Optimization of Geometry Parameters of Inkjet-Printed Silver Nanoparticle Traces on PDMS Substrates Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. PDMS Surface Treatment

2.3. Silver NP Patterning on O2-Plasma Treated PDMS

2.4. Development of Experimental Framework

2.4.1. Background

2.4.2. Response Surface Methodology

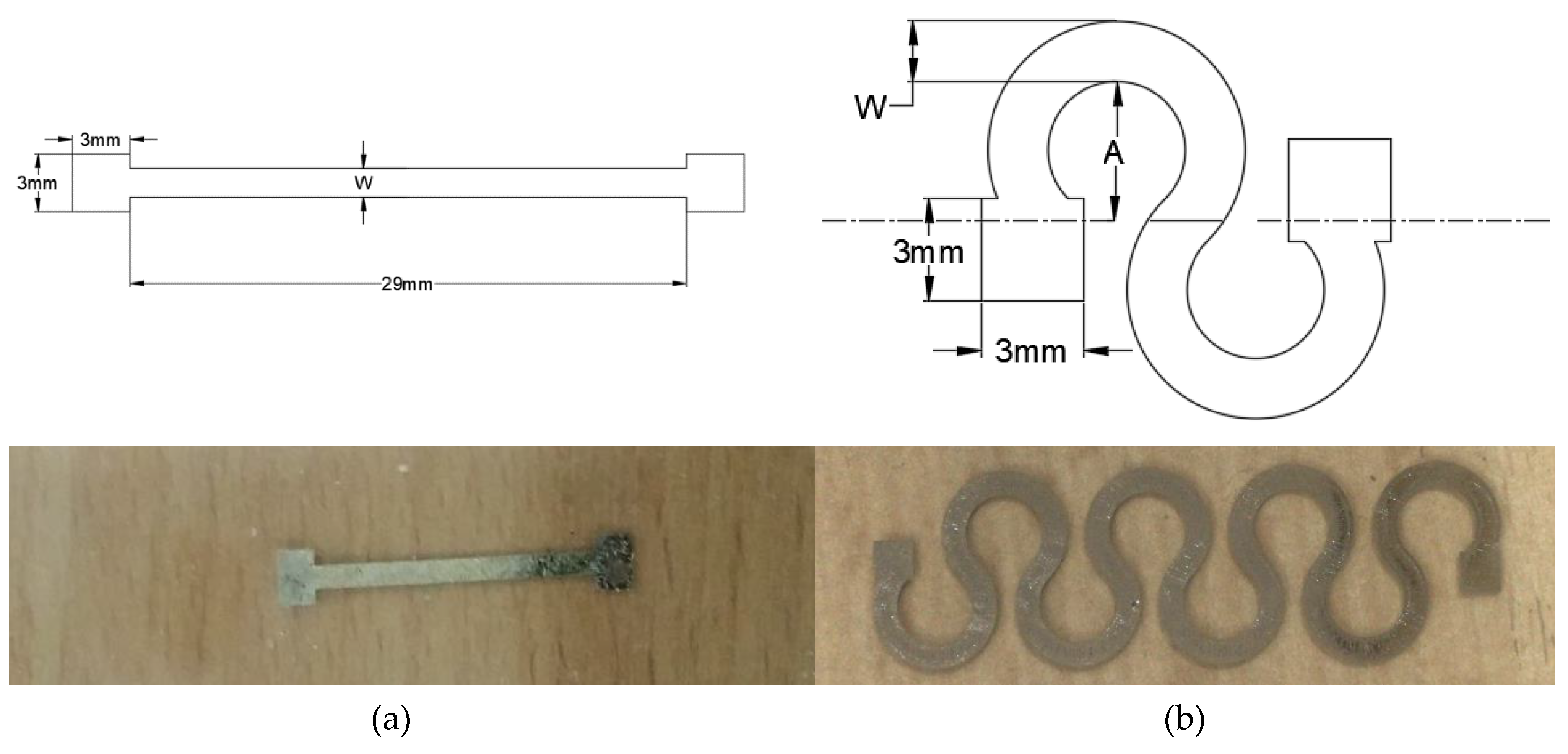

2.4.3. Pattern Design: Straight Line and Horseshoe

3. Results and Discussion

3.1. Data Analysis

3.1.1. Straight Line

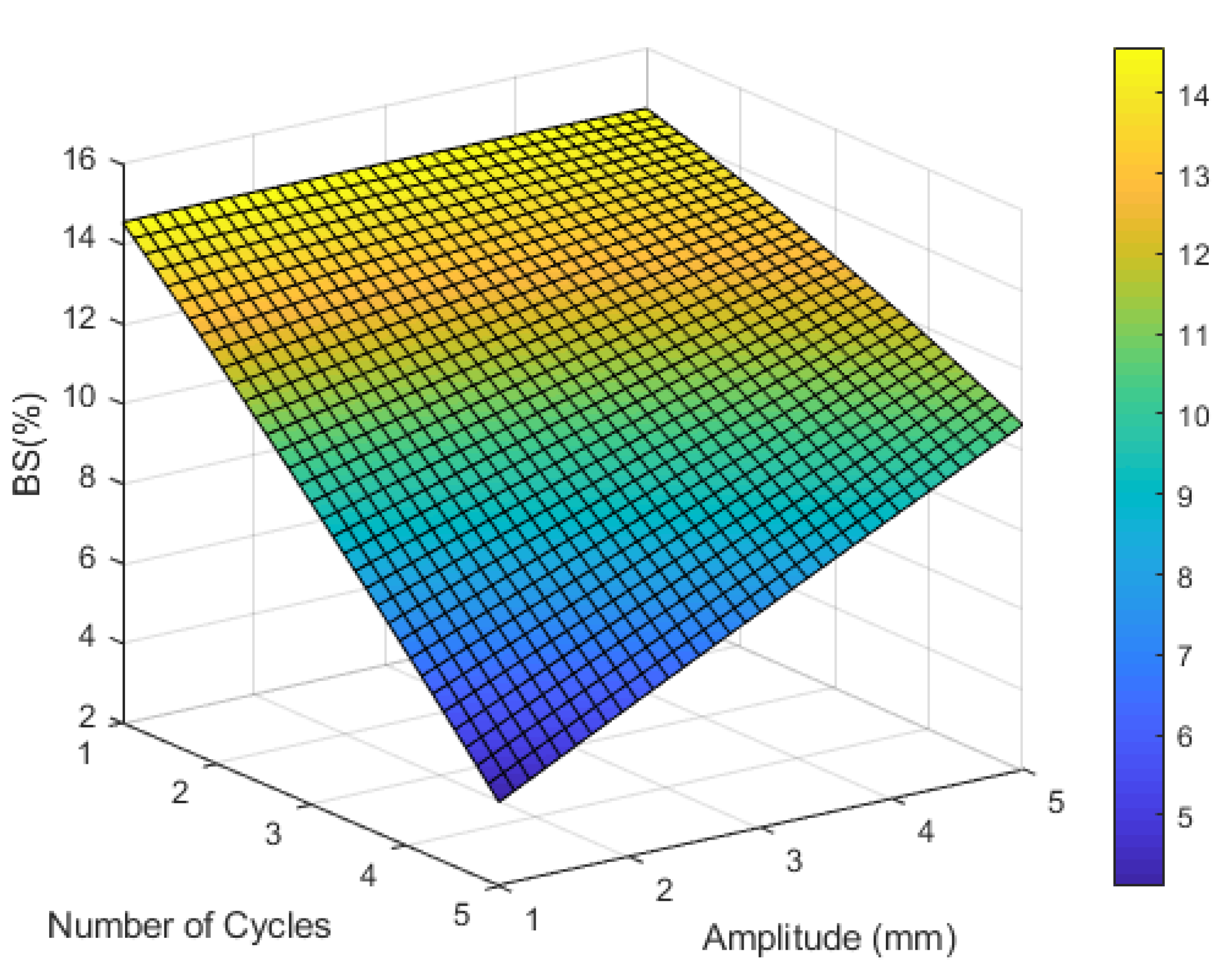

3.1.2. Horseshoe

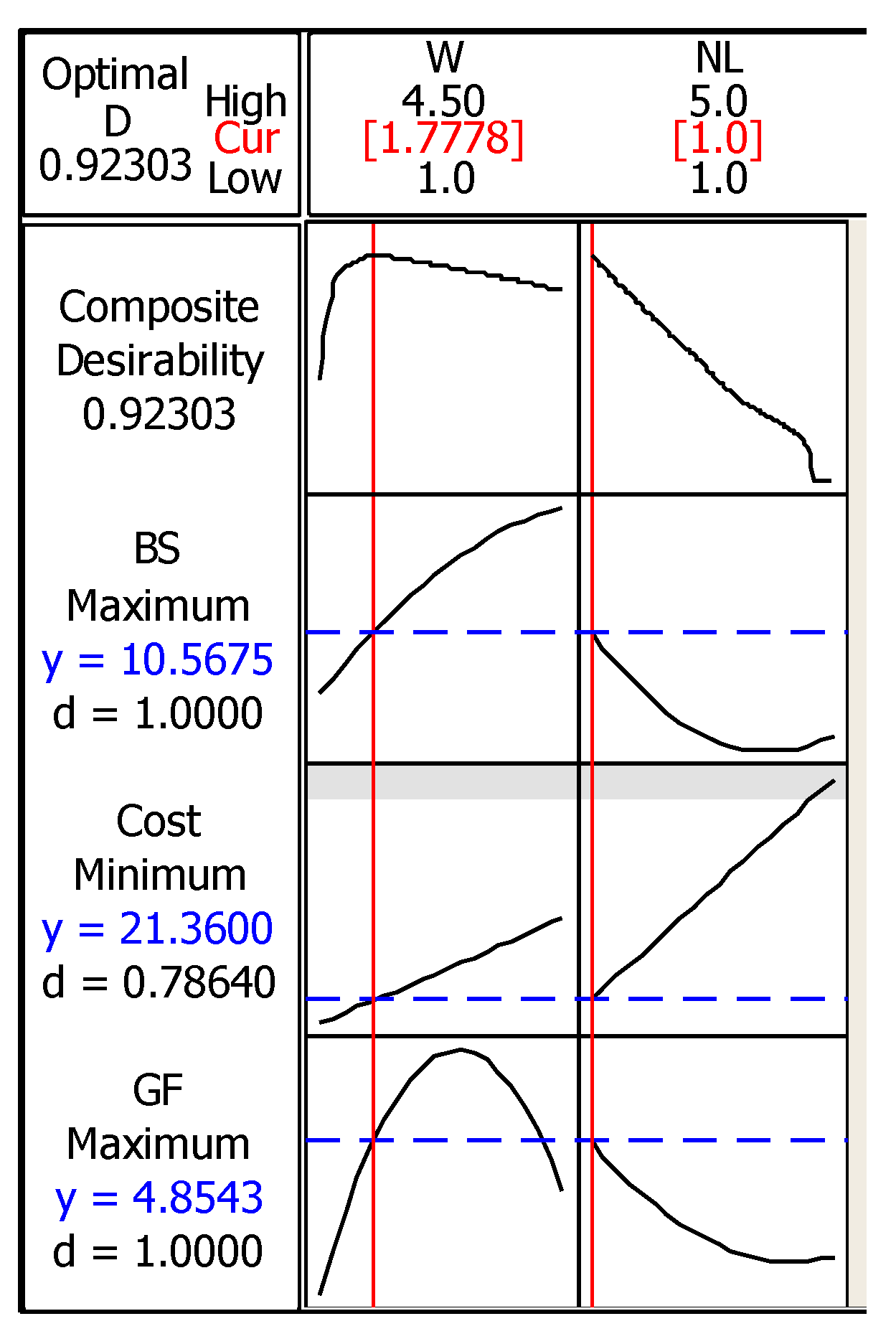

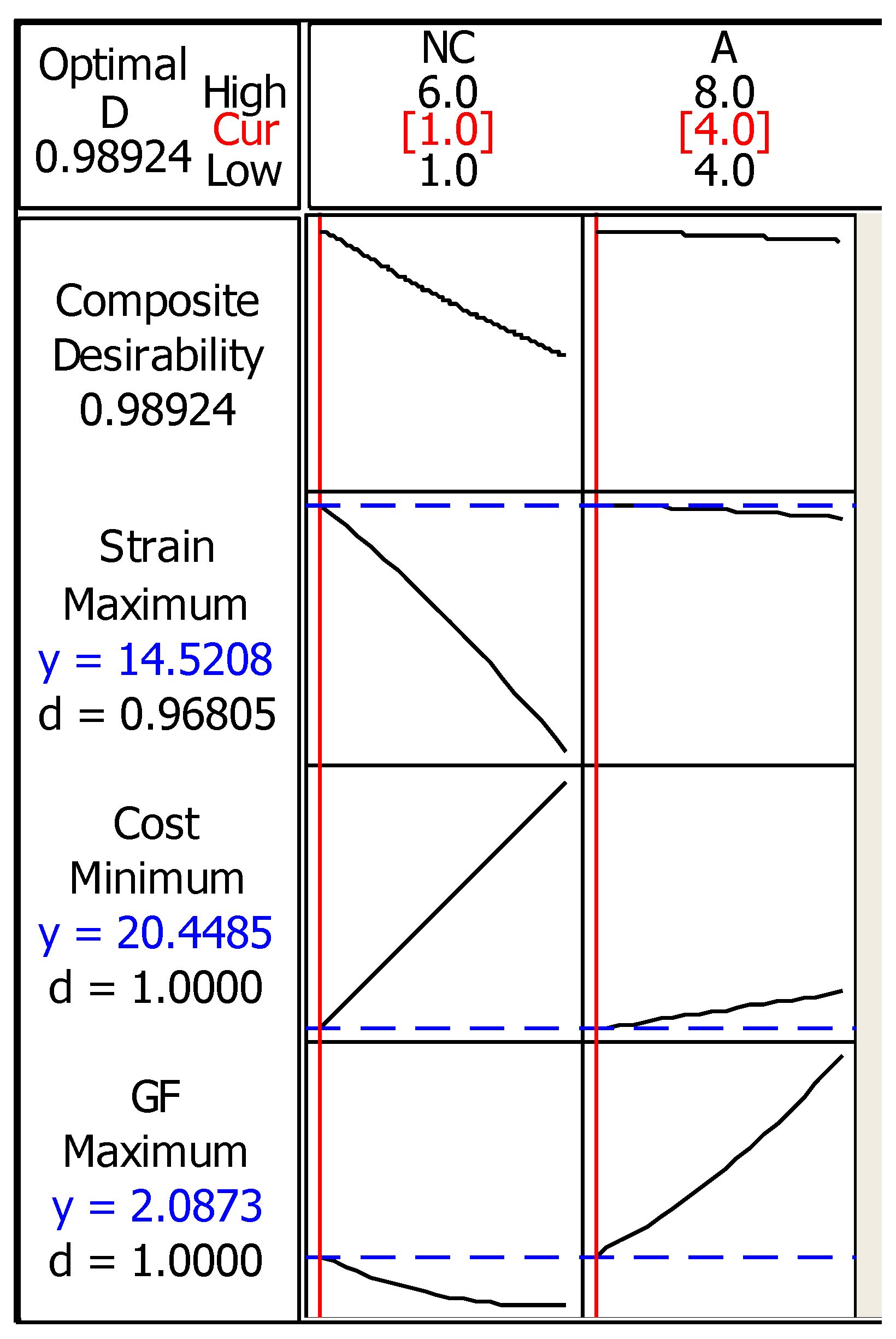

3.2. Optimization of Geometrical Parameters

3.2.1. Straight Line

3.2.2. Horseshoe

3.3. Limitation and Future Work

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing technologies on flexible substrates for printed electronics. In Flexible Electronics; InTech: London, UK, 2018; Volume 1, p. 13. [Google Scholar]

