Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles

Abstract

1. Introduction

2. Discrete Element Analysis with Ellipsoids

3. Calibration of the Micro Parameters

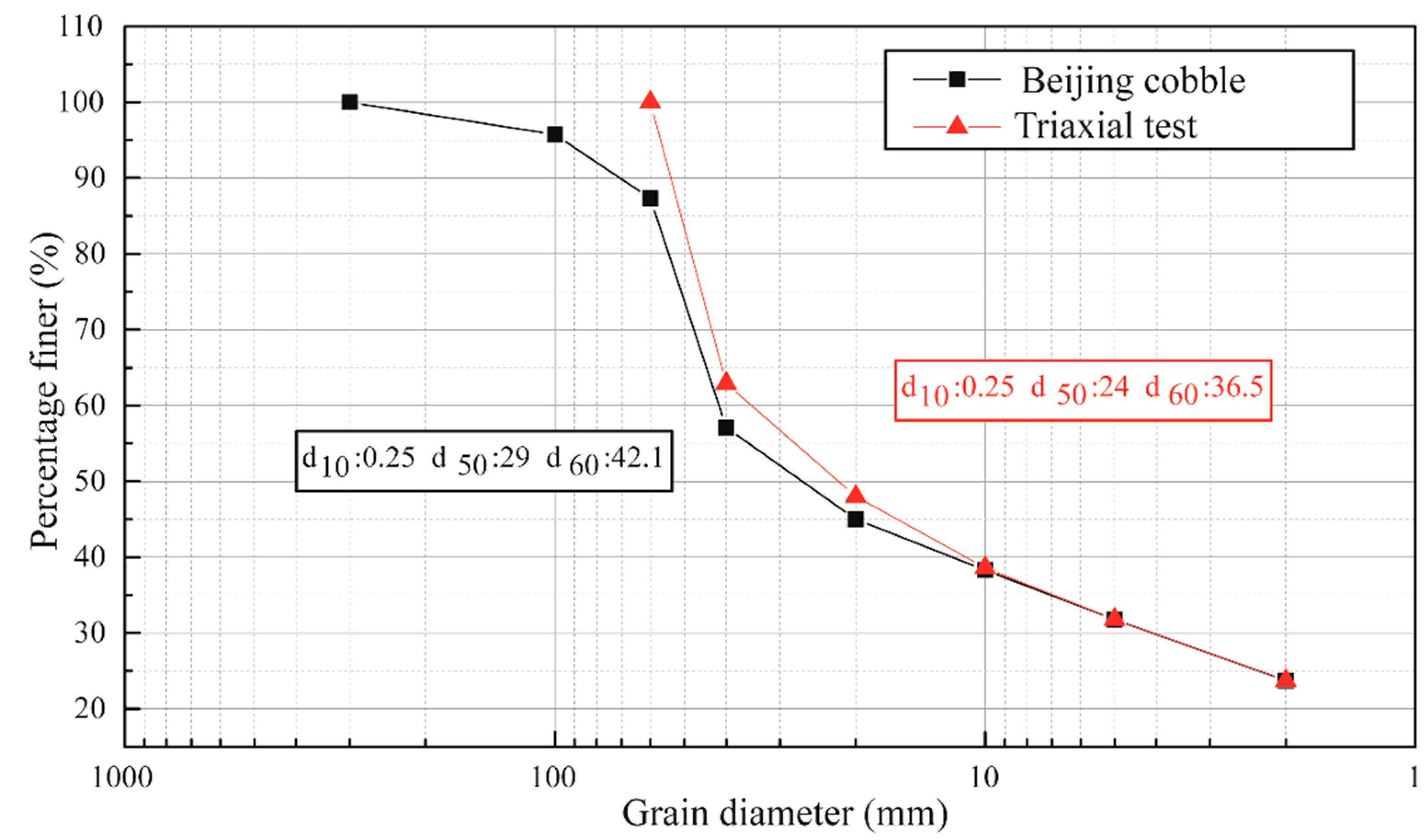

3.1. Triaxial Test

3.2. Preparation of Discrete Element Samples

- (1)

