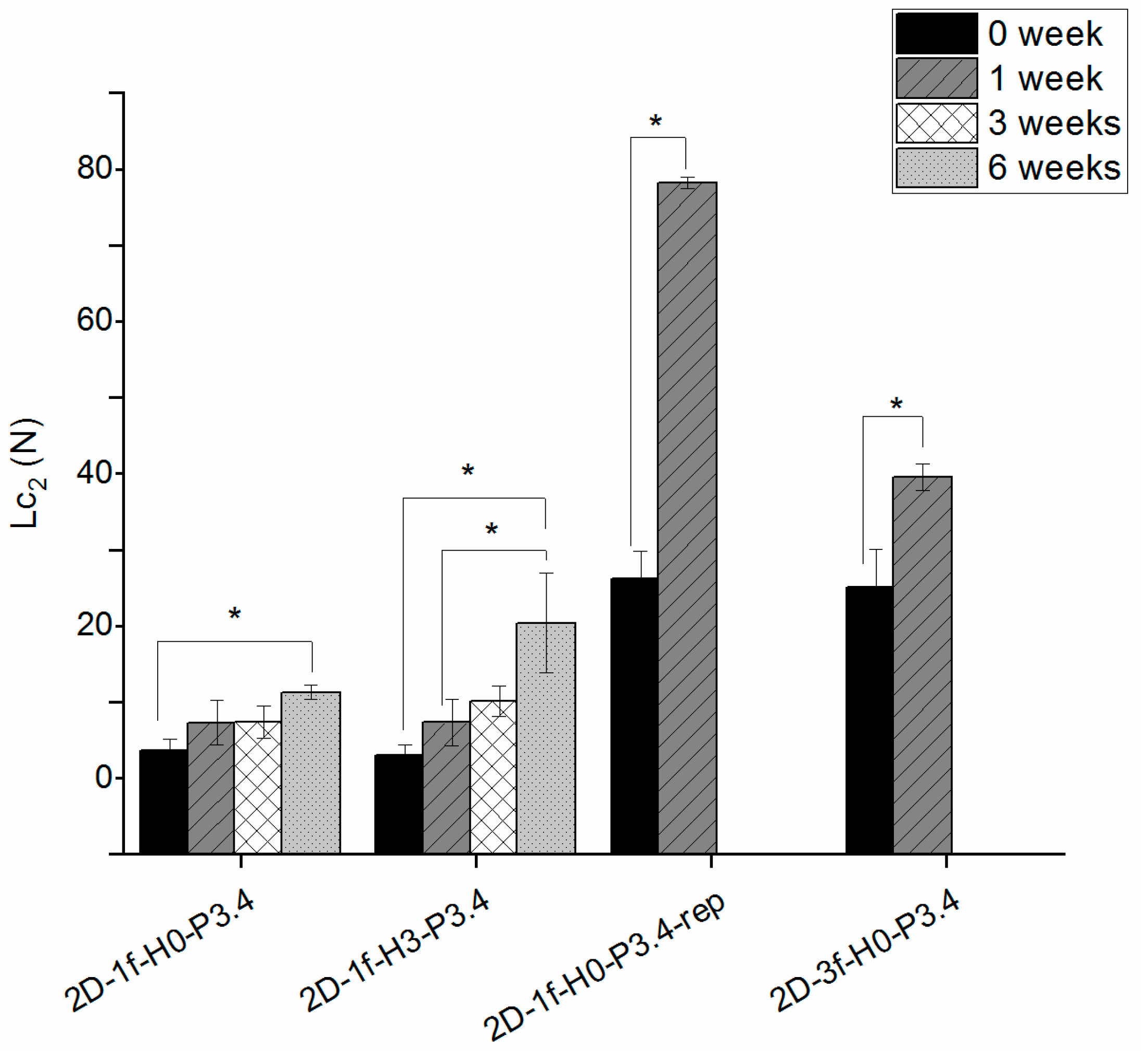

3.3. Scratch Resistance over Time

3.4. Wear Resistance

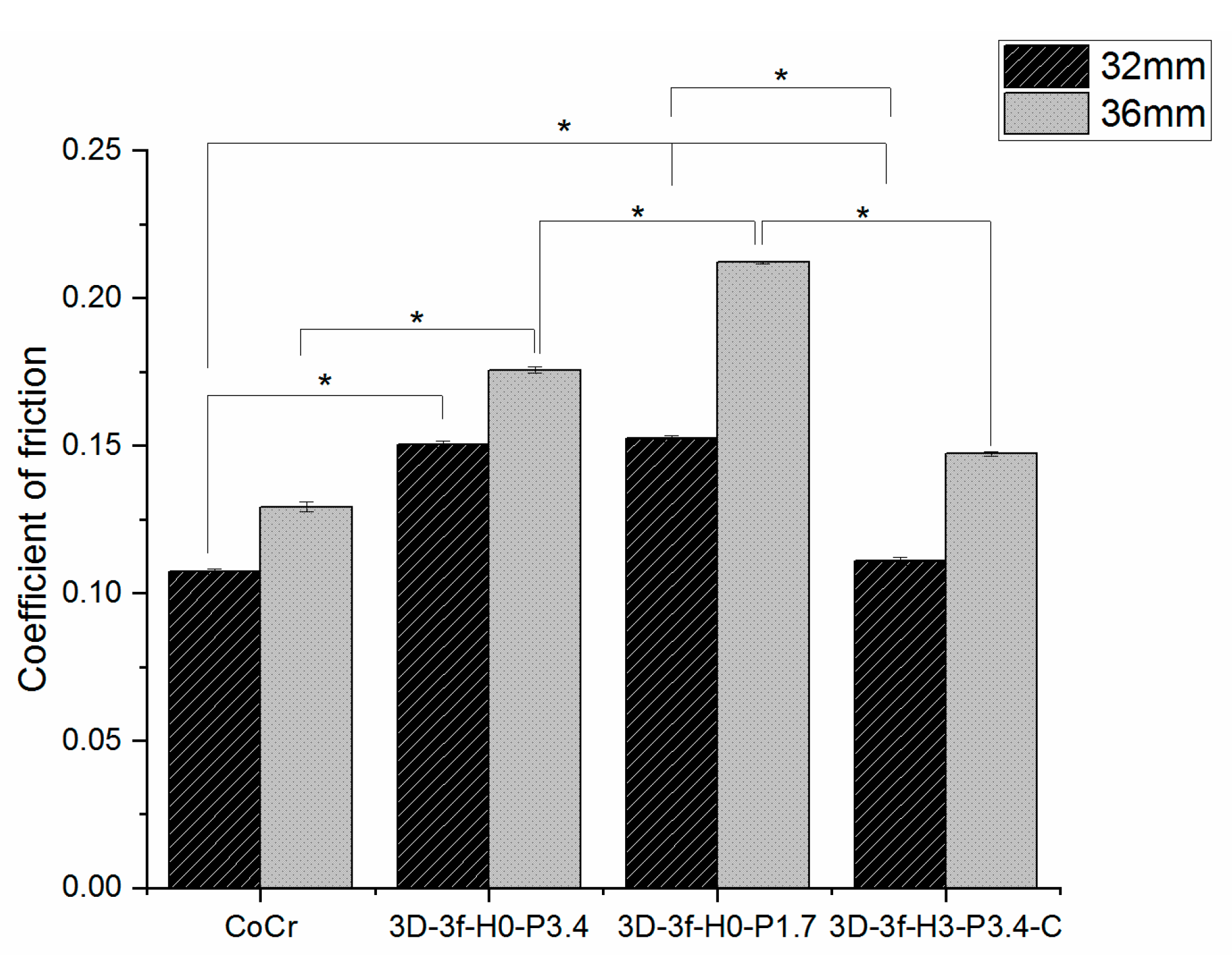

3.4.1. Coefficient of Friction

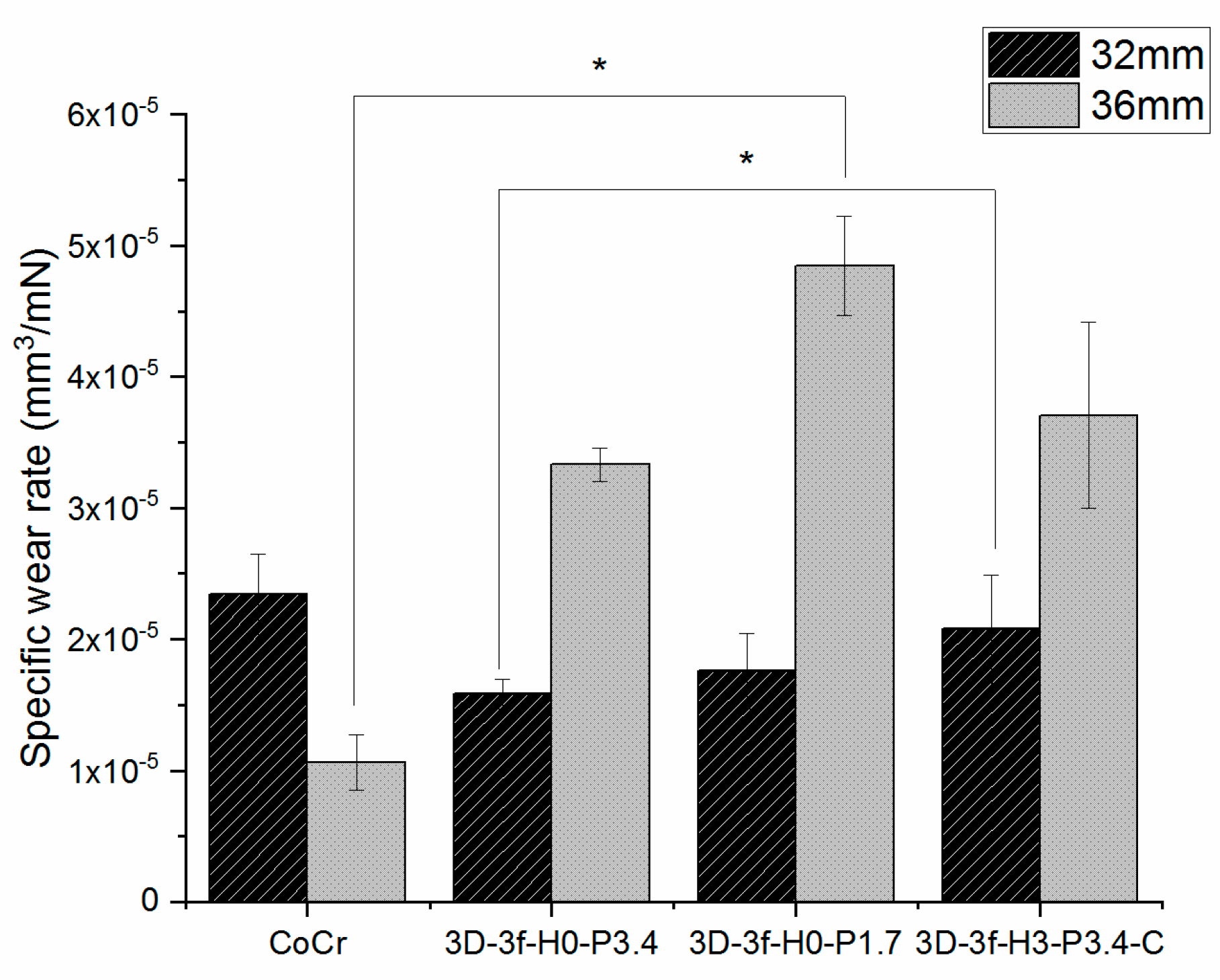

3.4.2. Specific Wear Rate

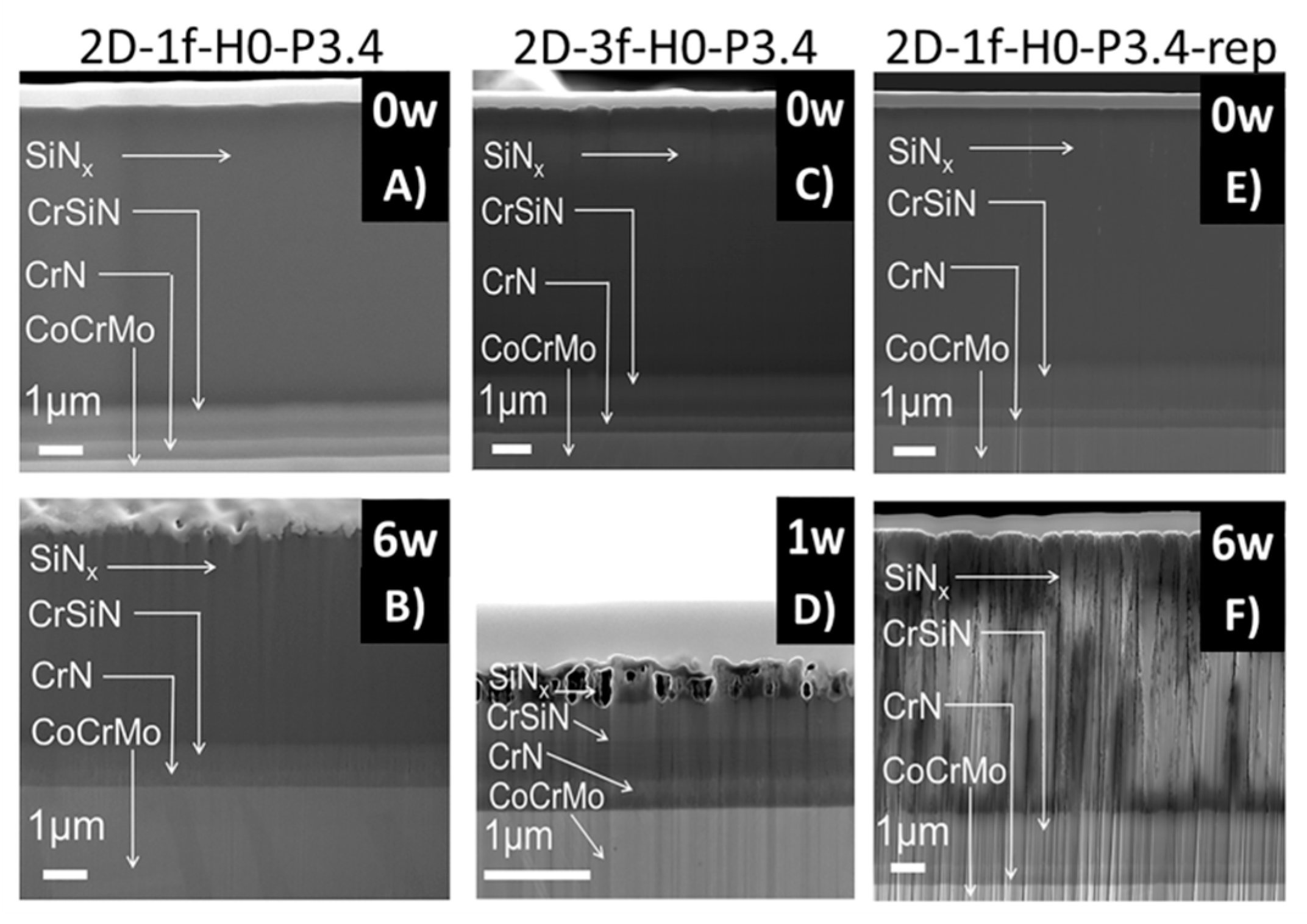

3.5. Cross Sectional Morphology

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bal, B.S.; Garino, J.; Ries, M.; Oonishi, H. Ceramic bearings in total knee arthroplasty. J. Knee Surg. 2007, 20, 261–270. