The Rheology of PEOT/PBT Block Copolymers in the Melt State and in the Thermally-Induced Sol/Gel Transition Implications on the 3D-Printing Bio-Scaffold Process

Abstract

1. Introduction

2. Materials and Methods

3. Experimental Results and Discussion

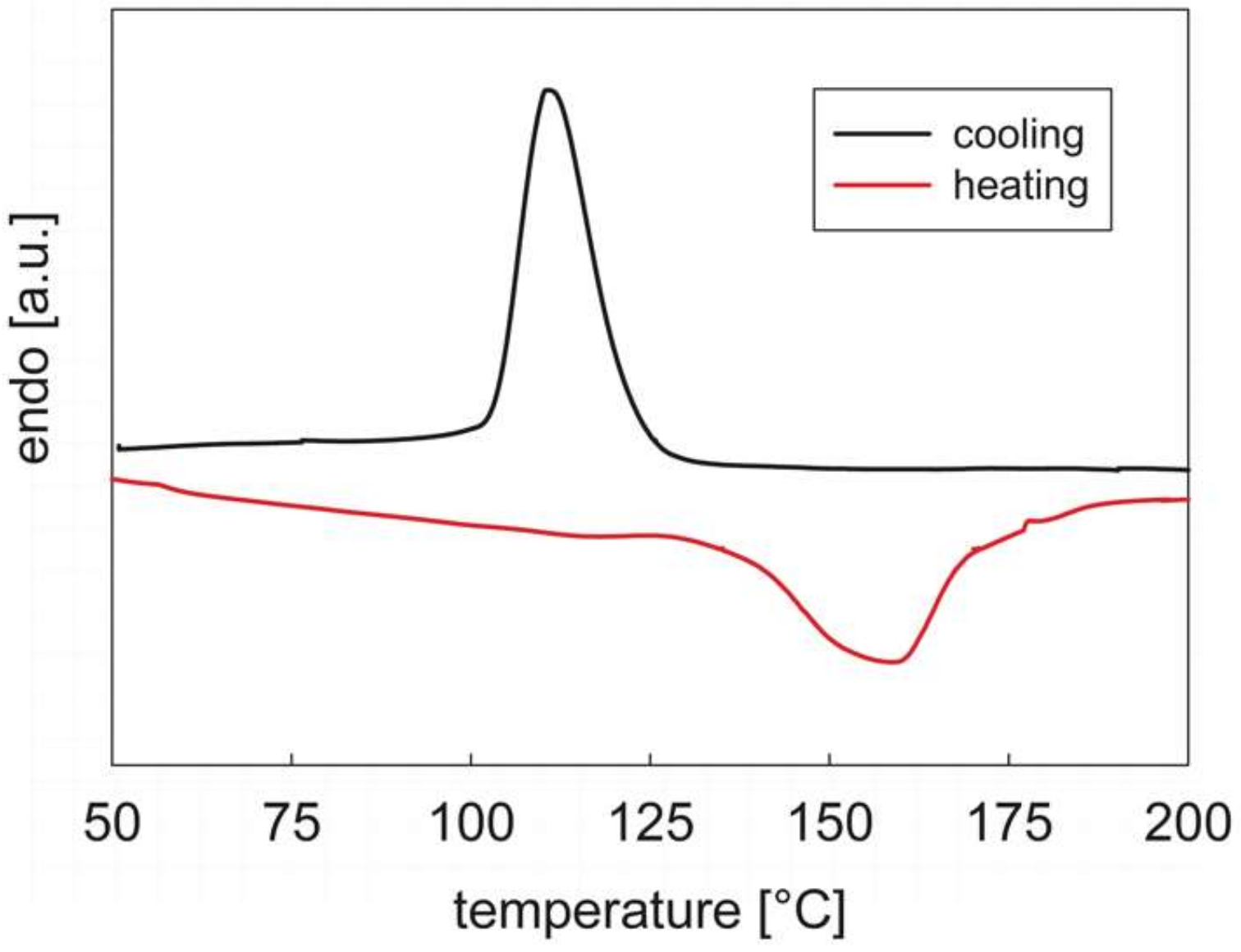

3.1. Calorimetry

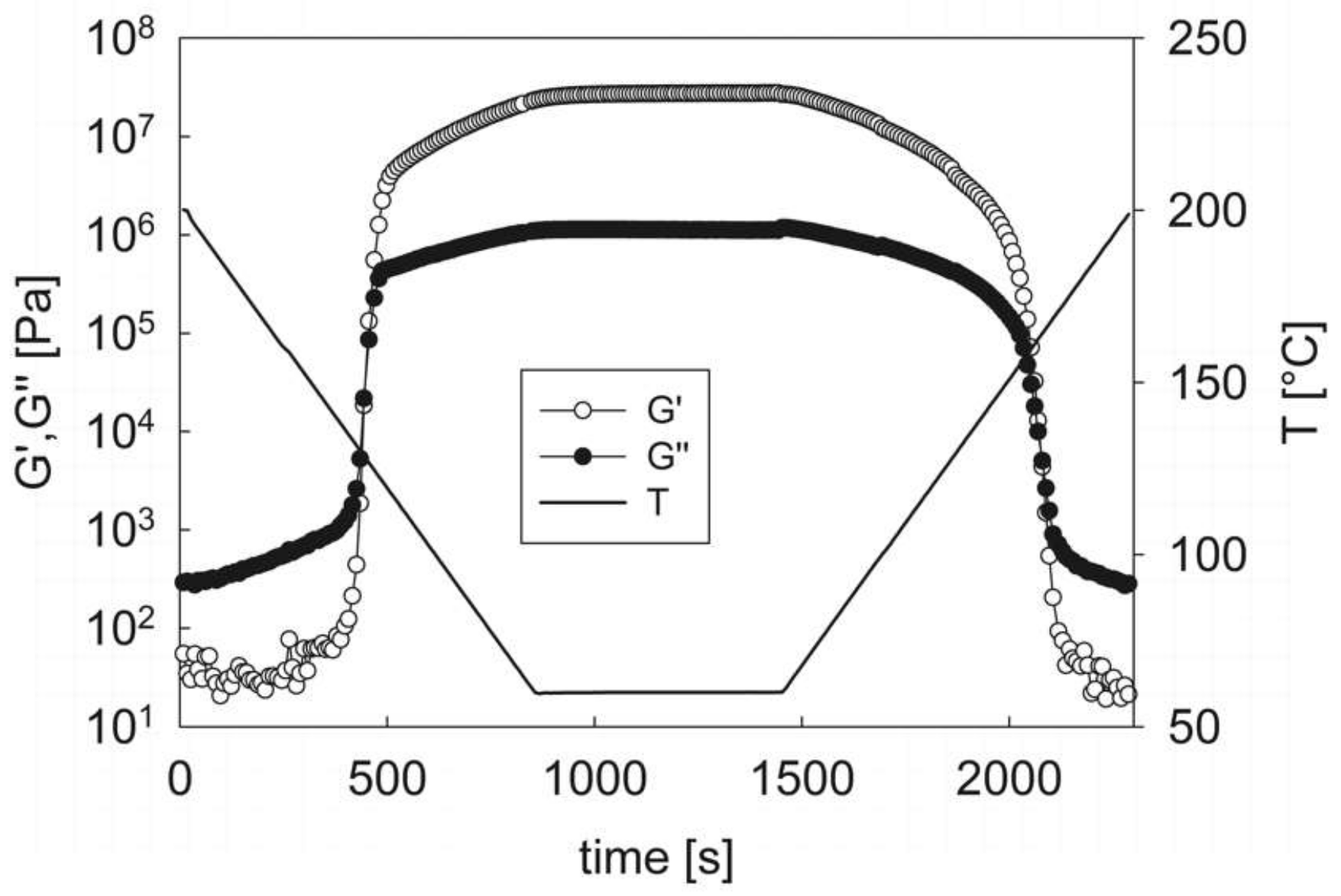

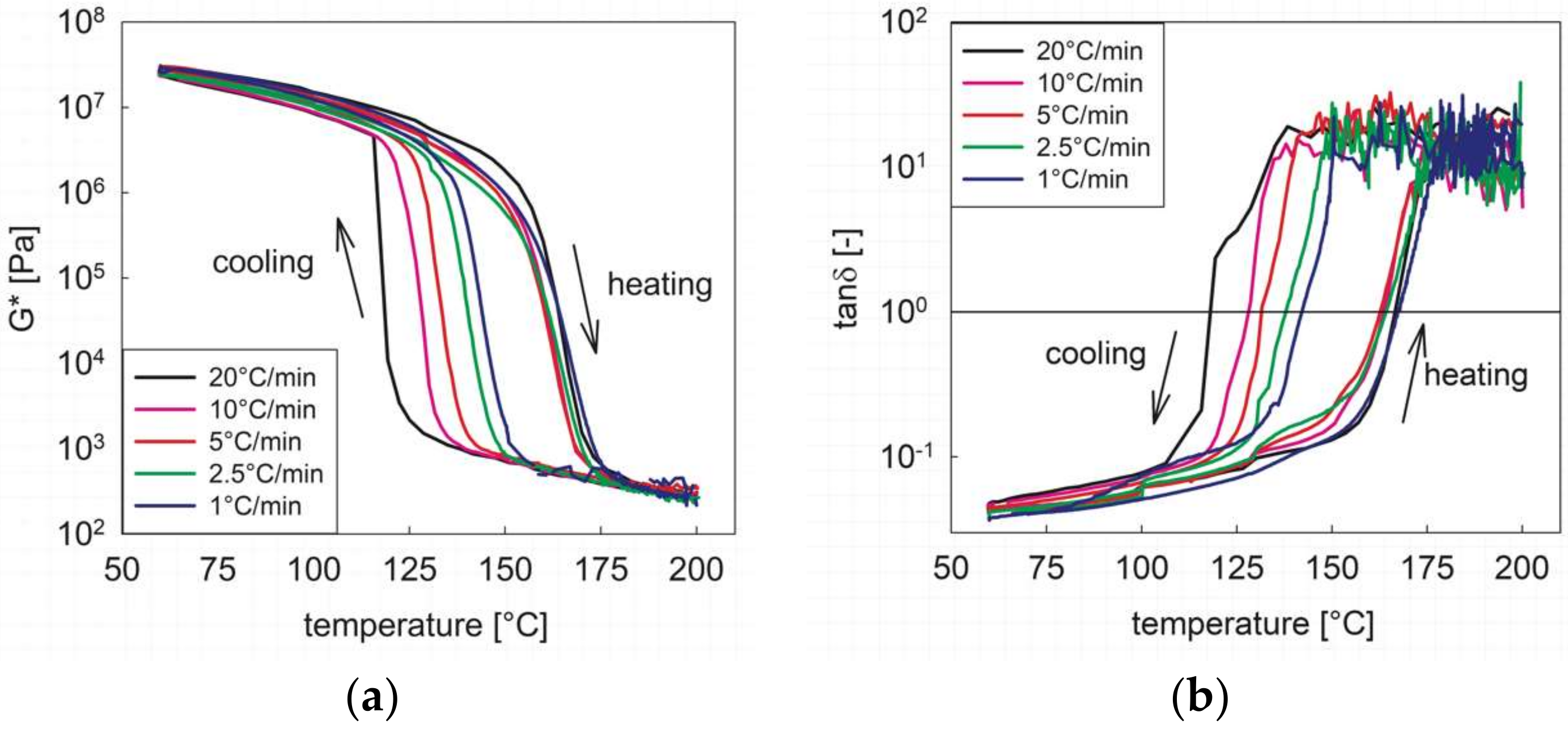

3.2. Non-Isothermal Rheology

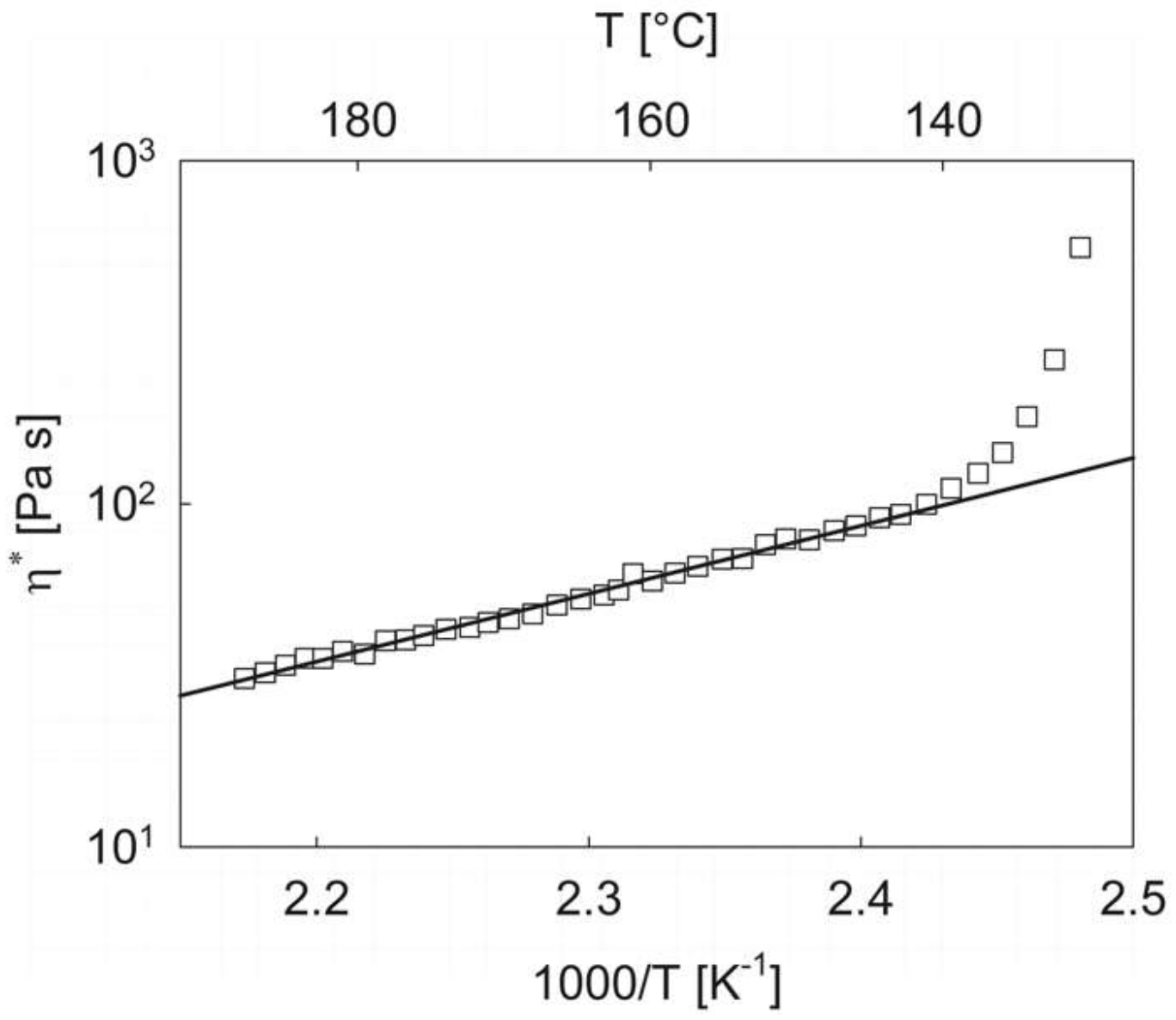

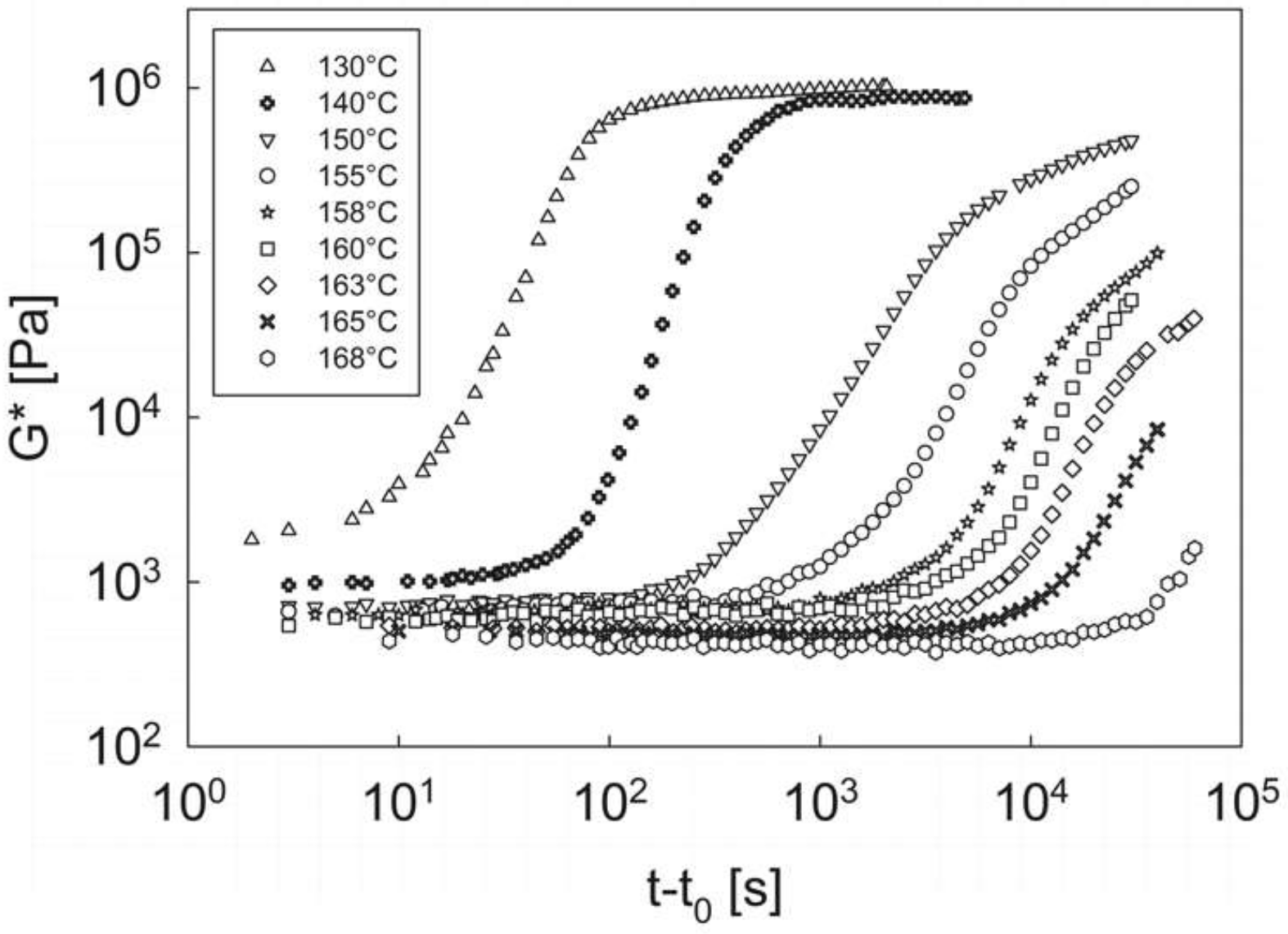

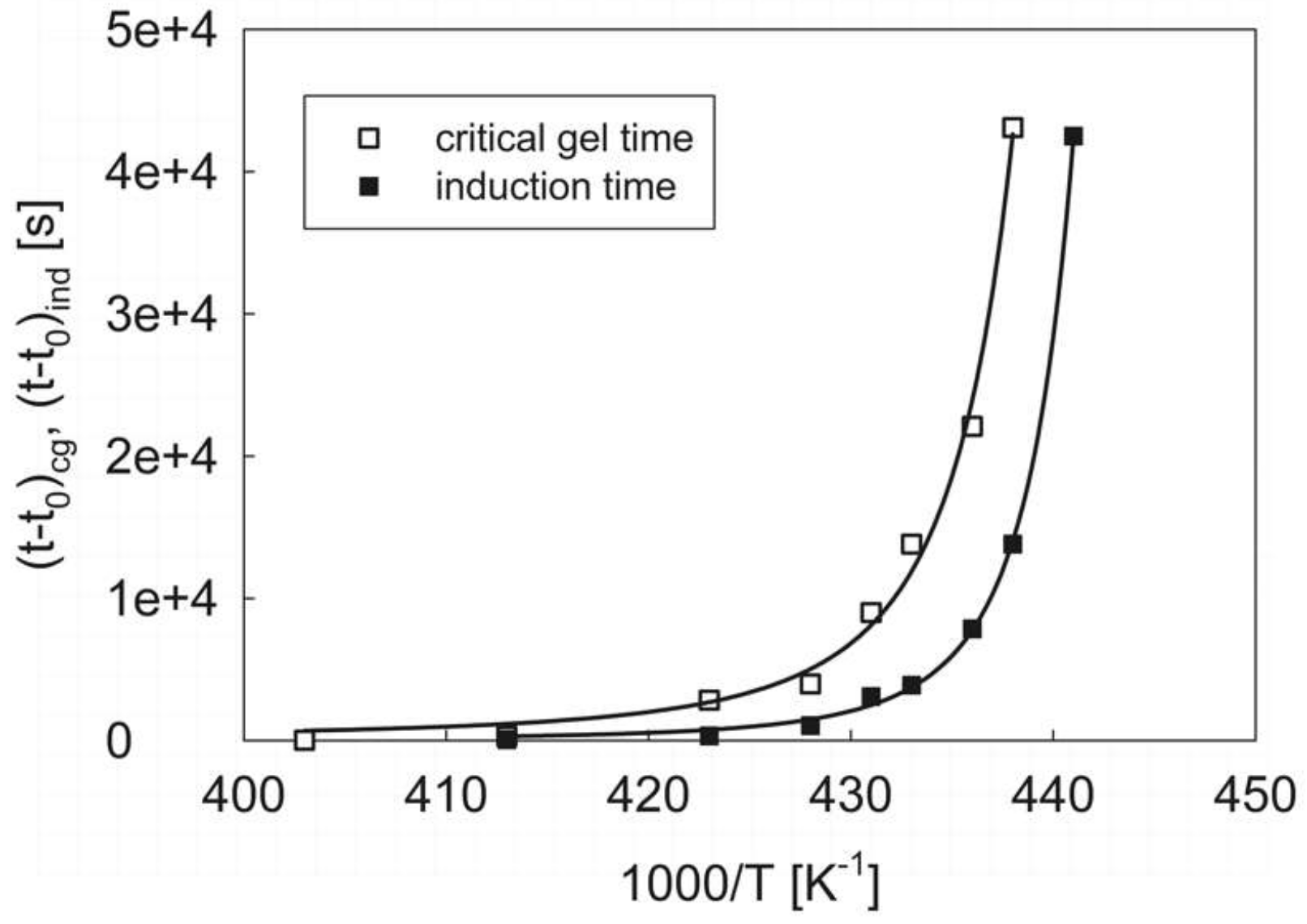

3.3. Isothermal Rheology

4. Concluding Remarks

- •