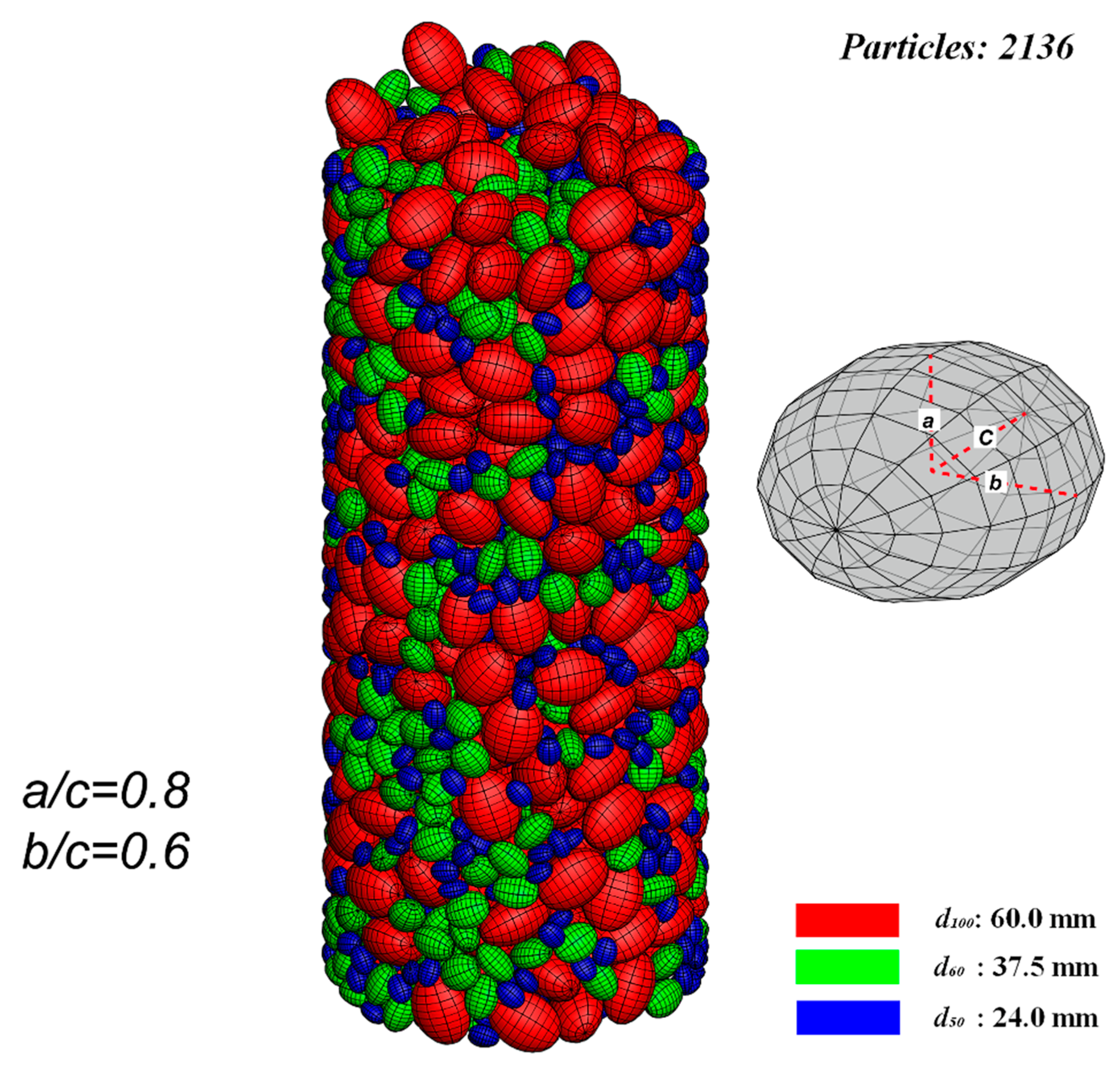

- A number of particles are randomly generated, floating over the bottom of the container. In order to avoid the decrease of computational efficiency induced by excessive small particles, three particle sizes, i.e., d100 = 60 mm (d100: the grain diameter at 100% passing), d60 = 36.5 mm (d60: the grain diameter at 60% passing), and d50 = 24 mm (d50: the grain diameter at 50% passing) are selected in the simulation to generate particles. According to the sieve analysis performed prior to the triaxial compression test, the particles in the soil sample are characterized by a/c = 0.6 and b/c = 0.8, where a, b, and c denote the half the length of three principal axes of each ellipsoid with the relationship of a < b < c (as depicted in Figure 4).

- (2)

- As illustrated in Figure 4, a total number of 2136 particles are deposited finally to form the cobble sample used in following DEM simulation on triaxial tests;

- (3)

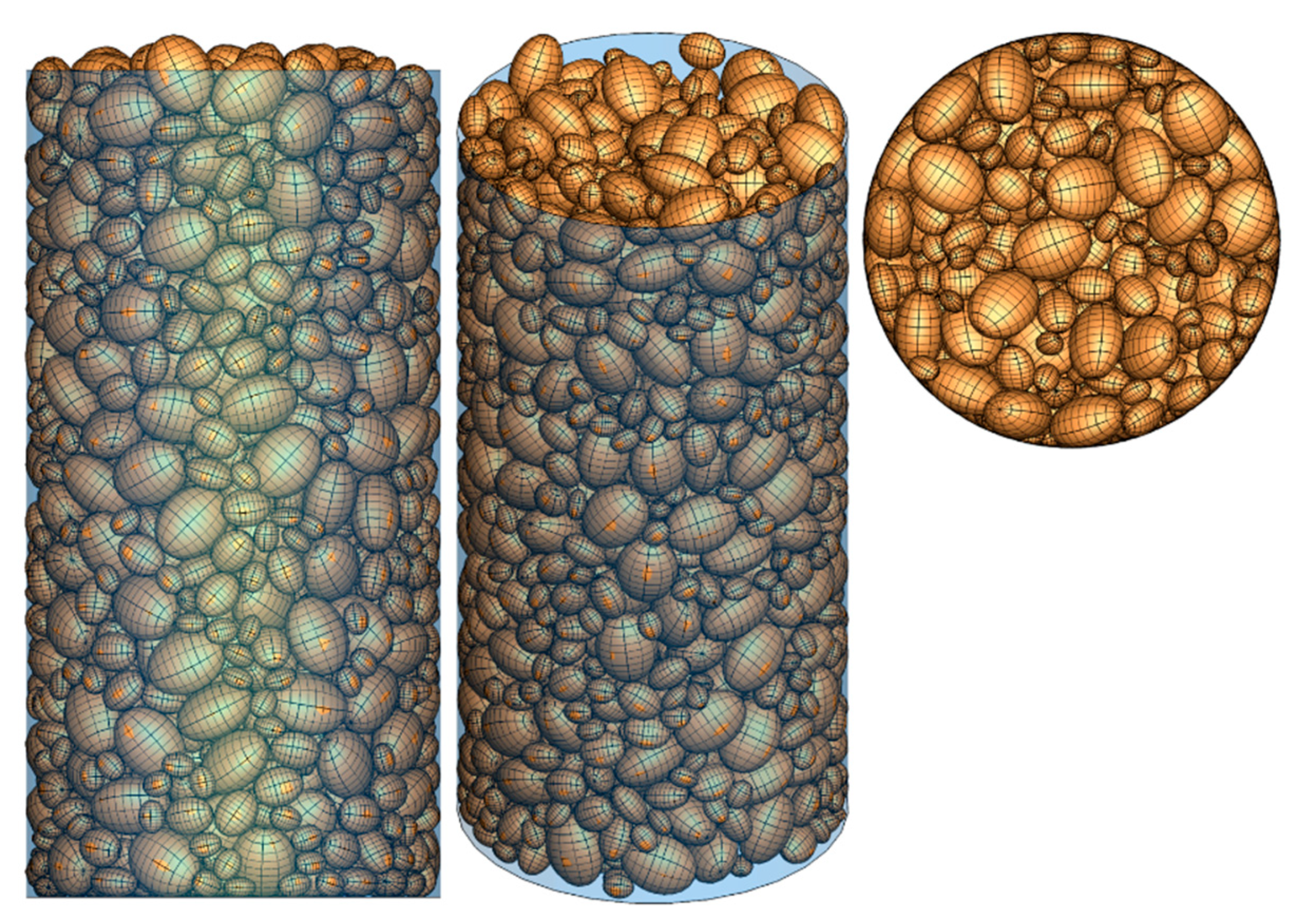

- The sample was deposited with a final height slightly greater than the height of the specimen of the triaxial test (i.e., 600 mm), and the particles outside of the specimen were deleted from the model (as shown in Figure 5);

- (4)

- A small pressure (10 kPa herein) was applied to the sample to make the particles fully contacted with the boundaries. Displacement boundaries (servo control) were applied to the top of the specimen. The boundaries were assumed to be rigid. It should be pointed out that the bottom of the specimen was fixed in the vertical direction according to the test prototype (as shown in Figure 6);

- (5)

- A confining pressure of 200 kPa was applied to the specimen for the isotropic compaction prior to triaxial loading;

- (6)

- The triaxial compression test was performed by moving the top boundary downward. The confining pressure σ3 is maintained at 200 kPa by adjusting the diameter of the cylindrical boundary at each time-step.