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, S.; Kobayashi, M.; Ito, H.; Nakamura, K.; Ueo, T.; Nakamura, T. The Bi-Surface total knee arthroplasty: minimum 10-year follow-up study. Knee 2010, 17, 274–278. [Google Scholar] [CrossRef] [PubMed]

- Maheshwari, A.V.; Shah, N.V.; Newman, J.M.; Pascal, S.; Sheth, N.P.; Grieco, P.W.; Stroud, S.G. New alternate bearing surfaces in total hip arthroplasty: A review of the current literature. J. Clin. Orthop. Trauma 2017, 9, 7–16. [Google Scholar] [CrossRef]

- Khanna, R.; Kokubo, T.; Matsushita, T.; Nomura, Y.; Nose, N.; Oomori, Y.; Yoshida, T.; Wakita, K.; Takadama, H. Novel artificial hip joint: A layer of alumina on Ti–6Al–4V alloy formed by micro-arc oxidation. Mater. Sci. Eng. C 2015, 55, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.N.; Yao, A.; Bal, B.S.; Garino, J.P.; Ries, M.D. Ceramics for prosthetic hip and knee joint replacement. J. Am. Ceram. Soc. 2007, 90, 1965–1988. [Google Scholar] [CrossRef]

- Sonntag, R.; Reinders, J.; Kretzer, J.P. What’s next? Alternative materials for articulation in total joint replacement. Acta Biomater. 2012, 8, 2434–2441. [Google Scholar] [CrossRef] [PubMed]

- Galvin, A.L.; Williams, S.; Hatto, P.; Thompson, J.; Isaac, G.; Stone, M.; Ingham, E.; Fisher, J. Comparison of wear of ultra high molecular weight polyethylene acetabular cups against alumina ceramic and chromium nitride coated femoral heads. Wear 2005, 259, 972–976. [Google Scholar] [CrossRef]

- Leslie, I.J.; Williams, S.; Brown, C.; Anderson, J.; Isaac, G.; Hatto, P.; Ingham, E.; Fisher, J. Surface engineering: A low wearing solution for metal-on-metal hip surface replacements. J. Biomed. Mater. Res.-Part B Appl. Biomater. 2009, 90, 558–565. [Google Scholar] [CrossRef]

