1. Introduction

Titanium alloys, as advanced lightweight materials, have been extensively used in the aerospace industry, due to their high strength, low density, and good corrosion resistance [

1]. The poor ductility at room temperature and loss of dimensional accuracy caused by springback drives engineers to manufacture titanium alloys, especially panel components, using hot forming techniques, such as superplastic forming (SPF) [

2], hot gas forming [

3], incremental forming [

4] and isothermal hot forming [

5]. SPF of titanium alloy is a robust technology, that has been extensively investigated and used for manufacturing extremely-complex components, normally integrated with diffusion bonding [

6]. To compensate the drawbacks of low productivity, high manufacture cost and over-thinning, hot gas forming technique has been developed aiming to manufacture parts at higher strain rates and improving thickness uniformity for thin-walled components [

7]. Hot gas forming is an isothermal process using high-pressure gas as loading medium, and the tube blank is heated by tools. In terms of relatively simple-shaped components, isothermal hot stamping using rigid dies is also widely used enabling forming titanium alloy sheets under the optimal process conditions. However, all the processes are carried out under an elevated temperature and isothermal condition with the forming dies heated simultaneously, which are mainly restricted by huge energy cost. Therefore, an innovative, low-cost technology for stamping titanium sheets is urgently required.

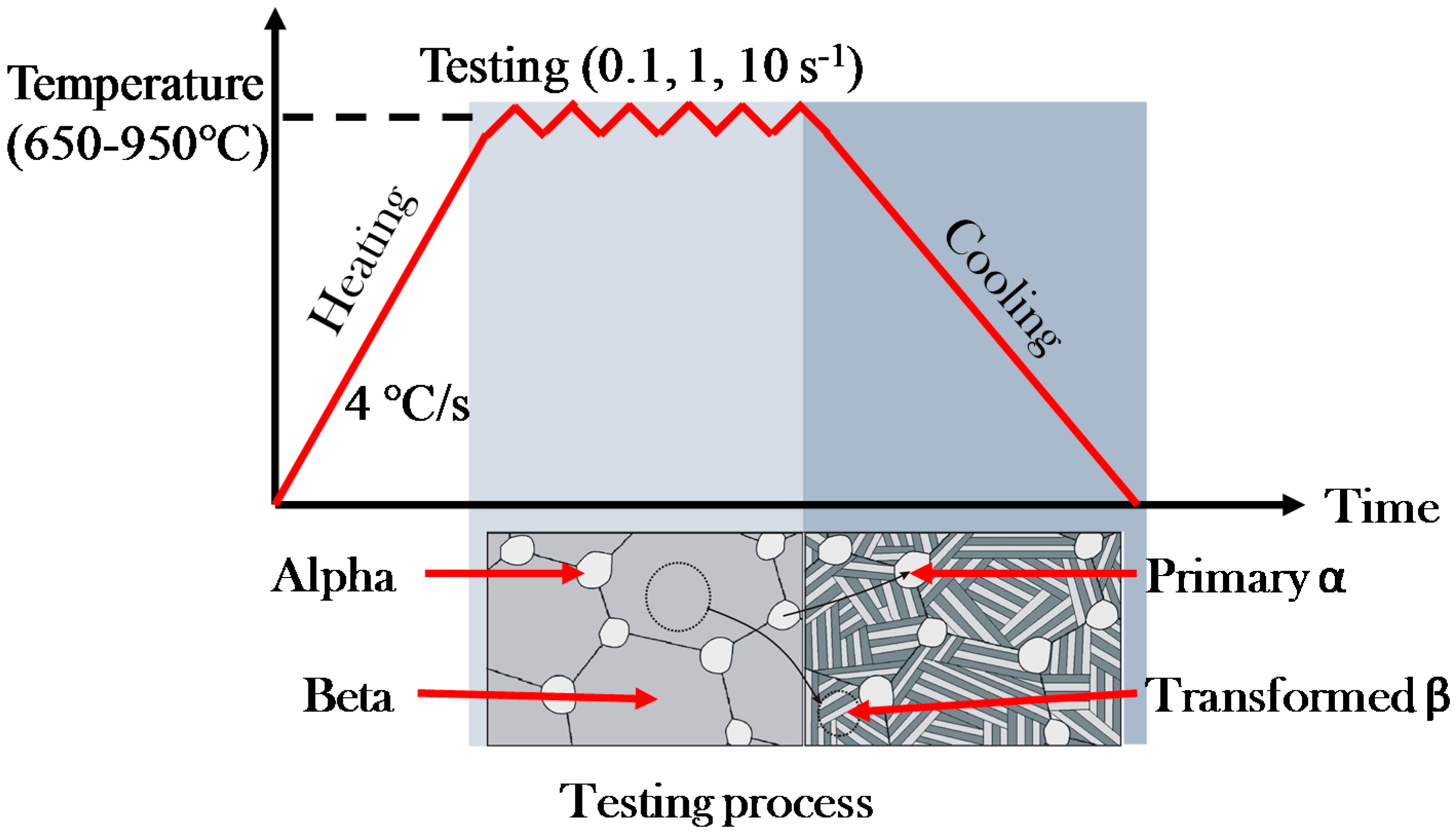

To address the above limitations, a novel hot stamping process is proposed and investigated in this study. In this process, a titanium alloy sheet is initially heated and soaked at the target temperature in a furnace. Then, the sheet is quickly transferred to the press to be hot stamped according to die profile non-isothermally. Finally, the hot stamped part is quenched by the forming dies to obtain the desired microstructure and guarantee the shape accuracy. The reasoned advantages of this novel process can be summarized as follows: (1) The absence of heating dies enables to significantly reduce the production cost, (2) relatively lower interface temperature results in a lower friction coefficient contributing to material flow, (3) the microstructure evolution is controlled by the parameters of heating, forming and subsequent quenching, so the optimal design of process can contribute to obtain the desired microstructure. Considering the process is exhibits a non-isothermal feature which results in the process windows, e.g., forming temperature, speed and transfer time etc., need to be optimized and precisely controlled. Kopec et al. [

