Experimentation and Predictive Models for Properties of Concrete Added with Active and Inactive SiO2 Fillers

Abstract

1. Introduction

2. Materials

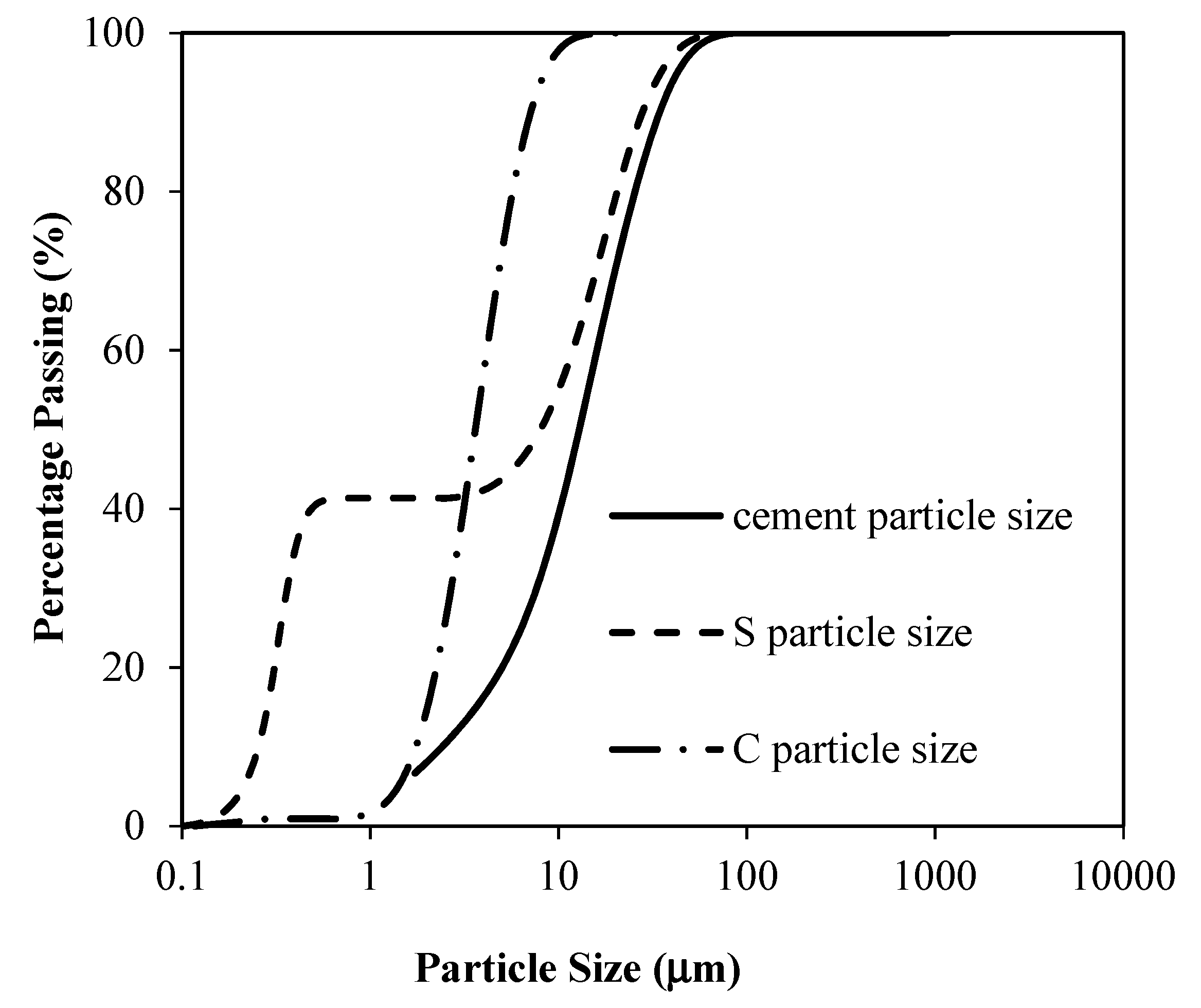

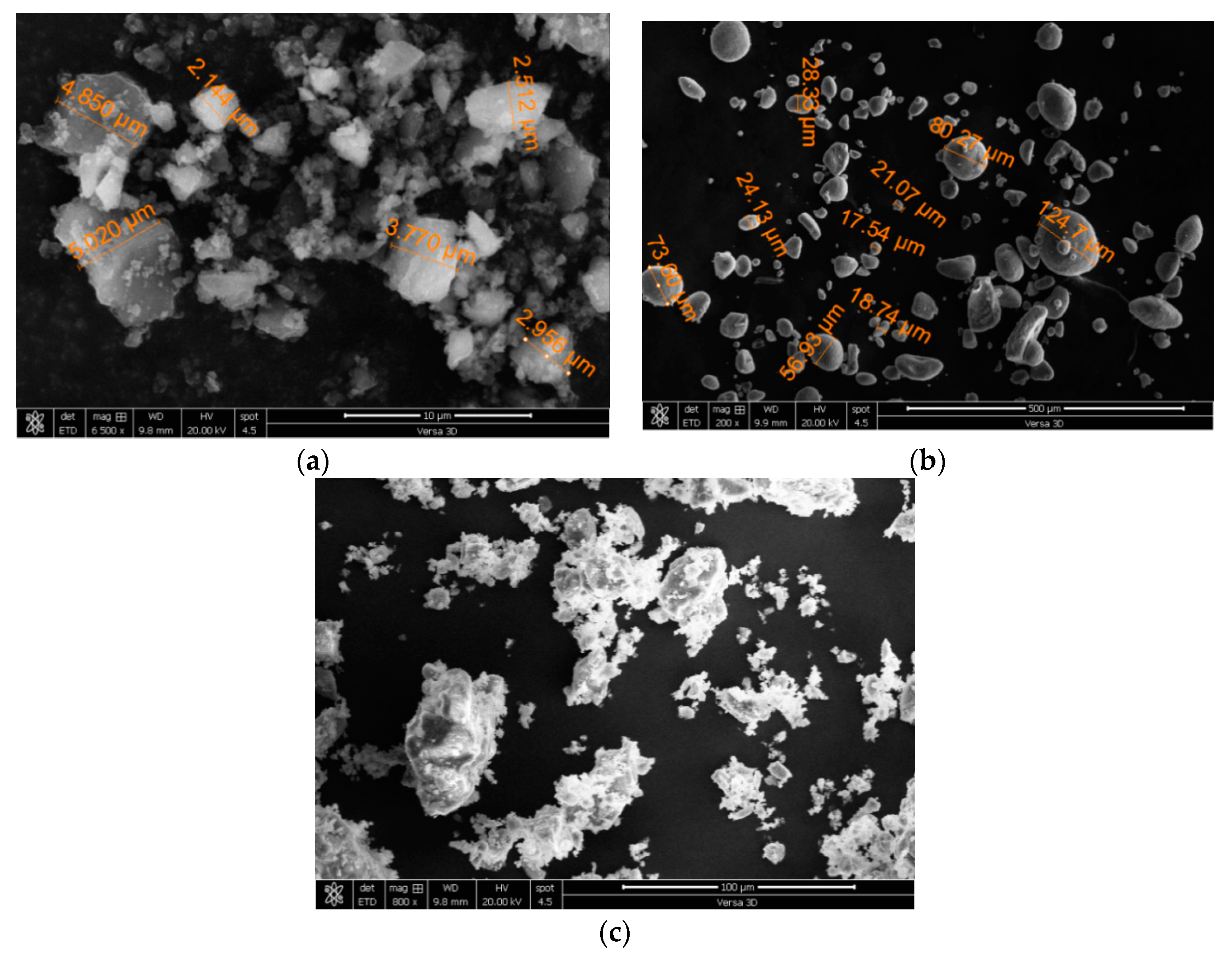

2.1. Cementitious Materials

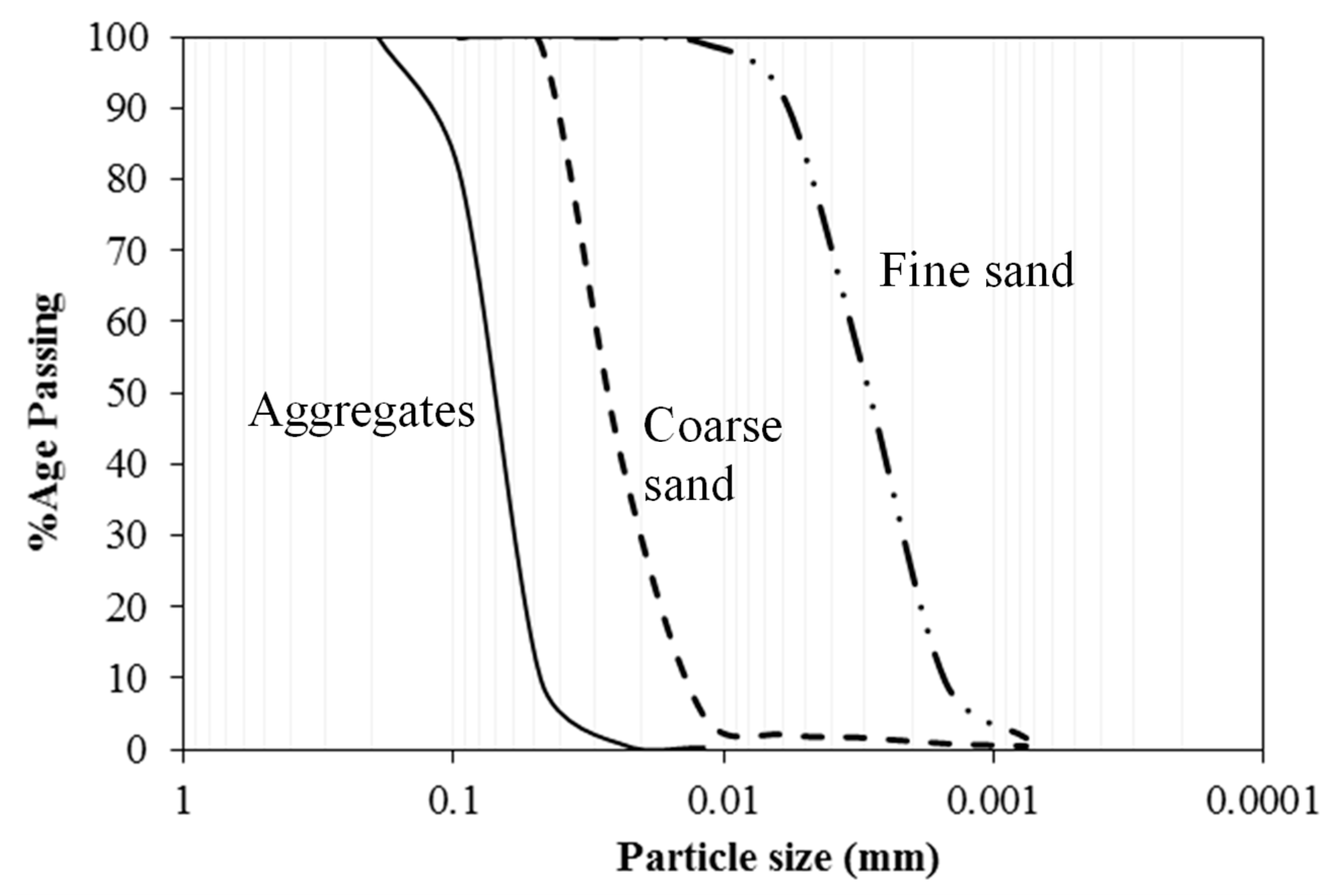

2.2. Fine and Coarse Aggregates

2.3. Chemical Admixtures

3. Mix Preparations and Test Setup

3.1. Mix Properties and Preparations

3.2. Experimental Method

4. Results and Discussion

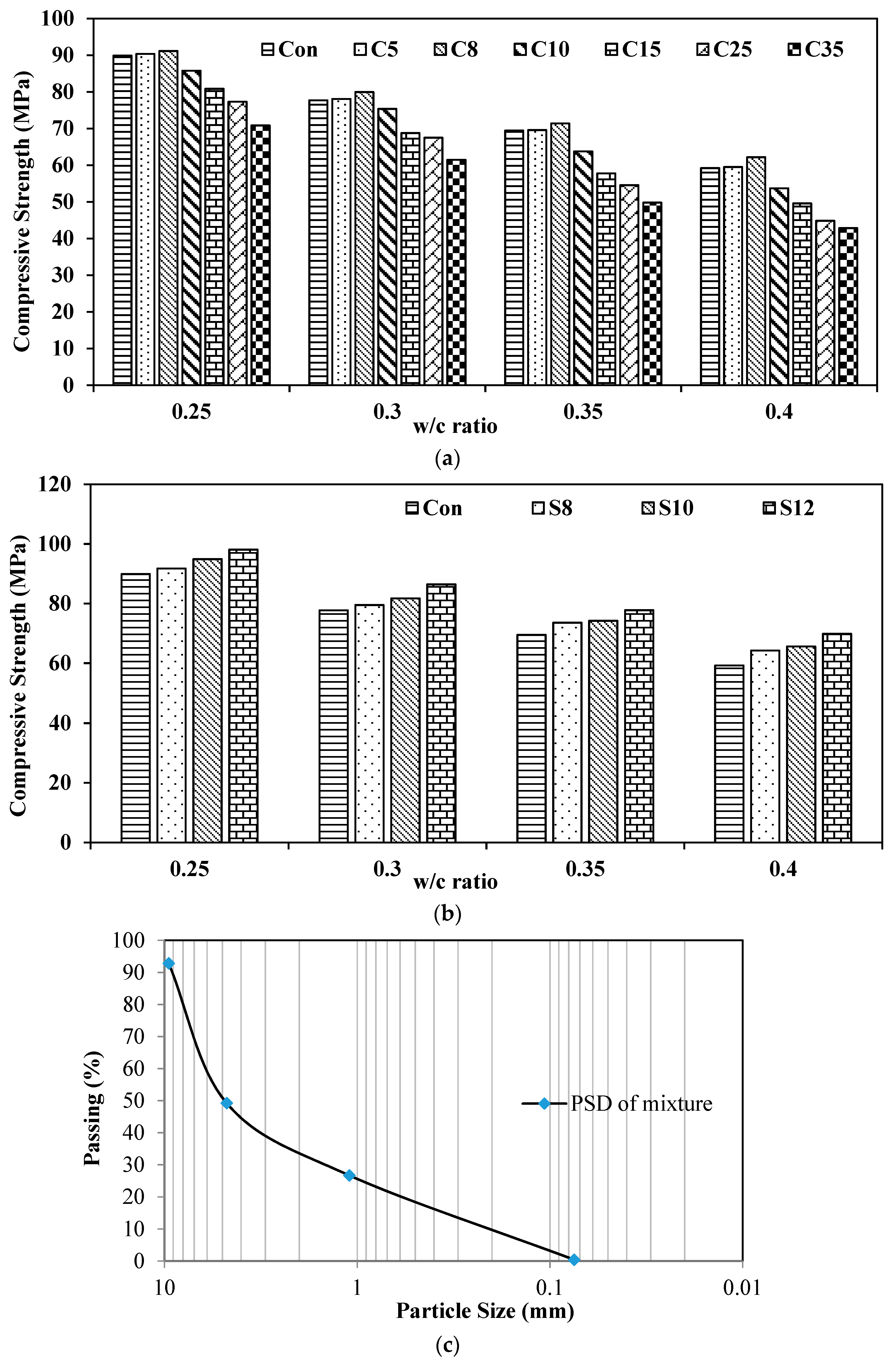

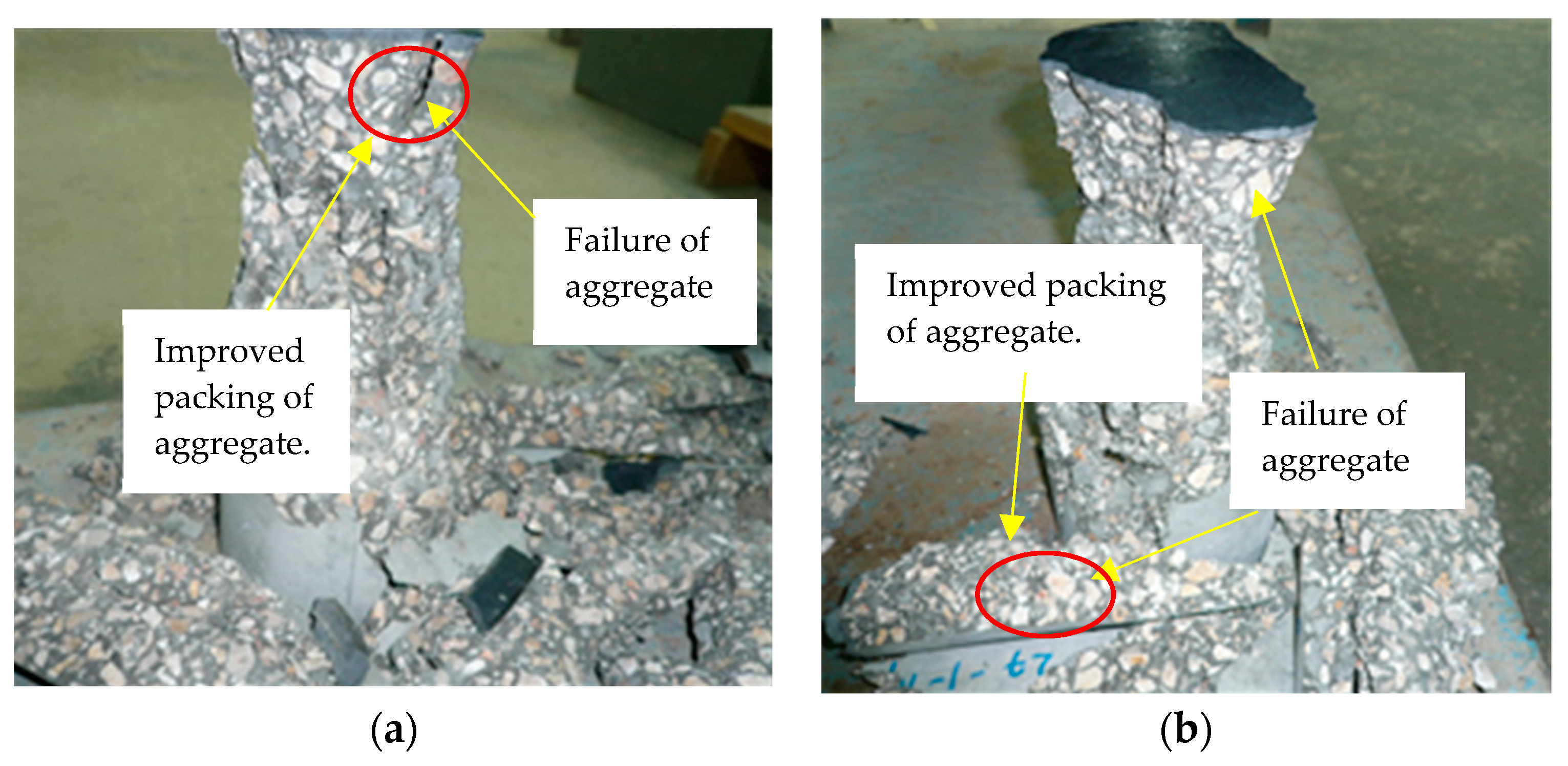

4.1. Effect of Cement Replacement on the Properties of Concrete at 28 Days

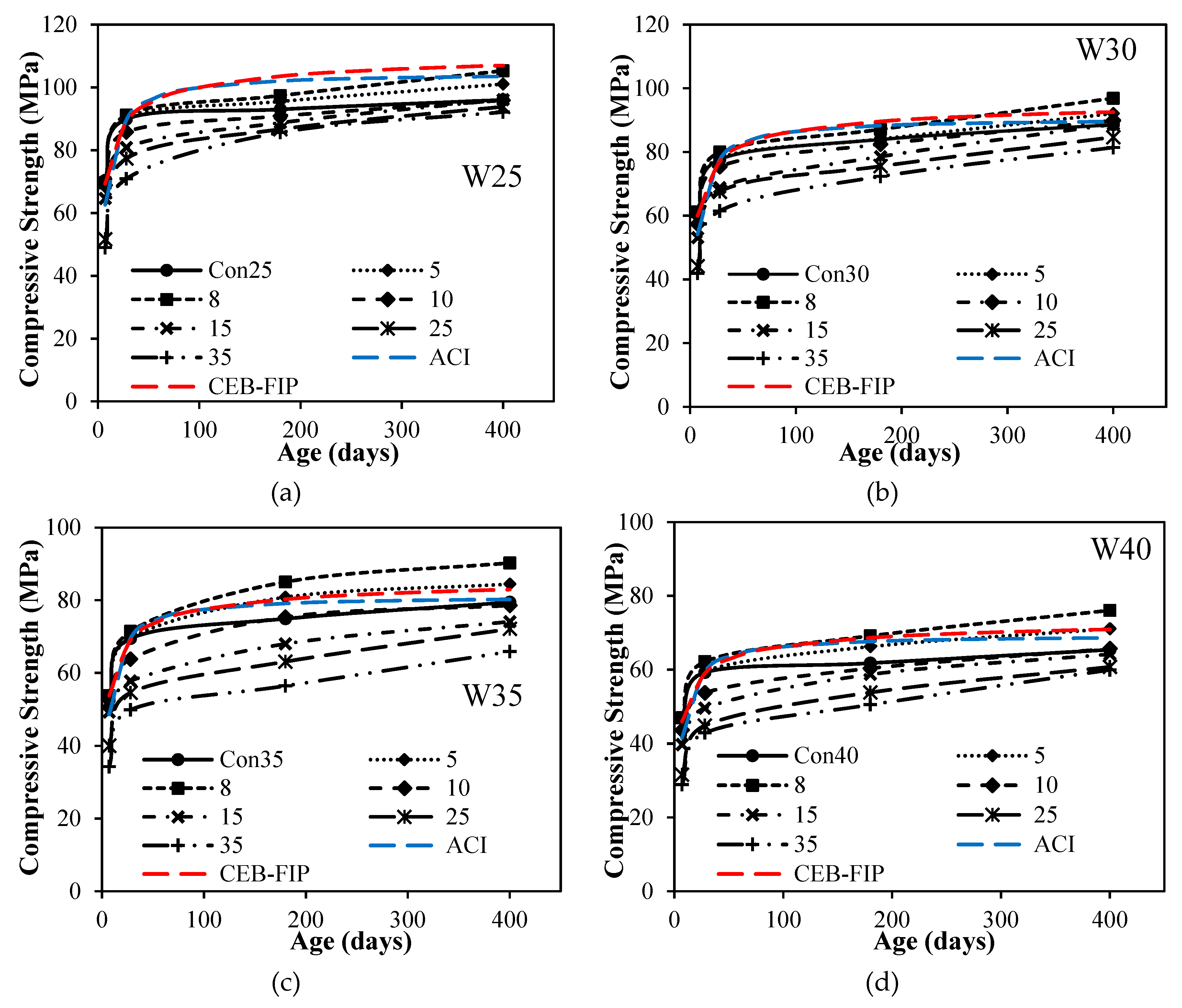

4.2. Age Effect on the Compressive Strength of Concrete

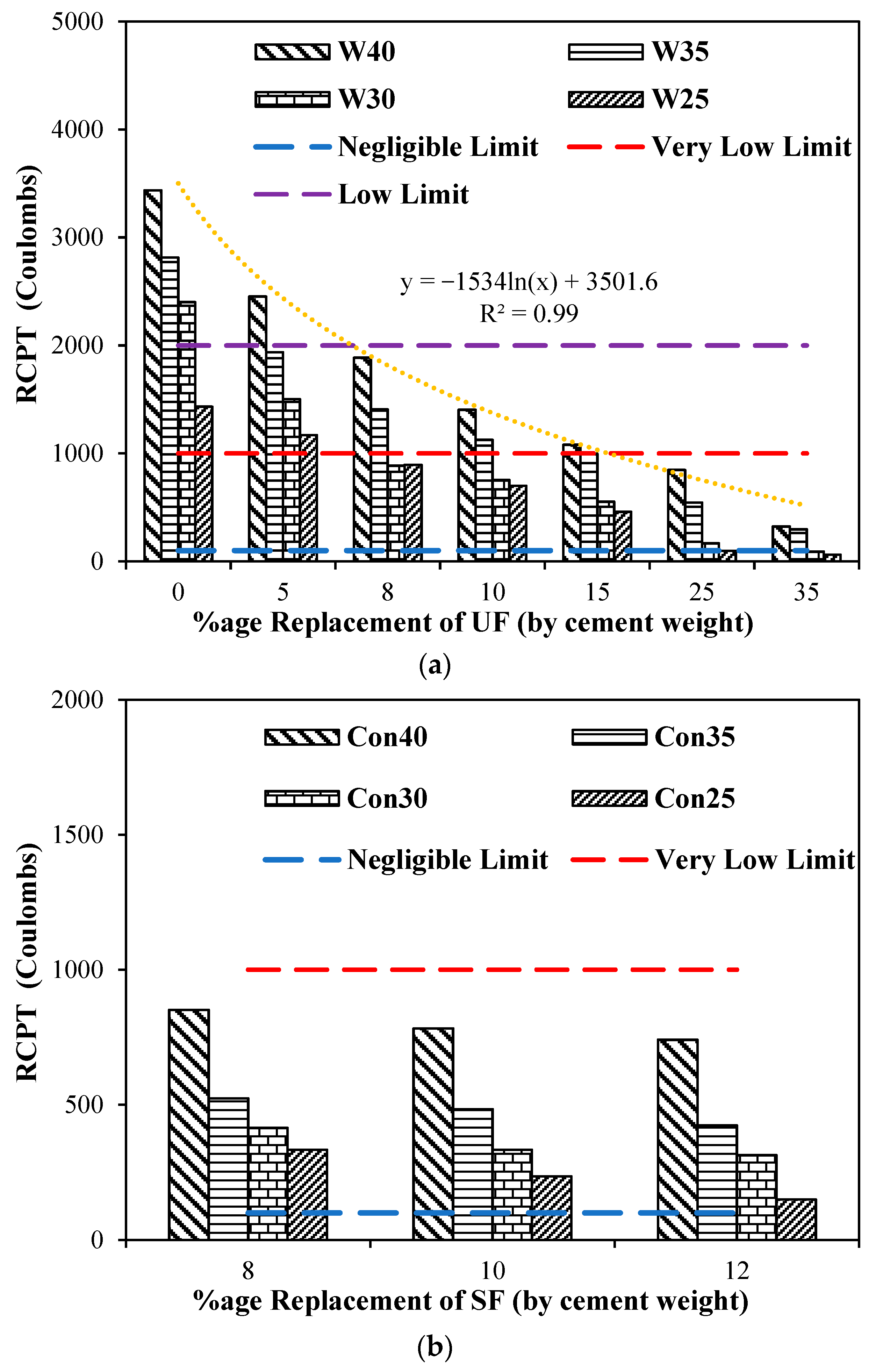

4.3. Rapid Chloride Ion Penetrability of Concrete

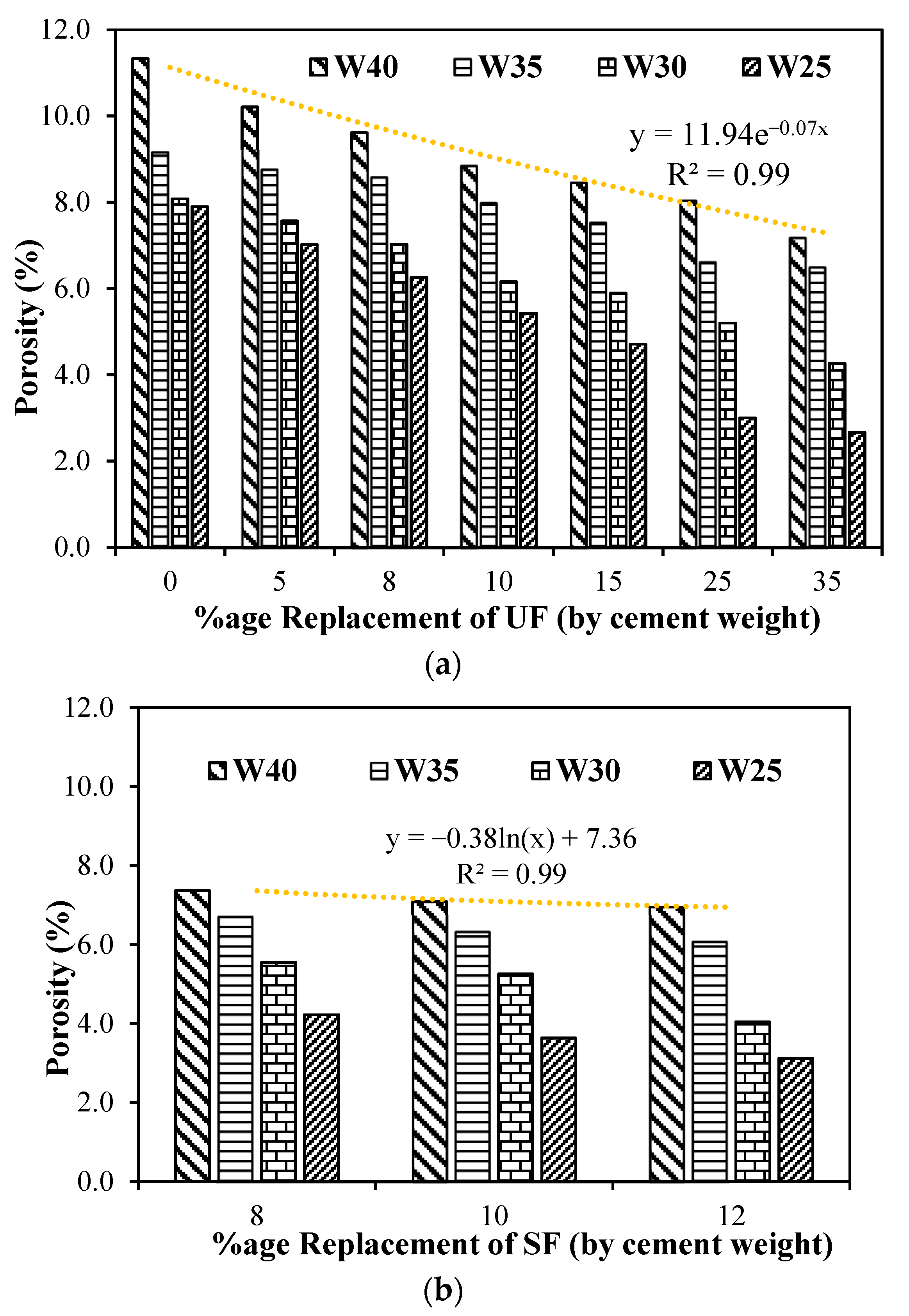

4.4. Porosity

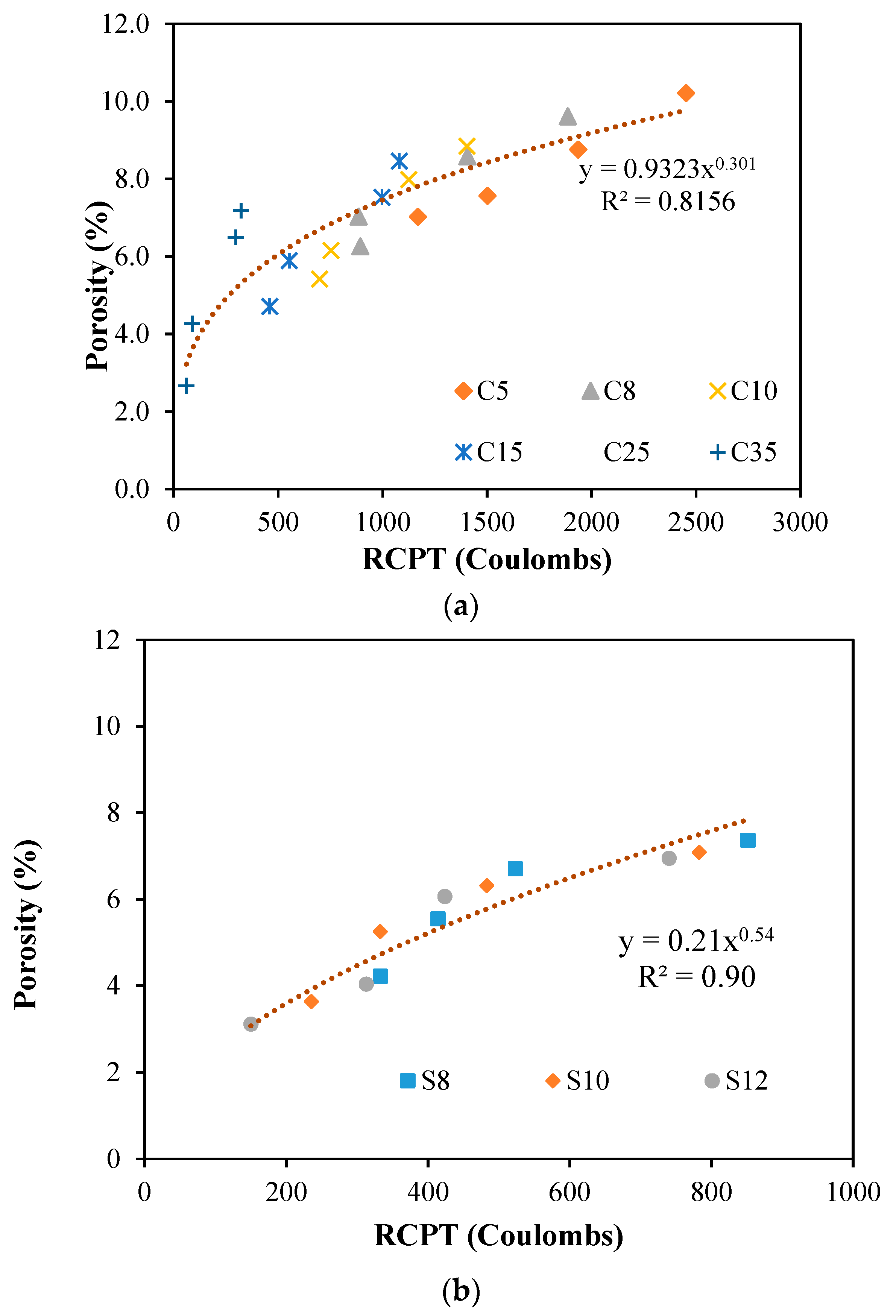