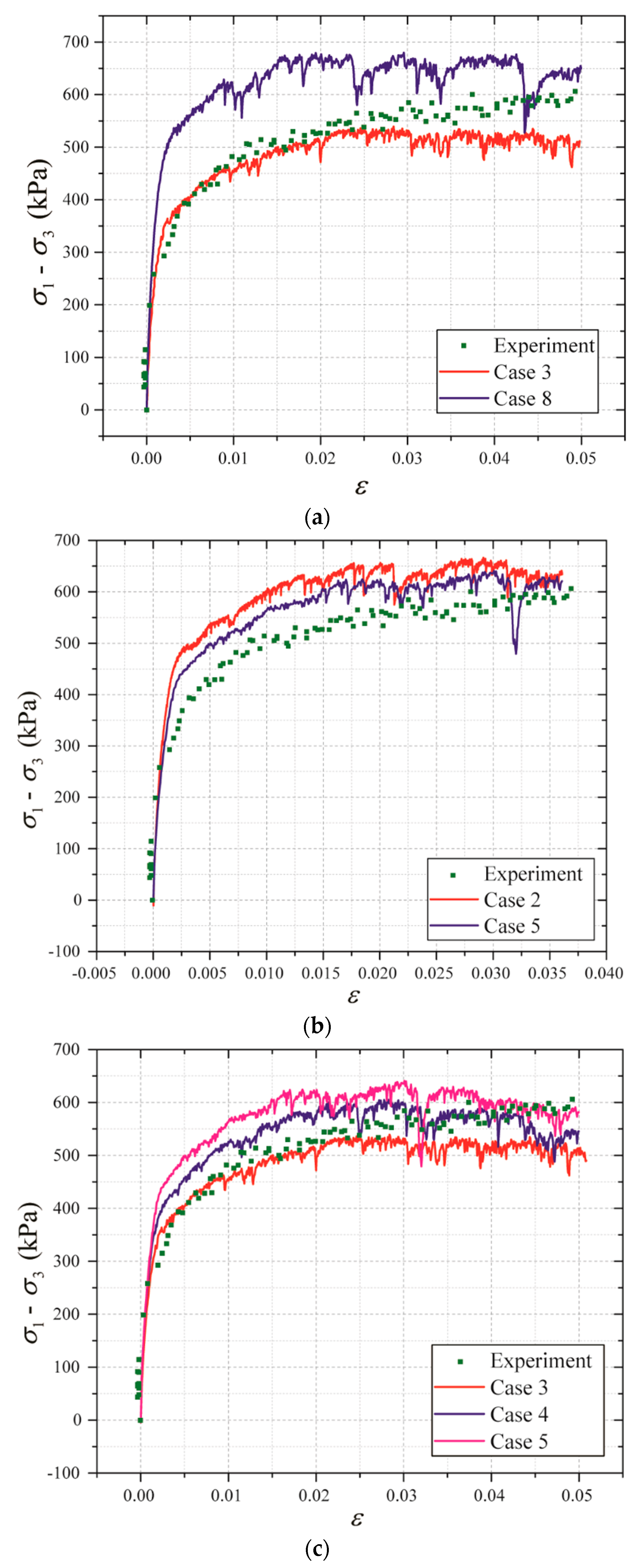

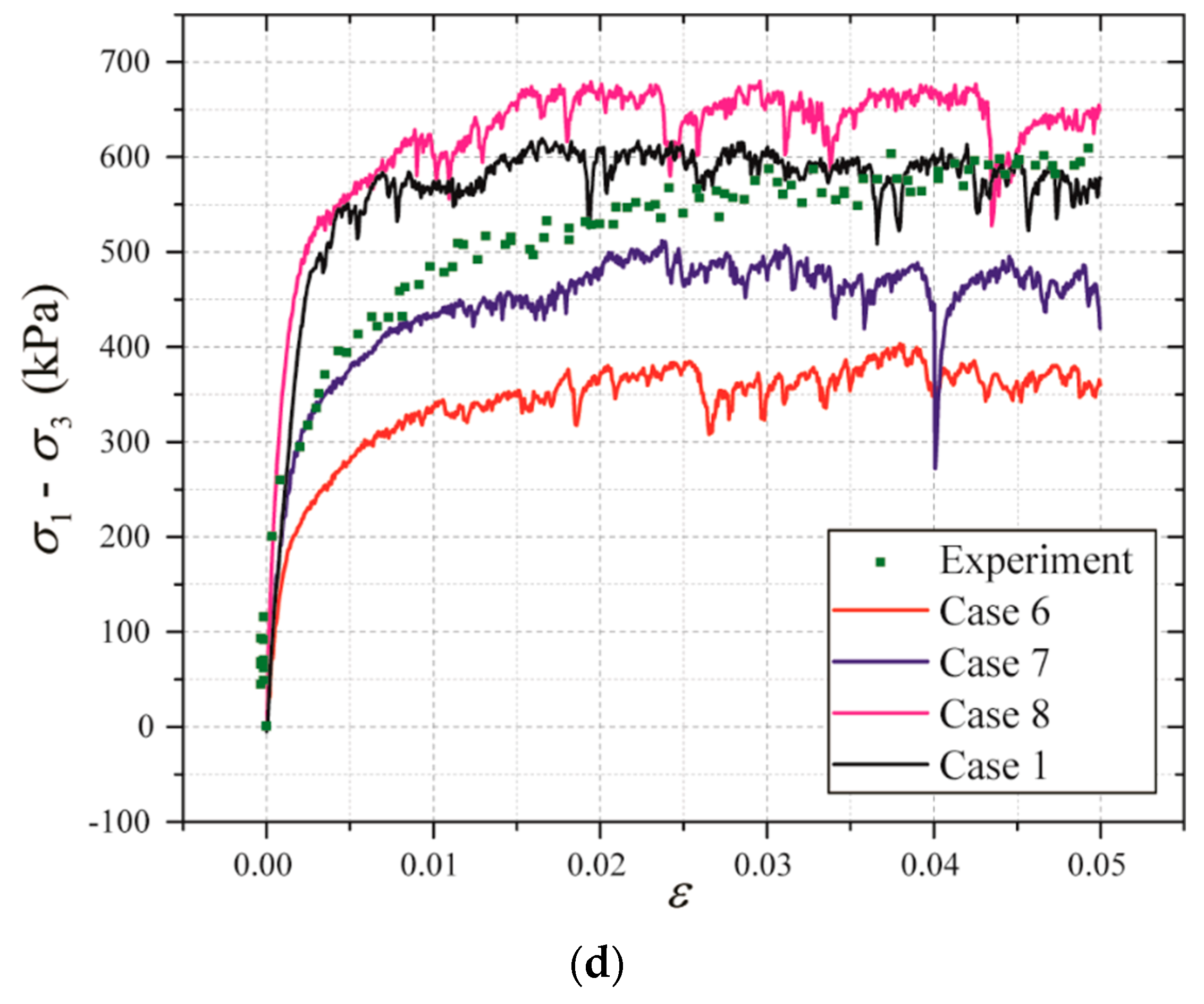

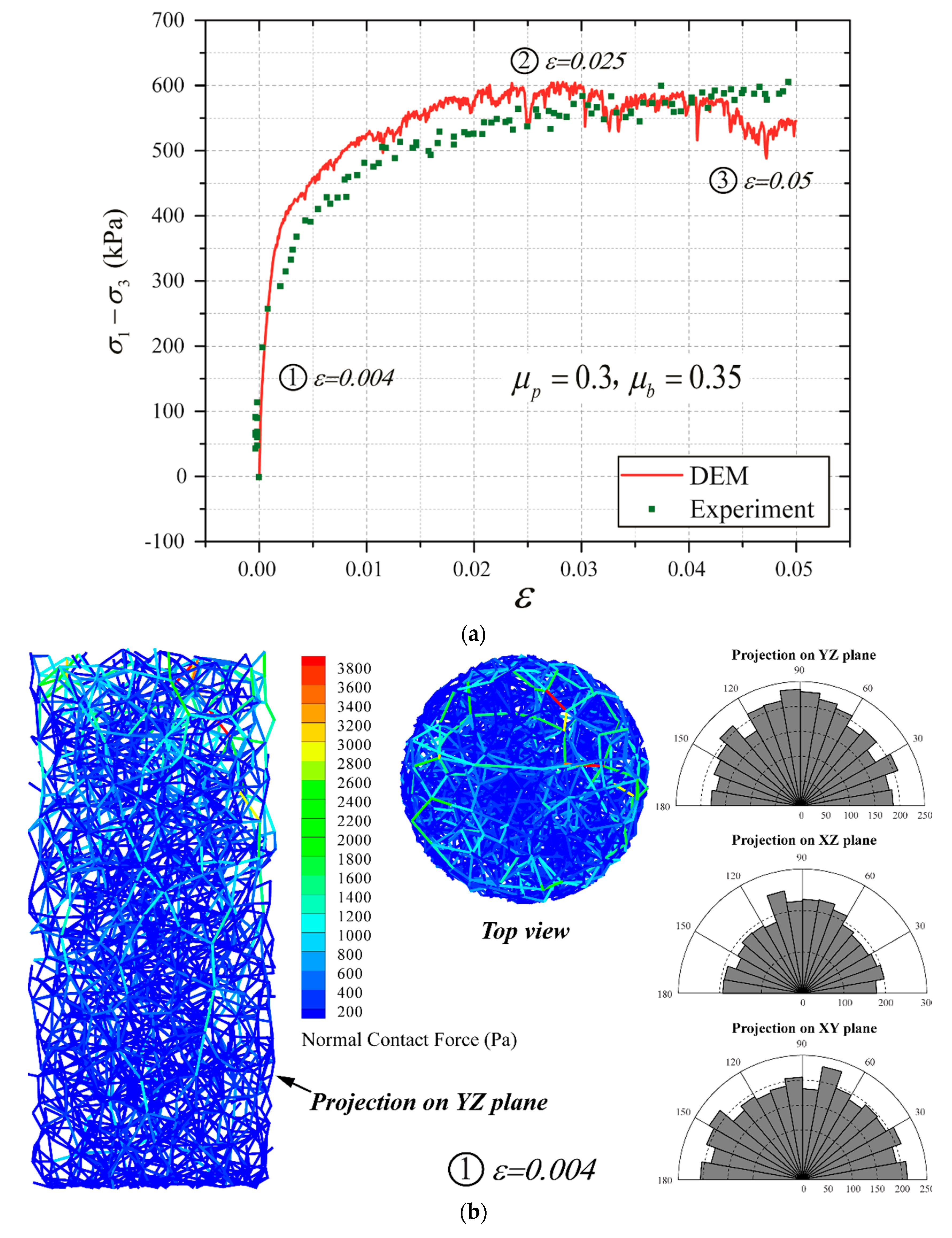

3.3. Microscopic Material Parameters

3.4. Evolution of the Sample Micro-Structure

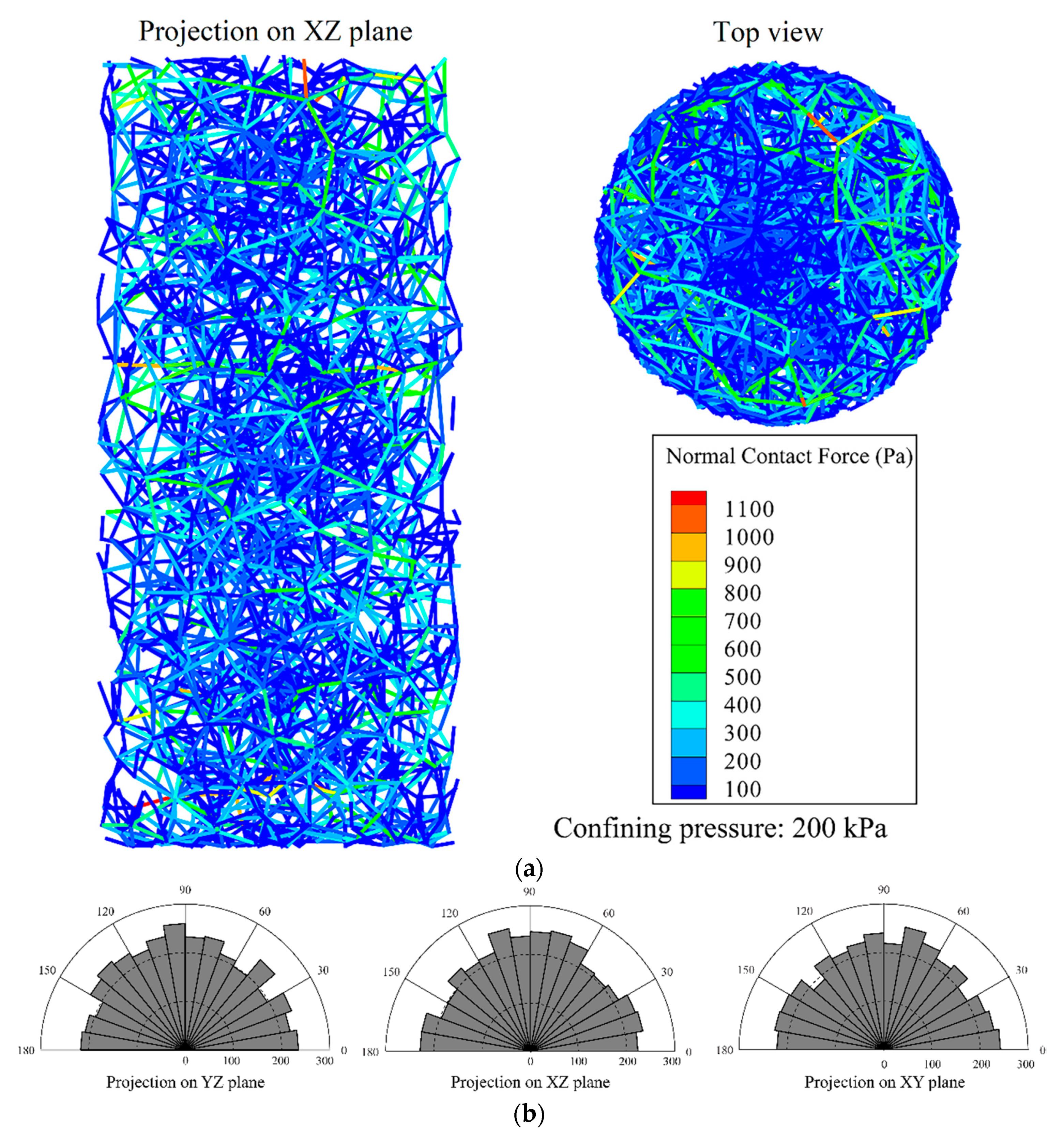

3.4.1. Gravity Deposition Stage

3.4.2. Isotropic Compression under a Confining Pressure of 200 kPa

3.4.3. Triaxial Compression (Confining Pressure 200 kPa)

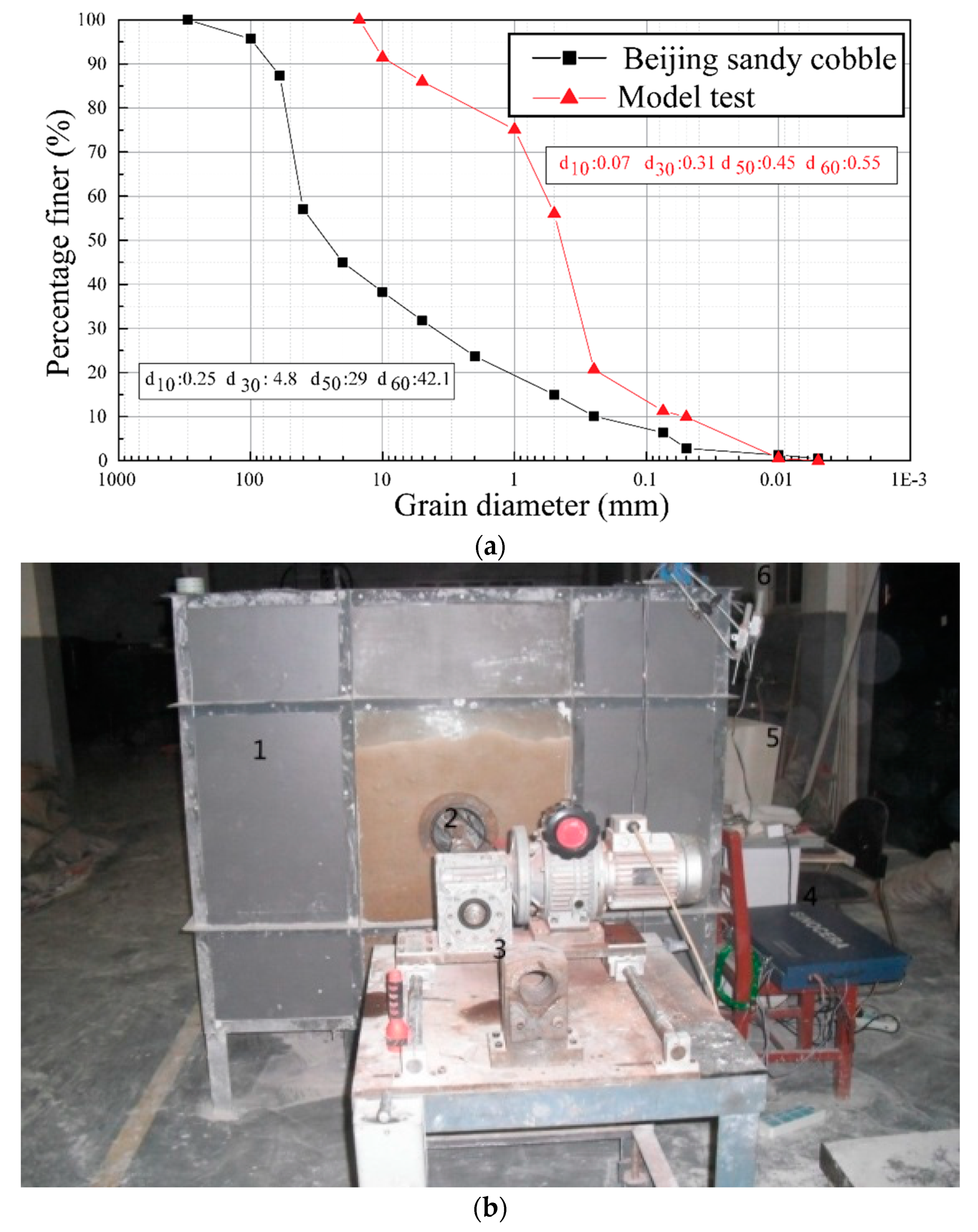

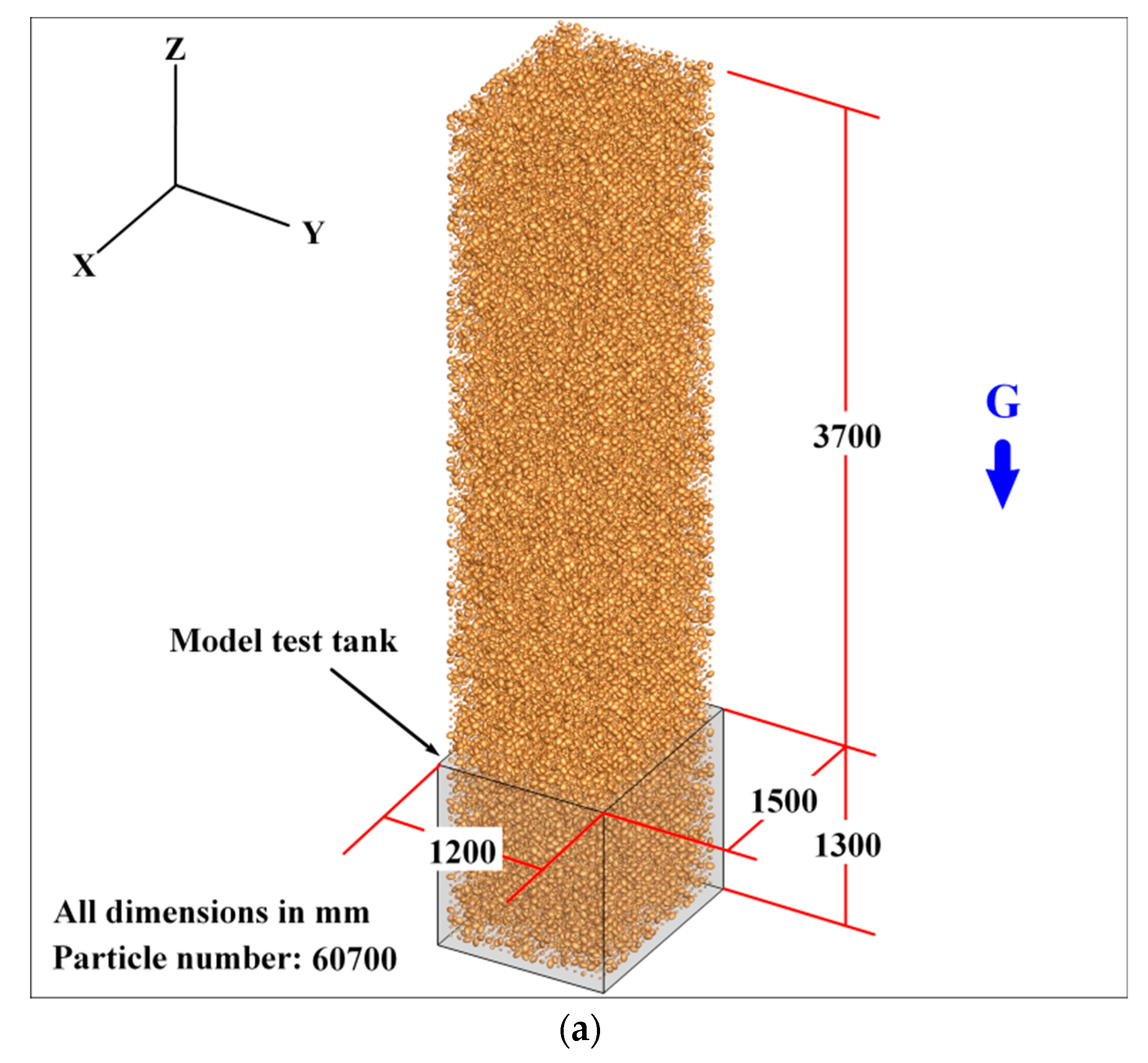

4. Discrete Element Modeling for 1 g Model Test of Tunnel Face Instability

4.1. Revisit of the 1 g Model Test

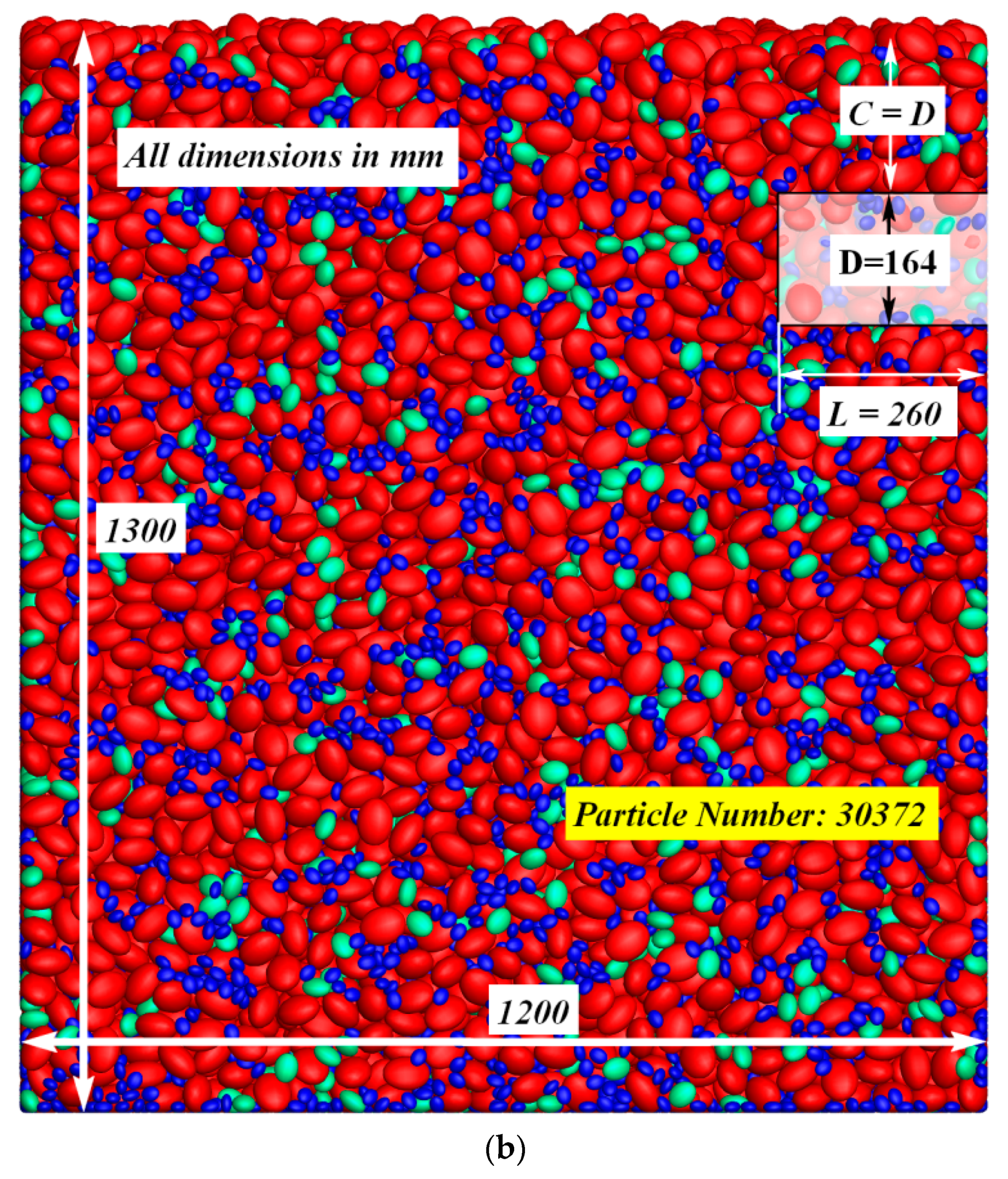

4.2. DEM Simulation on the 1 g Model Test

4.2.1. Parallelization of the Computation

4.2.2. Discrete Element Modeling for the Tunnel Face Instability

4.3. Results and Discussion

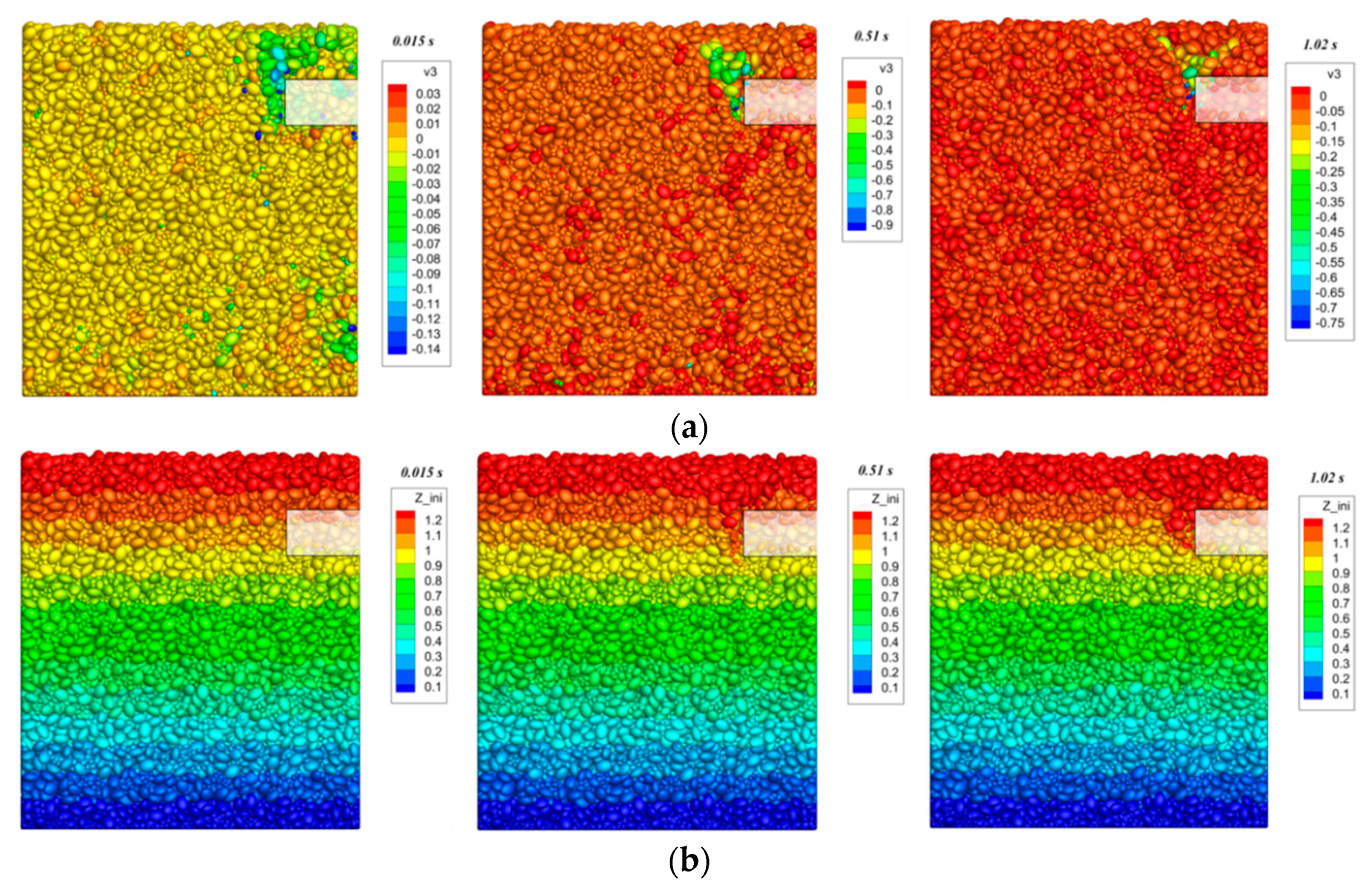

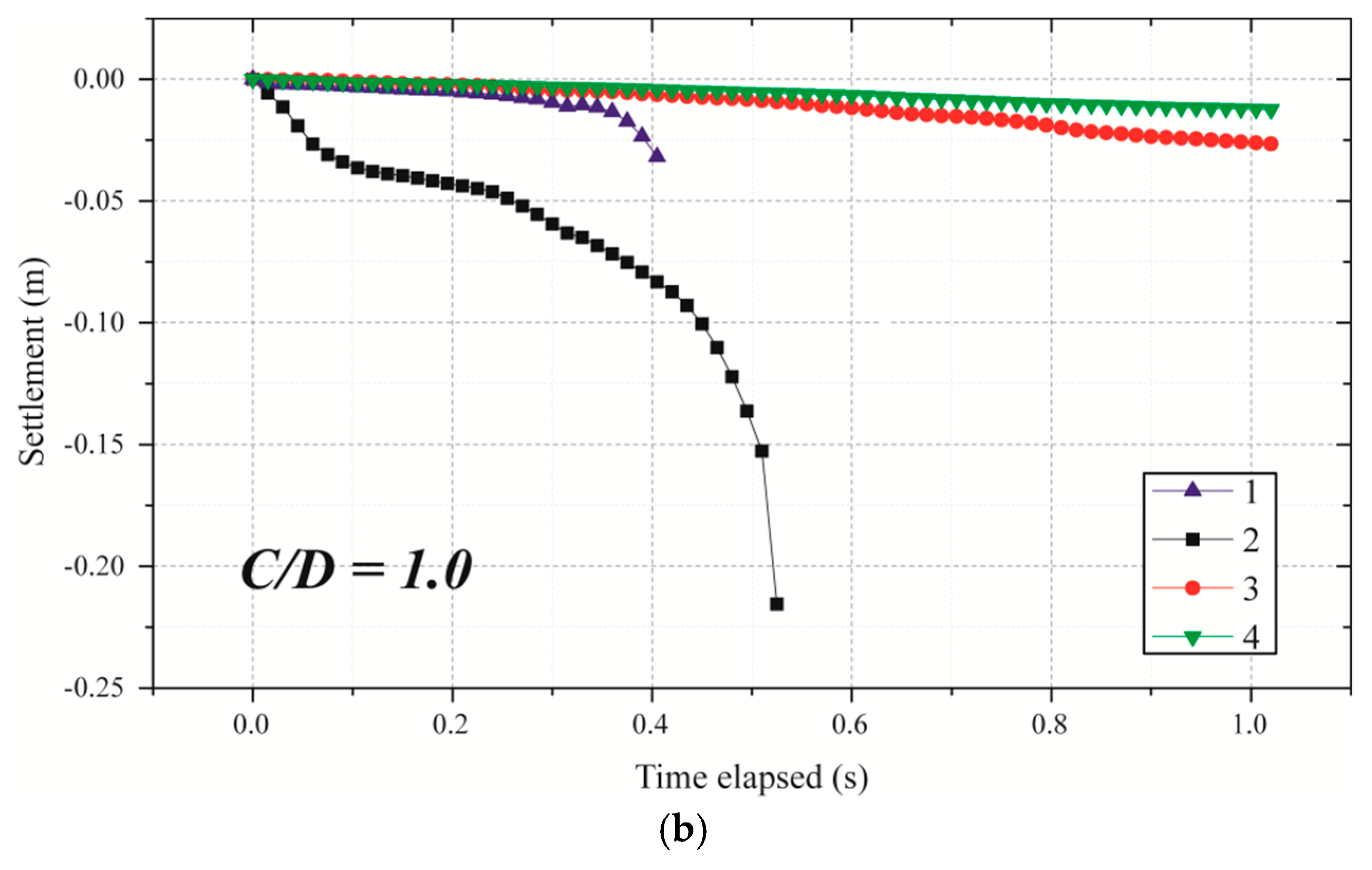

4.3.1. C/D = 1.0

4.3.2. C/D = 2.0

5. Conclusions