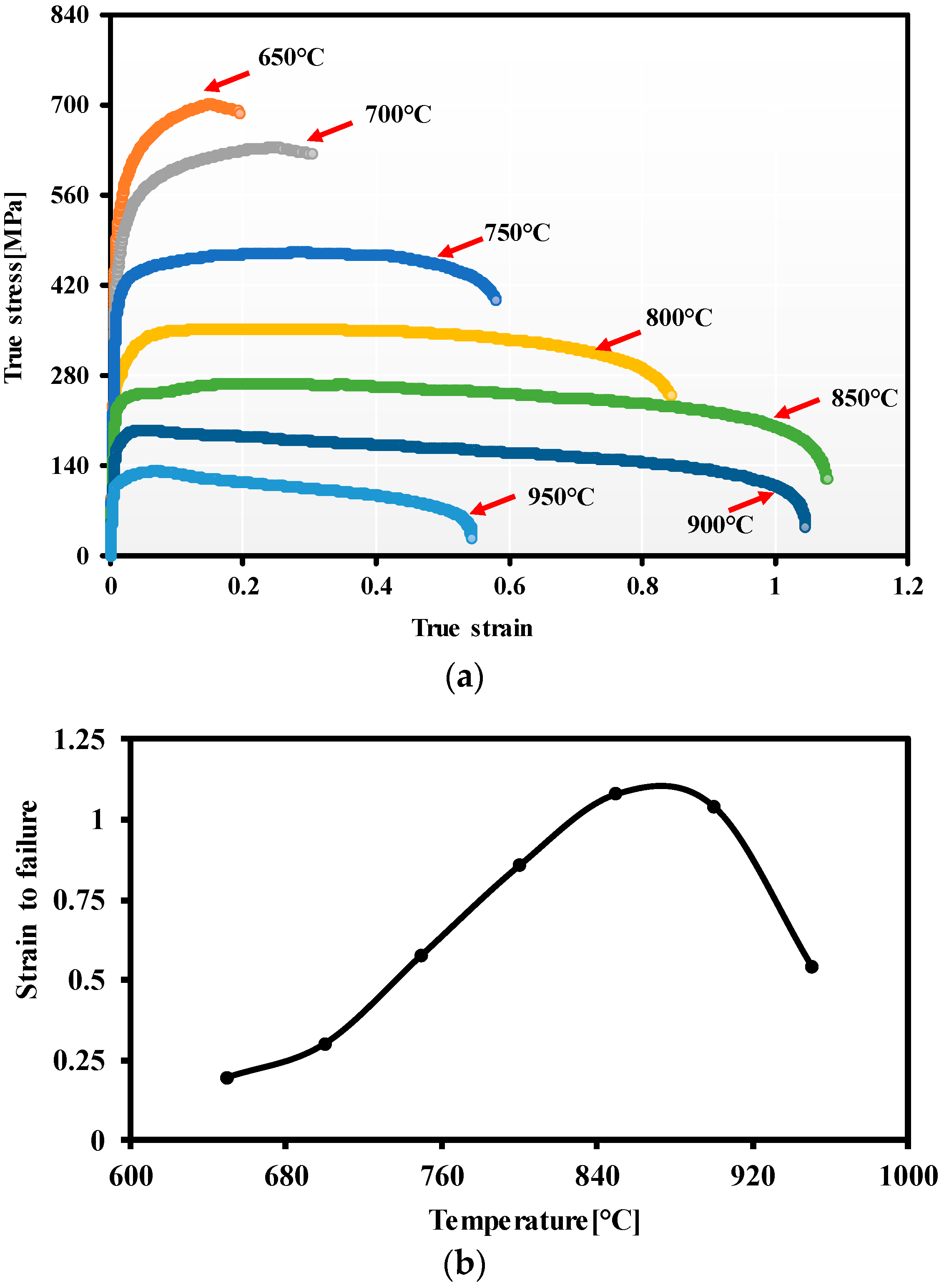

8] schematically investigated formability and microstructural evolution of Ti-6Al-4V using this novel hot stamping process. Various microstructure evolution mechanisms depending on the deformation temperature., i.e., recovery, phase transformation, and recrystallization, were identified. In addition, formability was also found to be sufficient to form sound parts at heating temperatures between 750 °C and 850 °C. The performed research successfully certificated the feasibility of hot stamping of titanium alloys. To the date, investigations of hot stamping mainly focused on two-phase titanium alloys, while another wide applied near-

titanium alloy with a higher service temperature has had limited study.