- non-isothermal experiments in the melt state allowed to determine the viscosity of PEOT/PBT in the liquid state and its quantitative dependence upon temperature. The material exhibited sufficiently low viscosities, ranging between about 30 and 100 Pa s in the temperature range 200–140 °C, with a relatively modest temperature dependence;

- •

- non-isothermal experiments at lower temperatures indicate that the sol/gel transition upon cooling is strongly affected by the thermal history, while the same does not hold in the symmetrical melting stages. Comparing rheological and calorimetric data also indicates that the transition from a liquid-like to a solid-like material takes place when the most part of the microphase separation has been completed, suggesting that the actual solidification is due to a rearrangement of the microstructure, rather than the mere phase transition. From the processing viewpoint, the results from the non-isothermal rheometry are extremely useful. The significant shift of the solidification to lower temperatures as the cooling rate increases provides relevant information to design both the characteristic time and the geometrical patterns of the filament deposition and cooling stages of the process. A too-high cooling rate would move the solidification to shorter times, but at the same time it would hinder a proper adhesion between two filaments deposited on successive layers. A too-low cooling rate would be detrimental to the dimensional stability of the scaffolds;

- •

- the isothermal rheology during phase transition, which allowed also the determination of a thermodynamic ODT temperature, suggests a different way to manage the above compromise between solid-like (bio-scaffold consistency) and liquid-like (inter-filament adhesion) behavior. Running the filament deposition stages at a suitable, higher than ambient, constant temperature, would allow to easily find the above compromise. Indeed, as indicated by Figure 6, Table 3 and Equation (2), a proper choice of the isothermal phase transition temperature determines a specific characteristic time for the phase transition. This, in turn, becomes a processing parameter, to be compared with the characteristic time of filament deposition in order to get the best 3D-printing conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Deschamps, A.A.; Grijpma, D.W.; Feijen, J. Poly(ethylene oxide)/poly(butylene terephthalate) segmented block copolymers: The effect of copolymer composition on physical properties and degradation behavior. Polymer 2001, 42, 9335–9345. [Google Scholar] [CrossRef]