- Alamán, J.; Alicante, R.; Peña, J.I.; Sánchez-Somolinos, C. Inkjet printing of functional materials for optical and photonic applications. Materials 2016, 9, 910. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhu, Y. Printing Conductive Nanomaterials for Flexible and Stretchable Electronics: A Review of Materials, Processes, and Applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Larmagnac, A.; Eggenberger, S.; Janossy, H.; Vörös, J. Stretchable electronics based on Ag-PDMS composites. Sci. Rep. 2014, 4, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Jung, K.H.; Jung, S.B. Design and fabrication of screen-printed silver circuits for stretchable electronics. Microelectron. Eng. 2014, 120, 216–220. [Google Scholar] [CrossRef]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv. Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef] [PubMed]

- Yokus, M.A.; Foote, R.; Jur, J.S. Printed Stretchable Interconnects for Smart Garments: Design, Fabrication, and Characterization. IEEE Sens. J. 2016, 16, 7967–7976. [Google Scholar] [CrossRef]

- Adrega, T.; Lacour, S.P. Stretchable gold conductors embedded in PDMS and patterned by photolithography: Fabrication and electromechanical characterization. J. Micromech. Microeng. 2010, 20, 055225. [Google Scholar] [CrossRef]

- Koch, E.; Dietzel, A. Stretchable sensor array for respiratory monitoring. In Proceedings of the 2017 19th International Conference Solid-State Sensors, Actuators Microsystems, Kaohsiung, Taiwan, 18–22 June 2017; pp. 2227–2230. [Google Scholar]

- Liimatta, T.; Halonen, E.; Sillanpaa, H.; Niittynen, J.; Mantysalo, M. Inkjet printing in manufacturing of stretchable interconnects. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; pp. 151–156. [Google Scholar]

- Abu-Khalaf, J.M.; Park, J.W.; Mascaro, D.J.; Mascaro, S.A. Stretchable fingernail sensors for measurement of fingertip force. In Proceedings of the World Haptics 2009-Third Joint EuroHaptics conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, Salt Lake City, UT, USA, 18–20 March 2009; pp. 625–626. [Google Scholar]

- Jiang, J.; Bao, B.; Li, M.; Sun, J.; Zhang, C.; Li, Y.; Li, F.; Yao, X.; Song, Y. Fabrication of transparent multilayer circuits by inkjet printing. Adv. Mater. 2016, 28, 1420–1426. [Google Scholar] [CrossRef]

- Huang, Q.; Al-Milaji, K.N.; Zhao, H. Inkjet printing of silver nanowires for stretchable heaters. ACS Appl. Nano Mater. 2018, 1, 4528–4536. [Google Scholar] [CrossRef]

- Al-Halhouli, A.; Qitouqa, H.; Alashqar, A.; Abu-Khalaf, J. Inkjet printing for the fabrication of flexible/stretchable wearable electronic devices and sensors. Sens. Rev. 2018, 38, 438–452. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Song, Y. Inkjet printing wearable electronic devices. J. Mater. Chem. C 2017, 5, 2971–2993. [Google Scholar] [CrossRef]

- Robinson, A.; Aziz, A.; Liu, Q.; Suo, Z.; Lacour, S.P. Hybrid stretchable circuits on silicone substrate. J. Appl. Phys. 2014, 115, 15–20. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Smith, P.J.; Shin, D.Y.; Stringer, J.E.; Derby, B.; Reis, N. Direct ink-jet printing and low temperature conversion of conductive silver patterns. J. Mater. Sci. 2006, 41, 4153–4158. [Google Scholar] [CrossRef]

- Kwak, Y.H.; Kim, W.; Park, K.B.; Kim, K.; Seo, S. Flexible heartbeat sensor for wearable device. Biosens. Bioelectron. 2017, 94, 250–255. [Google Scholar] [CrossRef] [PubMed]

- Kwak, Y.H.; Kim, J.; Kim, K. Sleep monitoring sensor using flexible metal strain gauge. Jpn. J. Appl. Phys. 2018, 57, 2–6. [Google Scholar] [CrossRef]

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1–19. [Google Scholar] [CrossRef]

- Sun, J.; Jiang, J.; Bao, B.; Wang, S.; He, M.; Zhang, X.; Song, Y. Fabrication of Bendable Circuits on a Polydimethylsiloxane (PDMS) Surface by Inkjet Printing Semi-Wrapped Structures. Materials 2016, 9, 253. [Google Scholar] [CrossRef]