The non-isothermal feature of hot stamping process results in the deformation temperature varies with different locations and proceeding of deformation, which determines the formability and post-form microstructure. Therefore, process parameters need to be strictly designed which can be optimized via FE simulations. To improve the simulation accuracy, a robust material model of alloy under hot stamping condition enabling the modelling of related microstructural evolutions are critical. Besides the commonly known microstructural evolutions, such as recovery, recrystallization, and dislocation accumulation and annihilation, softening is extremely important for stamping sheet metals since it determines the localized thinning and even failure. Softening of titanium alloys during hot working is determined by initial microstructure and hot working conditions. Extensive investigations were carried out. Qian et al. [

9] identified the dominant softening mechanism is globularization of the secondary alpha phase for Ti-6Al-4V under hot compression conditions. Yang et al. [

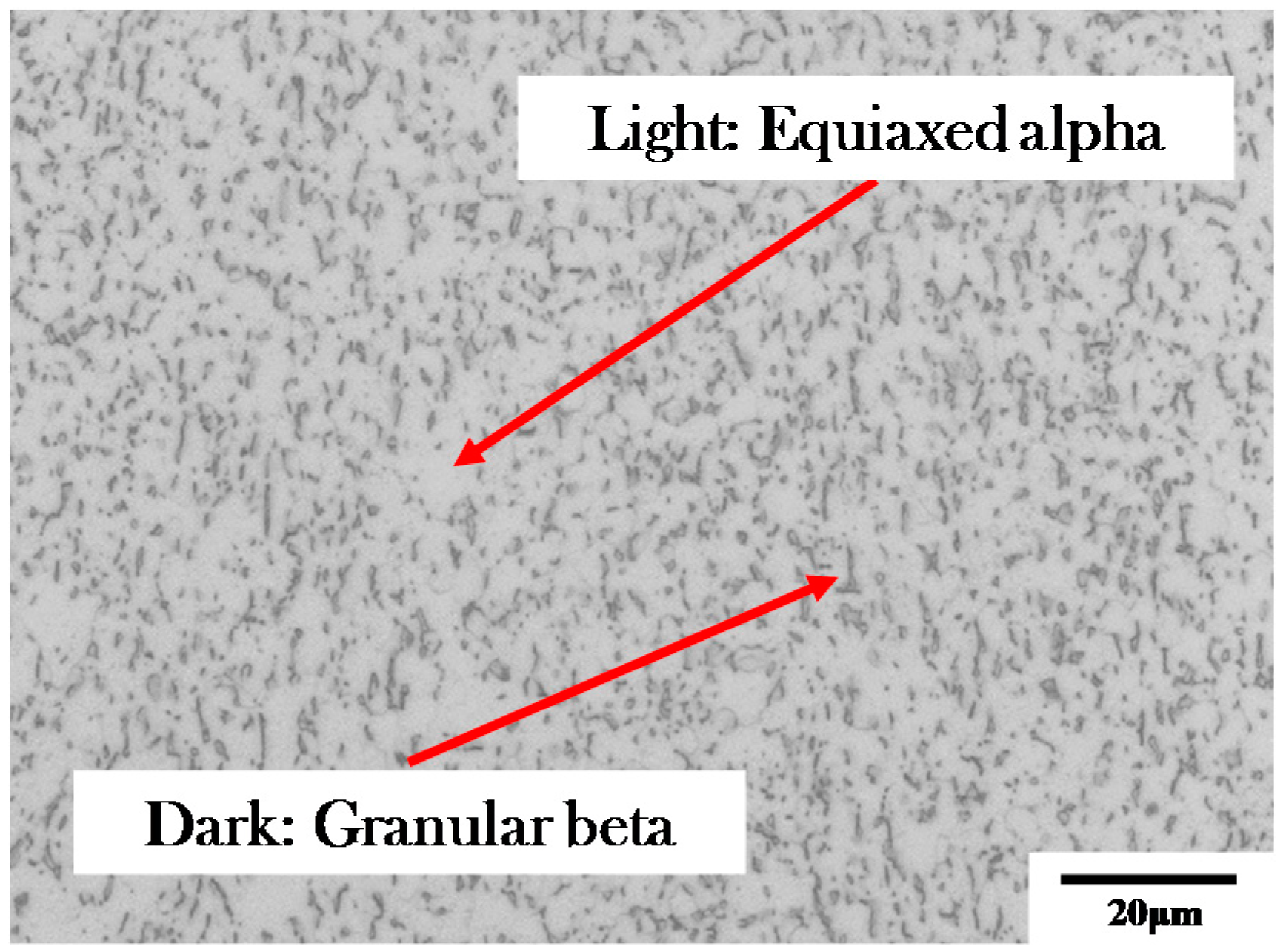

10] studied the flow softening and ductile damage of TA15 titanium alloy with an initial lamellar-structured

phase using hot tensile tests. Globularization was identified through SEM observations also. While for TA15 with an initial microstructure of equiaxed

phase with good fatigue resistance, the globularization is limited compared with the two-phase titanium alloy. The softening mechanism is believed to be mainly caused by recrystallization [

3] and damage [

10]. However, an advanced material model for near-

titanium alloy with an initial equiaxed alpha phase is lacked.