- It can be found from the laboratory triaxial compression test and discrete element modeling that the cobble sample does not show obvious strain softening property under the confining pressures of 200 kPa, 400 kPa, and 600 kPa; The cobble sample in the discrete element simulation shows softening behavior to a certain degree, ascribing to the removal of small particles in the discrete element model. The macro properties of the cobble sample (e.g., material softening) can be investigated microscopically via the variation of the force chain distribution;

- The tunnel excavation model test was simulated using the calibrated friction parameters, considering the two cover-diameter ratios (i.e., C/D = 1.0 and C/D = 2.0). A basin-like failure pattern can be observed for the tunnel face instability while C/D = 1.0, and a chimney-like failure pattern for the case of C/D = 2.0. For the case of C/D = 2.0, although the overall instability of the excavation surface did not occur during the calculation time, the surface settlement did not stabilize within 2.45 s. It can also be found from the force chain distribution that the arching effect of the cobble is forming gradually during the tunnel face instability while C/D = 2.0.

- The DEM simulation using ellipsoidal particles can obtain higher shear strength than spherical particles, but the computational efficiency is extremely low. This is not acceptable for the analysis of large-scale problems. However, with the development of computational power, the analysis of engineering problems will become feasible in the future.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Emeriault, F.; Kastner, R.; Zhang, Z. Stability analysis of large slurry shield-driven tunnel in soft clay. Tunn. Undergr. Space Technol. 2009, 24, 472–481. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Liu, C.; Huang, X. Numerical analysis of volume loss caused by tunnel face instability in soft soils. Environ. Earth Sci. 2017, 76, 563. [Google Scholar] [CrossRef]