- Gaharwar, A.K.; Mihaila, S.M.; Kulkarni, A.A.; Patel, A.; Di Luca, A.; Reis, R.L.; Gomes, M.E.; Van Blitterswijk, C.; Moroni, L.; Khademhosseini, A. Amphiphilic beads as depots for sustained drug release integrated into fibrillar scaffolds. J. Control. Release 2014, 187, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Bastianini, M.; Scatto, M.; Sisani, M.; Scopece, P.; Patelli, A.; Petracci, A. Innovative composites based on organic modified zirconium phosphate and PEOT/PBT copolymer. J. Compos. Sci. 2018, 2, 31. [Google Scholar] [CrossRef]

- Mensik, I.; Lamme, E.N.; Riesle, J.; Brychta, P. Effectiveness and safety of the PEGT/PBT copolymer scafford as dermal substitute in scar reconstruction wounds (feasibility trial). Cell Tissue Bank. 2002, 3, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Meijer, G.J.; van Dooren, A.; Gallard, M.L.; Dalmeijer, R.; de Putter, C.; Koole, R.; van Blitterswijk, C.A. Polyactive® as a bone-filler in a beagle dog model. Int. J. Oral Maxillofac. Surg. 1996, 25, 210–216. [Google Scholar] [CrossRef]

- Santos, D.; Wieringa, P.; Moroni, L.; Navarro, X.; Valle, J.D. PEOT/PBT Guides Enhance Nerve Regeneration in Long Gap Defects. Adv. Healthc. Mater. 2017, 6, 1600298. [Google Scholar] [CrossRef]

- Moroni, L.; De Wijn, J.R.; Van Blitterswijk, C.A. Three-dimensional fiber-deposited PEOT/PBT copolymer scaffolds for tissue engineering: Influence of porosity, molecular network mesh size, and swelling in aqueous media on dynamic mechanical properties. J. Biomed. Mater. Res. Part A 2005, 75, 957–965. [Google Scholar] [CrossRef]

- Barron, V.; Merghani, K.; Shaw, G.; Coleman, C.M.; Hayes, J.S.; Ansboro, S.; Manian, A.; O’Malley, G.; Connolly, E.; Nandakumar, A.; et al. Evaluation of cartilage repair by mesenchymal stem cells seeded on a PEOT/PBT scaffold in an osteochondral defect. Ann. Biomed. Eng. 2015, 43, 2069–2082. [Google Scholar] [CrossRef]

- Claase, M.B.; Grijpma, D.W.; Mendes, S.C.; De Bruijn, J.D.; Feijen, J. Porous PEOT/PBT scaffolds for bone tissue engineering: Preparation, characterization, and in vitro bone marrow cell culturing. J. Biomed. Mater. Res. Part A 2003, 64, 291–300. [Google Scholar] [CrossRef]

- Danti, S.; Mota, C.; D’alessandro, D.; Trombi, L.; Ricci, C.; Redmond, S.L.; De Vito, A.; Pini, R.; Dilley, R.J.; Moroni, L.; et al. Tissue engineering of the tympanic membrane using electrospun PEOT/PBT copolymer scaffolds: A morphological in vitro study. Hear. Balance Commun. 2015, 13, 133–147. [Google Scholar] [CrossRef]

- Jansen, E.J.P.; Pieper, J.; Gijbels, M.J.J.; Guldemond, N.A.; Riesle, J.; Van Rhijn, L.W.; Bulstra, S.K.; Kuijer, R. PEOT/PBT based scaffolds with low mechanical properties improve cartilage repair tissue formation in osteochondral defects. J. Biomed. Mater. Res. Part A 2009, 89, 444–452. [Google Scholar] [CrossRef] [PubMed]

- Leferink, A.M.; Hendrikson, W.J.; Rouwkema, J.; Karperien, M.; van Blitterswijk, C.A.; Moroni, L. Increased cell seeding efficiency in bioplotted three-dimensional PEOT/PBT scaffolds. J. Tissue Eng. Regen. Med. 2016, 10, 679–689. [Google Scholar] [CrossRef] [PubMed]

- Moroni, L.; Licht, R.; de Boer, J.; de Wijn, J.R.; van Blitterswijk, C.A. Fiber diameter and texture of electrospun PEOT/PBT scaffolds influence human mesenchymal stem cell proliferation and morphology, and the release of incorporated compounds. Biomaterials 2006, 27, 4911–4922. [Google Scholar] [CrossRef] [PubMed]

- Grande, S.; Cools, P.; Asadian, M.; Van Guyse, J.; Onyshchenko, I.; Declercq, H.; Morent, R.; Hoogenboom, R.; De Geyter, N. Fabrication of PEOT/PBT nanofibers by atmospheric pressure plasma jet treatment of electrospinning solutions for tissue engineering. Macromol. Biosci. 2018, 18, e1800309. [Google Scholar] [CrossRef] [PubMed]