- Abu-Khalaf, J.; Al-Ghussain, L.; Al-Halhouli, A. Fabrication of Stretchable Circuits on Polydimethylsiloxane (PDMS) Pre-Stretched Substrates by Inkjet Printing Silver Nanoparticles. Materials 2018, 11, 2377. [Google Scholar] [CrossRef]

- Wu, J.; Wang, R.; Yu, H.; Li, G.; Xu, K.; Tien, N.C.; Roberts, R.C.; Li, D. Inkjet-printed microelectrodes on PDMS as biosensors for functionalized microfluidic systems. Lab Chip 2015, 15, 690–695. [Google Scholar] [CrossRef]

- Wu, J.; Roberts, R.C.; Tien, N.C.; Li, D. Inkjet printed silver patterning on PDMS to fabricate microelectrodes for microfluidic sensing. In Proceedings of the SENSORS, 2014 IEEE, Valencia, Spain, 2–5 November 2014; pp. 1100–1103. [Google Scholar]

- Yin, Z.P.; Huang, Y.A.; Bu, N.B.; Wang, X.M.; Xiong, Y.L. Inkjet printing for flexible electronics: Materials, processes and equipments. Chin. Sci. Bull. 2010, 55, 3383–3407. [Google Scholar] [CrossRef]

- Abu-khalaf, J.M.; Saraireh, R.; Eisa, S.M.; Al-halhouli, A. Experimental characterization of inkjet-printed stretchable circuits for wearable sensor applications. Sensors 2018, 18, 3476. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Rogers, J.A. Stretchable electronics: Materials strategies and devices. Adv. Mater. 2008, 20, 4887–4892. [Google Scholar] [CrossRef]

- Lacour, S.P.; Jones, J.; Suo, Z.; Wagner, S. Design and performance of thin metal film interconnects for skin-like electronic circuits. IEEE Electron. Device Lett. 2004, 25, 179–181. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Kim, Y.; Ren, X.; Kim, J.W.; Noh, H. Direct inkjet printing of micro-scale silver electrodes on polydimethylsiloxane (PDMS) microchip. J. Micromech. Microeng. 2014, 24, 115010. [Google Scholar] [CrossRef]

- Al-Ghussain, L. Global warming: Review on driving forces and mitigation. Environ. Prog. Sustain. Energy 2018, 38, 13–21. [Google Scholar] [CrossRef]

- Ahmad, A.D.; Abubaker, A.M.; Salaimeh, A.A.; Akafuah, N.K. Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport. Coatings 2018, 8, 279. [Google Scholar] [CrossRef]

- Wilson, J.E.; Grib, S.W.; Ahmad, A.D.; Renfro, M.W.; Adams, S.A.; Salaimeh, A.A. Study of Near-Cup Droplet Breakup of an Automotive Electrostatic Rotary Bell (ESRB) Atomizer Using High-Speed Shadowgraph Imaging. Coatings 2018, 8, 174. [Google Scholar] [CrossRef]

- Darwish Ahmad, A.; Singh, B.B.; Doerre, M.; Abubaker, A.M.; Arabghahestani, M.; Salaimeh, A.A.; Akafuah, N.K. Spatial Positioning and Operating Parameters of a Rotary Bell Sprayer: 3D Mapping of Droplet Size Distributions. Fluids 2019, 4, 165. [Google Scholar] [CrossRef]

- Najjar, Y.S.H.; Abubaker, A.M. Exergy analysis of a novel inlet air cooling system with gas turbine engines using cascaded waste-heat recovery. Int. J. Exergy 2017, 22, 183–204. [Google Scholar] [CrossRef]

- Najjar, Y.S.H.; Abubaker, A.M. Using novel compressed-air energy storage systems as a green strategy in sustainable power generation–a review. Int. J. Energy Res. 2016, 40, 1595–1610. [Google Scholar] [CrossRef]

- Mypati, S.; Dhanushkodi, S.R.; McLaren, M.; Docoslis, A.; Peppley, B.A.; Barz, D.P.J. Optimized inkjet-printed silver nanoparticle films: Theoretical and experimental investigations. RSC Adv. 2018, 8, 19679–19689. [Google Scholar] [CrossRef]

- Sipilä, E.; Ren, Y.; Virkki, J.; Sydänheimo, L.; Tentzeris, M.M.; Ukkonen, L. Parametric optimization of inkjet printing and optical sintering of nanoparticle inks. In Proceedings of the 2015 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; pp. 1–4. [Google Scholar]

- Fauzia, V.; Umar, A.A.; Salleh, M.M.; Yahya, M. Optimizing of the inkjet printing technique parameters for fabrication of bulk heterojunction organic solar cells. In Proceedings of the 2010 IEEE International Conference on Semiconductor Electronics (ICSE2010), Melaka, Malaysia, 28–30 June 2010; pp. 60–63. [Google Scholar]

- Lee, A.; Sudau, K.; Ahn, K.H.; Lee, S.J.; Willenbacher, N. Optimization of experimental parameters to suppress nozzle clogging in inkjet printing. Ind. Eng. Chem. Res. 2012, 51, 13195–13204. [Google Scholar] [CrossRef]

- Dahne, L.; Radtchenko, I.; Antipov, A.; Gao, C.; Ser, S.S.; Gray, B.D.S.; Tien, J.; Chen, C.S. High-conductivity elastomeric electronics. Adv. Mater. 2004, 16, 393–397. [Google Scholar]