- Zou, J.; Chen, G.; Qian, Z. Tunnel face stability in cohesion-frictional soils considering the soil arching effect by improved failure models. Comput. Geotech. 2019, 106, 1–17. [Google Scholar] [CrossRef]

- Klar, A.; Klein, B. Energy-based volume loss prediction for tunnel face advancement in clays. Géotechnique 2014, 64, 776–786. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, X.; Scott, K.D. A discrete numerical approach for modeling face stability in slurry shield tunnelling in soft soils. Comput. Geotech. 2011, 38, 94–104. [Google Scholar] [CrossRef]

- Ukritchon, B.; Yingchaloenkitkhajorn, K.; Keawsawasvong, S. Three-dimensional undrained tunnel face stability in clay with a linearly increasing shear strength with depth. Comput. Geotech. 2017, 88, 146–151. [Google Scholar] [CrossRef]

- Chen, R.; Tang, L.; Ling, D.; Chen, Y. Face stability analysis of shallow shield tunnels in dry sandy ground using the discrete element method. Comput. Geotech. 2011, 38, 187–195. [Google Scholar] [CrossRef]

- Horn, M. Horizontal earth pressure on perpendicular tunnel face. In Proceedings of the Hungarian National Conference of the Foundation Engineer Industry, Budapest, Hungary, 7–16 November 1961; pp. 7–16. [Google Scholar]

- Anagnostou, G.; Kovari, K. The face stability of slurry-shield-driven tunnels. Tunn. Undergr. Space Technol. 1994, 9, 165–174. [Google Scholar] [CrossRef]

- Broere, W. Tunnel Face Stability and New CPT Applications. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Chen, R.P.; Tang, L.J.; Yin, X.S.; Chen, Y.M.; Bian, X.C. An improved 3D wedge-prism model for the face stability analysis of the shield tunnel in cohesionless soils. Acta Geotech. 2015, 10, 683–692. [Google Scholar] [CrossRef]

- Broms, B.B.; Bennermark, H. Stability of clay at vertical opening. J. Soil Mech. Found. Div. 1967, 93, 71–94. [Google Scholar]

- Davis, E.H.; Mair, R.J.; Seneviratine, H.N.; Gunn, M.J. The stability of shallow tunnels and underground openings in cohesive material. Géotechnique 1980, 30, 397–416. [Google Scholar] [CrossRef]