- Cools, P.; Asadian, M.; Nicolaus, W.; Declercq, H.; Morent, R.; De Geyter, N. Surface treatment of PEOT/PBT (55/45) with a dielectric barrier discharge in air, helium, argon and nitrogen at medium pressure. Materials 2018, 11, 391. [Google Scholar] [CrossRef] [PubMed]

- Leferink, A.M.; Reis, D.S.; Van Blitterswijk, C.A.; Moroni, L. An antibody based approach for multi-coloring osteogenic and chondrogenic proteins in tissue engineered constructs. Biomed. Mater. 2018, 13, 044102. [Google Scholar] [CrossRef] [PubMed]

- Collins, K.L.; Gates, E.M.; Gilchrist, C.L.; Hoffman, B.D. Bio-instructive cues in scaffolds for musculoskeletal tissue engineering and regenerative medicine. In Bio-Instructive Scaffolds for Musculoskeletal Tissue Engineering and Regenerative Medicine; Brown, J.L., Kumbar, S.G., Banik, B.L., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 3–35. [Google Scholar]

- Buckwalter, D.J.; Dennis, J.M.; Long, T.E. Amide-containing segmented copolymers. Prog. Polym. Sci. 2015, 45, 1–22. [Google Scholar] [CrossRef]

- Deschamps, A.A.; Claase, M.B.; Sleijster, W.J.; De Bruijn, J.D.; Grijpma, D.W.; Feijen, J. Design of segmented poly(ether ester) materials and structures for the tissue engineering of bone. J. Control. Release 2002, 78, 175–186. [Google Scholar] [CrossRef]

- Fakirov, S.; Gogeva, T. Poly(ether/ester)s based on poly(butylene terephthalate) and poly(ethylene glycol), 1. Poly(ether/ester)s with various polyether: Polyester ratios. Die Makromol. Chem. 1990, 191, 603–614. [Google Scholar] [CrossRef]

- Fakirov, S.; Gogeva, T. Poly(ether/ester)s based on poly(butylene terephthalate) and poly(ethylene glycol), 2. Effect of polyether segment length. Die Makromol. Chem. 1990, 191, 615–624. [Google Scholar] [CrossRef]

- Buckwalter, D.J.; Inglefield, D.L., Jr.; Enokida, J.S.; Hudson, A.G.; Moore, R.B.; Long, T.E. Effects of copolymer structure on the mechanical properties of poly(dimethyl siloxane) poly(oxamide) segmented copolymers. Macromol. Chem. Phys. 2013, 214, 2073–2082. [Google Scholar] [CrossRef]

- Chao, G.; Fan, L.; Jia, W.; Qian, Z.; Gu, Y.; Liu, C.; Ni, X.; Li, J.; Deng, H.; Gong, C.; et al. Synthesis, characterization and hydrolytic degradation of degradable poly(butylene terephthalate)/poly(ethylene glycol) (PBT/PEG) copolymers. J. Mater. Sci. Mater. Med. 2007, 18, 449–455. [Google Scholar] [CrossRef] [PubMed]

- Hendrikson, W.J.; Zeng, X.; Rouwkema, J.; van Blitterswijk, C.A.; van der Heide, E.; Moroni, L. Biological and tribological assessment of poly(ethylene oxide terephthalate)/poly(butylene terephthalate), polycaprolactone, and poly (l\dl) lactic acid plotted scaffolds for skeletal tissue regeneration. Adv. Healthc. Mater. 2016, 5, 232–243. [Google Scholar] [CrossRef] [PubMed]

- Kellomäki, M.; Paasimaa, S.; Grijpma, D.W.; Kolppo, K.; Törmälä, P. In vitro degradation of Polyactive® 1000PEOT70PBT30 devices. Biomaterials 2002, 23, 283–295. [Google Scholar] [CrossRef]

- Piesowicz, E.; Paszkiewicz, S.; Szymczyk, A. Phase separation and elastic properties of poly(trimethylene terephthalate)-block-poly(ethylene oxide) copolymers. Polymers 2016, 8, 237. [Google Scholar] [CrossRef]

- Winter, H.H.; Mours, M. Rheology of polymers near liquid-solid transitions. Adv. Polym. Sci. 1997, 134, 164–234. [Google Scholar]

- Brun-Graeppi, A.K.A.S.; Richard, C.; Bessodes, M.; Scherman, D.; Narita, T.; Ducouret, G.; Merten, O.-W. Study on the sol-gel transition of xyloglucan hydrogels. Carbohydr. Polym. 2010, 80, 556–563. [Google Scholar] [CrossRef]

- Nichetti, D.; Grizzuti, N. Determination of the phase transition behavior of thermoplastic polyurethanes from coupled rheology/DSC measurements. Polym. Eng. Sci. 2004, 44, 1514–1521. [Google Scholar] [CrossRef]

- Cossar, S.; Nichetti, D.; Grizzuti, N. A rheological study of the phase transition in thermoplastic polyurethanes. Critical gel behavior and microstructure development. J. Rheol. 2004, 48, 691–703. [Google Scholar] [CrossRef]