- Abu-khalaf, J.M.; Mascaro, S.A. Optimization of stretchable fingernail sensor fabrication based on finite element modeling. In Proceedings of the 2018 IEEE Sensors Applications Symposium (SAS), Seoul, Korea, 12–14 March 2018; pp. 1–6. [Google Scholar]

- Ponnamma, D.; Wan, C.; Thomas, S. Flexible and Stretchable Electronic Composites; Springer: Berlin/Heidelberg, Germany, 2015; pp. 6–7. [Google Scholar]

- Al-Halhouli, A.; Demming, S.; Alahmad, L.; Liobera, A.; Büttgenbach, S. An In-Line photonic biosensor for monitoring of glucose concentrations. Sensors 2014, 14, 15749–15759. [Google Scholar] [CrossRef] [PubMed]

- Sigma-Aldrich Silver Nanoparticle Ink 30 wt % Dispersion in Ethylene Glycol, Sigma-Aldrich. Available online: https://www.sigmaaldrich.com/catalog/product/aldrich/798738?lang=en®ion=JO (accessed on 10 October 2019).

- Cummins, G.; Desmulliez, M.P.Y.; Cummins, G.; Marc, P.; Desmulliez, Y. Inkjet printing of conductive materials: A review. Circuit World 2012, 38, 193–213. [Google Scholar] [CrossRef]

- Hanrahan, G.; Lu, K. Application of factorial and response surface methodology in modern experimental design and optimization. Crit. Rev. Anal. Chem. 2006, 36, 141–151. [Google Scholar] [CrossRef]

- Types of DOE’s. QualityTrainingPortal. Available online: https://qualitytrainingportal.com/resources/design-experiments/types-does/ (accessed on 23 May 2019).

- Ba, D.; Boyaci, I.H. Modeling and optimization i: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar]

- Van Osch, T.H.J.; Perelaer, J.; De Laat, A.W.M.; Schubert, U.S. Inkjet printing of narrow conductive tracks on untreated polymeric substrates. Adv. Mater. 2008, 20, 343–345. [Google Scholar] [CrossRef]

- Liu, H.; Guo, S.; Zheng, K.; Guo, X.; Kuramoto-Ahuja, T.; Sato, T.; Onoda, K.; Maruyama, H. Reliability and validity of measuring respiration movement using a wearable strain sensor in healthy subjects. J. Phys. Ther. Sci. 2017, 29, 1543–1547. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Al-Halhouli, A.; Al-Ghussain, L.; el bouri, S.; Liu, H.; Zheng, D. Fabrication and Evaluation of a Novel Non-Invasive Stretchable and Wearable Respiratory Rate Sensor Based on Silver Nanoparticles Using Inkjet. Polymers 2019, 11, 1518. [Google Scholar] [CrossRef] [PubMed]

- Izdebska, J.; Thomas, S. Printing on Polymers: Fundamentals and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780323374682. [Google Scholar]

| Printing Parameters | Values |

|---|---|

| Droplet Speed (m/s) | 8 |

| Firing Voltage (V) | 23 |

| Nozzle/Cartridge Temperature ( | 32 |

| Platen Temperature for Single Layer Patterns ( | 24 (Room Temperature) |

| Platen Temperature for Multiple layers Patterns ( | 60 |

| Sintering Temperature () | 110 |

| Sintering Time (mins) | 60 |

| Jetting Resolution (pL) | 10 |

| Straight Line | Horseshoe | ||

|---|---|---|---|

| Parameter | Values | Parameter | Values |

| Line Width (W) | 1,1.5,2,2.5,3.5,4.5 | Amplitude (A) | 4,6,8 |

| Number of Layers (NL) | 1,2,3,4,5 | Number of Cycles (NC) | 1,2,4 |

| Term | Breakdown Strain (%) * | Cost (Euro) ** | GF *** | |||

|---|---|---|---|---|---|---|

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| Constant | 2.90 | 0 | 3.75 × | 0 | −9.54 | 0.309 |