- Dormieux, L.; Leca, E. Upper and lower bound solutions for the face stability of shallow circular tunnels in frictional material. Géotechnique 1990, 40, 581–606. [Google Scholar]

- Soubra, A.H. Kinematical approach to the face stability analysis of shallow circular tunnels. In Proceedings of the 8th International Symposium on Plasticity, Vancouver, BC, Canada, 17–21 July 2000. [Google Scholar]

- Nam, S.W.; Ahn, J.H.; Lee, I.M. Effect of seepage forces on tunnel face stability. Can. Geotech. J. 2003, 40, 342–350. [Google Scholar]

- Mollon, G.; Dias, D.; Soubra, A.H. Face Stability Analysis of Circular Tunnels Driven by a Pressurized Shield. J. Geotech. Geoenviron. Eng. 2010, 136, 215–229. [Google Scholar] [CrossRef]

- Mollon, G.; Dias, D.; Soubra, A.H. Continuous velocity fields for collapse and blowout of a pressurized tunnel face in purely cohesive soil. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 2061–2083. [Google Scholar] [CrossRef]

- Vermeer, P.A.; Ruse, N.; Marcher, T. Tunnel heading stability in drained ground. Felsbau 2002, 20, 8–18. [Google Scholar]

- Lu, X.; Wang, H.; Huang, M. Upper Bound Solution for the Face Stability of Shield Tunnel below the Water Table. Math. Probl. Eng. 2014, 2014, 727964. [Google Scholar] [CrossRef]

- Zhang, C.; Han, K.; Zhang, D. Face stability analysis of shallow circular tunnels in cohesive–frictional soils. Tunn. Undergr. Space Technol. 2015, 50, 345–357. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Karim, A.S.M.M. Three-Dimensional Discrete Element Modeling of Tunneling in Sand. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2007. [Google Scholar]

- Bym, T.; Marketos, G.; Burland, J.B.; O’Sullivan, C. Use of a two-dimensional discrete-element line-sink model to gain insight into tunnelling-induced deformations. Geotechnique 2012, 63, 791. [Google Scholar] [CrossRef]

- Jiang, M.; Yin, Z.Y. Analysis of stress redistribution in soil and earth pressure on tunnel lining using the discrete element method. Tunn. Undergr. Space Technol. 2012, 32, 251–259. [Google Scholar] [CrossRef]

- O’Sullivan, C. Particulate Discrete Element Modelling: A Geomechanics Perspective; Spon Press: London, UK; New York, NY, USA, 2011. [Google Scholar]

- Yan, B.; Regueiro, R.A. Comparison between pure MPI and hybrid MPI-OpenMP parallelism for Discrete Element Method (DEM) of ellipsoidal and poly-ellipsoidal particles. Comput. Part. Mech. 2018, 6, 271–295. [Google Scholar] [CrossRef]

- Kozicki, J.; Donzé, F. A new open-source software developed for numerical simulations using discrete modeling methods. Comput. Methods Appl. Mech. Eng. 2008, 197, 4429–4443. [Google Scholar] [CrossRef]

- Yan, B.; Regueiro, R.A. A comprehensive study of MPI parallelism in three-dimensional discrete element method (DEM) simulation of complex-shaped granular particles. Comput. Part. Mech. 2018, 5, 553–577. [Google Scholar] [CrossRef]

- Yan, B.; Regueiro, R.A.; Sture, S. Three-dimensional ellipsoidal discrete element modeling of granular materials and its coupling with finite element facets. Eng. Comput. 2010, 27, 519–550. [Google Scholar] [CrossRef]

- Yan, B. Three-Dimensional Discrete Element Modeling of Granular Materials and Its Coupling with Finite Element Method; University of Colorado at Boulder: Boulder, CO, USA, 2008. [Google Scholar]

- Fan, Z.; Zhang, Z. Model test of excavation face stability of EPB shield in sandy cobble ground and adjacent building effect. Chin. J. Rock Mech. Eng. 2013, 32, 2506–2512. [Google Scholar]

- Lin, X.; Ng, T.T. Contact detection algorithms for three-dimensional ellipsoids in discrete element modelling. Int. J. Numer. Anal. Methods Géoméch. 1995, 19, 653–659. [Google Scholar] [CrossRef]

- Lu, G.; Third, J.; Müller, C. Discrete element models for non-spherical particle systems: From theoretical developments to applications. Chem. Eng. Sci. 2015, 127, 425–465. [Google Scholar] [CrossRef]

- Bagi, K. An algorithm to generate random dense arrangements for discrete element simulations of granular assemblies. Granul. Matter 2005, 7, 31–43. [Google Scholar] [CrossRef]

- Fan, Z. Study on Face Stability and Failure Mechanism of EPB Shield Tunneling in Sandy Cobble Ground; Tongji University Shanghai: Shanghai, China, 2014. [Google Scholar]

| Cases | E (Pa) | ν | μp | μb | ξ |

|---|---|---|---|---|---|

| Case 1 | 2.0 × 1010 | 0.25 | 0.5 | 0.5 | 0.03 |

| Case 2 | 2.0 × 1010 | 0.25 | 0.4 | 0.4 | 0.03 |

| Case 3 | 2.0 × 1010 | 0.25 | 0.3 | 0.3 | 0.03 |

| Case 4 | 2.0 × 1010 | 0.25 | 0.3 | 0.35 | 0.03 |

| Case 5 | 2.0 × 1010 | 0.25 | 0.3 | 0.4 | 0.03 |

| Case 6 | 2.0 × 1010 | 0.25 | 0.5 | 0 | 0.03 |

| Case 7 | 2.0 × 1010 | 0.25 | 0.5 | 0.1 | 0.03 |

| Case 8 | 2.0 × 1010 | 0.25 | 0.5 | 0.3 | 0.03 |

| Cases | Esample (MPa) | E50 (MPa) | Strength (kPa) |

|---|---|---|---|

| Experiment | 649.5 | 201.6 | 609.6 |

| Case 1 | 382.3 | 211.3 | 619.4 |

| Case 2 | 660.1 | 355.9 | 670.2 |

| Case 3 | 468.4 | 237.4 | 541.6 |

| Case 4 | 755.9 | 268.3 | 606.7 |

| Case 5 | 532.8 | 300.0 | 643.2 |

| Case 6 | 215.9 | 123.1 | 404.8 |

| Case 7 | 337.5 | 183.1 | 514.4 |

| Case 8 | 993.1 | 391.9 | 680.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Pan, L.; Wang, F.; Zhang, Z.; Cui, J.; Liu, H.; Duan, Z.; Ji, X. Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles. Materials 2019, 12, 3347. https://doi.org/10.3390/ma12203347

Liu C, Pan L, Wang F, Zhang Z, Cui J, Liu H, Duan Z, Ji X. Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles. Materials. 2019; 12(20):3347. https://doi.org/10.3390/ma12203347

Chicago/Turabian StyleLiu, Chao, Liufeng Pan, Fei Wang, Zixin Zhang, Jie Cui, Hai Liu, Zheng Duan, and Xiangying Ji. 2019. "Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles" Materials 12, no. 20: 3347. https://doi.org/10.3390/ma12203347

APA StyleLiu, C., Pan, L., Wang, F., Zhang, Z., Cui, J., Liu, H., Duan, Z., & Ji, X. (2019). Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles. Materials, 12(20), 3347. https://doi.org/10.3390/ma12203347