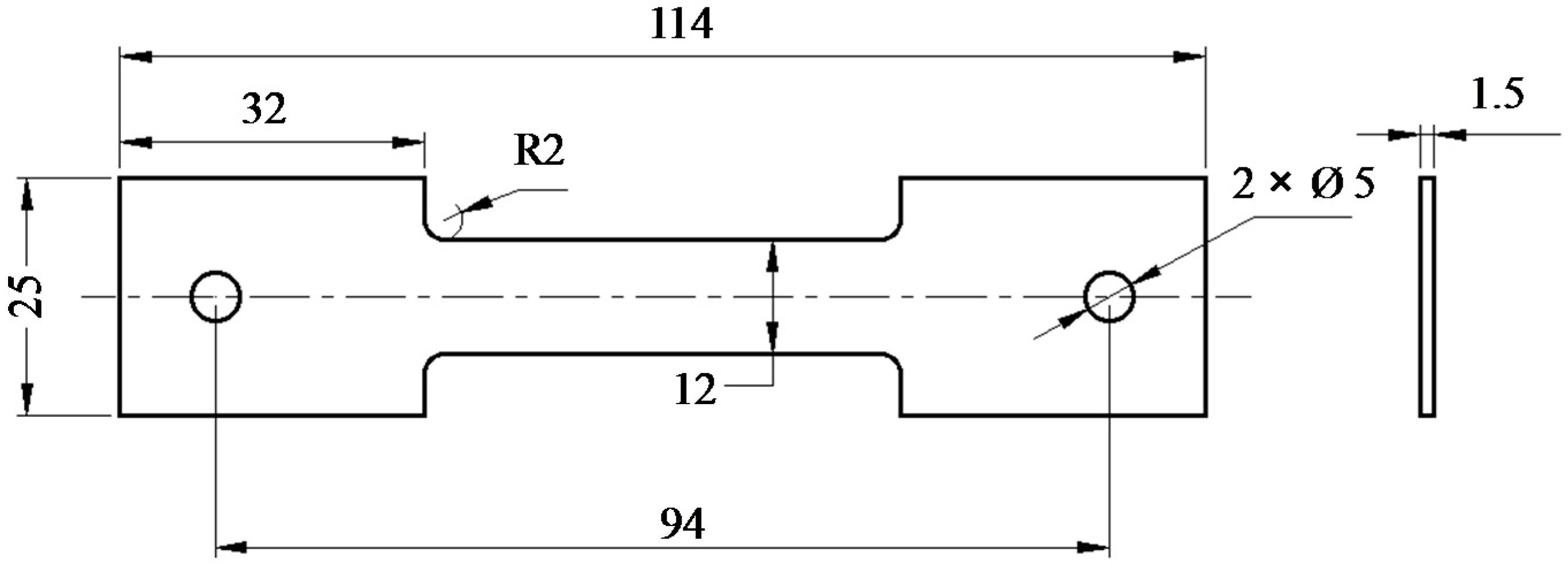

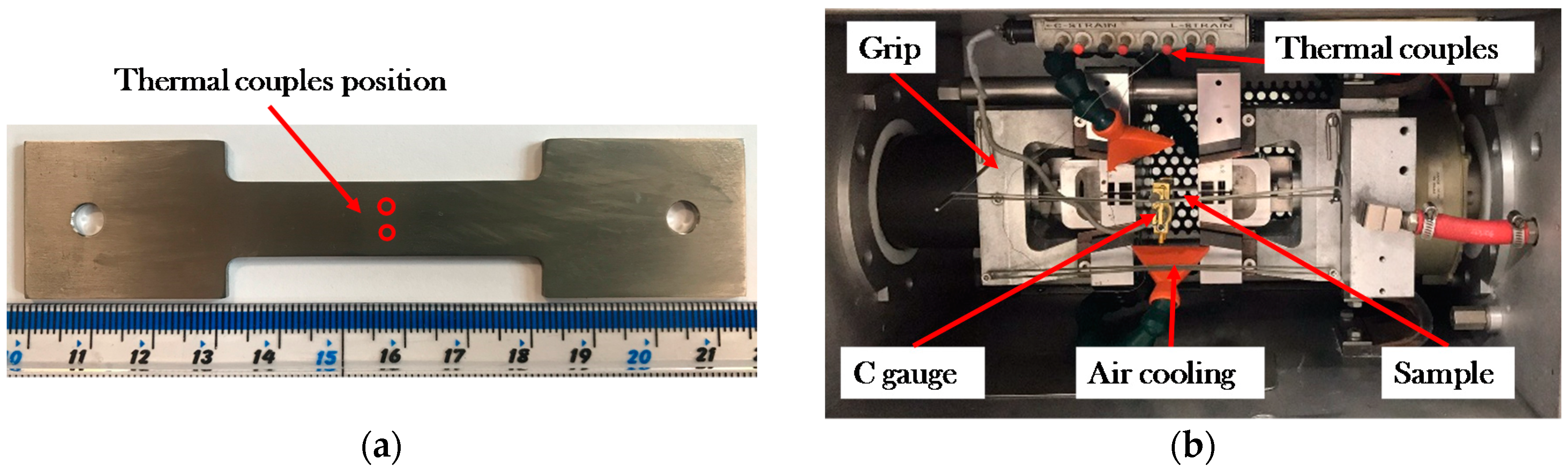

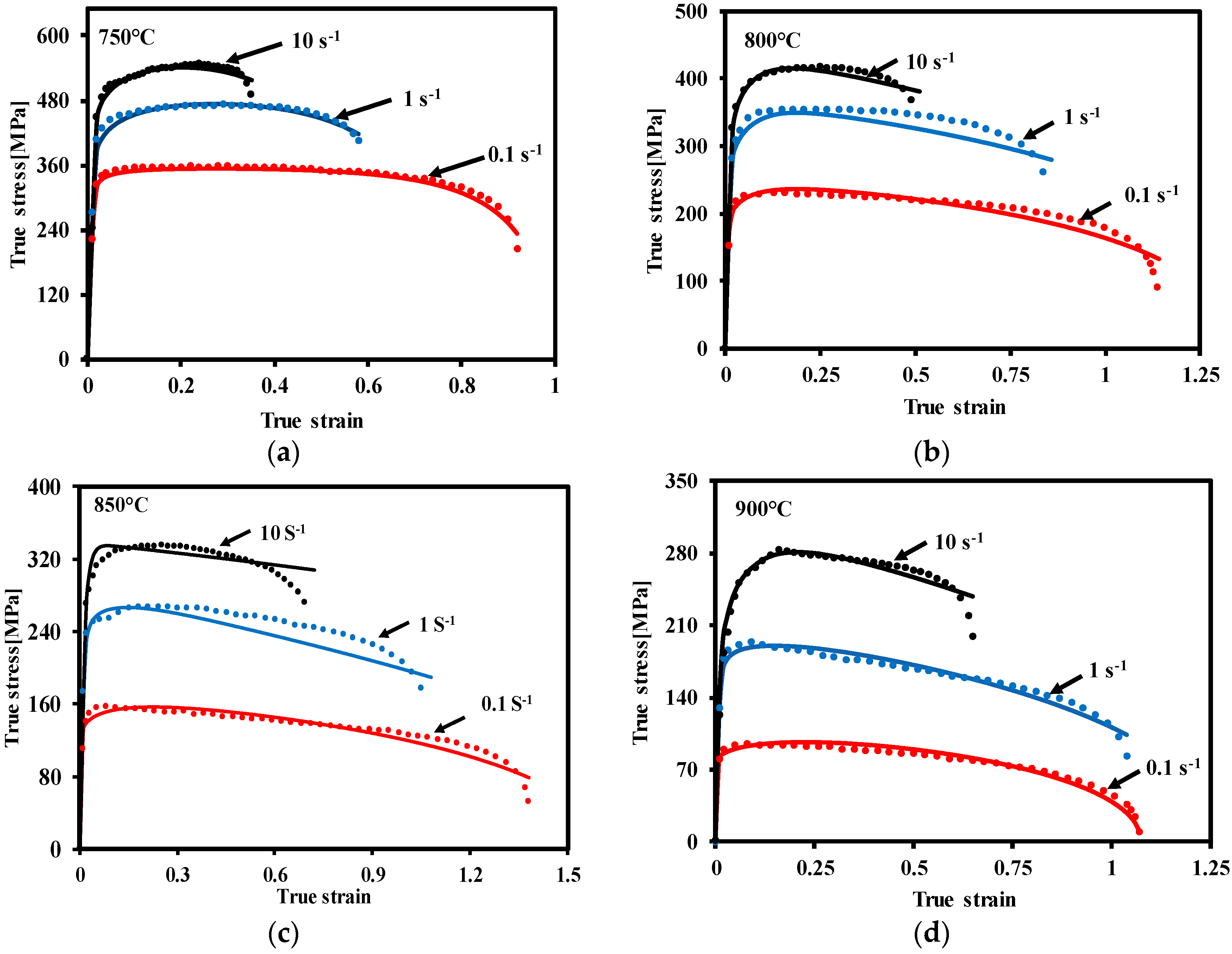

In this paper, experimental investigations of hot stamping of a near- titanium alloy, TA15, were performed focusing on hot formability and microstructural evolution. Schematic hot tensile tests were carried out to investigate hot deformation characteristics. SEM and Electron Backscattered Diffraction (EBSD) microstructure observations were used to identify the phase transformation and grain size evolution to provide evidence for experimental results. More importantly, using the obtained stress-strain relationships, the performed research established a mechanisms-based constitutive material model for near- titanium alloy under hot stamping condition with considerations of a series of microstructural evolutions, especially recrystallization and damage for the softening. The developed material model can be further implemented into FE simulations to determine optimal process window and provide useful guides for manufacturing structural panel parts for the aerospace industry.

3. Material Modelling

In order to establish a robust physical mechanism-based material model for hot stamping TA15, involved microstructural evolutions during hot stamping need to be known and identified first. With regard to hot forming of near-

α titanium alloys, for

α phase, typical microstructural evolutions, e.g., dynamic recovery (DRV), dynamic recrystallization (DRX), dynamic grain growth and phase transformation were observed [

3,

10]. Globularization is limited as the initial equiaxed microstructure, which is neglected in this model. While for

β phase, dynamic recovery is dominant softening mechanism, due to the high stacking fault energy [

11], so the dynamic recrystallization for the phase is not considered. Based on the above microstructure characteristics, viscoplastic constitutive equations taking into account work hardening, recovery, recrystallization and grain size evolution that were proposed by Lin et al. [

12], were used as the fundamental equations in this study to predict the microstructure evolution and post-form properties, and this material models can be used for guiding the production practice and optimizing the forming parameters. The establishment of this model is given as follows in details.

The general viscoplastic flow for the alloy when considering grain size effect is expressed using Equation (1):

where

is the plastic strain rate,

σ is the flow stress,

D is the damage factor,

H is the hardening stress, due to dislocation evolution,

k is the initial yield stress,

d is the grain size.

K,

n1 are temperature dependent material parameters, and

n2 is a temperature independent material constant.

For the investigated alloy,

α and

β phase should be considered separately. The viscoplastic flow are given in Equations (2) and (3),

where the subscript represents the phase.