| W (mm) | 9.58 | 0.417 | −3.75 × | 0 | 12.79 | 0.027 |

| NL | −5.19 | 0 | 1.62 × | 0 | 0.295 | 0.001 |

| W2 | −0.742 | 0.081 | 1.49 × | 0.019 | −1.85 | 0.003 |

| NL2 | 1.03 | 0 | 3.75 × | 0.266 | 0.326 | 0.252 |

| NL × W | −1.61 | 0.01 | 1.12 × | 0 | −1.75 | 0.011 |

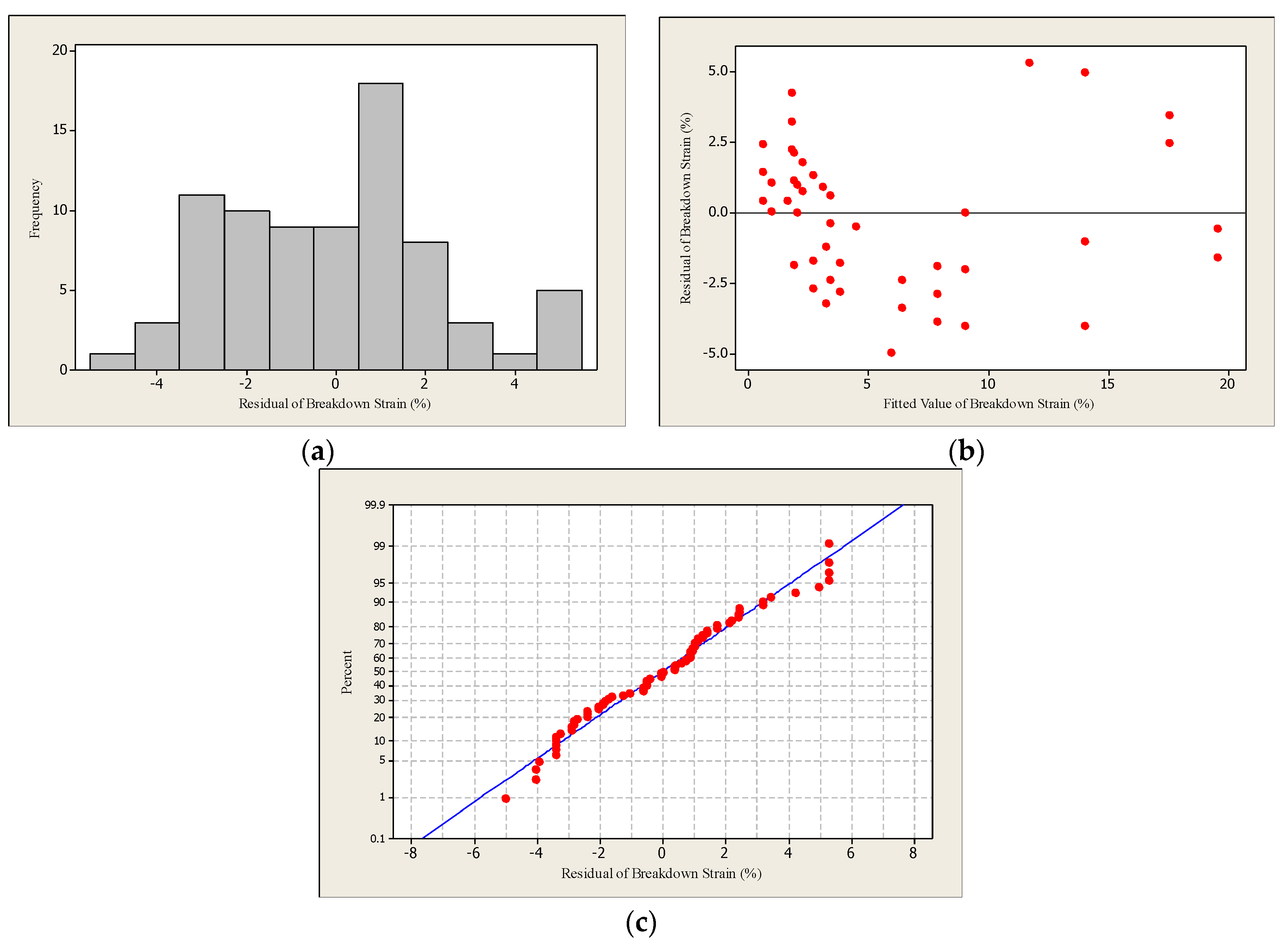

| Plot | Results |

|---|---|

| Histogram | The histogram is roughly bell-shaped which means that the residual error data are normally distributed. |

| Residuals versus fitted values | The points are randomly scattered around the zero reference which supports the assumption of constant variance. |

| Normal probability plot | The plot confirms that the data are normally distributed with some outliers. Moreover, the data show strong correlation to one another, resulting in a high Coefficient of Correlation (R = 82.44%). |

| Term | Breakdown Strain (%) * | Cost (Euro) ** | GF *** | |||

|---|---|---|---|---|---|---|

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| Constant | 17.23 | 0 | 4.94 | 0 | 0.772 | 0.012 |