4.5. Relationship between RCPT and Porosity

5. Predictive Models

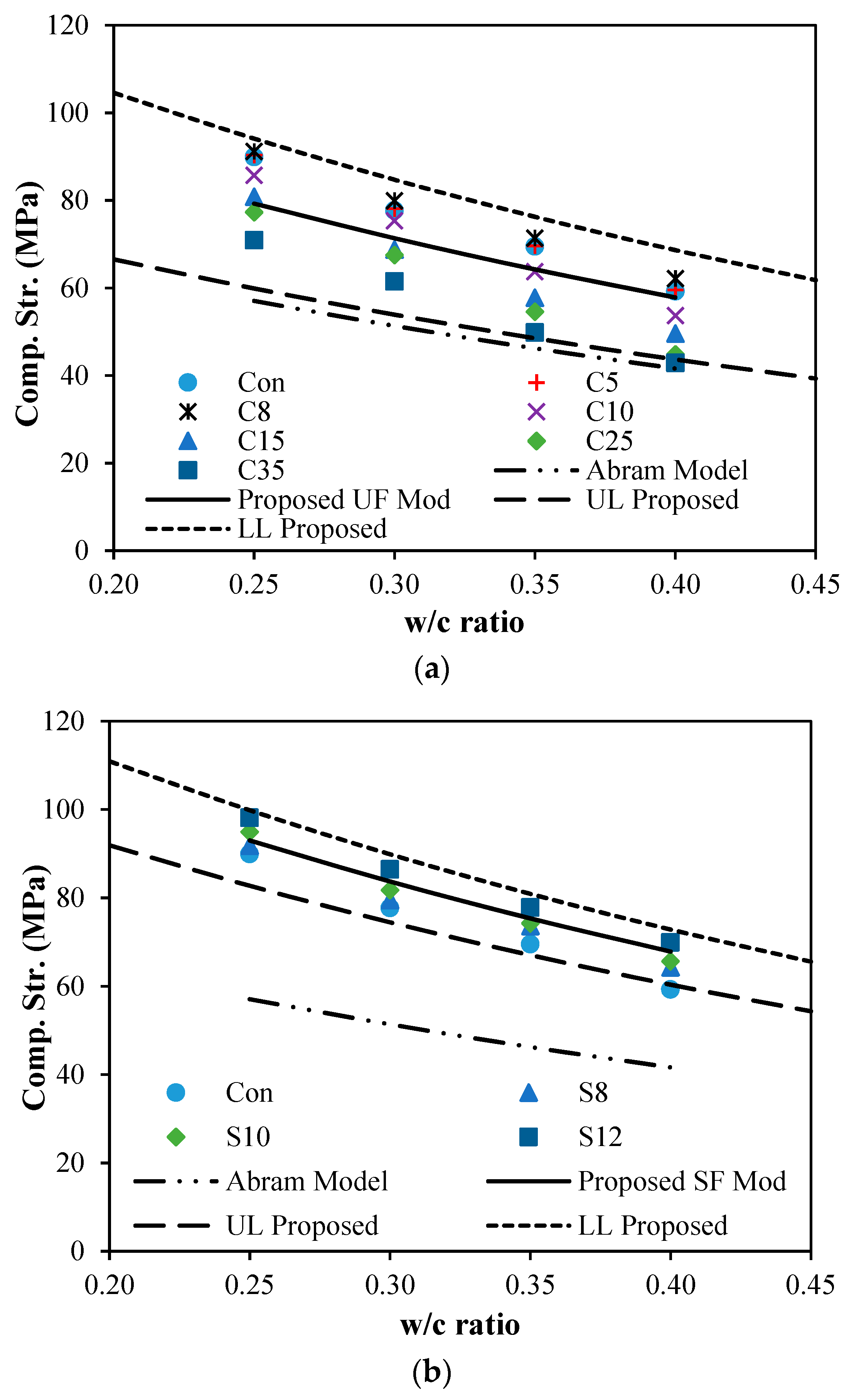

5.1. Predictive Model of Compressive Strength for Different Water-to-Cement Ratios

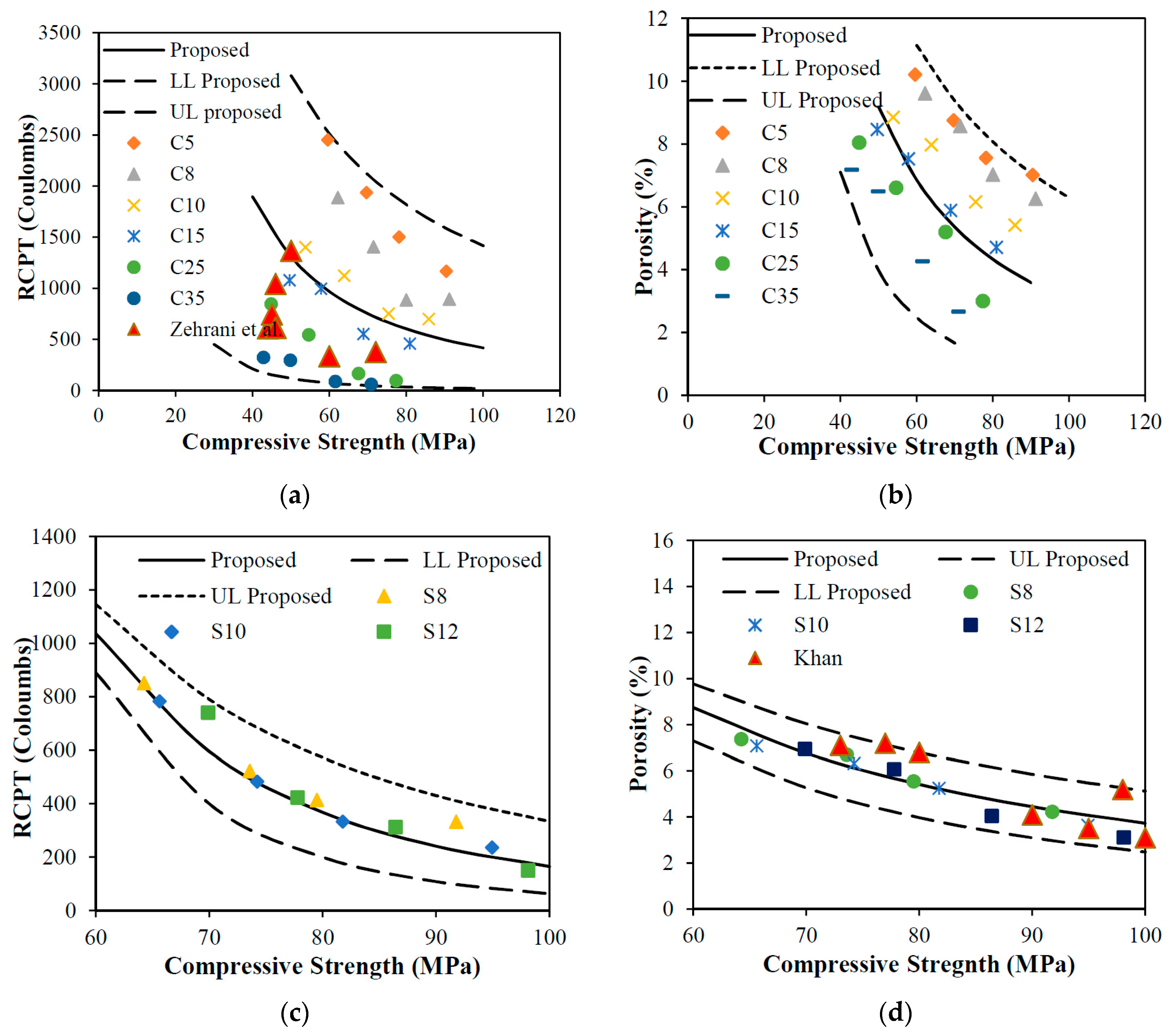

5.2. Predictive Models for RCPT and Porosity Based on Compressive Strength

6. Conclusions

- ➢

- Maximum increase of 12% in compressive strength with 12% partial replacement of silica fume was observed, whereas partial replacement of cement with 35% dosage of ultrafines showed about a 28% decrease in compressive strength. This decrease in the compressive strength was attributed to a non-pozzolanic activity of inactive ultrafine filler. However, partial replacement of cement with ultrafine up to 8% showed around a 5% increase in compressive strength.

- ➢

- All the mixtures with silica fume and ultrafines have produced higher compressive strength than given by Abram’s predictive model, and the increase in compressive strength with partial replacement of silica fume and ultrafine was 63% and 38%, respectively, as compared to Abram’s predictive equation.