- Williams, S.; Tipper, J.L.; Ingham, E.; Stone, M.H.; Fisher, J. In vitro analysis of the wear, wear debris and biological activity of surface-engineered coatings for use in metal-on-metal total hip replacements. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2003, 217, 155–163. [Google Scholar] [CrossRef]

- Fisher, J.; Hu, X.Q.; Tipper, J.L.; Stewart, T.D.; Williams, S.; Stone, M.H.; Davies, C.; Hatto, P.; Bolton, J.; Riley, M.; et al. An in vitro study of the reduction in wear of metal-on-metal hip prostheses using surface-engineered femoral heads. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2002, 216, 219–230. [Google Scholar] [CrossRef]

- Piconi, C.; De Santis, V.; Maccauro, G. Clinical outcomes of ceramicized ball heads in total hip replacement bearings: a literature review. J. Appl. Biomater. Funct. Mater. 2017, 15, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Khanna, R.; Kokubo, T.; Matsushita, T.; Takadama, H. Fabrication of dense $α$-alumina layer on Ti-6Al-4V alloy hybrid for bearing surfaces of artificial hip joint. Mater. Sci. Eng. C 2016, 69, 1229–1239. [Google Scholar] [CrossRef] [PubMed]

- van Hove, R.P.; Sierevelt, I.N.; van Royen, B.J.; Nolte, P.A. Titanium-nitride coating of orthopaedic implants: a review of the literature. Biomed Res. Int. 2015, 2015. [Google Scholar] [CrossRef] [PubMed]

- Türkan, U.; Öztürk, O.; Eroğlu, A.E. Metal ion release from TiN coated CoCrMo orthopedic implant material. Surf. Coat. Technol. 2006, 200, 5020–5027. [Google Scholar] [CrossRef]

- Skoog, S.A.; Kumar, G.; Zheng, J.; Sumant, A.V.; Goering, P.L.; Narayan, R.J. Biological evaluation of ultrananocrystalline and nanocrystalline diamond coatings. J. Mater. Sci. Mater. Med. 2016, 27, 187. [Google Scholar] [CrossRef]

- Amaral, M.; Dias, A.G.; Gomes, P.S.; Lopes, M.A.; Silva, R.F.; Santos, J.D.; Fernandes, M.H. Nanocrystalline diamond: in vitro biocompatibility assessment by MG63 and human bone marrow cells cultures. J. Biomed. Mater. Res. Part A 2008, 87, 91–99. [Google Scholar] [CrossRef]

- Maru, M.M.; Amaral, M.; Rodrigues, S.P.; Santos, R.; Gouvea, C.P.; Archanjo, B.S.; Trommer, R.M.; Oliveira, F.J.; Silva, R.F.; Achete, C.A. The High performance of nanocrystalline CVD diamond coated hip joints in wear simulator test. J. Mech. Behav. Biomed. Mater. 2015, 49, 175–185. [Google Scholar] [CrossRef]

- Liao, T.T.; Deng, Q.Y.; Wu, B.J.; Li, S.S.; Li, X.; Wu, J.; Leng, Y.X.; Guo, Y.B.; Huang, N. Dose-dependent cytotoxicity evaluation of graphite nanoparticles for diamond-like carbon film application on artificial joints. Biomed. Mater. 2017, 12, 15018. [Google Scholar] [CrossRef]

- Choudhury, D.; Urban, F.; Vrbka, M.; Hartl, M.; Krupka, I. A novel tribological study on DLC-coated micro-dimpled orthopedics implant interface. J. Mech. Behav. Biomed. Mater. 2015, 45, 121–131. [Google Scholar] [CrossRef]

- Choudhury, D.; Lackner, J.M.; Major, L.; Morita, T.; Sawae, Y.; Mamat, A.B.; Stavness, I.; Roy, C.K.; Krupka, I. Improved wear resistance of functional diamond like carbon coated Ti–6Al–4V alloys in an edge loading conditions. J. Mech. Behav. Biomed. Mater. 2016, 59, 586–595. [Google Scholar] [CrossRef]

- Choudhury, D.; Lackner, J.; Fleming, R.A.; Goss, J.; Chen, J.; Zou, M. Diamond-like carbon coatings with zirconium-containing interlayers for orthopedic implants. J. Mech. Behav. Biomed. Mater. 2017, 68, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 014402. [Google Scholar] [CrossRef] [PubMed]

- Kunčická, L.; Kocich, R.; Lowe, T.C. Advances in metals and alloys for joint replacement. Prog. Mater. Sci. 2017, 88, 232–280. [Google Scholar] [CrossRef]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Guedes e Silva, C.C.; Higa, O.Z.; Bressiani, J.C. Cytotoxic evaluation of silicon nitride-based ceramics. Mater. Sci. Eng. C 2004, 24, 643–646. [Google Scholar] [CrossRef]