Then, the total viscoplastic flow behavior is expressed as [

13]:

where

fβ represents the volume fraction of the

β phase.

In order to characterize the phase volume fraction variation during the non-isothermal hot stamping process, Equation (5) was used to describe the evolution rate of the volume fraction of the

β phase [

14,

15].

where

X,

α,

γ are temperature independent material constants.

The hardening stress

H in Equation (1) is related to dislocation density evolution, as expressed in Equations (6) and (7) for

α and

β phase respectively [

16].

where

B is a temperature dependent material parameter, and

is the normalized dislocation density, as detailed explained in Reference [

11]. The subscript represents different phases.

The dislocation evolution involves dislocation accumulation and concurrent dislocation annihilation. For

α and

β phase, the dislocation evolutions can be expressed using Equations (8) and (9) respectively [

17].

where

represents the normalized dislocation density. t

1, t

2, t

3, t

4, t

5, t

6, t

7 are temperature independent material constants.

n4 is the temperature independent material constant.

S represents the volume fraction of recrystallization.

For the normalized dislocation density in

α phase, the first term represents dislocation accumulation resulting from strain hardening and static recovery. It should be noted that, grain size has a great effect on dislocation density. Dislocation is more significant when the grain size is bigger. This is because when the grain size is bigger, more grain deformation and intergranular dislocation slip would happen. Therefore, the effect of grain size on dislocation evolution is introduced in the first term. The second term represents the dislocation restoration caused by dynamic recovery. The third term represents the reduction of dislocation caused by recrystallization. Titanium alloy can have two different crystal structures, due to allotropic phase transformation: Hcp

α phase and bcc

β phase. The volume fraction of the

α phase decreases as temperature increases, and complete transformation is obtained above the

β transus temperature after a sufficient soaking, and the

β transus temperature is 990 °C [

18].

During the thermomechanical processing of titanium alloys, recovery and recrystallization are two important restoration processes. Defects like dislocation, due to the introduction of plastic deformation will provide the driving force for the initiation of both recovery and recrystallization. For materials with high stacking fault energy, recovery consumes most of the dislocations and is the dominant softening mechanism. While for materials with moderate or low stacking fault energy, recrystallization may occur when the dislocation density is higher than a threshold value. This critical threshold value of dislocation density for initiating the recrystallization is generally described by Equation (10) [

19],

where Q

cr is the activation energy, R and

T are ideal gas constant and the absolute temperature in Kelvin. C

cr and cr are material constants.

When the dislocation density is higher than

ρcr, recrystallization may occur. The recrystallization rate can be expressed by Equation (11) [

19],

where q

1, q

2 are temperature independent material constants. Recrystallization involves the formation of fine dislocation-free grains and the subsequent growth of these new formed grains. Therefore, recrystallization will result in the evolution of grain size during hot stamping. The grain size evolution is described using Equation (12) [

20],

where

u2,

w2,

w3,

w4 are temperature independent material constants and

u1,

w1,

u3 are temperature dependent material parameters.

In Equation (12), the first term represents the grain growth during deformation, which is related to the grain boundary mobility. The second term represents the grain refinement, due to recrystallization.

Another typical softening mechanism refers to the hot stamping process is damage accumulation, due to the micro-voids and cracks. The continuum damage mechanism is utilized in this material model using a damage factor to represents the volume fraction of voids compared to the initial virtual microstructure. The evolution of damage is given in Equation (13),

where

d2 are temperature independent material constants and

d1,

d3,

d4,

d5,

d6 are temperature dependent material parameters. In Equation (13), the first term represents the damage caused by void nucleation, which is the broken of the compatibility requirements at the alpha/beta interface and the second term represents the damage caused by void growth and coalescence [

21].

The total flow stress can be obtained according to Hook’s law, as given in Equation (14).

where

εt is the total strain,

εp is the plastic strain and

E is Young’s modulus.

Finally, a set of constitutive equations are established. The related equations of temperature-dependent material constants are followed Arrhenius equation, as expressed in the general formula in Equation (15).

where

Θ represents the specific temperature-dependent material constant.

QΘ is the activation energy.

5. Conclusions

The hot deformation and microstructural evolution of TA15 under a novel hot stamping process were experimentally investigated in this paper. A physical-based material model for near- titanium alloy with an initial equiaxed microstructure was successfully established. The results enable to provide useful guidance for the aerospace industry with the following conclusions:

(1) With the increasing temperature, the formability of TA15 became better resulted from the recovery and recrystallization. To avoid severe β phase transformation, due to requirements for better fatigue properties of aircraft components, and failure of oxidation resistance lubricant at very high temperatures, i.e., 950 °C, the optimal hot forming temperature window is from 750 °C to 900 °C.