| NC | −2.65 | 0.005 | 4.51 | 0 | 0.397 | 0.002 |

| A (mm) | −0.362 | 0.002 | −0.111 | 0 | 0.148 | 0.278 |

| NC2 | −0.0623 | 0.662 | −0.028 | 0 | 0.042 | 0.724 |

| A2 | −0.0124 | 0.944 | 0.016 | 0.035 | 0.07 | 0.633 |

| NC × A | 0.413 | 0.008 | 2.80 | 0 | −0.21 | 0.091 |

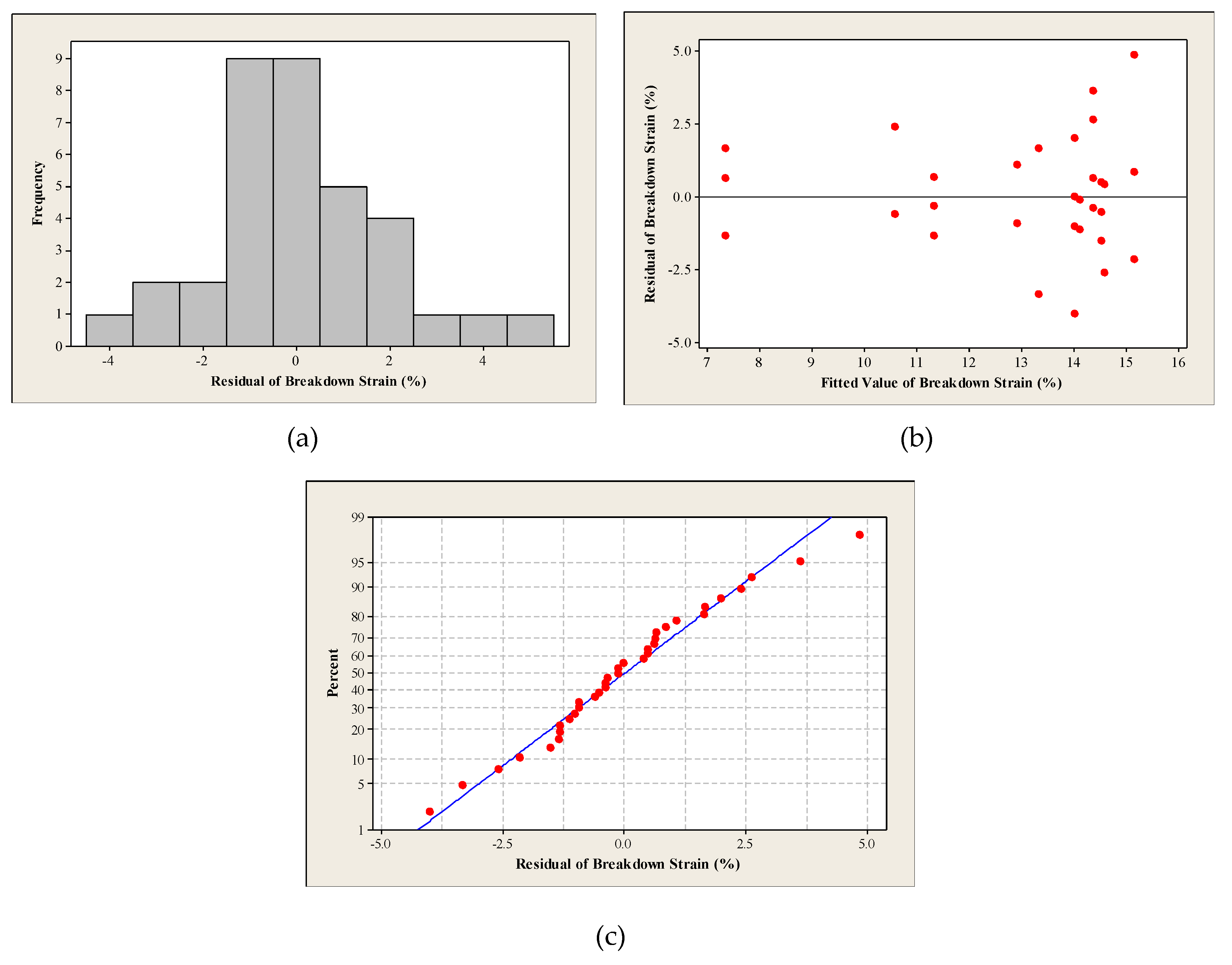

| Plot | Results |

|---|---|

| Histogram | The histogram is bell-shaped which means that the residual error data are normally distributed. |

| Residuals versus fitted values | The points are randomly scattered around the zero reference which supports the assumption of constant variance. |

| Normal probability plot | The plot confirms that the data are normally distributed with some outliers. Moreover, the data show good correlation to one another, with acceptable Coefficient of Correlation (R = 59.02%). |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu-Khalaf, J.; Al-Ghussain, L.; Nadi, A.; Saraireh, R.; Rabayah, A.; Altarazi, S.; Al-Halhouli, A. Optimization of Geometry Parameters of Inkjet-Printed Silver Nanoparticle Traces on PDMS Substrates Using Response Surface Methodology. Materials 2019, 12, 3329. https://doi.org/10.3390/ma12203329

Abu-Khalaf J, Al-Ghussain L, Nadi A, Saraireh R, Rabayah A, Altarazi S, Al-Halhouli A. Optimization of Geometry Parameters of Inkjet-Printed Silver Nanoparticle Traces on PDMS Substrates Using Response Surface Methodology. Materials. 2019; 12(20):3329. https://doi.org/10.3390/ma12203329

Chicago/Turabian StyleAbu-Khalaf, Jumana, Loiy Al-Ghussain, Ahmad Nadi, Razan Saraireh, Abdulrahman Rabayah, Safwan Altarazi, and Ala’aldeen Al-Halhouli. 2019. "Optimization of Geometry Parameters of Inkjet-Printed Silver Nanoparticle Traces on PDMS Substrates Using Response Surface Methodology" Materials 12, no. 20: 3329. https://doi.org/10.3390/ma12203329

APA StyleAbu-Khalaf, J., Al-Ghussain, L., Nadi, A., Saraireh, R., Rabayah, A., Altarazi, S., & Al-Halhouli, A. (2019). Optimization of Geometry Parameters of Inkjet-Printed Silver Nanoparticle Traces on PDMS Substrates Using Response Surface Methodology. Materials, 12(20), 3329. https://doi.org/10.3390/ma12203329