- Olofsson, J.; Grehk, T.M.; Berlind, T.; Persson, C.; Jacobson, S.; Engqvist, H. Evaluation of silicon nitride as a wear resistant and resorbable alternative for total hip joint replacement. Biomatter 2012, 2, 94–102. [Google Scholar] [CrossRef]

- Pezzotti, G.; Marin, E.; Adachi, T.; Rondinella, A.; Boschetto, F.; Zhu, W.; Sugano, N.; Bock, R.M.; McEntire, B.; Bal, S.B. Bioactive silicon nitride: A new therapeutic material for osteoarthropathy. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Bal, B.S.; Rahaman, M.N. Orthopedic applications of silicon nitride ceramics. Acta Biomater. 2012, 8, 2889–2898. [Google Scholar] [CrossRef]

- Bock, R.M.; McEntire, B.J.; Bal, B.S.; Rahaman, M.N.; Boffelli, M.; Pezzotti, G. Surface modulation of silicon nitride ceramics for orthopaedic applications. Acta Biomater. 2015, 26, 318–330. [Google Scholar] [CrossRef]

- Das, M.; Bhimani, K.; Balla, V.K. In vitro tribological and biocompatibility evaluation of sintered silicon nitride. Mater. Lett. 2018, 212, 130–133. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- McEntire, B.; Bock, R.; Rahaman, M.; Bal, B.S.; Webster, T.; Pezzotti, G. ANTI-INFECTIVE AND OSTEOINTEGRATION CHARACTERISTICS OF SILICON NITRIDE SPINAL FUSION IMPLANTS | Orthopaedic Proceedings. Orthop. Proc. 2016, 98, 32. [Google Scholar]

- Webster, T.J.; Patel, A.A.; Rahaman, M.N.; Bal, B.S. Anti-infective and osteointegration properties of silicon nitride, poly (ether ether ketone), and titanium implants. Acta Biomater. 2012, 8, 4447–4454. [Google Scholar] [CrossRef] [PubMed]

- Reffitt, D.M.; Ogston, N.; Jugdaohsingh, R.; Cheung, H.F.J.; Evans, B.A.J.; Thompson, R.P.H.; Powell, J.J.; Hampson, G.N. Orthosilicic acid stimulates collagen type 1 synthesis and osteoblastic differentiation in human osteoblast-like cells in vitro. Bone 2003, 32, 127–135. [Google Scholar] [CrossRef]

- Mazzocchi, M.; Bellosi, A. On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part I: Processing, microstructure, mechanical properties, cytotoxicity. J. Mater. Sci. Mater. Med. 2008, 19, 2881–2887. [Google Scholar] [CrossRef]

- McEntire, B.; Lakshminarayanan, R.; Ray, D.; Clarke, I.; Puppulin, L.; Pezzotti, G. Silicon Nitride Bearings for Total Joint Arthroplasty. Lubricants 2016, 4, 35. [Google Scholar] [CrossRef]

- Mazzocchi, M.; Bellosi, A. On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part II: chemical stability and wear resistance in body environment. J. Mater. Sci. Mater. Med. 2008, 19, 2889. [Google Scholar] [CrossRef]

- Filho, L.; Schmidt, S.; Leifer, K.; Engqvist, H.; Högberg, H.; Persson, C. Towards Functional Silicon Nitride Coatings for Joint Replacements. Coatings 2019, 9, 73. [Google Scholar] [CrossRef]

- ASTM F1537 - 11. Standard Specification for Wrought Cobalt-28chromium-6molybdenum Alloys for Surgical Implants (UNS R31537, UNS R31538, and UNS R31539); ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar] [CrossRef]

- Kärrholm, J.; Mohaddes, M.; Odin, D.; Vinblad, J.; Rogmark, C.; Rolfson, O. Swedish Hip Arthroplasty Register Annual Report 2017; The Swedish Hip Arthroplasty Register: Gothenburg, Sweden, 2017; ISBN 9789188017208. [Google Scholar]

- ASTM F75-18. Standard Specification for Cobalt-28 Chromium-6 Molybdenum Alloy Castings and Casting Alloy for Surgical Implants (UNS R30075); ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Schmidt, S.; Hänninen, T.; Goyenola, C.; Wissting, J.; Jensen, J.; Hultman, L.; Goebbels, N.; Tobler, M.; Högberg, H. SiN x Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering: Process Parameters Influencing the Nitrogen Content. ACS Appl. Mater. Interfaces 2016, 8, 20385–20395. [Google Scholar] [CrossRef]