- ➢

- The partial replacement of 8% of silica fume has yielded the RCPT value to a very low limit and low porosity for all water-to-cement ratios. However, the partial replacement with 8% of ultrafines has yielded RCPT to a very low limit at a water-to-cement ratio of 0.3, but at a replacement level of 15% ultrafines. Concrete mixture with all water-to-cement ratios yielded a very low limit of RCPT value.

- ➢

- The relationships for RCPT and porosity of all mixtures was attained which suggested that there is strong correlation between porosity and RCPT for both ultrafines and silica fume, as expected.

- ➢

- Predictive models have been proposed for RCPT and porosity by compressive strength with consideration of dosage of replacements of ultrafines and silica fume using experimental data.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lagerblad, B.; Gram, H.E.; Westerholm, M. Evaluation of the quality of fine materials and filler from crushed rocks in concrete production. Constr. Build. Mater. 2014, 67, 121–126. [Google Scholar] [CrossRef]

- Andrade, C.; Sanjuán, M. Updating Carbon Storage Capacity of Spanish Cements. Sustainability 2018, 10, 4806. [Google Scholar] [CrossRef]

- Sanjuána, M.Á.; Argiz, C.; Gálvez, J.C.; Moragues, A. Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr. Build. Mater. 2015, 96, 55–64. [Google Scholar] [CrossRef]

- Gleize, J.P.; Müller, A.; Roman, H.R. Micro-Structural Investigation of Silica Fume-Cement-Lime Mortar. Cem. Concr. Compos. 2003, 25, 171–175. [Google Scholar] [CrossRef]

- Poppe, A.M.; de Schutter, G. Cement Hydration in the Presence of High Filler Contents. Cem. Concr. Res. 2005, 35, 2290–2299. [Google Scholar] [CrossRef]

- Agarwal, S.K. Pozzolanic Activity of Various Siliceous Materials. Cem. Concr. Res. 2006, 36, 1735–1739. [Google Scholar] [CrossRef]