- Wang, G.; Fang, B.; Zhang, Z. Study of the domain structure and mechanical properties of the ethylene oxide endcapped poly(propylene oxide) polyol/4,4′-diphenylmethane diisocyanate/ethylenediol polyurethane system. Polymer 1994, 35, 3178–3183. [Google Scholar] [CrossRef]

- Coppola, S.; Acierno, S.; Grizzuti, N.; Vlassopoulos, D. Viscoelastic behavior of semicrystalline thermoplastic polymers during the early stages of crystallization. Macromolecules 2006, 39, 1507–1514. [Google Scholar] [CrossRef]

- Arias, A.; Sojoudiasli, H.; Heuzey, M.-C.; Huneault, M.A.; Wood-Adams, P. Rheological study of crystallization behavior of polylactide and its flax fiber composites. J. Polym. Res. 2017, 24, 46. [Google Scholar] [CrossRef]

- Coppola, S.; Balzano, L.; Gioffredi, E.; Maffettone, P.L.; Grizzuti, N. Effects of the degree of undercooling on flow induced crystallization in polymer melts. Polymer 2004, 45, 3249–3256. [Google Scholar] [CrossRef]

- Hadinata, C.; Gabriel, C.; Ruellmann, M.; Kao, N.; Laun, H.-M. Correlation between the gel time and quiescent/quasi-quiescent crystallization onset time of poly(butene-1) as determined from rheological methods. Rheol. Acta 2006, 45, 631–639. [Google Scholar] [CrossRef]

- Khandpur, A.K.; Förster, S.; Bates, F.S.; Hamley, I.W.; Ryan, A.J.; Bras, W.; Almdal, K.; Mortensen, K. Polyisoprene-polystyrene diblock copolymer phase diagram near the order-disorder transition. Macromolecules 1995, 28, 8796–8806. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Lauritzen, J., Jr.; Passaglia, E.; Ross, G.S.; Frolen, L.J.; Weeks, J.J. Kinetics of polymer crystallization from solution and the melt. Kolloid-Zeitschrift und Zeitschrift für Polymere 1969, 231, 564–592. [Google Scholar] [CrossRef]

- Tirella, A.; Ahluwalia, A. The impact of fabrication parameters and substrate stiffness in direct writing of living constructs. Biotechnol. Prog. 2012, 28, 1315–1320. [Google Scholar] [CrossRef] [PubMed]

| Cooling/Heating Rate (°C/min) | Tc,rheol (°C) | Tm,rheol (°C) |

|---|---|---|

| 20 | 121 | 166 |

| 10 | 128 | 163 |

| 5 | 132 | 164 |

| 2.5 | 138 | 165 |

| 1 | 142 | 167 |

| Annealing Temperature (°C) | (t − t0)cg (s) | (t − t0)ind (s) |

|---|---|---|

| 130 | 25 | – |

| 140 | 288 | 68 |

| 150 | 2840 | 325 |

| 155 | 3980 | 1050 |

| 158 | 8990 | 3090 |

| 160 | 13,800 | 3900 |

| 163 | 22,100 | 7850 |

| 165 | 43,100 | 13,800 |

| 168 | >60,000 | 42,500 |

| Characteristic Time | A (s) | B × 10−4 (K2) | TODT (K) |

|---|---|---|---|

| (t − t0)cg | 41.1 | 6.35 | 459 |

| (t − t0)ind | 5.50 | 7.94 | 461 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanzanella, V.; Scatto, M.; Zant, E.; Sisani, M.; Bastianini, M.; Grizzuti, N. The Rheology of PEOT/PBT Block Copolymers in the Melt State and in the Thermally-Induced Sol/Gel Transition Implications on the 3D-Printing Bio-Scaffold Process. Materials 2019, 12, 226. https://doi.org/10.3390/ma12020226

Vanzanella V, Scatto M, Zant E, Sisani M, Bastianini M, Grizzuti N. The Rheology of PEOT/PBT Block Copolymers in the Melt State and in the Thermally-Induced Sol/Gel Transition Implications on the 3D-Printing Bio-Scaffold Process. Materials. 2019; 12(2):226. https://doi.org/10.3390/ma12020226

Chicago/Turabian StyleVanzanella, Veronica, Marco Scatto, Erwin Zant, Michele Sisani, Maria Bastianini, and Nino Grizzuti. 2019. "The Rheology of PEOT/PBT Block Copolymers in the Melt State and in the Thermally-Induced Sol/Gel Transition Implications on the 3D-Printing Bio-Scaffold Process" Materials 12, no. 2: 226. https://doi.org/10.3390/ma12020226

APA StyleVanzanella, V., Scatto, M., Zant, E., Sisani, M., Bastianini, M., & Grizzuti, N. (2019). The Rheology of PEOT/PBT Block Copolymers in the Melt State and in the Thermally-Induced Sol/Gel Transition Implications on the 3D-Printing Bio-Scaffold Process. Materials, 12(2), 226. https://doi.org/10.3390/ma12020226