- ASTM F2025-06. Standard Practice for Gravimetric Measurement of Polymeric Components for Wear Assessment; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- ISO 20502:2005. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Adhesion of Ceramic Coatings by Scratch Testing; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- Fialho, J.C.; Fernandes, P.R.; Eça, L.; Folgado, J. Computational hip joint simulator for wear and heat generation. J. Biomech. 2007, 40, 2358–2366. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- ASTM F2033-12. Standard Specification for Total Hip Joint Prosthesis and Hip Endoprosthesis Bearing Surfaces Made of Metallic, Ceramic, and Polymeric Materials; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Giannuzzi, L.A. Introduction to Focused Ion Beams: Instrumentation, Theory, Techniques and Practice; Springer US: New York, NY, USA, 2004. [Google Scholar]

- Pettersson, M.; Bryant, M.; Schmidt, S.; Engqvist, H.; Hall, R.M.; Neville, A.; Persson, C. Dissolution behaviour of silicon nitride coatings for joint replacements. Mater. Sci. Eng. C 2016, 62, 497–505. [Google Scholar] [CrossRef] [PubMed]

- Dean, J.A. LANGE’S HANDBOOK OF CHEMISTRY. Mater. Manuf. Process. 1990, 5, 687–688. [Google Scholar] [CrossRef]

- Pettersson, M.; Berlind, T.; Schmidt, S.; Jacobson, S.; Hultman, L.; Persson, C.; Engqvist, H. Structure and composition of silicon nitride and silicon carbon nitride coatings for joint replacements. Surf. Coat. Technol. 2013, 235, 827–834. [Google Scholar] [CrossRef]

- Sharp, J.; Müller, I.C.; Mandal, P.; Abbas, A.; Nord, M.; Doye, A.; Ehiasarian, A.; Hovsepian, P.; MacLaren, I.; Rainforth, W.M. Characterisation of a High-Power Impulse Magnetron Sputtered C/Mo/W wear resistant coating by transmission electron microscopy. Surf. Coat. Technol. 2019, 377, 124853. [Google Scholar] [CrossRef]

- Paulitsch, J.; Mayrhofer, P.H.; Münz, W.-D.; Schenkel, M. Structure and mechanical properties of CrN/TiN multilayer coatings prepared by a combined HIPIMS/UBMS deposition technique. Thin Solid Films 2008, 517, 1239–1244. [Google Scholar] [CrossRef]

- Panjan, M.; Šturm, S.; Panjan, P.; Čekada, M. The influence of rotation during sputtering on the stoichiometry of TiAlN/CrNx multilayer coating. Surf. Coat. Technol. 2008, 203, 554–557. [Google Scholar] [CrossRef]

- Paulitsch, J.; Schenkel, M.; Zufraß, T.; Mayrhofer, P.H.; Münz, W.-D. Structure and properties of high power impulse magnetron sputtering and DC magnetron sputtering CrN and TiN films deposited in an industrial scale unit. Thin Solid Films 2010, 518, 5558–5564. [Google Scholar] [CrossRef]

- Ma, Q.; Li, L.; Xu, Y.; Gu, J.; Wang, L.; Xu, Y. Effect of bias voltage on TiAlSiN nanocomposite coatings deposited by HiPIMS. Appl. Surf. Sci. 2017, 392, 826–833. [Google Scholar] [CrossRef]

- Lin, J.; Wei, R. A comparative study of thick TiSiCN nanocomposite coatings deposited by dcMS and HiPIMS with and without PEMS assistance. Surf. Coat. Technol. 2018. [Google Scholar] [CrossRef]

- Datta, S.; Das, M.; Balla, V.K.; Bodhak, S.; Murugesan, V.K. Mechanical, wear, corrosion and biological properties of arc deposited titanium nitride coatings. Surf. Coat. Technol. 2018, 344, 214–222. [Google Scholar] [CrossRef]