- Khan, M.I. Permeation of High Performance Concrete. J. Mater. Civ. Eng. 2003, 15, 84–92. [Google Scholar] [CrossRef]

- Kadri, E.H.; Duval, R. Hydration heat kinetics of concrete with silica fume. Constr. Build. Mater. 2009, 33, 388–3392. [Google Scholar] [CrossRef]

- Muller, A.C.A.; Scrivener, K.L.; Skibsted, J.; Gajewicz, A.M.; McDonald, P.J. Influence of silica fume on the microstructure of cement pastes: New insights from 1 H NMR relaxometry. Cem. Concr. Res. 2015, 74, 116–125. [Google Scholar] [CrossRef]

- Rossen, J.E.; Lothenbach, B.; Scrivener, K.L. Composition of C–S–H in pastes with increasing levels of silica fume addition. Cem. Concr. Res. 2015, 75, 14–22. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Ouyang, P.; Yang, Y. Hydration of the silica fume-Portland cement binary system at lower temperature. Constr. Build. Mater. 2015, 93, 919–925. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.M.R. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Tavares, L.M.; Filho, R.D.T. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cem. Concr. Res. 2016, 89, 269–275. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Mineral admixtures in mortars: Quantification of the physical effects of inert materials on short-term hydration. Cem. Concr. Res. 2005, 35, 719–730. [Google Scholar]

- Argiz, C.; Menéndez, E.; Sanjuán, M.A. Effect of mixes made of coal bottom ash and fly ash on the mechanical strength and porosity of Portland cement. Mater. De Constr. 2013, 63, 49–64. [Google Scholar]

- Cordeiro, G.C.; Kurtis, K.E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cem. Concr. Res. 2017, 97, 41–49. [Google Scholar] [CrossRef]

- Moosberg-Bustnes, H.; Lagerblad, B.; Forssberg, E. The function of fillers in concrete. Mater. Struct. 2004, 37, 74–81. [Google Scholar] [CrossRef]

- ASTM C150. Standard Specification for Portland Cement; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C1202. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Cheerarot, R.; Tangpagasit, J.; Jaturapitakkul, C. Compressive strength of mortars due to pozzolanic reaction of fly ash. Am. Concr. Inst. J. 2004, 221, 411–426. [Google Scholar]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011, 25, 4287–4293. [Google Scholar] [CrossRef]

- Tangpagasit, J.; Cheerarot, R.; Jaturapitakkul, C.; Kiattikomol, K. Packing effect and pozzolanic reaction of fly ash in mortar. Cem. Concr. Res. 2005, 35, 1145–1151. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Jamil, M.; Karim, M.R.; Zain, M.F.M.; Kaish, A.B.M.A. Filler Effect of Pozzolanic Materials on the Strength and Microstructure Development of Mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- ACI 234R-06. Guide for the Use of Silica Fume in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2012; p. 63. [Google Scholar]