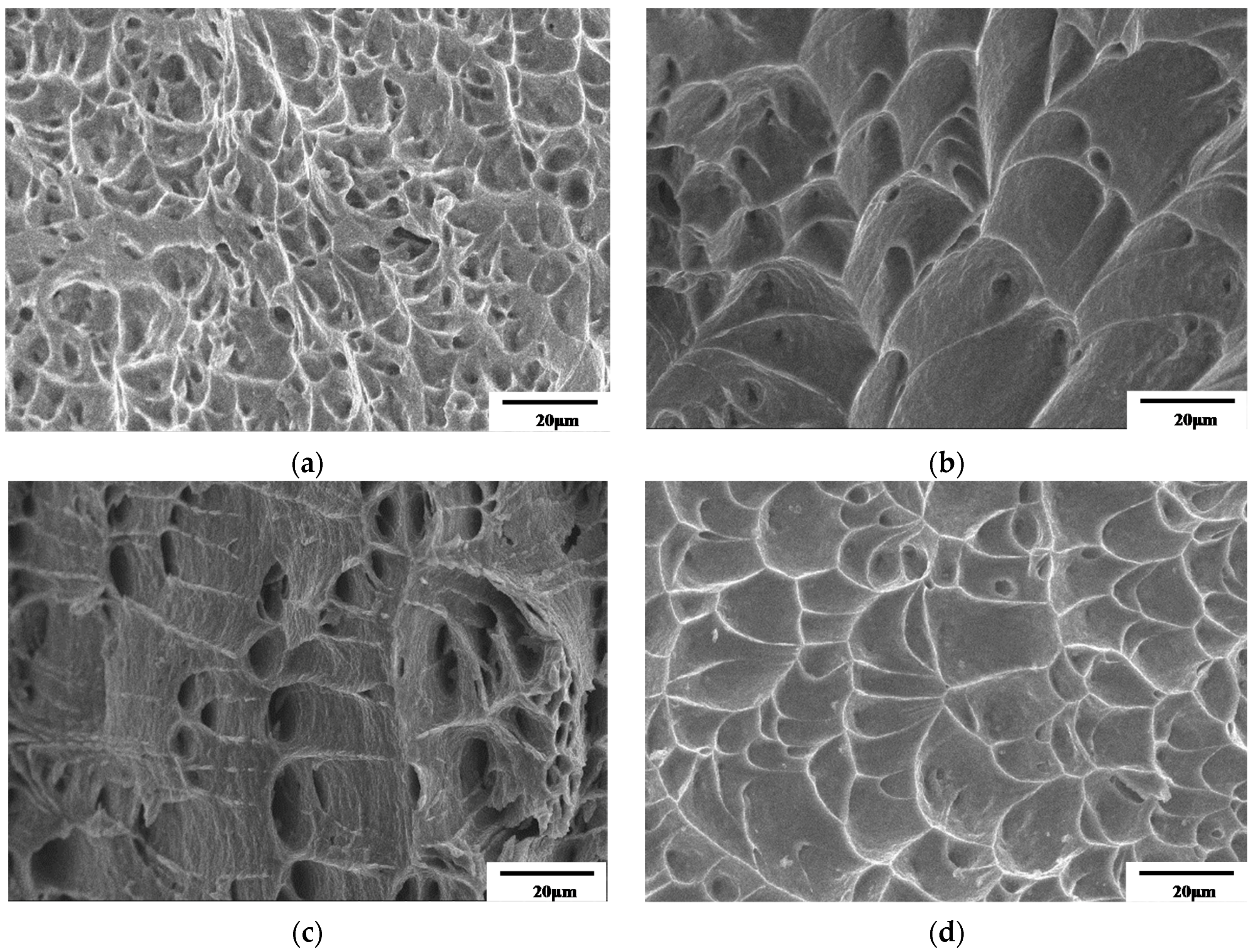

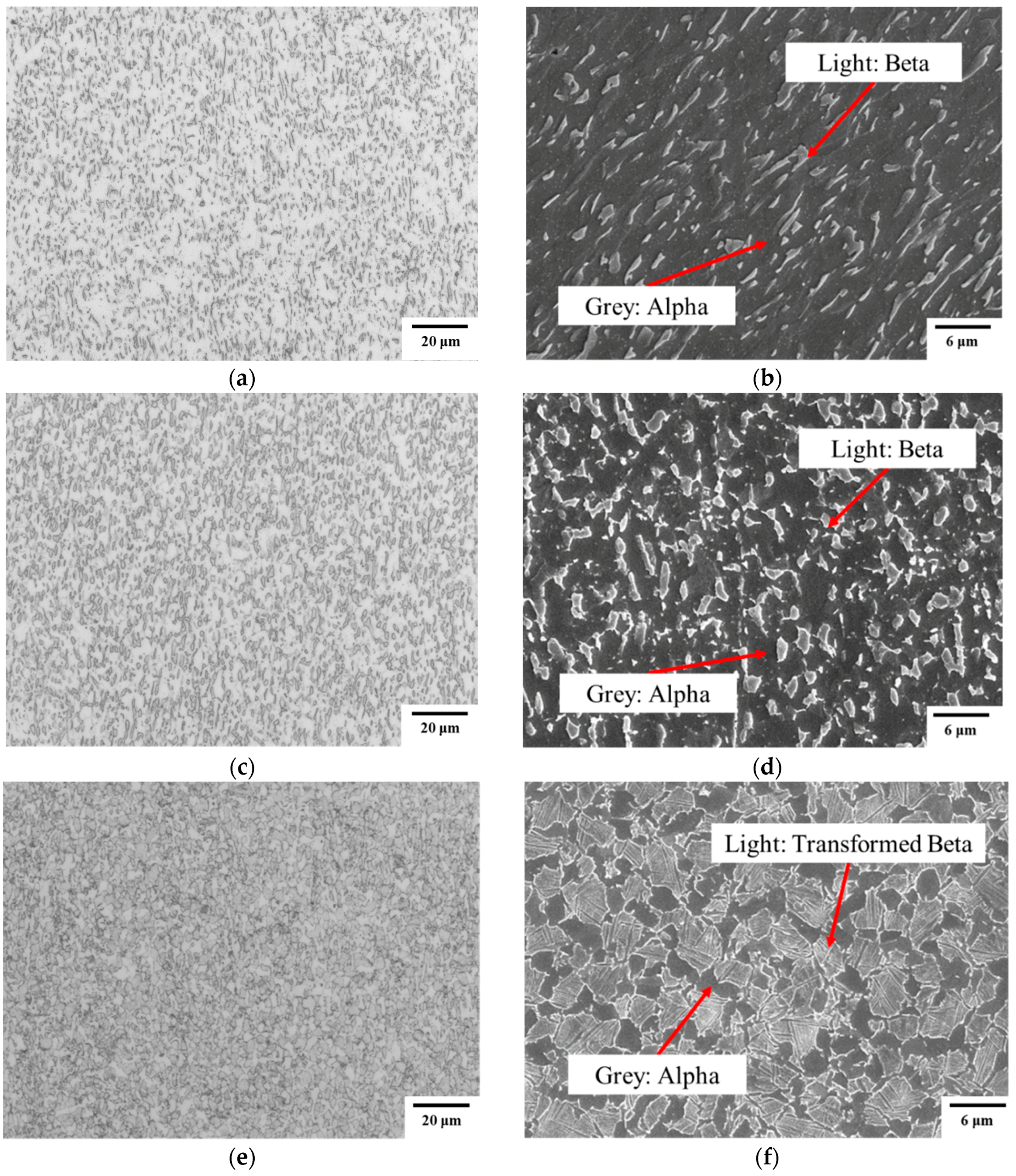

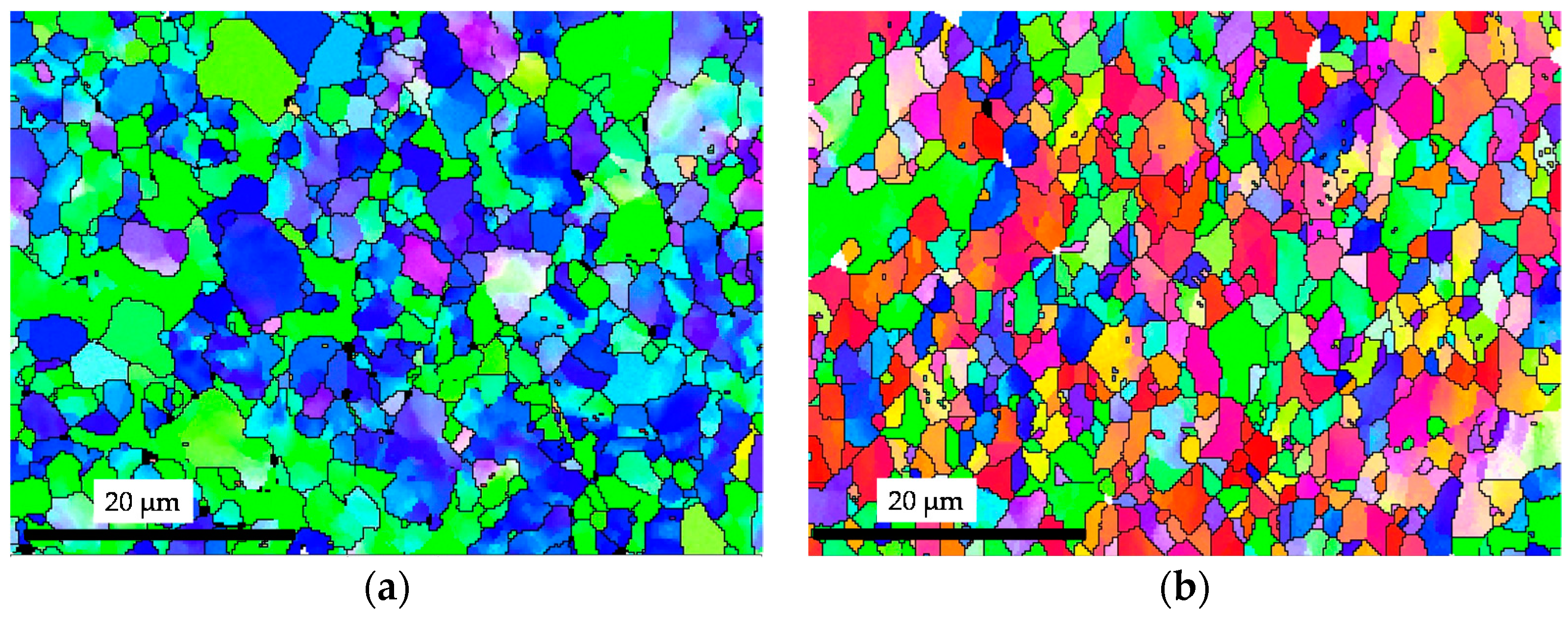

(2) According to SEM and EBSD observations, when the temperature is below 750 °C, alpha grains were elongated, and strain hardening occurred because of dislocation accumulation with no obvious softening, i.e., recovery and recrystallization. From 750 to 850 °C, β grains became equiaxed and grew bigger; recrystallization of α grains started to occur. Over 850 °C, the lamellar secondary α precipitated and grew thicker with higher temperature.

(3) The physical-based material model, taking into account of phase transformation effect, recovery, recrystallization and damage, was established for the near-α titanium alloy. The developed model enables to precisely predict the deformation behaviors of TA15 under hot stamping conditions.