- Berni, M.; Marchiori, G.; Gambardella, A.; Boi, M.; Bianchi, M.; Russo, A.; Visani, A.; Marcacci, M.; Pavan, P.G.; Lopomo, N.F. Effects of working gas pressure on zirconium dioxide thin film prepared by pulsed plasma deposition: roughness, wettability, friction and wear characteristics. J. Mech. Behav. Biomed. Mater. 2017, 72, 200–208. [Google Scholar] [CrossRef] [PubMed]

| Substrate | Group Name | Process Heating (kW) | Substrate Temperature (°C) | Deposition Pressure (MPa) | N2/Ar | SiNx Thickness (nm) | Interlayer Thickness (nm) |

|---|---|---|---|---|---|---|---|

| CoCrMo discs | 2D-1f-H0-P3.4 | 0 | 120 | 600 | 0.255 | 5385 | 1100 |

| 2D-1f-H3-P3.4 | 3 | 300 | 600 | 0.255 | 5240 | 1030 | |

| 2D-1f-H0-P3.4-rep | 0 | 120 | 600 | 0.26 | 6050 | 1700 | |

| 2D-3f-H0-P3.4 | 0 | 120 | 600 | 0.26 | 4399 | 1461 | |

| CoCrMo hip heads, 32 and 36 mm | 3D-3f-H0-P3.4 | 0 | 120 | 600 | 0.28 | 4399 | 1461 |

| 3D-3f-H0-P1.7 | 0 | 120 | 600 | 0.28 | 4492 | 1140 | |

| 3D-3f-H3-P3.4-C | 3 | 300 | 600 | 0.28 | 4391 | 1169 |

| Substrate | Process | Si (at.%) | N (at.%) | N/Si | O (at.%) | C (at.%) |

|---|---|---|---|---|---|---|

| CoCrMo disc | 2D-1f-H0-P3.4 | 49.2 | 46.7 | 0.95 | 2.3 | 0.5 |

| 2D-1f-H3-P3.4 | 47.4 | 48.8 | 1.03 | 1.7 | 0.8 | |

| 2D-1f-H0-P3.4-rep | 48.49 | 44.19 | 0.91 | 6.51 | 0.81 | |

| 2D-3f-H0-P3.4 | 46.1 | 37.8 | 0.82 | 14.2 | 1.87 | |

| CoCrMo hip head 32 and 36 mm | 3D-3f-H0-P3.4 | 46.1 | 37.8 | 0.82 | 14.2 | 1.87 |

| 3D-3f-H0-P1.7 | 41.6 | 39.4 | 0.95 | 16.5 | 2.52 | |

| 3D-3f-H3-P3.4-C | 40.6 | 31.5 | 0.78 | 12.2 | 15.7 |

| Samples | Ra (nm) |

|---|---|

| 2D-1f-H0-P3.4 | 15.6 ± 3.9 |

| 2D-1f-H3-P3.4 | 8.3 ± 0.6 |

| 2D-1f-H0-P3.4-rep | 36.1 ± 15.5 |

| 2D-3f-H0-P3.4 | 8.9 ± 0.5 |

| Samples | Coated (3D) Implants | UHMWPE Discs | ||

|---|---|---|---|---|

| 32 mm | 36 mm | 32 mm | 36 mm | |

| Ra (nm) | Ra (µm) | |||

| CoCr | 11.7 ± 1.6 | 9.6 ± 1.8 | 1.1 ± 0.2 | 1.6 ± 0.4 |

| 3D-3f-H0-P3.4 | 39.9 ± 3.7 | 31.8 ± 1.8 | 0.8 ± 0.2 | 1.1 ± 0.5 |

| 3D-3f-H0-P1.7 | 43.1 ± 4.9 | 40.0 ± 5.5 | 0.7 ± 0.0 | 1.5 ± 0.3 |

| 3D-3f-H3-P3.4-C | 29.5 ± 3.7 | 29.5 ± 3.5 | 1.1 ± 0.5 | 1.9 ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filho, L.C.; Schmidt, S.; López, A.; Cogrel, M.; Leifer, K.; Engqvist, H.; Högberg, H.; Persson, C. The Effect of Coating Density on Functional Properties of SiNx Coated Implants. Materials 2019, 12, 3370. https://doi.org/10.3390/ma12203370

Filho LC, Schmidt S, López A, Cogrel M, Leifer K, Engqvist H, Högberg H, Persson C. The Effect of Coating Density on Functional Properties of SiNx Coated Implants. Materials. 2019; 12(20):3370. https://doi.org/10.3390/ma12203370

Chicago/Turabian StyleFilho, Luimar Correa, Susann Schmidt, Alejandro López, Mathilde Cogrel, Klaus Leifer, Håkan Engqvist, Hans Högberg, and Cecilia Persson. 2019. "The Effect of Coating Density on Functional Properties of SiNx Coated Implants" Materials 12, no. 20: 3370. https://doi.org/10.3390/ma12203370

APA StyleFilho, L. C., Schmidt, S., López, A., Cogrel, M., Leifer, K., Engqvist, H., Högberg, H., & Persson, C. (2019). The Effect of Coating Density on Functional Properties of SiNx Coated Implants. Materials, 12(20), 3370. https://doi.org/10.3390/ma12203370