- Loland, K.E.; Hustad, T. Report 2 Mechanical Properties. FCB/SINTEF; Norwegian Institute of Technology: Trondheim, Norway, 1981. [Google Scholar]

- Sellevold, E.J.; Nilson, T. Condensed Silica Fume in Concrete: A World Review; Supplementary Cementing Materials for Concrete; CANMET: Ottawa, ON, Canada, 1987; pp. 165–243. [Google Scholar]

- Newman, J.; Choo, B.S. Advanced Concrete Technology Concrete Properties; Elsevier Ltd.: London, UK, 2003. [Google Scholar]

- Lamond, J.E.; Pielert, J.H. Significance of Test and Properties of Concrete and Concrete Making Materials; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete Microstructure Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- De Larrard, F.; Belloc, A. On the Long-Term Strength Losses of Silica-Fume High-Strength Concretes. Mag. Concr. Res. 1991, 43, 109–119. [Google Scholar] [CrossRef]

- Burg, R.G.; Ӧst, B.W. Engineering Properties of Commercially Available High-Strength Concretes (Including Three-Year Data). Research and Development Bulletin RD 104; Portland cement Association: Skokie, IL, USA, 1994; Volume 104, p. 62. [Google Scholar]

- Persson, B. Pozzolanic Interaction between Portland Cement and Silica Fume in Concrete. CANMET/ACI Sixth International Conference; American Concrete Institute: Farmington Hills, MI, USA, 1998; pp. 631–660. [Google Scholar]

- Malhotra, V.M.; Chevrier, R. Long-Term Strength Development of Silica Fume Concrete. Spec. Publ. 1992, 132, 1017–1044. [Google Scholar]

- ACI COMMITTEE 209. Creep Shrinkage Temperature in Concrete Structures; American Concrete Institute: Detroit, MI, USA, 2008; pp. 258–269. [Google Scholar]

- CEB. Structural Concrete-Textbook on Behaviour, Design and Performance. Updated Knowledge of the CEB/FIP Model Code 1990, fib Bulletin 2, V. 2; Federation Internationale du Beton: Lausanne, Switzerland, 1999; pp. 37–52. [Google Scholar]

- Detwiler, R.J.; Mehta, P.K. Chemical and physical effects of silica fume on the mechanical behavior of concrete. Am. Concr. Inst. J. 1989, 86, 609–614. [Google Scholar]

- Goldman, A.; Bentur, A. Properties of cementitious systems containing silica fume or nonreactive micro fillers. Adv. Cem. Based Mater. 1994, 1, 209–215. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Hamid, R.; Taha, M.R. Strength and microstructure of mortar containing nano silica at high temperature. Am. Concr. Inst. Mater. J. 2014, 111, 163–170. [Google Scholar]

- Elaty, M.A. Compressive strength prediction of Portland cement concrete with age using a new model. HBRC J. 2014, 10, 145–155. [Google Scholar] [CrossRef]

- Oluokun, F.A. Fly Ash Concrete Mix Design and the Water-Cement Ratio Law. ACI Mater. J. 2006, 91, 362–371. [Google Scholar]

- Al-Zahrani, M.M.; Maslehuddin, M.; Al-Dulaijan, S.U.; Ibrahim, M. Mechanical properties and durability characteristics of polymer- and cement-based repair materials. Cem. Concr. Compos. 2003, 25, 527–537. [Google Scholar] [CrossRef]

| Oxide Composition (%) | Ordinary Portland Cement | Silica Fume (S) | Ultrafine (C) |

|---|---|---|---|

| SiO2 | 20.2 | 93.2 | 99.5 |

| Al2O3 | 5.49 | 0.2 | 0.20 |

| Fe2O3 | 4.12 | 0.03 | 0.03 |

| CaO | 65.43 | 0.72 | 0.01 |

| MgO | 0.71 | 0.14 | - |

| Na2Oeq | 0.26 | 0.07 | - |

| SO3 | 2.61 | <0.01 | - |

| Loss on ignition (%) | 1.38 | 5.4 | - |

| Specific gravity | 3.14 | 2.27 | - |

| Fineness (m2/kg) | 373 | 19,000 | 16,500 |

| Properties/Material | Specific Gravity | Absorption (%) | Unit Weight (kg/m3) |

|---|---|---|---|

| White Sand | 2.63 | 0.77 | 1725 |

| Crushed Sand | 2.68 | 1.52 | 1552 |

| Coarse Aggregate (10 mm) | 2.65 | 1.45 | 1570 |

| Mix | Ultrafine Content | Water to Cement Ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SF (%) | UF (%) | 0.25 | 0.30 | 0.35 | 0.40 | |||||

| Cement Kg/m3 | Slump (mm) | Cement Kg/m3 | Slump (mm) | Cement Kg/m3 | Slump (mm) | Cement Kg/m3 | Slump (mm) | |||

| Control | 0 | 0 | 550 | 185 | 500 | 190 | 450 | 200 | 400 | 150 |

| S8 | 8 | 0 | 506 | 202 | 460 | 180 | 414 | 165 | 368 | 185 |

| S10 | 10 | 0 | 495 | 175 | 450 | 170 | 405 | 200 | 360 | 160 |

| S12 | 12 | 0 | 484 | 190 | 440 | 160 | 396 | 158 | 352 | 170 |

| C5 | 0 | 5 | 522.5 | 171 | 475 | 184 | 422.5 | 194 | 380 | 182 |

| C8 | 0 | 8 | 506 | 175 | 460 | 192 | 414 | 202 | 368 | 201 |

| C10 | 0 | 10 | 495 | 198 | 450 | 179 | 405 | 191 | 360 | 184 |

| C15 | 0 | 15 | 467.5 | 200 | 425 | 155 | 382.5 | 195 | 340 | 160 |

| C25 | 0 | 25 | 412.5 | 200 | 375 | 180 | 337.5 | 185 | 300 | 180 |

| C35 | 0 | 35 | 357.5 | 205 | 325 | 210 | 292.5 | 155 | 260 | 185 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbass, W.; Khan, M.I.; Mourad, S. Experimentation and Predictive Models for Properties of Concrete Added with Active and Inactive SiO2 Fillers. Materials 2019, 12, 299. https://doi.org/10.3390/ma12020299

Abbass W, Khan MI, Mourad S. Experimentation and Predictive Models for Properties of Concrete Added with Active and Inactive SiO2 Fillers. Materials. 2019; 12(2):299. https://doi.org/10.3390/ma12020299

Chicago/Turabian StyleAbbass, Wasim, Mohammad Iqbal Khan, and Shehab Mourad. 2019. "Experimentation and Predictive Models for Properties of Concrete Added with Active and Inactive SiO2 Fillers" Materials 12, no. 2: 299. https://doi.org/10.3390/ma12020299

APA StyleAbbass, W., Khan, M. I., & Mourad, S. (2019). Experimentation and Predictive Models for Properties of Concrete Added with Active and Inactive SiO2 Fillers. Materials, 12(2), 299. https://doi.org/10.3390/ma12020299